A/C-D/C

Battery Backup

Sump Pump System

Instruction Manual & Safety Warnings

Table of Contents

Important Safety Warnings and

Instructions

Electrical precautions 1

Battery preparation 1

Battery precautions 1

Introduction

Items included in system 2

Additional items needed 2

Replacement parts list 2

System specifications 2

Pump & Pipe

Installation Instructions

Installation options 3

Direct discharge to outside 4

Connection to existing discharge 5

Direct discharge for narrow sumps 6

Connection to existing discharge

for narrow sumps 7

Battery Instructions 8,9

Control Unit Connections

Positioning the float switch 9

Connecting the pump 9

Installing the battery fluid sensor 10

Connecting the battery 10

Connecting two batteries 10

Connecting to AC power 10

Understanding the Warning

Lights and Alarms

Silencing the alarm 10

Battery fluid is low 11

Battery problem 11

Cleaning battery terminals 11

Replacing the battery 12

Power failure 13

Pump or fuse failure 13

Pump was activated 14

Replacing the pump 14

Battery power level 14

Testing the System

Testing the float switch 15

Connecting the Remote Alarm 15

Parts & Service Information

Technical support 15

Troubleshooting Guide 16

Warranty 17

Other Products 18

IMPORTANT: Even if you have the Pro Series backup sump pump

system installed by someone else, you must read and follow the

safety information contained in this manual. Failure to do so

could result in property damage, serious injury, or death.

Important Safety

Warnings & Instructions

SAVE THESE INSTRUCTIONS. This manual

contains important SAFETY WARNINGS and

OPERATING INSTRUCTIONS for the PHCC Pro

Series 2400 battery backup sump pump system.

You will need to refer to it before attempting any

installation or maintenance. ALWAYS keep these

instructions with the unit so that they will be

easily accessible.

Failure to read and follow these warnings and

instructions could result in property damage,

serious injury, or death. It is important to read

this manual, even if you did not install the Pro

Series backup sump pump system, since this

manual contains safety information regarding

the use and maintenance of this product. DO

NOT DISCARD THIS MANUAL.

ELECTRICAL PRECAUTIONS

DANGER

!

Risk of electrical and fire hazard. May result

in death, serious injury, shock or burns. To

help reduce these risks, observe the

following precautions:

• DO NOT walk on wet areas of the basement

until all power has been turned off. If the

main power supply is in a wet basement, call

an electrician.

• NEVER handle the control unit with wet

hands or while standing on a wet surface.

• ALWAYS unplug the control unit and

disconnect the cables from the battery before

attempting any maintenance or cleaning.

• ALWAYS unplug the main pump when

installing or servicing the backup pump or

float switch to avoid electric shock.

• DO NOT expose the control unit to rain or

snow.

• DO NOT pull the cord when disconnecting the

control unit. Pull the plug.

• MAKE SURE THERE IS A PROPERLY

GROUNDED RECEPTACLE AVAILABLE. This

pump is wired with a 3-prong grounded plug.

To reduce the risk of electrical shock, be

certain that it is only connected to a properly

grounded 3-prong receptacle. If you have a

2-prong receptacle, have a licensed

electrician replace it with a 3-prong

receptacle according to local codes and

ordinances.

• DO NOT use an extension cord. The electrical

outlet should be within the length of the

pump’s power cord, and at least 4 feet above

the floor.

• DO NOT use an attachment not recommended

or sold by the manufacturer. It may result in

a risk of fire or injury from an electrical shock.

• DO NOT operate the computer control unit if

it has received a sharp blow, been dropped, or

otherwise damaged in any way.

• DO NOT disassemble the control unit.

• DO protect the electrical cord from sharp

objects, hot surfaces, oil and chemicals.

Avoid kinking the cord.

• MAKE SURE the supply circuit has a fuse or

circuit breaker rated to handle the power

requirements of this system.

• DO NOT use in pits handling raw sewage, salt

water or other hazardous materials.

When service is required, contact Glentronics

technical support at 800-991-0466, option #3,

or send an e-mail to service@glentronics.com.

Return the control unit to the manufacturer for

any repairs at the following address:

Glentronics, Inc.

645 Heathrow Drive

Lincolnshire, IL 60069-4205

BATTERY PREPARATION

WARNING / POISON

!

Sulfuric acid can cause blindness or severe

burns. Avoid contact with skin, eyes, or

clothing. In the event of an accident, flush

with water and call a physician immediately.

KEEP OUT OF REACH OF CHILDREN.

To help reduce these risks, observe the

following precautions:

• Someone should be within range of your voice

or close enough to come to your aid when you

work near a lead-acid battery.

• Have plenty of fresh water and soap nearby in

case battery acid contacts skin, clothing or

eyes.

• Wear eye and clothing protection and avoid

touching your eyes while working with

battery acid or working near the battery.

• If battery acid contacts skin or clothing, wash

immediately with soap and water. If acid

enters eye, immediately flood eye with

running cold water for at least 15 minutes

and get prompt medical attention.

• Battery posts and terminals contain lead and

lead compounds, chemicals known to the

State of California to cause cancer and

reproductive harm. Wash hands after

handling.

BATTERY PRECAUTIONS

DANGER

!

Explosive gases could cause serious injury or

death. Cigarettes, flames or sparks could

cause battery to explode in enclosed spaces.

Charge in a well-ventilated area. Always

shield eyes and face from battery. Keep vent

caps tight and level.

To help reduce these risks, observe the

following precautions:

• NEVER smoke or allow a spark or flame in the

vicinity of the battery.

• Use the Pro Series control unit for charging a

LEAD-ACID battery only. DO NOT use the

control unit for charging dry-cell batteries

that are most commonly used with home

appliances.

• Be sure the area around the battery is wellventilated.

• When cleaning or adding water to the battery,

first fan the top of the battery with a piece of

cardboard (or another non-metallic

to blow away any hydrogen or oxygen gas that

may have been emitted from the battery.

• DO NOT drop a metal tool onto the battery. It

might spark or short-circuit the battery and

cause an explosion.

• Remove personal metal items such as rings,

bracelets, watches, etc. when working with a

lead-acid battery. A short circuit through one

material)

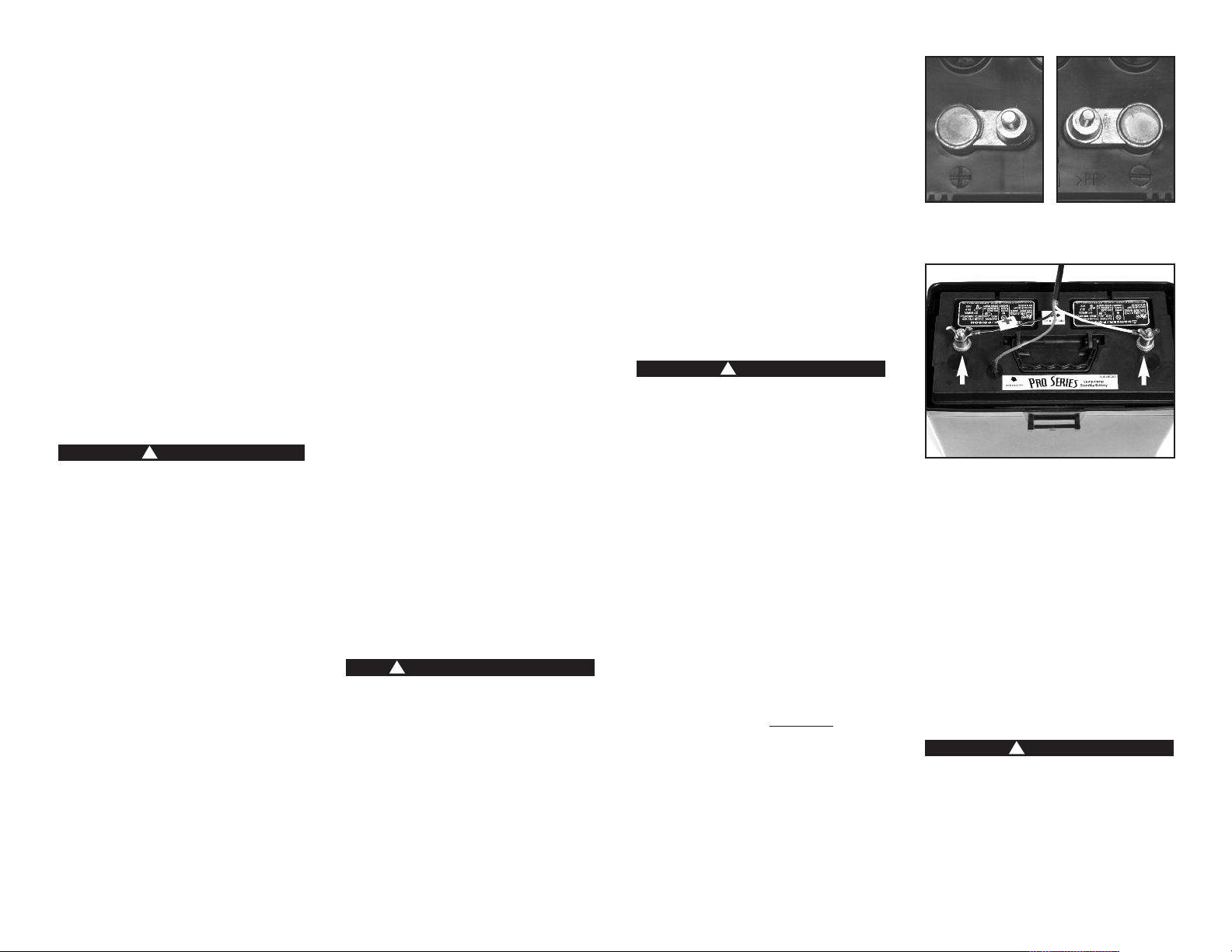

POSITIVE POST HAS

LARGER DIAMETER

POSITIVE

POST

of these items can melt it, causing a severe

burn.

• ALWAYS remove the power cord from the

electrical outlet before connecting or

disconnecting the battery cables.

• Check the polarity of the battery posts. The

POSITIVE (+) battery post usually has a larger

diameter than the NEGATIVE (-) post.

• When connecting the battery cables, first

connect the small ring on the end of the

WHITE wire to the NEGATIVE (-) post of the

battery, and then connect the large ring on

the end of the BLACK wire to the POSITIVE (+)

post of the battery.

Do not use this system to pump flammable

or explosive fluids such as gasoline, fuel oil,

kerosene, etc.

NEGATIVE POST HAS

SMALLER DIAMETER

DANGER

!

NEGATIVE

POST

Page 1

Introduction

The PHCC Pro Series 2400 A/C-D/C backup sump

pump is designed as an emergency backup

system to support your main AC sump pump, and

it will automatically begin pumping any time the

float switch is activated by rising water.

If your main AC pump breaks or is unable to keep

up with all the incoming water, the Pro Series

pump is capable of running without discharging

the battery, as long as the AC power is on. As

soon as the AC power is interrupted, the battery

takes over. Should any malfunction or emergency

occur that involves the sump pump, the battery,

or the AC power, the Pro Series system will sound

an alarm. A light on the display panel of the

control unit will indicate the cause of the alarm

and the corrective action.

For added reliability, the float switch has, not

one, but two floats mounted within a protective

cage. Should one float fail to operate, the second

float automatically activates the pump. The

protective cage prevents debris or other wires

from interfering with the movement of the floats.

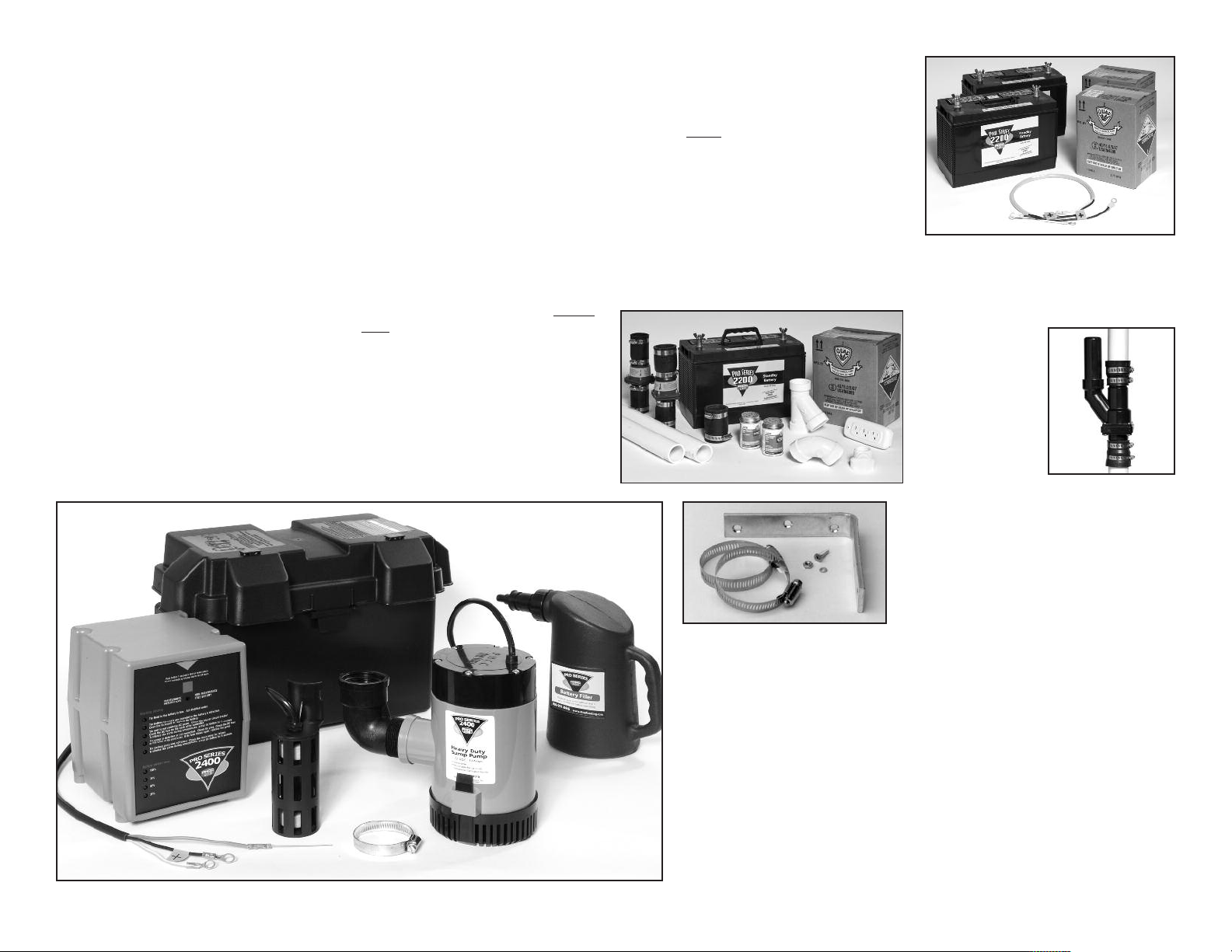

Control Unit

To extend the battery run time, two batteries may

be connected to the Pro Series 2400 system by

purchasing a second battery and acid pack, as

well as a set of battery jumper cables. Jumper

cables specifically designed for this use are

available from the manufacturer, Glentronics, Inc.

The Pro Series Sump Pump System includes:

• A control unit with a dual float switch, a

battery fluid level sensor, battery cables, a 5

amp AC fuse, and a 20 amp DC fuse

• A metal hose clamp for mounting the float

switch

• A pump

• A battery box

• A battery filler bottle for adding distilled

water to the battery

You will also need to supply:

• A Pro Series 2200 Standby Battery or a Pro

Series Maintenance-Free Battery (B12-90)

DO NOT use an automotive battery with this

system

DO NOT use a Pro Series 1000 battery with this

system. It will not run the pump as long as the

Pro Series 2200 or B12-90 battery

Battery Box

The internal construction of some wet cell batteries

may not be compatible with this system.

Glentronics can not guarantee the compatibility of

other brands of batteries. The use of a Pro Series

battery is HIGHLY

• 1½” rigid PVC pipe and fittings

• PVC primer and cement

• A union with hose clamps or a “Y” connector

and two (2) check valves, depending on the

installation method you use

• A 1½” PVC pipe adapter (1½” SLIP x 1½”

MIPT)

• A surge protector (recommended)

• Six (6) quarts of 1.265 specific gravity battery

acid

recommended.

• Two (2) acid packs to fill the dry batteries

• A set of battery cables with rings on both

ends to connect the two batteries together

(available from Glentronics, Inc.)

Use of a Pro Series

Klunkless Check

Valve™ will provide

quieter operation.

(See page 18 for

more information.)

Replacement Part Numbers

Pump . . . . . . . . . . . . . . . . . . . . . . .1011010

Float switch assembly w/hose clamp . .1020011

Fluid sensor assembly . . . . . . . . . . . .1014001

Battery box . . . . . . . . . . . . . . . . . . .1113003

Battery filler bottle . . . . . . . . . . . . . . .BFB-P

Battery jumper cable for 2 batteries . . . . . .BJC

Battery Wires

Fluid Sensor

Dual

Float

Switch

Hose Clamp

Pump

Battery

Filler

Bottle

For narrow sump pits you will need

some additional parts:

• An “L” bracket at least six (6) inches

long (preferably one that will not

rust)

• Two (2) stainless steel hose clamps

• One (1) stainless steel screw (#8-32

x 3/4”), a matching washer & nut

To connect two batteries you will

need:

• Two (2) batteries of similar age and

capacity (so they will have equal

power)

• Another battery box (optional)

Call 800-991-0466, option #3 to order parts.

System Specifications

Power supply requirements . . . . . .115 volts AC

Pumping capacity . . . . . . . . . .4000 GPH @ 0’

Pumping capacity . . . . . . . . .2400 GPH @ 10'

Pumping capacity . . . . . . . . .1600 GPH @ 12'

Pumping capacity . . . . . . . . . .600 GPH @ 15'

Pump dimensions w/elbow . . . . . .8

Pump housing & strainer . . . . . .non-corrosive,

Pump . . .can run dry for short periods of time;

can be used in sumps with water softener

Float switch . . . . . . . . . .independent, can be

1

⁄2 H x 9” W

will not rust

set at any level

Page 2

Pump & Pipe

P

UMP

WIRE

PIPE

ADAPTER

F

LOOR

J

OIST

MAIN

AC PUMP

RIGID

1-1/2"

P

VC PIPE

CHECK

VALV E

1/8" HOLE

4

5º ELBOW

"Y" CONNECTOR

CHECK

VALV E

PRO SERIES

BACKUP PUMP

DRAIN TILE

SLOPE

PIPE

DOWN

"Y"

CONNECTOR

DRAIN TILE

SLOPE

PIPE

DOWN

"Y"

CONNECTOR

45º ELBOW

PUMP WIRE

1/8" HOLE

PIPE ADAPTER

HOSE

CLAMPS

MAIN

AC PUMP

PRO SERIES

BACKUP PUMP

"L" BRACKET

CHECK

VALVE

CHECK

VALVE

FLOOR

JOIST

RIGID

1-1/2"

PVC PIPE

RIGID

1-1/2"

PVC PIPE

PUMP

WIRE

PIPE ADAPTER

DRILL 1/8" HOLE

IF CHECK

VALVE USED

FLOOR

J

OIST

MAIN

AC PUMP

S

LOPE

PIPE

DOWN

R

IGID

1-1/2"

P

VC PIPE

PRO SERIES

BACKUP PUMP

DRAIN TILE

U

NION

OR CHECK

VALVE

CHECK

VALVE

PUMP WIRE

HOSE

CLAMPS

"L" BRACKET

FLOOR

JOIST

MAIN

AC PUMP

SLOPE

PIPE

DOWN

RIGID

1-1/2"

PVC PIPE

PIPE ADAPTER

DRILL 1/8" HOLE

IF CHECK

VALVE USED

PRO SERIES

BACKUP PUMP

DRAIN TILE

UNION

OR CHECK

VALVE

CHECK

VALVE

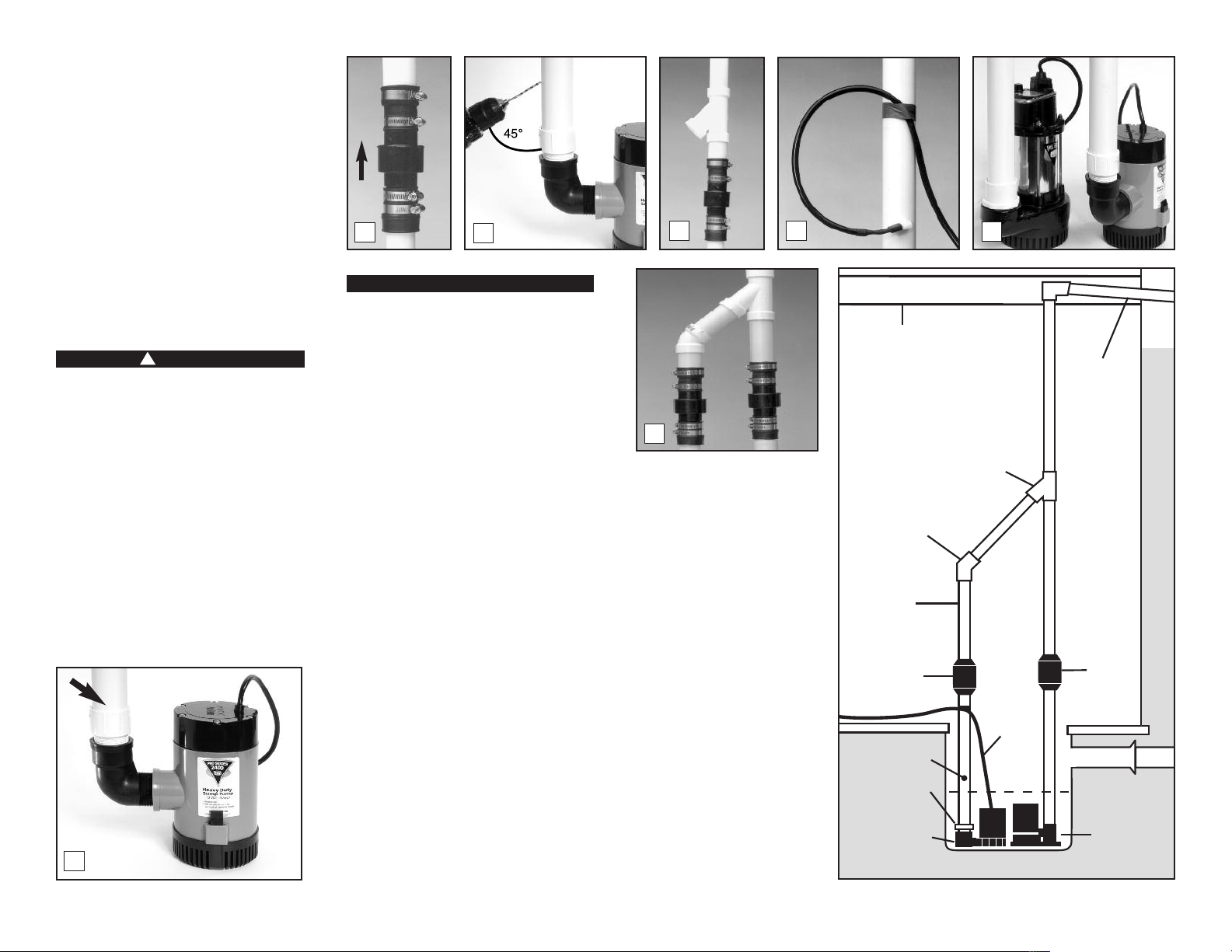

Installation Instructions

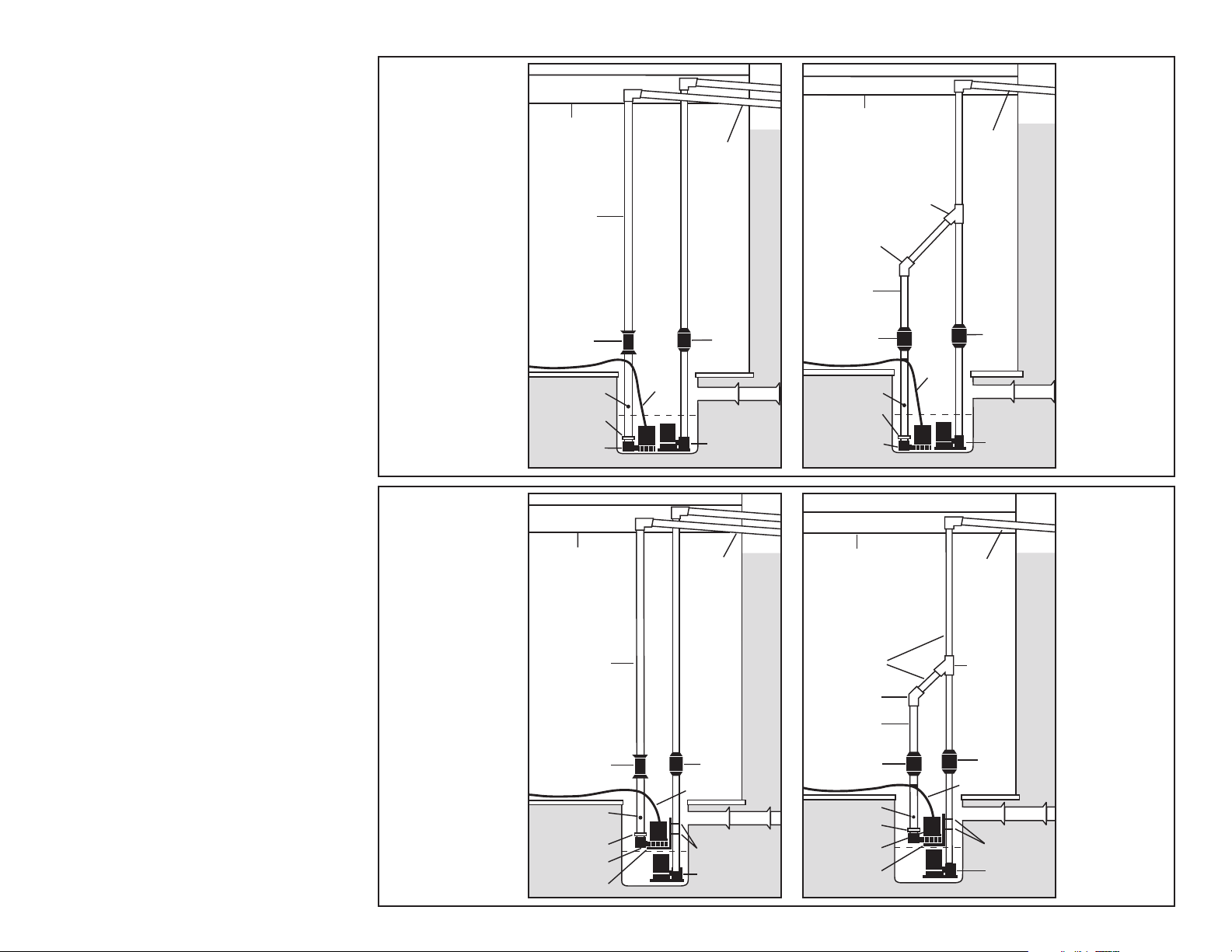

There are two basic methods that can be used to

install the pump, a direct discharge to the

outside of the building, or a connection to an

existing discharge pipe. The same two options

apply in very narrow sump pits where the backup

pump must be mounted above the main pump.

Whenever possible, install your Pro Series

backup pump with a direct discharge to the

outdoors. By using this method, there will

always be an outlet for the water from the sump.

During times of very heavy rain, many storm

sewers fill up. If your pump is trying to

discharge water into a full sewer, there is

nowhere for the water to go. By discharging

directly outdoors, there is always an outlet for

the water that is pumped out of the sump. For

this method, you will need to drill a hole

through a floor joist or the foundation from the

basement to the outside of the house.

If the direct discharge method is not possible or

convenient, the Pro Series pump can be

connected to the same line as your main AC

sump pump by installing a “Y” connector and

two (2) check valves.

NORMAL SUMP PIT

INSTALLATIONS

Installation A

Direct Discharge

to Outside

Page 4

NARROW SUMP PIT

INSTALLATIONS

Installation B

Connection

to Existing

Discharge Pipe

Page 5

In most cases, the backup pump will fit next to

the main AC pump in the sump pit. In very

narrow pits, the backup pump can be mounted

above the main AC pump. Try to fit the backup

pump on the floor of the sump first. Make sure

there is enough room so the backup pump and

the main pump do not touch each other.

Select the installation method that will best suit

your needs from the diagrams at the right. Full

instructions for each installation method are

provided on the following pages.

Installation will take a couple hours.

Page 3

Installation C

Direct Discharge

to Outside

Page 6

Installation D

Connection

to Existing

Discharge Pipe

Page 7

Pump & Pipe

PUMP

WIRE

PIPE ADAPTER

DRILL 1/8" HOLE

IF CHECK

VALVE USED

FLOOR

JOIST

MAIN

AC PUMP

SLOPE

PIPE

DOWN

RIGID

1-1/2"

PVC PIPE

PRO SERIES

BACKUP PUMP

DRAIN TILE

UNION

OR CHECK

VALVE

CHECK

VALVE

Installation Instructions

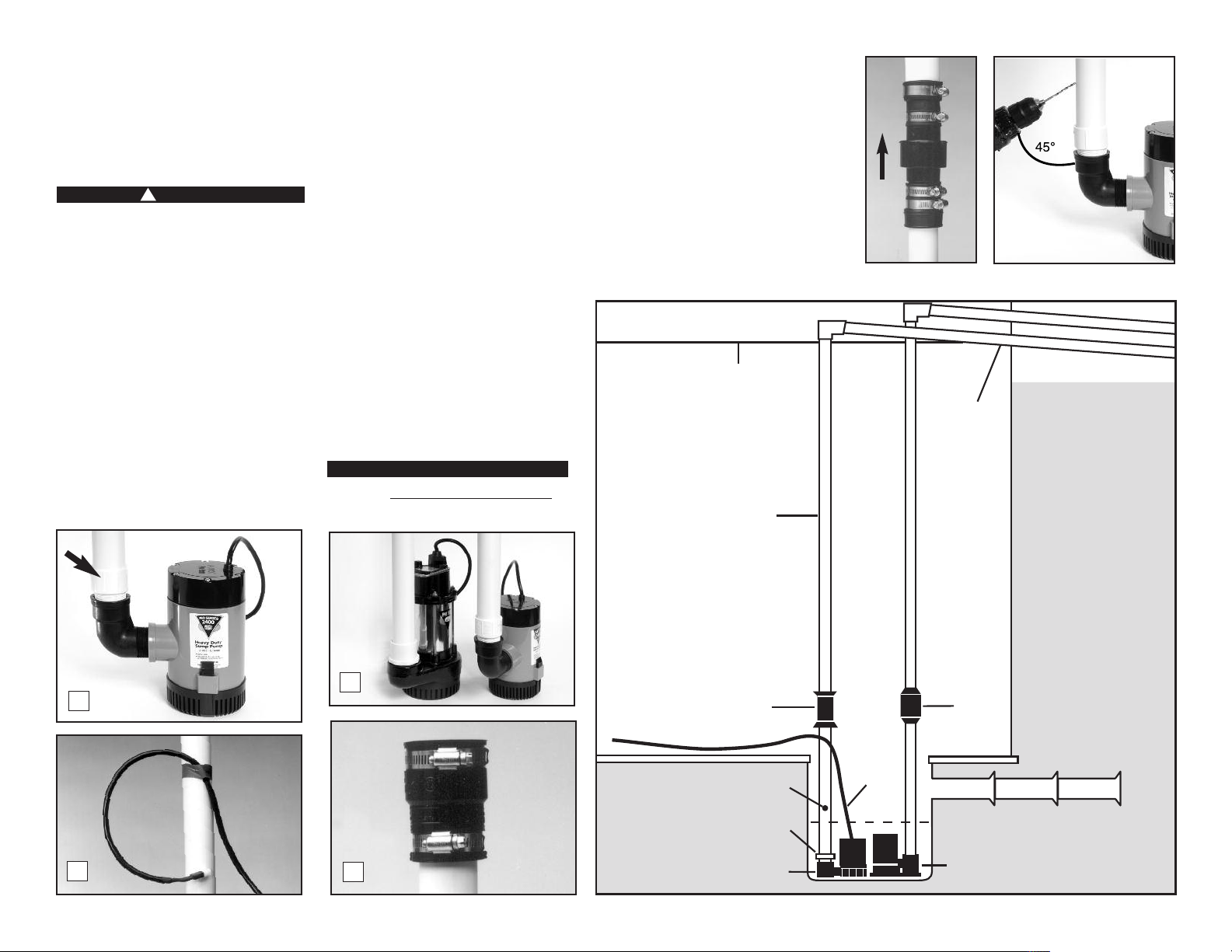

INSTALLATION A:

DIRECT DISCHARGE TO THE OUTSIDE OF THE

BUILDING (Diagram A)

DANGER

!

Unplug the main AC pump when installing

the backup pump to avoid electric shock.

Failure to do so could cause serious injury

or death.

1. Cut a piece of 1½” rigid PVC pipe long

enough to reach from the bottom of the

sump pit to one (1) foot above the floor.

Prime and cement it to a 1½” pipe adapter,

then screw the adapter into the pump.

2. Secure the pump wire so that the plug on the

end will not fall into the sump. Attach the

wire to the pipe with a piece of tape.

3. Place the pump with the PVC pipe

attachment on the bottom of the sump floor

next to the main AC pump. The pumps

should not touch each other. Do not mount

the pump to any existing pipes; it should be

placed on the floor of the sump. A brick may

be placed under the pump if there are rocks

or other debris on the sump floor that may

clog the pump.

4. Attach a union or a check valve to the top of

the 1½” pipe. This will allow the pump to

be removed easily, should the need arise.

The path of the rest of the pipe and the details

of each installation will vary. Using sound

plumbing practices, route the discharge pipe to

an exterior wall via the shortest path with the

fewest turns. More turns will reduce the

pumping capacity. The pipe section exiting the

building should be on a downward slope so that

the water in the pipe will exit outside instead of

returning to the sump pit. Be sure to seal the

hole in the wall where the pipe exits, and prime

and cement or clamp all connections securely to

prevent leaking. When directly discharging to

the outside of the building, no check valve is

required. However, a check valve will prevent

water from flowing back into the pit when the

pump has stopped.

If you use more than a total of 20 feet

CAUTION

pipe in the installation (including vertical

and horizontal runs), install a check valve in

place of the union. Make sure it is installed

with the arrow pointing up, or it will not

prevent the backflow of water. When a check

valve is used, a 1/8” hole must be drilled in

the PVC pipe above the Pro Series pump.

Drill the hole at a 45° angle toward the

bottom of the sump to avoid splashing water

outside the sump pit. Make sure the hole is

above the water line and below the check

valve. If a hole is not drilled above the

pump, an air lock may prevent the pump

from operating.

of

1

2

3

4

Diagram A

Page 4

Pump & Pipe

PUMP

WIRE

PIPE

ADAPTER

FLOOR

JOIST

MAIN

AC PUMP

RIGID

1-1/2"

PVC PIPE

CHECK

VALVE

1/8" HOLE

45º ELBOW

"Y" CONNECTOR

CHECK

VALVE

PRO SERIES

BACKUP PUMP

DRAIN TILE

SLOPE

PIPE

DOWN

Installation Instructions

INSTALLATION B:

CONNECTION TO AN EXISTING DISCHARGE PIPE

(Diagram B)

Depending on your installation requirements,

PVC pipe lengths will vary. Cut the pipes and

assemble them as shown in photo #7. Do not

cement them together until you are sure they are

cut to the correct lengths. It is important to

keep the discharge pipes on both pumps parallel

to each other, so that the pumps remain flat on

the floor of the sump. More detailed

instructions follow.

DANGER

!

Unplug the main AC pump when installing

the backup pump to avoid electric shock.

Failure to do so could cause serious injury or

death.

1. Cut a piece of 1½” rigid PVC pipe long enough

to reach from the bottom of the sump pit to

one (1) foot above the floor. Prime and

cement it to a 1½” pipe adapter, then screw

the adapter into the pump.

2. Install a check valve on the top of the PVC

pipe attached to the Pro Series pump. Make

sure it is installed with the arrow pointing up

or it will not prevent the backflow of water.

2

3. When a check valve is used, a 1/8” hole

must be drilled in the PVC pipe above the

Pro Series pump. Make sure it is above the

water line and below the check valve. Drill

the hole at a 45º angle toward the bottom

of the sump to avoid splashing water

outside the sump pit. If a 1/8” hole is not

drilled in the pipe above the pump, an air

lock may prevent the pump from operating.

4. If there is no check valve on the discharge

pipe of the main AC pump, one must be

installed at this time. Cut the discharge pipe

approximately one (1) foot above the floor.

Install a check valve on the top of the pipe

and tighten the bottom hose clamp. Now

prime and cement a small piece of 1½” PVC

pipe to the bottom of a “Y” connector. Prime

and cement the top of the “Y” assembly to the

discharge pipe with the “Y” extension facing

down toward the backup pump. Now connect

the bottom of the assembly to the check valve

and tighten the hose clamp.

5. Secure the pump wire so that the plug on the

end will not fall into the sump. Attach the

wire to the pipe with a piece of tape.

3

CAUTION

4

7

under the pump if there are rocks

or other debris on the sump floor

that may clog the pump.

7. Connect a piece of 1½” PVC pipe

above the check valve of the Pro

Series pump, and attach a 45°

elbow to that pipe. Extend

another piece of pipe to reach

from the 45° elbow to the “Y”

connector on the other pipe.

8. Prime and cement all pipe

connections securely to prevent

leaking, and tighten all the hose

clamps.

5

6

1

Page 5

6. Place the pump with the PVC pipe attachment

on the bottom of the sump floor next to the

main AC pump. The pumps should not touch

each other. Do not mount the pump to any

existing pipes; it should be placed on the

floor of the sump. A brick may be placed

Diagram B

Loading...

Loading...