Page 1

Obstetrical Care

SERVICE GUIDE

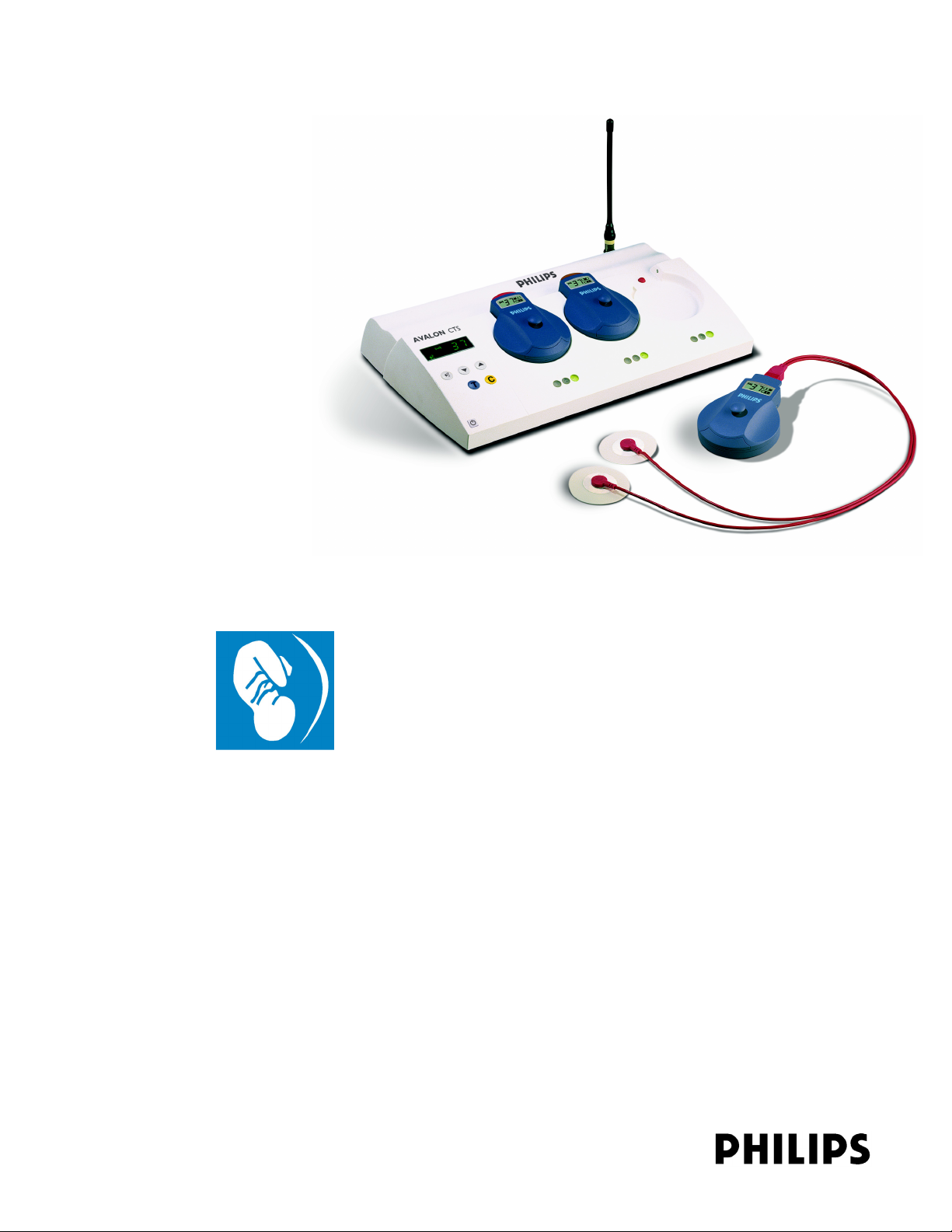

Avalon CTS

Cordless Fetal Transducer System

M2720A

FETAL MONITORING

Page 2

Printed in Germany 10/04

*M2720-9000C*

Part Number M2720-9000C

4512 610 04681

S

Page 3

Avalon CTS

Cordless Fetal Transducer System

M2720A

SERVICE GUIDE

M2720-9000C

October 2004

Printed in Germany

Page 4

ii

Page 5

Contents

1 General Information 1

Who Should Read This Guide 1

What to Do Next 1

Repair Strategy 2

Pre-Installation Considerations 2

When is the Avalon CTS Customer Installable? 2

When are Special Configurations Needed? 3

Warnings, Cautions and Important Information 3

Symbols on the System 3

Patient Safety 4

Protective Earth 5

Environment 5

General Description 5

Mounting Solutions 6

Applying the Velcro Fixing Tape 7

Antenna Extension Mounting Kit 8

Mounting on Philips Carts 8

Mounting on Wooden Carts and Other Flat Surfaces 9

Considerations for Choice of Configuration 9

Frequency Bands 9

Standard Delivery Configuration 10

When is a Different Configuration Needed? 10

When the Area of Reach is Not Sufficient 10

When the Standard Configuration is Unsuitable 10

Japanese Systems 10

Multi-Region Base Station 11

Frequency Planning 11

Setting Expectations 11

Antenna System Guidelines 12

Before You Install an Antenna System 12

Specifications 13

Mixed Telemetry Devices on the Same M2600A Antenna System 13

2 Theory of Operation 15

Receiver Board 16

Human Interface Board 16

Power Supply 16

Slot Control and Monitor Interface Board Hardware 16

Page 6

Transducer Hardware Overview 17

Functional Description of the RF/CPU Hardware 17

Base Station Communication 18

Power Supply and Battery Charger 18

Modulator 18

RF Transmitter 18

Toco Frontend Hardware 18

Ultrasound Frontend Hardware 18

ECG Frontend Hardware 18

3 System Interfaces 21

Fetal Monitor Interface 21

Service Interface 22

Compatible Fetal Monitors 23

4 Disassembly/Reassembly 25

Introduction 25

Removing the Top Cover Assembly 26

Replacing the Top Cover Assembly 27

Changing Fuses 28

Changing the Power Supply/Metal Chassis Assembly 31

5 Spare Parts 39

Exchange Parts 39

Non-Exchange Parts 40

Supplies and Accessories 40

Antenna and Base Station Part Numbers 41

6 Preventive Maintenance and Safety 43

Care and Cleaning 43

Recommended Frequency of Testing 43

Performance Assurance Tests 44

Self Test 44

Parameter Test 44

Testing Alarms 45

Safety Tests 45

Safety Test Procedures 46

When to Perform Safety Tests 46

How to Carry Out the Test Blocks 47

Description of Applicable Safety Tests 48

S(1): Protective Earth Test 48

S(2): Enclosure Leakage Current Test

- Normal Condition (NC) 48

S(3): Enclosure Leakage Current Test

- Single Fault Condition (SFC) Open Supply 49

Page 7

S(4): Enclosure Leakage Current

- SFC Open Earth (Ground) 49

Instrument Safety Test 50

System Test 50

What is a Medical Electrical System? 50

General Requirements for a System 50

System Example 51

Regular Preventive Maintenance 51

Mechanical Inspection 51

Visual Check 52

Toco Ventilation/Belt Button 52

Testing the Ventilation Membrane 52

Battery Check 53

Starting the Battery Check 53

Stopping the Battery Test 54

Stages of the Battery Check 54

Reading Battery Check Data Using the Service Support Tool 55

Battery Exchange 55

7 Troubleshooting 57

System is Completely Inoperative 57

System Reset 57

Common Problems 58

Troubleshooting a Cordless System: an Overview 59

Checking Contacts 60

Checking the Fetal Monitor 60

RF Problems 60

Carrier to Noise Ratio 60

Gathering Data 61

Observe System Performance 61

Question the User 61

Area of Reach 62

Range Definition 62

Using the Base Station 62

Using the Service Support Tool 63

RF Interference 63

One-Channel or Narrowband Interference 63

Broadband Interference 64

Guidelines for Channel/Frequency Configuration 64

Scanning the Available Frequency Range 64

Excluding Frequencies 65

Base Station with Fixed Frequency 65

Transducers with Fixed Frequency 66

Transducers for Japan 66

Page 8

Multi-Region Base Station 66

Delivery Status 66

Installation 66

Testing Transducers 67

Ultrasound Transducer Electrical Check 67

TOCO Transducer Electrical Check 68

ECG Transducer Electrical Check 69

In DECG Mode 69

In MECG Mode 70

Troubleshooting the Top Cover 71

Function Buttons 71

Display/Window 72

LEDs 72

Magnets 72

Factory Information Code Log 72

8 Changing Settings 73

Configuration Settings 73

Function Settings 74

Bed Label Appearance 74

Enabling/Disabling Fixed Frequency 74

Selecting the Channel Frequency Spacing 75

Action Settings 77

Displaying the Software Revision 77

Clearing the Factory Information Code (FIC) Log 77

Starting the Battery Check 78

9 Upgrades 79

10 Specifications 81

General 81

Base Station 81

Tr a n s d u c e r s 82

Frequency Bands 83

Frontends 83

Cables 84

Electromagnetic Compatibility (EMC) Specifications 85

Emissions and Immunity 85

Electromagnetic Immunity 85

Finding Recommended Separation Distances 86

Recommended Separation Distances from Portable and Mobile RF Communication

Equipment

88

Page 9

A Removing and Replacing the Transducer Battery 89

B Removing and Replacing the Transducer Belt Button 91

C Avalon CTS Frequency Table 93

Page 10

Page 11

1

1General Information

This guide tells you how to service and repair the base station (M2720A) and transducers (M2725A,

M2726A, and M2727A) of the Avalon CTS Cordless Fetal Transducer System. It describes the system

hardware and software, tells you how to diagnose operating and servicing problems, and how to test the

system.

As this system is intended to be installed by the customer, refer to the Instructions for Use for details of how to

install the system. See also “Pre-Installation Considerations” on page 2.

The Avalon CTS Cordless Fetal Monitoring System Service Guide supplements the maintenance and

troubleshooting procedures, carried out by the operator, that are described in the Instructions for Use. Refer to

the Instructions for Use for maintenance and troubleshooting procedures that may be performed during

normal operation.

Only qualified service personnel should attempt to install the system, disassemble the base station, remove or

replace any internal assemblies, or replace the transducer batteries or belt buttons.

Who Should Read This Guide

This guide is for any qualified technical personnel servicing and repairing the Avalon CTS Cordless Fetal

Transducer System.

You must:

•understand English

• be familiar with standard medical equipment installation procedures

• be familiar with current conventional technical terms as used throughout this guide

What to Do Next

Familiarize yourself with the contents of this guide and the Instructions for Use before attempting to service or

repair the system.

1

Page 12

1 General Information Repair Strategy

Repair Strategy

The Service Support Tool software helps you to determine whether a fault is a hardware, software or RFrelated problem. Any maintenance and repair procedures beyond the level covered in the Instructions for

Use are limited to:

• unit exchange for

–the base station

–the transducers

•replacement of

– the top cover assembly, including human interface board

– the power supply, including metal chassis

– two fuses in the power supply

– the transducer battery

– the transducer ventilation knob

Repair or replacement of individual components on the boards is not supported, and should never be

attempted.

For any problem related to connecting the base station to an antenna system, refer to the M2600A

Telemetry System’s Service Training and Reference Guide.

For tests that you are required to perform after repairs, refer to “When to Perform Safety Tests” on

page 38.

Pre-Installation Considerations

There are a number of factors you need to consider that influence how you install the Avalon CTS.

When is the Avalon CTS Customer Installable?

The Avalon CTS is intended to be customer installable under the following conditions:

• The system in its standard configuration is an “out-of-the-box”, standalone system, delivered with

automatic frequency allocation, and is intended to be used with the standard antenna supplied, giving a

line-of-sight operating range up to 100m/300ft.

• There are less than ten stand-alone systems in the institution.

• Connection to an antenna system is not planned.

• No other telemetry devices are used in the institution that can influence, or be influenced by, the

Avalon CTS.

• There are no other sources of RF interference that influence the operation of the Avalon CTS.

• There are no country-specific regulations requiring special configuration.

Installation should be carried out by qualified technical personnel.

If you need to mount the Avalon CTS, or use the antenna extension mounting kit (M1361A Option

1AA), see page 8 for further details.

2

Page 13

Warnings, Cautions and Important Information 1 General Information

When are Special Configurations Needed?

If one or more of the conditions above are not met, you need a special configuration of the Avalon CTS

(refer also to “Considerations for Choice of Configuration” on page 9). For instance, you may need to:

• Set fixed frequencies when there are other telemetry systems installed in the same institution. (In Japan,

local regulations always require the setting of fixed frequencies.) This configuration should be carried out

by qualified service personnel, either from the hospital’s biomedical department, or from Philips.

• Connect the Avalon CTS to an antenna system because the standard antenna is not sufficient to cover

the area intended for cordless monitoring. Site preparation, antenna system design (including guidelines

for mixed telemetry equipment installations), and installation should be carried out by qualified service

personnel from Philips.

• There are country-specific regulations requiring special configuration (in Japan, for example), or your

country requires a Multi-Region base station.

Warnings, Cautions and Important Information

WARNING A warning alerts you to a potential serious outcome, adverse event or safety hazard. Failure to observe a

warning may result in death or serious injury to the user or patient.

CAUTION A caution alerts you to circumstances where special care is necessary for the safe and effective use of the

product. Failure to observe a caution may result in minor or moderate personal injury, damage to the

product or other property, and possibly in a remote risk of more serious injury.

In this book, graphical symbols (indicators or elements of the base station or transducer

displays) depicted in this way indicate that they are blinking.

© Copyright 1995-2004 Koninklijke Philips Electronics N.V. All Rights Reserved.

Symbols on the System

This attention symbol indicates that you should consult this book and the Instructions for Use, and

particularly any warning messages.

Power-On/Stand-by Switch.

Power-On/Stand-by Indicator.

Equipotential Terminal.

This symbol identifies terminals that are connected together, bringing various equipment or parts

of a system to the same potential. This is not necessarily earth potential. The value of potentials of

earth may be indicated adjacent to the symbol.

3

Page 14

1 General Information Patient Safety

Protective Earth Terminal.

This symbol identifies the terminal for connection to an external protective earth system.

Antenna input symbol.

Service socket symbol.

This symbol appears on the device adjacent to the CE mark and defines Class 2 radio equipment

per Radio and telecommunications Terminal Equipment Directive 1995/5/EC.

IPX1

IP68

Ingress Protection code according to IEC 60529. Base station is rated IP X1 (protection against

vertical water drops only).

Ingress Protection code according to IEC 60529. All transducers are rated IP 68 (protection

against dust, access to hazardous parts, and the effects of continuous immersion in water to a

depth of 0.5 meter for five hours).

Type CF equipment.

Patient Safety

The Telemetry System should only be used by, or under the direct supervision of, a licensed physician or

other health care practitioner who is trained in the use of fetal heart rate monitors and in the

interpretation of fetal heart rate traces. US federal law restricts this device to sale by, or on the order of, a

physician.

The base station (telemetry receiver) is a Protection Class 1 instrument.

The device complies with the following safety standards:

• EN 60601-1:1990+A1:1993+A2:1995 / IEC 60601-1:1988+ A1:1991+A2:1995

• EN 60601-1-1:2001 / IEC 60601-1-1:2000

• UL2601-1:1997

• CAN/CSA C22.2 No. 601.1-M90

• JIS T 1001-1992

• JIS T 1002-1992

• AS 3200.1.0-1998

The cordless transducers are battery operated devices, applied parts (patient connectors) are Type CF

.

4

Page 15

Protective Earth 1 General Information

Protective Earth

WARNING Check each time before use that the system is in perfect working order and the base station is properly

grounded.

This equipment is intended for use only within healthcare facilities. It is not suitable for use in domestic

establishments and in establishments directly connected to a low voltage power supply network, which

supplies buildings used for domestic purposes.

Do not use additional AC mains extension cords or multiple portable socket-outlets. If a multiple portable

socket-outlet without a separation transformer is used, the interruption of its protective earthing may result

in enclosure leakage currents equal to the sum of the individual earth leakage currents.

To protect hospital personnel and the patient, the cabinet must be grounded. Accordingly, the base station

is equipped with a 3-wire power cable which grounds it to the power line ground when plugged into an

appropriate 3-wire receptacle. Do not use a 3-wire to 2-wire adapter with the base station. Any interruption

of the protective earth grounding will cause a potential shock hazard that could result in serious personal

injury.

Whenever it is likely that the protection has been impaired, the base station must be made inoperative and

be secured against any unintended operation.

The patient cable must be positioned so that it does not come into contact with any other electrical

equipment.

Before operation, make sure that the base station is free from condensation. This can form when

equipment is moved from one building to another, and is exposed to moisture and differences in

temperature.

Environment

Before operation, make sure that the base station is free from condensation. This can form when

equipment is moved from one building to another, and is exposed to moisture and differences in

temperature.

Use the system in an environment which is reasonably free from vibration, dust, corrosive or explosive

gases, extremes of temperature, humidity, and so forth. It operates within specifications at ambient

temperatures between 0°C and +45°C/32°F and +113°F. Ambient temperatures that exceed these limits

can affect the accuracy of the system, the transmitter radio frequency transmission, and can damage the

components and circuits.

The system can be stored at ambient temperatures between -20°C and +60°C/-4°F and +158°F.

The transducers are watertight to a depth of 0.5 meter/1.64 feet (rated IP 68).

The base station is protected against vertically falling water drops only (rated IP X1 according to IEC 60529).

General Description

Refer to the Instructions for Use for operating information for the base station and the transducers. It

includes descriptions of the installation and setup of the system and modes of operation.

5

Page 16

1 General Information Mounting Solutions

Mounting Solutions

You can mount the Avalon CTS as follows:

• In a standard cart drawer. The base station with docked transducers fits into Philips Carts CL, CX and

CM.

Note: if you mount the base station in a cart or in such a way that the standard antenna cannot be

attached directly to the base station, or does not provide sufficient transmission range, use the antenna

extension mounting kit (M1361A Option 1AA).

• On top of carts, desks or other flat surfaces using the mounting brackets.

• In a wide variety of situations using the GCX mounting adapter for mounting the base station (order

directly from GCX, part number PH-0042-80).

• On top of Series 50 IX/XM/XMO fetal monitors using the mounting brackets.

Mounting Brackets

Contact your local Philips representative for additional cart mounting options.

Refer also to the fitting instructions that come with the relevant solution.

6

Page 17

Applying the Velcro Fixing Tape 1 General Information

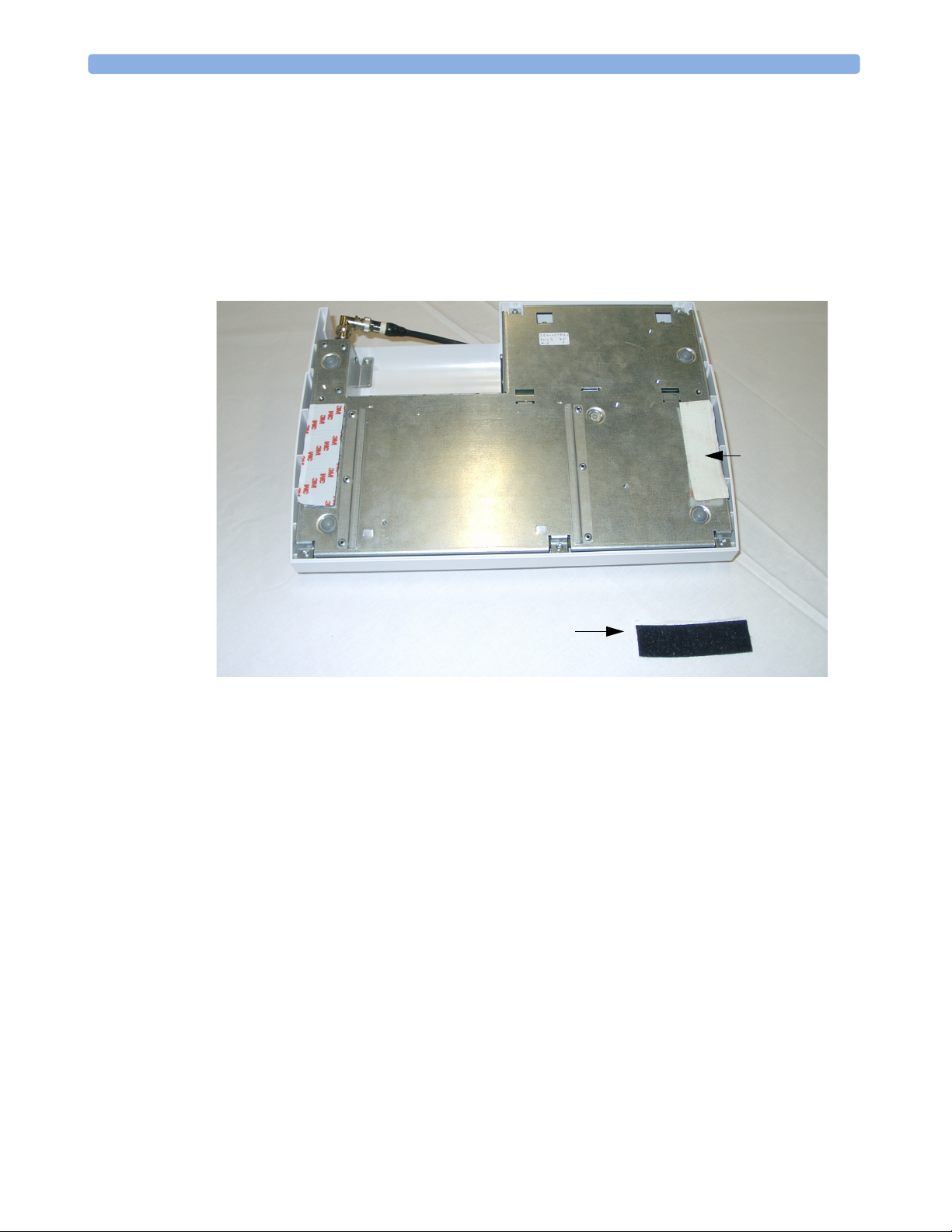

Applying the Velcro Fixing Tape

Two self-adhesive Velcro fixing tape sets are supplied, each set consisting of two halves.

1 Strip off the paper backing on one half of the Velcro set and attach to one side of the underneath of the

base station. Repeat for the other side.

2 Strip off the paper backing on the other half of the Velcro set and attach to the fixing surface so that the

two halves of the Velcro set mate up when the base station is correctly positioned.

Apply one

half of

Velcro

tape in

position

shown

Apply other half of

Velcro tape to appropriate

place on fixing surface

7

Page 18

1 General Information Antenna Extension Mounting Kit

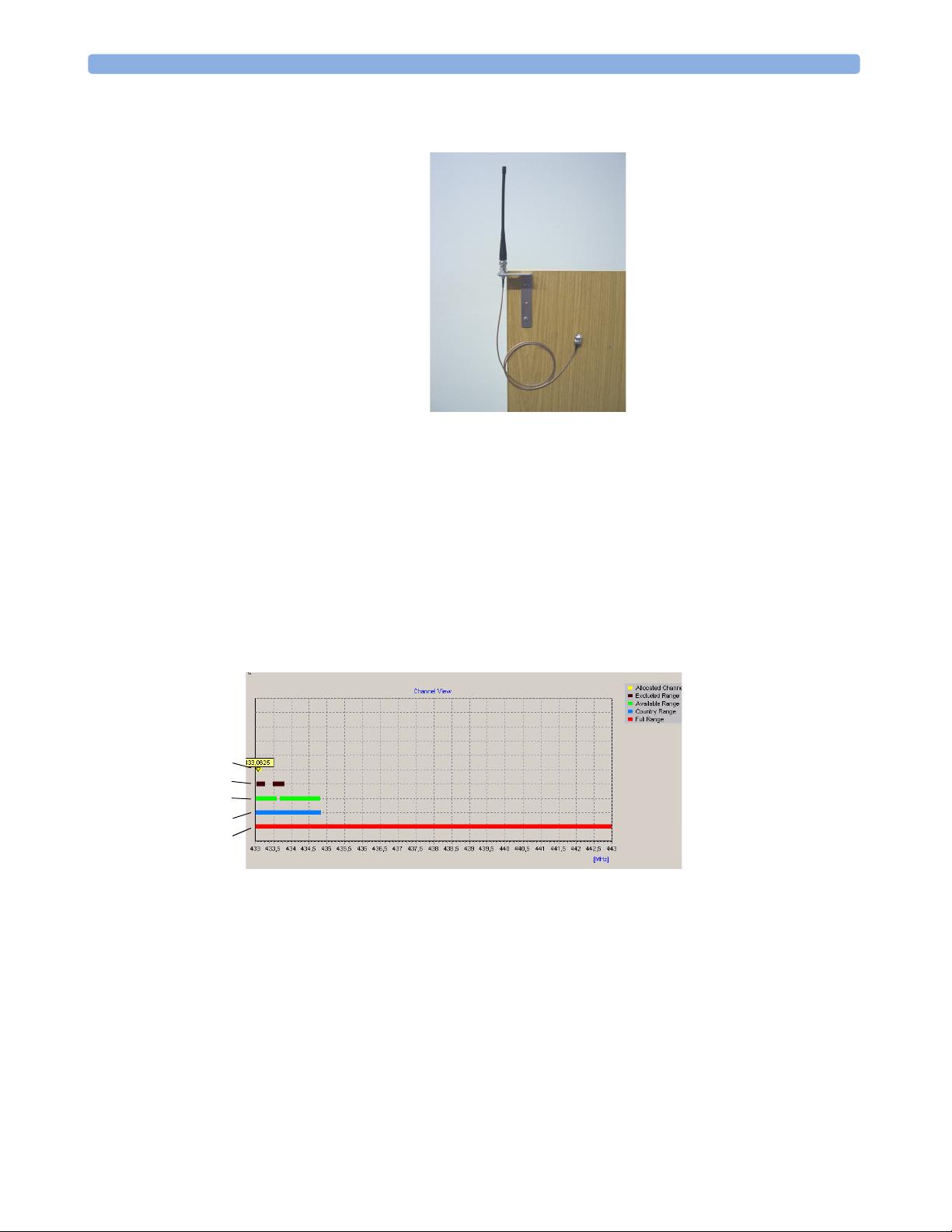

Antenna Extension Mounting Kit

If the base station is installed in a cart or other mounting solution where the standard antenna cannot be

attached directly to the base station, or does not provide sufficient transmission range, use the antenna

extension mounting kit (M1361A Option 1AA).

The kit contains:

• Antenna extension cable with BNC connectors (1.0m/3.3 ft. approx.)

• Mounting bracket, including fixings, for mounting onto Philips Carts.

The mounting bracket can also be fitted on walls, wooden carts, or other flat surfaces using fixings (not

supplied) appropriate for the surface material.

Mounting on Philips Carts

A

C

B

1 Remove the plastic cover (A).

2 Slide the fixings for the mounting bracket (C) into the groove (B) in the cart.

3 Replace the plastic cover (A) before sliding the mounting bracket fully down.

4 Slide the mounting bracket downwards in the groove (B) in the cart until the antenna holder part of the

bracket rests on the plastic cover.

5 Tighten the fixing screws to secure the mounting bracket.

8

Page 19

Considerations for Choice of Configuration 1 General Information

Mounting on Wooden Carts and Other Flat Surfaces

Considerations for Choice of Configuration

There are a number of factors that can influence how you finally configure the Avalon CTS.

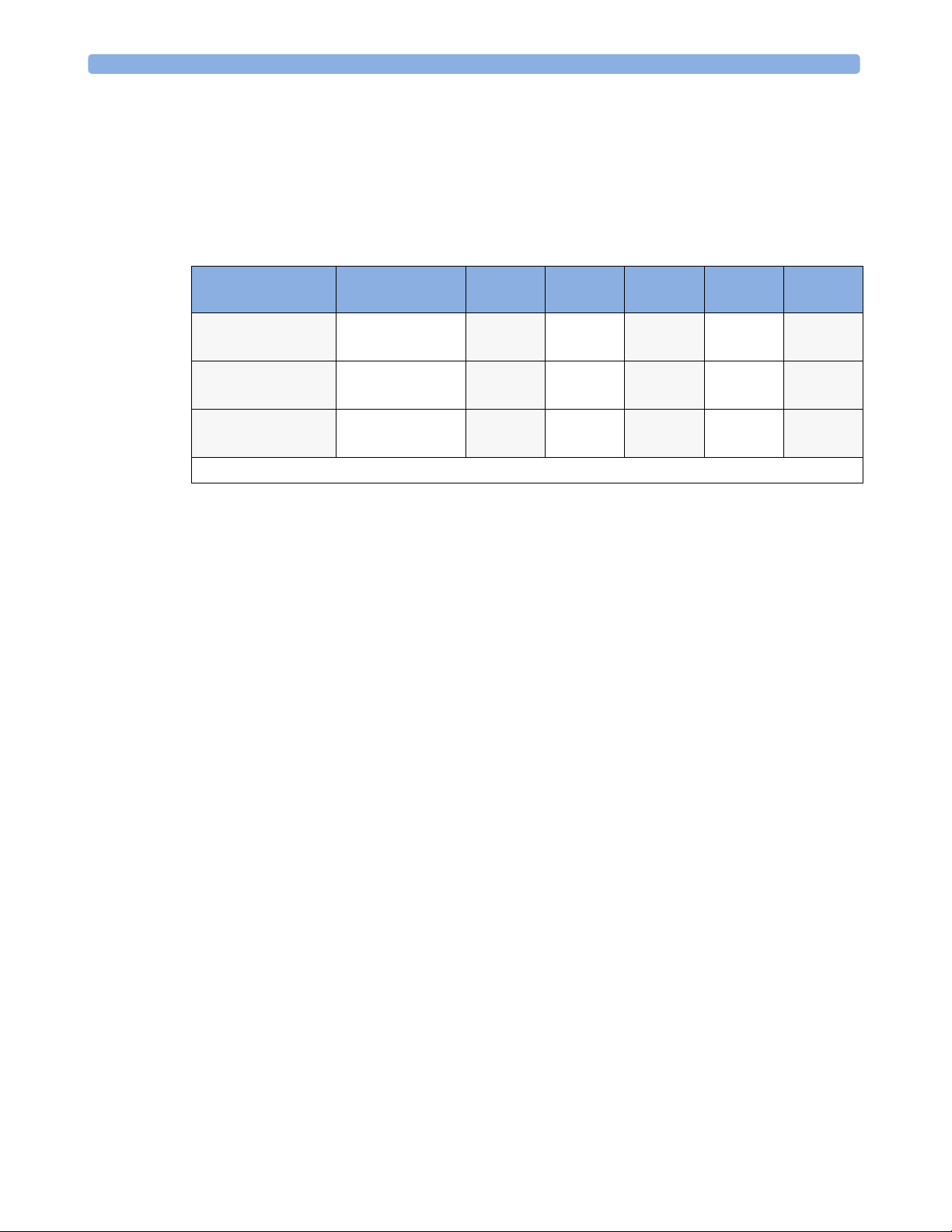

Frequency Bands

Depending on the country of use, the system uses radio frequencies within one of three ranges, the Wireless

Medical Telemetry Systems (WMTS) band, the Industrial, Scientific and Medical (ISM) band, or a range

of bands specific to Japan. The actual approved frequencies used depend on country-specific regulations.

The following diagram gives an example overview of the system’s frequency band configuration.

5

4

3

2

1

1 = The full (hardware) frequency range (10 MHz wide).

2 = The country-specific frequency range governed and approved by local regulatory bodies.

3 = The available frequency range: shows the real, current frequency range available within the country

range. This will differ from the country range due to:

– excluded frequency ranges

– frequency ranges already allocated to other Avalon CTS systems in the same establishment.

4 = Excluded frequency ranges (ranges occupied by other telemetry systems, or other RF interferers).

5 = Fixed frequency ranges.

9

Page 20

1 General Information Considerations for Choice of Configuration

Standard Delivery Configuration

The Avalon CTS is normally delivered with:

• Automatic channel search.

• A standard antenna.

Using the standard antenna, the potential operating range is up to 100 meters/300 feet. The actual

effective area of reach will vary according to the geographical and physical characteristics of the building

where the system is installed, and is also influenced by the presence of other radio frequency (RF) devices

or interference. We recommend that you define effective operating range prior to putting the system into

operation.

If the area of reach is adequate for the intended monitoring area, and the system’s operation is not

influenced by other RF sources, then the normal delivery configuration is sufficient.

When is a Different Configuration Needed?

This section deals with possible reasons why the standard delivery configuration may not be adequate.

When the Area of Reach is Not Sufficient

If the area of reach is not sufficient using the standard antenna supplied with the system, there are a few

things to consider:

– The placement of the antenna has an effect on the operating range. If it is located inside a metal cart

or other RF-absorbing material, then place the antenna externally by using the Antenna Extension

Mounting Kit (M1361A Option 1AA) to increase the range.

– Check the orientation of the antenna. In general, the antenna provides the greatest range when it is

positioned vertically.

– If the area of reach is still insufficient, consider installing an antenna system.

When the Standard Configuration is Unsuitable

The standard configuration, with free base station channel search, may be unsuitable if:

• There are other telemetry or RF systems installed in the hospital.

• There are multiple (more than ten) stand-alone Avalon CTS systems.

• There are other sources of RF interference, for instance, broadcasting stations, microwave devices, and

wireless temperature sensors.

• You connect the Avalon CTS to an antenna system.

• There are country-specific regulations requiring special configuration (in Japan, for example), or your

country requires a Multi-Region base station.

Japanese Systems

Transducers must use fixed frequencies. They are initially shipped from the factory with no frequencies

assigned to them. During installation, they are initialized, and their frequencies are set. (See also

“Transducers for Japan” on page 66.)

10

Page 21

Setting Expectations 1 General Information

Multi-Region Base Station

For countries requiring the Multi-Region base station (for example, Norway and Singapore), the receiver in

the base station is “disabled” before it leaves the factory. The correct approved frequency range is then

enabled locally during installation using the Service Support Tool. (See also “Multi-Region Base Station”

on page 66.)

Frequency Planning

For Japan and countries using the Multi-Region base station, and for multiple cordless/telemetry

installations in the same hospital, an RF frequency plan should be implemented. Document all frequencies

or frequency ranges occupied by:

• Other telemetry systems (adult and fetal).

• Multiple Avalon CTS systems (operating on fixed frequencies). Remember that the Avalon CTS is also a

potential interference source for other RF systems.

• Other sources of RF interference (other electrical equipment, broadcasting stations, or paging systems,

for instance).

Once you have identified all the occupied frequencies or frequency ranges (for example, by using the

Service Support Tool software) you can change the system’s configuration by following the guidelines for

RF channel/frequency configuration.

• Exclude frequency ranges already occupied by other telemetry systems or that are subject to interference

from other RF sources (see page 65).

• Use fixed frequencies for the base station, possibly in conjunction with altering the channel spacing (see

page 74).

• Use fixed frequencies for the transducers (see page 66).

Setting Expectations

No matter how good a telemetry system design is, it will always experience occasional loss of radio

communications, resulting in US/Toco/ECG dropouts. A telemetry system will never be as reliable as a

hard-wired monitor that transmits its signal through a wire. If occasional loss of US/Toco/ECG

monitoring is not acceptable for certain patients, they should be connected to a hard-wired bedside

monitor.

WARNING Telemetry should not be used for primary monitoring in applications where the momentary loss of the US/

Toco/ECG signal is unacceptable.

Following are guidelines to set proper expectations of hospital staff and to improve system performance:

• Clinicians will tend to see more motion related artifact on the US/Toco/ECG measurements of

ambulatory patients than on patients that are restricted to a bed.

• Patients should be restricted to the designated coverage area. Monitoring performance will degrade if

patients go outside the radius of coverage of the receiving antenna.

11

Page 22

1 General Information Antenna System Guidelines

• Keep the size of the antenna system as small as possible. Telemetry system performance will degrade as

the system size increases. The larger a system is, the greater the potential for receiving interfering

signals. In addition, as more devices are added to the antenna system, the noise generated by the

antenna system itself increases.

• A patient location protocol is critical to a telemetry system. If a life-threatening event occurs, the

clinician must be able to locate the patient quickly. The importance of this increases as the antenna

system size increases.

• Philips Medical Systems has no control over the RF environment in the hospital. If interference exists at

the operating frequencies, telemetry system performance will be affected. Careful selection of

frequencies for all wireless devices used within a facility (telemetry transmitters, walkie-talkies,

ambulance radios, other wireless medical devices, etc.) is important to prevent interference between

them. Frequency management is the responsibility of the hospital.

Antenna System Guidelines

The Avalon CTS (M2720A) is compatible with the dual band antenna system components used with the

M2600A adult telemetry system. Antenna systems must be designed according to adult telemetry system

rules, and presales activities and site preparation must be done according to the existing M2600A series

antenna system rules. These activities are not bundled into the product price and have to be ordered

separately from the Philips Medical Support Organization.

In addition to the M2600A antenna system design rules, the following antenna specifications apply to the

Avalon CTS:

• Only original M2600A antenna system components will be supported.

• The antenna spacing must not exceed a radius of 10m (32ft).

• Existing antenna systems used for M1310A with 15.5m (51ft) antenna radius spacing do not comply

and must be redesigned to work with the Avalon CTS.

• A mixture of Avalon CTS and other supported Philips telemetry devices (for example, M1310A or

M2600A Adult Telemetry Transmitter/Receiver) on the same antenna system may be supported. Please

see below for further details of how to configure and design a mixed telemetry system.

• Frequency converters used in USA with M2600A adult telemetry cannot be used with the Avalon CTS.

• Contact Philips Support regarding antenna system design.

Before You Install an Antenna System

In general, before each antenna system installation, a site frequency plan is required which includes an

appropriate frequency plan for M2720A and all other telemetry devices used in the same hospital.

Using the results of this frequency survey, the appropriate frequency allocation mode must be set for the

M2720A, for example, automatic frequency allocation mode or fixed frequency mode for the base station.

Under normal circumstances, the fixed frequency mode for the transducer should not be used, except for

Japan. See the Service Support Tool Help for further information about choices of frequency allocation

modes.

12

An antenna system for the M2720A should be designed by an antenna expert experienced in designing

M2600A antenna systems. For antenna system calculations, the specifications for M2720A can be added

to the Antenna System Design Spreadsheet. This is important, because most antenna systems for the

M2720A are non-standard in design, as the RF signal typically needs to be distributed to several rooms.

Page 23

Antenna System Guidelines 1 General Information

Specifications

Antenna system calculations for fetal telemetry differ from those of adult M1402A or M2602A mainframe

systems. The M2720A uses an internal signal amplifier, requiring the antenna system to have a 0db to

-3db gain at the final antenna connection to the Avalon CTS.

The minimum carrier to noise ratio (CNR) should be 8dB.

M2720A Avalon CTS typical specifications:

M2720A

Frequency Band

ISM

(433-443 MHz)

Japan

(420-430 MHz)

WMTS

(608-614 MHz)

Maximum Input

Before Saturation

0 to -3db 8 dB 14.1 dB* 7.36* 5 dBm* -4 dBm*

0 to -3db 8 dB 14.6 dB* 6.86* 5 dBm* -4 dBm*

0 to -3db 8 dB 11.1 dB* 8.55* 5 dBm* -4 dBm*

CNR Gain NF

TOI

@100KHz

*Can be added to the antenna design spreadsheet as M2720A-specific parameters

Mixed Telemetry Devices on the Same M2600A Antenna System

A mixture of M2720A and other supported Philips telemetry devices (for example, M1310A or M2600A

Adult Telemetry Transmitter/Receiver) on the same antenna system are supported under the following

conditions:

• M2600A antenna system design rules are followed.

• Antenna input must be within the range of 0dB to -3dB.

• Each Avalon CTS channel must be separated by a minimum of 100 KHz from any non-Avalon

frequency channel.

• The internal channel frequency spacing between Avalon CTS transducers should be 25 KHz (factory

default setting).

P1dB

Example:

A Series 50 T Fetal Telemetry System (M1310A) is already connected to an antenna system, and its

transmitter is set to 433.650 MHz. You need to connect an Avalon CTS to the same antenna system. In

this case, the first usable frequency channel for any M2720A transducer is either 433.550 MHz or 433.750

MHz, as each transducer frequency channel must be separated by at least 100 KHz from any frequency

channel used by any telemetry device other than Avalon CTS transducers.

13

Page 24

1 General Information Antenna System Guidelines

14

Page 25

2

2Theory of Operation

This chapter describes the functional operation of the system, including the base station and transducers. It

incorporates features of the mechanical design, indicating the physical relationship of the assemblies and

components.

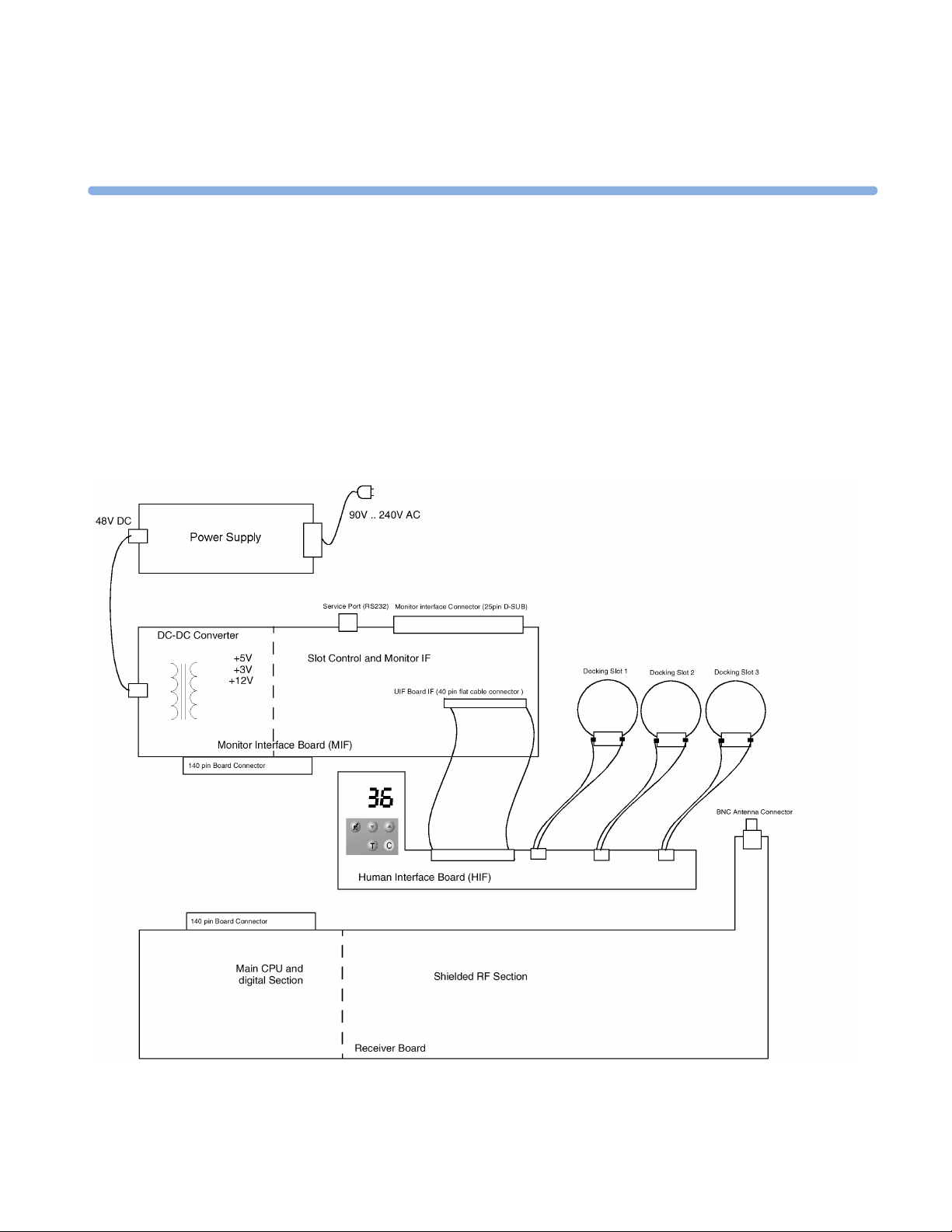

Base Station Hardware Overview

Figure 1 Base Station Boards

15

Page 26

2 Theory of Operation

The Base Station consists of four functional components:

Receiver Board

The receiver is a double superheterodyne narrowband frequency modulation (FM) receiver, with two

mixers and two intermediate frequencies (IFs). Three radio frequency (RF) signals can be received

independently with three identical receiver channels.

for frequency shift key (FSK) detection, analog-to-digital conversion of the low frequency (LF signal),

signal filtering, and radio frequency (RF) channel management.

transducers.

and each docking slot.

While charge power is on, a serial communication link is established between the base station

Human Interface Board

The Human Interface (HIF) board provides the user interface, and the display, indicators, keys and the

slot charging contacts are all located on this board.

Power Supply

The power supply is a wide-range input swtching unit, with an output of +48V. It is located on the chassis

assembly.

The digital section of the main CPU is responsible

The main CPU communicates with the

Slot Control and Monitor Interface Board Hardware

The Monitor Interface (MIF) board provides the interface to the fetal monitor as well as the

communication interface to the transducer slots. Power conversion is performed by a DC-DC converter.

The digital (active) parts of the human interface also reside on this board.

The MIF board consists of the following functional blocks:

• DC-DC Converter - the 48V DC input for the DC-DC converter comes from the primary AC-DC

converter. Since the 48V DC voltage is sufficiently stabilized, two fixed pulse width step down

transformers are used to transform the high voltage down to the required 3V, 5V and 12V (postregulated for accuracy).

The +12V supply is mainly used for battery charging and you can access this voltage at the charge

contacts. The fuse on the MIF board are not replaceable, and if it blows, the board must be replaced. If

there is a short to ground, unlimited current will blow the fuse. To avoid this, a current limiter is used

to limit the output current.

• Monitor interface - three major blocks make up the monitor interface:

– PWM Toco digital-to-analog (D/A) converter

– Two PWM wave D/A converters for FHR low frequency (LF) 1, and FHR LF 2.

– Digital status ports

• Tr a ns d u c er s l o t in te r f a ce - this block is responsible for transducer detection, safety features of the

charge power switch, serial communication between base station and transducers and synchronization

clock generation for the power supply.

contacts when there is no transducer docked in a slot, charge power in each slot is only applied after a

transducer has been detected.

To ensure that there is no charge power applied to the charge

16

• Drivers for the HIF board interface - this block contains the multiplexing and driving components for

the function buttons, the display backlight and the seven-segment LEDs.

Page 27

Transducer Hardware Overview 2 Theory of Operation

Transducer Hardware Overview

The system has three transducer types:

•Toco

•US

•ECG

They all share the same modulation and digital processor circuitry, power supply, liquid crystal display, and

RF transmitter. The processor software is also the same for all transducers. The frontends, however, are

specific to each transducer type.

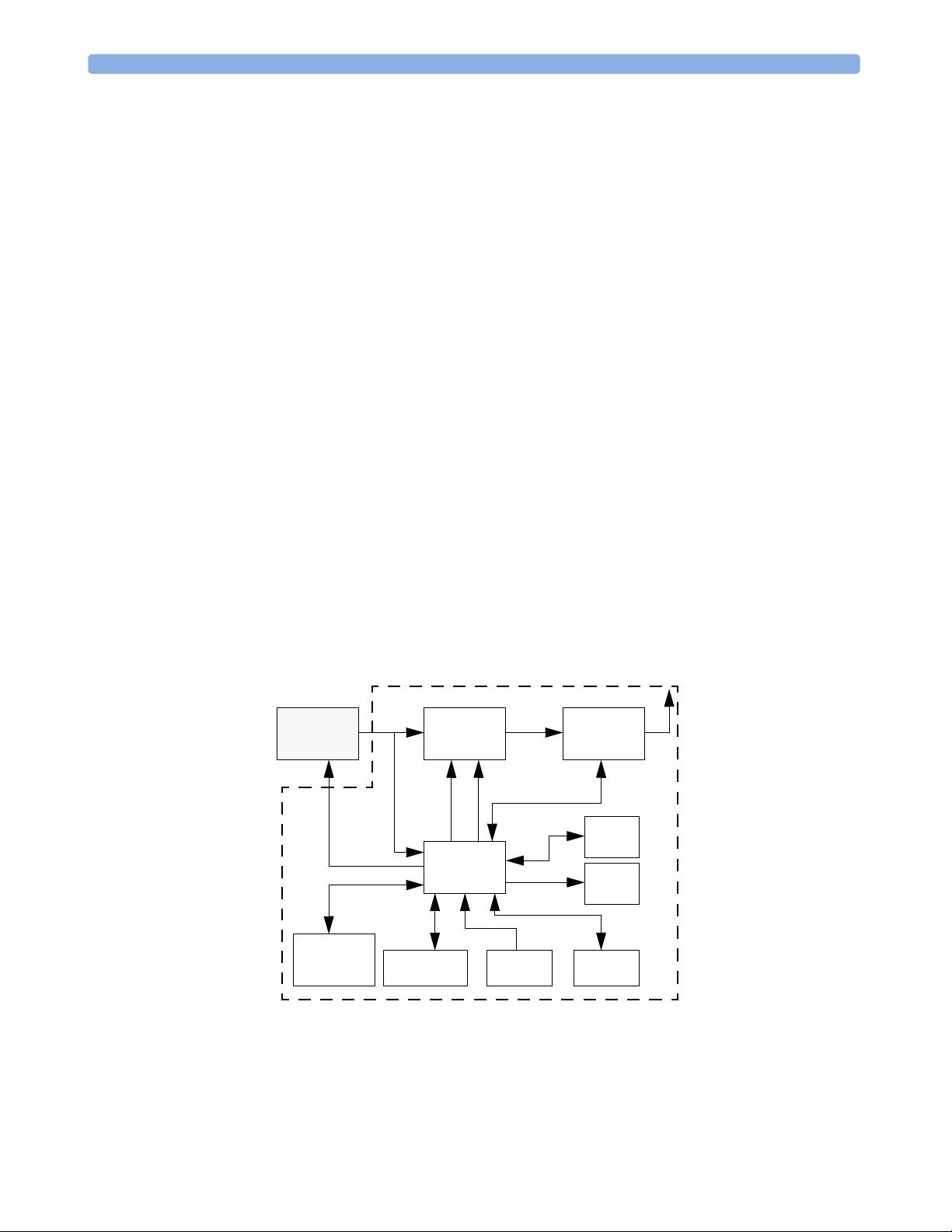

Functional Description of the RF/CPU Hardware

The RF/CPU section of the transducers is made up of the following functional blocks:

• CPU (micro controller)

•LCD

• Base Station communication

• EEPROM

•FLASH download port

• Clock generator

• Power supply and battery charger

•Modulator

• RF transmitter

Boards: M2725-66501,

M2726-66501,

M2727-66501

parameter

frontends

(see separate description)

power supply

and battery

charger

frontend control

power management

wave

gain control

base station

communication

Modulator

CPU

(micro

controller)

Figure 2 Transducer Block Diagram

FSK signal

modulation signal

(wave +FSK)

frequency control

Clock

generator

RF

transmitter

FLASH

download

port

LCD

EEPROM

17

Page 28

2 Theory of Operation Toco Frontend Hardware

Base Station Communication

An active base station communicates with docked transducers to check the correct transducer type, serial

number, to program the RF frequency, to initiate test cycles, and to check the current battery status.

Power Supply and Battery Charger

A Lithium-Ion (Li-Ion) battery powers the transducer. Batteries are charged whenever a transducer is

docked in an base station connected to AC power. Charge power is transferred by the spring-loaded, twopin charge contacts. Communication between the base station and the transducer processors is also done

using these contacts.

An intelligent Li-Ion charging circuit in the transducer controls the battery management. See page 72 for

battery charging times.

Modulator

The analog heart rate signals (ultrasound Doppler or fetal ECG) are pre-processed and band-limited by

filters. The signals are then fed into a programmable gain amplifier controlled by an automatic gain

control circuit and a digital FSK modulated subcarrier (1.6 kHz or 2.4 kHz) is added to the RF carrier

signal. The subcarrier is responsible for the digital transmission of the Toco data, along with safety and

status information, such as serial number, bed label, fetal movement data, battery information.

RF Transmitter

The RF transmitter block contains:

• a PLL synthesizer that divides the reference frequency down to 12.5 kHz, and can be tuned in steps of

12.5 kHz.

• a voltage controlled ocillator (VCO).

• a power amplifier (antenna driver).

Toco Frontend Hardware

Uterine activity is measured by evaluating the hardness of the mother’s abdomen with a pressure sensitive

resistor bridge (DMS element). The DMS element requires an excitation voltage and its differential

output signal is proportional to the pressure applied to the DMS element. An AC excitation voltage is

used, and the resulting AC output signal is amplified and converted to a pressure proportional DC voltage

by a synchronous rectifier followed by a low pass filter.

Ultrasound Frontend Hardware

The ultrasound frontend is a pulsed Doppler system with a 1.0 MHz ultrasound frequency, and a pulse

repetition rate of 3.2 kHz. Seven ultrasound crystals are used as transmitter and receiver.

ECG Frontend Hardware

Several parameter frontends are combined on the ECG frontend board. Currently supported parameters

are DECG and MECG.

18

Page 29

ECG Frontend Hardware 2 Theory of Operation

A seven-pin ‘D-type’ socket carries all parameter related inputs and outputs. An external mode resistor,

connected to one of the pins, detects which ECG mode to set when an adapter cable is plugged in. The

M1362B ECG adapter cable, used with the M1364A patient module, is also used for the fetal scalp or

adult electrodes.

19

Page 30

2 Theory of Operation ECG Frontend Hardware

20

Page 31

The Avalon CTS has two system interfaces:

• Fetal monitor interface

•Service Interface

Fetal Monitor Interface

The Fetal Monitor Interface on the base station allows digital and analog outputs to the Series 50 fetal

monitors. The interface is enhanced to support additional transducer combinations for future fetal monitors.

The following table lists the signals at each pin.

3

3System Interfaces

PIN 13

PIN 25

Pin

1 MECG supported (Series 50 B/C fetal monitors only).

2 +3V RF (10 kΩ internal resistance)

3 +12V RF (10 kΩ internal resistance)

4 +48V RF (100 kΩ internal resistance)

5 Base station on (L).

6Reserved.

7 DECG inop (L).

8 DECG Mode (L).

9 Reserved for future functionality.

10 US Mode (L).

11 Reserved.

12 IUP Mode (L).

Signal Details

PIN 1

PIN 14

21

Page 32

3 System Interfaces Service Interface

Pin

13 TOCO External Mode (L).

14 US LF or ECG Signal.

15 TOCO/IUP signal.

16 Not connected.

17 Ground.

18 Ground.

19 Reserved. (Tele-Marker on the fetal monitor side.)

20 Tele-FMP on (L) if FMP available.

21 Tele-Fetal movement on (L).

22 MECG Inop.

23 Not connected.

24 Ground.

25 MECG Mode.

Service Interface

The service socket on the rear of the base station takes a stereo phone jack for RS232 connection to an

industry standard compatible PC installed with the Service Support Tool software. Use the interface cable

M1350-61675. The transducers must be docked in the base station for communication with the Service

Support Tool.

Signal Details

22

Figure 3 Interface cable for connecting an industry standard compatible PC to the Avalon

base station.

Page 33

Compatible Fetal Monitors 3System Interfaces

Compatible Fetal Monitors

A list of compatible fetal monitors (including interfaces) is given in the following table.

Parameter

Monitor / Interface (IF)

M1350x

with M1350-66531 IF

M1350x

with M1350-66536 IF

M1351A

with M1353-66531 IF

M1351A

with M1353-66531 E IF

M1353A

with M1353-66531 IF

M1353A

with M1353-66531 E IF

Key: ! = supported; - = not supported

*M1351A is not able to measure DECG/MECG

HR 1 - HR 1 !!Only one FHR is transmitted.

HR 1

HR 1 --- ! No ECG processing. DECG mode generates

HR 1 ! - - ! Software revision A.02.00 or greater.

HR 1 - HR 1 - ! Only one HR transmitted.

HR 1 ! HR 1 - ! Software revision A.02.00 or greater.

!

CommentsUS FMP DECG MECG Toco

HR 1 !!Software revision A.04.01 or greater.

“Err 9”.

23

Page 34

3 System Interfaces Compatible Fetal Monitors

24

Page 35

4Disassembly/Reassembly

WARNING • Performance verification: do not place the system into operation after repair or maintenance has been

performed, until all performance tests and safety tests listed in Chapter 6 of this service manual have been

performed. Failure to perform all tests could result in erroneous parameter readings, or patient/operator

injury.

• Energized circuits are accessible with the covers open. Do not work on the base station with the covers open

and AC power connected. Only qualified service personnel should open or disassemble the base station.

• Before attempting to open or disassemble the base station, disconnect it from the AC mains supply.

CAUTION Observe ESD (electrostatic discharge) precautions when working within the unit.

4

Introduction

Remember to store all screws and parts in a safe place for later refitting.

How to Use this Chapter

The disassembly sections detail the step-by-step procedures you use to access replaceable parts of the base

station.

All the transducers are sealed at the factory and are not repairable. Replacement transducers are supplied

complete with both battery and belt button fitted.

The Avalon base station consists of two major assemblies:

•The top cover assembly

• The chassis assembly

The top cover assembly contains the human interface (HIF) board, the keypad inlay, and the battery charge

contacts and wiring. The top cover assembly is only available as a complete assembly, and a repair to any part

of the top cover assembly is effected by replacement of the whole assembly.

The chassis assembly contains the metal chassis and power supply, the receiver board and the monitor

interface (MIF) board. The power supply always comes complete with the chassis (without boards), and a

repair to either the power supply or the chassis is effected by replacement of this chassis/power supply

assembly.

25

Page 36

4 Disassembly/Reassembly Removing the Top Cover Assembly

There are no boards available individually as replacement parts. In the case of a defective receiver board or

MIF board, a repair is effected by exchanging the whole base station assembly (unit exchange).

All part numbers of spare parts are listed in Chapter 5.

Tools Required

CAUTION When replacing the front cover, do not over-torque the screws. Excessive torque may damage the plastic

screw mountings.

You need the following tools:

•Torx-head screwdriver, size T-10

or

•Torx bit, for suitable driver, size T-10

Removing the Top Cover Assembly

1 Carefully place the base station upside down. To avoid scratches, place the unit on some cloth or other

soft surface.

Screw locations

2 Remove the six screws securing the top cover assembly to the chassis, using a T-10 Torx driver.

3 Holding both top cover and chassis assemblies together, place the base station upright again.

26

Page 37

Replacing the Top Cover Assembly 4 Disassembly/Reassembly

4

Lift the front edge of the top cover and disconnect the spade connector for the ESD ground wire from

the terminal on the metal chassis.

ESD ground

spade connector

5 Now raise the cover a little more, and disconnect the multipin connector of the ribbon cable from the

MIF board. Pull straight up to avoid bending the pins. The top cover assembly is now free of the chassis

assembly.

Top

cover

assembly

Ribbon cable

connector

Replacing the Top Cover Assembly

The serial number appears initially in two places on the base station - on the rear of the top cover

assembly, and on the bottom of the metal chassis. A replacement top cover does not carry a serial

number.

1 Ensure all items are replaced in the top cover assembly.

2 Reconnect the multipin ribbon cable connector to the socket on the MIF board.

Reconnect ribbon cable connector

Chassis

assembly

27

Page 38

4 Disassembly/Reassembly Changing Fuses

3 Important! Reconnect the ESD ground wire spade connector to the terminal on the chassis.

ESD ground

spade connector

4 Place the front cover back to its normal position.

5 Holding both assemblies together, carefully place the unit upside down, preferably on a soft surface to

prevent scratching or other damage.

Screw locations

6 Make sure the screw holes in the metal chassis align with the screw mountings in the top cover

moulding.

CAUTION When replacing the front cover, do not over-torque the screws. Excessive torque may damage the plastic

screw mountings.

7 Drive in the six screws that hold the front cover and chassis assemblies together using a T-10 Torx

driver.

Changing Fuses

There are two versions of power supply, the Celestica version (earlier build), and the Frei version (later

build).

There are two field-replaceable fuses located in the power supply. They are of type T1.6A. In the

photographs that follow in this section, the MIF and receiver boards are removed for clarity, but the

power supply cover can be removed with the boards in place. To gain access to the fuses:

1 Remove the top cover assembly (see page 26).

28

Page 39

Changing Fuses 4 Disassembly/Reassembly

2

Remove the three screws securing the power supply cover.

Boards shown

removed for

illustration

purposes

Screw locations

3 Unplug the connector for the power supply cable from the power supply.

Remove power

supply cable

4 Slide the power supply cover to the edge of the chassis, as shown, to clear the lugs on the chassis.

Power supply

cover

Slide power supply

cover to the outer

edge of chassis

to clear lugs

Chassis lugs

(Lugs cleared)

5 Then remove the cover by lifting it straight up.

29

Page 40

4 Disassembly/Reassembly Changing Fuses

Power supply

cover removed

Important! Replace the fuses with new fuses of exactly the same type and rating (T1.6A).

6

FREI

version

30

CELESTICA

version

7 Replace the power supply cover, and secure it with the three screws.

T1.6A

Fuse

Page 41

Changing the Power Supply/Metal Chassis Assembly 4 Disassembly/Reassembly

8

Reconnect the power supply cable connector to the power supply.

9 Replace the top cover assembly (see page 27).

Changing the Power Supply/Metal Chassis Assembly

The power supply and the metal chassis come as one unit (they are not available independently). The

power supply cable is reusable, and also comes with the new chassis/power supply assembly.

To change the power supply/metal chassis assembly:

Step1: Remove the Top Cover Assembly

See page 26.

Step2: Remove the MIF Board

1 Remove the six-pin power supply connector from the MIF board.

Six-pin power

connector

2 Remove the two screws (A) using a T-10 Torx driver.

Screws (A)

31

Page 42

4 Disassembly/Reassembly Changing the Power Supply/Metal Chassis Assembly

3

Then remove the two screws (B) for the fetal monitor interface socket using a 6mm socket driver.

Screws (B)

4 Disconnect the multipin connector joining the MIF board to the receiver board by lifting the corner of

the MIF board nearest to the power supply cover.

Multipin connector

5 Then lift the MIF board clear of the chassis assembly.

MIF board removed

32

Page 43

Changing the Power Supply/Metal Chassis Assembly 4 Disassembly/Reassembly

Step 3: Removing the Receiver Board

1 First remove the MIF board (see Step 1).

2 Remove the four screws securing the receiver board to the chassis using a T-10 Torx driver.

Screw locations

3 Gently lift the front right hand corner of the receiver board, at the same time pulling it forward.

Screw fixing post

4 Next, lift the rear left hand corner of the board so that the board is clear of the metal screw fixing post.

33

Page 44

4 Disassembly/Reassembly Changing the Power Supply/Metal Chassis Assembly

Lift left hand side of board to clear screw

fixing post

5

Then lift the board clear of the chassis.

Step 4: Replace Metal Chassis/Power Supply Assembly

Take the new metal chassis assembly.

Power supply

Chassis

34

Page 45

Changing the Power Supply/Metal Chassis Assembly 4 Disassembly/Reassembly

Step 5: Replacing the Receiver Board

1 Insert the antenna socket into its aperture in the new metal chassis and locate the metal screw fixing post

through the hole in the left hand side of the receiver board.

Locate screw

fixing post

through hole

Insert antenna

socket through

hole in chassis

in board

2 Position the receiver board so that all the screw holes on the board align with the screw fixing points on

the chassis.

Screw locations

3 Drive in the four screws (A) using a T-10 Torx driver to secure the receiver board to the chassis.

35

Page 46

4 Disassembly/Reassembly Changing the Power Supply/Metal Chassis Assembly

Step 6: Replacing the MIF Board

1 Carefully locate the multipin connector plug, on the underside of the MIF board, in the socket on the

receiver board, ensuring it is accurately aligned.

Multipin connector

2 Carefully apply a little pressure on the left hand rear corner of the MIF board to seat the multipin

connector into the socket on the receiver board below.

3 Ensure that the screw holes in the board align with the screw fixing points below.

4 Drive in the two screws (B) with a T-10 Torx driver.

Screws (B)

5 Then drive in the two screws (A) using a T-10 Torx driver. The MIF board is now secure.

36

Screws (A)

Page 47

Changing the Power Supply/Metal Chassis Assembly 4 Disassembly/Reassembly

6

Reconnect the power supply connector plug to the socket at the front left hand corner of the MIF board.

Reconnecting

six-pin power

connector

Step 7: Replace The Top Cover Assembly

Replace the top cover assembly taking care not to over-torque the screws (see page 27).

37

Page 48

4 Disassembly/Reassembly Changing the Power Supply/Metal Chassis Assembly

38

Page 49

5

5Spare Parts

Spare parts, along with part numbers, are listed in the tables that follow.

All transducers and accessories are latex-free, unless indicated otherwise in the tables below.

Exchange Parts

Exchange Part Number New Part Number

Description“5x5” 12 NC “5x5” 12 NC

M2720-69030 453563474101 M2720-60030 453563473001 Base station (without transducers) - WMTS*

M2720-69031 453563474111 M2720-60031 453563473011 Base station (without transducers) - ISM*

M2720-69032 453563474121 M2720-60032 453563473021 Base station (without transducers) - Japan*

M2720-69034 451261002071 M2720-60034 451261002061 Base station (without transducers) - Multi-Region

(for example for Norway, Singapore*)

M2725-69001 453563474341 M2725-60001 453563474301 Cordless Toco transducer - USA/Australia

M2725-69002 453563474351 M2725-60002 453563474311 Cordless Toco transducer - Europe

M2725-69003 453563474361 M2725-60003 453563474321 Cordless Toco transducer - Canada

M2725-69004 453563474371 M2725-60004 453563474331 Cordless Toco transducer - Japan

M2726-69001 453563474421 M2726-60001 453563474381 Cordless US transducer - USA/Australia

M2726-69002 453563474431 M2726-60002 453563474391 Cordless US transducer - Europe

M2726-69003 453563474441 M2726-60003 453563474401 Cordless US transducer - Canada

M2726-69004 453563474451 M2726-60004 453563474411 Cordless US transducer - Japan

M2727-69001 453563474501 M2727-60001 453563474461 Cordless ECG transducer - USA/Australia

M2727-69002 453563474511 M2727-60002 453563474471 Cordless ECG transducer - Europe

M2727-69003 453563474521 M2727-60003 453563474481 Cordless ECG transducer - Canada

M2727-69004 453563474531 M2727-60004 453563474491 Cordless ECG transducer - Japan

*See “Antenna and Base Station Part Numbers” on page 41.

39

Page 50

5 Spare Parts Non-Exchange Parts

Non-Exchange Parts

Part Number

Description“5x5” 12 NC

M2720-67701 453563474091 Base station metal chassis (housing bottom) including power supply and DC

cable

M2720-64003 453563474081 Base station top cover assembly including warning label and screws

2110-0495CP 453563071821 Fuses for power supply T1.6A

0950-2028 453563044001

0950-2029 453563044011

1250-0076 453563473991 BNC connector, 90 degrees

M2720-64001 453563474061 Battery replacement kit (includes tool and instruction sheet)

M2720-64002 453563474071 Knob replacement kit, contains three knobs (includes tool and instruction

M2720-03201 453563474041 Mounting brackets

Antenna. See ““Antenna and Base Station Part Numbers” on page 41”.

sheet)

Supplies and Accessories

Part Number

Description of Supplies/Accessories“5x5” 12 NC

15133D 989803100741 Fetal scalp electrode (EU and Asia-Pacific version) - shipment country depen-

dent

15133E 989803100751 Fetal scalp electrode (US version) - shipment country dependent

40483A 989803101601 Aquasonic US gel

40493E 989803101681 Electrodes (pre-gelled)

M1349A 989803103421 Disposable fetal adhesive pad electrode

8120-2961 453563198651 Ground cable with clamp

8120-4808 453563199211 ground cable IEC

M2720-61603 453563474051 Interface cable (for connecting the Avalon CTS to a fetal monitor)

M2725A 862488 Cordless Toco transducer

M2726A 862489 Cordless US transducer

M2727A 862490 Cordless ECG transducer

M1362B 989803103551 DECG adapter cable

M1363A 989803103561 MECG adapter cable (for use with M1364A or M1365A)

M1562A 989803104111 Fetal belts, washable (pack of 3, contain latex)

M1562B 989803129891 Waterproof fetal belts, washable (pack of 3)

M2208A 989803106021 Disposable abdominal belts (case of 100)

M1360-61675 453563277381 PC service cable for Service Support Tool

40

Page 51

Antenna and Base Station Part Numbers 5Spare Parts

Antenna and Base Station Part Numbers

Frequencies for medical telemetry devices are not yet harmonized. Consequently, frequencies vary

according to country-specific regulations, and are subject to change.

Base Station Part Numbers

Band

Antenna Part Number

WMTS Band 0950-2028 453563044001 M2720-69030 453563474101 M2720-60030 453563473001

(internal code

#214)

ISM Band

(internal code

#212)

Japanese Band

0950-2029 453563044011 M2720-69031 453563474111 M2720-60031 453563473011

0950-2029 453563044011 M2720-69032 453563474121 M2720-60032 453563473021

Exchange Parts New Parts

‘5x5” 12 NC “5x5” 12 NC

(internal code

#215

Multi-Region Base

Station - ISM Band

(uses #212

hardware)

0950-2029 453563044011 M2720-69034 451261002071 M2720-60034 451261002061

41

Page 52

5 Spare Parts Antenna and Base Station Part Numbers

42

Page 53

6Preventive Maintenance and

Safety

This chapter contains maintenance and safety information for the Avalon CTS and accessories.

All checks that require the instrument to be opened must be made by qualified service personnel. Contact

your local Philips representative if you wish safety and maintenance checks to be carried out by Philips

personnel.

To ensure proper functioning of your system you must adhere to the standards described in this book for:

" Cleaning

" Performance assurance checks (system self test, parameter test)

" Safety tests (safety test blocks, instrument safety test, system test)

" Accessory testing (transducer checks, patient module checks)

6

CAUTION

Failure on the part of the responsible individual hospital or institution using this equipment to implement a

satisfactory maintenance schedule may cause undue equipment failure and possible health hazards.

Care and Cleaning

For detailed instructions on how to care for and clean the base station, transducers and the monitoring

accessories, see the

Instructions for Use.

Recommended Frequency of Testing

Perform the procedures as indicated in the suggested testing timetable. These timetable recommendations do

not supercede local requirements.

Suggested Testing Timetable

Test Frequency

Performance Assurance (see page 44) and Safety

Checks (see page 45).

Regular Preventive Maintenance (see page 51). Once a year or after repair.

Battery Check (see page 53). As necessary.

Once a year (or as specified by local laws) and after repair where the power supply is replaced.

43

Page 54

6 Preventive Maintenance and Safety Performance Assurance Tests

Performance Assurance Tests

Self Test

The system performs a basic-level self test when you switch it on. You hear a beep, and all the display

elements are shown for about one second, and then the display reverts to normal display mode.

Parameter Test

This tests the entire signal path from the individual transducers connected via radio frequency, through

the base station, to the fetal monitor with artificially generated test signals. We recommend you perform

this test once a day, and whenever you doubt the reliability of the measurements. The parameter test does

not test the transducers themselves, there is a separate test for this (see “Testing Transducers” on page 67).

Signal quality

Value of artificial signal

Base station display

Ultrasound

transducer display

(slot 1)

Toco transducer

display

(slot 2)

Artificial HR

signal

In this example, one US transducer and one Toco transducer are

docked. No other transducers are active.

Initial displays appear as shown. The battery indicator is lit on the

base station.

The bed label is visible on both displays.

The transducer display shows which slot is occupied.

To start the test, with no transducers or alarms active:

1 Press and hold down .

The test mode remains active for as long as you keep

pressed.

Battery charging stops, and the transducers behave like normal,

active transducers. However, to differentiate between test mode

and normal operation of a registered transducer, the two-digit

numeric display in the LCD window shows the two segment

bars (--) blinking.

If you remove a transducer while the parameter test is still in

progress, the transducer shuts down.

2 Each transducer transmits an artificial signal, via the

programmed RF channel, to its registered slot on the base

station.

After decoding and processing, the artificial signals are fed via

the analog connection to the telemetry interface input of the

fetal monitor. The signals coming from the base station are

then processed and displayed by the fetal monitor.

44

Page 55

Safety Tests 6 Preventive Maintenance and Safety

3 Check the values displayed by the fetal monitor to get an overview of the condition of the entire system. The

following table specifies the signals that are generated during the test. As the mode of the ECG transducers is

unknown to the base station (as it is configured outside of the base station), an ECG transducer is always mapped

to the MECG mode. This avoids potential mode errors.

4 To stop the test, release the key.

Expected signals generated during the system test:

Test Outputs

Value on fetal monitor

LED display, Recorder,

OBMS-IF

US DECG*

(Place in

Slot 1 Slot 3

Slot 1)

190 bpm 170 bpm 200 bpm

Note: Ensure

there is no

US

transducer in

slot 3 (Error

9 will appear)

Signal with 30 units

amplitude range and 20s

period duration

TOCO

(Place in Slot 2)

ECG

Transducer is

in Slot 2

An IUP reading

appears on the

fetal monitor. IUP

measurements are

not currently

supported.

Disregard any

measurement you

get.

MECG*

(Place in

Slot3)

120 bpm

Fetal monitor speaker Artificial HR signal N/A N/A “click”

Test tolerance** +/- 2.5 bpm +/- 2.5 bpm +/- 10% period duration N/A +/- 2.5 bpm

*Test ECG transducers without the adapter cables attached.

**Signal is variable. Jitter should normally be within +/- 2.5 bpm. However, this could possibly be higher due to external

factors, such as interference or the environment. On slot 1, the jitter can be higher than on slot 3.

Testing Alarms

Details of how to test alarms is given in the Instructions for Use.

Safety Tests

WARNING

This section defines the test and inspection procedures applicable to the Avalon CTS Cordless Fetal

Transducer System. Use the tables in the following section to determine what test and inspection results

must be reported after an installation, upgrade, or repair has been carried out.

" Test Blocks in Table 1 tells you when to carry out the safety tests.

" Test and Inspection Matrix in Table 2 tells you how to carry out the safety tests.

Safety test requirements are set acccording to international standards, such as IEC/EN 60601-1 and IEC

60601-1-1, their national deviations, such as UL2601-1, CAN/CSA-C22.2 No. 601.1-M90 and No

601.1-S1-94, and specific local requirements.

The safety tests detailed in this chapter are derived from international standards but may not be sufficient

to meet local requirements.

45

Page 56

6 Preventive Maintenance and Safety Safety Tests

CAUTION The correct and accurate functioning of the equipment is ensured by the successful completion of the

safety tests, performance test, and the system test.

Safety Test Procedures

The test procedures outlined in this section are to be used only for verifying the safe installation or service

of the product in its place of use. The safety tests described here refer specifically to installation, setup,

repair and upgrade activities, and not to the aspects of safety that have already been tested during final

acceptance at the factory.

Use safety testers complying with IEC 60601-1 internationally, or any local regulations applicable to the

country of the installation. For safety test procedures see the operation instructions of the safety tester

used, and follow any local regulations.

If you use the Metron safety tester, the Metron Report should print results as detailed in this chapter,

along with other data.

For information and ordering guides for Metron products contact:

Metron AS, Vegamot 8, N-7048 Trondheim, Norway

www: http://www.metron-biomed.com

When to Perform Safety Tests

This table tells you when to perform specific safety tests. See page 47 for test details.

Table 1: M2720A: When to perform safety test blocks

Service Event Test Block(s) Required - Complete These tests

Installation

The product is customer installed.

For installation instructions refer to

the Instructions for Use for your

monitor.

Preventive Maintenance

Preventive maintenance is the

responsibility of the customer (see

page 51).

Repair

This Service Guide contains repair

instructions for the Avalon CTS.

Upgrade

For upgrade information refer to

“Upgrades”, on on page 69.

Combining or Exchanging System

Components

All other service events

Perform Visual, Power On, Performance and Safety test blocks

(see Table 2).

Perform Visual test block (see Table 2).

Perform Visual, Power On and Performance test blocks (see

Table 2), and whenever power supply or fuses are removed/

replaced, perform Safety test block.

Perform Visual, Power On, Performance test blocks

(see Table 2).

Perform the System Test (see Table 2 and “System Test” on

page 50).

Perform Visual, Power On and Performance test blocks

(see Table 2).

46

Page 57

Safety Tests 6 Preventive Maintenance and Safety

How to Carry Out the Test Blocks

Key to Table 2 P = Pass, F = Fail, X = test result value to be recorded.

Table 2: M2720A: Test and Inspection Matrix

What to Record

Test Block Test or Inspection to be Performed Expected Test Results

Visual Inspect the unit, transducers and cables for

any damage.

Are they free of damage? If Yes, Visual test is passed. V:P or V:F

Power On Power on the unit.

Does the self-test complete successfully? If Yes, Power On test is passed. PO:P or PO:F

Performance Perform the parameter test with all parame-

ters as described on page 44.

Do these tests complete without errors? If Yes, Performance Test is passed. P:P or P:F

on Service

Record (Philips

Personnel only)

Safety (1) Perform Safety Test: Protective Earth. With mains cable:

Maximum impedance = X1

(<= 100 mOhms)

Safety (2) Perform Safety Test: Enclosure Leakage

Current - Normal Condition.

Safety (3) Perform Safety Test: Enclosure Leakage

Current - Single Fault Condition - Open

Supply.

Safety (4) Perform Safety Test: Enclosure Leakage

Current - Single Fault Condition - Open

Earth.

System Perform the system test according to IEC

60601-1-1, if applicable, after combining

equipment to form a system.

With mains cable:

Maximum leakage current = X2

(<= 100µA)

With mains cable:

Maximum leakage current = X3

(<= 500µA)

(Note: maximum leakage current in

the US: 300µA)

With mains cable:

Maximum leakage current = X4

(<= 500µA)

(Note: maximum leakage current in

the US: 300µA)

See Safety Test (2) and Safety Test

(3)

S(1):P/X1 or

S(1):F/X1

S(2):P/X2or

S(2):F/X2

S(3):P/X3or

S(3):F/X3

S(4):P/X4or

S(4):F/X4

See Safety Test (2)

and Safety Test (3)

47

Page 58

6 Preventive Maintenance and Safety Safety Tests

Description of Applicable Safety Tests

Abbreviations

AP: Applied Parts IUT: Instrument Under Test

GND: Ground PE: Protective Earth

S(1): Protective Earth Test

Test to perform:

The protective earth test measures impedance of Protective Earth (PE) terminal to all exposed metal parts

of Instrument under Test (IUT), which are connected to the Protective Earth (PE) for safety reasons.

Normally it includes the wiring in the mains cable (max. 200 mOhm).

A test current of 25 Amps is applied for five to ten seconds. It is recommended to flex the main cable

during the test to identify potential bad contact or damage to the earth wire.

Safety Test according to IEC 60601-1 (Clause 18).

Report the highest value.

Instrument under test

L (N)

Ri

50 Hz 25 A or 1.5 Ir

S(2): Enclosure Leakage Current Test

- Normal Condition (NC)

Test to perform:

The enclosure leakage current: normal condition is applicable to Class 1 and 2 equipment, type B, BF,

and CF Applied Parts. The test measures leakage current of exposed metal parts of the Instrument Under

Test; it tests normal and reversed polarity.

For Type BF and CF Applied Parts the test measures AP/GND.

Safety Test according to IEC 60601-1 (Clause 19.4g).

Report the highest value.

Ohm

N (L)

PE

6V

(*)

Insulating pad

(*) If equipotential connection present : measure also

with yellow/green E.P. conductor connected.

Applied part

48

Page 59

Safety Tests 6 Preventive Maintenance and Safety

Medical electrical system

Instrument under test

L (N)

Signal parts

in- and/or

output

Signal parts

(**)

in- and/or

output

S2

MD

N (L)

S1

S4

(*)

S(3): Enclosure Leakage Current Test

- Single Fault Condition (SFC) Open Supply

Test to perform:

The enclosure leakage current: single fault condition open supply is applicable to Class 1 and 2 equipment,

type B, BF, and CF Applied Parts. The test measures leakage current of exposed metal parts of Instrument

Under Test with one supply lead interrupted; it tests normal and reversed polarity.

For type BF and CF Applied Parts measures AP/GND.

Safety Test according IEC 60601-1 (Clause 19.4g).

Report the highest value.

Other

Instrument

PE

(*) Not present in Class 2.

(**) Can be multiple different connections to different equipment at same time.

Applied part

S(4): Enclosure Leakage Current

- SFC Open Earth (Ground)

Test to perform:

The enclosure leakage current: single fault condition open earth (ground) is applicable to Class 1

equipment, type B, BF and CF Applied Parts. The test measures leakage current of exposed metal parts of

Instrument Under Test with Protective Earth open-circuit; it tests normal and reversed polarity.

For type BF and CF Applied Parts the test measures AP/GND.

Safety Test according IEC 60601-1 (Clause 19.4g).

Report the highest value.

49

Page 60

6 Preventive Maintenance and Safety System Test

Medical electrical system

L (N)

S1

N (L)

S4

Instrument Safety Test

You must perform the instrument safety test every time you exchange, repair, upgrade or in any other way

work on the power supply or the power inlet. You must test the system as a stand-alone system, and as a

system in conjunction with the fetal monitor.

The instrument safety test is made up of four separate tests :

" Protective Earth Test

" Enclosure Leakage Current - Normal Condition

" Enclosure Leakage Current - Single Fault Condition

" Patient Leakage Current - Single Fault Condition

MD

S2

PE

Instrument under test

(**) Can be multiple different connections to different equipment at sam e time.

Signal parts

in- a n d /o r

output

Applied part

(**)

Signal parts

in- and/or

output

Other

Instrum e n t

System Test

After mounting and setting up a system, perform system safety tests.

What is a Medical Electrical System?

A medical electrical system is a combination of at least one medical electrical device and other electrical

equipment, interconnected by functional connection or use of a multiple portable socket-outlet.

General Requirements for a System

After installation or subsequent modification, a system must comply with the requirements of the system

standard IEC/EN 60601-1-1. Compliance is checked by inspection, testing or analysis, as specified in the

IEC 60601-1-1 or in this book.

Medical electrical equipment must comply with the requirements of the general standard IEC/EN 606011, its relevant particular standards and specific national deviations. Non-medical electrical equipment shall

comply with IEC and ISO safety standards that are relevant to that equipment.

Relevant standards for some non-medical electrical equipment may have limits for enclosure leakage

currents higher than required by the standard IEC 60601-1-1. These higher limits are acceptable only

outside the patient environment. It is essential to reduce enclosure leakage currents when non-medical

electrical equipment is to be used within the patient environment.

50

Page 61

Regular Preventive Maintenance 6 Preventive Maintenance and Safety

WARNING Do not connect any devices that are not supported as part of a system.

System Example

This illustration shows a system where both the medical electrical equipment and the non-medical

electrical equipment is situated at the patient’s bedside.

Non-Medical Devices

Personal

Computer

Separation

Device

Key:

Power cables:

Data cables:

WARNING Any non-medical device placed and operated in the patient’s vicinity (within a distance of 1.5m from the

patient’s bed) must be powered via an approved separation device (for example, an isolation transformer).

If the personal computer (or any other non-medical electrical device) is situated outside the medically used

room, you must take measures to reduce leakage currents, such as providing an additional protective earth,

a non-conducting enclosure, or a separation device.

Medical Devices

Avalon CTS

Fetal Monitor

We highly recommend using a separation device whenever you connect non-medical electrical equipment.

Regular Preventive Maintenance

The care and cleaning requirements that apply to the Avalon CTS and the monitoring accessories are

described in the Instructions for Use. This section details the periodic maintenance recommended for the

base station, transducers and accessories.

Mechanical Inspection

All rear panel connections must be tight. Check all exterior housings for cracks and damage. Check the

condition of all external cables, especially for splits or cracks and signs of twisting. If serious damage is

evident, the cable should be replaced immediately. Check that all mountings are correctly installed and

secure. Refer to the instructions that accompany the relevant mounting solution. Check that the protective

earth cable is properly and securely connected.

51

Page 62