Page 1

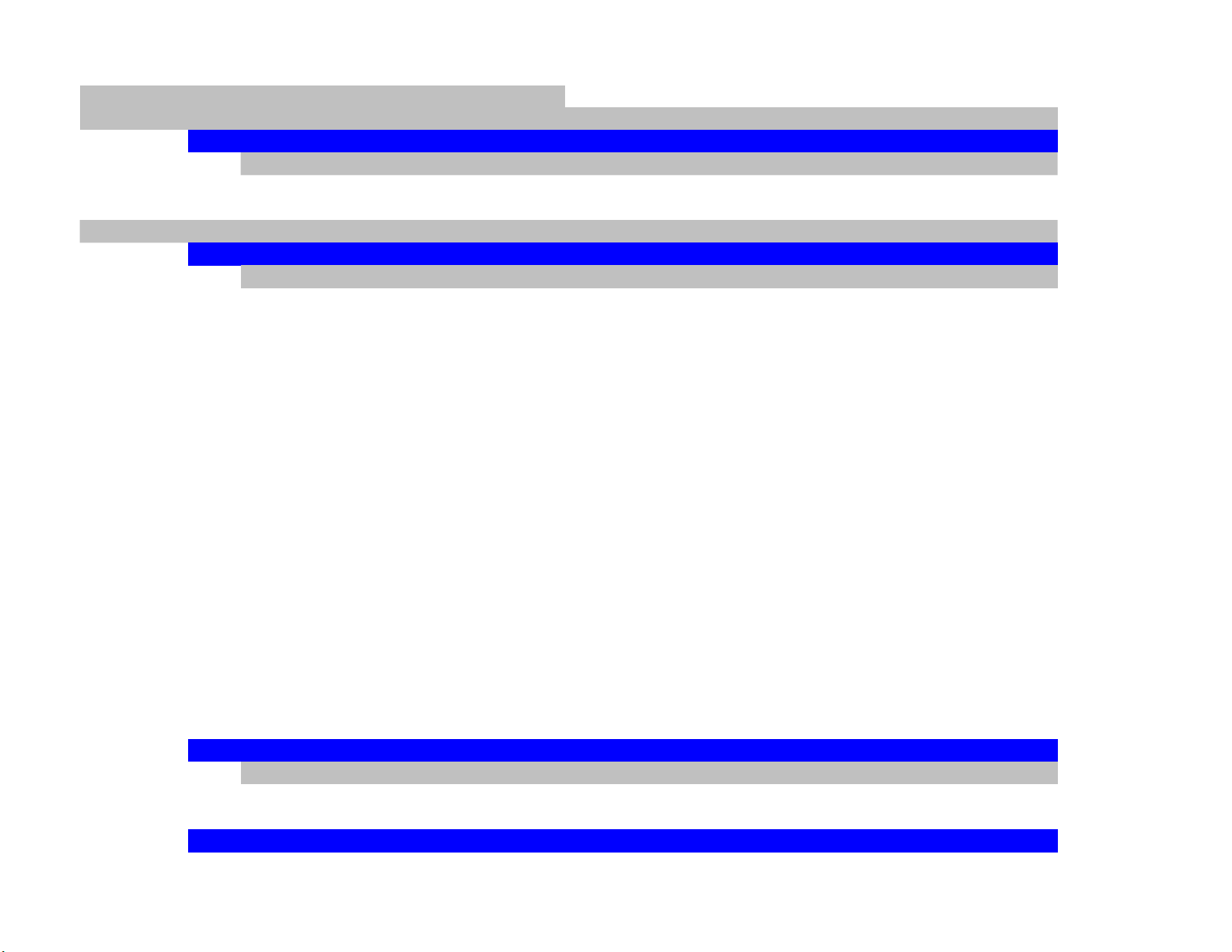

System type:

78107

GYROSCAN ACS-NT

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

Run SPT

Visual Inspection

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

2.1.1 Phantom check

2.1.2 PIQT Periodic Image Quality Test

2.3 Dust filters and fans

2.6 Check site conditions

Temperature Examination Room

°C

20.000

24.000

Temperature Technical Room

°C

15.000

24.000

Temperature Control Room

°C

18.000

24.000

Relative Humidity Examination Room

%

40.000

60.000

Relative Humidity Technical Room

%

30.000

70.000

Relative Humidity Control Room

%

30.000

70.000

Amount of Dust

4.3 Replacem. date Ion. Cartridge

4.5 Verify Heat Exchanger settings

7.1.1 Check finger prot. plate & alarm

8.4 RF Power Ref. & PU coil adjustment

9. Monitor adjustment

10.1 Non-Optical Mouse Cleaning

11.1 Clean up Directories

11.2 Total Backup

11.6 Check Statistical Logging

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

5.1.1 Pressure value Supply

PSI

5.1.1 Pressure value Return

PSI

Module: MR Coil Replacement

Chapter: SPT executed Cycle: Work:

Module: Gyroscan NT PM-man. (All releases)

Chapter: Checks 4 Months Cycle: 4 Months Work:

Chapter: Check pressure of the compressor Cycle: 4 Months Work:

Chapter: Check value hour counter Cycle: 4 Months Work:

Page 2

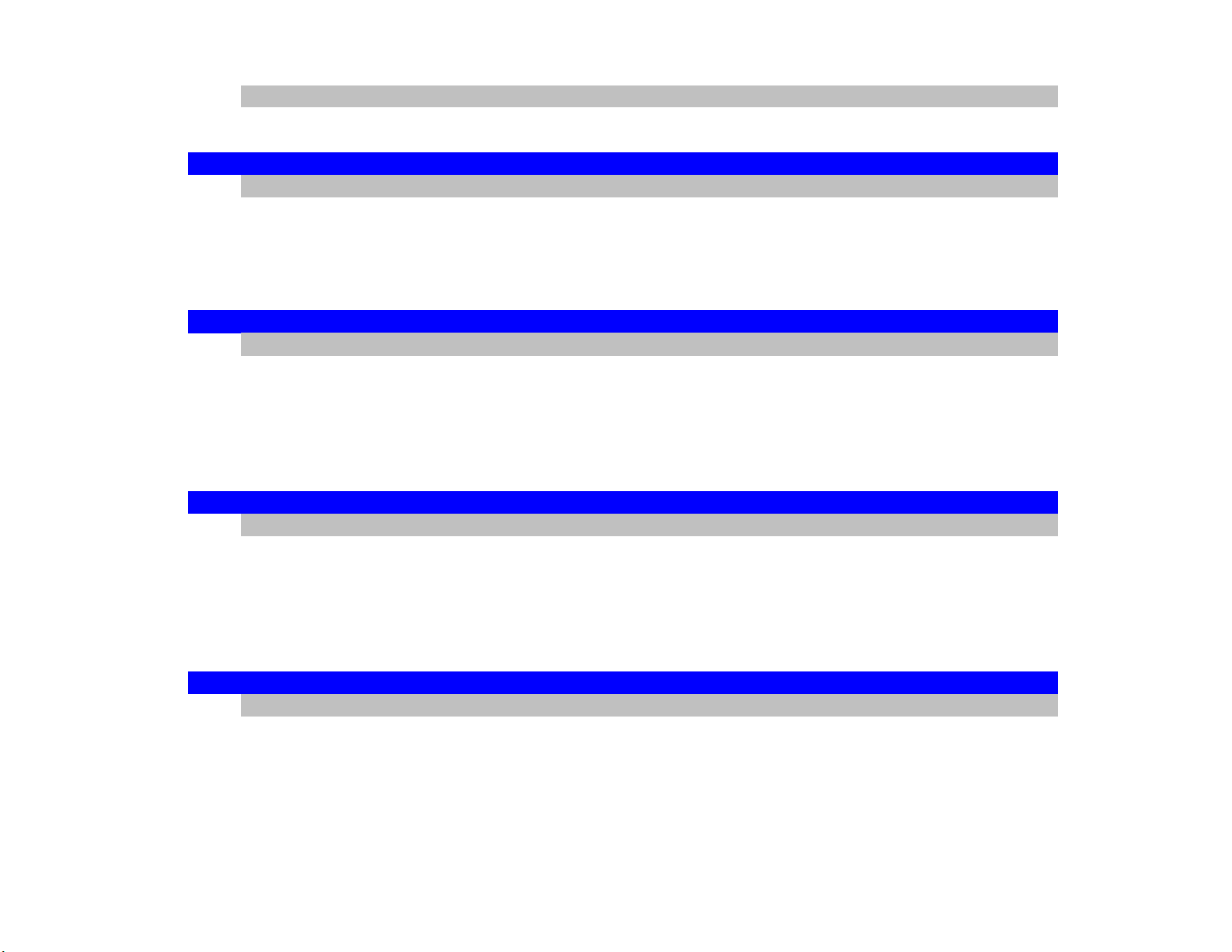

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

5.1.2 Readout of the hour counter

h

5.1.2 Date of last check

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

6.1 Helium level

%

6.1 Date of last check

6.1 Date of last refill

6.1 Liters of He refilled

l

6.1 Boil-off

ml/h

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

2.3.1 Fan(s) of the Reconstructor

2.3.2 Dust filters and fans BDAS

2.3.3 Dust filters & fans RF power amp

2.3.5 Fan units gradient system

2.4 RF cage

2.5 Check the RF coils

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

8.2 The Automatic NTDAC Tests

8.2.1 Automatic BDAS procedures

8.4.1 Resonance Freq. determination

8.3 RF power Amplifier measurements

8.4.2 Power Reference measurement

8.4.3 Pickup-coil measurement

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

2.4.1 Helium Exhaust Pipe

6.2.2 Seals Quench Switches

6.4 Check Cables at the Magnet

6.4.2 Adjust B0 circuit (option)

7.1.5 Check hydraulic system

7.1.6 Check moving cables on degrad.

Chapter: Check of the Helium level and boil off Cycle: 4 Months Work:

Chapter: Checks 8 Months I Cycle: 8 Months Work:

Chapter: Checks 8 Months II Cycle: 8 Months Work:

Chapter: Checks 12 months I Cycle: 12 Months Work:

Page 3

7.1.7 Check Patient support lights

7.1.8 Check Emergency stop circuit (MT)

7.1.9 Check Patient Support Fans (MT)

8.5.1 Gradient parameters determination

8.6 Spike check

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

2.2.7 Visual Inspection

4.4 Clean strainers heat exch (PT 3/6)

5.1.3 Check water and oil circuits

2.2.1 Check stop Function

2.2.2 Check door Switch (NA)

2.2.3 Helium Overpressure det. Switch

2.2.4 Check Gradient Airflow Circuit

2.2.5 Gradient coil Temperature Sensors

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

6.2.3 Check the ERDU (Availability)

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

From MDU to Heat Exchanger

mOhm

180.000

From MDU to Gradient Amplifier

mOhm

100.000

From SFB to Patient Table

mOhm

20.000

From SFB to Patient Table Box

mOhm

20.000

From SFB to Ring Frame Front

mOhm

20.000

From SFB to Ring Frame Rear

mOhm

20.000

From SFB to PFEI

mOhm

20.000

From SFB to TFEI

mOhm

20.000

From SFB to PICU front

mOhm

20.000

From SFB to Cold Head

mOhm

20.000

From SFB to Gradient Coil Shield

mOhm

20.000

From MDU to RF Amplifier

mOhm

100.000

From MDU to NTDAC

mOhm

100.000

From MDU to Magnet Power Supply (MMU)

mOhm

100.000

Chapter: Checks 12 months II Cycle: 12 Months Work:

Chapter: Checks 12 months III Cycle: 12 Months Work:

Chapter: 3.1 Mains distribution Cycle: 12 Months Work:

Page 4

From MDU to Compressor

mOhm

100.000

From MDU to System Filterbox (SFB)

mOhm

100.000

From MDO to Monitor Console

mOhm

100.000

From SFB to NTDAC

mOhm

50.000

From SFB to Magnet

mOhm

20.000

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

Measure leakage curr. at system standby

mA

0.000

10.000

Measure leakage curr.during acquisition

mA

0.000

10.000

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

5.1.5 Date of Adsorber Replacement

5.2 Date of Coldhead Replacement

2.7 Check for dust in Hybrid box & QBC

4.1.1 Check Gradient Cables

Clean Computer system

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

6.2.1 Battery Date of Replacement

6.3 Check DPS

10.2 Computer Cleaning

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

7.2 Oil Filter Date last exchange

7.3 Gear wheels Date last lubrication

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

7.4 Date last oil exchange

Action name

Unit

Min

Max

Min (D)

Max (D)

Min (%)

Max (%)

Results

Modem Test

Chapter: 2.2.6 Leakage current measurements Cycle: 12 Months Work:

Chapter: Checks 24 months I Cycle: 24 Months Work:

Chapter: Checks 24 months II Cycle: 24 Months Work:

Chapter: Checks 48 months Cycle: 48 Months Work:

Chapter: Checks 96 months Cycle: 96 Months Work:

Module: Remote Modem

Chapter: Modem Test Cycle: 6 Months Work:

Loading...

Loading...