Batter y Backup

Sump Pump System

Instruction

Manual

Push button 1 second to test or reset alarm.

Push 5 seconds to silence alarm for 24 hours.

Warning alarms

The fluid in the battery is low. Add distilled water.

•

The battery terminals are corroded or the battery is defective.

Clean the terminals or replace the battery.

•

The unit is not receiving AC power. Check the plug or circuit breaker.

To silence the alarm during emergencies, press the button for 5 seconds.

•

The pump is defective or not connected. Check plug or replace pump.

•

The pump was activated. Check the main pump for failure.

To silence the alarm during emergencies, press the button for 5 seconds.

•

Battery power level

100%

•

75%

•

50%

•

25%

•

Table of Contents

Important Safety Instructions

General . . . . . . . . . . . . . . . . . . . . . . .1

AC Power Requirements . . . . . . . . . .1

Personal Precautions . . . . . . . . . . . . .1

Preparing to Charge . . . . . . . . . . . . .1

DC Connection Precautions . . . . . . . .1

Introduction

Items Included in System . . . . . . . . .2

Additional Items Needed . . . . . . . . . .2

Pump & Pipe

Installation Instructions

Direct Discharge to Outside . . . . . .3,4

Hookup to Existing Discharge Pipe .5,6

Battery Instructions

Preparation of the Battery . . . . . . . . .7

Control Unit Hookup

Positioning the Control Unit . . . . . . . .8

Positioning the Float Switch . . . . . . . .8

Installing the Battery Fluid Sensor . . .8

Hooking Up the Pump . . . . . . . . . . . .8

Hooking Up the Battery . . . . . . . . . . .8

Understanding the Warning

Lights and Alarms

Battery Fluid is Low . . . . . . . . . . . . . .9

Battery Problem . . . . . . . . . . . . . . . .9

Cable or Terminal Problem . . . . . .9,10

Replacing the Battery . . . . . . . . . . .10

Power Failure . . . . . . . . . . . . . . . . .10

Pump is Defective . . . . . . . . . . . . . .10

Pump was Activated . . . . . . . . . . . .10

Replacing the Pump . . . . . . . . . . . .11

Battery Power Level . . . . . . . . . . . . .11

Testing the Float Switch . . . . . . . . . .11

Parts & Service Information

Technical Support . . . . . . . . . . . . . .11

Important

Safety Instructions

General

Do not expose the control unit to rain or

snow.

Pull the plug rather than the cord when

disconnecting the control unit.

An extension cord should not be used

unless absolutely necessary. If an extension cord must be used, be sure the

plug has the same configuration as the

plug on the control unit.

To reduce the risk of electric shock,

unplug the control unit and disconnect

the cables from the battery before

attempting any maintenance or cleaning.

Do not disassemble the control unit.

When service is required contact

Glentronics technical support at (800)

991-0466, select option 3.

AC Power Requirements

The control unit must receive 115 volts A C

+/- 5% from the AC outlet. Any voltage

lower than this will cause the power f ailure

alarm to activate. Lower voltages can be

caused by utility company brown outs or

heavy power draw from other appliances

on the same circuit.

Personal Precautions

Wear eye protection and avoid touching your eyes while working near the

battery.

If battery acid contacts skin or clothing,

wash immediately with soap and water.

If acid enters eye, immediately flood eye

with running cold water for at least 10

minutes and get medical attention.

Never smoke or allow a spark or flame

in the vicinity of the battery.

Remove personal metal items such as

rings, bracelets, watches, etc. when

working with a lead-acid battery.

Preparing to Charge

Charge only LEAD-ACID batteries with

the Pro Series 2200 control unit. Do not

use the control unit for charging dry-cell

batteries that are most commonly used

with home appliances.

Be sure the area around the battery is

well-ventilated.

When cleaning or adding water to the

battery, gas can be forcefully blown

away by using a piece of cardboard or

other

nonmetallic material as a fan.

Clean the battery terminals. Be careful

to keep corrosion from coming in contact with your eyes.

DC Connection Precautions

Connect and disconnect the battery

cable rings only after removing the

power cord from the electric outlet.

Never allow the rings to touch each

other.

Coat the terminals with a thin coat of

petroleum jelly to retard corrosion.

Attach the rings on the ends of the

battery cables to the battery posts and

secure them with wing nuts to insure a

good connection.

Follow these steps when the battery is

installed. A spark near the batter y may

cause a battery explosion. To reduce

the risk of a spark near the battery:

Check the polarity of the battery posts.

The POSITIVE (+) battery post usually has a larger diameter than the

NEGATIVE (-) post.

Connect the large ring on the POSITIVE

(BLACK) wire from the control unit to the

POSITIVE (+) post of the battery.

Connect the small ring on the NEGATIVE (WHITE) wire from the control

unit to the NEGATIVE (-) post of the

battery.

When disconnecting the control unit,

first disconnect the AC power cord, and

then remove the rings from the battery

terminals.

Page 1

POSITIVE

POST HAS

LARGER

DIAMETER

NEGATIVE

POST HAS

SMALLER

DIAMETER

Introduction

The Pro Series 2200 AC/DC backup

sump pump system is battery-operated.

It is designed as an emergency backup

system to support your regular AC sump

pump, and it will automatically begin

pumping if your main AC pump fails.

Should any malfunction or emergency

occur that involves the sump pump, the

battery, or the AC power, your Pro

Series 2200 battery backup sump pump

system will sound an alarm and indicate

the nature of the problem and the

solutions by means of a lighted display

on the control panel.

If the main pump breaks or is unable to

keep up with all the incoming water, the

Pro Series pump is capable of running

without discharging the battery as long

as the AC power is on.

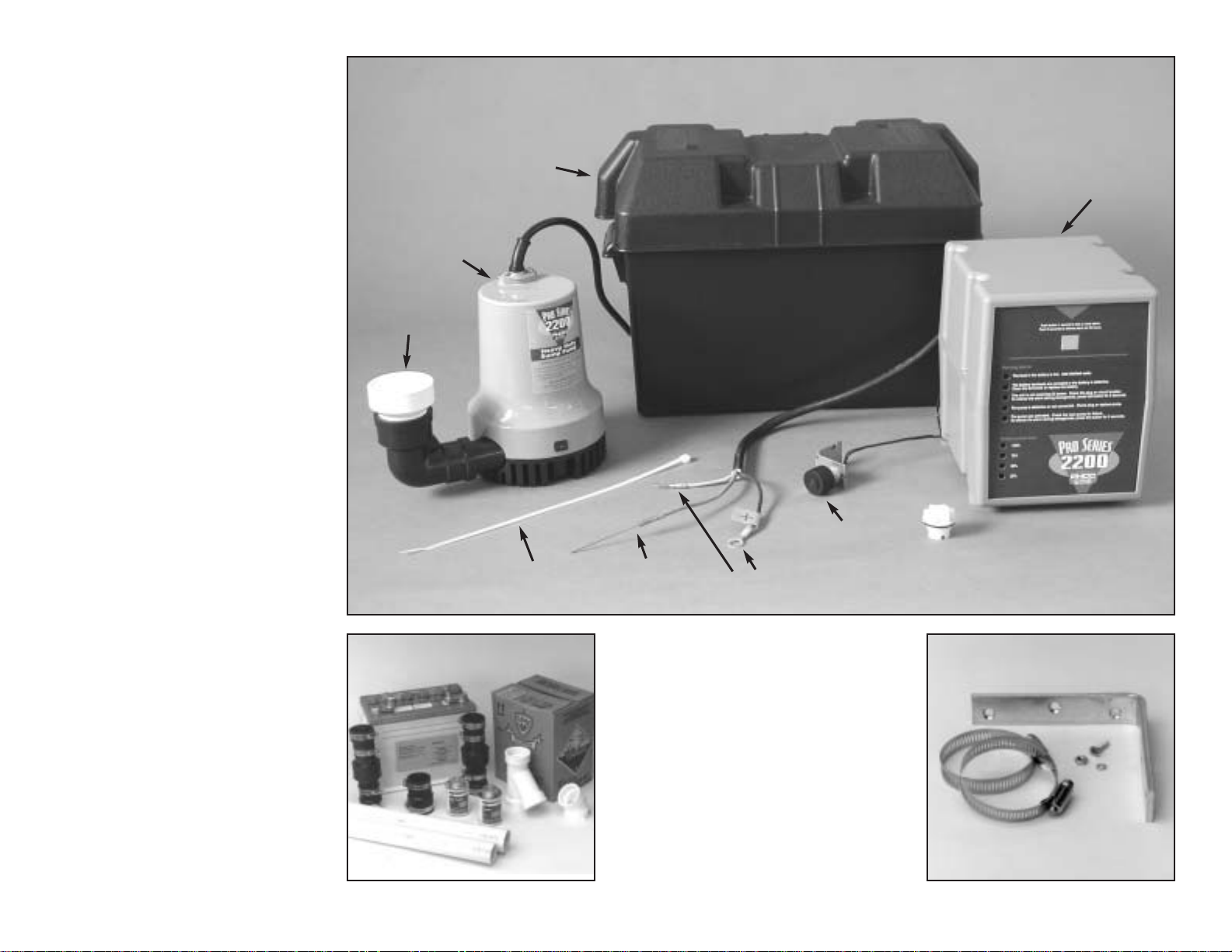

The Pro Series 2200 Battery Backup

Sump Pump System includes:

1 Control unit with a float switch and a

battery fluid level sensor

1 Pump with 11⁄2" PVC pipe adapter

1 Battery box with safety strap

1 Plastic wire tie for mounting the float

switch

1 Battery cap with a hole to accommo-

date the fluid sensor

You will also need to supply:

A Pro Series 2200 Standby Battery

(A maintenance-free battery is not

recommended)

1

1

⁄2" PVC pipe and fittings

PVC cement and primer

A rubber union with hose clamps

or a "Y" connector and two (2)

check valves depending on the

installation method you use

Six (6) quarts of 1.265 specific

gravity battery acid

For narrow sump pits you will need

some additional parts:

An "L" bracket at least 6 inches

long. (Preferably one that will not

rust.)

Two (2) stainless steel hose

clamps

One (1) stainless steel screw

(#8-32 x

3

⁄4"), a matching washer

& nut

Page 2

CONTROL UNIT

BATTERY

BOX

CAP

WIRE TIE

FLOAT

SWITCH

PIPE

ADAPTER

PUMP

FLUID

SENSOR

BATTERY

CABLES

Pump & Pipe

Installation Instructions

(Direct Discharge to Outside)

There are two basic methods that can

be used to install the pump, (A) a direct

discharge to the outside of the building,

or (B) a hookup to an existing discharge

pipe.

Whenever possible, install your Pro

Series 2200 backup sump pump with a

direct discharge to the outdoors. By

using this method, there will always be

an outlet for the water from the sump.

During times of very heavy rain, many

storm sewers fill up. If your pump is

trying to discharge water into a full

sewer, there is nowhere for the water to

go. This defeats the purpose of the

backup system. By discharging directly

outdoors, there is always an outlet for

the water that is pumped out of the

sump.

There are two options for installing your

sump pump with a direct discharge to

the outside. If you have a sump pit wide

enough to place the backup pump next

to the main pump, use Method A. If your

sump pit is too narrow , the pump may be

mounted above the main pump. In this

instance use the instructions for Method

Aa.

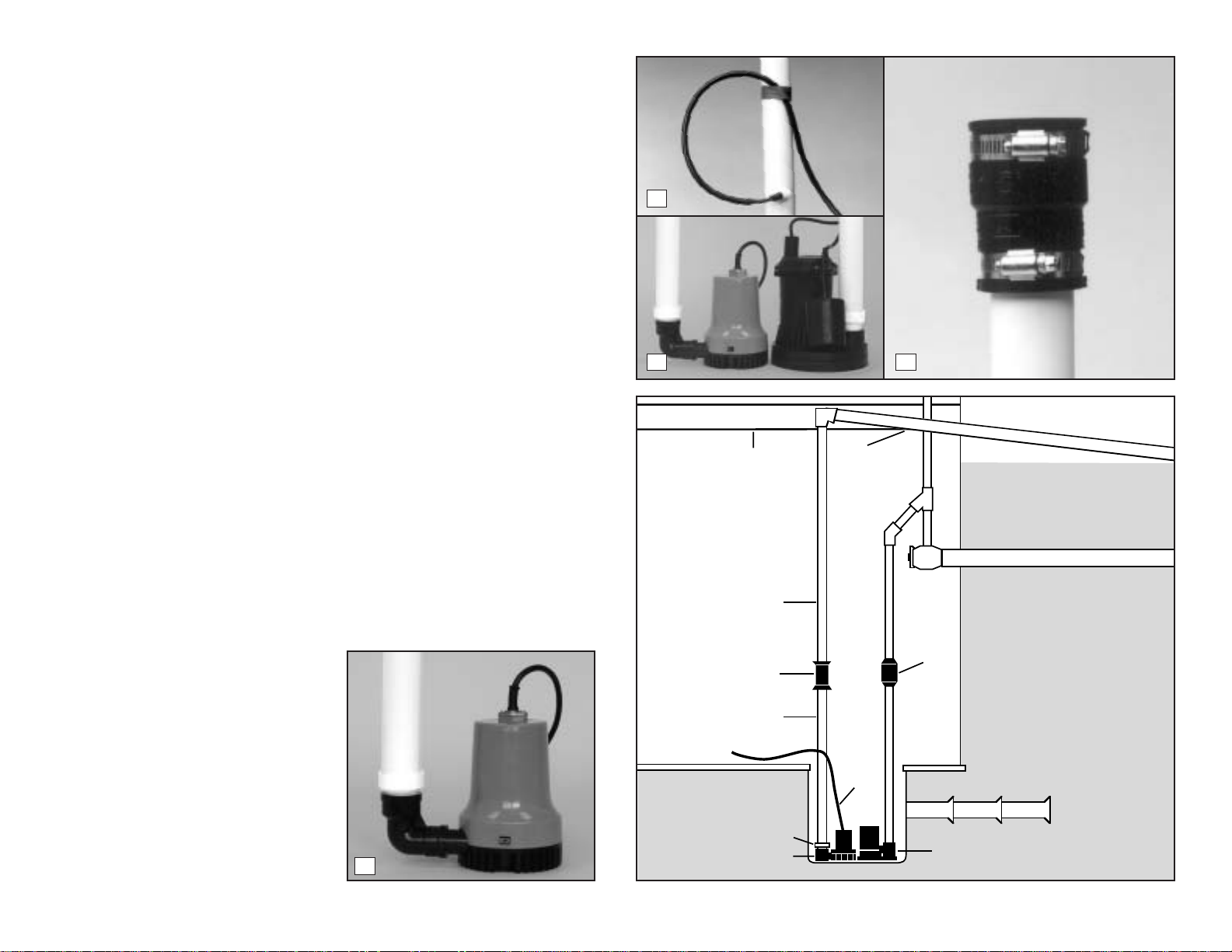

METHOD A: DIRECT DISCHARGE

TO THE OUTSIDE OF THE

BUILDING (Diagram A)

1. Cut a four-foot (4’) piece of 11/2"

rigid PVC pipe and cement it to the

threaded fitting that is attached to

the elbow on the pump.

2. Secure the pump wire so that the

plug on the end will not fall into the

sump. Attach the wire to the pipe

with a piece of tape.

3. Place the pump with the 4’ PVC

pipe attachment on the bottom of

the sump floor next to the main AC

pump.

Do not mount the pump to

any existing pipes...it should be

placed on the floor of the sump.

A

brick may be placed under the

pump if there are rocks or other

debris on the sump floor.

4. Attach a rubber union (sold separately) to the top of the 1

1

/2" pipe.

This will allow the pump to be

removed easily, should the need

arise.

The path of the rest of the pipe and the

details of each installation will vary.

Using sound plumbing practices, try to

route the discharge pipe to an exterior

wall via the shortest path with the fewest

turns. The pipe section exiting the

building should be on a downward slope

so that the water in the pipe will exit

outside rather than return to the sump.

Extend the discharge pipe outside the

building as far as possible to avoid the

return of discharged water to the sump.

Be sure to seal the hole in the wall where

the pipe exits and cement or clamp all

connections securely to prevent leaking.

No check valve is needed with this

method of installation, as long as you

use less than 20 feet of pipe.

Page 3

1

2

3 4

Diagram A

FLOOR

JOIST

RIGID

1-1/2"

PVC PIPE

RUBBER

UNION

RIGID

1-1/2"

PVC PIPE

PIPE ADAPTER

PRO SERIES PUMP

SLOPE

PIPE

DOWN

CHECK

VALVE

PUMP

WIRE

DRAIN TILE

MAIN AC PUMP

Loading...

Loading...