Philips 19PFL3403-10 Schematic

Colour Television Chassis

TPS1.2E

LA

I_17620_000.eps

260308

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 4

3. Directions for Use 5

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 11

6. Block Diagrams, Test Point Overview, and

Waveforms

Wiring Diagram19PFL3403 15

Block Diagram Scaler Board 19PFL3403 16

7. Circuit Diagrams and PWB Layouts Diagram PWB

19PFL3403 Power Board Adapter (PB01) 17 19

19PFL3403 Power Board Inverter (PB02) 18 19

Scaler Board: Video Input (SB01) 20 30-31

Scaler Board: SCART & YPbPr (SB02) 21 30-31

Scaler Board: VGA (SB03) 22 30-31

Scaler Board: HDMI Input (SB04) 23 30-31

Scaler Board: Panel I/F (SB05) 24 30-31

Scaler Board: MST9x980

Scaler Board: DDR & SDRAM (SB07) 26 30-31

Scaler Board: Audio Amplifier (SB08) 27 30-31

Scaler Board: Power (SB09) 28 30-31

Scaler Board: Sub MCU (SB10) 29 30-31

Keyboard & Control Panel (KB01) 32 33

IR & LED Panel (IB01) 34 35

8. Alignments 37

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 39

Abbreviation List 40

IC Data Sheets 42

10. Spare Parts List 49

11. Revision List 56

(SB06) 25 30-31

©

Copyright 2008 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by CS 0864 BG CD Consumer Care Printed in the Netherlands Subject to modification EN 3122 785 17600

EN 2 TPS1.2E LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen Size : 19"

Display area (mm) : 408.2 (H) x 255.2 (V)

Number of Pixel : 1440 (H) x 900 (V)

Pitch (mm) : 0.2835x 0.2835

Colour pixel arrangement : RGB vertical stripe

Display operating mode : TN Mode, Normally

White

Colour depth : 16.7M colours (RGB

6-bits + HiFRC)

Brightness (cd/m^2) : 300 cd/m2 (typ)

Viewing angle : R/L 170, U/D 160 (typ)

Surface treatment : Hard coating (3H), AG

(Haze 25%)

Electrical interface : Dual Channel LVDS

Response time (ms, typ) : 5ms (typ)

Contrast ratio : Typical 1000:1

Backlight : 4 EEFL

Support Video Formats : 720 x 400@ 70Hz

: 640 x 480@ 60Hz

: 640 x 480@ 67Hz

: 800 x 600@ 60Hz

: 1024 x 768@ 60Hz

: 1280 x 960@ 60Hz

: 1440 x 900@ 60Hz

1.1.2 Sound

Sound systems : Virtual Surround

Maximum power (W) : 3Wx2

1.1.3 Miscellaneous

Power supply:

Power consumption : 47 W

AC line voltage range : 90~264 V

AC line frequency range : 50 - 60 Hz

Inrush current : < 40 A at 240 Vac

when cold start

Leakage current : < 0.5 mA at 240 Vac

Horizontal scan:

Horizontal : 30~81 kHz

Vertical : 56~76 Hz

1.2 Connection Overview

1.2.1 Rear Connections

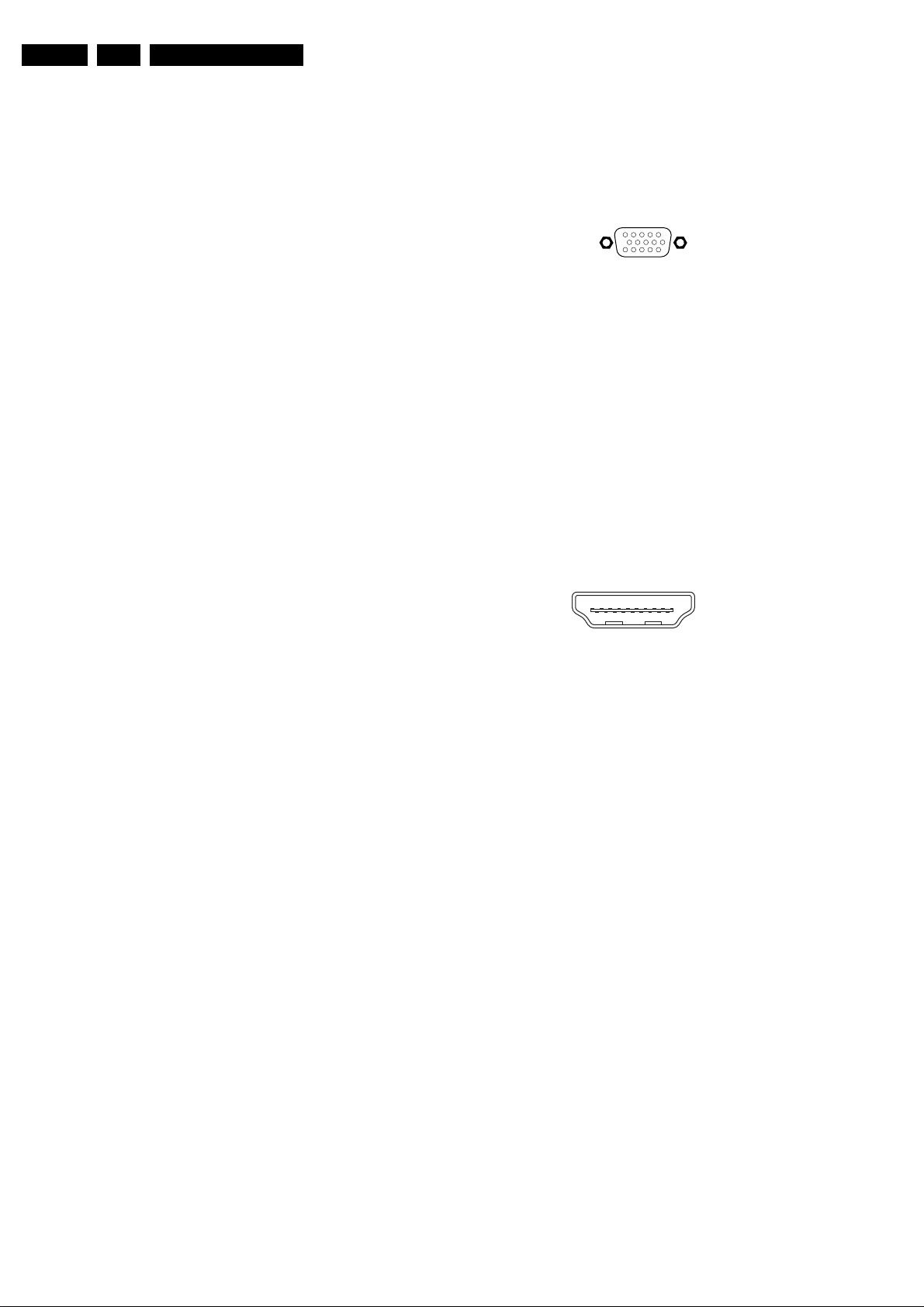

VGA: Video RGB - In

1

5

10

6

15

11

E_06532_002.eps

050404

Figure 1-1 VGA Connector

1 - Video Red 0.7 V

2 - Video Green 0.7 V

3 - Video Blue 0.7 V

4-n.c.

5 - Ground Gnd H

6 - Ground Red Gnd H

7 - Ground Green Gnd H

8 - Ground Blue Gnd H

9-+5V

+5 V j

DC

10 - Ground Sync Gnd H

11 - n.c.

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

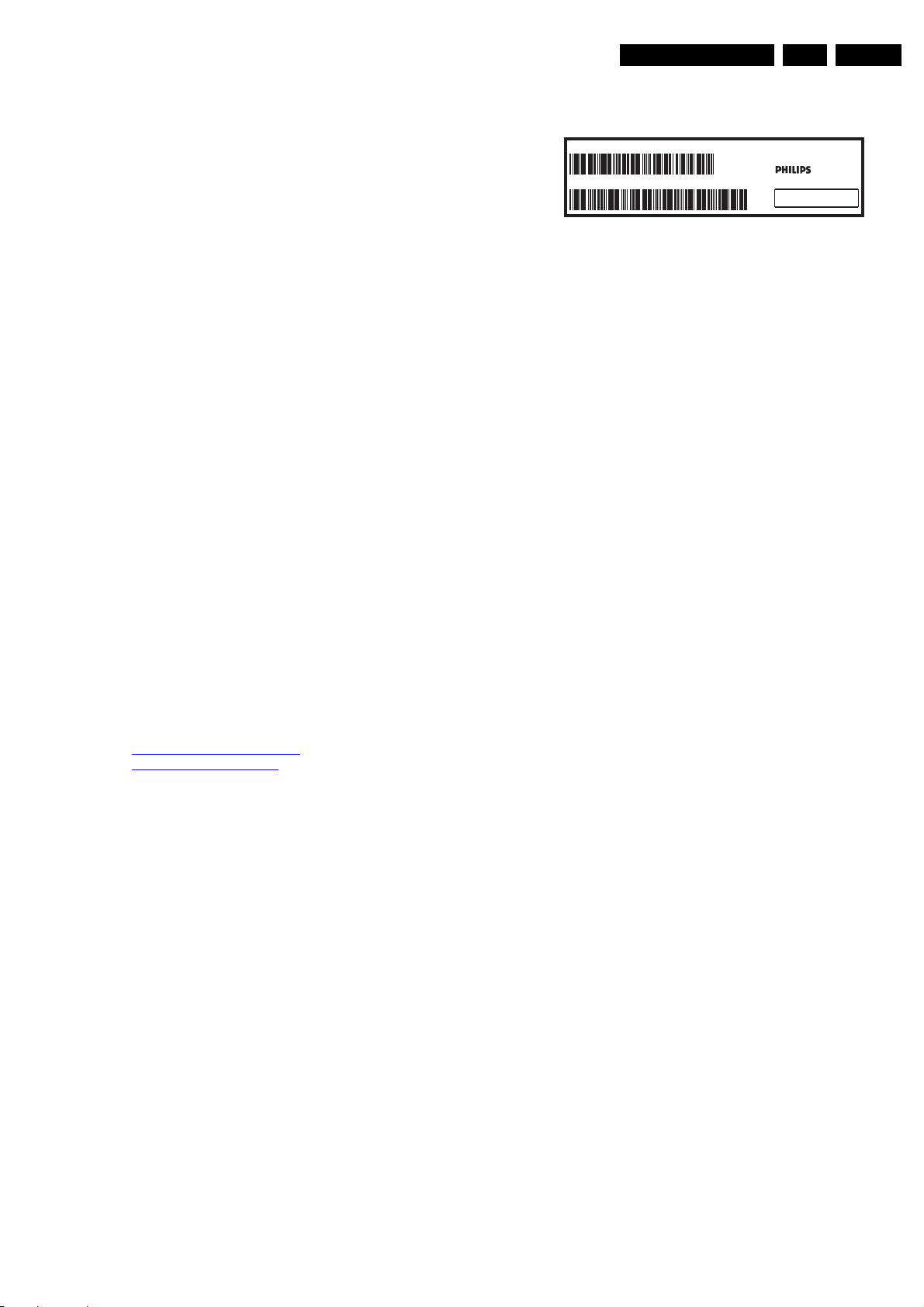

HDMI: Digital Video, Digital Audio - In

19

18 2

Figure 1-2 HDMI (type A) connector

1 - D2+ Data channel j

2 - Shield Gnd H

3 - D2- Data channel j

4 - D1+ Data channel j

5 - Shield Gnd H

6 - D1- Data channel j

7 - D0+ Data channel j

8 - Shield Gnd H

9 - D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - CEC

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

1

E_06532_017.eps

250505

Box (WxDxH, mm) : 512 x 136 x 458

Product (with stand) (HxWxD, mm) : 392.3 x 467.3 x 69.3

Technical Specifications, Connections, and Chassis Overview

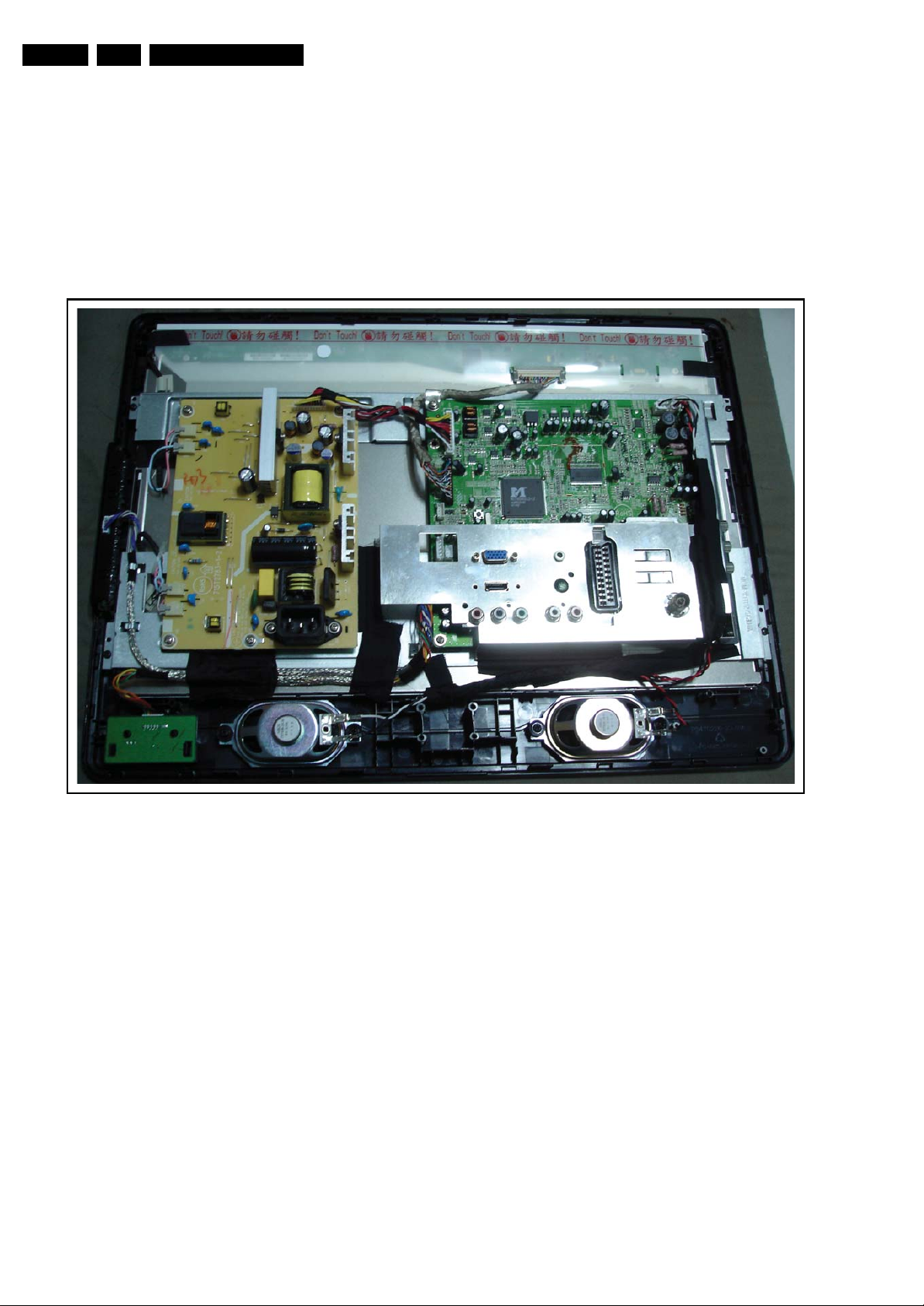

1.3 Chassis Overview

EN 3TPS1.2E LA 1.

Figure 1-3 Chassis Overview (19PFL3403)

I_17600_021.eps

010408

EN 4 TPS1.2E LA2.

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

-9

), or pico-farads (p= x10

-12

-6

),

).

Directions for Use

EN 5TPS1.2E LA 3.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

MODEL :

PROD.NO:

32PF9968/10

AG 1A0617 000001

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

S

128W

BJ3.0E LA

E_06532_024.eps

260308

Figure 2-1 Serial number (example)

2.3.6 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

EN 6 TPS1.2E LA4.

Mechanical Instructions

4. Mechanical Instructions

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

4.1 Cable Dressing

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassembly instructions in the described order.

Figure 4-1 Cable dressing (19PFL3403)

I_17600_003.eps

010408

Mechanical Instructions

EN 7TPS1.2E LA 4.

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging (see figure "Rear cover").

• Foam bars (created for Service).

4.2.1 Foam Bars

1

Required for sets

1

42"

E_06532_018.eps

171106

Figure 4-2 Foam bars

4.3 Assy/Panel Removal

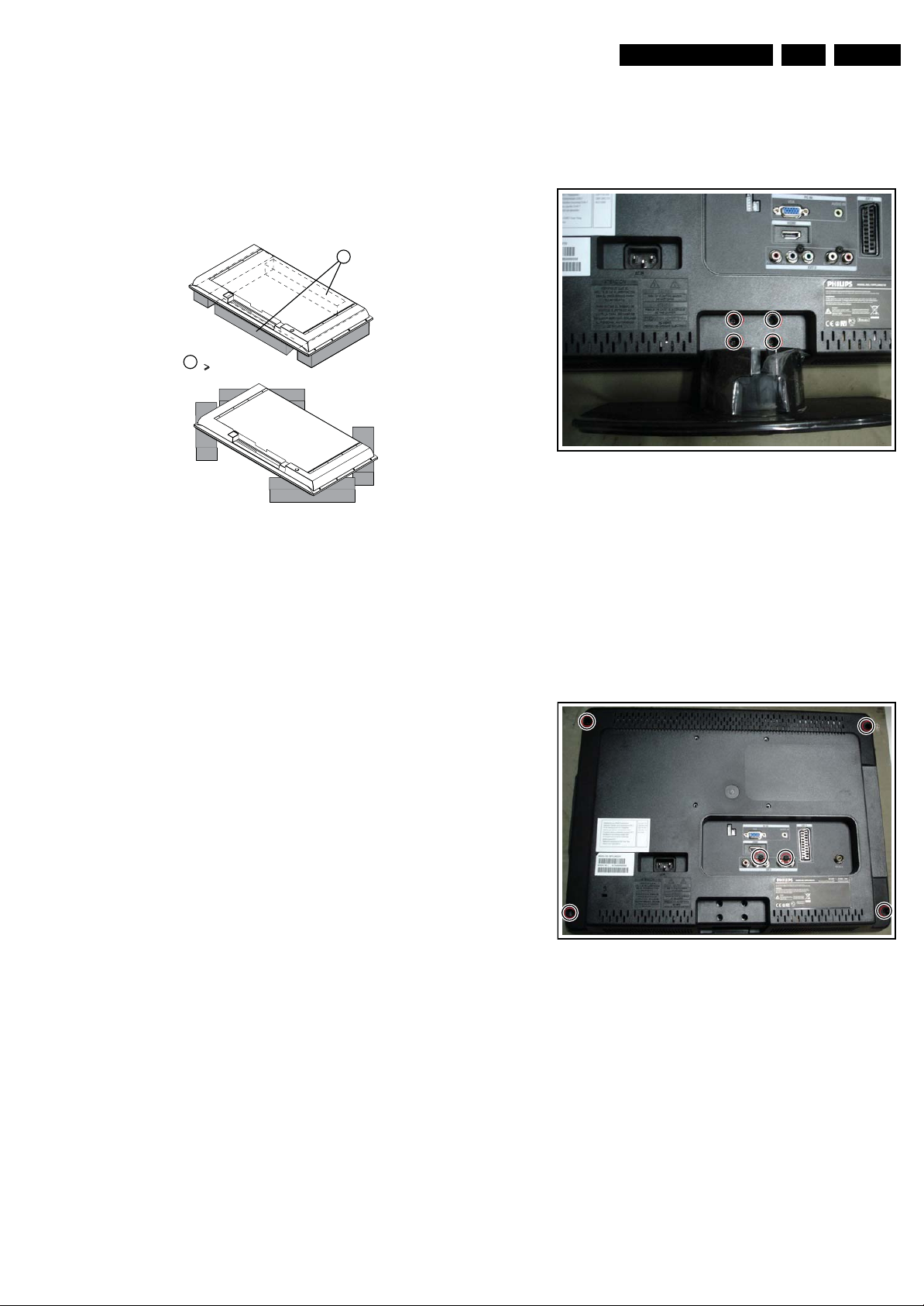

4.3.1 Stand Assy

Unscrew the marked screws to remove the stand assy.

Figure 4-3 Remove Stand ASSY

4.3.2 Rear Cover

I_17600_004.eps

010408

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

bars” for details. Sets with a display of 42” and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display. Caution:

Failure to follow these guidelines can seriously damage the

display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

1. Remove the six marked screws that secure the rear cover.

2. Pay attention to the internal hooks while removing the rear

cover. Use e.g. a plastic putty knife to release the hooks on

the bottom, the top, the left and the right side, then you can

easily remove the rear cover from the bezel.

Please refer to the photos attached below and next page.

This a good method to open the rear cover and avoid

causing scratches.

I_17600_014.eps

010408

Figure 4-4 Remove Rear Cover (1)

EN 8 TPS1.2E LA4.

Mechanical Instructions

Figure 4-5 Remove Rear Cover (2)

Figure 4-6 Remove Rear Cover (3)

I_17600_015.eps

010408

I_17600_016.eps

010408

Figure 4-8 Remove Rear Cover (5)

Figure 4-9 Remove Rear Cover (6)

I_17600_018.eps

010408

I_17600_019.eps

010408

Figure 4-7 Remove Rear Cover (4)

I_17600_017.eps

010408

Figure 4-10 Remove Rear Cover (7)

I_17600_020.eps

010408

Mechanical Instructions

EN 9TPS1.2E LA 4.

4.3.3 Bezel

1. Refer to the next figure.

2. Unplug marked connectors.

3. Release the marked screws and remove the bezel.

When defective, replace the whole unit.

Figure 4-11 Bezel

4.3.4 Shielding-EMI

1. Refer to next figure.

2. Release the marked screws and remove the shielding.

When defective, replace the whole unit.

I_17600_005.eps

010408

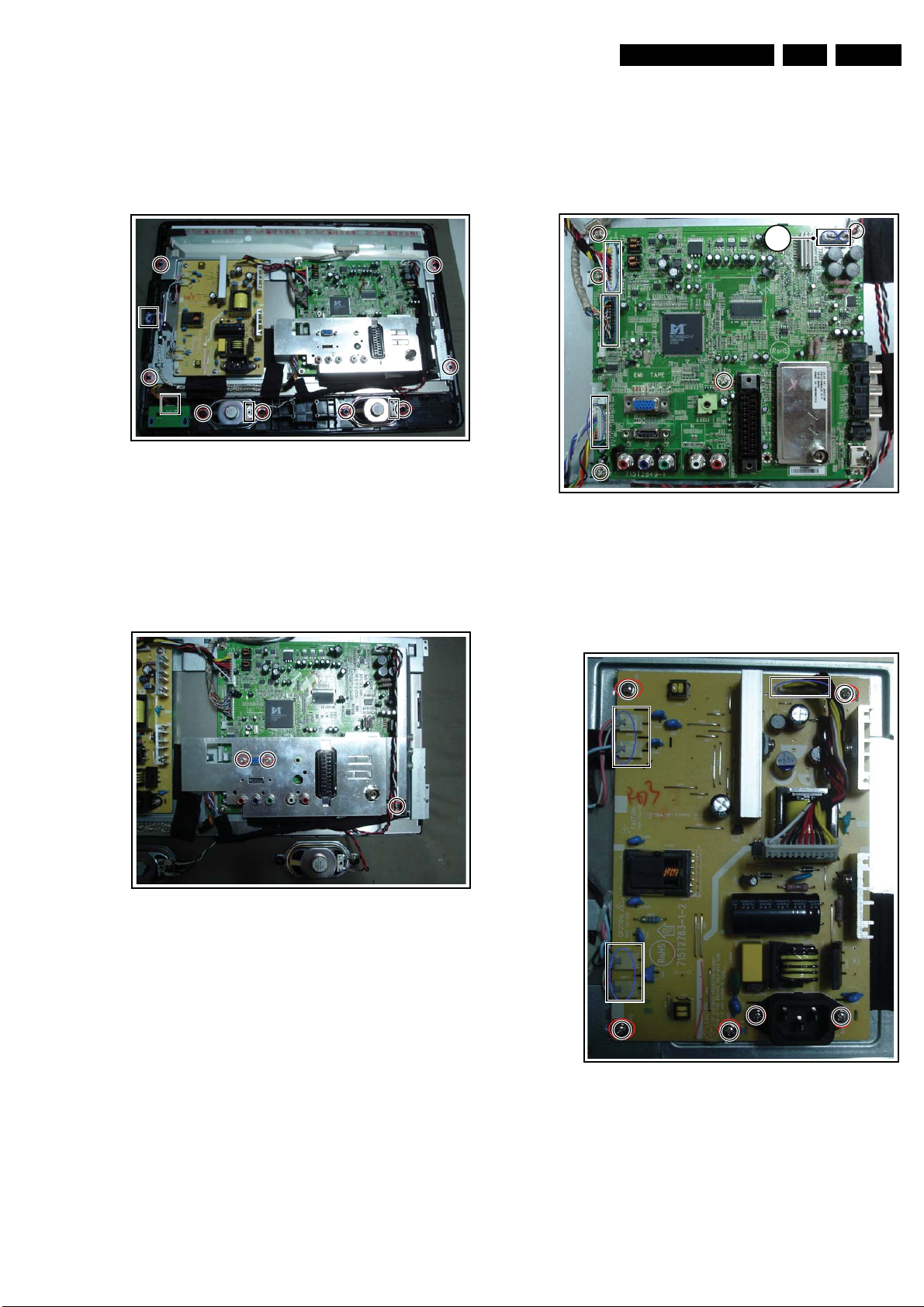

4.3.5 Main Board

1. Refer to next figure.

2. Unplug all connectors.

3. Remove the marked screws and then remove the main

board.

When defective, replace the whole unit.

(2x)

Figure 4-13 Main Board

4.3.6 Power Board

1. Refer to next figure. Unplug the connectors.

2. Unscrew the marked screws to remove the power board.

I_17620_007.eps

250308

Figure 4-12 EMI Shielding

I_17600_006.eps

010408

Figure 4-14 Power Board

I_17600_022.eps

010408

EN 10 TPS1.2E LA4.

4.3.7 Bracket

1. Refer to next two figures.

2. Remove the screws remarked in red.

Figure 4-15 Bracket1

Mechanical Instructions

I_17600_007.eps

010408

I_17600_008.eps

010408

Figure 4-16 Bracket2

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure "Cable

dressing".

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Mode

5.3 Service Tools

5.4 Tips and Tricks

5.1 Test Points

This chassis is NOT equipped with test points in the service

printing.

5.2 Service Mode

5.2.1 Factory Mode

How to Enter

To enter the Factory mode, use one of the following methods:

• Turn on the monitor, press the “menu” key.

• Press remote control code ”062596”, then press “Info [i+]”

key. When you press the “menu” key again, the OSD

will show as below, then you can just select “F3 EU

0.22d” to carry out the factory OSD.

Caution: This function is available for development and

service personnel only, not for end customers.

After entering factory mode, the following screen is visible, the

values can be adjusted according to the requested.

How to EXIT

Choose ‘EXIT”, then press “OK” button on remote control.

Figure 5-2 Factory mode menu 2

EN 11TPS1.2E LA 5.

I_17600_010.eps

010408

Figure 5-1 Factory mode menu 1

I_17600_009.eps

010408

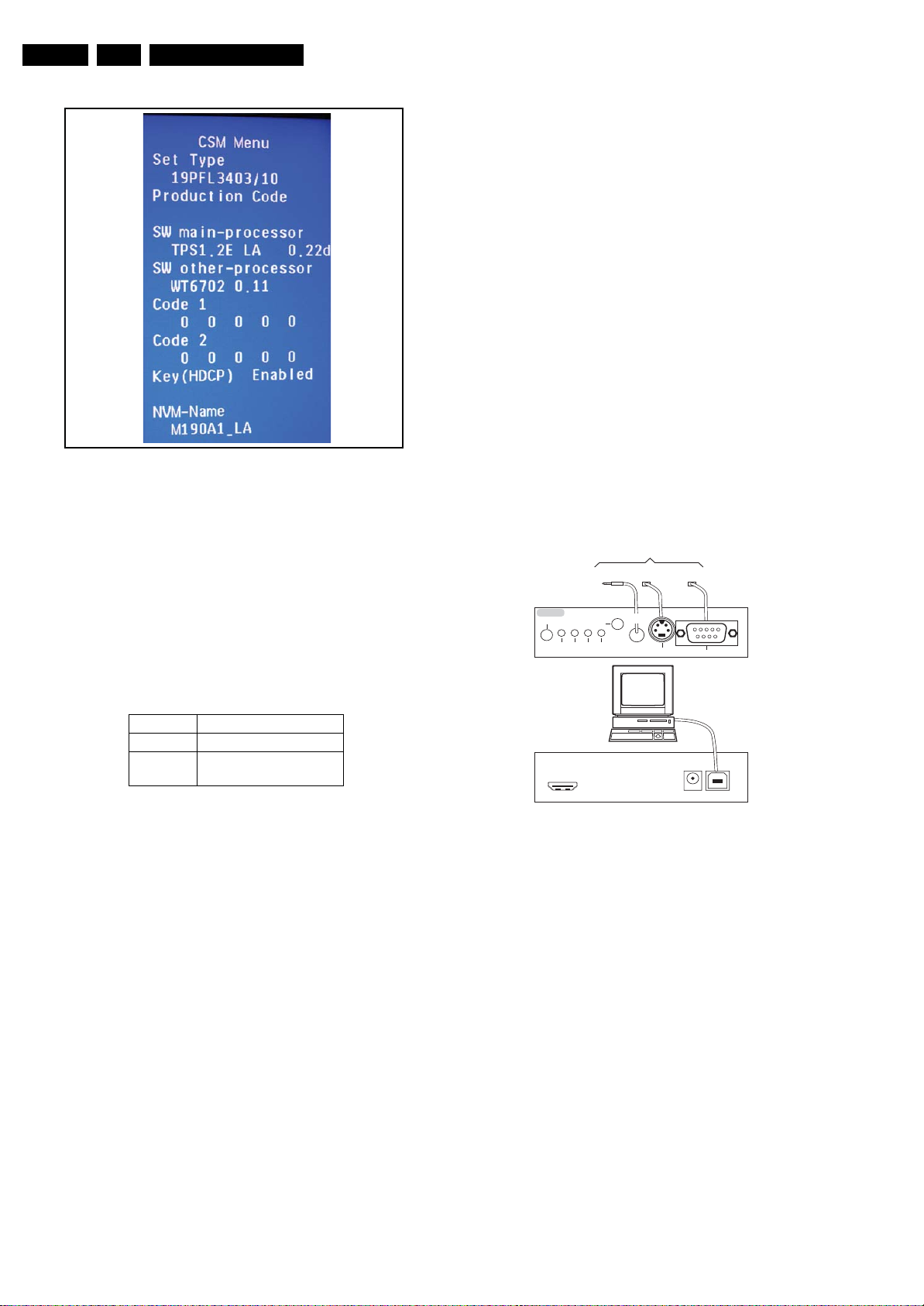

5.2.2 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Helpdesk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer. The

CSM is a read only mode; therefore, modifications in this mode

are not possible.

How to Activate CSM

Press the “menu” key and key in the code”123654” via the

standard RC transmitter.

How to Navigate

By means of the “CURSOR-DOWN/UP” knob on the RCtransmitter on the screen.

EN 12 TPS1.2E LA5.

Service Modes, Error Codes, and Fault Finding

Contents of CSM

I_17600_011.eps

010408

Figure 5-3 CSM Menu (19PFL3403)

Menu Explanation

1. Set Type: Type number and region.

2. Production code: Product serial no.

3. SW main-processor: SW-naming of Mstar/Trident, see

format in generic service document.

4. SW other-processor: if valid.

5. Code 1: Logging I2C error codes in NVM/EEPROM (5 last

logged errors).

6. Code 2: Logging I2C error codes in NVM/EEPROM (5 first

logged errors).

For the data of the Code 1/2, please refer to the table as

below.

Error Code Error Code Type

00 OK

04 The checksum for

EEPROM failed

7. Key (HDCP): Indicates if the HDCP-key are valid.

8. NVM-Name: Indicates the used LCD panel type and region

(NVM content and main SW depend on the used LCD

panel).

How to exit

Press ”MENU” on the RC-transmitter.

5.3 Service Tools

5.3.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products. and offers the following:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short and effective way.

2. ComPair allows very detailed diagnostics and is therefore

capable of accurately indicating problem areas. You do not

have to know anything about I

yourself, because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the uP

is working) and all repair information is directly available.

4. ComPair features TV software upgrade possibilities.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The (new) ComPair II interface box is connected to the PC via

an USB cable. For the TV chassis, the ComPair interface box

and the TV communicate via a bi-directional cable via the

service connector(s).

How to Connect

This is described in the ComPair chassis fault finding database.

TO

UART SERVICE

CONNECTOR

CONNECTOR

ComPair II

RC in

Optional

Switch

Power ModeLink/

Activity

HDMI

I

2

C only

RC out

Multi

function

Figure 5-4 ComPair II interface connection

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

TO TV

TO

UART SERVICE

I2C SERVICE

CONNECTOR

2

C

I

PC

ComPair II Developed by Philips Brugge

Optional power

5V DC

2

C or UART commands

TO

RS232 /UART

E_06532_036.eps

150208

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• For SW see Philips service website.

•ComPair I

2

C interface cable: 9965 100 09269.

Note: If you encounter any problems, contact your local

support desk.

Service Modes, Error Codes, and Fault Finding

5.4 Tips and Tricks

Below find some repair tips and tricks.

5.4.1 Soft Reset

When a consumer has forgotten his lock code, you can set the

TV back in Virgin mode by keying in the code”978450” via the

standard RC transmitter. The NVM is not erased.

The standard unlock code will then be “0711”.

5.4.2 Hard Reset (erase NVRAM)

A hard reset is executed by together pressing the “P+” and “V+”

buttons on the TV, while unplugging and replugging the mains

cord.

Note: By using this hard reset mode, the TV will be brought

back in Virgin mode, but also all TV settings will be erased!

TV must completely be re-aligned via the “Factory” mode.

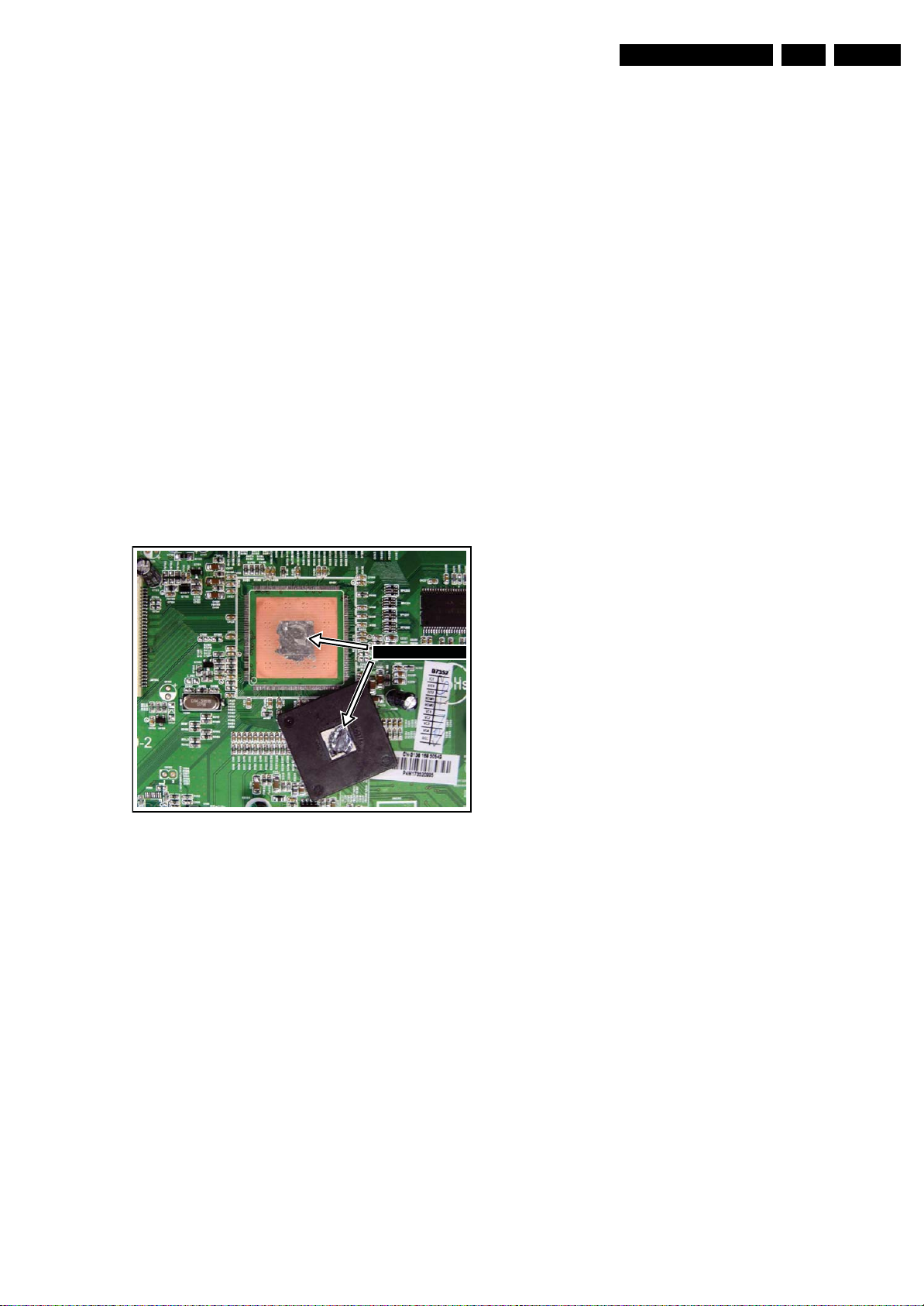

5.4.3 Removal of Morning Star Microprocessor

The Morning Star uP is fitted with a so-called E-pad (see photo

below). This is an extra surface for cooling and grounding. This

E-pad is soldered to the PWB.

To remove/place this IC on the PWB, use dedicated

equipment.

EN 13TPS1.2E LA 5.

Soldered E-Pad

I_17620_046.eps

Figure 5-5 E-pad (photo from TPS1.0 chassis)

280308

EN 14 TPS1.2E LA5.

Personal Notes:

Service Modes, Error Codes, and Fault Finding

E_06532_012.eps

131004

Block Diagrams, Test Point Overview, and Waveforms

6. Block Diagrams, Test Point Overview, and Waveforms

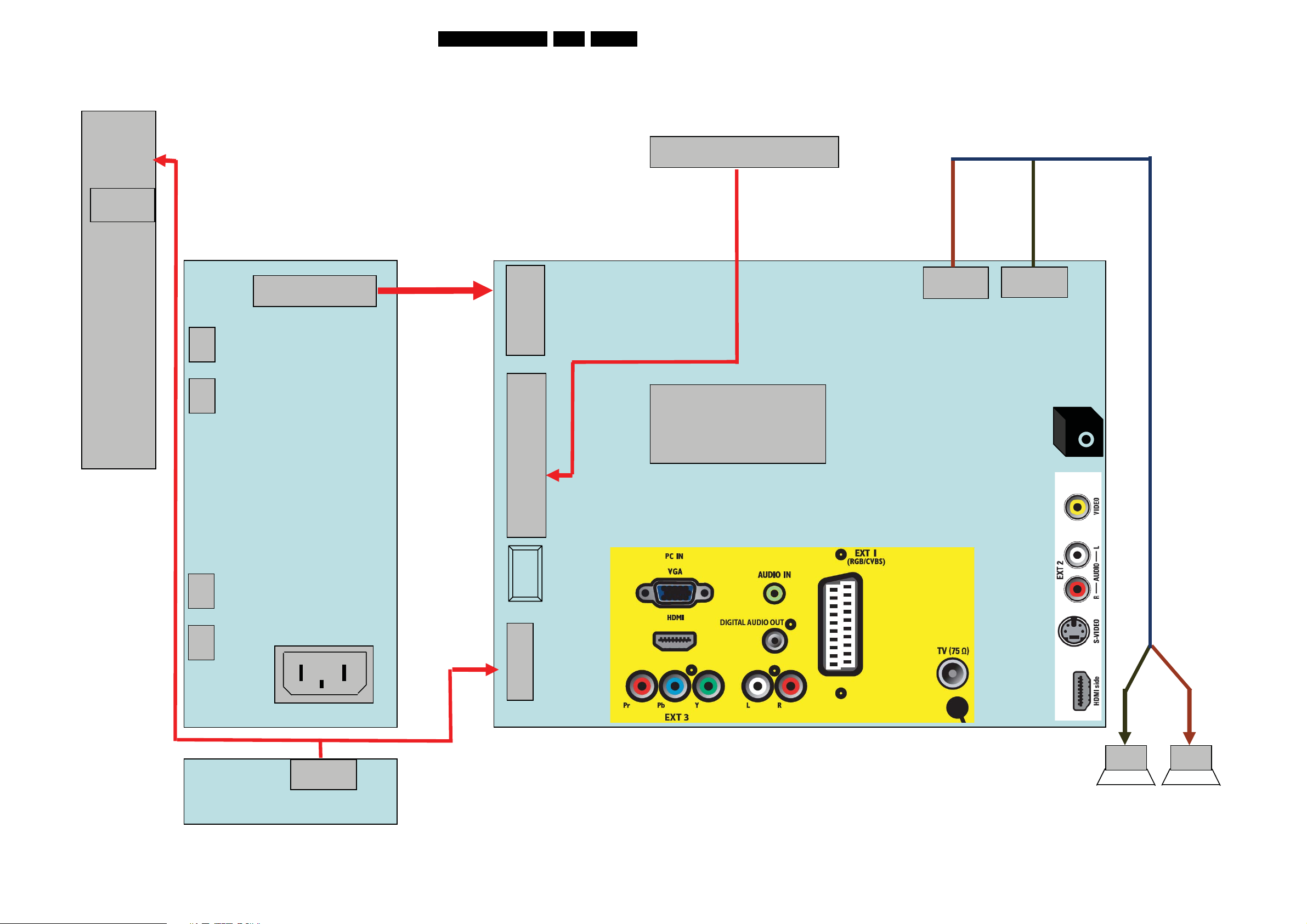

Wiring Diagram19PFL3403

15TPS1.2E LA 6.

Key

Board

5 Pin

CN101

Panel

095T8013 3D 72

095T8013 2D 73

5

LVDS Cable

1

11

11 Pin

CN902

CN802

1

12

CN702

12 Pin

3 Pin 2Pin

2131

1

095T801830D168

CN602

CN601

30

CN801

CN108

30 Pin

MST98980CLD-LF

U401

Head Phone

Power Board

CN804

CN803

IR Board

AC IN

CN901

1

6 Pin

CN1

Main Board

VIDEO

1

AUDIO R/L

11

095T801411D 5

11Pin

S-VIDEO

CN401

HDMI

1

6

Speaker R/L

I_17600_001.eps

010408

Block Diagrams, Test Point Overview, and Waveforms

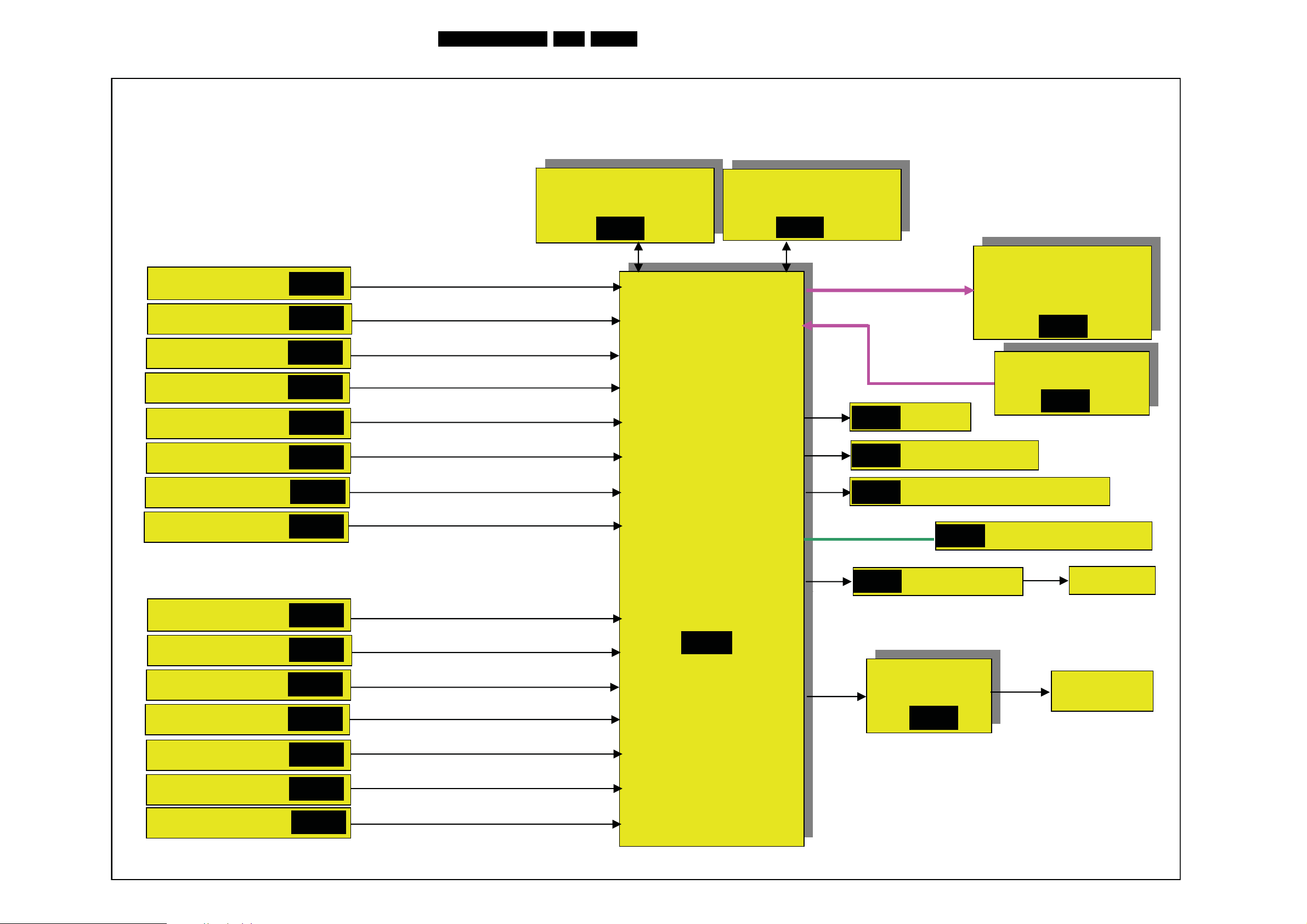

Block Diagram Scaler Board 19PFL3403

PHILIPS 19W ATV Block Diagram

16TPS1.2E LA 6.

Video Block

Tuner PACK

CVI

S_VIDEO

VGA

HDMI 1

HDMI 2

AV

SB-01

SB-02

SB-01

SB-03

SB-04

SB-04

SB-01

Tuner_CVBS

YPbPr

Y/C

PC(R,G,B&H,V)

CVBS

WT6702F_OG200WT

(Sub MCU)

SB-10

EM638165TS-6G

SB-07

SB-06

SB-06

SB-06

LVDS to panel

M190A1-L0A CMO

SB-05

INVERTER POWER

SB-09

KEY/IR

IR Receiver LED

Flash MX25L8005M2I-15G

SCART

HDMI-1

Audio Block

Tuner_SIF

CVI L/R

AVS_VIDEO L/R

PC AUDIO

HDMI 1

HDMI 2

SCART L/R

SB-02

SB-01

SB-01

SB-01

SB-08

SB-04

SB-04

SB-02

MST98980CLD

MST98980CLD

TV

TV

CONTROLLER

CONTROLLER

SB-06

2

I

C BUS

SB-08

SB-06

EARPHONE AMP

YDA148

SB-08

EEPROM AF24BC32

Headphone

speakers

I_17600_002.eps

010408

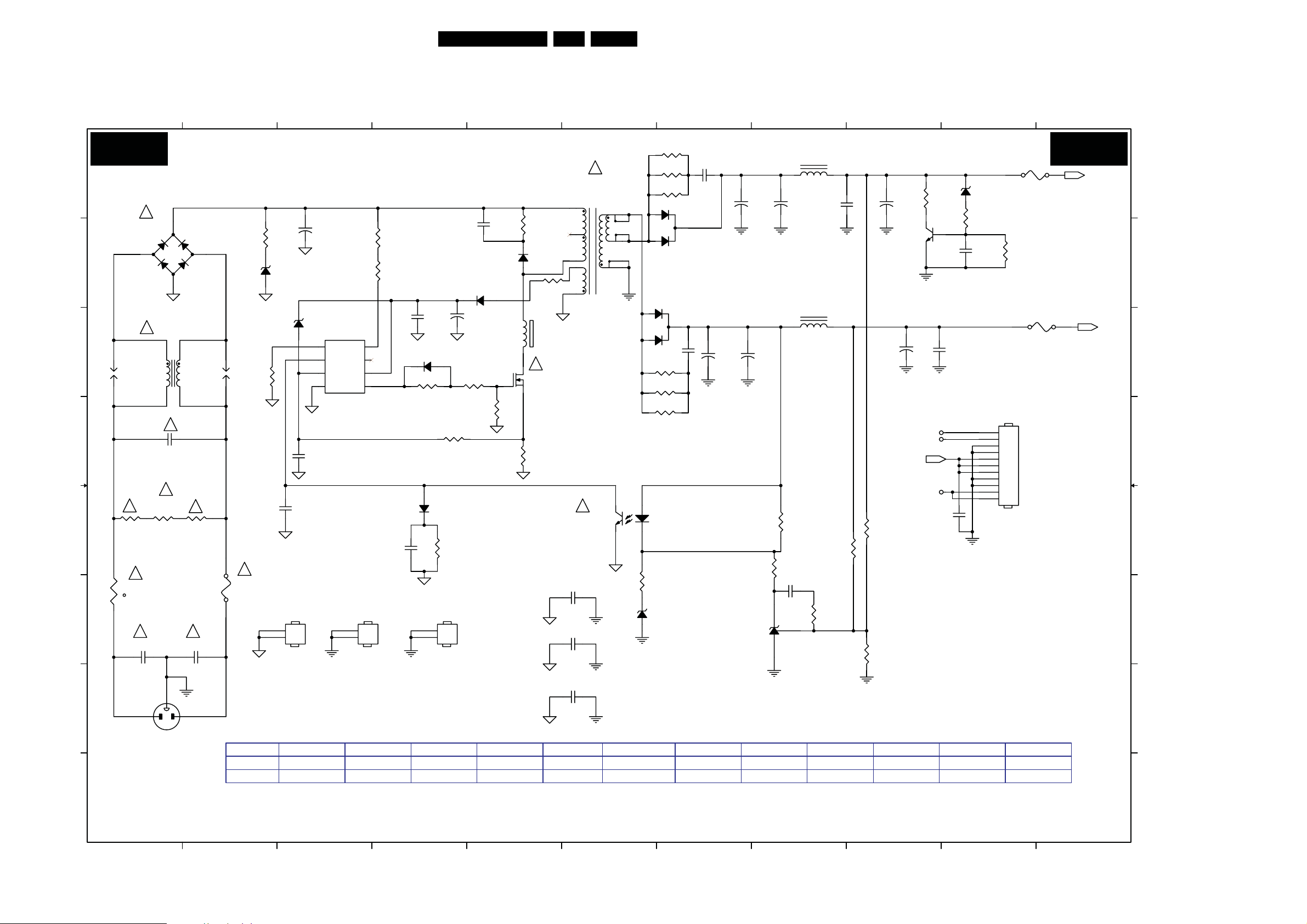

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

19PFL3403 Power Board Adapter

17TPS1.2E LA 7.

1

2

3

POWER BOARD: ADAPTER

PB01 PB01

A A

!

L902

!

L

73L 174 40LSG

C903

0.47UF

!

R902

620K 1/4W

1

+

-

4

1

4

SPARK GAP

2

3

!

!

R901

620K 1/4W

!

C902

0.001uF/250VAC

FG

3

12

2

SG902

R906

10R 1/4W

ZD903

P6KE440A

R941

100K 1/8W 1%

C923

470pF/25V

!

F901

FUSE

84G 56 4 B

ZD901

NC

HS1

HEAT SINK(Q901)

1

2

+

C905

120uF450VAC

67G315Z12115K

IC901

1

RT

2

COMP

3

CS

4

GND OUT

LD7575APS

56T 379107

C924

220pF

R904

8K2 1/4W

R905

8K2 1/4W

8

HV

7

NC

6

VCC

5

NC

HS2

HEAT SINK (D904)

1

2

BD901

GBU408

93G 50460900

3

B B

C C

SG901

SPARK GAP

D D

!

E E

F F

G G

R900

620K 1/4W

12

!

NR901

NTCR

61G 58 9T

t

!

C901

0.001uF/250VAC

C925

4

C919

0.1uF

D909

LL4148

R907

10R 1/8W

1

2

D910

NC

C906

2200pF 2KV

D902

FR103

93G 6038T52T

+

C908

22uF/50V

R912

10R 1/8W

R938

10K 1/8W

R922

200 1/8W

R931

NC

HS3

HEAT SINK(D906)

5

R908

100K 2W

D901

FR107

R909

3.3R 1/4W

12

FB901

Jumper

!

Q901

STP10NK70ZFP

57G 667 21

R914

0.39R 2W (19”)

0.36R 2W (22”)

T901

POWER X'FMR

80TL19T 33 N

4

5

6

3

2

!

IC903

PC123X2YFZOF

56G 139 3A

C931

0.001uF/250V

C907

NC

FG

C900

NC

FG

NC

8

L904

3.5uH

+

C918

L903

3.5uH

C920

0.1uF

9

+

C922

470uF/25V

PMBS3904

57G 417 4

C915

470uF/16V

Q903

+

R940

150R 2W

C916

0.1uF

6

R918

100R 1/4W

!

R919

7

C921

0.001uF

100R 1/4W

C914

+

C917

330uF/16V

+

C930

1000uF/16V

8

7

12

11

10

9

1

3

1

3

C929

0.001uF

R935

100R 1/4W

R903

R920

100R 1/4W

2

D906

YG865C15

93G 60268

D904

SP10100

93G 60267

2

+

1000uF/16V

10

ZD920

RLZ13B

R943

470R 1/8W

C932

0.001uF

F902

Jumper

R936

1K 1/4W

11

+12V

F903

+5V

Jumper

100R 1/4W

10

11

1

2

3

4

5

6

7

8

9

CN902

CONN

R934

100R 1/4W

12

43

R924

NC

R929

33K 1/8W 1%

DIM

ON/OFF

+5V

+12V

C927

0.1uF

R927

R937

NC

ZD902

NC

R925

150R 1/8W

IC902

KIA431VLA

56G 158 12

0.022uF/25V

C912

3K6 1/8W 1%

R928

0 1/8W

R930

2.43K 1/8W 1%

BD901 B1 CN901 G1

CN902 D10 C900 G6

C901 F1 C902 F2

C903 D1 C905 B3

C906 B5 C907 F6

C908 B4 C912 F8

C914 C7 C915 C9

C916 C9 C917 A7

C918 A8 C919 C4

C920 A8 C921 A7

C922 A9 C923 E2

C924 D3 C925 E4

C927 E10 C929 C7

C930 C7 C931 F6

C932 B10 D901 B5

D902 B4 D904 B6

D906 A6 D909 C4

D910 E4 FB901 C5

F901 E2 F902 A10

F903 C10 HS1 F3

HS2 F3 HS3 F4

IC901 C3 IC902 F8

IC903 E6 L902 C1

L903 C8 L904 A8

NR901 E1 Q901 C5

Q903 B9 R900 E1

R901 E2 R902 E1

R903 C6 R904 B3

R905 B3 R906 B2

R907 C4 R908 A5

R909 B5 R912 C4

R914 D5 R918 A6

R919 A6 R920 A6

R922 D4 R924 E8

R925 E8 R927 E8

R928 F8 R929 E9

R930 F9 R931 E4

R934 D6 R93

R936 B10 R937 E6

R938 C5 R940 A9

R941 C2 R943 A10

SG901 C1 SG902 C2

S4 F1 S5 F2

S6 E1 S7 E1

S8 D1 S9 E2

S10 E2 S11 D1

S12 C1 S14 A1

S15 C5 S16 E6

S17 A6 T901 A6

ZD901 C3 ZD902 F6

ZD903 B2 ZD920 A10

5 C6

CN901

SOCKET

H

1

MODE

22W ATV(12V)

22W DTV(16V)

2

ZD920

93G 39S 40 T

RLZ13B ROHM

93G 39S 44 T

RLZ18B

3

R929

61G0805330 2F

33K 1/8W 1%

61G0805430 2F

43K 1/8W 1%

T901

80TL19T 33 N

80TL22T 5 L

4

C917

67T 2043313KT

67G215S1024KV

5

C918

67G215S1024KV

C914 C930

NC 67T 2046

6

67G215S1023KV

812KT

7

D906

YG865C15RSC

93G 64 53 F

YG906C2RSC

86206 G39VK3201S512G76CN

H

I_17620_016.eps

8

9

10

010408

11

Loading...

Loading...