1

Colour Television Chassis

Comet

765320029_001

030697

ServiceManual

Content

1 Technical specifications 2

2 Connection facilities 3

3 Safety instructions, Maintenance instructions, 4

Warnings and notes

4 Mechanical instructions 6

5 Repair facilities 7

6 Overview oscillograms 9

Survey of testpoints 9

Block diagram 10

Fault finding tree 11

7 Electrical Diagrams and print lay-outs

Diagram PWB

Power supply & Line stage (Diagram A1) 12 20,21

Tuner IF (Diagram A2) 13 20,21

Sound & Chroma (Diagram A3) 14 20,21

Controls & teletext (Diagram A4) 15 20,21

CRT panel (Diagram B) 16

Deflection module 110 degrees (Diagram D) 17 17

2 x 3W amplifier (Diagram C2) 19 18

Seperate controls & Mains module(Diagram J) 22

8 Electrical adjustments 23

9 Circuit Description 24

10 Directions for use/Exploded view cabinets 28, 35

11 List of abbreviations 36

Published by LV 9865 TV Service DepartmentPrinted in The NetherlandsCopyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The Netherlands. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwisewithout the prior permision of Philips.Subject to modification5 4822 727 21614

12 Spareparts list 38

Published by LV 9865 TV Service Department Printed in The Netherlands ©Copyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The Netherlands. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical,

2 Comet

I

7

1 Technical specifications

Mains Voltage: : 220-240V ± 10% AC;

1 Technical specifications

50-60Hz (± 5%)

Mains frequency : 50 Hz

: 60 Hz

Power Consumption in stand-by : < 5 Watt

Power Consumption normal mode : 28” : 75Watt +/- 10%

Aerial input impedance TV : 75 Ohm - coax

Min. aerial input VHF: : 30mV

Min. aerial input UHF: : 40mV

Max. aerial input VHF/UHF: : 180mV

Pull-in range colour sync: : ± 300Hz

Pull-in range horizontal sync: : ± 600Hz

Pull-in range vertical sync: : ± 5Hz

Picture tube range : 25” and 28”

Sound output power : 3 Watt mono

execution

: 2 X 3 Watt stereo

execution

TV Systems: : PAL I

: PAL BG

: PALBG / SECAM DK

: PAL BG / SECAM LL'

Indications: : On Screen Display

(OSD) green/red

: 1 LED ( red high

intensity, red low

intensity,

: "RC5' and error

codes blinking red)

VCR programs: : 0

Tuning and operating system: : VST

UV913E / IEC (VST): : VHFa:46 - 102 MHz

: VHFb:138 - 224 MHz

: UHF:471 - 855 MHz

UV915E / IEC (VST): : VHFa:48 - 168 MHz

: VHFb:175 - 448 MHz

: UHF300 - 860 MHz

UV917E / IEC (VST): : VHFa:48 - 118 MHz

: VHFb:118 - 300 MHz

: UHF:470 - 861 MHz

U943 / IEC (VST): : UHF:470 - 861 MHz

Local operating functions: : MENU / - / +

MENU

-+

IR LED,

76532029_002.A

03069

2 Connection facilities

2 Connection facilities

1- Audio R (0.5Vrms ≤1kΩ) k

2- Audio R (0.5Vrms ≥10kΩ) j

3- Audio L (0.5Vrms ≤1kΩ) k

4- Audio v

5- Blue v

6- Audio L (0.5Vrms ≥10kΩ) j

7- Blue (0.7Vpp/75Ω)

8- CVBS-

status 0-1.3V:INT, 4.5-7V:EXT 16:9, 9.5-

12V:EXT 4:3 j

9- Green v

1011- Green (0.7Vpp/75Ω)

1213- Red v

14- v

15- Red (0.7Vpp/75Ω)

16- RGB-

status (0-0.4V:INT, 1-3V:EXT/75Ω)

17- CVBS v

18- CVBS v

19- CVBS (1Vpp/75Ω) k

20- CVBS (1Vpp/75Ω) j

21- Earth

socket

3Comet

4 Comet

3 Safety instructions, Maintenance instruction,

3 Safety instructions, Maintenance instruction, Warnings and Notes

3.1 Safety instructions for repairs

Figure 3-1

1. Safety regulations require that during a repair:

– the set should be connected to the mains via an

isolating transformer;

– safety components, indicated by the symbol (see fig.

3.1), should be replaced by components identical to

the original ones;

– when replacing the CRT, safety goggles must be worn.

2. Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– As a strict precaution, we advise you to resolder the

solder joints through which the horizontal deflection

current is flowing, in particular:

• all pins of the line output transformer (LOT);

• fly-back capacitor(s);

• S-correction capacitor(s);

• line output transistor;

• pins of the connector with wires to the deflection

coil;

• other components through which the deflection

current flows.

Note: This resoldering is advised to prevent bad

connections due to metal fatigue in solder joints and is

therefore only necessary for television sets older than

2 years. The wire trees and EHT cable should be

routed correctly and fixed with the mounted cable

clamps.

– The insulation of the mains lead should be checked for

external damage.

– The mains lead strain relief should be checked for its

function in order to avoid touching the CRT, hot

components or heat sinks.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets which have a mains isolated power supply). This

check can be done as follows:

• unplug themainscordand connect a wire between

the two pins of the mains plug;

• set the mains switch to the on position (keep the

mains cord unplugged!);

• measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 MW and 12 MW;

• switch off the TV and remove the wire between the

two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

– When the set is used in circumstances with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is 1 year.

– The maintenance inspection containsthefollowingactions:

• Execute the above mentioned 'general repair

instruction'.

• Clean the power supply and deflection circuitry on the

chassis.

• Clean thepicturetube panel andtheneck of the picture

tube.

3.3 Warnings

1. ESD

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handling during

repair can reduce life drastically. When repairing, make

sure that you are connected with the same potential as the

mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

– Available ESD protection equipment:

– anti-static table mat (large 1200x650x1.25mm) 4822

466 10953

– anti-static table mat (small 600x650x1.25mm) 4822

466 10958

– anti-static wristband 4822 395 10223

– connection box (3 press stud connections, 1 M ohm)

4822 320 11307

– extension cable (2 m, 2 M ohm; to connect wristband

to connection box) 4822 320 11305

– connecting cable (3 m, 2 M ohm; to connect table mat

to connection box) 4822 320 11306

– earth cable (1 M ohm; to connect any product to mat or

connection box) 4822 320 11308

– complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

– wristband tester 4822 344 13999

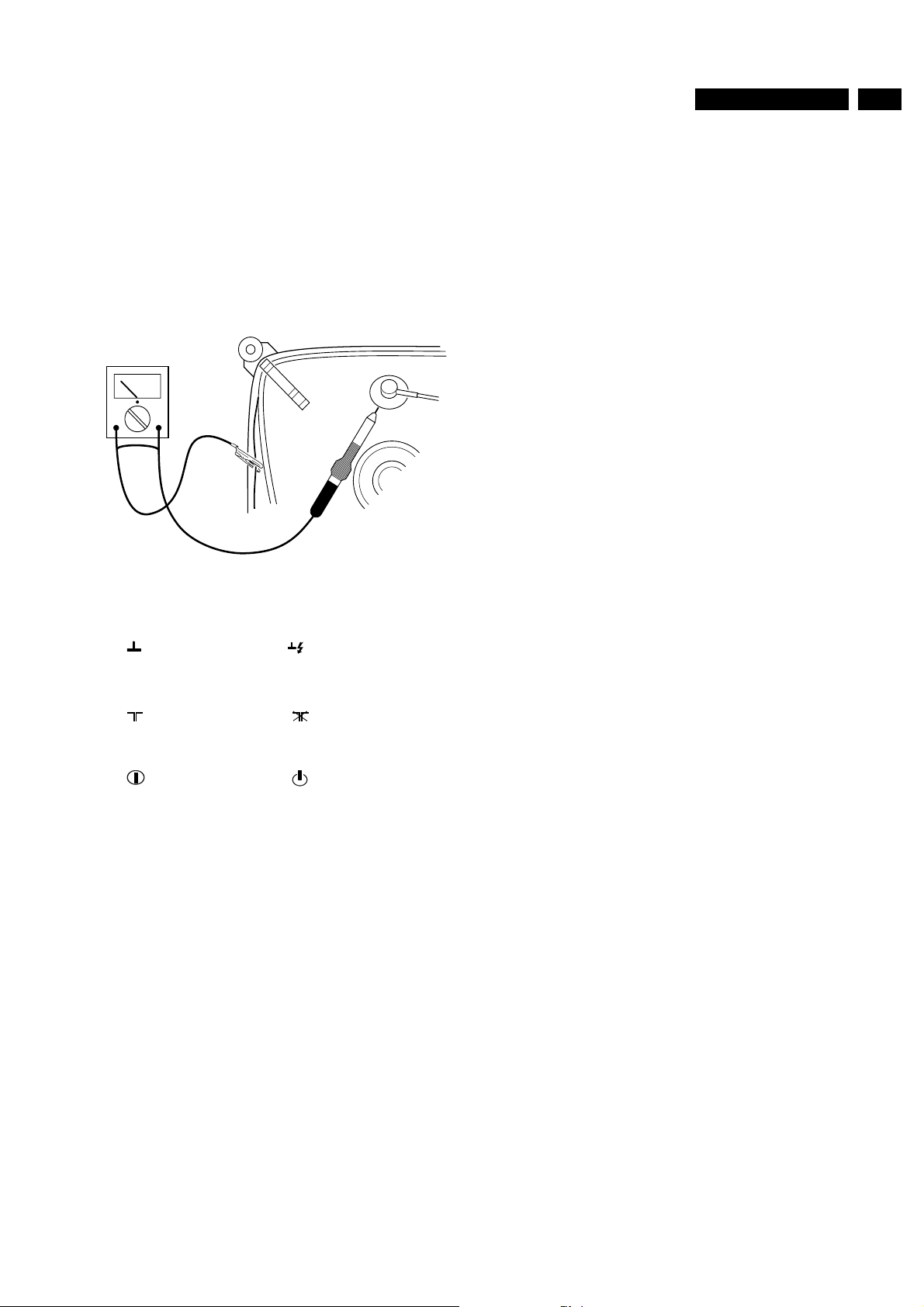

2. In order to prevent damage to ICs and transistors, all highvoltage flashovers must be avoided. In order to prevent

damage to the picture tube, the method shown in Fig. 3.2

should be used to discharge the picture tube. Use a highvoltageprobeandamultimeter(position DC-V). Discharge

until the meter reading is 0V (after approx. 30s).

3. Together withthedeflectionunit and any multipole unit, the

flat square picture tubes used from an integrated unit. The

deflection and the multipole units are set optimally at the

factory.Adjustmentof this unit duringrepairis therefore not

recommended.

4. Be careful during measurements in the high-voltage

section and on the picture tube.

5. Never replace modules or other components while the unit

is switched on.

6. When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

7. Wear safetygogglesduringreplacementofthe picture tube

3.2 Maintenance instruction

It is recommended to have a maintenance inspection carried

out by a qualified service employee. The interval depends on

the usage conditions:

– When the set is used under normal circumstances, for

example in a living room, the recommended interval is 3 to

5 years.

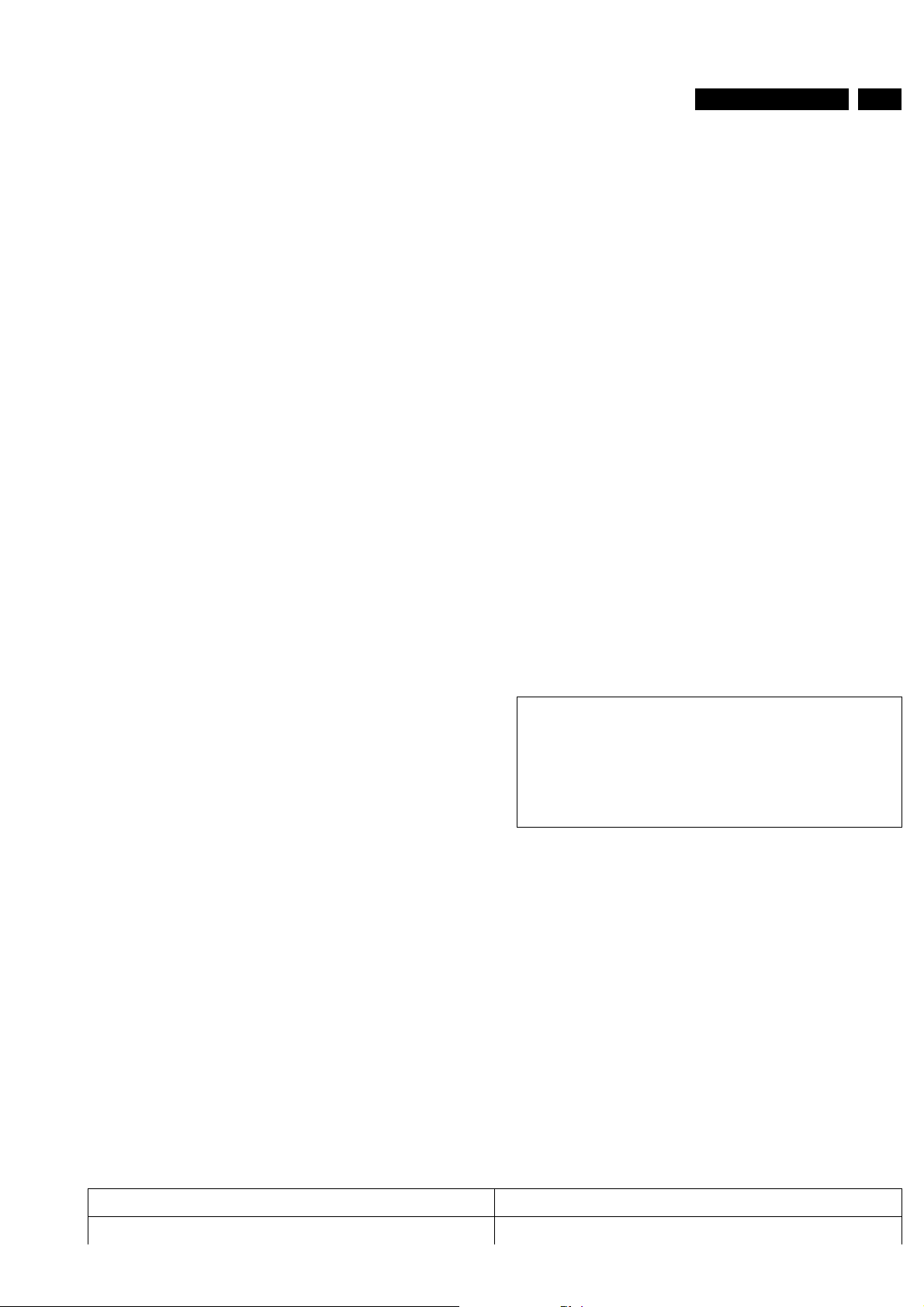

3.4 Notes

1. The direct voltages and oscillograms should be measured

with regard to the tuner earth , or hot earth as this is called

(see fig. 3.3)

2. The direct voltages and oscillograms shown in the

diagrams are indicative and should be measured in the

Service Default Mode (see chapter 8) with a colour bar

signal and stereo sound (L:3 kHz, R:1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz.

3 Safety instructions, Maintenance instruction,

3. Where necessary,theoscillogramsanddirectvoltages are

measured with and without aerial signal. Voltages in the

power supply section are measured both for normal

operation and in standby . These values are indicated by

means of the appropriate symbols (see fig. 3.3).

4. The picture tube PWB has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

5. The semiconductors indicated in the circuit diagram and in

the parts lists are completely interchangeable per position

with the semiconductors in the unit, irrespective of the type

indication on these semiconductors.

V

CL 26532098/042

140792

Figure 3-2

5Comet

tuner earth

tuner aarde

la masse du tuner

Tuner-Erde

massa del tuner

tierra del sintonizador

with aerial signal

met antenne signaal

avec signal d'antenne

mit Antennensignal

con segnale d'antenna

con la señal de antena

normal condition

normaal bedrijf

fonctionnement normal

normaler Betrieb

funzionamento normale

funcionamiento normal

massa calda

zonder antenne signaal

Figure 3-3

hot earth

hete aarde

la terre directe

heißen Erde

tierra caliente

without aerial signal

sans signal d'antenne

.ohne Antennensignal

senza segnale d'antenna

sin la señal de antena

stand by

stand by

position de veille

in Bereitschaft

modo di attesa

posición de espera

6 Comet

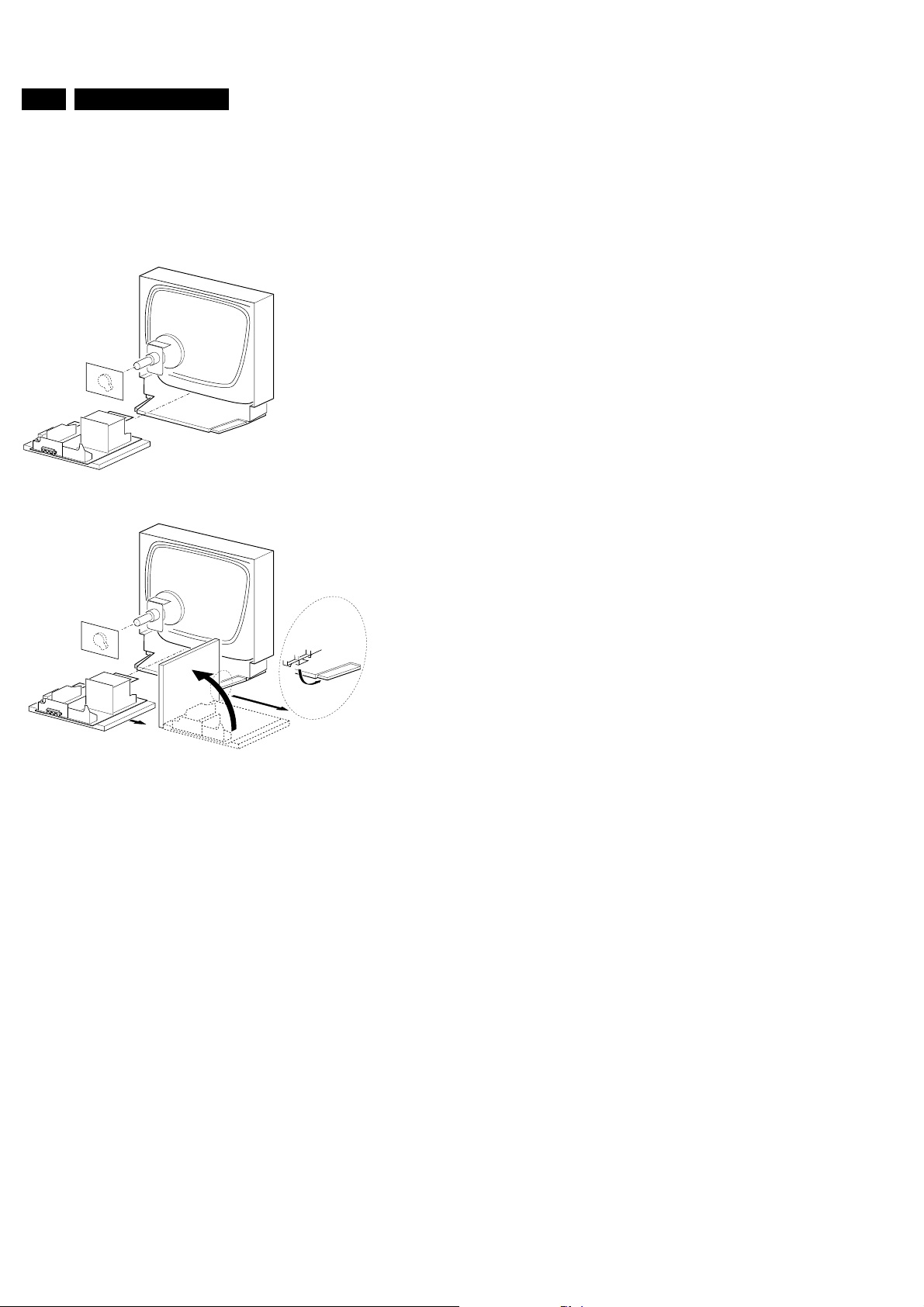

4 Mechanical instructions

For the main carrier two service positions are possible:

4 Mechanical instructions

a. For faultfinding on the component side of the main carrier

b. For (de)soldering activities on the copper side of the main

carrier.

Position A can be reached by first removing the mains cord

fromit'sfixation, then loosenthecarrier lips and thenpullingthe

carrier panel for approximately 10 cm.

Position B can be reached from position A after disconnecting

the degaussing cable. A stable service position can be created

with the left hand side clip on the carrier panel and the cabinet

(see fig.4.1).

B

76532029_003

170697

5 Repair facilities

7Comet

5 Repair facilities

5.1 Functional blocks

On both the service printing on the copper and the component

side, functional blocks are indicated by lines and text.

5.1.1 Test points

The L6 chassis is equipped with test points in the service

printing on both sides of mono-board. These test points are

referring to the functional blocks as mentioned above:

• P1-P2-P3, etc:Test points for the power supply

• L1-L2-L3, etc:Test points for the line drive and line output

circuitry

• F1-F2-F3, etc:Test points for the frame drive and frame

output circuitry

• S1-S2-S3, etc:Test points for the synchronisation circuitry

• V1-V2-V3, etc:Test points for the video processing circuitry

• A1-A2-A3, etc:Test points for the audio processing circuitry

• C1-C2-C3, etc:Test points for the control circuitry

• T1-T2-T3, etc:Test points for the teletext processing

circuitry

The numbering is done in a for diagnostics logical sequence;

always start diagnosing within a functional block, in the

sequence of the relevant test points, for that functional block.

5.1.2 Service default-alignment mode (SDAM)

Service default-alignment menu: new option settings are

activated immediately.

1. Software version of the microprocessor used in that typical

set is displayed in the right top corner

2. A counter in the middle of the screen indicate the normal

operation hours of the set in a hexadecimal code (every

time the set is switched "on" the counter is incremented by

1 hour, so +1 at the counter).

3. The "S" in the middle of the screen next to the counter

indicate that the set is in the service default-alignment

mode

4. Option codeThis code indicates the Options setting of the

set.

5. Error code history;

The 5 last different error codes occurred are stored in the

EEPROM memory; last error code detected will be displayed

on the left side (see for an overview of all possible error codes

Fig. 8.x), so e.g.:

0 0 0 0 0 means no error codes present in the buffer

30000meansoneerrorcode present in the buffer; error code

3

3 2 0 0 0 means two error codes present in the buffer; last

detected error code is error code 3, previous detected error

code is error code 2

The service default-alignment mode is a pre-defined mode

which can be used for faultfinding (especially when the TV

gives no picture at all). All oscillograms and DC voltages in this

service manual are measured in the service default-alignment

mode.

Activatingtheservicedefault-alignmentmodecanbe done in 2

ways:

1. By short-circuiting the service pins S1 and S2 of the

microcomputer (pin 14 of IC7600).

2. From normal operation mode by pressing the button

"DEFAULT" or "ALIGN" on the DST (Dealer Service Tool)

RC7150.

Leaving the service default-alignment mode to normal

operation can only be done by the stand-by on the remote

control or by pressing diagnose 99 followed by the OK-button

on the DST (so not via mains switch "off"; after mains switch

"off" and then "on" again the set will start up in the service

default-alignment mode again to enable easy faultfinding).

Functions of the service default-alignment mode:

1. All analogue settings (volume, contrast, brightness and

saturation) are in the mid position.

2. Set is tuned to program number 1

3. Delta volume settings are not used (delta volume setting =

a delta on the volume setting)

4. OSD error message (present available error code) is

displayed continuously

5. The OSD-key will act as search and auto store on the

maximum program number.

6. Automatic switch off function (set switches "off" after 15

minutes no IDENT) will be switched off

7. Hotel mode will be disabled

8. All other functions remain normal controllable

The errorcodehistorybufferisclearedwhenthe Service Menu

is left by the stand-by command or by diagnose 99 command.

In case the Service Menu is left by the mains switch "off" the

error code history buffer will not be cleared.

Optioncode +Counter +"S" for

service menu active +

software version->

Error code history --> 23000

Option setting row --> - SYSTE

Option setting:

In the bottom line the options are given.

Control of the options is with the following keys on the remote

control:

• PROGRAM +/-: Select the option to be changed; Via the

"PROGRAM +/-" button the option to be changed can be

selected.Theselectedoptionis implemented immediately.

• CONTROL up/down: Changes the setting of the option.

• MENU +/-: Changes toasubmenu;via"MENU +/-" buttons

a submenu is selected in which in a stereo version the

sound/sync alignment can be done.

The options are stored immediately in the EEPROM.

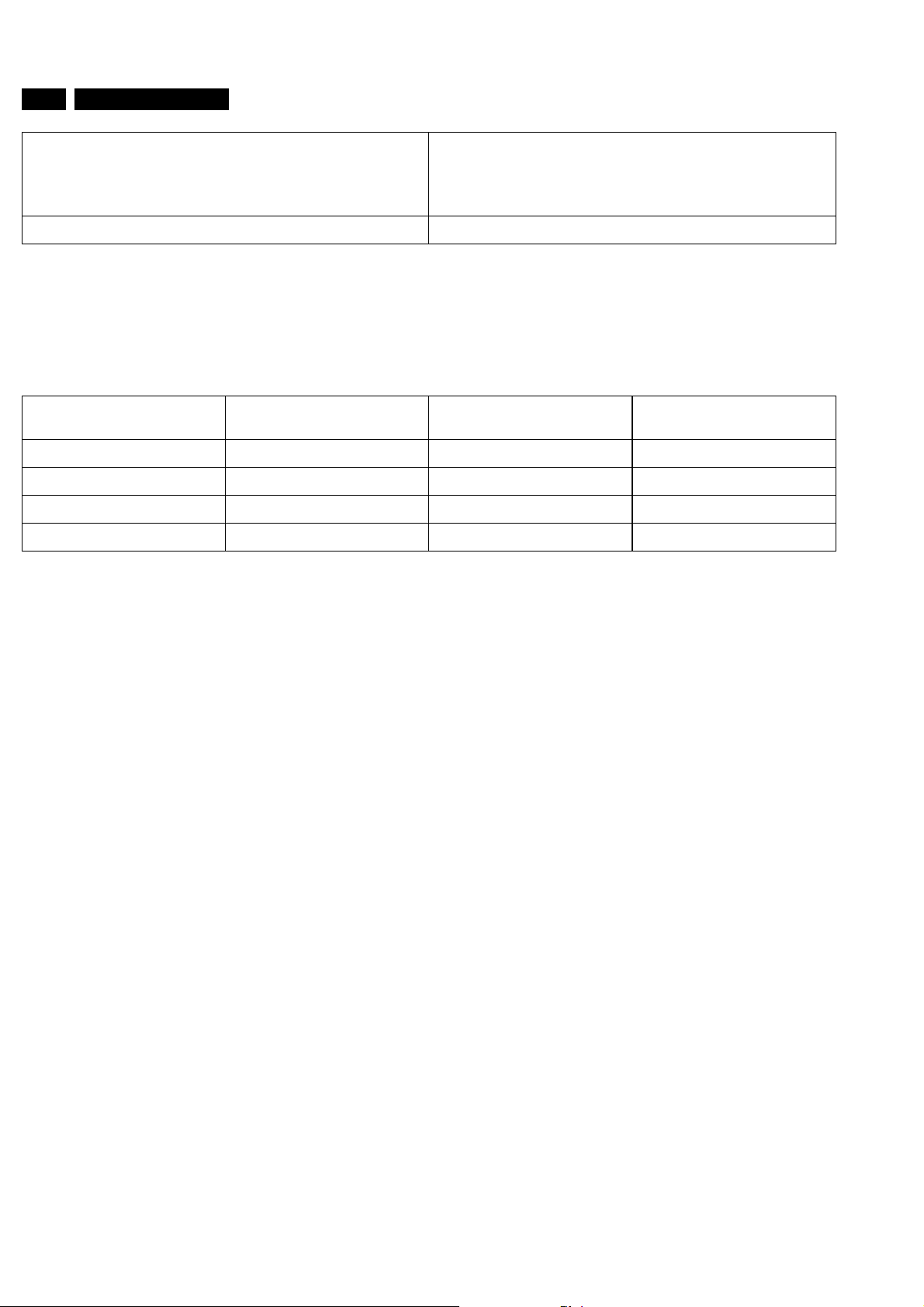

The following table indicates the possible hardware and

software options and their technical consequences:

001 0023S 1.0

M BG + I

+

Text displayed in the option row in the service menu The technical consequence for the selected option

SINGLE --> For a PAL BG only or PAL BG/SECAM BGDK set

8 Comet

SYSTEM I:UK --> For a PAL I only set

SYSTEM BG+LL' -->For a PAL BG/SECAM LL' set

SYSTEM BG+DK --> For a PAL BGI/SECAM LL' set

NATIONAL BRAND MAxxxxx --> Selects MENU-Layout National Brand styling

5 Repair facilities

5.1.3 Error messages

The microcomputer also detects errors in circuits connected to

the I2C (Inter IC) bus. These error messages are

communicated via OSD (On Screen Display) and a flashing

LED in the service default-alignment mode. (error code history

buffer):

"OSD error number"

(servicemenu)

0 No blinking LED No error -1 LED blinks ones mC error IC7600

2 LED blinks twice General I2C error I2C bus is blocked

3 LED blinks three times EEPROM error IC7605

"LED behaviour" Error description Possible defective component

1. In normal operation; in normal operation no errors are

indicated.

2. In the service default-alignment mode; in the service

default-alignmentmode both the"OSDerror message"and

the "LED error" indication will display the present detected

error continuously.

8 Electrical adjustments

8 Electrical adjustments

8.1 Adjustments on the 110 module panel

1. Horizontal amplitude: Is adjusted with potentiometer

R3924

2. Vertical centring: Is adjusted with potentiometer R3921

3. Picture height: Is adjusted with potentiometer R3903

4. East-west correction: Is adjusted by potentiometer R3913

5. Horizontal centring (main pcb):Is adjusted with

potentiometer R3129 on the main PCB

6. Focusing: Is adjusted with the focusing potentiometer in

the line output transformer

7. AFC

– Adjustment of the AFC and picture demodulator (all

versions).

– Select a non secam L/L' system in the SDAM mode

(negativemodulation).Switch the tuner toHIGHBAND

(pin 11 of tuner 1100 grounded). Connect a pattern

generator to pin17ofthetunerviaacapacitorof4.7nF

andputa82Wresistor from the output of the generator

toground.Connecta DC voltmeter to pin 44 ofIC7100.

Adjust coil 5100 to get 3V5 on pin 44 of IC7100.

– The signal of the generator has to be 38.9 MHz.

– Adjustment of the AFC and picture demodulator.

(BAND 1 L. France versions only).

– Same story as a) only the frequency of the generator

has to be 33.9Mhz with positive modulation.

23Comet

8. RF AGC

9. If the picture of a strong local transmitter is reproduced

distorted, adjust potentiometer R3130 until the picture is

undistorted.

or: Connectapatterngenerator(e.g.PM5518)to the aerial

input with RF signal amplitude = 1mV. Connect a

multimeter (DC) at pin 5 of the tuner. Adjust R3130 so that

voltage at pin 5 of the tuner is 8V5 +/- 0V5 DC.

8.2 Adjustments on the CRT panel

VG2 cut-off points of picture tube

Apply a black CVBS signal at the input pin 20 of scart. Adjust

thebrightnessin order to have 1.6V duringtheline at the R,G,B

outputs of the BIMOS pin 18,19,20 of IC7100. Put

potentiometers R3326, R3316 and R3306 to the minimum

value (maximum voltage on the CRT cathodes). Adjust now

VG2 till the colour that luminates first is not visible anymore.

Adjust now the other two potentiometers in such a way that

they just don't luminate.

Potentiometer R3308 should always be in the mid-position.

24 Comet

9 CIRCUIT DESCRIPTION

9 CIRCUIT DESCRIPTION

9.1 Description of the power supply:

9.1.1 General

Note: The voltages +96S and +96s are not mains isolated.

Thepower-supplyused in this chassis is aself-oscillatingdown

converter with an auxiliary winding to help the FET to switch.

9.1.2 Principle of the down-converter (Fig 8.1):

WhenswitchTS7504 is closed,thevoltage on L2-3 isVin-Vout.

During this time, energy is stored in the coil and energy is

delivered to the load. When switch TS7504 opens, the energy

stored in the coil will be stored in the output capacitor (C2515).

This is due to the fact that the current through the coil has to

decrease linear. When the switch is open the current is floating

through D6504, L2-3 and C2515. By controlling the duty-cycle

of the switch, the output voltage can be regulated.

9.1.3 Start-up (see diagram A1):

When the switch TS7504 is closed, the input voltage is placed

over winding 2-3 of transformer 5500, which acts as coil L2-3

in Fig 8.1. Via resistors R3513,R3518 and R3512 the switch is

turned on for the first time. Zener diode D6502 prevents that

the Ugs of the FET becomes higher than 15V. When the input

voltage is on winding 2-3, there is also a voltage on winding 1-

2. Via winding 1-2 the correct switching voltage is obtained.

The DC-part of this voltage is blocked by capacitor C2503.

DiodeD6510actsasa protection in start-up and in short-circuit

situations.Duringstart-up the outputcapacitorC2515 is empty.

It takes a relative long time to charge the gate to a voltage high

enough to switch on the FET. This is due to the fact the diode

D6510 is conducting. When this diode is conducting, the

currentthatwould normally flow into the gateofthefet to switch

on the FET, is now flowing into C2515. In this way a smooth

start-up is guaranteed.

9.1.4 General way of working (Fig 8.2):

The state of the power-supply can be divided into three areas:

– T-on;In this state the FET is conducting and energy is

stored in the coil and in the output capacitor.

– T-off;In this state the fet is non conducting and the energy

stored in the coil is fed to the output capacitor.

– T-dead;Fet is out of conduction and there is no energy in

the coil.

T-on; In the T-on state, switch TS7540 is switched on. When

the switch is on the voltage over resistors R3514-R3515 is a

direct measure for the current through winding 2-3. This is a

negative voltage. When this voltage becomes below a certain

level, TS7501 starts conducting and will switch off the fet. In

this way it is prevented that the coil can go into saturation. This

could be the case when the output voltage is very low. (long on

time of the FET). When the output-voltage becomes too high

during T-on the FET will be switched off. (see Output-voltage

regulation)

T-off; Due to the stored energy a current will start to flow

throughD6504,C2515 and winding 2-3. Duetothefact that the

current is flowing through this circuit, a voltage with reverse

polarity is on winding 1-2. In this way the fet remains off until

thecurrentthroughwinding2-3 reaches zero. Now a new cycle

will start. The fet will be switched on and all starts over again.

T-dead; If the output voltage is too high (for example in a low

load situation) the FET remains off till the output-voltage is not

to high anymore.

9.1.5 Output voltage regulation:

This is done by the circuit D6501, R3509, TS7502, R3505,

R3507, R3510. Transistor TS7502 can only conduct when the

voltage on the base is 0V7 lower than the voltage the voltage

on the emitter. This means that the voltage drop over resistors

R3505 and R3507 should be 5V6(zenerdiode) + 0V7(baseemitter). This is reached when the output voltage exceeds the

100V. Now transistor TS7502 starts conducting, which brings

transistor TS7501 in conduction. As a consequence the gate

voltage of the fet becomes very low and the fet stops

conducting. As long as the output voltage is too high the fet

stays out of conduction.

9.2 Protections:

9.2.1 Overvoltage protection:

A disadvantage of a down converter is that if the switch

becomes a short-circuit, the output voltage will increase to the

input voltage. This could damage circuits. In this power-supply

there is a protection to prevent this. If the output voltage

becomes higher than 130V, zenerdiode D6514 starts to

conduct.TheVin will be shortcircuited.This will blown themain

fuse 1501 and protect in this way all the other circuits.

9.2.2 Short-circuit and start-up protection:

The short-circuit protection works the same as the start-up

protection. If the output-voltage is very low in case of a start-up

orashort-circuit condition, The gate willbecharged very slowly

due to the fact that zenerdiode D6510 is conducting. So the

current is not only charging the gate but is also flowing into the

output capacitor. In this way it takes a few milliseconds to

switch on the fet. Diode D6510 takes also care that the fet

never remains in his power consuming (linear) area.

9.2.3 Undervoltage protection

Iftheoutputvoltage is very low, it also takes a largetimebefore

the current through winding 2-3 reaches zero. The power

supplied to the circuit is in this way very low and protects in this

way the circuit.

9.2.4 Other output voltages:

The output voltages +8S, +9S and +5S are made by winding 5-

6.Duringthetime that the fet TS7504 is notconducting,energy

is transformed to this winding (flyback principle) and the

voltages mentioned above are created. From the +9S, the +5S

voltage is derived. This voltage is stabilized by transistors

TS7505, TS7500 and zenerdiode D6500. D6500 is the

reference voltage and TS7505 is delivering the current. When

zenerdiode D6500 starts conducting, the voltage over resistor

R3502 becomes high and a POR signal is created.

9.3 Degaussing:

R3516 is a dual PTC (2 PTC's in one housing). After switching

"on" the set, the PTC is cold, so low ohmic. This makes the

degaussing current high. After degaussing the PTC is heated,

so high ohmic. This makes the degaussing current low. After

degaussing the PTC remains heated by the mains.

9.4 Line-circuit (Diagram A1):

The primary side of the line-circuit and the deflection coil are

connected to the hot earth. The driver-circuit contains an optocouplertocreate isolation between the low-signal partsandthe

9 CIRCUIT DESCRIPTION

25Comet

mains. The optocoupler is driven by pin 37 of IC7100-6E via

transistorTS7103.When TS7103 isnotconducting,(the LED of

the optocoupler is also out of conduction) TS7421 is also not

conducting. In this way TS7422 will conduct and the 96V is

placed over winding 2-1 of the LOT. A voltage over winding 21 of the LOT will cause a voltage over the windings 8-10, 6-10

and 9-10. Now energy will be transformed from the primary to

the secondary-side and charge capacitors C2424 and C2425.

C2430 will be charged to the difference of the +40D and +14D

(=26V) when TS7422 is conducting. When TS7422 stops

conducting, the voltage of pin 8 of the LOT will become very

negative. This forces C2430 to be charged to 26V plus the

absolute value of pin 8. When TS7422 starts conducting again

the voltage of pin 8 of the LOT will increase and so the voltage

on the anode of D6422. In this way the 160V is created. This

means that during the off-time of TS7422, C2430 is charged

andduringthe on-time of TS7422, theenergyinC2430 is given

to C2426. When transistor TS7103 conducts, the LED of the

opto-coupler will be activated. This causes the transistor of the

opto-coupler to conduct, which drives TS7421 in conduction.

ThisbringsTS7422outofconduction.Due to this construction,

this circuit is protected against missing line-drive pulses. When

a line-drive pulse is missed, the line-transistor stays out of

conduction, due to the fact that the diode of the opto-coupler is

forced into conduction by TS7103. In this way nothing can be

damaged when there is no line-drive.

Winding 4-3 is an extra winding to help TS7422 to switch.

On the secondary-side of the LOT there is a circuit consisting

of TS7423, R3422, R3433, R3434, C2431 and C2432. This

circuit creates a pulse when TS7422 switches off. This pulse

indicatesthathorizontal flyback takes place. Thisinformationis

fed to IC7100-6E to blank the picture.

9.5 Stand-by:

Thestandbysignal from the mC is lowincaseof stand-by. Now

TS7103 is brought into conduction by R3100. As mentioned

before this will switch off the line-output stage completely.

9.6 Deflection :

9.6.1 Horizontal deflection:

The voltage over capacitor C2422 is the same as the voltage

over C2515 (96V). When TS7422 is conducting this voltage is

placed over the horizontal deflection coil. This causes a linear

increasing current through this coil. In this way deflection is

created. When TS7422 switches of flyback takes place and it

starts all over again. L5424 is used for linearity correction.

9.6.2 Vertical deflection:

Vertical deflection is based on a balance amplifier. Or TS7401

or TS7402 is conducting. This depends on the signal V-drive. If

V-drive is high TS7401 conducts and the voltage of C2401 is

placedoverthe deflection coil. Now thepictureis written. When

V-drive is low, TS7402 conducts and the +40V supply voltage

minusthevoltage over C2401 is placed over thedeflectioncoil.

Flyback takes now place. In this way deflection is generated.

R3407 is used to adjust the vertical shift. With this resistor the

level of the signal VFB is adjusted. R3402 and C2404 are used

to damp oscillation of the deflection coil with his parasitic

capacitance. The signal NIL from the mC is used to create a

non-interlaced mode. This is done by creating a small DC

current through the deflection coil.

9.7 110 degrees deflection module

For the 25" and 28" sets a 110 degrees module is needed for

East/West correction. This panel is allocated on the right hand

side of the mainboard (seen from the rear). East/west

correction in this module is based on the diode-modulator

principle; the current through the horizontal deflection coil is

modulated. As this is done by a parabolic-shaped voltage, E/W

distortion is corrected. This parabolic-shaped voltage is

derived from a saw-tooth-shaped voltage of the frame

deflection.

9.7.1 Frame (time base frame)

Because the raster part is fed by the primary side a galvanic

isolator must be applied between IC 7100 (= so called Bimos

ic) in the secondary side and the raster amplifier on primary

side. This is realised by opto coupler (7422); this opto coupler

will be switched and it will block the saw-tooth of the Bimos ic.

So we don't use the saw-tooth of the Bimos((pin 42) or the

feedback frame input(pin 41). The only information from the

Bimosic(=IC7100) is the flyback command(pin43).The output

of this pin is a pulse of 6 to 0 Volts during 1 mS with a period of

20mS. This signal blocks transistor 7424 and this causes

conduction of the opto coupler diode (7422). The internal

transistor also conduct and pins 11 and 12 (connector 00820)

of the 110 module will be short circuited.

9.7.2 Raster part

A saw-tooth must be created because we don't use it from the

Bimos ic(see annex 5). Via 150V C2901 will be charged via

R3901, R3900 and D6900; the function of D6901 is to

determine the lower part of the potential level. After 20mS a

signalcomingfromthe Bimos ic will short-circuit pins 11and12

of connector 0082 and C2901 will be discharged. It is a must to

have an amplitude on the screen independent of the 50Hz or

60Hz frequency of the mains; see circuit diagram annex 6. The

emitter voltage of T7900 can be adjusted with potentiometer

3903; this is the top Voltage of the saw-tooth. This is the circuit

for adjusting the vertical amplitude independent of the 50/60Hz

frequency. The saw-tooth will control T7901 and this transistor

controls the amplifier (= T7902, T7903 and T7904).D6902,

D6903, T7905 and C2904 determines the flyback. This flyback

pulse is negative and is created by an inverted polarity of

C2904.During the deflection T7905 is blocked and C2904

charges; during the flyback T7905 conducts and the flyback

pulse will be made.

9.7.3 East-West modulator

The parabola is taken on C2907; R3916 and D6905

determines the shape of the parabola and they corrects the

upper and lower parts. The parabola is fed via C2908 to

potentiometer 3913; this for adjusting the pin-cushion

correction. Via T7904 this signal goes to MosFet 7908; the Vgs

command has two functions by changing the Voltage of Vgs by

potentiometer 3924: pin-cushion correction and horizontal

amplitude adjustment.

Special components:

• D6904 + R3916: temperature compensation of Vbe

(T7904)

• R3935: trapezium correction

• C2909: to avoid external radiation

• C2918: to avoid "twisted or broken" lines

26 Comet

9 CIRCUIT DESCRIPTION

9.7.4 Line timebase

The control voltage of pin 37 of the Bimos ic (=ic7100) is

derived via opto coupler pos 7420 to transistor T7421; then

send via C2428 and C2421 to pins 5 and6 of connector 0082;

this is the control of the base of T7906 (=BU1508AX). At the

flyback diode between collector and mass there are two parts

present to allow the East/west modulation. One part of this

modulator consists of D6906, T7908, C2910 and C2911. The

second part another diode is not visible in the circuit diagram

but it is present in the MosFet 7908.

On pins 1 and 2 of the module the primary side of the LOT is

connected. The LOT supplies the following voltages:

• 3-5 : 26 Volts after smoothing

• 10-8: 14 Volts

• 9 : 160 volts for video amplifiers.

9.8 BIMOS IC: PAL I Version

9.8.1 Introduction

The TDA 8361 is a single chip video and audio processor and

it incorporates a built in IF-detector, Luminance and

Chrominance separator, PAL/NTSC Chroma Decoder, RGB

processing, Horizontal and Vertical Oscillators, Sync

Separators and the FM Sound demodulation circuit.

9.8.2 Bimos Start Up

The Bimos device (Line Oscillator) starts up via pin 36,

however it will only start up when the voltage on this pin has

reached 5.6 Volts. At 5.6 Volts the output frequency will be

about 25kHz. The supply voltage at this pin (Pin 36) is

produced by the Switched Mode Power Supply and not by the

Line Out Put Stage. Once the supply voltage on Pin 10 has

(Line Output Stage) reached the 8-volt threshold the output

frequency will switch to 15.625 kHz. The voltage on this pin is

prevented from exeading 8 volts by zener diode 6106 (Page

10)

9.9 Vertical Synchronisation and Frame Amplifier

9.9.1 The Vertical Sync Separator

This functional block separates the Frame Synchronisation

pulses from the CVBS signal, once these pulses have been

separated the pulses are then used to synchronise the Frame

Oscillator.

9.9.2 Amplitude

The voltage on pin 42 of the BIMOS device determines the

amplitude of the frame sawtooth.

9.9.3 Frame Pre Amplifier

This internal amplifier increases the amplitude of the Frame

sawtooth, from here the frame sawtooth is available at pin 43.

9.9.4 BCI Input Pin

This Input is fed into the BIMOS device form the Tube Base

Board, It is used to provide frame correction for changes in the

EHT voltage. For example if the EHT decreases (more white)

the picture will get larger. This results in the BCI decreasing

and the picture size being automatically corrected by the

BIMOS.

9.9.5 The IF Demodulator

The IF bandpass characteristic is determined by SAW filter

1001. The IF signal is then fed from here into BIMOS pins 45

and 46. Pin 1 of the IC is used for the selection of positive or

negative video modulation. It is high for positive modulation

and low for negative.

9.9.6 AGC

Pin 47 is used for AGC (AGC is used to adjust the gain of the

Tuner so that over modulation is avoided).

9.8.3 Horizontal Sync Separator

Thisfunctionalblockseparatesthehorizontal sync pulses from

the CVBS and then locks the pulses to the free running

horizontal sawtooh generator. However both the vertical and

horizontal oscillators are also internally locked to the 4.43 MHz

Chroma reference Crystal item 1100.

• The Horizontal Oscillator Saw Tooth Generator The

sawtoothisconverted to a squarewaveformwith a variable

duty cycle. This square waveform is then fed to the Line O/

P stage via a Galvanic Isolator. The correct line time

constant is automatically determined, internally by the

BIMOS IC.

• Pin 38 This is pin has two purposes, these are.

1. The Sandcastle Pulse O/P

2. Horizontal Flyback Pulse Input

1. The Sandcastle Pulse has an output current of a few

micro amps; the amplitudes of the sandcastle pulse

components are: Burst 5V3; Line Blanking 3V and

Frame Blanking 2V.

2. TheHORFLYBACK input has a currentof100-300 uA.

The Horizontal flyback pulse input, allows the phase of

the flyback pulse to be compared internally with the

phase of the horizontal oscillator; if the phase is not

correct, the horizontal oscillators duty cycle will be

adjusted accordingly.

9.9.7 AGC Threshold Adjustment

Variable resistor R3130 which is connected to pin 49 adjusts

the AGC Threshold

9.9.8 Automatic Frequency Control/ Pin 44

The AFC control signal is available at pin 44 of the BIMOS

device. It is obtained from the internal IF reference signal.

C2100 is used to smooth the AFC voltage.

9.9.9 IDENT Signal/ Pin 4

The IDENT signal on pin 4 is "High" when horizontal sync is

detected in the video signal and low when no sync is detected.

The IDENT line is connected to the main Microprocessor.

(Pin15)

9.9.10 What does the IDENT line do ?

It is used for tuning control (for switching from fast to the slow

tuning mode) Pin 4 (BIMOS) is also used by the

microprocessor (Pin15) for "No Signal Standby" after 15

minutes. Used to provide a stable OSD - Time constant

switched by the BIMOS.

Loading...

Loading...