Page 1

Obstetrical Care

SERVICE GUIDE

Avalon Fetal Monitor

FM40 / FM50

FETAL MONITORING

Page 2

Printed in Germany

*M2703-9000C*

Part Number M2705-9000A

451261025951

S

Page 3

M2705-9000A

1Table of Contents

1 Introduction 1

Who Should Read This Guide 1

What to Do Next 1

Repair Strategy 2

Manufacturer’s Information 2

Passwords 3

Warnings and Cautions 3

2 Site Preparation 5

Introduction 5

Site Planning 5

Roles and Responsibilities 5

Site Preparation Responsibilities 5

Procedures for Local Staff 6

Procedures for Philips Personnel 7

Site Requirements 7

Space Requirements 7

Environmental Requirements 7

Safety Requirements (Customer or Philips) 8

Electrical Requirements (Customer or Philips) 8

Connecting Non-Medical Devices 8

Cabling Options and Requirements for Connection to OB TraceVue 9

Mounting Options 9

PS/2 Input Devices 10

Displays and Touch Devices 10

M8031B: 15” TFT Medical Grade Touch Display 10

M8033C: 17” TFT Medical Grade Touch Display 10

Video Cables for Remote Displays 11

3 Installation Instructions 13

Initial Inspection 13

Visual Inspection 13

Electrical Inspection 13

Claims for Damage 13

Repackaging for Shipment or Storage 14

Mounting Instructions 14

Line Voltage Selection 14

Rear View 15

Connecting the Monitor to AC Mains 15

i

Page 4

Connecting the Monitor to Non-Medical Devices 15

Connecting a Remote Display via the MIB/RS232 Interface 16

Installing a Remote Display 16

Mounting Remote Displays 16

Before Using the Monitor 16

Checking and Setting Line Frequency 17

Checking/Setting Paper Scale 17

Checking/Setting Paper Speed 18

Configuring the Equipment Label 18

Configuring SmartKeys 18

PS/2 Keyboard/Mouse 18

4 Theory of Operation 19

Monitor Hardware Overview 19

Power Supply 20

Fetal Sensor Connector Block 20

API (All Peripheral Interfaces) Board 20

Main CPU Board 21

Fetal Recorder (Thermal Printer Unit) 21

Thermal Line Printhead (TLPH) 21

Paper Sensor 21

Stepper Motor 21

LCD Display and Touchscreen 21

Noninvasive Blood Pressure Assembly 21

SpO2 Assembly 21

Input/Output Interface Boards 22

Transducer Hardware Overview 22

Tr a n s d u c e r Ty p e s 23

Functional Description of the Transducer CPU 23

CPU (Micro Controller) 23

Analog-to-Digital Converter 23

Communication Transceiver (CAN Bus Driver) 23

EEPROM 23

Toco Transducer Frontend 23

Ultrasound Transducer Frontend 23

Toco+ Transducer Frontends 24

To co Fr o n te n d 24

IUP Frontend 24

ECG Frontend 24

Patient Module Frontends 24

Avalon CTS Interface Cable (TMIF) 24

5 Rear Interfaces 25

LAN / RS232 Interface 25

Dual PS/2 Interface 26

MIB / RS232 Interface 26

ii

Page 5

Telemetry Interface 26

VGA Video Out 26

6 Connection to a Network 27

Network Infrastructure Requirements 27

Connection Indication Messages 27

Broadcast 27

Unicast 28

Equipment Label and OB TraceVue Fetal Monitor Domain Name 28

7 Testing and Maintenance 29

Recommended Frequency 29

When to Perform Test Blocks 30

Preventive Maintenance Procedures 31

Noninvasive Blood Pressure Measurement Calibration 31

Fetal Recorder Maintenance 31

Testing Sequence 31

Visual Inspection 32

Before Each Use 32

After Each Service, Maintenance or Repair Event 32

Safety Tests 32

Warnings, Cautions, and Safety Precautions 32

Safety Test Procedures 33

S(1): Protective Earth Resistance Test 34

S(2): Equipment Leakage Current Test - Normal Condition 34

S(3): Equipment Leakage Current Test - Single Fault Condition 35

S(4): Applied Part Leakage Current - Mains on Applied Part 35

System Test 37

What is a Medical Electrical System? 37

General Requirements for a System 37

System Example 37

Performance Assurance Tests 38

Noninvasive Blood Pressure Performance Tests 38

Accuracy Test 38

Leakage Test 39

Linearity Test 39

Valve Test 40

Expected Test Results 40

SpO2 Performance Test 40

Expected Test Results 40

Measurement Validation 40

Reporting of Test Results 41

Carrying Out and Reporting Tests 42

Other Regular Tests 43

Transducers and Patient Modules: Functional Tests 43

Ultrasound Transducer Electrical Check 43

iii

Page 6

Toco Transducer Electrical Check 44

Testing the Patient Module (M2738A)/Toco+ Transducer (M2735A): DECG Mode 45

Testing the Patient Module (M2738A)/Toco+ Transducer (M2735A): MECG Mode 46

Testing the Patient Module (M2738A)/Toco+ Transducer (M2735A): IUP Mode 47

To uc h s cr e e n C a l i b ra ti o n 48

Disabling/Enabling Touch Operation 49

Checking the Fetal Recorder Offset 49

Setting the Fetal Recorder Offset 49

Fetal Recorder Selftest Report 50

8 Troubleshooting 53

Who Should Perform Repairs 53

Replacement Level Supported 53

Checking Revision Information 53

Trace Header 54

Hardware Revision Check 54

Software Revision Check 55

Obtaining Replacement Parts 55

Troubleshooting Guide 55

Checks for Obvious Problems 55

Checks Before Opening the Instrument 55

Checks with the Instrument Switched On, AC connected 55

Individual Parameter INOPs 56

Initial Instrument Boot Phase 57

Troubleshooting Tables 57

How to Use the Troubleshooting Tables 57

Boot Phase Failures 58

Screen is Blank 58

Touchscreen not Functioning 59

General Monitor INOP Messages 60

Network Status Icons 61

Alarm Tones 61

Alarm Behavior 61

Fetal Recorder 61

LAN / RS232 64

Keyboard/Mouse not Functioning 64

Remote Touch Display not Responding (MIB/RS232) 65

No Video on Remote Display 65

Tr a n s du c e r s 6 6

Status Log 67

Troubleshooting with the Support Tool 68

Troubleshooting the Individual Measurements or Applications 68

9 Parts 71

Monitor 71

Tr a n s d u c e r s 73

iv

Page 7

Patient Modules 74

Interface Cables 74

Assemblies and Kits 75

Front Bezel Assembly 75

Main CPU Board 76

API Board Kit 76

Noninvasive Blood Pressure Assembly 76

Recorder Assembly 77

Thermal Line Printhead (TLPH) 77

Loudspeaker Assembly 77

To p C o ve r 78

AC/DC Power Supply 78

SpO2 Board 78

Interface Boards 79

Fetal Sensor Socket Connector Kit 79

Rear (Telemetry) Connector Kit 79

SpO2 Connector Kit 80

Noninvasive Blood Pressure (NBP) Connector Kit 80

Camlock Kit 80

FM Small Parts Kit - Plastic Parts and Labels 81

FM Small Parts Kit - Screws and Cables 83

Transducer Cable Assembly 84

Belt Button Kit 84

10 Disassembly and Reassembly 85

Introduction 85

How to Use this Chapter 85

Tools Required 86

Screws Used 86

Screw Map 87

Serial Numbers 87

Removing the Top Cover 88

Refitting the Top Cover 89

Removing the Power Supply Assembly 90

Refitting the Power Supply Assembly 91

Removing the Loudspeaker Assembly 91

Refitting the Loudspeaker Assembly 92

Removing the Noninvasive Blood Pressure Assembly 92

Refitting the Noninvasive Blood Pressure Assembly 93

Removing the SpO2 Assembly 94

Refitting the SpO2 Assembly 94

Removing the Interface Boards 95

Refitting the Interface Boards 96

Removing the Main CPU Board 96

Refitting the Main CPU Board 98

Removing the Front Bezel Assembly 99

v

Page 8

Refitting the Front Bezel Assembly 101

Removing the Telemetry Socket Connector Block 102

Refitting the Telemetry Socket Connector Block 102

Removing the Sensor Socket Connector Block 103

Refitting the Sensor Socket Connector Block Assembly 104

Removing the API Board 105

Refitting the API Board 107

Removing the Recorder Assembly 107

Refitting the Recorder Assembly 110

Removing the Thermal Line Printhead (TLPH) 111

Refitting the TLPH 112

Transducer Disassembly/Reassembly 113

Exchanging the Transducer Cable 113

Exchanging the Transducer Belt Button 115

11 Upgrades 117

FM40/50 Upgrade Options 117

Installing Upgrade Options 118

Option C73 118

Options J22 and J70 118

Software and Firmware Upgrades 118

12 Understanding Configuration 119

What is Configuration Mode? 119

Understanding Settings 120

Entering and Leaving Configuration Mode 120

Storing Changes in the User Defaults 121

Loading the Factory Default 122

Loading the User Defaults 122

Loading Configurations Using the Support Tool 123

About Configuration Files (.cfg) 123

Selecting the Correct Configuration 123

13 Configuration Settings Appendix 125

Documenting Monitor Configurations 125

Using the Configuration Tables 125

Configuration Table Example 126

Understanding Configuration Implications 126

Measurement-Related Settings 127

Color Configuration 127

Configuring FHR (Ultrasound) 127

FHR Configuration Implications 127

Configuring Toco 128

Configuring IUP 128

Configuring DFHR (DECG) 128

DFHR Configuration Implications 128

vi

Page 9

Configuring MHR (ECG)/Pulse 129

ECG/Pulse Configuration Implications 129

Configuring SpO

Configuration Implications 130

SpO

2

2

130

Configuring Noninvasive Blood Pressure (NBP) 132

NBP Configuration Implications 132

Monitor-Related Settings 133

Configuring Alarms 133

Alarm Settings Configuration Implications 133

Configuring the NST Timer 134

NST Timer Configuration Implications 134

Configuring Fetal Recorder Settings 135

Recorder Configuration Implications 135

Configuring User Interface Settings 136

User Interface Configuration Implications 136

Configuring Global SmartKeys 138

Global SmartKeys Configuration Implications 138

Changing the Selection and Sequence of Global SmartKeys 138

Hardware Settings 139

Global Settings 139

Global Settings Configuration Implications 139

vii

Page 10

viii

Page 11

1

1Introduction

This Service Guide contains technical details for the Avalon FM40 and FM50 Fetal/Maternal

Monitors. It provides a technical foundation to support effective troubleshooting and repair. It is not a

comprehensive, in-depth explanation of the product architecture or technical implementation. It offers

enough information on the functions and operations of the monitoring systems so that engineers who

repair them are better able to understand how they work. It covers the physiological measurements and

the monitor hardware that acquires and displays them.

The Avalon FM40/FM50 Fetal Monitor Service Guide supplements the maintenance and

troubleshooting procedures, carried out by the operator, that are described in the Instructions for Use.

Refer to the Instructions for Use for maintenance and troubleshooting procedures that may be

performed during normal operation.

Only qualified service personnel should attempt to install the system, disassemble the monitor, remove

or replace any internal assemblies, or replace the transducer cable or belt buttons.

Who Should Read This Guide

This guide is for biomedical engineers or technicians responsible for troubleshooting, repairing, and

maintaining Philips’ Avalon fetal monitors.

You must:

•understand English

• be familiar with standard medical equipment installation procedures

• be familiar with current conventional technical terms as used throughout this guide

What to Do Next

Familiarize yourself with the contents of this guide and the Instructions for Use before attempting to

service or repair the system.

1

Page 12

1 Introduction Repair Strategy

Repair Strategy

The Service Support Tool software helps you to determine whether a fault is a hardware or software

problem. The main replaceable parts are:

• unit exchange for the transducers

•replacement of

–the top cover

– the power supply assembly

– the loudspeaker assembly

– the noninvasive blood pressure assembly

–the SpO

– the interface boards (RS232/LAN, dual PS/2 and MIB/RS232)

–the main CPU board

– the front bezel assembly

– the telemetry socket connector block

– the sensor socket connector block

–the API board

– the recorder assembly

– the thermal line printhead (TLPH)

–the transducer cable

– the transducer belt button

See Chapter 9, “Parts” for part numbers, and Chapter 10, “Disassembly and Reassembly” for repair

details.

assembly

2

Repair or replacement of individual components on the boards is not supported, and should never be

attempted.

For tests that you are required to perform after repairs, refer to “When to Perform Test Blocks” on

page 30.

Manufacturer’s Information

© Copyright 2003 - 2008. Koninklijke Philips Electronics N.V.

All Rights Reserved.

Philips Medizin Systeme Böblingen GmbH

Hewlett-Packard-Str. 2

71034 Böblingen, Germany

2

Page 13

Passwords 1 Introduction

Passwords

In order to access different modes within the monitor a password may be required. The passwords are

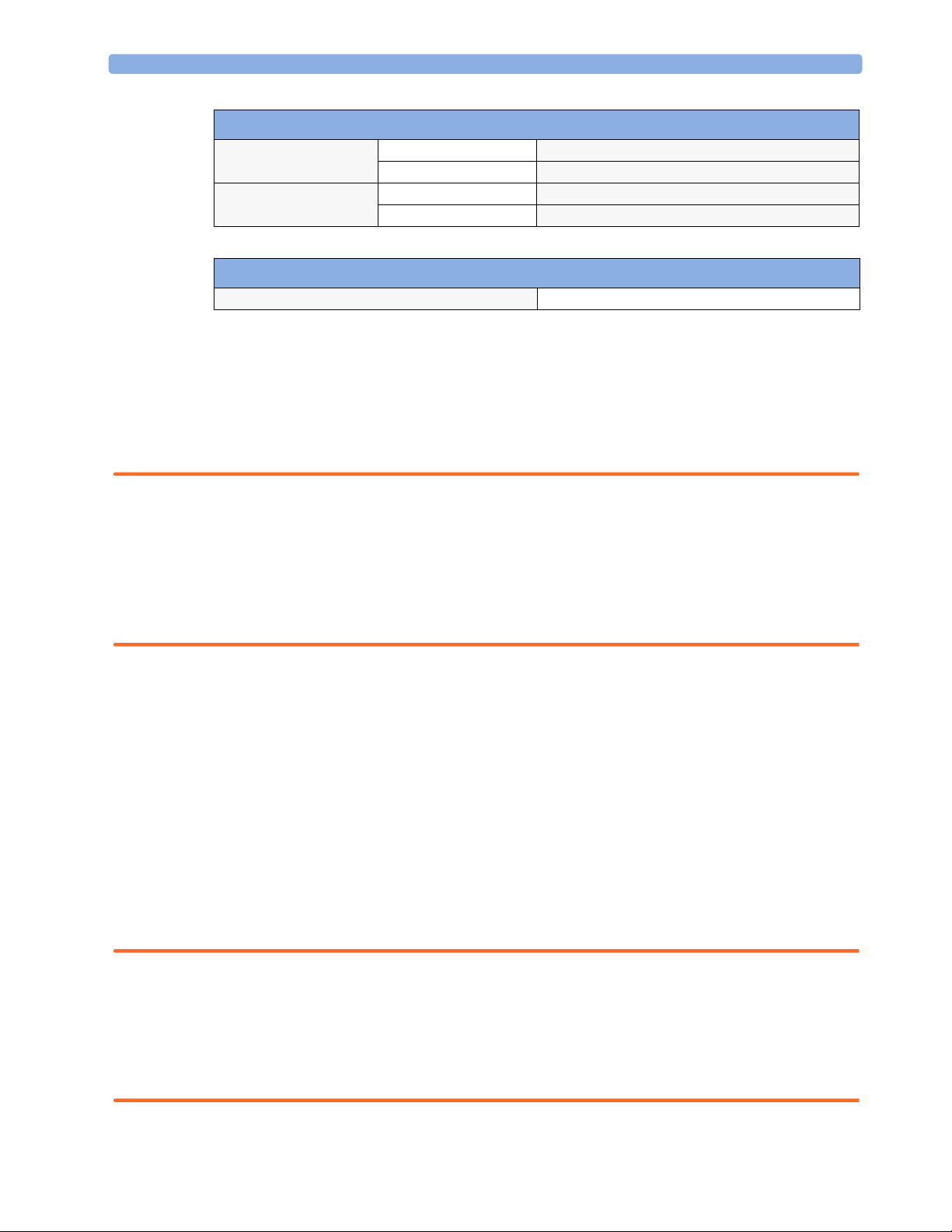

listed below.

Monitoring Mode: No password required

Configuration Mode: 71034

Demo Mode: 14432

Service Mode: 1345

Refer to Chapter 12, “Understanding Configuration” before making any changes to the monitor

configuration.

Warnings and Cautions

In this guide:

•A warning alerts you to a potential serious outcome, adverse event or safety hazard. Failure to

observe a warning may result in death or serious injury to the user or patient.

•A caution alerts you where special care is necessary for the safe and effective use of the product.

Failure to observe a caution may result in minor or moderate personal injury or damage to the

product or other property, and possibly in a remote risk of more serious injury.

3

Page 14

1 Introduction Warnings and Cautions

4

Page 15

Introduction

This section describes the procedures you should follow to plan and prepare a site for an Avalon

FM40/FM50 fetal monitor installation.

• Site planning.

• Roles and responsibilities for local and Philips personnel.

Site Planning

The careful planning of the site for the FM40/FM50 monitor is essential for its safe and efficient

operation. A consulting schedule should be established between the Customer and Philips Sales and

Support Representatives, to ensure that all preparations are completed when the system is delivered.

2

2Site Preparation

The site planning phases prior to equipment installation are:

Location: Planning the location of the various system components.

Environment: Confirming and correcting, as necessary, the environment of the proposed installation

site(s).

System Capabilities: Explaining the possibilities for system expansion.

Mounting: Referencing the mounting hardware information website for the listing of suitable

mounting hardware recommended for use with the various system components, and all details on the

available mounts and accessories.

Cabling: Identifying the requirements for the cabling, conduiting and faceplates for connecting the

various system components.

Roles and Responsibilities

This section describes the procedures necessary to prepare a site for a system installation. The

procedures are grouped into two parts: procedures that local staff or contractors are responsible for, and

procedures that Philips personnel are responsible for.

Site Preparation Responsibilities

Local Staff

• Ensure that all safety, environmental and power requirements are met.

• Provide power outlets.

• Prepare mounts, and consult Philips for detailed mounting requirements.

5

Page 16

2 Site Preparation Introduction

• Pull cables, install conduit, install wallboxes.

Philips Personnel

• Provide the customer with the safety, environmental and power requirements.

•Assemble mounts, as necessary.

• Provide requirements for cabling.

Procedures for Local Staff

The following tasks must be completed before the procedures for Philips personnel may be started.

• Providing Power Outlets

Provide a power outlet in the vicinity (1 m or 3 ft) or any peripheral equipment.

WARNING Only the power cables provided with the system may be used. For reasons of safety, power (mains)

extension cables or adapters shall not be used.

• Preparing Mounts

Where ceiling, wall, or shelf mounts are required for mounting the equipment, the customer is

responsible for the following:

– Providing and installing all hardware which is required to install the mounting hardware supplied

by Philips as detailed in the installation notes.

– Making sure that all ceilings, walls, and mounting rails that supports mounting hardware are

suitable for their proposed load.

WARNING It is the customer's responsibility to have the attachment of the mounting hardware to the ceiling, wall,

or mounting rail and the construction of the ceiling, wall, or mounting rail evaluated for structural

integrity and compliance with all local, state and any other required codes by a registered, professional,

structural and/or mechanical engineer.

Although considerable effort has been made to ensure the safety of the ceiling mount installation and

or mounting guidelines, it is to be understood that the installation itself is beyond the control of Philips

Medical Systems. Accordingly, Philips Medical Systems will not be responsible for the failure of any

such installation.

• Providing Conduit

– Providing conduit and/or trunking of a sufficient cross-sectional area for the planned cables and

possible future expansion (for additional components or systems).

– Providing and/or installing suitable wall boxes to accommodate the faceplates.

•Pulling Cables

WARNING NEVER run power cables through the same conduit or trunking used for system cables.

•Installing Wall Boxes

6

Page 17

Site Requirements 2 Site Preparation

It is the customer's responsibility to provide and install wallboxes to house faceplates. The customer

must notify the Philips installation coordinator of which size is to be used.

Procedures for Philips Personnel

Before you begin the procedures in the installation sections, ensure that the customer has completed all

necessary preparations outlined in the previous section, “Procedures for Local Staff.”

Site Requirements

The site requirements are listed in this section.

Space Requirements

The situating of the monitor should be planned such that the nursing staff are able to monitor the

patient with relative ease, with all patient connectors and controls readily available and the displays

clearly visible. The location should also allow access to service personnel without excessive disruption

and should have sufficient clearance all round to allow air circulation.

Dimensions and weight:

Monitor:

Size (W x H x D): 420 x 172 x 370 mm (16.5 x 6.8 x 14.6 in)

Weight; < 9.0 kg (19.8 lb)

Transducer:

Size (diameter): 83 mm (3.27 in)

Weight (without cable): 190g (6.7 oz.)

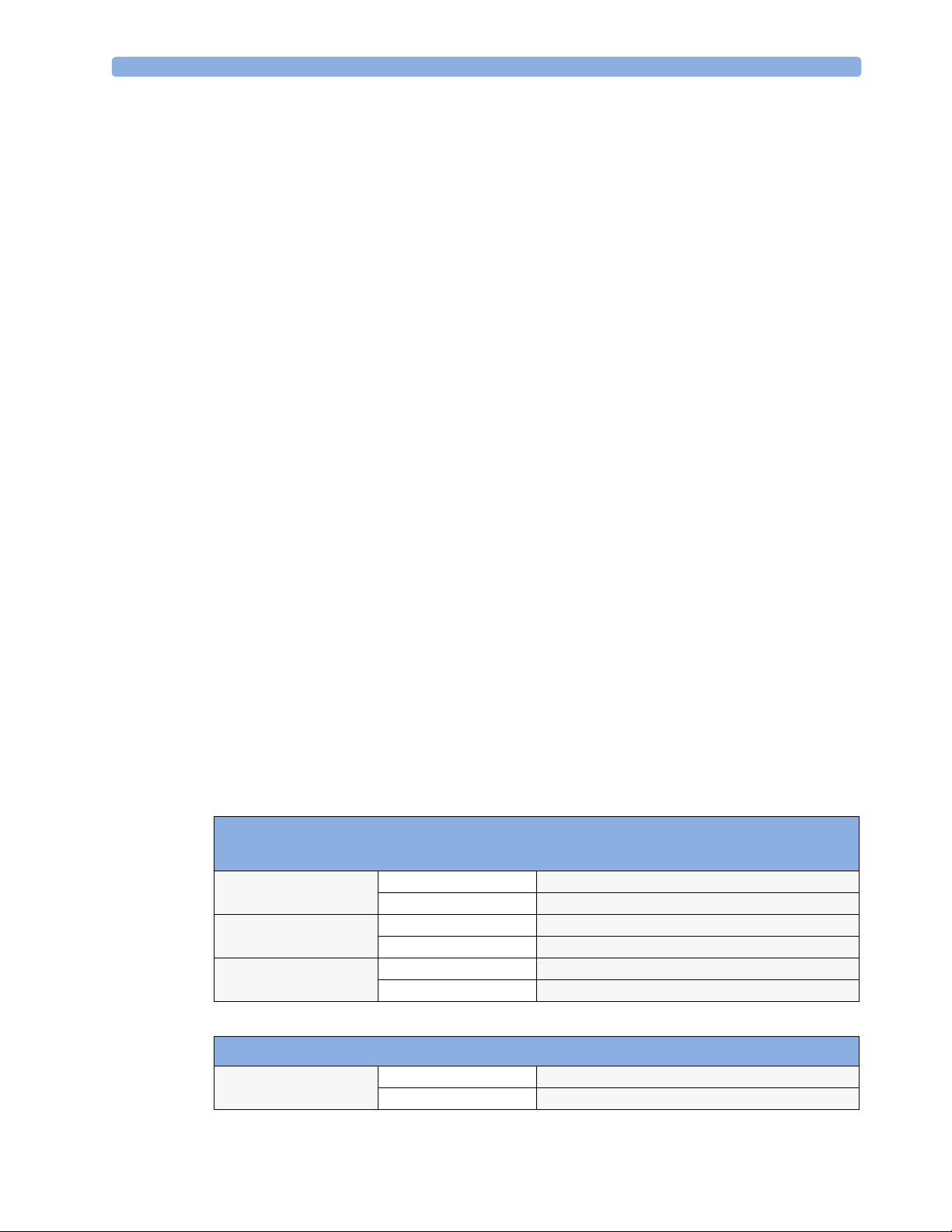

Environmental Requirements

The environment where the FM40/FM50 monitor will be used should be reasonably free from

vibration, dust and corrosive or explosive gases. The ambient operating and storage conditions for the

FM40/FM50 monitor must be observed. If these conditions are not met, the accuracy of the system

will be affected and damage can occur.

.

Monitor (M2704A/M2705A)

Interface Cable for Avalon CTS (M2731-60001/M2732-60001)

Temperature Range Operating 0°C to 45°C (32°F to 113°F)

Storage

Humidity Range Operating <95% relative humidity @ 40°C/104°F

Storage

Altitude Range Operating -500 to 3000 m/-1640 to 9840 ft.

Storage

-20°C to 60°C (-4°F to 140°F)

<90% relative humidity @ 60°C/140°F

-500 to 13100 m/-1640 to 43000 ft.

Transducers (M2734A/M2735A/M2736A/M2738A)

Temperature Range Operating 0°C to 40°C (32°F to 104°F)

Storage

-20°C to 60°C (-4°F to 140°F)

7

Page 18

2 Site Preparation Site Requirements

Transducers (M2734A/M2735A/M2736A/M2738A)

Humidity Range Operating <95% relative humidity @ 40°C/104°F

Storage

Altitude Range Operating -500 to 3000 m/-1640 to 9840 ft.

Storage

SpO2 Sensors

Operating Temperature Range 0°C to 37°C (32°F to 98.6°F)

<90% relative humidity @ 60°C/140°F

-500 to 13100 m/-1640 to 43000 ft.

Safety Requirements (Customer or Philips)

The monitor is an electrical Class I device in which protection against electric shock does not rely on

basic insulation only, but which includes an additional safety precaution, in that means are provided

for the connection of the equipment to a protective earth conductor in the fixed wiring installation in

such a way that accessible metal parts cannot become live in the event of a failure of the basic

insulation.

WARNING • Always use the supplied power cord with the earthed mains plug to connect the monitor to an

earthed AC mains socket. Never adapt the mains plug from the power supply to fit an unearthed AC

mains socket.

• Do not use additional AC mains extension cords or multiple portable socket-outlets. If a multiple

portable socket-outlet without an approved separating transformer is used, the interruption of its

protective earthing may result in equipment leakage currents equal to the sum of the individual

earth leakage currents, so exceeding allowable limits.

Electrical Requirements (Customer or Philips)

Line Voltage Connection

The FM40/FM50 monitor uses < 60 W.

Line Voltage: the FM20/FM30 monitor may be operated on ac line voltage ranges of

100 to 240V (50/60 Hz).

Connecting Non-Medical Devices

The standard IEC/EN 60601-1-1 applies to any combination of devices, where at least one is a medical

device. Therefore IEC/EN 60601-1-1 must still be met after all devices are connected.

WARNING • Do not use a device in the patient vicinity if it does not comply with IEC/EN 60601-1. The whole

installation, including devices outside of the patient vicinity, must comply with IEC/EN 60601-1-1.

Any non-medical device, including a PC running an OB TraceVue system, placed and operated in

the patient’s vicinity must be powered via a separating transformer (compliant with IEC/EN 606011-1) that ensures mechanical fixing of the power cords and covering of any unused power outlets.

• Do not connect any devices that are not supported as part of a system.

8

Page 19

Site Requirements 2 Site Preparation

Whenever you combine equipment to form a system, for example, connecting the monitor to an OB

TraceVue system, perform a system test according to IEC/EN 60601-1-1 (see “System Test” on

page 38).

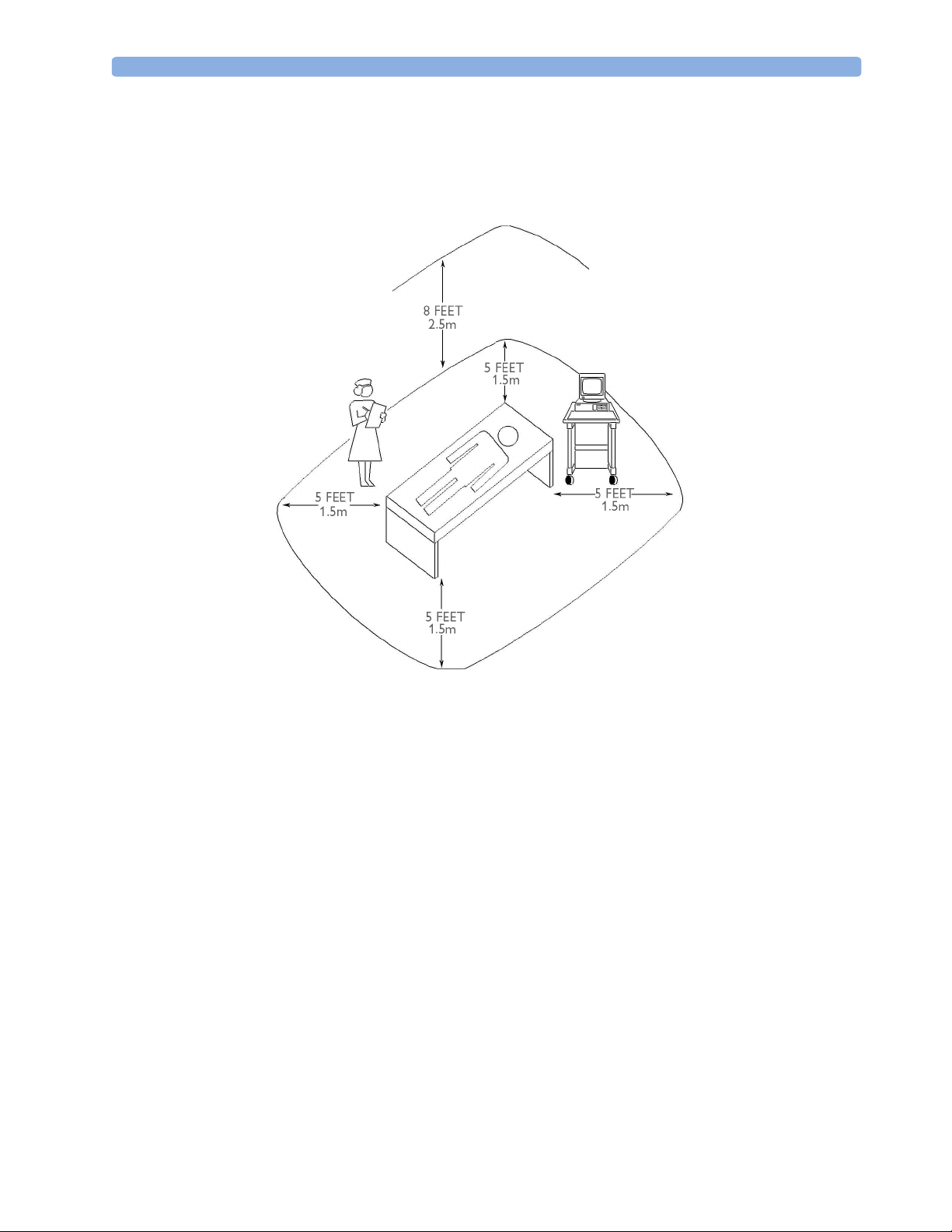

Figure 1 Equipment Location in the Patient Vicinity

Cabling Options and Requirements for Connection to OB TraceVue

For cabling options and requirements for connection to an OB TraceVue system, refer to the OB

TraceVue Site Preparation Guide and the OB TraceVue Service Guide.

Mounting Options

See “Mounting Hardware” on page 61 for a list of mounting options. Refer to “Mounting

Instructions” on page 12, or contact your local Philips representative for advice on mounting the

monitor.

9

Page 20

2 Site Preparation Site Requirements

PS/2 Input Devices

The following table describes the input devices which can be connected to the monitor via the optional

PS/2 interface.

Product Option

Number

M8024A #A01 862454 989803124741 Slimline Keyboard with integrated Trackball

M8024A #B01 M4046-60104 451261000661 Optical Mouse USB / PS/2

M8024A #C01 M4046-60103 451261000651 Wired Track Ball USB / PS2

M8024A #C02 M4046-60105 451261000671 Wireless Track Ball

M8024A #C03 M4046-60106 451261000681 Wired off table Track Mouse

Part Number 12NC Part

Number

Description

Displays and Touch Devices

The following two tables describe the remote displays that can be connected to the monitor’s video

output connector.

For touch operation, the MIB/RS232 interface is required. See “Connecting a Remote Display via the

MIB/RS232 Interface” on page 16.

M8031B: 15” TFT Medical Grade Touch Display

Product Number Part Number 12NC Part

Number

M8031B M8031-60001 45121001911 15” Medical Grade Display with Touch

- M8031-68001 451261001941 Exchange 15” Medical Grade Display with Touch

- M8031-60005 451261001921 Power Supply 12V for M8031B Display

- M8031-64001 451261001931 Power Supply Mounting for M8031B Display

- M8031-04701 451261001901 Monitor Desk Stand for M8031B/M8033C

- 2090-0860 453563463201 Backlights for M8031B

Description

M8033C: 17” TFT Medical Grade Touch Display

Product Number Part Number 12NC Part

Number

M8033C M8033-60071 451261009151 17” Medical Grade Display with Touch

- M8033-68071 451261009161 Exchange 17” Medical Grade Display with Touch

- M8031-04701 451261001901 Monitor Desk Stand for M8031B/M8033C

- M8033-64603 451920880311 Backlights for M8033C

10

Description

Page 21

Site Requirements 2 Site Preparation

Video Cables for Remote Displays

Product Option

Number

M8022 #VA2 M3080-61606 453563484451 1.5 m Analogue Video Cable Kit

M8022 #VA3 M3080-61602 453563334661 3 m Analogue Video Cable Kit

M8022 #VA6 M3080-61603 453563334671 10 m Analogue Video Cable Kit*

Both ends are terminated with HDSUB15 (“VGA”) straight connectors.

*Built on demand

Part Number 12NC Part

Number

Description

11

Page 22

2 Site Preparation Site Requirements

12

Page 23

3Installation Instructions

The information contained in this chapter, in addition to that given in the Instructions for Use, should

enable the monitor to be installed ready for use (the preparation and planning should be adhered to as

specified in the “Site Preparation” chapter). Safety checks and inspection procedures for mounts are

explained in the “Testing and Maintenance” chapter, and configuration of the system is explained in

the “Configuration” chapter.

Please keep the packing materials until you have completed the initial inspection, in case there is a

defect on arrival.

Initial Inspection

Inspect the delivery on arrival.

3

Visual Inspection

Open the shipping container(s) and examine each part of the instrument for visible damage, such as

broken connectors or controls, or scratches on the equipment surfaces. If the shipping carton/container

is undamaged, check the cushioning material and note any signs of severe stress as an indication of

rough handling in transit. This may be necessary to support claims for hidden damage that may only

become apparent during subsequent testing.

Electrical Inspection

The instrument has undergone extensive testing prior to shipment. Safety testing at installation is not

required (except in situations where devices are interconnected forming a system, see “Connecting

Non-Medical Devices” on page 8). An extensive self check may be performed. This recommendation

does not supersede local requirements.

All tests are described in the “Testing and Maintenance” chapter of this manual.

Claims for Damage

When the equipment is received, if physical damage is evident or if the monitor does not meet the

specified operational requirements of the patient safety checks or the extended self check, notify the

carrier and the nearest Philips Sales/Support Office at once. Philips will arrange for immediate repair or

replacement of the instrument without waiting for the claim settlement by the carrier.

13

Page 24

3 Installation Instructions Repackaging for Shipment or Storage

Repackaging for Shipment or Storage

If the instrument is to be shipped to a Philips Sales/Support Office, securely attach a label showing the

name and address of the owner, the instrument model and serial numbers, and the repair required (or

symptoms of the fault). If available and reusable, the original Philips packaging should be used to

provide adequate protection during transit. If the original Philips packaging is not available or reusable

please contact the Philips Sales/Support Office who will provide information about adequate

packaging materials and methods.

Mounting Instructions

Every type of compatible mounting solution is delivered with a complete set of mounting hardware

and instructions. Refer to the Site prep chapter for a list of mounting options. Refer to the

documentation delivered with the mounting hardware for instructions on assembling mounts.

WARNING It is the customer's responsibility to have the attachment of the mounting hardware to the ceiling, wall,

or mounting rail and the construction of the ceiling, wall, or mounting rail evaluated for structural

integrity and compliance with all local, state and any other required codes by a registered, professional,

structural and/or mechanical engineer.

Ensure that this commitment has been met before assembling mounts.

Line Voltage Selection

You do not need to set the line voltage, as this is done automatically by the power supply. The monitor

has a wide-range power supply that allows you to operate the monitor from an AC (alternating current)

power source of 100 V to 240 V (± 10%) and 50/60 Hz (± 5%).

14

Page 25

Rear View 3 Installation Instructions

Rear View

1 Reserved for future use: protective

earth intended for use in system

installations.

2 Equipotential grounding point

3 Power cord connector

4 Loudspeaker

5 Slot 01 for optional LAN / RS232

12

3

4

(A)(B)

6

9

8

5

7

system interface (for connection to an

obstetrical information and

surveillance system)

6 Slot 02 for optional interfaces:

• Either dual PS/2 system interface

(A) for mouse and keyboard

connection)

• Or MIB interface (B) for external

touch screen connection

7 Slot 03 reserved for future use

8 Video output (VGA)

9 Telemetry interface. If not using one of

the fetal sensor sockets, one Avalon

CTS can be connected at a time to

either socket using the M2732-60001

interface cable (with black connector).

Connecting the Monitor to AC Mains

The monitor is an electrical Class I device in which protection against electric shock does not rely on

basic insulation only, but which includes an additional safety precaution, in that means are provided

for the connection of the equipment to a protective earth conductor in the fixed wiring installation in

such a way that accessible metal parts cannot become live in the event of a failure of the basic

insulation.

WARNING • Always use the supplied power cord with the earthed mains plug to connect the monitor to an

earthed AC mains socket. Never adapt the mains plug from the power supply to fit an unearthed AC

mains socket.

• Do not use AC mains extension cords or multiple portable socket-outlets.

Connecting the Monitor to Non-Medical Devices

Connect the monitor to an obstetrical surveillance system, such as OB TraceVue, via the optional

system interface. For cabling requirements, refer to “Cabling Options and Requirements for

Connection to OB TraceVue” on page 9. For safety-related information, refer to “Connecting NonMedical Devices” on page 8, and “System Test” on page 38.

15

Page 26

3 Installation Instructions Connecting a Remote Display via the MIB/RS232 Interface

Connecting a Remote Display via the MIB/RS232 Interface

The configuration of a specific MIB/RS232 port can be viewed in Configuration Mode and altered in

Service Mode. This is required when a remote display with touchscreen is installed. To configure an

MIB/RS232 port to support a slave display with touchscreen:

1 Select Main Setup.

2 Select Hardware.

3 Select Interfaces.

4 Select MIB/RS232.

5 Select Touch 1.

NOTE Be aware that if you configure a port, this assignment is retained after a boot up. If the MIB/RS232

board is removed and replaced with a different type of board the settings are deleted. If the MIB/

RS232 board is then refitted, you must reconfigure the MIB/RS232 port. The configuration of MIB/

RS232 is not cloned between monitors.

After loading the Factory Defaults, you will need to reconfigure the MIB/RS232 port to re-enable

the touch operation of the connected remote display.

Installing a Remote Display

The monitor is tested and approved for use with the following remote displays:

• Philips M8031B 15” Remote Display

• Philips M8033C 17” Remote Display

The monitor has an analog-only video output signal, with VGA resolution. Use a standard VGA video

cable to connect the remote display to the video output on the rear of the monitor.

Mounting Remote Displays

Mounting solutions for the M8031B and M8033C remote displays must be purchased separately.

Please refer to the installation instructions which ship with the mounting solution purchased.

Before Using the Monitor

WARNING Before starting monitoring, check that the configuration meets your requirements.

Check that the following configuration settings are suitable:

•Line Frequency

• Paper Scale

16

•Paper Speed

•Equipment Label

•Configured SmartKeys

Page 27

Before Using the Monitor 3 Installation Instructions

• Input device configuration (if using an external keyboard or mouse)

• Remote display settings (if using a remote display, see “Connecting a Remote Display via the MIB/

RS232 Interface” on page 16).

If you need to enter configuration mode to change settings:

1 In the Main Setup menu, select Operating Modes.

2 Select Config and enter the passcode.

The passcode for configuration mode is given in the monitor’s service documentation.

The monitor displays Config at the right hand side of the status line and in the center of the Screen

while you are in configuration mode.

Before you leave configuration mode, always be sure to store any changes you made. You must store

changes made to each Settings Block and to each Profile, individually. As it may be difficult to

remember whether the settings you changed belong to a Monitor Settings block or a Measurement

Settings block, we recommend that you store each block before you leave configuration mode.

To leave configuration mode:

1 Enter the Main Setup menu.

2 Select Operating Modes.

3 Select Monitoring.

Checking and Setting Line Frequency

Before using the monitor, check that the line frequency setting is correct for your location, and change

the setting if necessary in Service Mode.

WARNING An incorrect line frequency setting can affect the ECG filter, and disturb the ECG measurement.

Ensure the line frequency setting is correct.

To set the line frequency:

1 Enter the Main Setup menu.

2 Select Global Settings.

3 Select Line Frequency and select 50Hz or 60Hz from the pop-up list.

Checking/Setting Paper Scale

Check the paper Scale Type (US for paper with a scale of 30-240, or Internat’l for paper with a

scale of 50-210) in the Fetal Recorder menu. In Monitoring Mode, you can see this setting (grayed

out), but you cannot change it. It can be changed in Configuration Mode.

1 Enter the Main Setup menu by selecting the SmartKey .

2 Select Fetal Recorder.

3 Check the current setting for Scale Type. If it is not appropriate, change it in the Fetal Recorder

menu in Configuration Mode:

Select Scale Type to toggle between US and Internat’l.

17

Page 28

3 Installation Instructions Before Using the Monitor

Checking/Setting Paper Speed

Check the paper speed before using the monitor. You can choose a paper speed of 1, 2, or 3

centimeters per minute (cm/min). The default setting is 3 cm/min. In Monitoring Mode, you can see

this setting (grayed out), but you cannot change it. It can be changed in Configuration Mode.

As a change in paper speed results in a change in the appearance of a FHR trace, you are advised to

ensure ALL monitors in your institution are set to the same speed.

To set the paper speed:

1 Enter the Main Setup menu using the SmartKey .

2 Select Fetal Recorder.

3 In the Recorder menu, you can see the current speed setting. Select Recorder Speed.

4 Select the desired speed from the given choices: 1, 2 or 3 cm/min.

Configuring the Equipment Label

OB TraceVue requires a unique equipment label. In OB TraceVue, is possible to prevent connection

to monitors with specific equipment labels by means of a filtering mechanism. For more details, see the

OB TraceVue Instructions for Use.

1 Select the Bed Label screen element to call up the Bed Info menu.

2 Select Equipment Label to call up the onscreen keyboard.

3 Enter the system identifier.

Configuring SmartKeys

Check that the configured SmartKeys are suitable. Configure the SmartKeys preferred by the

institution from a global list Global Smart Keys. The global list of SmartKeys is stored as a unique

monitor setting in the monitor configuration. See the section “Configuring Global SmartKeys” on

page 138 for details on how to configure the global SmartKey list.

PS/2 Keyboard/Mouse

Switch off the monitor before connecting any PS/2 compatible device.

Connect the PS/2 connector to the PS/2 Interface board in the monitor at the slot indicated by the

appropriate symbol.

The default keyboard language setting for all initial configurations is “US”.

To configure the keyboard language manually, go to Service Mode, select Main Setup ->

Hardware -> Keyboard and then select the proper language. Please note that this setting does not

clone.

18

Page 29

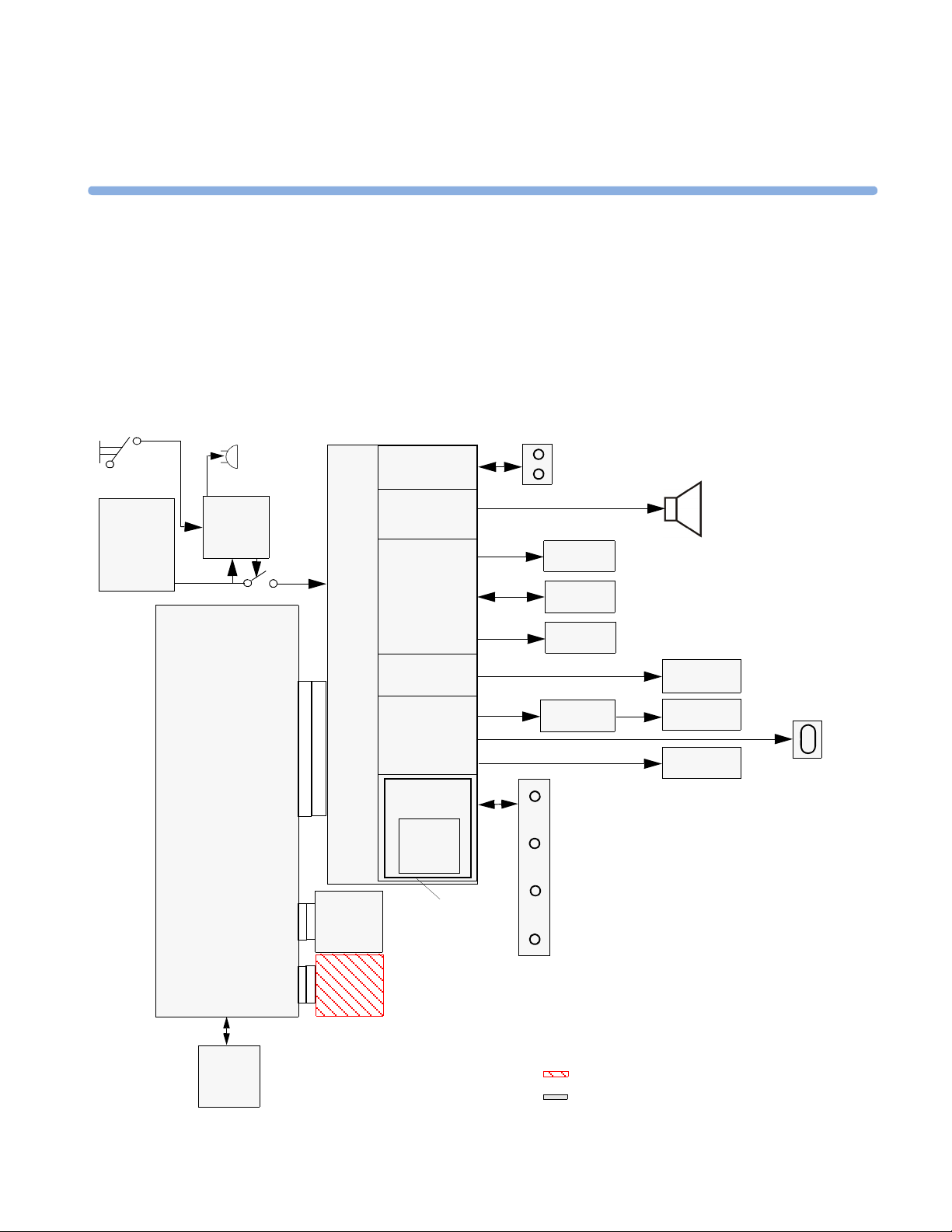

4Theory of Operation

This chapter describes the functional operation of the monitor and the transducers. It incorporates features of

the mechanical design, indicating the physical relationship of the assemblies and components.

Monitor Hardware Overview

Standby

Button

AC-DC

Power

Interrupt

Bleeper

Stand-by

Control

Telemetry

Interface

Audio

Amplifier

4

Telemetry

Connector Block

Loudspeaker

Printhead

Main CPU Board

API

(All Peripheral Interfaces Board)

IF Board 1

(LAN/

RS232)

IF Board 2

Printer

Control

Touch

Control

Display

Control

Bus

Master

SpO

Floating

Isolation

Paper

Sensor

Stepper

Motor

Touch

Screen

Display

Adapter

2

Fetal Sensor Connector Block

Display

Panel

Backlight

Converter

VGA

Connector

NBP

optional boards

standard boards

19

Page 30

4 Theory of Operation Power Supply

The monitor consists of the following main functional components:

•Power supply

• API (All Peripheral Interfaces) Board

• Main CPU Board

• Fetal Recorder (Thermal Printer Unit)

• Fetal Sensor Connector Block

• Noninvasive Blood Pressure Board

•SpO

• Input /Output Interface Boards:

Board

2

–LAN / RS232

–Dual PS/2 (optional)

– MIB / RS232 (optional)

Power Supply

The power supply is a wide-range input switching unit, with an output of 24V. It is located in the chassis

assembly.

Fetal Sensor Connector Block

Any compatible fetal transducer can be connected in any order to the monitor via the sockets on the

Connector Block. The Connector Block is located on the Bus Master section of the All Peripheral

Interfaces (API) Board, and is exchangeable.

API (All Peripheral Interfaces) Board

The All Peripheral Interfaces (API) Board is connected to the Main CPU Board by a 154-pin 0.5 mm

pitch press fit connector.

20

The recorder is controlled by the Printer Control section of the API Board, which is connected to the

Stepper Motor and the Thermal Printer Unit.

The signals from the transducers or sensors are conveyed from the sensor sockets to the Bus Master section

of the API Board. The Telemetry Interface is also integrated into the API Board.

The Bus Master section is responsible for transducer detection, communicates with the connected

transducers via a CAN bus, and communicates parameter data to the Main CPU Board via a serial link for

further processing and display. It has floating power isolation.

The API Board also controls the display panel and the backlight converter, and also controls the

touchscreen. The display panel is connected to the API Board. The VGA connector is also connected to

the API Board.

The API Board incorporates an audio amplifier which controls the loudspeaker.

Page 31

Main CPU Board 4 Theory of Operation

Main CPU Board

The Main CPU Board controls the monitor’s human interface, and is responsible for the final processing of

data from the Bus Master Board. It sends this data to the TFT display, and to the thermal printer unit for

recording traces and other patient data. It also controls the LAN/RS232 interface board, and the optional

PS/2 and MIB interface boards.

Fetal Recorder (Thermal Printer Unit)

The fetal recorder is located in the front of the chassis assembly. The recorder consists of the following

major parts:

•Thermal Line Printhead (TLPH)

•Paper Sensor

•Stepper Motor

Thermal Line Printhead (TLPH)

The TLPH is located on its own holder in the recorder chassis.

Paper Sensor

The paper sensor hardware consists of a reflective light sensor that detects the black marks on the trace

paper, and paper-out. It is attached to the RFI Bracket, and connected to the Recorder Adapter Board via a

removable cable connector.

Stepper Motor

The stepper motor is a bipolar motor controlled by a micro-stepping motor driver on the Recorder Adapter

Board. The motor is located on the recorder chassis and is connected to the Recorder Adapter Board via a

removable cable connector.

LCD Display and Touchscreen

The LCD Display Assembly consists of a five-wire resistive touchscreen, a 6.5” TFT panel, and a backlight

inverter, all connected to the API Board and fitted into the front bezel assembly.

Noninvasive Blood Pressure Assembly

The optional Noninvasive Blood Pressure Assembly is located in the rear lefthand corner of the chassis

assembly. It is connected via a serial link to the Main CPU Board.

SpO2 Assembly

The optional SpO2 Assembly is physically located on the Bus Master section, but sends data directly to the

Main CPU Board via a serial link.

21

Page 32

4 Theory of Operation Input/Output Interface Boards

Input/Output Interface Boards

There are three interface boards available:

• LAN/RS232 Interface Board, used for connecting to a PC running the Support Tool and to a

surveillance and documentation system such OB TraceVue.

• PS/2 Interface Board (optional), used for connecting an external keyboard or mouse.

• MIB Interface Board (optional), used for connecting external touchscreen displays.

The interface boards plug into the two interface slots on the rear panel of the device, and are controlled by

the Main CPU Board.

Transducer Hardware Overview

Analog Signal

Analog/ Digital conversion

A

D

Timing and Mode Control

EEPROM

Master Clock recovery

Signal

processor

Power supply

and reset

Ultrasound frontend board

or alternatively

Transducer

cable

Communication Transceiver

Power and

Identification

Transducer CPU board

22

TOCO/ECG frontend board

1

Page 33

Transducer Types 4 Theory of Operation

Transducer Types

All transducers that can connect to the fetal sensor sockets can be used.

Functional Description of the Transducer CPU

The CPU section of the transducers is made up of the following main functional blocks:

• CPU (micro controller)

• Analog-to-Digital Converter

• Communication Transceiver (CAN bus driver)

• EEPROM

CPU (Micro Controller)

A single-chip processor is used to control the transducer, generate the frontend control signals, control the

analog-to-digital signal conversion, and to perform the signal processing.

Analog-to-Digital Converter

Analog-to-digital (A/D) signal conversion is carried out by the 16-bit AD converter. Digital signals are

directly communicated from the A/D converter to the CPU.

Communication Transceiver (CAN Bus Driver)

The communications transceiver (CAN bus driver) communicates directly with the transducer CPU, and

allows the transducer to communicate with the Bus Master Board via the CAN bus.

EEPROM

The serial EEPROM stores all non-volatile data required to operate the transducer (for example, calibration

and correction factors for frontend gains and offsets, country-specific information, serial numbers and error

logs).

Toco Transducer Frontend

Uterine activity is measured by evaluating the hardness of the mother’s abdomen with a pressure sensitive

resistor bridge (strain gauge sensor element). The strain gauge sensor element requires an excitation voltage

and its differential output signal is proportional to the pressure applied to it. A DC excitation voltage is

used, and the resulting output signal is fed directly to an A/D signal converter before being sent to the

processor.

Ultrasound Transducer Frontend

The ultrasound frontend is a pulsed Doppler system with a 1.0 MHz ultrasound frequency, and a pulse

repetition rate of 3 kHz. Seven ultrasound crystals are used as transmitter and receiver.

23

Page 34

4 Theory of Operation Toco+ Transducer Frontends

Toco+ Transducer Frontends

Several parameter frontends are combined on one board. In addition to the Toco frontend, additional

supported parameters are DECG, MECG and IUP.

A seven-pin ‘D-type’ socket carries all parameter related inputs and outputs. An external mode resistor,

connected to one of the pins, automatically detects which mode to set when an adapter cable is plugged in

(whether it is DECG, MECG, or IUP).

Toco Frontend

See “Toco Transducer Frontend” on page 23.

IUP Frontend

Intrauterine pressure (IUP) is measured via a piezo resistive bridge with AC excitation connected to the

RA / LA input pins of the ECG amplifier. A/D conversion of the IUP signal is done by the 16-bit A/D

converter.

ECG Frontend

The ECG frontend measures both DECG and MECG, using a 3-lead system (RA, LA and reference

electrode). The ECG mode is automatically detected when an adapter cable is attached. Input lines are

ESD protected.

Patient Module Frontends

The patient module shares the same parameter frontends as the Toco+ transducer, with the exception of

the Toco frontend.

Avalon CTS Interface Cable (TMIF)

The Avalon CTS Interface Cable contains the Telemetry Module Interface (TMIF). The TMIF shares the

signal processing circuitry with the rest of the Avalon transducers, with the exception that it has no

frontend board. The TMIF is responsible for converting the analog signals from the parameter frontends

of the Avalon CTS transducers into digital signals for transmission to the fetal monitor.

24

Page 35

5Rear Interfaces

All the interfaces can be found on the recessed rear panel of the monitor.

There are three interface boards available for the Avalon FM40 and FM50 fetal monitors:

• LAN / RS232 system interface

• Dual PS/2 interface (optional)

• MIB interface (optional)

Slot 02:

MIB interface

OR

Dual PS/2

interface

5

Slot 01:

LAN / RS232

system

interface

Telemetry

interface

The interfaces are “plug-and-play” boards, and fit into dedicated slots on the rear panel of the monitor. See

“Removing the Interface Boards” on page 105 for details of how to remove and fit the boards.

LAN / RS232 Interface

The LAN / RS232 system interface has two fully isolated ports:

• The LAN connection can be used for connecting the monitor to a PC for configuration or upgrade using

the Support Tool, for connecting the monitor to an OB TraceVue obstetrical information system on a

network, and for future system expansion.

• The RS232 connection can be used for connecting the monitor to an obstetrical information and

surveillance system, such as OB TraceVue.

Slot 03:

(reserved)

VGA Video

Out

25

Page 36

5 Rear Interfaces Dual PS/2 Interface

Dual PS/2 Interface

This interface provides two PS/2 ports to enable the monitor to be connected to off-the-shelf, “plug-andplay” input devices:

• Mouse: any specified PS/2 mouse or trackball may be used for navigation and data entry.

• Computer keyboard: a PS/2 computer keyboard can be used for data entry instead of the on-screen

pop-up keyboard.

MIB / RS232 Interface

The MIB interface (IEEE P1073) provides two independently configurable ports for connection to an

external touch device.

Telemetry Interface

The telemetry interface is for connecting an Avalon CTS Cordless Fetal Transducer System. If you are not

already using the M2731-60001 interface cable (with red connector) to connect to one of the fetal sensor

sockets, one Avalon CTS can be connected at a time to either rear socket using the M2732-60001

interface cable (with black connector).

VGA Video Out

This connector is for connecting an external analog display. The video output has VGA resolution.

26

Page 37

6Connection to a Network

You can connect the fetal monitor to an OB TraceVue obstetrical information and surveillance system on a

network using the LAN connection on the optional LAN / RS232 interface (see “LAN / RS232 Interface” on

page 21).

Network Infrastructure Requirements

The Avalon FM40/50 sends Connection Indication messages that OB TraceVue processes to establish an

ethernet connection to the fetal monitor. The general requirements for connecting the Avalon FM40/50 to an

OB TraceVue obstetrical surveillance system over a network are as follows:

• The fetal monitor and the data acquisition PC must be in the same network segment.

• The Avalon FM40/50 can be allocated a valid IP address either manually, or from a BOOTP service. If no

IP address is entered manually, the Avalon FM40/50 requires a BOOTP service to obtain a valid IP address

automatically, therefore BOOTP service must be available in each network segment. If the OB TraceVue

internal server is part of that network segment, then it can be configured to serve BOOTP requests.

6

• The ethernet port of the Avalon FM40/50 supports only 10 M-bit half-duplex data transfer.

Connection Indication Messages

Connection Indication (CI) messages can be sent by the Avalon FM40/50 in two ways: by Broadcast or by

Unicast.

Broadcast

When CI messages are sent by broadcast, they have the potential to reach any data acquisition PC in the same

network segment, and the connection to the fetal monitor is made dynamically by the next available host PC

(the data acquisition PC with the least active connections).

Broadcast is the default, and recommended, method for sending CI messages. This is because if there are

multiple host PCs available in the same network segment, the broadcast method provides greater availability

by allowing load balancing and failure-tolerant functionality. If a particular host PC happens to be

unavailable, the next available PC takes over the connection. In the

Server

entry is 0.0.0.0.

Bed Information menu, the IP OB

27

Page 38

6 Connection to a Network Connection Indication Messages

Unicast

When CI messages are sent by unicast, the fetal monitor sends a request to a specific target OB TraceVue

data acquisition hosting PC in the same network segment. The CI message contains the IP address of the

target PC, and only this PC will host the connection.

An example where CI messages are typically sent by unicast is where the fetal monitor and OB TraceVue

PC are installed in the same cart, and you therefore always want the fetal monitor to be hosted by the same

PC.

To avoid conflicts where there are multiple OB TraceVue systems operating in the same network segment,

we recommend that you configure the fetal monitors to send the CI messages by unicast.

To enter the IP address of the target PC:

1 Enter Configuration Mode.

2 Select Main Setup.

3 Select Bed Information.

4 In the Bed Information menu, select IP OB Server.

5 Using the pop-up keypad, enter the IP address of the target server, and press Enter when you are done.

Equipment Label and OB TraceVue Fetal Monitor Domain Name

For connection to an OB TraceVue system over a network, OB TraceVue requires each fetal monitor to

have an unique equipment label.

When a fetal monitor is configured with an equipment label, this equipment label is sent as part of the CI

message. In OB TraceVue, it is possible to specify a Fetal Monitor Domain Name in the fetal monitor

configuration user interface (see OB TraceVue Instructions for Use for details). The OB TraceVue system

compares this name with the fetal monitor equipment label. Only if the domain name matches the

beginning of the equipment label string is the CI message processed and accepted. Otherwise the CI

message is ignored.

Using this filtering process, you can avoid conflicts where there are multiple OB TraceVue systems

operating in the same network segment by controlling which monitors connect to a specific OB TraceVue

system, and which monitors are excluded.

To enter or change the equipment label:

1 Enter Service Mode.

2 Select Main Setup.

3 Select Bed Information.

4 In the Bed Information menu, select Equipment Label.

5 Enter the desired equipment label for your monitor (up to 12 alphanumeric characters are displayed),

then press

Enter.

28

Page 39

7Testing and Maintenance

This chapter contains the testing and maintenance procedures to ensure the proper functioning of the

monitor and accessories, covering preventive maintenance, performance assurance and safety.

Carry out the procedures as specified in the following sections.

For detailed instructions on how to clean the monitor, transducers and accessories, see the monitor’s

Instructions for Use.

Recommended Frequency

Perform the procedures as indicated in the suggested testing timetable. These timetable

recommendations do not supersede local requirements.

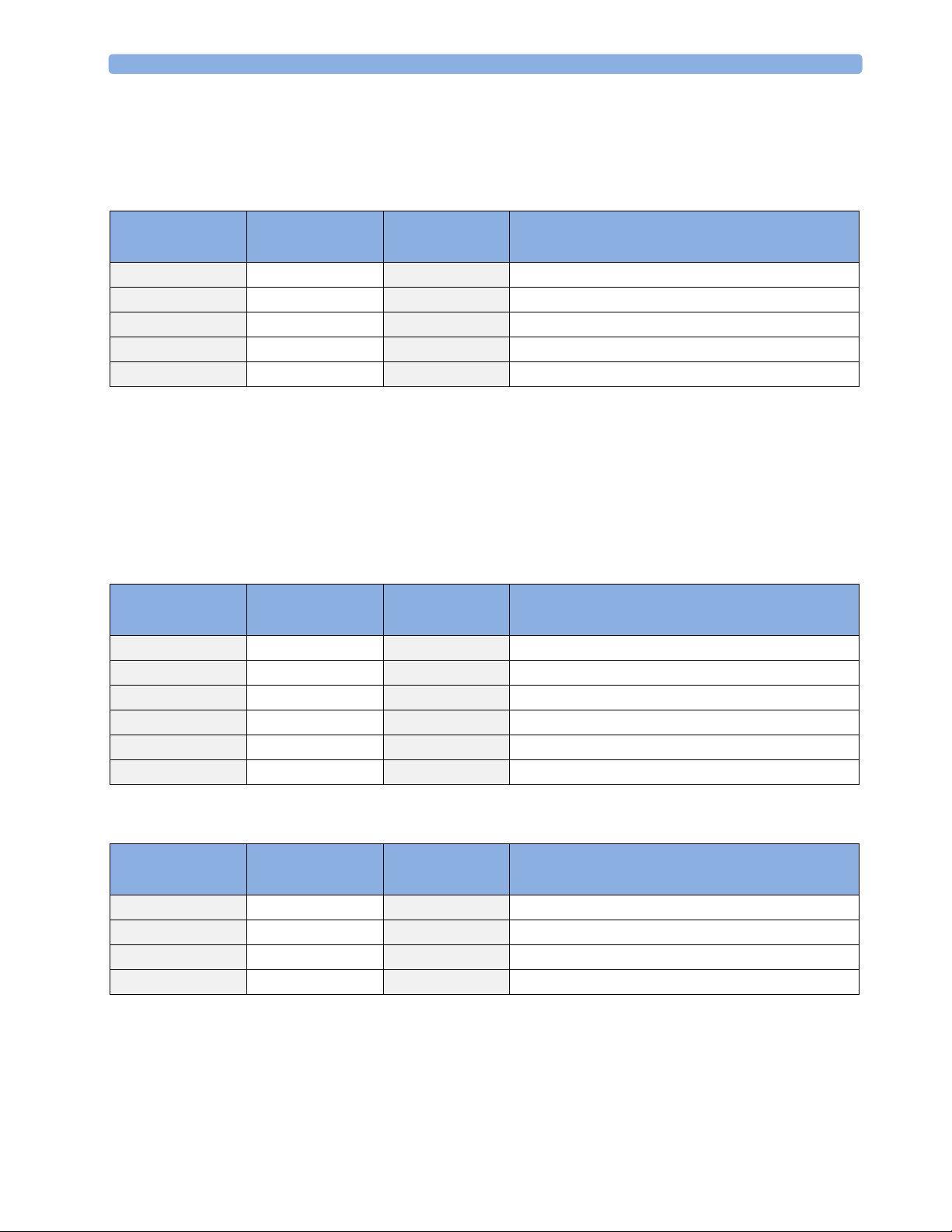

Table 1: Suggested Testing Timetable

7

Te s ts Frequency

Preventive Maintenance

Other Regular Tests

Performance Assurance

Te s ts

Safety Tests Visual

Electrical

Noninvasive Blood Pressure Calibration Once every two years, or as specified by

local laws (whichever comes first).

Visual Inspection Before each use.

Recorder Maintenance Once a year, or if the printout is

degraded.

Testing Transducers and Patient Modules Once a year, or if you suspect the

measurement is incorrect.

Noninvasive Blood Pressure Performance Tests Once every two years, or if you suspect

SpO

Performance

2

Visual Inspection Once every two years and after repairs

Protective Earth

Equipment Leakage Current

Patient Leakage Current

the measurement is incorrect.

where the power supply is removed or

replaced, or if the NBP assembly, SpO

board, or fetal sensor connector block

is removed or replaced, or the monitor

has been damaged by impact.

2

29

Page 40

7 Testing and Maintenance When to Perform Test Blocks

When to Perform Test Blocks

This table tells you when to perform specific test blocks. See page 31 for test details.

Table 2: When to perform test blocks

Service Event Test Block(s) Required - Complete these tests

Installation

Installation of standalone monitor Perform Visual Inspection and Power On Test Blocks (see Table 3).

Installation of monitor with a display

connected to the video output

Installation of networked monitor

(LAN)

Preventive Maintenance

Noninvasive Blood Pressure

performance testing

Other Regular Tests and Tasks

Visual Inspection Perform Visual Inspection test block (see Table 3).

Transducer and Patient Module

Testing

Recorder Maintenance Regular cleaning and maintenance (see “Fetal Recorder Maintenance” on

Perform Visual Inspection, Power On and System test blocks (see Table 3).

Perform Visual Inspection, Power On and System test blocks (see Table 3).

Perform Noninvasive Blood Pressure Performance tests blocks (see Table 3).

See “Performance Assurance Tests” on page 38.

page 31

Perform the recorder selftest (see “Fetal Recorder Selftest Report” on page 50).

Repairs

Repairs when the monitor has been

damaged by impact.

Repairs where the power supply has

been removed or replaced.

All repair events involving any of the

following: Noninvasive Blood

Pressure connector, SpO

board or the red fetal sensor sockets.

All other repair events. Perform Visual Inspection, Power On and Performance test blocks (see

Upgrades

Software upgrades. Perform Visual Inspection and Power On test blocks (see Table 3.)

Combining or Exchanging System

Components

All other service events Per form Visual Inspection, Power On and Performance test blocks (see

connector/

2

Perform Visual Inspection, Power On, Performance and all Safety test blocks

(see Table 3).

Perform Visual Inspection, Power On, Performance test blocks and all Safety

test blocks (see Table 3).

Table 3).

Perform the System Test (see Table 3 and “System Test” on page 37).

Table 3).

30

Page 41

Preventive Maintenance Procedures 7 Testing and Maintenance

Preventive Maintenance Procedures

Noninvasive Blood Pressure Measurement Calibration

Carry out the noninvasive blood pressure measurement performance tests at least every two years, or as

specified by local laws (whichever comes first).

Fetal Recorder Maintenance

The recorder platen, thermal printhead and paper sensor should be cleaned at least once a year, or

when needed (when traces become faint).

Clean the assemblies as follows:

• Clean the recorder roller with a lint-free cloth using a soap/water solution.

• Wipe the printhead using a cotton swab moistened with 70% Isopropyl alcohol based solution.

• Check the paper sensing mechanism is dust free.

Testing Sequence

Here is a summary of the recommended sequence of testing:

Start

Select the test

Visual Inspection

Safety Tests

Performance Tests

Reporting of Results

Evaluation of Results

See “When to Perform Test Blocks” on page 30.

See ““Visual Inspection” on page 32.

See “Safety Test Procedures” on page 33.

See “Performance Assurance Tests” on page 38.

See “Reporting of Test Results” on page 41.

Check and prepare for normal use

NOTE If any single test fails, testing must be discontinued immediately and the device under test must be

repaired or labeled as defective.

31

Page 42

7 Testing and Maintenance Visual Inspection

Visual Inspection

Before Each Use

Check all exterior housings for cracks and damage. Check the condition of all external cables, especially

for splits or cracks and signs of twisting. If serious damage is evident, the cable should be replaced

immediately. On the Toco

not damaged. Check that all mountings are correctly installed and secure. Refer to the instructions that

accompany the relevant mounting solution.

After Each Service, Maintenance or Repair Event

Ensure all fuses accessible from the outside comply with the manufacturer’s specification.

Check:

• the integrity of mechanical parts, internally and externally.

• any damage or contamination, internally and externally.

• that no loose parts or foreign bodies remain in the device after servicing or repair.

• the integrity of all relevant accessories.

+

transducer and the patient module, ensure that the adapter cable socket is

Safety Tests

Safety test requirements are set according to international standards, their national deviations and

specific local requirements. The safety tests detailed in this Service Guide are derived from

international standards but may not be sufficient to meet local requirements. We recommend that you

file the results of safety tests. This may help to identify a problem early particularly if the test results

deteriorate over a period of time.

Warnings, Cautions, and Safety Precautions

• These tests are well established procedures of detecting abnormalities that, if undetected, could

result in danger to either the patient or the operator.

• Disconnect the device under test from the patient before performing safety tests.

• You need test equipment (for example, a Safety Analyzer) to perform the tests. Ensure the test

equipment is specified to be suitable for the respective test(s). Refer to the documentation that

accompanies the test equipment. Only skilled technicians should perform safety testing.

• The consistent use of a Safety Analyzer as a routine step in closing a repair or upgrade is emphasized

as a mandatory step to maintain approval agency status. You can also use the Safety Analyzer as a

troubleshooting tool to detect abnormalities of line voltage and grounding plus total current loads.

• During safety testing, high voltage and electrical currents are applied to the device under test. This

could result in danger to the safety analyzer operator.

32

• For Europe and Asia/Pacific, the monitor complies with:

IEC60601-1:1988 + A1:1991 + A2:1995 = EN60601-1:1990 +A1:1993 + A2:1995

For USA, the monitor complies with:

UL60601-1

For Canada, CAN/CSA C22.2#601.1-M90

Page 43

Safety Tests 7 Testing and Maintenance

• Additional tests may be required according to local regulations.

• Any device that is connected to the medical device must comply with IEC/EN 60601-1, and

UL60601-1:2003 for the USA, if within the patient vicinity and be separately tested at the same

intervals as the monitor.

• Perform safety tests as described on the following pages.

Safety Test Procedures

Use the test procedures outlined here only for verifying safe installation or service of the product. The

setups used for these tests and the acceptable ranges of values are derived from local and international

standards but may not be equivalent. These tests are not a substitute for local safety testing where it is

required for an installation or a service event. If using an approved safety tester, perform the tests in

accordance with the information provided by the manufacturer of the tester and in accordance with

your local regulations, for example IEC/EN 60601-1, UL60601-1 (US), IEC/EN 62353, and IEC/EN

60601-1-1. The safety tester should print results as detailed in this chapter, together with other data.

Please refer to Annex C of IEC/EN 62353 for requirements for the measurement equipment and for

measurement circuits for protective earth resistance and leakage currents.

The following symbols are used in the diagrams illustrating the safety tests:

Supply mains Protective earth

L, N

.........

CAUTION After each service, maintenance or repair event:

Ensure all fuses accessible from the outside comply with the manufacturer’s specification.

Check:

• the integrity of mechanical parts, internally and externally.

Supply mains terminals

Mains part Applied part

F-type applied part Measuring device

Resistance measuring device Connection to accessible parts

Optional connection

PE

Protective earth terminal

• any damage or contamination, internally and externally.

• that no loose parts or foreign bodies remain in the device after servicing or repair.

• the integrity of all relevant accessories.

33

Page 44

7 Testing and Maintenance Safety Tests

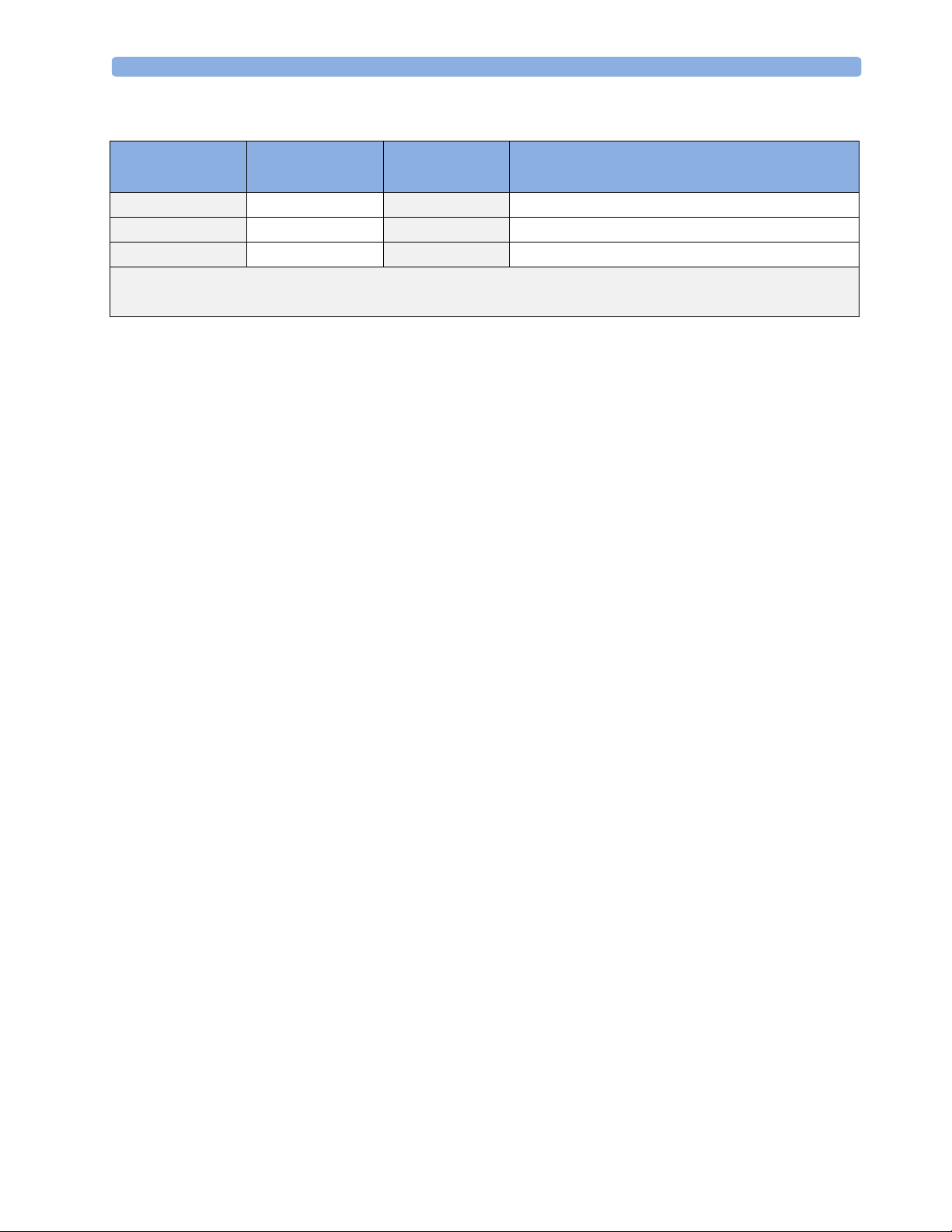

S(1): Protective Earth Resistance Test

Test to perform:

Measuring circuit for the measurement of Protective Earth Resistance in medical electrical

equipment that is disconnected from the supply mains.

This measures the impedance of the Protective Earth (PE) terminal to all exposed metal parts of the

Instrument under Test (IUT), which are for safety reasons connected to the Protective Earth (PE).

Measurements shall be performed using a measuring device capable to deliver a current of at least

200 mA.

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, and

For measurement limits, refer to test block Safety (1), “Test and Inspection Matrix” on page 42.

Report the highest value (X1).

NOTE If the protective earth resistance test fails, testing must be discontinued immediately and the device

under test must be repaired or labeled as defective.

UL2601-1 Ed. 2/UL60601-1:2003.

S(2): Equipment Leakage Current Test - Normal Condition

Test to perform:

34

Measuring circuit for the measurement of Equipment Leakage Current - Direct method according to

IEC/EN 62353.

Page 45

Safety Tests 7 Testing and Maintenance

This test measures leakage current of exposed metal parts of the FM40/FM50 monitor and the

functional earth leakage current. It tests normal and reversed polarity. Perform the test with S1 closed

(Normal Condition).

There are no parts of the equipment that are not protectively earthed.

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, and

UL2601-1 Ed. 2/UL60601-1:2003.

For measurement limits, refer to test block Safety (2), “Test and Inspection Matrix” on page 42.

Report the highest value (X1).

S(3): Equipment Leakage Current Test - Single Fault Condition

Test to perform:

Measuring circuit for the measurement of Equipment Leakage Current - Direct method according to

IEC/EN 62353.

This test measures leakage current of exposed metal parts of the FM40/FM50 monitor and the

functional earth leakage current. It tests normal and reversed polarity. Perform the test with S1 open

(Single Fault Condition).

There are no parts of the equipment that are not protectively earthed.

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, and

UL2601-1 Ed. 2/UL60601-1:2003.

For measurement limits, refer to test block Safety (3), “Test and Inspection Matrix” on page 42.

Report the highest value (X2).

S(4): Applied Part Leakage Current - Mains on Applied Part

NOTE During measurement of the Applied Part Leakage Current it is possible that the measured current can

exceed the allowed limit (per IEC/EN 60601-1 or IEC/EN 62353).

This can occur when the safety tester is connected to more than one connector simultaneously, that is,

either to two fetal sensor connectors at the same time, or to a fetal sensor connector and the SpO

connector at the same time during the applied leakage current measurement.

The connectors for the fetal sensors and for SpO

are independently functioning connectors.

2

2

35

Page 46

7 Testing and Maintenance Safety Tests

SpO2 Connector Fetal Sensor Connectors

Test one connector at a time! Do not connect the tester to the SpO2 connector at the same time as

one of the fetal sensor sockets.

Although there are individual connectors on the front end, internally those parameters use the same

electrical insulation interface and are hardwired to each other. This results in an electrical short of those

connectors during measurement if a test current is applied simultaneously. Therefore this should be

avoided.

Due to the combined insulation interface, it is sufficient to connect to only one parameter interface

(that is, one of the fetal sensor connectors or SpO

) of the fetal sensor/SpO2 measurement block. This

2

avoids a short and the potential of exceeding the limit for the current.

Test to perform:

MECG Electrodes

DECG Electrodes

Measuring circuit for the measurement of Applied Part Leakage Current - Direct method according

to IEC/EN 62353.

This test measures applied part leakage current from applied part to earth caused by external main

voltage on the applied part of 264V. Each polarity combination possible shall be tested. This test is

applicable for ECG measurement inputs.

There are no parts of the equipment that are not protectively earthed.

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, and

UL2601-1 Ed. 2/UL60601-1:2003.

For measurement limits and test voltage, refer to test block Safety (4), “Test and Inspection Matrix” on

page 42.

Report the highest value. (X1).

36

Page 47

System Test 7 Testing and Maintenance

System Test

After mounting and setting up a system, perform system safety tests according to IEC/EN 60601-1-1.

What is a Medical Electrical System?

A medical electrical system is a combination of at least one medical electrical device and other electrical

equipment, interconnected by functional connection or use of a multiple portable socket-outlet.

• Devices forming a system must comply with IEC/EN 60601-1-1.

• Any device that is connected to the medical device must comply with IEC/EN 60601-1-1 if outside

the patient vicinity and be tested accordingly.

General Requirements for a System

After installation or subsequent modification, a system must comply with the requirements of the

system standard IEC/EN 60601-1-1. Compliance is checked by inspection, testing or analysis, as

specified in the IEC/EN 60601-1-1 or in this book.

Medical electrical equipment must comply with the requirements of the general standard IEC/EN

60601-1, its relevant particular standards and specific national deviations. Non-medical electrical

equipment shall comply with IEC and ISO safety standards that are relevant to that equipment.

Relevant standards for some non-medical electrical equipment may have limits for equipment leakage

currents higher than required by the standard IEC/EN 60601-1-1. These higher limits are acceptable

only outside the patient environment. It is essential to reduce equipment leakage currents when nonmedical electrical equipment is to be used within the patient environment.

System Example

This illustration shows a system where both the medical electrical equipment and the non-medical

electrical equipment are situated at the patient’s bedside.

Key:

Non-Medical Devices

Distance to patient

must be >= 1.5m

Power cables:

Data cables:

Personal

Computer

Isolation

Transformer

Medical Devices

Fetal Monitor

37

Page 48

7 Testing and Maintenance Performance Assurance Tests

WARNING • Do not use additional AC mains extension cords or multiple portable socket-outlets. If a multiple

portable socket-outlet is used, the resulting system must be compliant with IEC/EN 60601-1-1.

• Do not connect any devices that are not supported as part of a system.

• Do not use a device in the patient vicinity if it does not comply with IEC/EN 60601-1. The whole

installation, including devices outside of the patient vicinity, must comply with IEC/EN 60601-1-1.

Any non-medical device, including a PC running an OB TraceVue system, placed and operated in

the patient’s vicinity must be powered via a separating transformer (compliant with IEC/EN 606011-1) that ensures mechanical fixing of the power cords and covering of any unused power outlets.

Performance Assurance Tests

Some of the following test procedures must be performed in service mode. To enter service mode select

Operating Modes in the main menu. Then select Service Mode and enter the password.

Noninvasive Blood Pressure Performance Tests

This section describes noninvasive blood pressure test procedures. The monitor must be in service

mode.

Table 3 gives the expected test results for each of the tests.

Accuracy Test

This test checks the performance of the noninvasive blood pressure measurement. Connect the

equipment as shown:

Tools required:

• Reference manometer (includes hand pump and valve), accuracy 0.2% of reading.

• Expansion chamber (volume 250 ml +/- 10%)

• Appropriate tubing.

Expansion Chamber

Tubing

Connect to Noninvasive Blood

Pressure socket

Manometer

38

In service mode, the systolic and diastolic readings indicate the noise of noninvasive blood pressure

channels 1 and 2 respectively. When static pressure is applied, the reading in noninvasive blood

pressure channel 1 should be below 50. The value in parentheses indicates the actual pressure applied

to the system.

Page 49

Performance Assurance Tests 7 Testing and Maintenance

Connect the manometer and the pump with tubing to the noninvasive blood pressure connector

1

on the monitor and to the expansion chamber.

2 In service mode, select the Setup NBP menu.

3 Select Close Valves: On

4 Raise the pressure to 280 mmHg with the manometer pump.

5 Wait 10 seconds for the measurement to stabilize.

6 Compare the manometer values with the displayed values.

7 Document the value displayed by the monitor (X1).

8 If the difference between the manometer and displayed values is greater than 3 mmHg, calibrate

the noninvasive blood pressure measurement. If not, proceed to the leakage test.

9 To calibrate the noninvasive blood pressure measurement, select Close Valves off then

Calibrate NBP and wait for the instrument to pump up the expansion chamber.Wait a few

seconds after pumping stops until EnterPrVal is highlighted and then move the cursor to the

value shown on the manometer. If one of the following prompt messages appears during this step,

check whether there is leakage in the setup:

– NBP unable to calibrate–cannot adjust pressure

– NBP unable to calibrate–unstable signal

10 Press Confirm.

If the INOP NBP Equipment Malfunction message occurs in monitoring mode, go back to service

mode and repeat the calibration procedure.

Leakage Test

The noninvasive blood pressure leakage test checks the integrity of the system and of the valve. It is

required once every two years and when you repair the monitor or replace parts.

1 If you have calibrated, repeat steps 2 to 6 from the accuracy test procedure so that you have 280

2 Watch the pressure value for 60 seconds.