Pfeiffer Vacuum PASCAL Series, PASCAL 2010, PASCAL 2015, PASCAL 2021, PASCAL 2005 Maintenance Instructions Manual

MAINTENANCE INSTRUCTIONS

EN

Translation of the original instructions

PASCAL SERIES

Rotary vane pumps 5 to 21 m

3

/h

MAINTENANCE INSTRUCTIONS

Translation of the original instructions

PASCAL SERIES

Rotary vane pumps 5 to 21 m

3

/h

EN

Dear customer,

This Maintenance instructions is

intended for customers of the

Pfeiffer Vacuum Company.

It describes the product

maintenance operations which

can be performed by the user

on the product concerned.

This documentation must

be used together with the

operating manual for the

product of the same name.

Rotary vane pumps

Maintenance

Safety instructions for maintenance ............................................................ 3

Tools and consumable products .................................................................. 4

Replacement of external shaft seal.............................................................. 7

Disassembling the pump ............................................................................. 8

Cleaning components ................................................................................. 13

Replacement of shaft seals ......................................................................... 14

Reassembling the pump .............................................................................. 15

Service ....................................................................................................... 19

Nomenclature

Spare parts lists ............................................................................N - 1 à N - 23

EN – 1

MaintenanceNomenclature EN

MANUAL P/N: 103275M

EDITION: 04 - April 2017

Translated from original version

EN – 2

Indicates a potentially hazardous situation which, if not avoided, could result

in property damage.

Indicates a potentially hazardous situation which, if not avoided, could result

in moderate or minor injury. It may also be used to alert against unsafe

practices.

Indicates a potentially hazardous situation which, if not avoided, could result

in death or severe injury.

Indicates an imminently hazardous situation that, if not avoided, will result

in death or severe injury (extreme situations).

Before switching on the product, study operating instructions and make sure

you follow the safety instructions it gives. You can recognise these by the

‘Caution’, ‘Warning’ and ‘Danger’ symbols.

Good practice tips and manufacturer’s recommendations are in a grey box.

Safety instructions for maintenance

General precautions

For normal operation, the maintenance of 5 to 21 m3/h series pumps only require

regular oil changes (see Operating instructions).

Maintenance must be performed by a skilled maintenance operator trained

in the relevant health and safety aspects (EMC, electrical hazards, chemical

pollution, etc.).

Isolate the product from all energy sources (mains electricity, compressed air,

etc.) before starting work.

Certain gases can become corrosive and toxic after decomposing when

trapped in oil. Always wear protective gloves when handling used and

dirty pump oil, drain it into a closable container, and do not breathe the oil

fumes. Always use fully self-contained breathing apparatus.

During pump removal, draining or maintenance operator could be in

contact with process residues which could cause severe injury or death.

Ask your safety department for instructions according to the local

regulations.

We recommend:

- To purge the pumping installation with dry nitrogen.

- To wear gloves, protective glasses, breathing mask or any appropriated

safety equipment.

- To ventilate the premises well.

- Not to eliminate maintenance waste via standard disposal channels. Have

it destroyed by a qualified company if necessary.

- To install the inlet and exhaust blanking plates, these accessories are

delivered with the pump.

Decontamination – product dismantling

According to the regulations 2012/19/EU about Waste of electrical and

electronical equipments, and 2011/65/EU about Restriction of Hazardous

substances, the manufacturer provides a recycling paid service for the

end of-life of electrical and electronic equipment.

Any obligation of the manufacturer to take back such equipment shall

apply only to complete not amended or modified equipment, using Pfeiffer

Vacuum original spare parts, delivered by Pfeiffer Vacuum, containing i.e.

all its components and sub-assemblies.

This obligation will not cover the shipping cost to a Pfeiffer Vacuum taking

back facility.

Whenever you return the product to an repair service center, please

make sure you follow the Service procedure and fill in the declaration of

contamination found on our website.

ENMaintenance

Insufficient tightness after servicing could result in chemical hazards. Always

perform a leak test after maintenance.

EN – 3

Tools and consumable products

Special precautions

Spare parts

Seal kit This kit contains all the seals on the pump which must be replaced at each complete

Overhaul kit

Read the safety instructions at the beginning of the maintenance chapter.

Before disassembling the pump, drain it (see Operating instructions).

All the seals and faulty parts should be replaced: provide a seal kit or an

overhaul kit.

For fasted service, specify the following when ordering:

- Pump type.

- Serial number (on pump label).

- Part number (see list at end of operating instructions).

Overhaul kits containing the most frequently used parts are always available at our sales

outlets. Be sure to use these kits so you will have all the parts necessary.

disassembly.

Pumps 1005 1015 2005 2010 2015 2021

I – 105515 103912

SD / SDI 103911 105515 103911

C1 104975

C2 – 104975

Keep this kit in a dry place, away from heat and light (sunlight and ultraviolet light),

in order to prevent any hardening of the elastomers (see AFNOR standards: “storage

conditions for vulcanized elastomer based products” - FD T.46 022).

In addition to the seal kit, this kit contains a set of spare parts to perform overhaul on

the pump for a two year period, under normal operating conditions.

Pumps 1005 1015 2005 2010 2015 2021

I – 104643 103906 103907 103908 103909

SD / SDI * 104622 104643 103902 103903 103904 103905

C1 104617 104619 104976 104977 104978 104979

C2 – – 104614 104615 104616

* For SDI pump with no flanged stator, use a major kit P/N 108308.

The pumps are equipped with :

• a shouldered not chromed ring (36) for I, SD and SDI models with serial number

< AM656245

• a shouldered chromed ring (36) for I, SD and SDI models with serial number

≥ AM656245

• a shouldered chromed ring (36) for C1 and C2 models.

The shouldered not chromed ring is a spare part that must be replaced with a

chromed ring.

The shouldered chromed ring needn’t systematically to be changed.

EN – 4

Spare parts (cont’d)

Vane kits for 2-stage pumps This kit contains only vanes and springs in order to maintain several pumps of the same

model (see table here after).

Pumps 2005 2010 2015 2021

LP stage vane kit 108417 108396 108397 108398

Vane / Spring (quantity) 20 / 22 20 / 42 20 / 62 20 / 62

HP stage vane kit* 108417 108399 108399 108399

Vane / Spring (quantity) 20 / 22 20 / 22 20 / 22 20 / 22

* except models C1 and C2.

Pumps 2005 2010 2015 2021

Oil vane pump kit** 108407 (10 vanes)

** except models SD and C2.

External shaft seal replacement

kit (parts for shaft passage

tightness on motor side)

This kit contains all the parts which

must be replaced in the event of a leak

on the shaft on the motor side.

Pump models P/N

All pumps 065612

ENMaintenance

Screw kit

Capacitor kit for single-

phase motors

This kit contains all screws and

washers for the range of Pascal’s

pump.

For safety reasons, the manufacturer recommends that single-phase motors be properly

maintained. Although there is only an extremely small risk of flammability, you are

advised to replace the capacitors and/or the motor in the following cases:

Single-phase motor with ID number < 110000 :

• replace the motor immediately by ordering a new motor.

• then, every 5 years, replace the capacitors and the relays by ordering a kit.

Single-phase motor with ID number > 110000 :

• every 5 years, replace the capacitors and the relays by ordering a capacitor kit.

• after 15 years, replace the motor by ordering a new motor.

Single-phase motor

to maintain

ID

number

< 110000

103749 110944

103750 110913 108696

104734 110600 108697

105132 110946 108698

106442 110947 108699S

107876 110948 111701

ID

number

> 110000

111695

Capacitor/relay kit

P/N Description Ordering P/N

Capacitors (300μF, 2 0 μF) +

Capacitors (300μF, 2 5 μF) +

Pump models P/N

All pumps 104919

New equipped

motor

108694

relay

relay

108802S

The procedure for replacing capacitors and relays is provided with the capacitor kit.

EN – 5

Specific tools

Tools kit This kit contains the usefull tools to

Tools and consumable products

(cont’d)

disassemble and reassemble the shaft

seals in the different flanges and

flanged stators (see table bellow).

Pump models P/N

All pumps 112397

Lip seal assembly mandrel

Protective sleeve

Lip seal disassembly mandrel

Recommended tools

HP and LP no flanged

stator (plan D)

A462651 A462651 A462651

A463545 A463545 A463545

– – A462649

• Two 5.5 x 100 flat screwdrivers

• Thin spanner: 10 mm on face

• Male hexagonal wrench: 2.5 - 3 - 4 - 5 - 12 mm 5

• 12 mm female hexagonal wrench

HP flanged stator

(plan C)

LP flanged stator

(plan C)

EN – 6

Replacement of external shaft seal

In the event of an external oil leak on the pump, it is necessary to change the

external shaft seal on the motor side (see page N – 4).

You will need:

a front seal replacement kit (see page 5),

a screwdriver,

a 3, 4 and 5 mm Allen wrench,

a lip seal mandrel (see page 6).

Stop the pump and disconnect the power cord motor.

Disconnect the pump from the installation to which it is connected.

If possible, position the pump vertically, with the motor at the top, resting on the front

side of the oil case; in this position, it is not necessary to drain the oil case. Otherwise,

disassemble the pump in the horizontal position, resting it on its base, after it has been

drained (see Operating instructions).

Disconnect the motor by unscrewing the 4 fastening screws, simultaneously and

alternately.

Remove the motor vertically.

Unscrew the fan fastening screw. Remove

the fan, the key and the support washer.

With a screwdriver, remove the shouldered

ring (36) and its O-ring (35).

Unscrew the two seal-holder fastening

screws (37, 38) and remove the seal-holder

(39).

Remove the seal (40) from the seal-holder

as described on page 14 (picture 1) and

discard it.

Clean the metal parts. Inspect the wearing

side of the shaft sleeve: after cleaning, the

sleeve may show a perfectly normal trace

of rubbing (caused by polishing). Should

the sleeve show any signs of indentation or

grooves, it must be replaced.

Use new parts from the external shaft seal

replacement kit or from the overhaul kit.

Reassemble the lip seal (40) in its housing as

described on page 14.

Reinsert the new O-ring (41a) on the seal-holder (39).

Insert the shaft sleeve inside the shouldered ring (36).

Engage the reassembled seal-holder on its axis and screw onto the frame.

Insert the O-ring (35) in the shaft sleeve. Position the support washer. Then, install the

key, reassemble the fan and the motor in the reverse order of disassembly.

Immediately order an external shaft seal replacement kit or an overhaul kit (see

page 5).

35

37

36 39

40

41a

38

ENMaintenance

EN – 7

Disassembling the pump

Removing pump from

system

Disassembling

the motor block

cover

Study the general precautions listed on Maintenance chapter page 3.

The following steps are necessary to protect the pump as far as possible from the

effects of corrosion:

• Flush pump with a neutral gas (dry nitrogen) during half an hour to prevent toxic or

corrosive gases accumulating in the pump.

• C2 Model: Disconnect the nitrogen lines to the pump.

• Disconnect the pump from the system and seal off the inlet and exhaust ports. Bring

the pump to the maintenance area immediately.

• Drain pump (see Operating instructions).

Do not store a pump in this condition for any length of time: once the

neutral gas has dissipated, the inside of the oil case will be in contact with

the ambient air laden with water vapor; this may react with the pumped

gases to form acids that may corrode the pump even at room temperature.

The first phase of disassembly is to disassemble the motor, the second is to disassemble

the pumping module.

Follow the chronological order of disassembling instructions.

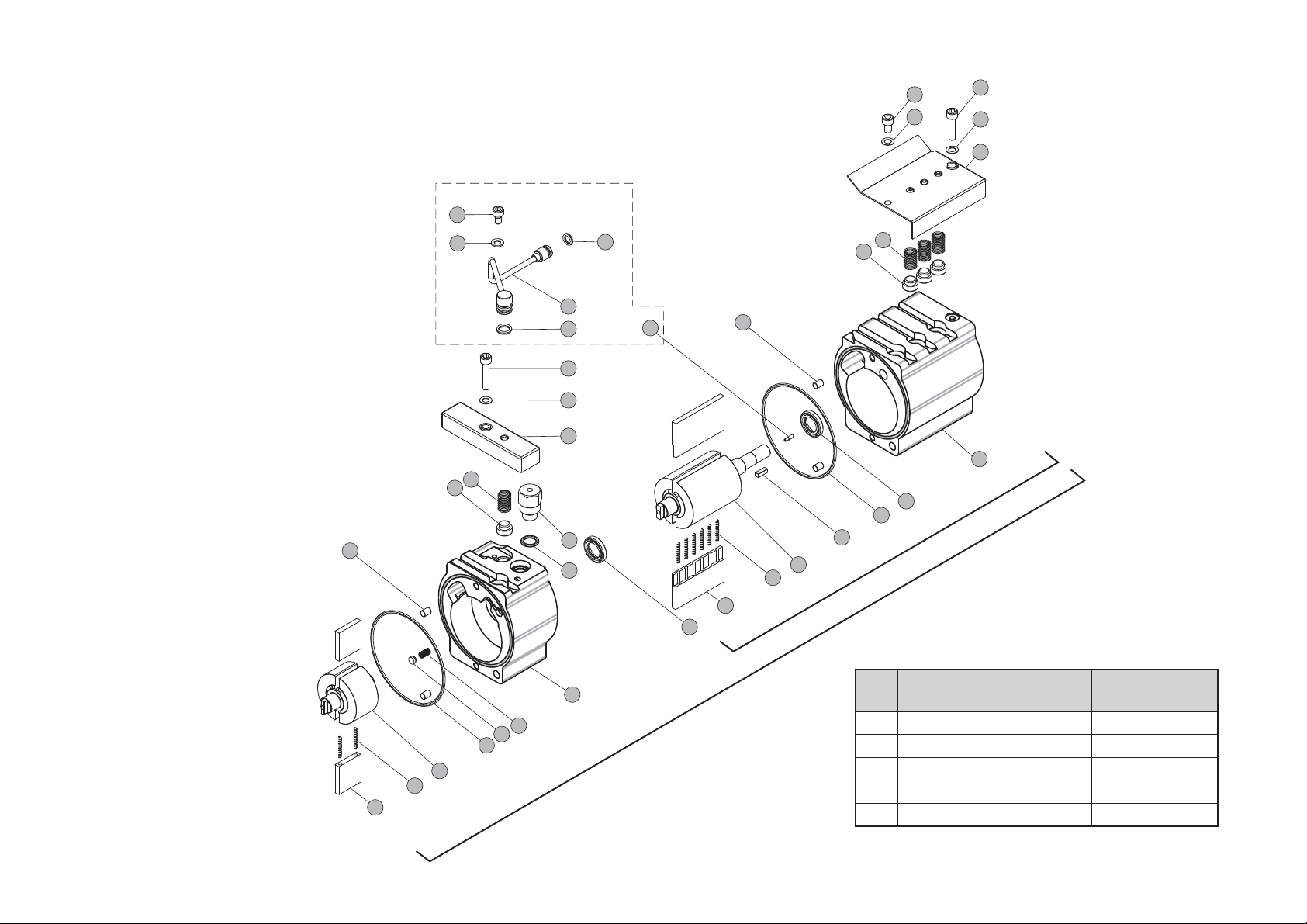

See the drawings and their part lists in pages N – 1 to N – 23.

Remove the motor cover.

5

Remove the motor attachment screws

(5) (see page N – 18).

3

1

If the motor is damaged, replace it (see

page N – 19).

EN – 8

5

Disassembling

the fan coupling

(see page N – 2)

Replacing

the front seal

Disassembling

the gas ballast

except model pump C2

(see page N – 2)

Remove the fan (33) fastening screw

(28) and the support washer (26).

Remove the key.

See page 7.

Remove the gas ballast cover (58)

(2 screws), the adjustment button (55),

the spring (54) and the sleeve (53).

Remove the tank feed-through (49)

(2 screws) and its seal (48).

6

28

33

55 58 54

49

48

53

Disassembling

the oil sight glass

(see page N – 2)

Remove the sight glass cover (3).

Remove the plate (1), the ring (4a), the

sight glass (4) and the O-ring (5).

1 4 4a

Removing

the oil case

(see page N – 2)

Disassembling the

bubbler (C2 pump)

(see page N – 20)

Disassembling the

exhaust valve cover

(see page N – 6)

5

Remove the oil case (6) and its

O-ring (11) after removing the 4 fastening

screws (9).

Disconnect the nitrogen inlet.

Remove the nitrogen inlet and disconnect

the coupling (2) without unscrewing the

connector (6).

Disconnect the nut (16) which secures the

tube on the functional block and pull the

bubble (8) to release it from the frame.

5

Remove the screws (4) (13) (15) and the

cover(s) (6) (17), the exhaust valves (2) (11)

and their springs (3) (12).

5

2 8

4 13

15

6 17

ENMaintenance

Disassembling the

sniffer pipe

(SDI model)

(see page N – 10)

5

Remove the screw (41) and its washer.

Insert a flat screwdriver near to the stator

connector, and use it as lever arm to

remove the sniffer pipe (38) from the stator.

Then, pull on the other end of the pipe to

remove it from the housing.

41

38

EN – 9

Disassembling the pump (cont’d)

Disassembling the

SD/SDI pump oil

system

(except 1015 SD)

(see page N – 16)

Disassembling

the pump oil system

I, C1, C2 pumps

and 1015 SD

see page N – 14)

(

The oil system is set in the factory,

it must be reset in the event of

disassembly (see reassembly). However, the

rear flange (4) can be disassembled without

modifying the setting.

Remove the spinner-cam (6) by removing the

circlip (7).

Do not disassemble the nozzle (8) to clean

it. During the reassembly, check that it is not

blocked by sending a jet of compressed air

through it.

5

Remove the cover from the oil pump (1).

Release the cylinder (13) equipped with the

washer (14), piston (11) and spring (12).

Release the stop valve (10) from its housing.

In the rear flange, unscrew the seat of

the stop valve (9) and remove the O-ring (8).

Then remove the vane (4), the oil pump

rotor (3) and the Oldham coupling (5).

4

8

6

7

1

7

Disassembling the

rear flange

(see pages N – 14 et N – 16)

8

14

1

13

10

Remove the 4 nuts. Release the flange (7) in the axis.

11

9

3

12

4

5

EN – 10

Disassembling the

pumping module

with flanged stator

(see N – 10)

2 stages models: steps 1 to 4

1 Insert two screwdrivers in the notches

and release the set HP stator (34) and

HP rotor (31) in the axis.

31

34

2 Release the HP rotor (31) from the HP

stator (34) and the vanes.

34 31

ENMaintenance

1 stage models: steps 3 to 4

3 Insert two screwdrivers in the notches

and release the set BP stator (26) and

BP rotor (23) in the axis.

26

4 Release the BP rotor (23) from the BP

stator (26) and the vanes.

232623

EN – 11

Disassembling the pump (cont’d)

Disassembling the

pumping module

with

no flanged stator

(see N – 6)

1 Remove the HP stator (34) by sliding it

along the HP rotor (31).

Remove the HP rotor and the vanes.

31

34

3 Insert two screwdrivers in the notches

and release the BP stator (26) by sliding

it along the BP rotor (23).

Remove the BP rotor and the vanes.

2 Insert two screwdrivers in the notches

and release the central plate (29) in the

axis.

29

4 Release the front plate (19).

23

26

Note : If one of the pumping module part with no flanged stator is damaged and

must be replaced, it is necessary to replace it by new parts from a flanged stator

configuration (refer to N - 21, N - 23 for spare part list).

19

EN – 12

Cleaning components

Cleaning metal

components

Cleaning the oil level

sight glass

I, SD, SDI, C2 series pumps

Solvents are required to clean components.

Standard precautions should be taken in compliance with the manufacturer's

instructions.

After use in mineral or synthetic oil, clean the metal components with a mineral

products based solvent such as AXAREL

NAPHTESOL

(4)

. Proceed as follows:

(1)

, CARECLEAN

(2)

, PREMACLEAN

(3)

,

• Clean when cold or hot (max. 45 °C) by dipping or using a cloth

• Vacuum dry in a ventilated oven

• The component must be cleaned a second time with alcohol.

After use in (perfluorinate) synthetic oil, clean the metal components in a solvent

such as GALDEN S 90™

(5)

and proceed as follows:

• Clean when cold by dipping or using a cloth

• Dry the components in the air or with compressed air

After use in (non-perfluorinate) synthetic or mineral oil, clean the metal

components with a solvent such as alcohol and proceed as follows:

• Clean when cold by dipping or using a cloth

• Dry the components in the air

• Industrial washing solutions can also be used. The cleaning operation should be

followed by vacuum drying.

When cleaning this plastic sight glass, avoid contact with alcohol or alcohol-based

washing solutions. Clean the component with a solvent, but do not steep it, and rinse

it immediately.

ENMaintenance

C1 series pumps

The sight glass of these pumps is made of glass: it can be cleaned with common used

solvents.

(1) DUPONT DE NEMOURS registered trademark

(2)

CASTROL registered trademark

(3)

DOW registered trademark

(4)

Nippon Oil Corporation registered trademark

(5)

MONTEDISON registered trademark

EN – 13

Replacement of shaft seals

Specific tools

Recommended tools

Extracting a shaft

seal from its housing

Assembling

the shaft seal

• Specific extraction tool.

• Specific assembly mandrel.

• A support plate (or washer).

• A flat screwdriver

.

• A hammer.

• Flange (picture 1): the seal is extracted

using a screwdriver, resting on the plate

(or washer) so as not to damage the seal

housing, or

• Flanged stator (picture 2): the seal is

extracted with the specific extraction tool.

The seal housing and the seal lip are

lubricated with the lubricant used in the

pump.

The flange is resting on a flat surface.

According to the direction of assembly,

the seal is fitted on the assembly mandrel.

Using a press or a hammer, the seal is

inserted in its housing.

Check the position of the seal: it must lean

against its bearing.

Picture 1

Picture 2

extraction tool

ø 14

washer

ø 24.5 ± 0.1

+0.2

0

105*

5.5 ± 0.2

+0.2

1

0

at 45°

Mandrel

Direction of assembly

of shaft seals

They are fitted using the assembly mandrel according to the direction of assembly

below:

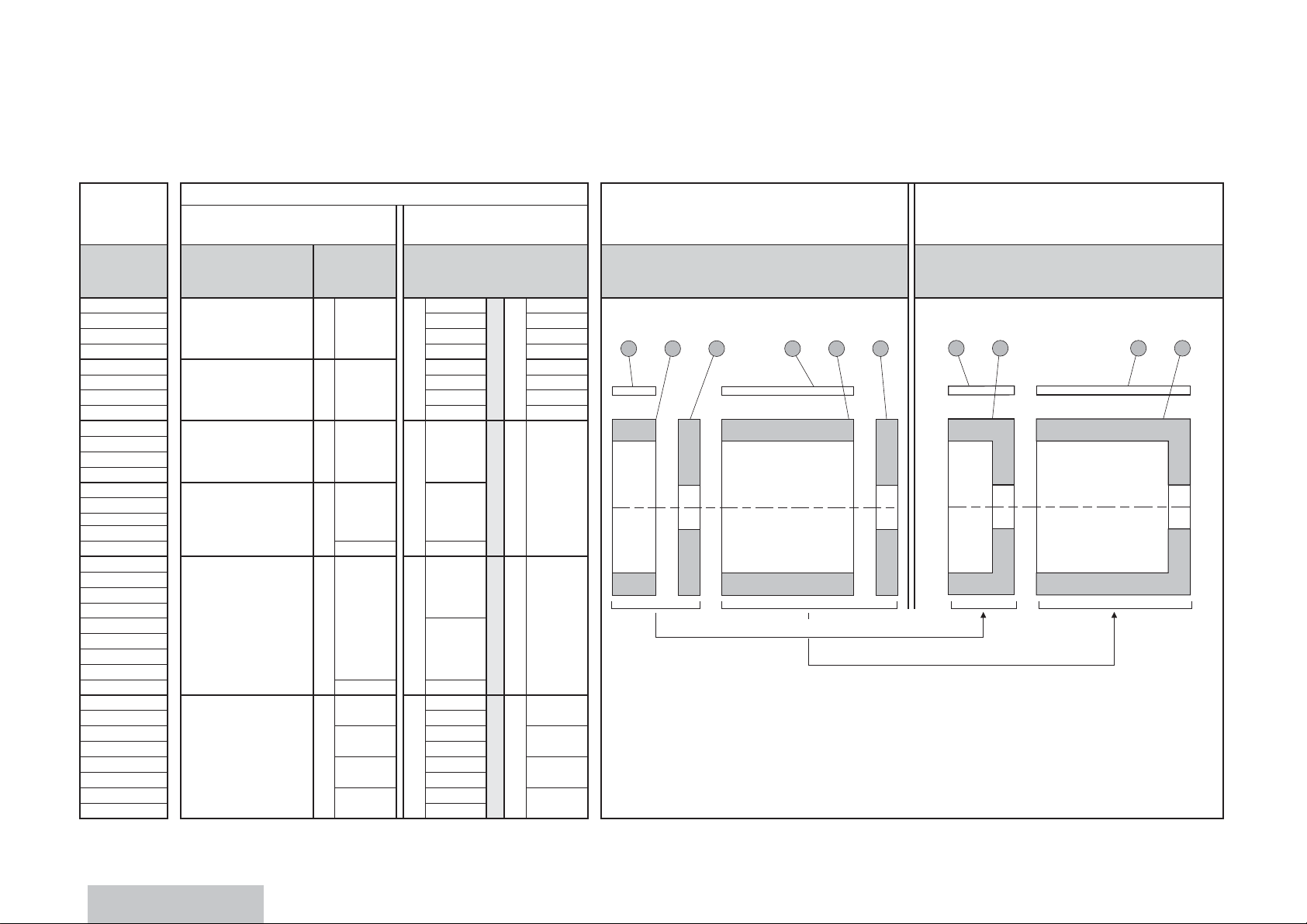

Assembly of pumping module with flanged stator

drawing (C)

frame

rear

fl ange

HP stator

HP rotor

LP stator

LP rotor

EN – 14

sealholder

Assembly of pumping module with no flanged stator

drawing (D)

rear

fl ange

HP stator

HP rotor

LP stator

LP rotor

median

fl ange

front

fl ange

frame

sealholder

* minimum dimension for the specific extraction tool.

Reassembling the pump

Component

preparation

Reassembling the

pumping module

with flanged stator

(see page N – 10)

2 stages models: steps 1 to à 6

• All surfaces in contact are coated with oil (rotors, vanes...).

• Check that the lubrication holes are not blocked.

• Observe the nominal clamping torques for the reassembly of the functional

block (see chapter “Nomenclature”).

• Rest the frame (42) on a flat surface in order to raise the pump.

1 Place the BP stator (26) on the

frame (42).

If there is no centering pin, align the

top of the stator with the exhaust

notch in the housing.

2 For not damage the shaft seal, use

protective sleeve on the rotor axis (or

wrap end of shaft with adhesive tape)

and oil it.

Sleeve

26

3 Slide the BP rotor (23) equipped with

its vanes and springs (rounded edges

facing outwards) in the BP stator (26).

Remove the protective sleeve.

4 Place the HP stator (34) on the BP

stator (26).

ENMaintenance

1 stage models:

steps 1, 2, 3 and 6

23

5 Slide the HP rotor (31) equipped with

its vanes and springs (rounded edges

facing outwards) in the HP stator (34).

31

34

26

6 Place the rear flange (7) on the HP

stator (34).

7

EN – 15

Reassembling the pump (cont’d)

Reassembling the

pumping module

with no flanged

stator

(see page N – 6)

1 Fit the front plate (19) on the

frame (42).

19

3

Place the BP Rotor (23) equipped with

its vanes and springs (rounded edges

facing outwards) on the front plate (19).

Remove the protective sleeve.

23

2 For not damage the shaft seal, use

protective sleeve on the rotor axis (or

wrap end of shaft with adhesive tape)

and oil it.

Sleeve

4 Slide the BP stator (26)

on the BP rotor (23).

26

5 Place the central plate (29) on the BP

stator (26).

29

7 Slide the HP stator (34) on the HP

rotor (31).

34

6

Place the HP rotor (31) equipped with its

vanes and springs (rounded edges facing

outwards) on the central plate (29).

31

8 Place the rear plate (7) on the HP

stator (31).

7

EN – 16

Reassembling

the oil system

Spinner-cam, SD and SDI pumps

(except 1015 SD)

(see page N – 16)

Spinner-cam settings

Oil pump, I, C1 and C2 pumps

(and 1015 SD)

(see page N – 14)

Oil pump settings

Check that the nozzle is not blocked by sending a jet of compressed air through it.

Place the spinner-cam system on the rear plate (4) and fix it with the clips (7).

Offset the spinner-cam (a) by pressing on the

blades.

Turn the shaft up to the maximum

displacement of the lever (b).

The distance between the seat (c) and the

stop valve (d) must be 0.9 to 1.2 mm (0.035

to 0.047 inch): it is set by adjusting the

orientation of the lever.

The stop valve face must be perpendicular to

the axis of the oil inlet hole; when free,the

stop valve should rest on its seat: check the parallelism of the lever in relation to the

bearing face of the stop valve seat. Orient the seat to obtain the correct setting.

In the rear plate (7), place the Oldham coupling (5), the vane (4) and the rotor (3).

Screw the seat (9) equipped with its O-ring (8). Place the piston (11) with its antisckback device (10), the spring (12), the cylinder (13) and the washer (14).

Position the rotor of the oil pump so that the slot is horizontal (or parallel with the

pump base). To turn it, use the fan.

a

b

c

d

ENMaintenance

Reassembling the

exhaust valve cover

(see page N – 6)

Reassembling the

bubble device

C2 pump (see page N – 20)

Reassembling

the oil casing

(see page N – 6)

Reassembling the oil

level sight glass

(see page N – 2)

Reassembling

the gas ballast

(see page N – 2)

Pump in a horizontal position, pour a small quantity of oil beforehand around the

exhaust valve holes.

Place the valves (2) or (11) equipped with the springs (3) or (12)

Place the valve covers (6) or (17) and fix them with screws and washers.

Insert the bubbler (8) equipped with its o-ring in the frame.

Position the tube fastener (9) on the pin and tighten the nut on the rear plate (7).

Insert the ball (4), the spring (5) in the coupling (2) and tighten it on the connector (6).

Fit the oil casing (6) equipped with its o-ring (11) on the frame (42).

Tighten it with screw (9) and washers (10) ( after making sure that the seal is positioned

in its seal groove).

Place the o-ring (5) in its groove and fit the sight glass (4), the flat ring (4a) (according

to the model), the oil sight glass cover (3) and tighten with screws (2). Comply with the

recommended tightening torque.

C1 series pump: The sight glass is made of glass: gradually tighten the two

attachment screws in alternation to avoid placing the sight glass under

stress.

Position the oil case feed-through (49) equipped with its o-ring (48) in its housing by

centering it on the gas ballast tube (46). Assemble using the screws (52).

Equip the adjustment knob (55) with the sleeve (53) and the spring (54). Position

the assembly in the cover (58) and secure on the oil case feed-through (49) with

screws (57).

EN – 17

Reassembling the pump (cont’d)

Reassembling

the seal-holder

(see page N – 2)

Reassembling the fan

and the motor side

components

(see page N – 2)

Fill with oil

Reassembling of the

pumping pipe

(model SDI)

(See page 7).

Fit the shaft key (22) (N – 10) on HP rotor.

Fit the coupling fan (33) and secure it with the screw (28) and washer (26).

Fit the drive key on the motor shaft. Install the motor coupling (3) (N – 18) down to

the stop on the motor shaft and secure it with the screw (2) (N – 18).

Install the plastic coupling (4) (N – 18) on the motor coupling (3) (N – 18).

Fit the motor on the frame and secure with the 4 mounting bolts (5) (N – 18).

After reassembling, fill the pump with oil before start-up the pump (see Operating

instructions).

Position one the end of the pipe (38) into the housing hole designed for this purpose

and the other end on the stator (34).

Do not forget to install o-rings (39) and (40) after having checked their status (no cuts).

EN – 18

Service

Pfeiffer Vacuum

offers first-class

customer service!

Overhaul and repair

in the Pfeiffer

Vacuum Service

Center

On-Site maintenance for many products

Overhaul / repair in the nearby Service Location

Fast replacement with refurbished exchange products in mint condition

Advice on the most cost-effi cient and quickest solution

Detailed information, addresses and forms at: www.pfeiffer-vacuum.com (Service).

The following general recommendations will ensure a fast, smooth servicing process:

Fill out the «Service Request/Product return» form and send it to your local Pfeiffer

Vacuum Service contact.

Include the confirmation on the service request from Pfeiffer Vacuum with your

shipment.

Fill out the declaration of contamination and include it in the shipment (mandatory!).

The Declaration of contamination is valid for any product/device including a part

exposed to vacuum.

Dismantle all accessories and keep them.

Close all the ports flange openings by using the original protective covers or metallic

airtight blank flanges for contaminated devices.

If possible, send pump or unit in its original packaging.

ENMaintenance

Sending of

contaminated pumps

or devices

Exchange or repaired

devices

Service orders

No devices will be accepted if they are contaminated with micro-biological, explosive

or radioactive substances. “Hazardous substances” are substances and compounds in

accordance with the hazardous goods regulations (current version).

Neutralize the pump by flushing it with nitrogen or dry air.

Close all openings airtight.

Seal the pump or device in suitable protective film.

Return the pump/device only in a suitable and sturdy transport container and send it

in while following applicable transport conditions.

Pump or device returned without declaration of contamination form fully

completed and/or non-secured in a suitable packaging, will be decontaminated

and/or returned at the shipper’s expense.

The factory operating parameters are always preset with exchange or repaired devices.

If you use specific parameters for your application, you have to set these again.

All service orders are carried out exclusively according to our general terms and

conditions for the repair and maintenance, available in our website.

EN – 19

Composants de maintenance / Maintenance components / Ersatzteilliste

Plan de montage cuve et bâti .............................................Oil casing and central housing assembly drawing .................... Gesamtplan Ölbehälter und Pumpenträger ..................................2 / 4

Nomenclature cuve et bâti ..................................................Oil casing and central housing part list ....................................Nomenklatur Ölbehälter und Pumpenträger ................................3 / 5

Plan du bloc fonctionnel (avec stator non flasqué) (D) .........Pumping module drawing (with no flanged stator) (D) ............Gesamtplan: Funktionsblock mit Stator und Flanschen (D) ...........6 / 8

Nomenclature du bloc fonctionnel ......................................Pumping module part list (with no flanged stator) (D) .............Nomenklatur: Funktionsblock mit Stator und Flanschen (D) .........7 / 9

(avec stator non flasqué) (D)

Plan du bloc fonctionnel (avec stator flasqué) (C) ................Pumping module drawing (with flanged stator) (C) .................Gesamtplan: Funktionsblock mit Stator-Monoblock (C) ...........10 / 12

Nomenclature du bloc fonctionnel ......................................Pumping module part list (with flanged stator) (C) ................... Nomenklatur: Funktionsblock mit Stator-Monoblock (C) ..........11 / 13

(avec stator flasqué) (C)

Plan du système de lubrification pompe à huile (A) .............Oil pump system drawing (A) ..................................................Gesamtplan (A) Ölpumpsystem ......................................................14

Nomenclature du système de lubrification .........................Oil pump system part list (A) .................................................... Nomenklatur (A) Ölpumpsystem .....................................................15

pompe à huile (A)

Plan du système de lubrification levier moulinet (B) .............Oil system drawing (B) .............................................................Gesamtplan (B) Flügenrad-Ölsystem ...............................................16

Nomenclature du système de lubrification .........................Oil system part list (B) .............................................................. Nomenklatur (B) Flügenrad-Ölsystem ..............................................17

levier moulinet (B)

Plan ensemble motorisation (M) ..........................................Motor assembly drawing (M) ...................................................Gesamtplan (M) Motor ...................................................................18

Nomenclature ensemble motorisation (M) ...........................Motor assembly part list (M) ....................................................Nomenklatur (M) Motor .................................................................19

Plan du système bulleur ......................................................Bubbler system drawing ..........................................................Gesamtplan Bubbler system ...........................................................20

Nomenclature du système bulleur .......................................Bubbler system part list ............................................................ Nomenklatur Bubbler system ..........................................................20

Remplacement des pièces du bloc fonctionnel non flasqué .....Pumping module (with no flanged stator) spare parts .............. Pumpenblock (mit Stator und Flanschen) Unterhaltung Teile ...........21

N – 1

Nomenclature

N – 2

Plan de montage cuve et bâti

Oil casing and central housing assembly drawing

Ölbehälter und Pumpenträger Gesamtplan

M

10

55

57

8a

54

53

11

38

26

37

28

33

34

35

36

1015I

43a

Rep. Part

2 Screw FHC M5 x 10 4.0

9 Screw CHC M6 x 25 9.5

14 / 20 Screw FHC M6 x 12 12.5

28 Screw M5 x 16 (s.steel) 7.0

38 Screw CHC M6 x 12 9.5

43c

43b

43

Clamping torque

(N·m)

19

18

41a

41

23

40

39

45

20

21

22

42

43

43a

44

17a

17

16

15

14

13

12

D

C

or

B

A

or

46

47

48

49

52

45 Screw CHC M6 x 25 9.5

52 / 57 Screw CHC M4 x 10 2.0

1015I

59a

9

8

7

6

3

5

4

4a

2

1

59

58

Nomenclature cuve et bâti / Oil casing and central housing part list / Ölbehälter und Pumpenträger Nomenklatur

REP DÉSIGNATION SPECIFICATION BENENNUNG

1 Plaque de niveau Level plate Ölmesstab 11111 11111111 106610S

1 Plaque de niveau Level plate Ölmesstab 111111 106609S

2 Vis FHC M5 x 10 Screw FHC M5 x 10 Schraube FHC M5 x 10 2222222222222222222

3 Cache de niveau (gris) Oil sight glass cover (grey) Ölschauglassdeckel (grau) 1111111 102849

3 Cache de niveau (blanc) Oil sight glass cover (white) Ölschauglassdeckel (weiss) 1111 1111111 102848

4 Voyant Oil level sight glass Ölschauglas 1111111111111111111

4a Joint de niveau Flat ring Flachdichtung 1111111111111111111

5 Joint torique c 3,53 - d 63,1 O-ring c 3.53-d 63.1 Dichtung c 1,9 - d 7,2 1111111111111111111

6 Cuve équipée Oil casing Ölbehälter 1 1 1 1 119509

6 Cuve équipée Oil casing Ölbehälter 1 1 1 1 119508

6 Cuve équipée Oil casing Ölbehälter 1 1 119507

6 Cuve équipée Oil casing Ölbehälter 1 1 119506

6 Cuve équipée Oil casing Ölbehälter 11119512

6 Cuve équipée Oil casing Ölbehälter 11119511

6 Cuve équipée Oil casing Ölbehälter 11119510

6 Cuve équipée Oil casing Ölbehälter 1 119513

7 Joint torique c 2,7 - d 16,9 - Bague R13 O-ring c 2.7 - d 16.9 - Ring R13 Dichtung c 2,7 - d 16,9 - Ring R13 3333333333333333333

8 Bouchon G 3/8 Plug G 3/8 Blindstopfen G 3/8 2/3 2/3 2/3 2/3 2/2 2/3 2/3 2/3 2/3 2/3 2/3 2/3

8 Bouchon G 3/8 Plug G 3/8 Blindstopfen G 3/8 2/3 2/3 2/3 2/3 2/3 2/3 2/3 052752

8a Rallonge Extension lead Verlängerung 1 A459031

9 Vis CHC M6 x 25 Screw CHC M6 x 25 Schraube CHC M6 x 25 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6 4/6

10 Rondelle Washer Unterlegscheibe 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8 4/8

11 Joint torique c 3-d 165 O-ring c 3 - d 165 Dichtung c 3 - d 165 1111111111111111111

12 Joint torique c 2,5-d 33,5 O-ring c 2.5 - d 33.5 Dichtung c 2,5 - d 33,5 1111111111111111111

13 Bouchon G 1/8 Plug G 1/8 Blindstopfen G 1/8 1111 103421

14 Vis FHC M6 x 12 Screw FHC M6 x 12 Schraube FHC M6 x 12 2/4 2/4 2/4 2/4 2/3 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4

15 Obturateur M 30x1 Stopper M 30 x 1 Deckel M 30 x 1 222222222222 065821

15 Obturateur M 30x1 Stopper M 30 x 1 Deckel M 30 x 1 2222222 065816

16 Joint torique c 3,6-d 29,3 O-ring c 3.6-d 29.3 Dichtung c 3,6 - d 29,3 2/4 2/4 2/4 2/4 2/3 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4

17 Filtre d’aspiration Inlet filter Ansaugfilter 111111111111 065787

17 Filtre d’aspiration Inlet filter Ansaugfilter 1111111 103395

17a Embout d’aspiration Inlet nipple Ansaugstutzen 1111 1111111 065819

17a Embout d’aspiration Inlet nipple Ansaugstutzen 1111111 065814

17a Embout d’aspiration Inlet nipple Ansaugstutzen 1 A466199

18 Soupape de refoulement Exhaust valve Auspuffventil 1111 1111111

19 Entretoise poignée Handle brace Griffsteg 2222222222222222222 102930

20 Idem 14 Idem 14 Ebenso 14 2/4 2/4 2/4 2/4 1/3 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4

21 Embout refoulement DN 25 Exhaust nipple DN 25 Auspuffstutzen DN 25 1111 1111111 065820

21 Embout refoulement DN 25 Exhaust nippleDN 25 Auspuffstutzen DN 25 1111111 065815

N – 3

22 Idem 16 Idem 16 Ebenso 16 2/4 2/4 2/4 2/4 1/3 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4

23 Poignée Handle Griff 1111111111111111111 103342

26 Rondelle Washer Unterlegscheibe 1111111111111111111 065107

28 Vis à collerette M5 x 16 Screw M5 x 16 Schraube M5 x 16 1111111111111111111

33 Manchon ventilateur Fan coupling Ventilator Kupplungshälfte 1111111111111111111 103386

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz Lot palettes / Vane kit / Schieberssatz Kit joint avant / Front seal kit / Vorderer Dichtungssatz

2005 I

2010 I

2015 I

2021 I

1015 I

2005 SD

Types/model

2010 SD

2005 SDI

2015 SD

2021 SD

1005 SD

1015 SD

2010 C2

2015 C2

2021 C2

2005 C1

2010 C1

2015 C1

REF.

P/N

Bestell. Nr

2021 C1

Nomenclature

N – 4

Plan de montage cuve et bâti

Oil casing and central housing assembly drawing

Ölbehälter und Pumpenträger Gesamtplan

M

10

55

57

8a

54

53

11

38

26

37

28

33

34

35

36

1015I

43a

Rep. Part

2 Screw FHC M5 x 10 4.0

9 Screw CHC M6 x 25 9.5

14 / 20 Screw FHC M6 x 12 12.5

28 Screw M5 x 16 (s.steel) 7.0

38 Screw CHC M6 x 12 9.5

43c

43b

43

Clamping torque

(N·m)

19

18

41a

41

23

40

39

45

20

21

22

42

43

43a

44

17a

17

16

15

14

13

12

D

C

or

B

A

or

46

47

48

49

52

45 Screw CHC M6 x 25 9.5

52 / 57 Screw CHC M4 x 10 2.0

1015I

59a

9

8

7

6

3

5

4

4a

2

1

59

58

Nomenclature cuve et bâti / Oil casing and central housing part list / Ölbehälter und Pumpenträger Nomenklatur

REP DÉSIGNATION SPECIFICATION BENENNUNG

34 Rondelle d’appui Washer Unterlegscheibe 1111111111111111111 065847

35 Joint torique c 2,7 - d 12,1 Bague R1O O-ring c 2.7 - d 12.1 - Ring R1O Dichtung c 2,7 - d 12,1 - Ring R1O 1111111111111111111

36 Bague épaulée Shouldered ring Abnutzungring 1111111111111111111

37 Idem 10 Idem 10 Ebenso 10 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

38 Vis CHC M6 x 12 Screw CHC M6 x 12 Schraube CHC M6 x 12 2222222222222222222

39 Porte joint Seal holder Lippendichtung-sockel 1111111111111111111 A333660

40 Joint à lèvre 15 x 25,5 x 4,6 FMP81 Shaft seal 15 x 25.5 x 4.6 FMP81 Lippendichtung 15 x 25,5 x 4,6 FMP81 1111111111111111111

41 Feutre Felt Filz 1111111111111111111

41a Joint torique c 3,6-d 34,1 O-ring c 3.6-d 34.1 Dichtung c 3,6 - d 34,1 1111111111111111111

42 Bâti équipé* Equipped central housing* Pumpenträger einrichtet* 11111 1 103384S

42 Bâti équipé* Equipped central housing* Pumpenträger einrichtet* 1 1111 103385S

42 Bâti équipé* Equipped central housing* Pumpenträger einrichtet* 1 105834S

42 Bâti équipé* Equipped central housing* Pumpenträger einrichtet* 1111111 105832S

43 Socle Base Fuss 1111 11111111111111 108712

43 Socle Base Fuss 1 107134S

43a Amortisseur Shock mount Schwingunsdämpferm 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 065790

43a Amortisseur Shock mount Schwingunsdämpferm 4/4 082691

43b Rondelle Washer Unterlegscheibe 4/4

43c Vis CHC M6 x 12 Screw CHC M6 x 12 Schraube CHC M6 x 12 4/4

44 Idem 10 Idem 10 Ebenso 10 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

45 Idem 9 Idem 9 Ebenso 9 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6 2/6

46 Tube lest d’air Gas ballast tube Gasballasttrohr 1111 11111 1111111 104631

46 Tube lest d’air Gas ballast tube Gasballasttrohr 1 065842

46 Tube lest d’air Gas ballast tube Gasballasttrohr 1 1 065839

47 Joint torique c 1,9 - d 5,7 Bague R5 O-ring c 1.9 - d 5.7 - Ring R5 Dichtung c 1,9 - d 5,7 - Ring R5 2222 22222222222222

48 Joint torique c 3 - d 28 O-ring c 3 - d 28 Dichtung c 3 - d 28 1111 11111111111111

49 Traversée de cuve Oil case feedthrough Ölbehälterdurchfuhrung 1111 102853

49 Traversée de cuve Oil case feedthrough Ölbehälterdurchfuhrung 11111111 102852

49 Traversée de cuve Oil case feedthrough Ölbehälterdurchfuhrung 1111111 100952

52 Vis M4 x 10 Screw M4 x 10 Schraube M4 x 10 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4

53 Manchon lest d’air Gas ballast sleeve Gasballastmuffe 1111111111111111111

54 Ressort lest d’air Gas ballast spring Gasballastfeder 1111 1111111 1111

55 Bouchon de manoeuvre Gas ballast knob Gasballastknopf 1111 1 1111 102846

55 Bouchon de manoeuvre Gas ballast knob Gasballastknopf 111111 102845

57 Idem 52 Idem 52 Ebenso 52 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4 2/4

58 Couvercle lest d’air Gas ballast cover Gasballastdeckel 1111 1111 107789

58 Couvercle lest d’air Gas ballast cover Gasballastdeckel 1111111 107790

58 Couvercle lest d’air Gas ballast cover Gasballastdeckel 111 107792

58 Couvercle lest d’air Gas ballast cover Gasballastdeckel 1 107793

59 Idem 8 Idem 8 Ebenso 8 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3

N – 5

59 Idem 8 Idem 8 Ebenso 8 1/3 1/3 1/3 1/3 1/3 1/3 1/3 052752

59a Raccord rapide Quick connect Schnellkupplung 1 107523

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz Lot palettes / Vane kit / Schieberssatz Kit joint avant / Front seal kit / Vorderer Dichtungssatz

* Pour les pompes utilisées dans les détecteurs (sauf pompe 1005I),

utiliser le bâti A006731S

* For pumps used in detectors (except 1005I pump), use A006731S housing * Für Pumpen, die in den Lecksuchgeräten verwendet werden

2005 I

2010 I

2015 I

2021 I

1015 I

2005 SD

Types/model

2010 C2

2015 C2

2021 C2

2005 C1

2010 SD

2015 SD

2021 SD

1005 SD

2005 SDI

(außer Pumpe 1005l), den Rahmen A006731S verwenden

1015 SD

2010 C1

Bestell. Nr

2015 C1

2021 C1

REF.

P/N

065823

Nomenclature

N – 6

Plan du bloc fonctionnel (avec stator non flasqué) (D)

Pumping module drawing (with no flanged stator) (D)

Gesamtplan: Funktionsblock mit Stator und Flanschen (D)

9

4

5

6

3

2

1

7

8

10

29

11

43

12

28

13

14

15

16

18

17

19

20

21

22

23

24

25

26

27

37

36

35

34

33

32

31

30

Rep. Part

Clamping torque

(N·m)

4 Screw CHC M6 x 30 (s.steel) 9.0

13 Screw CHC M6 x 10 (s.steel) 9.0

15 Screw CHC M6 x 25 (s.steel) 9.0

Nomenclature du bloc fonctionnel

(avec stator non flasqué) (D)

Pumping module list

(with no flanged stator) (D)

Nomenklatur: Funktionsblock mit

Stator und Flanschen (D)

REP DÉSIGNATION SPECIFICATION BENENNUNG

1 Goupille D6 LG8 Centering pin D6 LG8 Zentrierstift 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

2 Soupape Valve Auslassventil 1 1/3 1/4 1/4 1 1 1/3 1/4 1/4 1/3 1/4 1/4 1/2 1/3 1/4 1/4

3 Ressort de soupape Valve spring Ventilfeder 1 1/3 1/4 1/4 1 1 1/3 1/4 1/4 1/3 1/4 1/4 1/2 1/3 1/4 1/4

4 Vis CHC M6 x 30 Screw CHC M6 x 30 Schraube CHC M6 x 30 1 1 1 1111111 1111111

5 Rondelle Washer Unterlegscheibe 1 1/2 1/2 1/2 1 1 1/2 1/2 1/2 1/2 1/2 1/2 1 1/2 1/2 1/2

6 Capot de soupape HP Valve cover HP Ventilgehäusedeckel HD 1 1 1 1 1 111111111111 103521

6 Capot de soupape HP Valve cover HP Ventilgehäusedeckel HD 1 A328571

7 Idem 1 Idem 1 Ebenso 1 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

8 Joint torique c 2,7 - d 10,5 - Bague R9 O-ring c 2.7 - d 10.5 - Ring R9 Dichtung c 2,7 - d 10,5 - Ring R9 1 1 1 111111 1111111

9 Bouchon support capot Cover holder Gehäusedeckelhalter 1 1 1 111111 1111111 103544

10 Idem 1 Idem 1 Ebenso 1 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/2 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/4

11 Idem 2 Idem 2 Ebenso 2 2/3 3/4 3/4 2/3 3/4 3/4 1 3 2/3 3/4 3/4 1/2 2/3 3/4 3/4

12 Idem 3 Idem 3 Ebenso 3 2/3 3/4 3/4 2/3 3/4 3/4 1 3 2/3 3/4 3/4 1/2 2/3 3/4 3/4

13 Vis CHC M6 x 10 Screw CHC M6 x 10 Schraube CHC M6 x 10 1 1 1 11111111 111

14 Rondelle Washer Unterlegscheibe 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2

15 Vis CHC M6 x 25 Screw CHC M6 x 25 Schraube CHC M6 x 25 1 1 1 11122111 111

16 Rondelle Washer Unterlegscheibe 1/3 1/3 1/3 1/3 1/3 1/3 1/2 2/2 1/3 1/3 1/3 1/3 1/3 1/3

17 Capot de soupape BP Valve cover LP Ventilgehäusedeckel ND 1 1 1 1 103523

17 Capot de soupape BP Valve cover LP Ventilgehäusedeckel ND 1 1 1 1 103525

17 Capot de soupape BP Valve cover LP Ventilgehäusedeckel ND 1 1 1 1 103394

18 Idem 1 Idem 1 Ebenso 1 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/2 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/4

19 Flasque avant assemblé Equipped front plate Einrichtet vorderer Flansche 1 1 1 11111111 103401S

19 Flasque avant assemblé Equipped front plate Einrichtet vorderer Flansche 1111111 103396S

N – 7

Joint à lèvre

20

15 x 25,5 x 4,6

21 Joint torique c 2 - d 90 O-ring c 2 - d 90 Dichtung c 2 - d 90 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/2 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/4

Clavette Parallèle

22

A4 x 4 x 12

23 Rotor BP LP rotor Niederdruckrotor 1 1 1 065745S

23 Rotor BP LP rotor Niederdruckrotor 1 1 065749S

23 Rotor BP LP rotor Niederdruckrotor 1 1 065750S

23 Rotor BP LP rotor Niederdruckrotor 1 1 065751S

23 Rotor BP LP rotor Niederdruckrotor 1 103880S

23 Rotor BP LP rotor Niederdruckrotor 1 103569S

23 Rotor BP LP rotor Niederdruckrotor 11065801S

23 Rotor BP LP rotor Niederdruckrotor 11065802S

23 Rotor BP LP rotor Niederdruckrotor 11065803S

23 Rotor BP LP rotor Niederdruckrotor 1 065601S

24 Ressort de palette Vane spring Schieberfeder 2/4 4/6 6/8 6/8 2/4 2/4 4/6 6/8 6/8 2 6 4/6 6/8 6/8 2/4 4/6 6/8 6/8

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz Lot palettes / Vane kit / Schieberssatz Kit joint avant / Front seal kit / Vorderer Dichtungssatz

Shaft seal

15 x 25.5 x 4.6

Shaft key

A4 x 4 x 12

Lippendichtung

15 x 25,5 x 4,6

Nutenstein

A4 x 4 x 12

Types/model

2005 I

2010 I

2015 I

2021 I

2005 SD

1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1 1 1/2 1/2 1/2 1/2 1/2 1/2 1/2

111111111111111111

2010 SD

2005 SDI

2015 SD

2021 SD

1005 SD

2010 C2

1015 SD

2015 C2

2021 C2

2005 C1

2010 C1

2015 C1

REF.

P/N

Bestell. Nr

2021 C1

Nomenclature

N – 8

Plan du bloc fonctionnel (avec stator non flasqué) (D)

Pumping module drawing (with no flanged stator) (D)

Gesamtplan: Funktionsblock mit Stator und Flanschen (D)

9

4

5

6

3

2

1

7

8

10

29

11

43

12

28

13

14

15

16

18

17

19

20

21

22

23

24

25

26

27

37

36

35

34

33

32

31

30

Rep. Part

Clamping torque

(N·m)

4 Screw CHC M6 x 30 (s.steel) 9.0

13 Screw CHC M6 x 10 (s.steel) 9.0

15 Screw CHC M6 x 25 (s.steel) 9.0

Nomenclature du bloc fonctionnel

(avec stator non flasqué) (D)

Pumping module list

(with no flanged stator) (D)

Nomenklatur: Funktionsblock mit

Stator und Flanschen (D)

Types/model

REF.

REP DÉSIGNATION SPECIFICATION BENENNUNG

2005 I

2010 I

2015 I

2021 I

2005 SD

25 Palette BP LP vane Niederdruckschieber 222222222222222222

26 Stator BP LP stator Niederdruckstator 1 1 1 1 103507S

26 Stator BP LP stator Niederdruckstator 1 1 1 1 103512S

26 Stator BP LP stator Niederdruckstator 1 1 1 1 103510S

26 Stator BP LP stator Niederdruckstator 1 1 1 1 103393S

26 Stator BP LP stator Niederdruckstator 1 103409S

26 Stator BP LP stator Niederdruckstator 1 103882

27 Idem 20 Idem 20 Ebenso 20 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2

28 Idem 21 Idem 21 Ebenso 21 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/2 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/4

29 Flasque médian Central plate Zwischenflansche 11111 111 103408S

29 Flasque médian Central plate Zwischenflansche 1111111 103410S

29 Flasque médian Central plate Zwischenflansche 1 105639

30 Idem 21 Idem 21 Ebenso 21 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

31 Rotor HP HP rotor Hochdruckrotor 1 065853S

31 Rotor HP HP rotor Hochdruckrotor 1 1 1 1 065852S

31 Rotor HP HP rotor Hochdruckrotor 1111 103417S

31 Rotor HP HP rotor Hochdruckrotor 1111111 102854S

32 Idem 24 Idem 24 Ebenso 24 2/4 2/6 2/8 2/8 2/4 2/4 2/6 2/8 2/8 2/6 2/8 2/8 2/4 2/6 2/8 2/8

33 Palette HP HP vane Hochdruckschieber 222222222 2222222

34 Stator HP HP stator Hochdruckstator 1 065722S

34 Stator HP HP stator Hochdruckstator 11111 111 1111111 103409S

35 Ressort clapet anti-retour Spring of the antisuck-back Federrückschlagventil 111111111 1111111

36 Clapet anti-retour Antisuck-back device Rückschlagventil 111111111 1111111 065798

37 Idem 21 Idem 21 Ebenso 21 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

43 Gicleur Injector Düse 1 105091

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz Lot palettes / Vane kit / Schieberssatz Kit joint avant / Front seal kit / Dichtungssatz

2010 SD

2005 SDI

2015 SD

2021 SD

1005 SD

2010 C2

1015 SD

2015 C2

2021 C2

2005 C1

2010 C1

2015 C1

* sauf C2 / except C2 / ausgemomen C2

P/N

Bestell. Nr

2021 C1

*

N – 9

Nomenclature

N – 10

Plan du bloc fonctionnel (avec stator flasqué) (C)

Pumping module drawing (with flanged stator) (C)

Gesamtplan: Funktionsblock mit Stator-Monoblock (C)

SDI

41

42

3

2

1

13

14

39

38

25

10

24

M

odèl

23

es 1 ét

ge /

a

u

40

4

5

6

9

8

43

27

11

22

1 stage m

fige Modelle

12

28

20

odels /

Einstufige Mode

15

16

17

26

le

l

33

32

31

37

36

35

34

/ 2 stage models / Zweist

es

g

a

ét

s 2

e

l

dè

o

M

Rep. Part

4 Screw CHC M6 x 30 (s.steel) 9.0

Clamping torque

(N·m)

9 Straight fitting M/F 1/4 BSPP 18.0

13 Screw CHC M6 x 10 (s.steel) 9.0

15 Screw CHC M6 x 25 (s.steel) 9.0

41 Screw CHC M5 x 8 (s.steel) 7.0

Nomenclature du bloc fonctionnel

(avec stator flasqué) (C)

Pumping module list

(with flanged stator) (C)

Nomenklatur: Funktionsblock mit

Stator-Monoblock (C)

REP DÉSIGNATION SPECIFICATION BENENNUNG

1 Goupille D6 LG8 Centering pin D6 LG8 Zentrierstift 1/4 1/4 1/4 1/5 1/5 1/5 1/5 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/5 1/5

2 Soupape Valve Auslassventil 1 1/3 1/4 1/4 1 1 1/3 1/4 1/4 1/3 1/4 1/4 1/2 1/3 1/4 1/4

3 Ressort de soupape Valve spring Ventilfeder 1 1/3 1/4 1/4 1 1 1/3 1/4 1/4 1/3 1/4 1/4 1/2 1/3 1/4 1/4

4 Vis CHC M6 x 30 Screw CHC M6 x 30 Schraube CHC M6 x 30 1 1 1 1 111111 1111111

4 Vis CHC M6 x 10 Screw CHC M6 x 10 Schraube CHC M6 x 10

5 Rondelle Washer Unterlegscheibe 1 1/2 1/2 1/2 1 1 1/2 1/2 1/2 1/2 1/2 1/2 1 1/2 1/2 1/2

6 Capot de soupape HP Valve cover HP Ventilgehäusedeckel HD 1 1 1 1 111111 1111111 A332166

8 Joint torique c 2,7 - d 10,5 - Bague R9 O-ring c 2.7 - d 10.5 - Ring R9 Dichtung c 2,7 - d 10,5 - Ring R9 1 1 1 1 11111 1111111

9 Bouchon support capot Cover holder Gehäusedeckelhalter 1 1 1 1 11111 1111111 103544

10 Idem 1 Idem 1 Ebenso 1 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/2 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/4

11 Idem 2 Idem 2 Ebenso 2 2/3 3/4 3/4 3 2/3 3/4 3/4 1 3 2/3 3/4 3/4 1/2 2/3 3/4 3/4

12 Idem 3 Idem 3 Ebenso 3 2/3 3/4 3/4 3 2/3 3/4 3/4 1 3 2/3 3/4 3/4 1/2 2/3 3/4 3/4

13 Vis CHC M6 x 10 Screw CHC M6 x 10 Schraube CHC M6 x 10 1 1 1 11111111 111

14 Rondelle Washer Unterlegscheibe 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2

15 Vis CHC M6 x 25 Screw CHC M6 x 25 Schraube CHC M6 x 25 1 1 1 2 11122111 111

16 Rondelle Washer Unterlegscheibe 1/3 1/3 1/3 2/2 1/3 1/3 1/3 1/2 2/2 1/3 1/3 1/3 1/3 1/3 1/3

17 Capot de soupape BP Valve cover LP Ventilgehäusedeckel ND 1 1 1 1 A332176

17 Capot de soupape BP Valve cover LP Ventilgehäusedeckel ND 1 1 1 1 A332266

17 Capot de soupape BP Valve cover LP Ventilgehäusedeckel ND 1 1 1 1 A332175

17 Capot de soupape Valve cover Ventilgehäusedeckel 1 A332900

17 Capot de soupape Valve cover Ventilgehäusedeckel 1 A216503

20 Joint à lèvre 15 x 25,5 x 4,6 Shaft seal 15 x 25.5 x 4.6 Lippendichtung 15 x 25,5 x 4,6 1/2 1/2 1/2 1/2 1 1/2 1/2 1/2 1/2 1/2 1 1 1/2 1/2 1/2 1/2 1/2 1/2 1/2

22 Clavette Parallèle A4 x 4 x 12 Shaft key A4 x 4 x 12 Nutenstein A4 x 4 x 12 1 1 1 1 111111111111111

23 Rotor BP LP rotor Niederdruckrotor 1 1 1 065745S

23 Rotor BP LP rotor Niederdruckrotor 1 1 065749S

23 Rotor BP LP rotor Niederdruckrotor 1 1 065750S

23 Rotor BP LP rotor Niederdruckrotor 1 1 065751S

23 Rotor Rotor Rotor 1 103880S

23 Rotor Rotor Rotor 1 1 103569S

23 Rotor BP LP rotor Niederdruckrotor 11065801S

23 Rotor BP LP rotor Niederdruckrotor 11065802S

23 Rotor BP LP rotor Niederdruckrotor 11065803S

23 Rotor BP LP rotor Niederdruckrotor 1 065601S

24 Ressort de palette Vane spring Schieberfeder 2/4 4/6 6/8 6/8 6 2/4 2/4 4/6 6/8 6/8 2 6 4/6 6/8 6/8 2/4 4/6 6/8 6/8

25 Palette BP LP vane Niederdruckschieber 2 2 2 2 222222222222222

26 Stator BP LP stator Niederdruckstator 1 1 1 A006001S

26 Stator BP LP stator Niederdruckstator 1 1 A006000S

N – 11

26 Stator BP LP stator Niederdruckstator 1 1 A005999S

26 Stator BP LP stator Niederdruckstator 1 1 A005997S

26 Stator Stator Stator 1 A006465S

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz Lot palettes / Vane kit / Schieberssatz Kit joint avant / Front seal kit / Dichtungssatz

2005 I

2010 I

2015 I

2021 I

1015 I

2005 SD

Types/model

2010 SD

2005 SDI

2015 SD

2021 SD

1005 SD

1015 SD

2010 C2

2015 C2

2021 C2

2005 C1

2010 C1

2015 C1

REF.

P/N

Bestell. Nr

2021 C1

Nomenclature

N – 12

Plan du bloc fonctionnel (avec stator flasqué) (C)

Pumping module drawing (with flanged stator) (C)

Gesamtplan: Funktionsblock mit Stator-Monoblock (C)

SDI

41

42

3

2

1

13

14

39

38

25

10

24

M

odèl

23

es 1 ét

ge /

a

u

40

4

5

6

9

8

43

27

11

22

1 stage m

fige Modelle

12

28

20

odels /

Einstufige Mode

15

16

17

26

le

l

33

32

31

37

36

35

34

/ 2 stage models / Zweist

es

g

a

ét

s 2

e

l

dè

o

M

Rep. Part

4 Screw CHC M6 x 30 (s.steel) 9.0

Clamping torque

(N·m)

9 Straight fitting M/F 1/4 BSPP 18.0

13 Screw CHC M6 x 10 (s.steel) 9.0

15 Screw CHC M6 x 25 (s.steel) 9.0

41 Screw CHC M5 x 8 (s.steel) 7.0

Nomenclature du bloc fonctionnel

(avec stator flasqué) (C)

Pumping module list

(with flanged stator) (C)

Nomenklatur: Funktionsblock mit

Stator-Monoblock (C)

Types/model

REF.

REP DÉSIGNATION SPECIFICATION BENENNUNG

2005 I

2010 I

2015 I

2021 I

1015 I

2005 SD

26 Stator Stator Stator 1 1 A006466S

26 Stator BP LP stator Niederdruckstator 1 A006037S

26 Stator BP LP stator Niederdruckstator 11A006038S

26 Stator BP LP stator Niederdruckstator 11A006039S

26 Stator BP LP stator Niederdruckstator 11A006040S

27 Idem 20 Idem 20 Ebenso 20 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2

28 Joint torique c 2 - d 90 O-ring c 2 - d 90 Dichtung c 2 - d 90 1/2 1/2 1/2 1/2 1 1/2 1/2 1/2 1/2 1/2 1 1 1/2 1/2 1/2 1/2 1/2 1/2 1/2

31 Rotor HP HP rotor Hochdruckrotor 11111 065852S

31 Rotor HP HP rotor Hochdruckrotor 1 1 1 1 103417S

31 Rotor HP HP rotor Hochdruckrotor 1111111 102854S

32 Idem 24 Idem 24 Ebenso 24 2/4 2/6 2/8 2/8 2/4 2/4 2/6 2/8 2/8 2/6 2/8 2/8 2/4 2/6 2/8 2/8

33 Palette HP HP vane Hochdruckschieber 2 2 2 2 22222 2222222

34 Stator HP HP stator Hochdruckstator 1 1 1 1 1 1 1 1 A005996S

34 Stator HP HP stator Hochdruckstator 1111111 A006042S

34 Stator HP HP stator Hochdruckstator 1 A006496S

35 Ressort clapet anti-retour Spring of the antisuck-back Federrückschlagventil 1 1 1 1 111111111111111

36 Clapet anti-retour Antisuck-back device Rückschlagventil 1 1 1 1 111111111111111 065798

37 Idem 28 Idem 28 Ebenso 28 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

38 Tube pompage Sniffer pipe Gaseinlassleitung 1 065627

39 Joint torique c 1,9 - d 7,2 O-ring c 1,9 - d 7,2 Dichtung c 1,9 - d 7,2 1

40 Joint torique c 1,9 - d 8,9 O-ring c 1,9 - d 8,9 Dichtung c 1,9 - d 8,9 1

41 Vis CHC M5 x 8 Screw CHC M5 x 8 Schraube CHC M5 x 8 1

42 Rondelle M5 Washer M5 Unterlegscheibe M5 1

43 Gicleur Injector Düse 1 105091

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz Lot palettes / Vane kit / Schieberssatz Kit joint avant / Front seal kit / Dichtungssatz

2010 SD

2005 SDI

2015 SD

2021 SD

1005 SD

2010 C2

1015 SD

2015 C2

2021 C2

2005 C1

2010 C1

2015 C1

P/N

Bestell. Nr

2021 C1

N – 13

Nomenclature

N – 14

Plan du système de lubrification pompe à huile (A)

Oil pump system drawing (A)

Ölpumpsystem Gesamtplan (A)

1015I

22

21

20

5

4

3

2

1

8

9

10

11

12

13

14

15

16

C

6

7

19

17

Rep. Part

Clamping torque

(N·m)

16 / 22 Screw CHC M6 x 16 (s.steel) 9.0

17 Pin (s.steel) 14.0

19 Nut HM6 (s.steel) 9.5

Nomenclature du système de lubrification pompe à huile / Oil pump system part list / Ölpumpsystem Nomenklatur

Types/model

REF.

REP DÉSIGNATION SPECIFICATION BENENNUNG

2005 I

2010 I

2015 I

2021 I

1015 I

1 Couvercle pompe à huile Oil pump cover Ölpumpendeckel 1 1 1 1 1 1 1 1 1 1 1 1 1 103416

2 Tube entrée d’air Air admission tube Lufteinlass 1 1 1 1 1 1 1 1 1 1 1 1 1 104334

3 Rotor pompe à huile Oil pump rotor Ölpumpenrotor 1 1 1 1 1 1 1 1 1 1 1 1 1 103412

4 Palette pompe à huile Oil pump vane Ölpumpenschieber 1 1 1 1 1 1 1 1 1 1 1 1 1

5 Joint de oldham Oldham coupling Oldham-Kupplung 1 1 1 1 1 1 1 1 1 1 1 1 1 103413

6 Joint à lèvre 15 x 25,5 x 4,6 Shaft seal 15 x 25.5 x 4.6 Lippendichtung 15 x 25,5 x 4,6 1 1 1 1 1 1 1 1 1 1 1 1 1

7 Flasque arrière Rear plate Hintererflansche 1 1 1 1 103411S

7 Flasque arrière Rear plate Hintererflansche 1 1 1 1 1 1 1 1 1 103398S

8 Joint torique c 1,5 - d 7,5 O-ring c 1.5 - d 7.5 Dichtung c 1,5 - d 7,5 1 1 1 1 1 1 1 1 1 1 1 1 1

9 Siège Seat Sitz 1 1 1 1 1 1 1 1 1 1 1 1 1 103389

10 Clapet anti-retour Antisuck-back device Rückschlagventil 1 1 1 1 1 1 1 1 1 1 1 1 1

11 Piston anti-retour Antisuck-back piston Kolber 1 1 1 1 1 1 1 1 1 1 1 1 1 102962

12 Ressort d’étanchéité Spring Feder 1 1 1 1 1 1 1 1 1 1 1 1 1

13 Cylindre anti-retour Oil pump antisuck-back cylinder Rückschlagzylinder 1 1 1 1 1 1 1 1 1 1 1 1 1 102963

14 Rondelle élastique Spring washer Scheibe 1 1 1 1 1 1 1 1 1 1 1 1 1

15 Rondelle Washer Unterlegscheibe 2 2 2 2 2 2 2 2 2 2 2 2 2

16 Vis CHC M6 x 16 Screw CHC M6 x 16 Schraube CHC M6 x 16 2 2 2 2 2 2 2 2 2 2 2 2 2

17 Goujon M6-106 / 12 Pin M6-106 / 12 Stift M6-106 / 12 4 4 103524

17 Goujon M6-129 / 19 Pin M6-129 / 19 Stift M6-129 / 19 4 4 102855

17 Goujon M6-142 / 12 Pin M6-142 / 12 Stift M6-142 / 12 4 4 4 065806

17 Goujon M6-164 / 12 Pin M6-164 / 12 Stift M6-164 / 12 4 4 4 065805

17 Goujon M6-187 / 12 Pin M6-187 / 12 Stift M6-187 / 12 4 4 4 065804

19 Ecrou à embase HM6 Shoudered nut HM6 Schraubenmutter HM6 4 4 4 4 4 4 4 4 4 4 4 4 4

20 Tole pare-eclat Oil protective cover Ölgehäusedeckel 1 1 104633

21 Rondelle Washer Unterlegscheibe 1 1 –

22 Vis CHC M6 x 10 Screw CHC M6 x 10 Schraube CHC M6 x 10 1 1 –

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz Lot palettes pompe à huile / Oil vane pump kit / Ölpumpenschieberssatz

2010 C2

1015 SD

2015 C2

2021 C2

2005 C1

2010 C1

2015 C1

P/N

Bestell. Nr

2021 C1

N – 15

Sous-ensemble A / Subassembly A / Gesamtplan A

Nomenclature

N – 16

Plan du système de lubrification levier moulinet (B)

Oil system drawing (B)

Flügenrad-Ölsystem Gesamtplan (B)

1

C

5

4

3

2

16

14

13

12

11

10

6

7

8

9

Rep. Part

Clamping torque

(N·m)

1 Screw CHC M6 x 16 (s.steel) 9.0

13 Screw CHC M6 x 10 (s.steel) 9.0

14 Pin (s.steel) 14.0

16 Nut (s.steel) 9.5

Nomenclature du système de lubrification levier moulinet / Oilsystem part list / Flügenrad-Ölsystem Nomenklatur

Types/model

REF.

REP DÉSIGNATION SPECIFICATION BENENNUNG

2005 SD

1 Vis CHC M6 x 16 Screw CHC M6 x 16 Schraube CHC M6 x 16 2 2 2 2 2 2

2 Rondelle Washer Unterlegscheibe 2/3 2/3 2/3 2/3 2/3 2/3

3 Levier oscillant Equipped lever Hebel 1 1 1 1 1 1

4 Flasque arrière Rear plate Hintererflansche 1 1 1 1 1 1 103485S

5 Joint à lèvre 15 x 25,5 x 4,6 Shaft seal 15 x 25.5 x 4.6 Lippendichtung 15 x 25,5 x 4,6 1 1 1 1 1 1

6 Came moulinet Impeller Flügenrad 1 1 1 1 1 1 052721

7 Bague d’arrêt Clips Sprengring 1 1 1 1 1 1

8 Rondelle Washer Unterlegscheibe 1 1 1 1 052758

8 Gicleur Jet Düse 1 102910

8 Gicleur Jet Düse 1 103314

9 Joint torique c 1,9 - d 5,7 - Bague R5 O-ring c 1.9 - d 5.7 - Ring R5 Dichtung c 1,9 - d 5,7 - Ring R5 1 1 1 1 1 1

10 Siège de clapet Seat Ventilsitz 1 1 1 1 1 1 052718

11 Bride Flange Klammer 1 1 1 1 1 1 052569

12 Idem 2 Idem 2 Ebenso 2 1/3 1/3 1/3 1/3 1/3 1/3

13 Vis CHC M6 x 10 Screw CHC M6 x 10 Schraube CHC M6 x 10 1 1 1 1 1 1

14 Goujon M6-129 / 19 Pin M6-129 / 19 Stift M6-129 / 19 4 4 102855

14 Goujon M6-142 / 12 Pin M6-142 / 12 Stift M6-142 / 12 4 065806

14 Goujon M6-164 / 12 Pin M6-164 / 12 Stift M6-164 / 12 4 065805

14 Goujon M6-187 / 12 Pin M6-187 / 12 Stift M6-187 / 12 4 065804

14 Goujon M6-72 / 19 Pin M6-72 / 19 Stift M6-72 / 19 4 065636

14 Goujon M6-84 / 12 Pin M6-84 / 12 Stift M6-84 / 12 103524

16 Ecrou à embase HM6 Shoudered nut HM6 Schraubenmutter HM6 4 4 4 4 4 4

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz

2010 SD

2005 SDI

2015 SD

2021 SD

P/N

Bestell. Nr

1005 SD

N – 17

Sous-ensemble B / Subassembly B / Gesamtplan B

Nomenclature

N – 18

Plan ensemble motorisation (M)

Motor assembly drawing (M)

Motor Gesamtplan (M)

1

1a

5

2

3

4

Rep. Part

5 Screw CHc M6 x 40 (s.steel) 9.5

2 Screw Hc M6 x 8.8 (s.steel) 2.5

Clamping torque

(N·m)

Nomenclature ensemble motorisation (M) / Motor assembly part list (M) / Motor Gesamtheit Nomenklatur (M)

MOTEUR UNIVERSEL / UNIVERSAL MOTOR / UNIVERSELLE MOTOR

REF.

REP DÉSIGNATION SPECIFICATION BENENNUNG Qty

1 Moteur monophasé standard avec interrupteur* Single phase motor with on/off switch* Wechselstrommotor* mit Schalter 1 108694

1 Moteur monophasé sans interrupteur* Single phase motor without switch* Wechselstrommotor* ohne Schalter* 1 108698

1 Moteur triphasé standard Three-phase motor Drehstrommotor 1 108695

1 Moteur monophasé Japon,basse tension, avec interrupteur* Japanese single phase motor, LV, with on/off switch* Niederspannung-Japan-Wechselstrommotor* mit Schalter 1 108802S

Kit d’adaptation pour moteur bride CEI

1a

(bride CEI + vis + 1/2 manchon + intercalaire)

2 Vis Hc M6 x 8,8 Screw Hc M6 x 8.8 Schraube Hc M6 x 8,8 1

3 1/2 Manchon moteur Motor side coupling Kupplungshälfte 1 065742

4 Intercalaire Plastic coupling Kupplungstern 1

5 Vis CHc M6 x 40 Screw CHc M6 x 40 Schraube CHc M6 x 40 4

* Moteur livré sans câble mais équipé avec 2+3+4 * Delivered without cable but equipped with 2+3+4 * ohne Netzkabel aber mit 2+3+4 einrichtet

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz

CEI flange motor coupling kit (CEI flange + screw +motor side

coupling+ plastic coupling)

CEI Klammer Motorflanschssatz (Klammer Motorflanschssatz +

Schraube +Kupplugshälfte + Küpplungsstern)

1 104558S

P/N

Bestell. Nr

CÂBLE ÉLECTRIQUE POUR MOTEUR MONOPHASÉ / ELECTRICAL CABLE FOR SINGLE PHASE MOTOR / NETZKABEL FÜR WECHSELSTROMMOTOR (L = 2M)

DÉSIGNATION SPECIFICATION BENENNUNG

USA (Basse tension) USA (Low voltage) Netzkabel (Niederspannung) (USA) 103567

USA (Haute tension) USA (High voltage) Netzkabel (Hochspannung) (USA) 103898

EUROPE EUROPE Netzkabel (EUROPA) 103566

JAPON (Basse tension) JAPAN (Basse tension) Netzkabel (Niederspannung) (JAPAN) 103567

JAPON (Haute tension) JAPAN (Haute tension) Netzkabel (Hochspannung) (JAPAN) 104559

ROYAUME UNI UNITED KINGDOM Netzkabel (GB) 104411

SUISSE (Coudé) SWITZERLAND (elbow) Netzkabel (SCHWEIZ) A459212

N – 19

Nomenclature

REF.

P/N

Bestell. Nr

N – 20

Plan du système bulleur

Bubbler system drawing

Bubbler system Gesamtplan

1

3

2

4

5

6

7

C

or

BA

8

9

Nomenclature du système bulleur / Bubbler system part list / Bubbler system Nomenklatur

Types/model

REP DÉSIGNATION SPECIFICATION BENENNUNG

2010 C2

2015 C2

1 Bouchon 1/8 NPT Plug 1/8 NPT Blindstopfen 1/8 NPT 1 1 1 082926

2 Manchon Coupling Kupplung 1 1 1 065866

3 Ruban teflon Teflon band Teflon band 1 1 1 060975

4 Bille inox 18/8 d. 5,8 Ball 18/8 d. 5.8 Kugel 18/8 d, 5,8 1 1 1 087593

5 Ressort Spring Feder 1 1 1 065149

6 Raccord G 1/8 -1/8 NPT Connector G 1/8 -1/8 NPT Verbindungselement 1 1 1 065867

7 Joint torique c 1,9 - d 7,2 O-ring c 1.9 - d 7.2 Dichtung c 1,9 - d 7,2 1 1 1

8 Bulleur Bubbler Bubler 1 1 065836

8 Bulleur Bubbler Bubler 1 065835

9 Attache tube Tube fastener Rohrbefestigung 1 1 1 065835

Lot de joints / Seal kit / Dichtungssatz Kit de révision / Overhaul kit / Revision kit Lot visserie / Screw kit / Schraubensatz

Bestell. Nr

2021 C2

REF.

P/N

Remplacement des pièces du bloc fonctionnel non flasqué

Pumping module (with no flanged stator) spare parts

Pumpenblock (mit Stator und Flanschen) Unterhaltung Teile

Modèles 2 étages / 2 stage models / Zweistufige Modelle

Modèle

Model

Modele

2005 C1 Flasque avant (C)

2010 C1 / C2 Front plate A006038S A332176

2015 C1 / C2 Einrichtet vorderer Flansche A006039S A332266

2021 C1 / C2 A006040S A332175

2005 I / SD / SDI Flasque avant (standard)

2010 I / SD Front plate A006000S A332176

2015 I / SD Einrichtet vorderer Flansche A005999S A332266

2021 I / SD A005997S A332175

2005 C1 Flasque médian (C)

2010 C1 / C2 Central plate

2015 C1 / C2 Zwischenflansche

2021 C1 / C2

2005 I / SD Flasque médian (standard)

2010 I / SD Central plate

2015 I / SD Zwischenflansche

2021 I / SD

2005 SDI * 105639 A006496S

2005 C1 Stator HP

2010 C1 / C2 HP stator

2015 C1 / C2 Hochdruckstator

2021 C1 / C2

2005 I / SD

2010 I / SD

2015 I / SD

2021 I / SD

2005 SDI * 065722S A006496S

2005 I / SD / SDI Stator BP

2005 C1 LP stator A006037S

2010 I / SD Niederdruckstator

2010 C1 / C2 A006038S

2015 I / SD

2015 C1 / C2 A006039S

N – 21

2021 I / SD

2021 C1 / C2 A006040S

Bloc fonctionnel / Pumping module / Pumpenblock

non flasqué / no flanged

mit Stator und Flanschen

Pièce à remplacer

Part to be replaced

Zu ersetzender Teil

Référence

Bestell. Nr

19 103396S

19 103401S

29 103410S

29

34

26

P/N

103408S A005996S

103409S

103507S

103512S

103510S

103393S

flasqué / flanged

mit Stator-Monoblock

Référence

Bestell. Nr

A006037S

26

A006001S -

A006042S

34

A006042S

34

A005996S

A006001S

A006000S

26

A005999S

A005997S

P/N

+17

+6 A332166

+6 A332166

A332176

+17

A332266

A332175

non flasqué / no flanged

mit Stator und Flanschen

-

6 34 29 17 26 19

Etage HP

HP stage

HD

-

Etage BP

LP stage

ND

A remplacer par / to be replaced by / zu ersetzender Teil

A remplacer par / to be replaced by / zu ersetzender Teil

Rep.

6 Capot de soupape HP / Valve cover HP / Ventilgehäusedeckel HD

34 Stator HP / HP stator / Hochdruckstator

29 Flasque médian / Central plate / Zwischenflansche

17 Capot de soupape BP / Valve cover LP / Ventilgehäusedeckel ND

26 Stator BP / LP stator / Niederdruckstator

19 Flasque avant / Front plate / Einrichtet vorderer Flansche

6 34 17 26

Etage HP

HP stage

HD

flasqué / flanged

mit Stator-Monoblock

Etage BP

LP stage

ND

* Dans ce cas, changer également le rotor HP (31) (voir nomenclature du bloc fonctionnel avec stator flasqué (C) (page N-13)) et utiliser le kit de révision SDI (voir page 47).

* In this case, replace also HP rotor (31) (refer to pumping module with flanged stator (C) (page N-13)) and use a SDI Overhaul kit (see page 47).

* In diesem Fall ebenfalls den Hochdruckrotor (31) auswechseln (siehe Nomenklatur des Funktionsblocks mit geflanschtem Stator (siehe Seite N - 13)) und SDI-Revision kit verwenden (siehe Seite 47).

Nomenclature

N – 22

Remplacement des pièces du bloc fonctionnel non flasqué

Pumping module (with no flanged stator) spare parts

Pumpenblock (mit Stator und Flanschen) Unterhaltung Teile

Modèles 2 étages / 2 stage models / Zweistufige Modelle

Modèle

Model

Modele

2005 C1 Capot de soupape HP

2010 C1 / C2 Valve cover HP

2015 C1 / C2 Ventilgehäusedeckel HD

2021 C1 / C2

2005 I / SD

2010 I / SD

2015 I / SD

2021 I / SD

2005 SDI* A006496S

2005 I / SD / SDI Capot de soupape BP

2005 C1 Valve cover LP A006037S

2010 I / SD Ventilgehäusedeckel ND

2010 C1 / C2 A006038S

2015 I / SD

2015 C1 / C2 A006039S

2021 I / SD

2021 C1 / C2 A006040S

* Dans ce cas, changer également le rotor HP (31) (voir nomenclature du bloc fonctionnel

avec stator flasqué (C) (page N-13)) et utiliser le lot de maintenance SDI (voir page 47).

* In this case, replace also HP rotor (31) (refer to pumping module with flanged stator (C)

(page N-13)) and use a SDI Overhaul kit (see page 47).