Philips 26PFL3403 Schematic

Colour TV Chassis

MG8

TCM1.0E

LA

MG8

I_17930_000.eps

240408

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 13

6. Block Diagrams, Test Point Overview, and

Waveforms

Wiring Diagram (not available yet) 19

Block Diagram MT8200 20

7. Circuit Diagrams and PWB Layouts Diagram PWB

Main Power Supply (19" & 20") (A)21 22

Main Power Supply (26") (A1)23 25

Standby Power Supply (26") (A2)24 26

SSB: Index /GPIO List /LDO (B01)27 38-39

SSB: MT8200 LQFP256 (B02)28 38-39

SSB: DDR Memory & Flash (B03)29 38-39

SSB: VGA Input (B04)30 38-39

SSB: LVDS /TTL Interface (B05)31 38-39

SSB: Tuner Block (B06)32 38-39

SSB: SCART Input Interface (B07)33 38-39

SSB: AV & S-Video & PC Audio Input (B08)34 38-39

SSB: Audio / Power / Headphone (B09)35 38-39

SSB: HDMI Input MT8293 (B10)36 38-39

SSB: DC DC / MCU for Stby/Protect (B11)37 38-39

Keyboard Control Panel (E)40 40

Inverter Panel (I)41 42

IR LED Panel (J)43 43

8. Alignments 45

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 46

Abbreviation List 48

IC Data Sheets 51

10. Spare Parts List & CTN Overview 55

11. Revision List 55

©

Copyright 2008 Koninklijke Philips Electronics N.V.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by JY 0871 BU TV Consumer Care Printed in the Netherlands Subject to modification EN 3122 785 17931

EN 2 TCM1.0E LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen size : 19" (48 cm), 4 : 3

: 20" (51 cm), 4 : 3

: 26" (66 cm), 16 : 9

Resolution (H × V pixels) : 640 × 480 (20")

Light output (cd/m

Contrast ratio : 800 : 1

Viewing angle (H × V degrees) : 170 × 160 (19")

Tuning system : PLL

Colour systems : PAL, SECAM

Video playback : PAL, SECAM, NTSC

Tuner bands : UHF, VHF, S & Hyper

Supported Computer Formats

60 Hz : 640 × 480

60 Hz : 800 × 600

60 Hz : 1024 × 768

60 Hz : 1280 × 1024 (19/26")

60 Hz : 1366 × 768 (26")

50 Hz, 75 Hz : 1440 × 900 (26")

Supported Video Formats

60 Hz : 480i

60 Hz : 480p

50 Hz : 576i

50 Hz : 576p

50 Hz, 60 Hz : 720p

50 Hz, 60 Hz : 1080i

2

) : 300 (20")

: 500 (26")

: 178 × 178 (20")

: 160 × 160 (26")

1.1.3 Miscellaneous

Power supply

- Mains voltage (V

- Mains frequency (Hz) : 50, 60

Power consumption (W) : 50 (19")

Stand-by (W) : < 0.3

Dimensions (W × H × D in mm) : 473 × 353 × 69 (19")

Weight (kg) : 4.9 (19")

) : 100 to 240

AC

: 45 (20")

: 80 (26")

: 470 × 406 × 71 (20")

: 671 × 458 × 90 (26")

: 5.8 (20")

: 7.7 (26")

1.1.2 Sound

Sound systems : Mono

Maximum power (W) : 2 × 3 (19")

:Stereo

:2 × 3 (20")

:2 × 5 (26")

Technical Specifications, Connections, and Chassis Overview

1.2 Connection Overview

Figure 1-1 Rear I/O connections

I_17930_001.eps

220408

EN 3TCM1.0E LA 1.

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

1.2.1 Rear Connections

1, Mini Jack: VGA Audio - In

Bk - Audio L/R 0.5 V

/ 10 kohm jq

RMS

2, HDMI: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-2 HDMI (type A) connector

1 -D2+ Data channel j

2 -Shield Gnd H

3 -D2- Data channel j

4 -D1+ Data channel j

5 -Shield Gnd H

6 -D1- Data channel j

7 -D0+ Data channel j

8 -Shield Gnd H

9 -D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

3, VGA PC: Video RGB - In and Service UART

1

5

6

11

10

15

E_06532_002.eps

171108

Figure 1-3 VGA Connector

1 -Video Red 0.7 V

2 -Video Green 0.7 V

3 -Video Blue 0.7 V

4-n.c.

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

5 -Ground Gnd H

6 -Ground Red Gnd H

7 -Ground Green Gnd H

8 -Ground Blue Gnd H

9 - +5V_dc +5 V j

10 - Ground Sync Gnd H

11 - n.c.

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

4, EXT 1: Video RGB/YC - In, CVBS - In/Out, Audio - In/Out

21

20

E_06532_001.eps

2

1

050404

Figure 1-4 SCART connector

1 - Audio R 0.5 V

2 - Audio R 0.5 V

3 - Audio L 0.5 V

/ 1 kohm k

RMS

/ 10 kohm j

RMS

/ 1 kohm k

RMS

4 - Ground Audio Gnd H

5 - Ground Blue Gnd H

6 - Audio L 0.5 V

7 - Video Blue/C-out 0.7 V

8 - Function Select 0 - 2 V: INT

/ 10 kohm j

RMS

/ 75 ohm jk

PP

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3 j

9 - Ground Green Gnd H

10 - Easylink P50 0 - 5 V / 4.7 kohm jk

11 - Video Green 0.7 V

12 - n.c.

/ 75 ohm j

PP

EN 4 TCM1.0E LA1.

13 - Ground Red Gnd H

14 - Ground P50 Gnd H

15 - Video Red/C 0.7 V

16 - Status/FBL 0 - 0.4 V: INT

17 - Ground Video Gnd H

18 - Ground FBL Gnd H

19 - Video CVBS 1 V

20 - Video CVBS/Y 1 V

21 - Shield Gnd H

5, EXT 2: Cinch: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

Bu -Video Pb 0.7 V

Rd - Video Pr 0.7 V

Ye -Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

6, EXT 3 Input: S-Video (Hosiden): Video Y/C - In

1 - Ground Y Gnd H

2 - Ground C Gnd H

3 - Video Y 1 V

4 - Video C 0.3 V

7, Aerial - In

- - IEC-type (EU) Coax, 75 ohm D

/ 75 ohm j

PP

1 - 3 V: EXT / 75 ohm j

/ 75 ohm k

PP

/ 75 ohm j

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

/ 75 ohm j

PP

P / 75 ohm j

PP

Technical Specifications, Connections, and Chassis Overview

8, Mini Jack: Audio Head phone - Out

Bk - Head phone 32 - 600 ohm / 10 mW ot

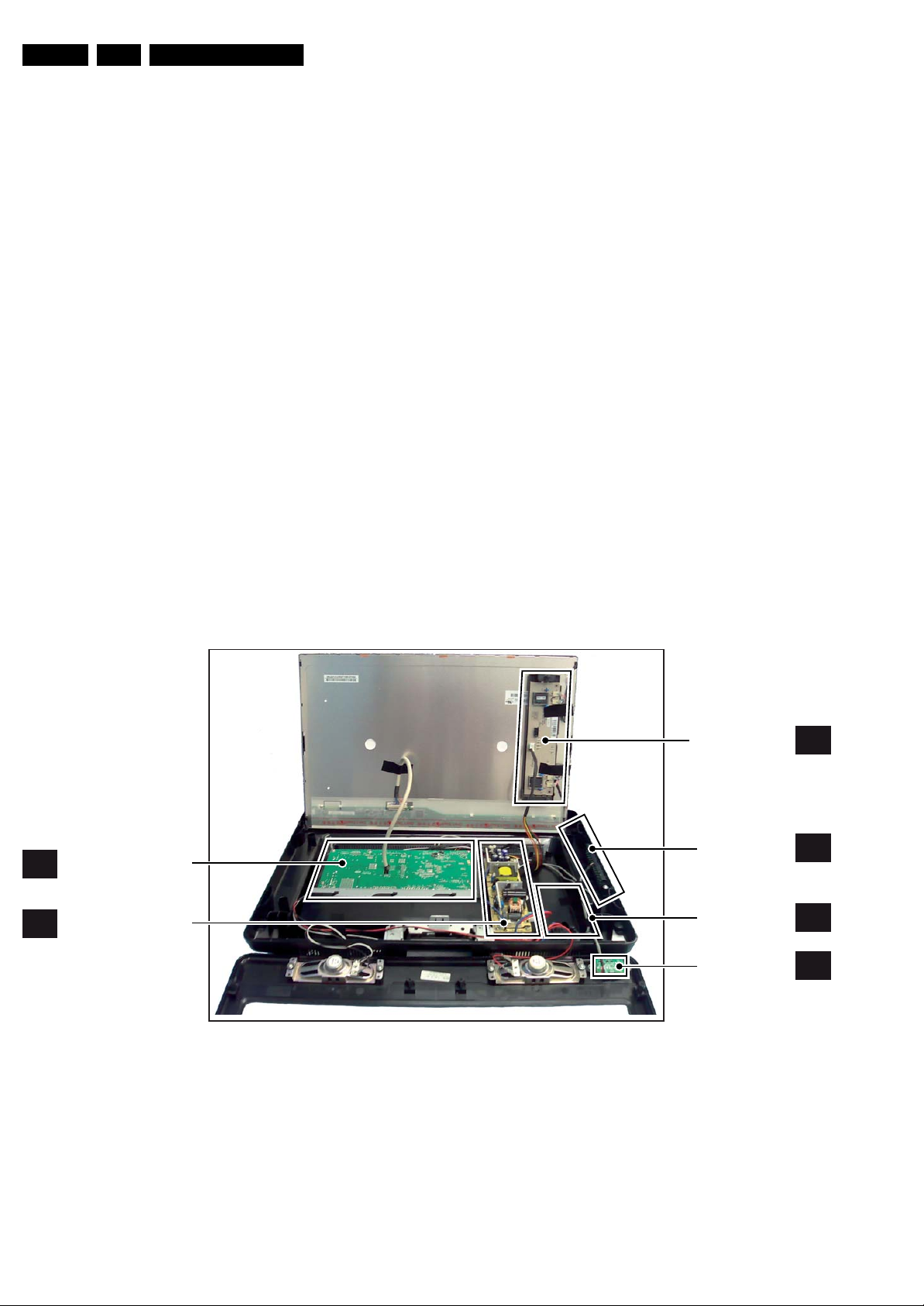

1.3 Chassis Overview

SMALL SIGNAL BOARD

B

MAIN POWER SUPPLY

A1

INVERTER PANEL

KEYBOARD

CONTROL PANEL

STANDBY POWER

SUPPLY UNIT

(OPTIONAL)

IR LED PANEL

I

E

A2

J

Figure 1-5 PWB/CBA locations

I_17930_068.eps

250408

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5TCM1.0E LA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates

220 ohm).

• All capacitor values are given in micro-farads (μ=× 10

nano-farads (n =× 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After log-in, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

-9

), or pico-farads (p =× 10

-12

-6

),

).

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

EN 6 TCM1.0E LA3.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

Directions for Use

MODEL :

PROD.NO:

2.3.6 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

• Always respect voltages. While some may not be

32PF9968/10

AG 1A0617 000001

Figure 2-1 Serial number (example)

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

MADE IN BELGIUM

220-240V 50/60Hz

VHF+S+H+UHF

S

~

BJ3.0E LA

E_06532_024.eps

128W

260308

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

4. Mechanical Instructions

Mechanical Instructions

EN 7TCM1.0E LA 4.

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassemble instructions in described order.

They apply mostly to the 26" model unless otherwise

specified, but the described method is comparable for the

other screen sizes.

Figure 4-1 Cable dressing (20" model)

I_17930_064.eps

240408

EN 8 TCM1.0E LA4.

Mechanical Instructions

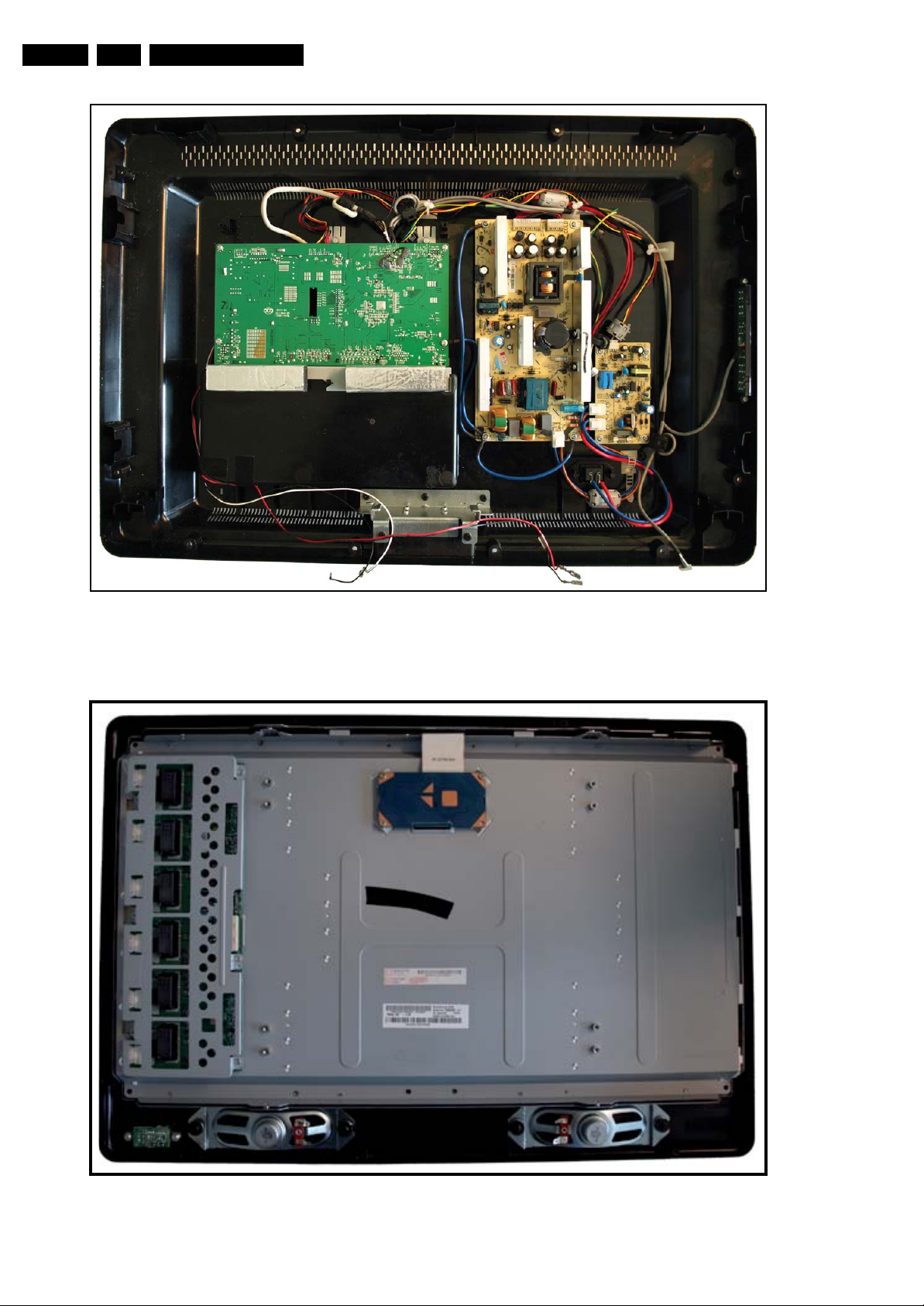

Figure 4-2 Cable dressing (26" model) [1/2]

I_17930_046.eps

240408

Figure 4-3 Cable dressing (26" model) [2/2]

I_17930_044.eps

240408

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging.

• Foam bars (created for Service).

Mechanical Instructions

EN 9TCM1.0E LA 4.

4.2.1 Foam Bars

Required for sets

1

42"

Figure 4-4 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

bars” for details. Sets with a display of 42” and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display.

Caution: Failure to follow these guidelines can seriously

damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

1

E_06532_018.eps

171106

1

1

Figure 4-5 Stand

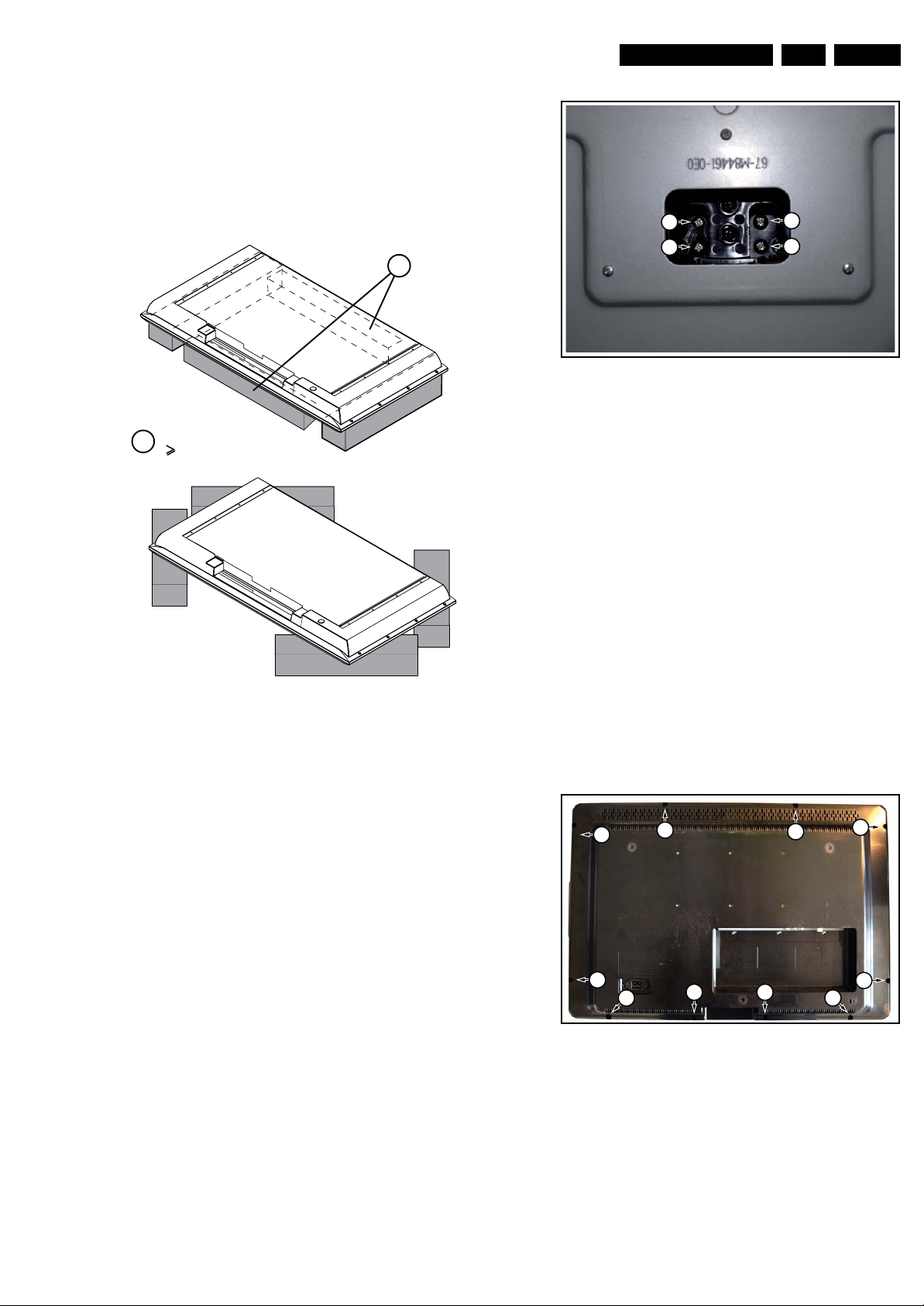

4.3.2 Rear Cover

Warning: Disconnect the mains power cord before you remove

the rear cover.

1. Refer to next figures.

2. Place the TV set upside down on a table top, using the

foam bars (see section “Service Positions”).

3. Remove the screws [1] that secure the rear cover. The

screws are located at the sides.

Be careful: Now the rear cover could be lifted but the SSB

and power supply panel(s) are mounted in the rear cover

and still connected to the LCD panel and other boards.

Those cables should be released first.

4. To release the LVDS cable lift the back cover a few

centimetres and move it downwards the set. Now unplug

the LVDS connector [2].

Caution: be careful, as this is a very fragile connector!

5. Remove the screw [3].

6. Now the rear cover can be lifted to gain access to the

speaker cables and the IR/LED panel cable. Release the

connectors [4].

1

1

1

1

1

I_17930_040.eps

240408

1

4.3 Assy/Panel Removal

4.3.1 Stand

1. Refer to next figure.

2. Place the TV set upside down on a table top, using the

foam bars (see section “Service Position”).

3. Remove the screws that secure the stand and remove the

stand.

1

1 1

Figure 4-6 Rear cover

11

1

I_17930_039.eps

240408

EN 10 TCM1.0E LA4.

Mechanical Instructions

4.3.3 Keyboard Control Board

1. Refer to next figure.

2. Unscrew two screws[1]

3. Unplug connector [2] and remove the board.

When defective, replace the whole unit

1

3

2

2

I_17930_041.eps

240408

Figure 4-7 LVDS release

4

4

4

I_17930_042.eps

Figure 4-8 Speaker and IR/LED panel cable release

240408

1

Figure 4-9 Keyboard control board

4.3.4 IR/LED Board and Speakers

1. Refer to next figure.

2. Remove the screws [1] and remove the IR/LED board.

3. Remove the screws [2] and remove the speakers.

When defective, replace the whole unit.

22 22

1 1

I_17930_063.eps

240408

Figure 4-10 IR/LED Board and Speakers

I_17930_043.eps

240408

Mechanical Instructions

EN 11TCM1.0E LA 4.

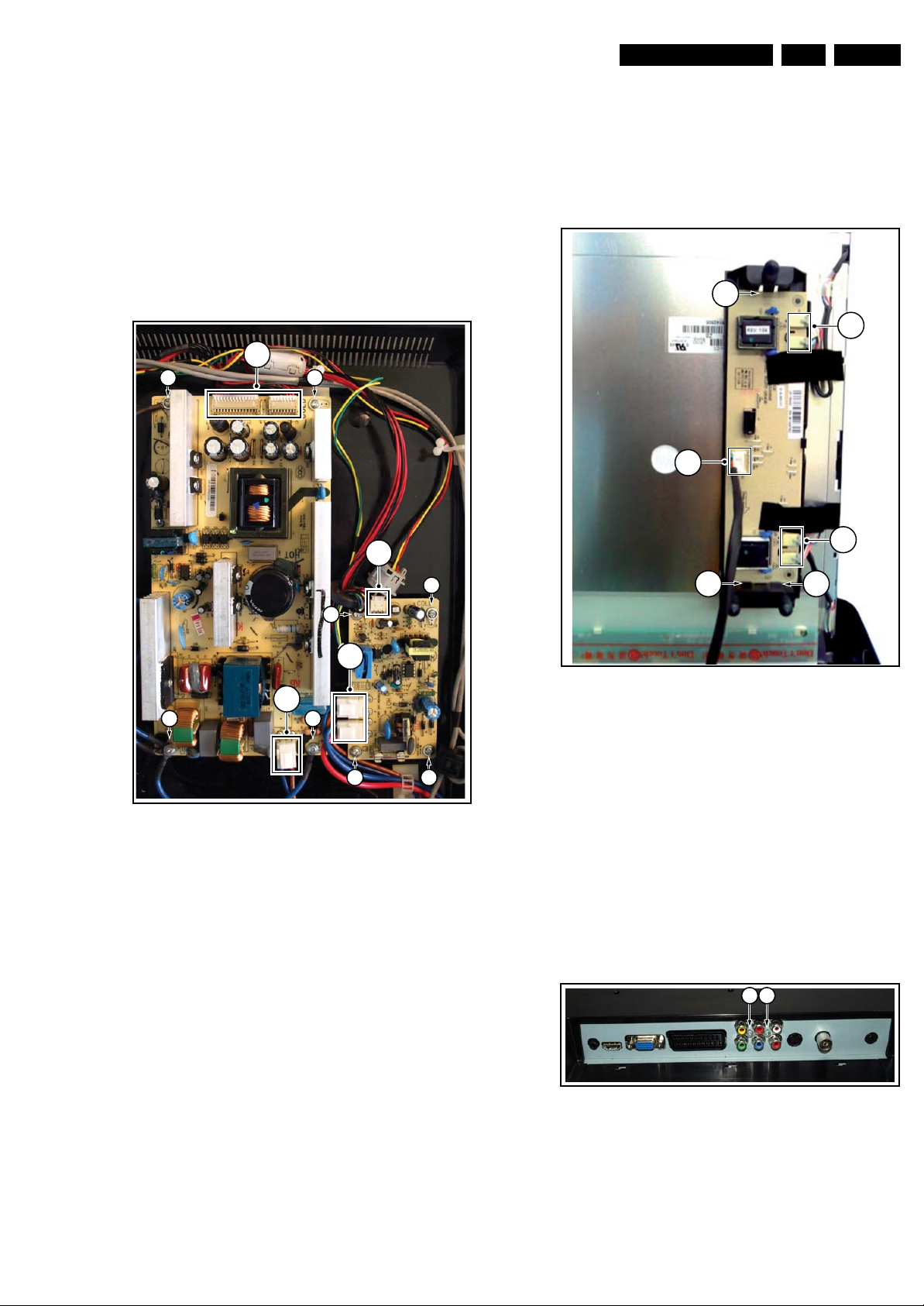

4.3.5 Power Supply Board

Due to different set executions this chassis is supplied with one

or two power supply boards and figures may differ.

Caution: it is absolutely mandatory to remount all different

screws and cables at their original position during re-assembly.

Failure to do so may result in damaging the power supply.

1. Refer to next figure.

2. Unplug all the connectors [1].

3. Remove the fixation screws [2]

4. Remove the main power supply board.

5. Unplug all the connectors [3].

6. Remove the fixation screws [4]

7. Remove the stand-by power supply board.

1

22

4.3.6 Inverter Board (19", 20" and 22" versions)

Due to different set executions this chassis some versions are

supplied with an inverter board. Figures may differ.

1. Refer to next figure.

2. Unplug all connectors [1].

3. Release the clips [2]

4. Take out the inverter board.

2

1

1

1

3

4

3

1

22

4 4

Figure 4-11 Power Supply Unit(s)

4

I_17930_045.eps

240408

2

Figure 4-12 Inverter Board

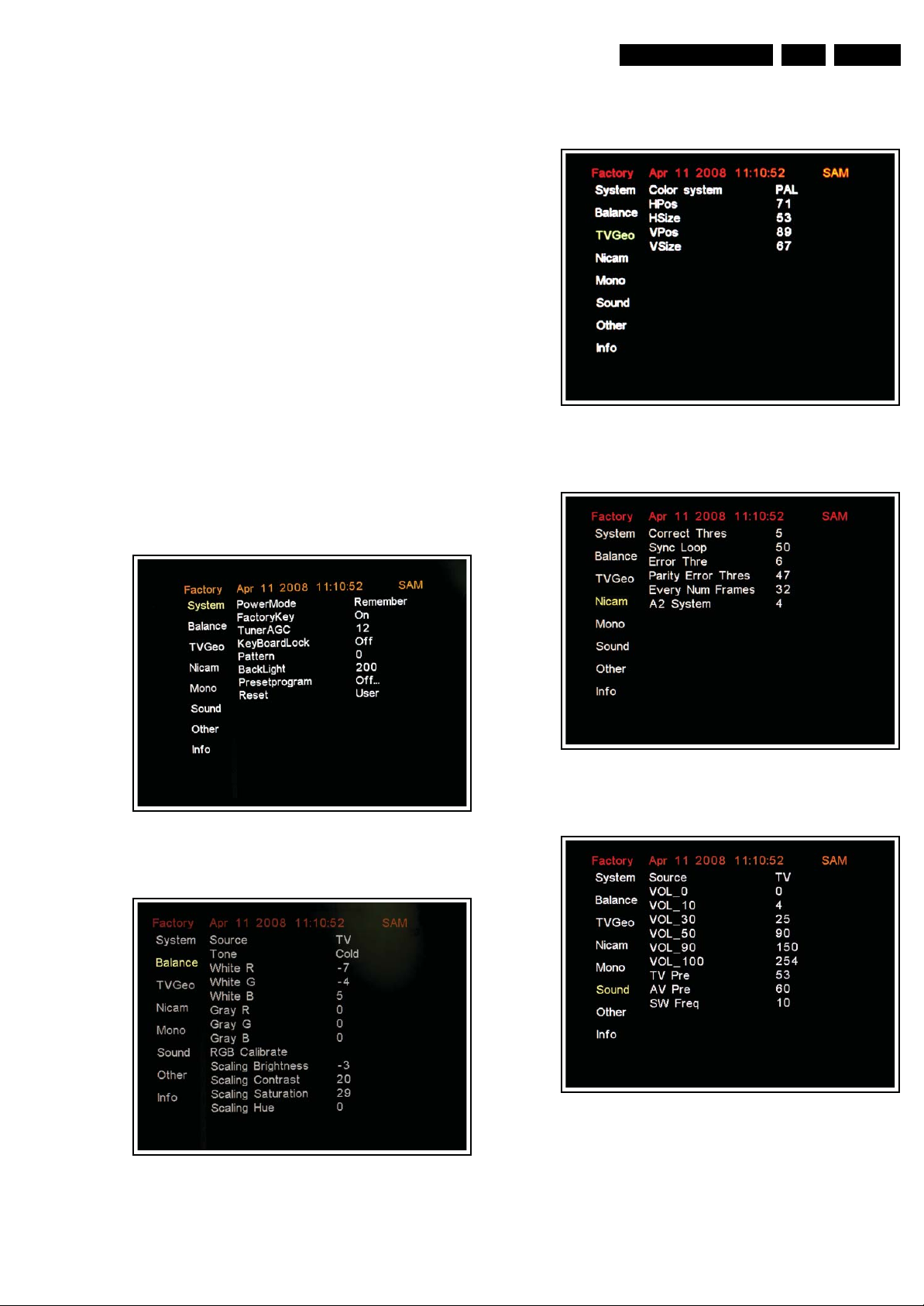

4.3.7 Small Signal Board (SSB)

Caution: it is absolutely mandatory to remount all different

screws at their original position during re-assembly. Failure to

do so may result in damaging the SSB.

Removing the SSB

1. See next figures.

2. Remove the screws [1] from the SSB connector plate.

3. Remove the screws [2] from the SSB.

4. Gently lift the board from the rear cover.

5. Now unplug the LVDS connector [3].

Caution: be careful, as this is a very fragile connector!

Unplug the rest of the cables [4].

1 1

2

I_17930_065.eps

240408

Figure 4-13 SSB connector plate

I_17930_047.eps

240408

EN 12 TCM1.0E LA4.

s

8

Mechanical Instructions

2

4

4

3

2

Figure 4-14 SSB

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure “Cable

dressing”.

• Pay special attention not to damage the EMC foams at the

SB shields. Make sure, that EMC foams are put correctly

on their places.

4

I_17930_048.ep

2

2

24040

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Mode

5.3 Error Codes

5.5 Software Upgrading

5.1 Test Points

This chassis is NOT equipped with test points in the service

printing. These test points are NOT specifically mentioned in

the service manual.

5.2 Service Mode

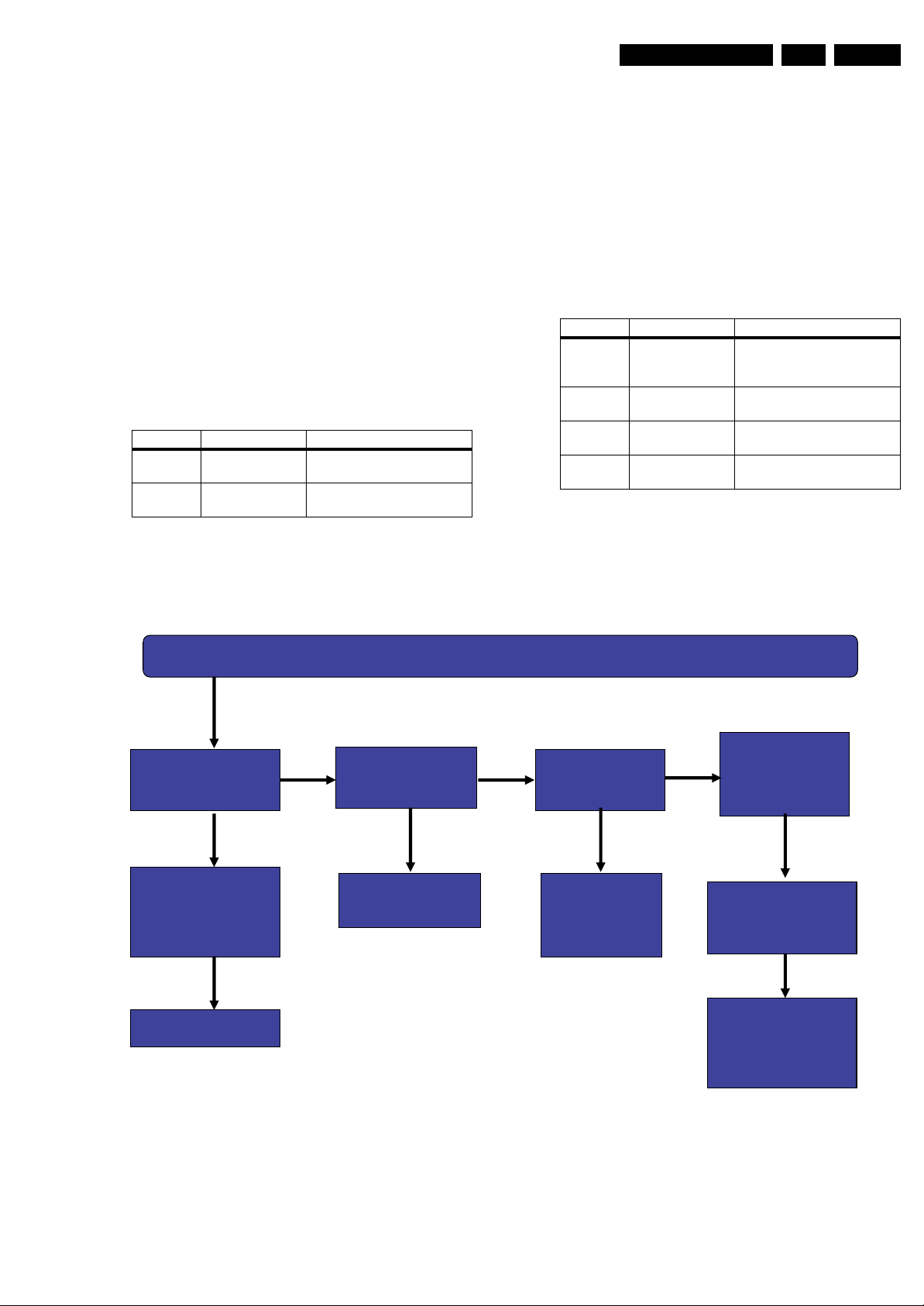

5.2.1 Factory Mode or Service Alignment Mode (SAM)

EN 13TCM1.0E LA 5.

How to Enter

To enter the Factory mode, use the following method:

• Press on the remote control the code “062596” directly

followed by the “INFO” key.

After entering the Factory mode, the following screen is visible,

the values can be adjusted according to the requested (see

Chapter 8).

I_17930_055.eps

240408

Figure 5-1 Factory mode menu, System

Figure 5-3 Factory mode menu, TV Geometry

Figure 5-4 Factory mode menu, Nicam

I_17930_057.eps

240408

I_17930_058.eps

240408

Figure 5-2 Factory mode menu, Balance

I_17930_056.eps

240408

Figure 5-5 Factory mode menu, Mono

I_17930_059.eps

240408

EN 14 TCM1.0E LA5.

Service Modes, Error Codes, and Fault Finding

5.2.2 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Help desk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer. The

CSM is a read only mode; therefore, modifications in this mode

are not possible.

How to Activate CSM

Key in the code “123654” via the standard RC transmitter.

Figure 5-6 Factory mode menu, Sound

Figure 5-7 Factory mode menu, Other

I_17930_060.eps

240408

I_17930_061.eps

240408

Contents of CSM

Figure 5-9 CSM Menu

I_17930_062.eps

240408

I_17930_061.eps

240408

Figure 5-8 Factory mode menu, Info

How to EXIT

Choose “EXIT”, then press the “MENU” button on the remote

control.

Service Modes, Error Codes, and Fault Finding

EN 15TCM1.0E LA 5.

Menu Explanation

1. Set Type Type number and region.

2. Production code Product serial no.

3. SW naming main-processor Software cluster and version

is displayed.

4. Standby MCU SW Software version stand-by μProcessor.

5. Code Error buffer contents.

6. NVM NVM version.

7. Signal Quality Yes/No (antenna signal).

8. System TV system (PAL)

9. Sound Audio system (Mono/Stereo/Nicam stereo)

5.3 Error Codes

The error code buffer contains all errors detected since the last

time the buffer was erased. The buffer is written from left to

right. When an error occurs that is not yet in the error code

buffer, it is displayed at the left side and all other errors shift one

position to the right.

Basically there are six kind of errors:

Error code Area Description

2 MT8293 Communication error with

MT8293

3 μP Control Communication error with

standby MCU

10. Key (HDCP) HDMI Shows Valid or invalid when HDMI

connected. Else blank.

11. HDMI input format Shows HDMI picture format display,

i.e. 480p30, when HDMI connected. Else blank.

12. HDMI audio Stream Show Yes/No when HDMI connected.

Else blank.

How to exit

Press “MENU” on the RC-transmitter.

Error code Area Description

4 IIC bus Error Communication error on I2C

6 System EEPROM

(NVM)

7 Tuner Communication error with

8 Demodulator Communication error with

bus (none of the I

respond)

Communication error with

system EEPROM

tuner.

demodulator.

2

C devices

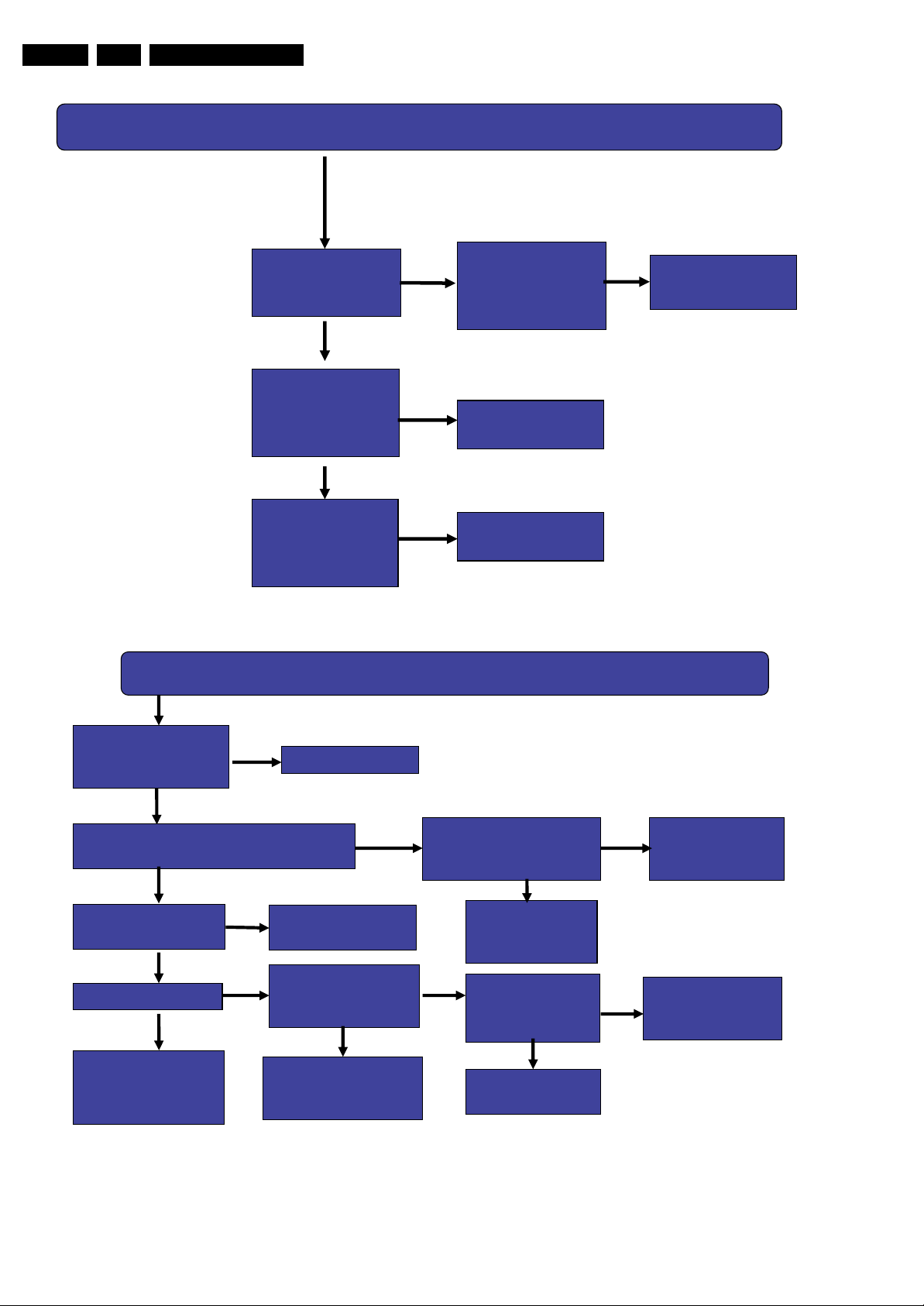

5.4 Fault Finding

No Picture, no sound, no Black light, Fuse Broken

Pin2~3 is 5v&Pin

8~11 is 12V of

P502 OK?

Check Pin7~8 of

P503 & pin8~9 of

J8

Check PSU

NO

Y

pin4~5 is 5V &

pin7~8 is12V of

SEYSE

Is U1-U5, U11

OK?

YES

U505 OK?

ONON

Check Pin 4 Of

UM01 is 3.3v

Replace Bad

NO

one of

u1~u5,u11

Check

LQPF jointing of

U6

YES

Check Y1,C23,C69

& IIC Bus &Reset

YES

Check jointing of

U8,u7,R213~R218,

R42,R44.

Figure 5-10 No Picture, no sound, noBlack light, Fuse Broken

I_17930_076.eps

250408

EN 16 TCM1.0E LA5.

Service Modes, Error Codes, and Fault Finding

No Picture, Black light & Sound OK

Check output

volt of u20 is

OK?

No

Cap of p504 is

better & C of

Q12 is low volt.

Yes

Check

waveform of

L201~L212 is

OK?

Yes

check the

cable to panel

No

Is

Pin207,216,225

of u6 shorted to

No

check pin

208~239 of u6

earth?

Figure 5-11 No Picture, Black light & Sound OK

Picture OK, No sound

Check

Yes

Replace U20

I_17930_077.eps

250408

Check 12v

Pin 3,13 of u001

OK?

Yes

Check stby

Pin 7 & Mute Pin6 of U001 OK?

Yes

Check audio DAC

R & L of u002 OK?

No

TV source

Yes

Check IF circuit

or Replace

U601

No

Yes

No

Check u505

NO

Check

R & L speaker

Check audio

ADC

R & L of u003 OK?

Yes

check pin31,32,35

of u6 or Replace

u002

Figure 5-12 Picture OK, No sound

Check C of Q002 is

5V,B of Q002 is Low

OK?

Yes

Check

Pin 7 of U001 is

6V

No

Check audio

Switch R&L of

U16 OK?

No

check u16

or Replace u16

No

Yes

Change the

component

pin31,32,33 of u6

or replace u003

damage

Check

I_17930_078.eps

250408

Service Modes, Error Codes, and Fault Finding

No colour

EN 17TCM1.0E LA 5.

Colour

system is

Yes

Dose the TV

signal too

Right?

No

Reset

To

Local system

5.5 Software Upgrading

5.5.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products. and offers the following:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short and effective way.

2. ComPair allows very detailed diagnostics and is therefore

capable of accurately indicating problem areas. You do not

have to know anything about I

yourself, because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the uP

is working) and all repair information is directly available.

4. ComPair features TV software upgrade possibilities.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The (new) ComPair II interface box is connected to the PC via

an USB cable. For the TV chassis, the ComPair interface box

and the TV communicate via a bi-directional cable via the

service connector(s).

How to Connect

This is described in the ComPair chassis fault finding database.

Tuner Input

cable & antenna

2

C or UART commands

weak?

YES

Check

NO

Figure 5-13 No colour

Check

Pin 17 of

U601 OK?

NO

Check

U601

YES

Check

U6

I_17930_079.eps

250408

TO TV

TO

UART SERVICE

I2C SERVICE

CONNECTOR

CONNECTOR

2

C

I

PC

ComPair II Developed by Philips Brugge

Optional power

5V DC

TO

RS232 /UART

E_06532_036.eps

150208

TO

UART SERVICE

CONNECTOR

ComPair II

RC in

Optional

Switch

Power ModeLink/

Activity

HDMI

I

2

C only

RC out

Multi

function

Figure 5-14 ComPair II interface connection

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• For SW see Philips service website.

• ComPair/UART interconnection cable: 3122 785 90630.

• ComPair/UART adapter cable: 3122 785 91070.

Note: If you encounter any problems, contact your local

support desk.

5.5.2 LVDS Tool

Support of the LVDS Tool has been discontinued.

Loading...

Loading...