Philips 43FDX01B, PDP42X3 Series Service Manual

Published by MW 0765 BG CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 16392

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Colour Television Module

LGE PDP 2K6

PDP42X3*

Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 12

6. Block Diagrams, Test Point Overviews, and

Waveforms 25

7. Circuit Diagrams and PWB Layouts 25

8. Alignments 26

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 29

10. Spare Parts List 34

11. Revision List 34

Technical Specifications, Connections, and Chassis Overview

EN 2 LGE PDP 2K61.

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications PDP42X3*

1.1.1 General Specification

1.1.2 Definitions

1.1.3 Chassis Overview

1.1 Technical Specifications PDP42X3*

The PDP Module is divided into a Panel part and a Drive part.

The Panel part consists of Electrodes, Phosphor, various

dielectrics, and gas, while the Drive part includes electronic

circuitry and PWBs.

1.1.1 General Specification

Table 1-1 General Specifications

1.1.2 Definitions

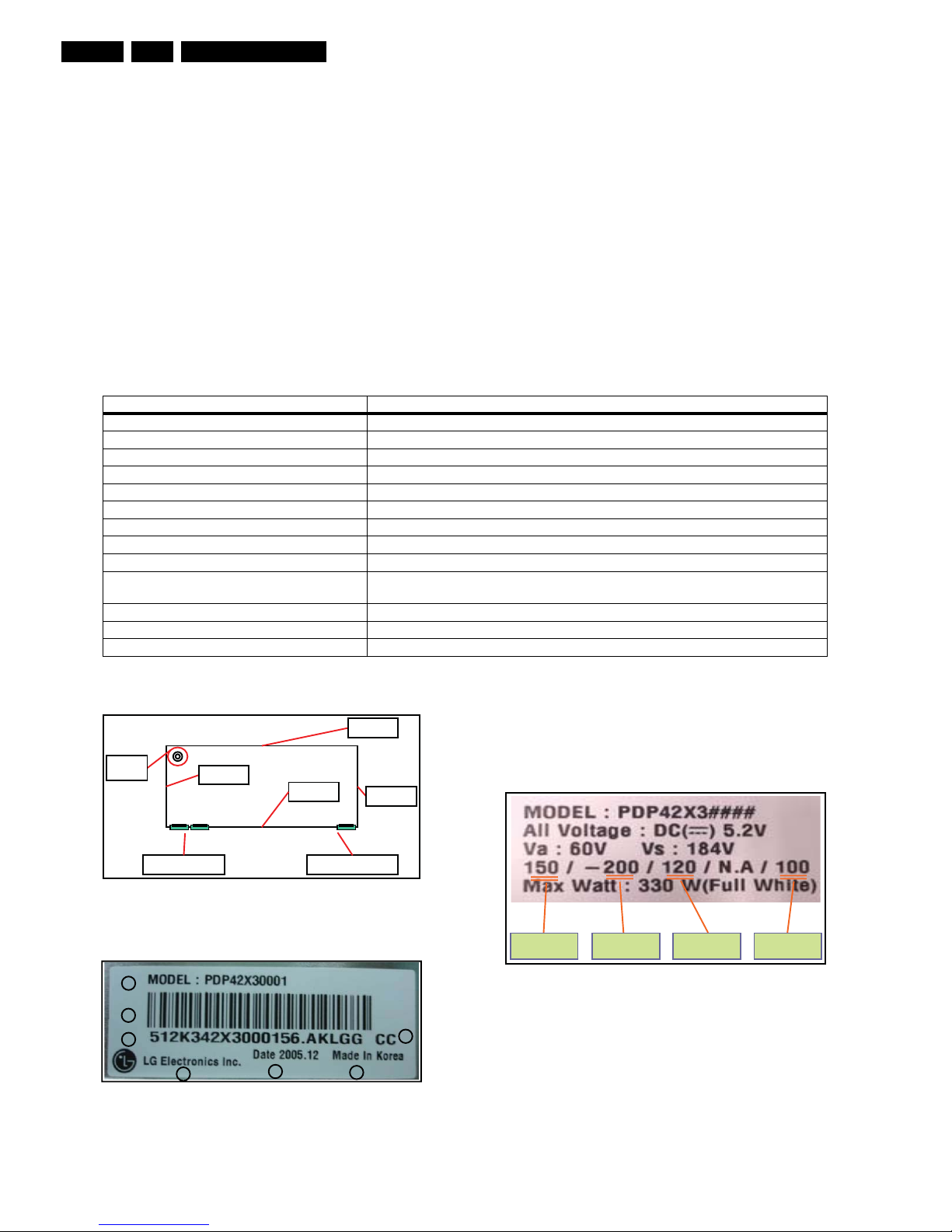

Figure 1-1 Definition of module position

Figure 1-2 Identification label

1. Model name.

2. Bar code (Code 128, contains the manufacture no.).

3. Manufacture no. (Module serial no.).

4. The trade name of LG Electronics.

5. Manufacture date (Year & Month).

6. The place of origin.

7. Model suffix.

Figure 1-3 Voltage label (on rear side of module)

Model Name

PDP42X3*

Number Of Pixels (H x V)

1024 (*3) x 768

Pixel Pitch (H x V µm) 900 x 676

Cell Pitch (H x V µm)

300 x 676 (base: Green Cell)

Display Area (H x V mm) 921.6 x 519.2 ± 0.5

Outline Dimension (H x V x D mm) 1005 x 597 x 61.2 ± 1

Colour Arrangement RGB closed type

Number Of Colours (R x G x B) 1024 x 1024 x 1024 (1,073,741,824)

Weight 15.3 ± 0.5 kg

Aspect Ratio 16 : 9

Peak Brightness

Typical 1200 cd/m

2

(1 % white window)

Average 140 : 1 (Light room 100 Lx at centre)

Contrast Ratio Typical 10000 : 1 (Dark room 1 % white window, white window pattern at centre)

Power Consumption Max. 330 W (Full White)

Lifetime Over 60,000 hours (initial brightness 1/2)

G_16390_001.eps

290607

t s u a h x E

e l o h

1 g n o l

2 g n o l

1 t r o h s

2 t r o

h s

g 2-1 n o l P C

T

• •

• • •

• •

•

2

2 - 2 g n o l P C T

e l u d o m f o e d i s Rear *

G_16390_002.eps

020806

1

2

3

4

5

6

7

c

s V

y

V -

p u t e s V b z V

G_16391_001.eps

290607

Technical Specifications, Connections, and Chassis Overview

EN 3LGE PDP 2K6 1.

Figure 1-4 Part number printing (on board)

Figure 1-5 Part number label (on board)

Figure 1-6 TCP serial number (on TCP)

PCB PART NO.

G_16390_008.eps

040806

G_16390_005.eps

020806

BOARD

SERIAL NR.

BOARD

NAME

BOARD ASSY

PART NR.

G_16390_007.eps

030806

TCP SERIAL NO.

Technical Specifications, Connections, and Chassis Overview

EN 4 LGE PDP 2K61.

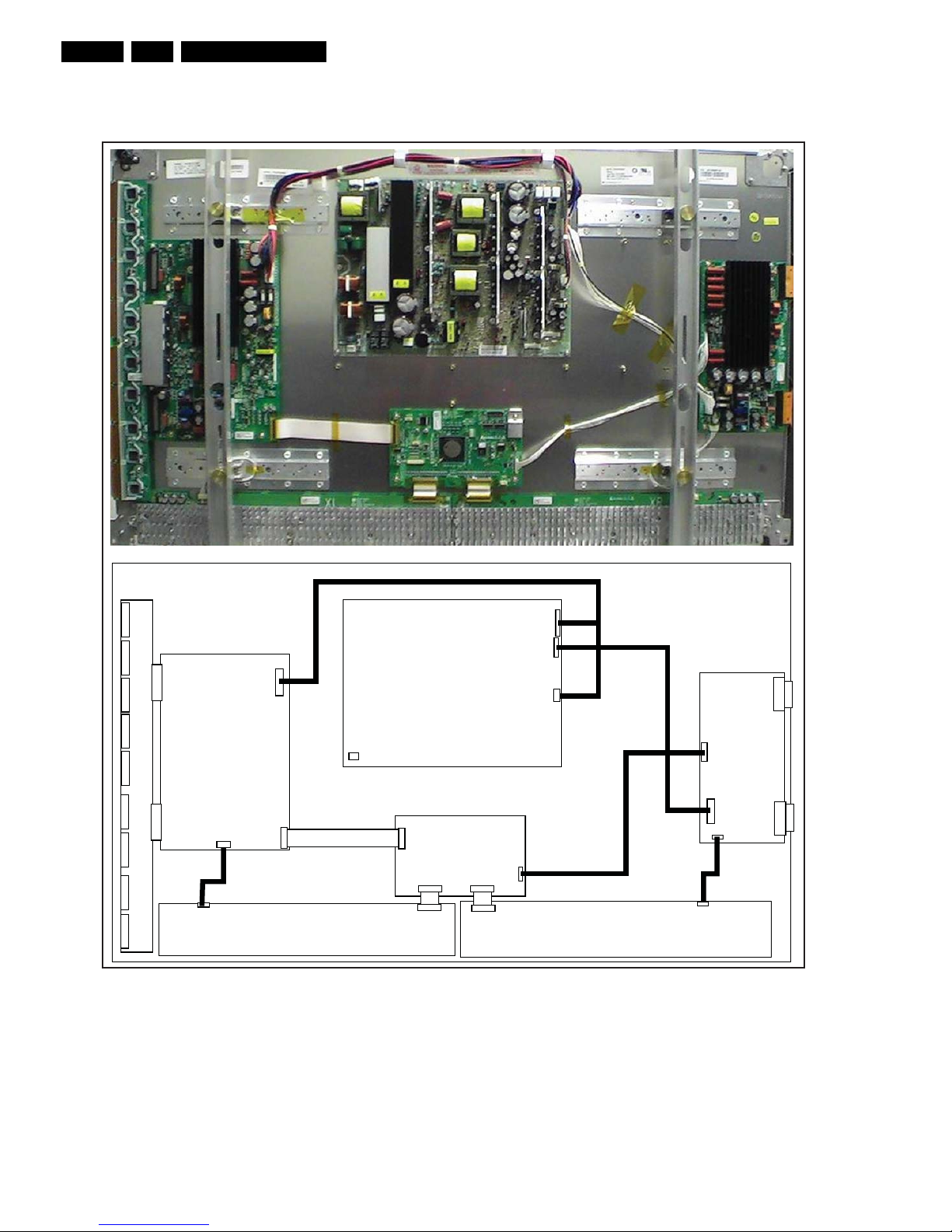

1.1.3 Chassis Overview

Figure 1-7 PWB location

G_16391_002.eps

290607

Control

Board

Z Sus

Board

Y Sus

Board

X Right Board

X Left Board

Y Driver Board

PSU

3501Q00203B

Safety Instructions, Warnings, and Notes

EN 5LGE PDP 2K6 2.

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Warnings

Notes:

• Only authorised persons should perform servicing of this

module.

• When using/handling this unit, pay special attention to the

PDP Module: it should not be enforced into any other way

then next rules, warnings, and/or cautions.

• "Warning" indicates a hazard that may lead to death or

injury if the warning is ignored and the product is handled

incorrectly.

• "Caution" indicates a hazard that can lead to injury or

damage to property if the caution is ignored and the

product is handled incorrectly.

2.1 Warnings

1. Do not touch the Signal and Power Connectors while this

product operates. Do not touch EMI ground part and Heat

Sink of Film Filter.

2. Do not supply a voltage higher than specified to this

product. This may damage the product or can create

hazardous situations.

3. Do not use this product in locations where the humidity is

extremely high, where it may be splashed with water, or

where flammable materials surround it. Do not install or

use the product in a location that does no satisfy specified

environmental conditions. This may damage the product or

can create hazardous situations.

4. If a foreign substance (such as water, metal, or liquid) gets

inside the product, immediately turn "OFF" the power.

Continuing to use the product may cause electric shock or

can create hazardous situations.

5. If the product emits smoke and abnormal smell, or makes

an abnormal sound, immediately turn "OFF" the power.

Continuing to use the product may cause electric shock or

can create hazardous situations.

6. Do not (dis)connect the connector while power to the

product is "ON". It takes some time for the voltage to drop

to a sufficiently low level after the power has been turned

"OFF". Confirm that the voltage has dropped to a safe level

before (dis)connecting the connector.

7. Do not pull out or insert the power cable from/to an outlet

with wet hands. It may cause electric shock.

8. Do not damage or modify the power cable. It may cause

electric shock or can create hazardous situations.

9. If the power cable is damaged, or if the connector is loose,

do not use the product, otherwise, this can lead to

hazardous situations or may cause electric shock.

10. If the power connector, or the connector of the power

cable, is dirty or dusty, wipe it with a dry cloth. Otherwise,

this can lead to hazardous situations.

11. The PDP module uses a high voltage (max. 450 V

DC

).

Keep the cautions concerning electric shock and do not

touch the device circuitry handling the PDP unit. And

because the capacitors of the device circuitry may remain

charged at the moment of Power "OFF", standing for 1

minute is required in order to touch the device circuitry.

12. Because the PDP module emits heat from the glass panel

part and the drive circuitry, the environmental temperature

must not be over 40 deg. C. The temperature of the glass

panel part is especially high owing to heat from internal

drive circuitry. And because the PDP module is driven by

high voltage, it must avoid conductive materials.

13. If inserting components or circuit boards in order to repair,

be sure to fix a lead line to the connector before soldering.

14. If inserting high-power resistors (metal-oxide film resistor

or metal film resistor) in order to repair, insert it 10 mm

away from a board.

15. During repairs, high voltage or high temperature

components must be put away from a lead line.

16. This is a cold chassis but you better use an isolation

transformer for safety during repairs. If repairing the

electricity source part, you MUST use the isolation

transformer.

17. Do not place an object on the glass surface of the display.

The glass may break or be scratched.

18. This product may be damaged if it is subjected to

excessive stresses (such as excessive voltage, current, or

temperature). The absolute maximum ratings specify the

limits of these stresses.

19. The recommended operating conditions are conditions in

which the normal operation of this product is guaranteed.

All the rated values of the electrical specifications are

guaranteed within these conditions. Always use the

product within the range of the recommended operating

conditions. Otherwise, the reliability of the product may be

degraded.

20. This product has a glass display surface. Design your

system so that excessive shock and load are not applied to

the glass. Exercise care that the vent at the corner of the

glass panel is not damaged. If the glass panel or vent is

damaged, the product is inoperable.

21. Do not cover or wrap the product with a cloth or other

covering while power is supplied to the product.

22. Before turning on power to the product, check the wiring of

the product and confirm that the supply voltage is within the

rated voltage range. If the wiring is wrong or if a voltage

outside the rated range is applied, the product may

malfunction or be damaged.

23. Do not store this product in a location where temperature

and humidity are high. This may cause the product to

malfunction. Because this product uses a discharge

phenomenon, it may take time to light (operation may be

delayed) when the product is used after it has been stored

for a long time. In this case, it is recommended to light all

cells for about 2 hours (aging).

24. This product is made from various materials such as glass,

metal, and plastic. When discarding it, be sure to contact a

professional waste disposal operator.

25. If faults occur due to arbitrary modification or disassembly,

LG Electronics is not responsible for function, quality or

other items.

26. Use of the product with a combination of parameters,

conditions, or logic not specified in the specifications of this

product is not guaranteed. If intending to use the product in

such a way, be sure to consult LGE in advance.

27. Within the warranty period, general faults that occur due to

defects in components such as ICs will be rectified by LGE

without charge. However, IMAGE STICKING due to

misapplying the above provision (12), is not included in the

warranty. Repairs due to the other faults may be charged

for depending on responsibility for the faults.

28. While assembling the PDP module into a set, use the EMI

ground part of the Film Filter for grounding, BEFORE

removing the protective film, to prevent that static electricity

can damage the TCPs or boards

Directions for Use

EN 6 LGE PDP 2K63.

3. Directions for Use

Not applicable.

Mechanical Instructions

EN 7LGE PDP 2K6 4.

4. Mechanical Instructions

Index of this chapter:

4.1 Mechanical Overviews

4.2 Panel/assy removal

4.2.1 Power Supply Unit

4.2.2 Control Board

4.2.3 Y Sustain Board

4.2.4 Y Driver Board

4.2.5 Z-Sustain board

4.2.6 X-board

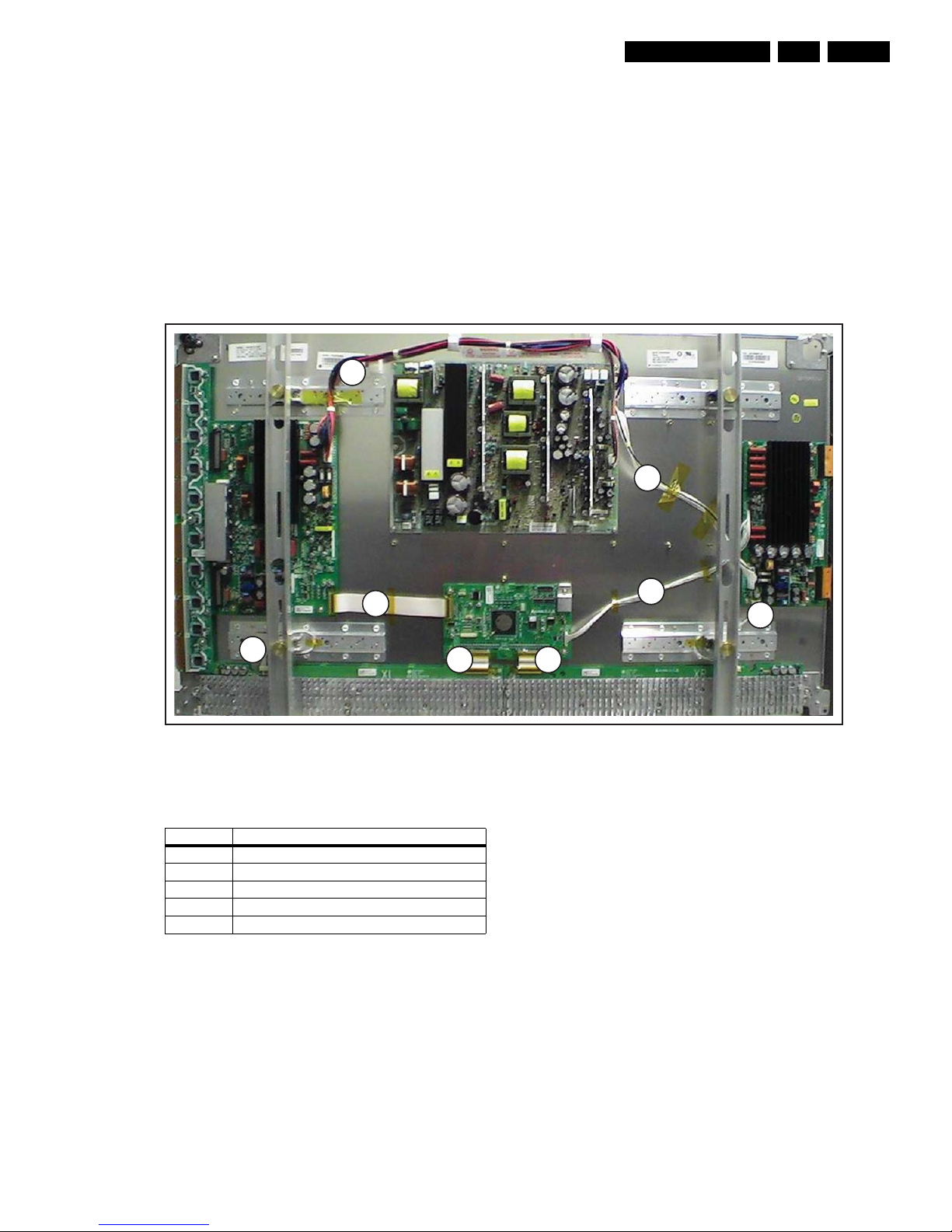

4.1 Mechanical Overviews

Figure 4-1 Cable dressing

Table 4-1 Cable function

G_16391_004.eps

020707

8

4

1

2 3

6

5

7

Cable No. Function

1 Drive signal for Y waveform

2 & 3 RGB data to be transferred to panel

4 & 5 5V and Va supply for X-boards Left and Right

6 Drive signal for Z-waveform

7 & 8 Va, Vs and 5 V supply for PDP operation

Mechanical Instructions

EN 8 LGE PDP 2K64.

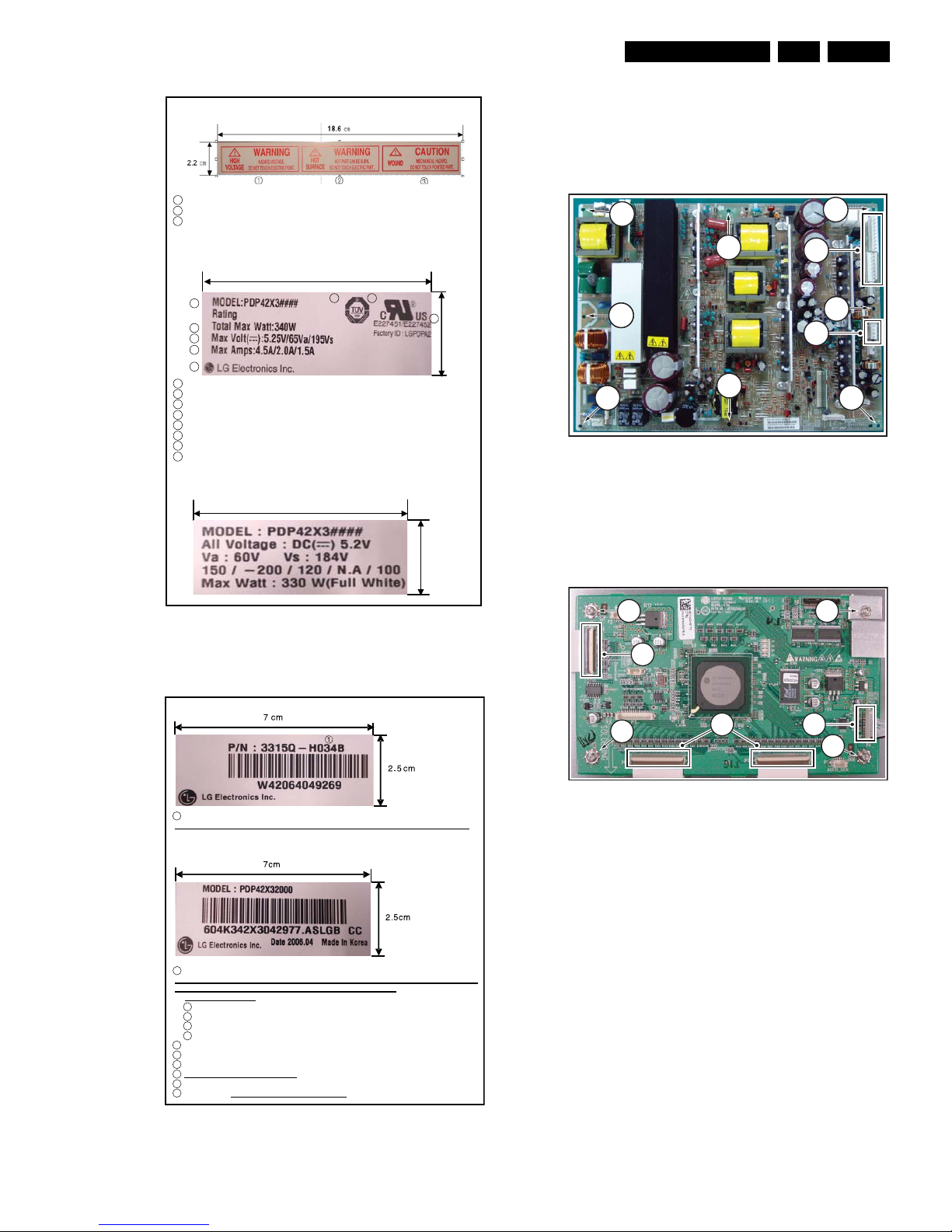

Figure 4-2 Label location on PWB’s

Figure 4-3 Label indication

G_16390_014.eps

070806

G_16390_013.eps

070806

Mechanical Instructions

EN 9LGE PDP 2K6 4.

Figure 4-4 Label information (1)

Figure 4-5 Label information (2)

4.2 Panel/assy removal

4.2.1 Power Supply Unit

1. Unplug the connectors [1].

2. Remove the fixation screws [2].

Figure 4-6 PSU removal

4.2.2 Control Board

1. Unplug the connectors [1].

2. Remove the fixation screws [2].

Figure 4-7 Control board removal

1. Warning & Caution Label : Warning and caution for High Voltage, Hot Surface, Wound

1 Warning (High Voltage, Hazard Voltage)

2 Warning (Hot Surface, Hot part)

3 Caution (Wound, Mechanical Hazard)

2. Safety Approval Label

8

67

5

4

3

2

1

2.5 cm

7 cm

1 Model Name

2 Max. Watt (Full White)

3 Max. Volts

4 Max. Amps

5 The Trade Name of LG Electronics

6 TUV Approval Mark

7 Safety Approval Mark

8 Safety Approval No.

3. Voltage Label : Model Name & Operational Voltage

2.5 ?

7 cm

G_16390_020.eps

020707

4. Serial No. for Frame Ass’y

1 Serial No of Frame Ass’y

Serial No. of Frame Ass’y for Philips are 3315Q-E037B, 3315Q-E037C and 3315Q-E037F .

5. Manufacture Serial No. Label of Module

1 Model Name

Model Names for Philips are PDP42X3A062, PDP42V7A012, PDP42V74112, PDP42V74102,

PDP42V74012, PDP42V74002, PDP42V70102 and PDP42V70002.

* PDP42V7????

1 : PSU Character

2 : Panel character

3 : Circuit character

4 : Mechanical character

2 Bar Code (Code 128, Contains the manufacture No.)

3 Manufacture No.

4 The trade name of LG Electronics

5 Manufactured date (Year & Month)

6 The place Origin

7 Model Suffix : ASLGB21 is Model Suffix for Philips

G_16390_021.eps

020707

G_16391_005.eps

220806

1

1

22

2

2

2

2

12

2

G_16390_030.eps

220806

1

2

2

2

1

2

1

Mechanical Instructions

EN 10 LGE PDP 2K64.

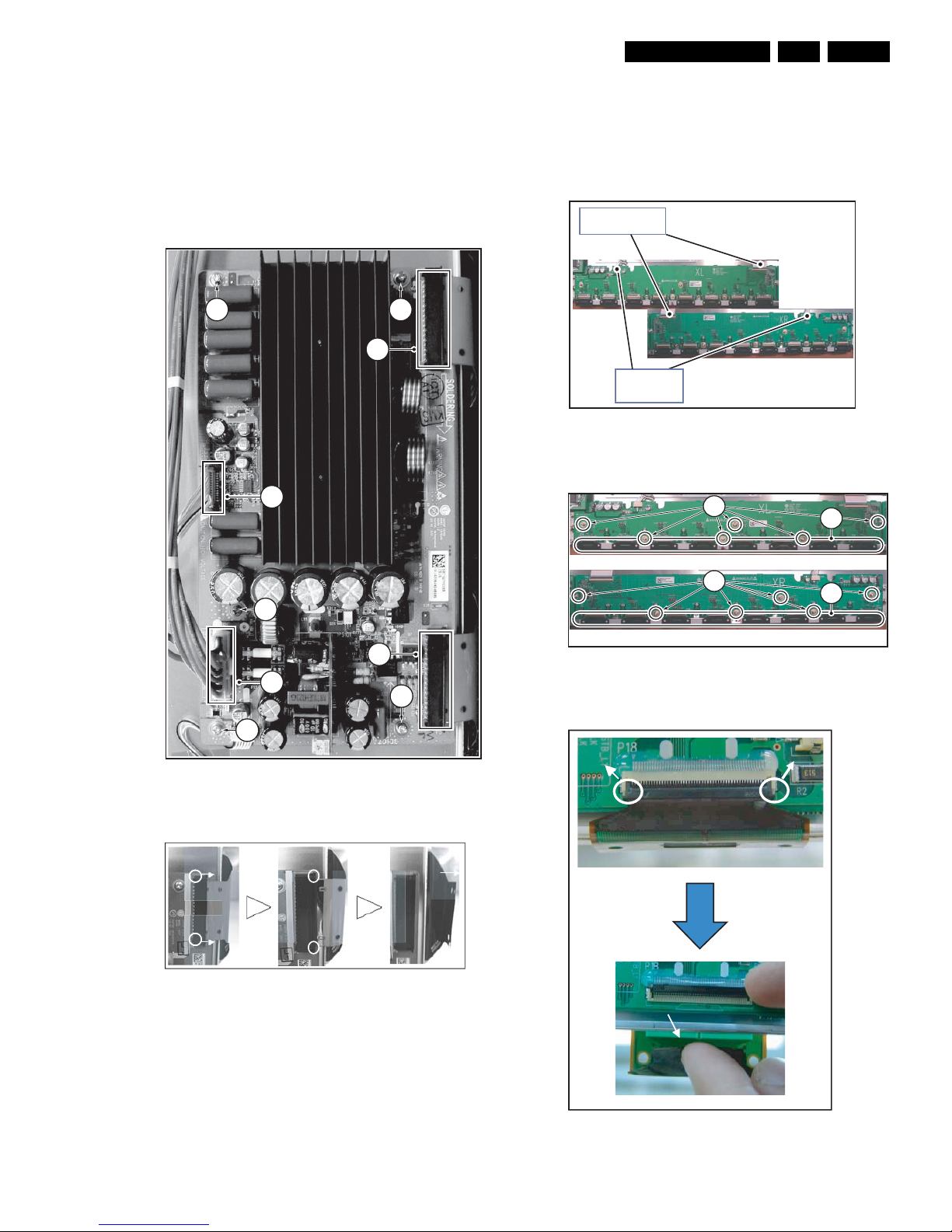

4.2.3 Y Sustain Board

1. Unplug the connectors [1].

2. Remove the fixation screws [2].

3. Slide the board to the right, while unplugging connectors

[3]. Do not touch the heatsink!

Figure 4-8 Y-SUS board removal

4.2.4 Y Driver Board

1. Remove the Y-SUS board [1], as described previously.

2. Remove the fixation screws [2].

3. Separate the TCP’s [3].

Figure 4-9 Y driver board removal

Figure 4-10 TCP Separation

G_16390_031.eps

010906

1

2

2

2

2

2

2

2

1

1

3

3

G_16390_032.eps

010906

3

2

2

1

2

F_15590_050.eps

040705

Mechanical Instructions

EN 11LGE PDP 2K6 4.

4.2.5 Z-Sustain board

1. Unplug the connectors [1].

2. Remove the fixation screws [2].

3. Slide the board to the right, while unplugging connectors

[3]. Do not touch the heatsink!

4. Pull out the locks of the FPC’s [3} as indicated by the

arrows.

5. Condition in Lock part is pulled.

6. Pull FPC as shown by arrow.

Figure 4-11 Z-SUS board removal

Figure 4-12 FPC removal

4.2.6 X-board

1. Unplug the power cable.

2. Unplug the signal cable.

3. Remove the heatsink.

4. Separate the TCP’s [1].

5. Remove the fixation screws [2].

Figure 4-13 X board removal 1/2

Figure 4-14 X board removal 2/2

Figure 4-15 TCP Separation

G_16390_033.eps

0108069

1

1

2

22

2

3

3

2

F_15590_052.eps

040705

Signal cables

G_16390_028.eps

010906

cables

Power

X Right board

G_16390_027.eps

220806

X Left board

2

1

1

2

G_16390_034.eps

100806

Loading...

Loading...