OPERATING INSTRUCTIONS

OME 40 M/MR, OME 40 C/CR

Oil Mist Eliminator

EN

Translation of the original instructions

PD 0053 BEN/D (1701)

Table of contents

Table of contents

1 About this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Transport and storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Product description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10 Technical data and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

12 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.1 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Improper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Product identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Installing the operating fluid return line . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Installing the operating fluid return line . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.4 Installing the saturation indicator optically/electrical (option) . . . . . . . . . . 12

7.1 Draining the operating fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.2 Changing the filter element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.3 Cleaning the operating fluid return line . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

10.1 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11.1 Spare parts packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2

About this manual

1 About this manual

1.1 Validity

This operating manual is for customers of Pfeiffer Vacuum. It describes the functioning

of the designated product and provides the most important information for safe use of

the unit. The description follows applicable EU guidelines. All information provided in this

operating manual refers to the current state of the product's development. The documentation remains valid as long as the customer does not make any changes to the product.

Up-to-date operating instructions can also be downloaded from

www.pfeiffer-vacuum.com.

1.2 Conventions

Safety instructions The safety instructions in Pfeiffer Vacuum operating instructions are the result of risk

evaluations and hazard analyses and are oriented on international certification standards as specified by UL, CSA, ANSI Z-535, SEMI S1, ISO 3864 and DIN 4844. In this

document, the following hazard levels and information are considered:

DANGER

Imminent danger

Indicates an imminent hazardous situation that will result in death or serious injury.

WARNING

Possibly imminent danger

Indicates an imminent hazardous situation that can result in death or serious injury.

CAUTION

Possibly imminent danger

Indicates an imminent hazardous situation that can result in minor or moderate injury.

NOTICE

Command or note

Command to perform an action or information about properties, the disregarding of

which may result in damage to the product.

3

About this manual

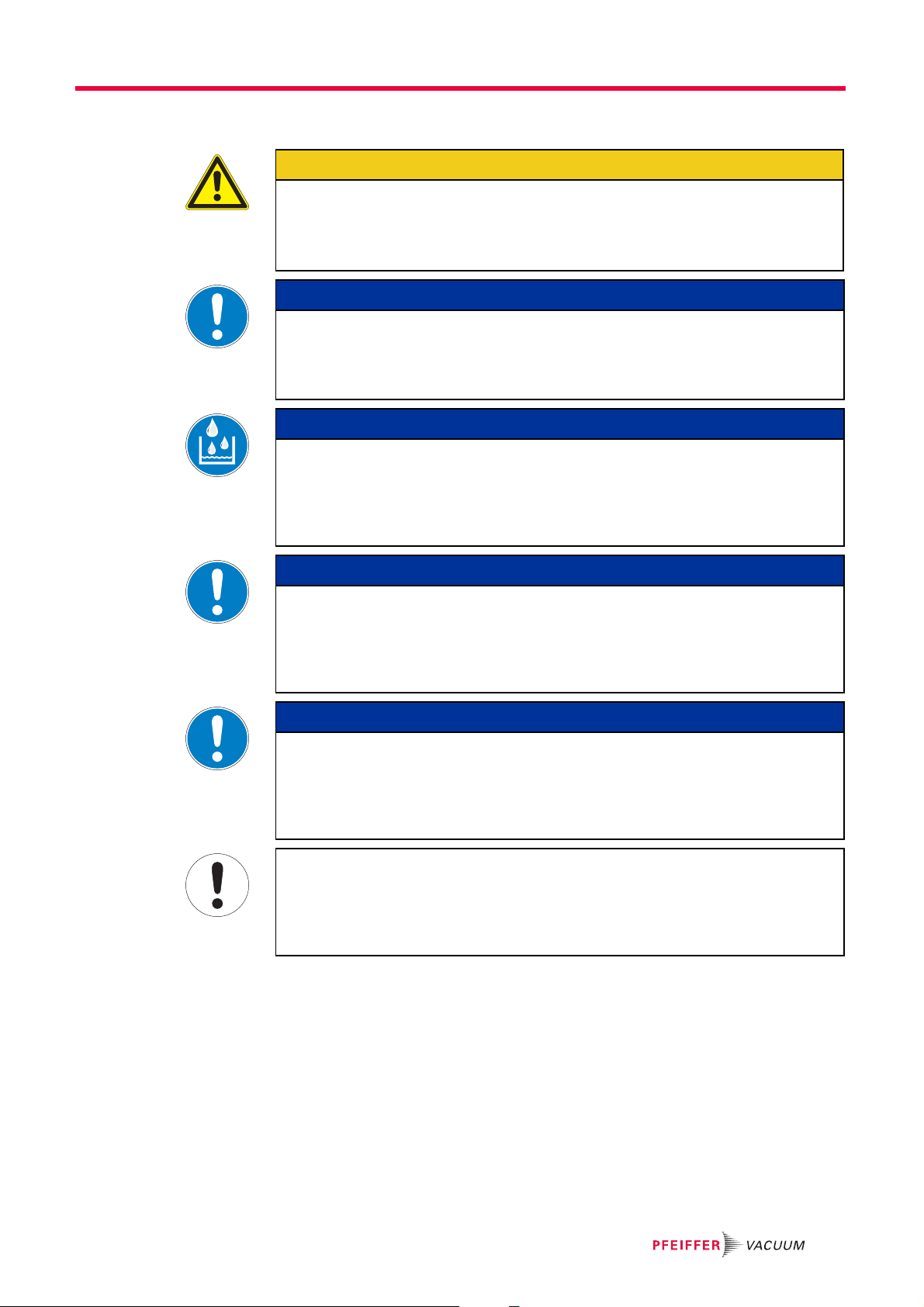

Pictographs

Instructions in the

Work instruction: here you have to do something.

Prohibition of an action to avoid any risk of accidents, the disregarding

of which may result in serious accidents

Warning of a displayed source of danger in connection with operation of

the unit or equipment

Command to perform an action or task associated with a source of danger, the disregarding of which may result in serious accidents

Important information about the product or this document

text

Abbreviations OME: Oil mist eliminator

OME_ R: Oil mist separator with return unit

C version: Corrosive gas version

Symbols used The following symbols are used consistently throughout in all illustrations:

V

Vacuum flange

Exhaust flange

X

Connection flange OME

4

2Safety

2.1 Safety precautions

Duty to inform

Each person involved in the installation or operation of the unit must read and observe

the safety-related parts of these operating instuctions.

The operator is obligated to make operating personnel aware of dangers originating

from the unit or the entire system.

Before carrying out any work read and observe the operating and safety instructions

of the pumping station and the individual components.

Observe the safety and accident prevention regulations.

Check regularly that all safety precautions are being complied with.

When returning the components to us please note the instructions in the Service sec-

tion.

2.2 Proper use

Only use the oil mist eliminator to filter oil mist from the gas flow of rotary vane pumps.

Simply mount the OME onto the exhaust port of rotary vane pumps.

Use the OME in accordance with the corresponding approved pumping speed.

Safety

2.3 Improper use

Improper use will cause all claims for liability and warranties to be forfeited. Improper use

is defined as usage for purposes deviating from those mentioned above, especially:

connection to pumps or units which are not suitable for this purpose according to their

operating instructions

connection to units which have exposed voltage-carrying parts

use of accessories or spare parts, which are not named in this manual

pumping-off of gases and vapors that may be prone to polymerization or may resinify

the filter inserts

5

Transport and storage

3 Transport and storage

3.1 Storage

The OME should be stored dry and protected from moisture. The filter elements can absorb moisture, and the lubrication properties of the oil and hence the end pressure can

be negatively influenced in pumps with an oil return unit.

4 Product description

4.1 Product identification

To correctly identify the product when communicating with Pfeiffer Vacuum, always have

the information from the rating plate available.

● Model and model number

● Date of manufacture

Variants

Range of application

Type Versions Characteristics

OME 40 M Standard model

OME 40 MR Version with operating fluid return

line to the intake side

OME 40 C Corrosive gas model for pump

model C/MC

OME 40 CR Corrosive gas model with operat-

ing fluid return line; applicable for

pump model C/MC

preinstalled

● Sight glass 13 of PCTFE

● Filter elements 14 of sintered carbon

● Integral leak rate: < 1 · 10

● Sight glass 13 of PCTFE

● Filter elements 14 of sintered carbon

● Integral leak rate: < 1 ·10

-7

Pa m3/s

-7

Pa m3/s

The operating fluid return unit operates without auxiliary power and is capable of operating in the final vacuum range of 800 hPa intake pressure (at 1000 hPa air pressure).

Moreover, its operation is not affected by rotational speed, gas ballast application or builtup exhaust-side pressure. During dynamic pump-down cycles such as load lock applications involving small volumes extended pump-down times are to be expected for intake

pressures < 5 · 10

-2

hPa.

6

4.2 Function

Product description

The oil mist filter is mounted on the exhaust port of rotary vane pumps. It filters oil mist

particles from the conveyed gas flow and thus reduces the escape of operating fluid mist.

The filter elements are installed in a corrosion-resistant aluminum casing and consist of

a cylindrical filter made from glass/polyester fleece in the standard and helium-tight versions, or from sintered carbon in the corrosive gas version. A baffle is also fitted over the

filter insert. An integrated pressure relief valve opens when the filter elements are excessively contaminated, so that the maximum operating pressure of 1500 hPa (absolute) is

not exceeded. The volume of filtered operating fluid can be viewed through a sight glass

and drained via a drain screw.

To return the filtered operating fluid from the OME into the pump without interrupting the

pump operation, an operating fluid return (optional) can be used.

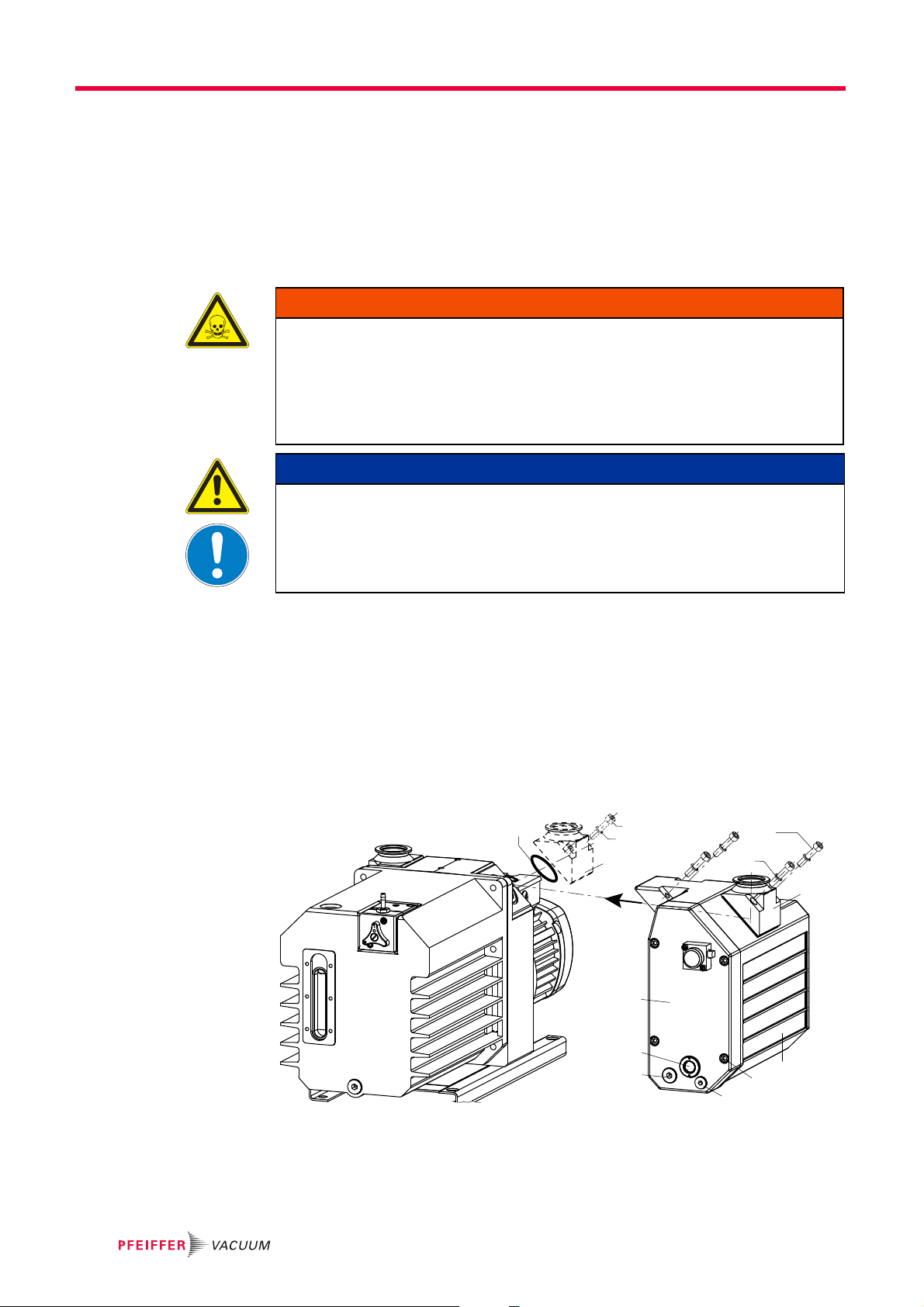

V

110

24

10 0

Operating fluid return

line (option)

15

55

13

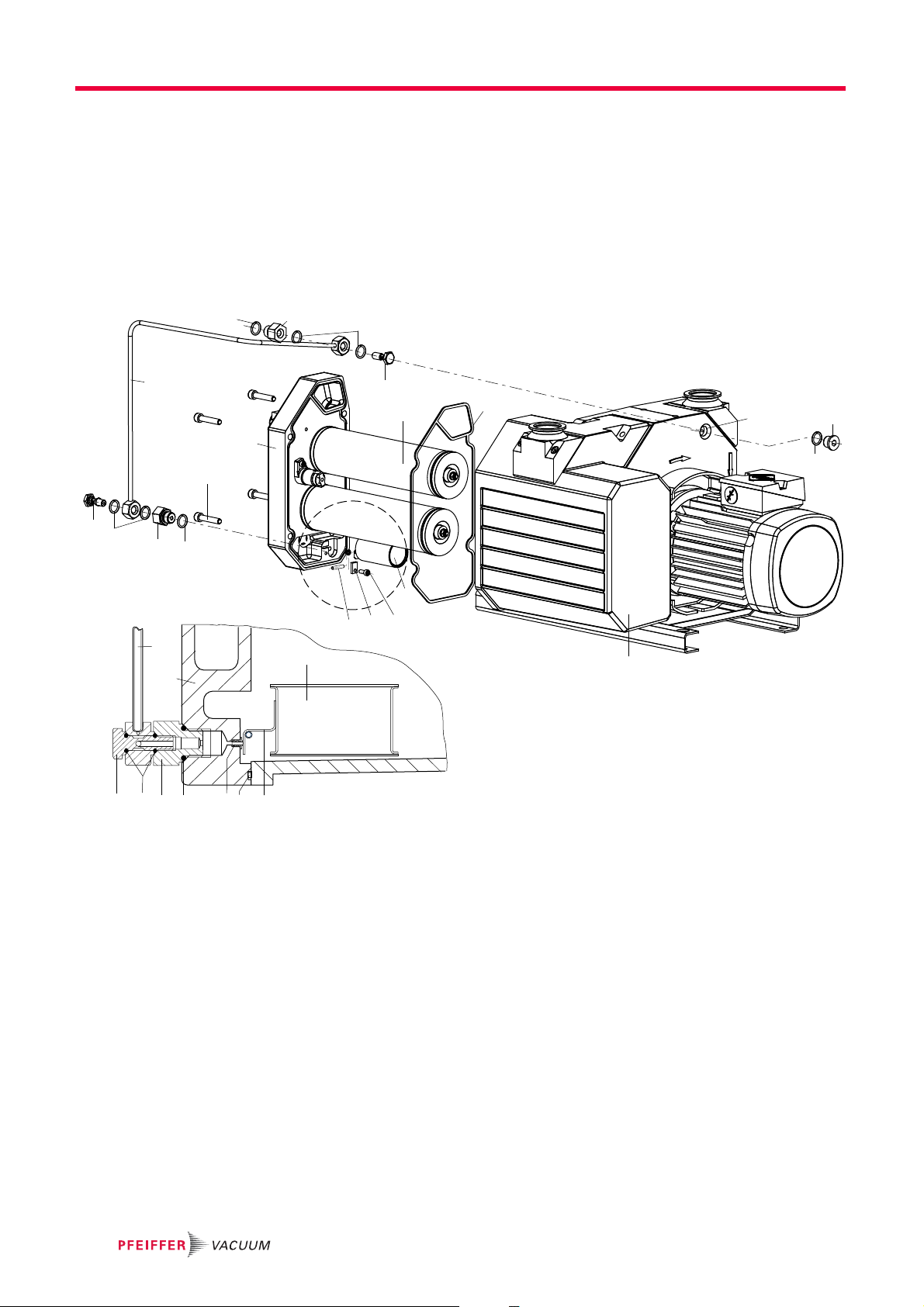

Fig. 1: Duo 35/65 with oil mist filter OME 40 MR

13 Sight glass

15 Filter element saturation

indicator

24 Interchangeable flange

55 Operating fluid drain

screw

100 Oil mist filter

110 Operating fluid return line

If the operating fluid accumulated in the OME reaches a specified level, a float valve

opens and the operating fluid is channeled via intake pressure back into the rotary vane

pump´s intake side. To avoid impairing the function of the pump, any process-related

condensate in the oil sump, must be drained as necessary.

The use of the operating fluid return increases the operational safety of the pump and

reduces the maintenance requirements.

7

Installation

5 Installation

5.1 Assembly

To install the ONF in a vacuum system, flange connections are provided on the input side

and output side.

If gases are being pumped that are not permitted to enter the atmosphere, a pressureless exhaust line must be connected to the exhaust flange.

WARNING

Poisonous substances exit from the exhaust!

There is a poisoning hazard from discharged gases or vapors that can be hazardous

and/or polluting during use.

Install and run the exhaust line so that overpressure cannot build up inside it.

Follow the vacuum pump installation instructions in the respective operating instruc-

tions.

NOTICE

Vacuum component

Dirt and damage impair the function of the vacuum component.

When handling vacuum components, ensure that they are kept clean and are protect-

ed against damage.

Ensure that the connection flange is clean, dry and free of grease.

Turn off the vacuum pump, vent to atmospheric pressure and allow to cool.

Unscrew screws 46 and dismantle the interchangeable flange 24 on the exhaust side

of the rotary vane pump.

Fit interchangeable flange 24 to the exhaust side of the OME, being careful with O-

ring 60 and spring washers 57.

Mount the OME on the pump in place of the interchangeable flange 24.

Lay exhaust line from the OME sloping downward so that no condensate can flow

back.

– If an air trap is created in the system, then a device for draining condensation water

must be provided at the lowest point.

60

24

57

46

46

(10 Nm)

57

24

2

13/62

54/63

45

1

55/64

Fig. 2: Assembling the OME

1Casing

2 Cover

13 Sight glass

24 Interchangeable flange

45 Screws

46 Screws

54 Screw plug

55 Operating fluid drain screw

57 Spring washer

60 O-ring

62 O-ring

63 O-ring

64 O-ring

8

5.2 Installing the operating fluid return line

54

28

67

63

25 63

13

2

63

27

100

63

25

67

28

142

Prior to conversion work check the pump's ultimate pressure to get a reference value.

For this purpose, measure the ultimate pressure at the intake side with a vacuum gauge

(e.g. Pirani).

Make sure that the return for the operating fluid is working properly.

The operating fluid can only be sucked out and returned when there is a minimum about

of operating fluid in the oil mist eliminator.

If necessary, top up with operating fluid in order to ensure the return of operating fluid

at the start of the evacuation phase.

Pour the operating fluid slowly into the outlet flange of the oil mist eliminator until it

can be seen in the sight-glass.

Installation

NOTICE

Fig. 3: Installing the operating fluid return line

2 Cover

13 Sight glass

25 Reducer

27 Operating fluid return line

Carry out preliminary work as described before.

Unscrew locking screw 54.

Screw reducing piece 25 with O-ring 63 into cover 2 from the outside.

Unscrew and remove locking screw 142 on the support.

Screw reducing piece 25 with O-ring 63 into connection 4 on the pump support while

ensuring that the sealing surfaces are clean.

Fit operating fluid return line 27 onto the two reducing pieces using hollow screws 28,

being careful with O-rings 67.

– Notice! Do not remove the spiral hose at the operating fluid return line 27; it serves

as a vibration damper.

Check the pump's ultimate pressure to ensure a leakproof assembly of the operating

fluid return line;

– compare the measurement result with the previously determined ultimate pressure.

Fill in additional operating fluid in OME in order to ensure the return of operating fluid.

28 Banjo bolt

54 Blanking plug

55 Drain screw for operat-

ing fluid

63 O-ring

67 O-ring

100 Oil mist filter

142 Blanking plug

9

Installation

5.3 Installing the operating fluid return line

Retrofit kit: PK 005 950 -T

Prior to conversion work check the pump's ultimate pressure to get a reference value.

For this purpose, measure the ultimate pressure at the intake side with a vacuum gauge

(e.g. Pirani).

Make sure that the return for the operating fluid is working properly.

The operating fluid can only be sucked out and returned when there is a minimum about

of operating fluid in the oil mist eliminator.

If necessary, top up with operating fluid in order to ensure the return of operating fluid

at the start of the evacuation phase.

Pour the operating fluid slowly into the outlet flange of the oil mist eliminator until it

can be seen in the sight-glass.

CAUTION

Escaping operating fluid!

Slip hazard and workplace contamination from spilled operating fluid.

Place suitable container underneath and collect escaping operating fluid.

NOTICE

Turn off the vacuum pump, vent to atmospheric pressure and allow to cool.

Screw out the operating fluid drain screw 55; pay attention to the O-ring 64.

Drain off operating fluid.

Separate the operating fluid from the condensate.

– If the drained operating fluid is free of contamination, it can be reused.

Screw in operating fluid drain screw 55; pay attention to O-ring.

Unscrew screws 45 and remove cover 2 with the filter elements from casing 100, col-

lect remaining operating fluid and clean the parts if necessary;

– pay attention to flat seal 3.

Unscrew locking screw 54.

Screw reducing piece 25 with O-ring 63 into cover 2 from the outside.

Lightly lubricate sealing nipple 37 and manually press into the hole in cover 2.

Push cylinder bolt 38 into floating support 35.1.

Insert the floating support and cylinder bolt 38 into the groove in cover 2 and mount

clamping plate 36 using screw 48.

– Floating support 35 should be able to move slightly.

Replace cover 2, being careful with flat seal 3.

Unscrew and remove locking screw 142 on the support.

Screw reducing piece 25 with O-ring 63 into connection 4 on the pump support while

ensuring that the sealing surfaces are clean.

Fit operating fluid return line 27 onto the two reducing pieces using hollow screws 28,

being careful with O-rings 67.

– Notice! Do not remove the spiral hose at the operating fluid return line 27; it serves

as a vibration damper.

Check the pump's ultimate pressure to ensure a leakproof assembly of the operating

fluid return line;

– compare the measurement result with the previously determined ultimate pressure.

Fill in additional operating fluid in OME in order to ensure the return of operating fluid.

10

Installation

X

Detail X

35

35.1

38

37

3

100

4

63

142

14

2

2

27

27

25

45

35

36

48

25

28

63

63

67

67

25

28

63

28

67

3

Fig. 4: Installing/retrofitting the operating fluid return line at the OME

45 Screws

48 Screw

63 O-ring

67 O-ring

100 Casing

142 Locking screw

2 Cover

3 Flat seal

4 Connection operating fluid return line

14 Filter element

25 Reducing piece

27 Operating fluid return line

28 Hollow screw

35 Floater

35.1 Floating support

36 Clamping plate

37 Sealing nipple

38 Cylinder bolt

11

Installation

5.4 Installing the saturation indicator optically/electrical (option)

In addition to the optical display of the back pressure, the condition of the filter elements

can also be monitored remotely using a switch contact. To enable this, the electrical connection for saturation indicator 15 must be set so that an alarm is triggered when the differential pressure reaches an impermissible level.

66

15

49

49

2

Fig. 5: Installing the saturation indicator optically/electrical (option)

Parameters Pressure switch for saturation indicator

Degree of protection IP 55

Contact Contact (n. o.)

Set point 700 hPa (delta p)

Switching voltage 120 V AC; 200 V DC

Switching current 0.7 A (V AC); 1 A (V DC)

Switching capacity 70 VA; 50 W

Switch off pump; ensure exhaust line is free of pressure.

Unscrew screw 49 and remove standard saturation indicator 15 from cover 2.

Mount the saturation indicator (optical/electronic) 15 on the cover; pay attention to O-

ring 66.

Tighten screw 49 to 3 Nm.

Create electrical connection.

Properties Abrupt gas throughput with a saturated filter element can temporarily move the indicator

to the red range or trigger (close) the switch contact.

Note the following:

● If a high gas throughput is required by the process, temporarily suppress the indicator

signal if necessary

● The red indicating range starts with a back pressure of 500 hPa, but the switch contact

is set to 700 hPa

● The saturation display does not respond to an impermissibly high pressure in the exhaust line, e.g. due to shut-off valves

● Corrosive gas versions (C version) develop an increased back pressure level.

12

6Operation

Watch out for excess pressure in the exhaust line.

There is a risk of damage to the seals, and a risk of rupture or overloading of the pump.

Ensure that there is no excess pressure at the OME exit point.

Open the inlet valves either before or at same time as starting the pump.

Pay attention to the back pressure in the C version!

There is a greater back pressure in the C version than with the standard version.

The saturation indicator only displays the correct saturation level of the filter elements

Damage to the pump due to condensate in the operating fluid!

Returned condensate generated by vapors or by temperature differences between the

oil mist eliminator and pump impairs the quality of the operating fluid and negatively impacts the pump's final vacuum.

Drain operating fluid built up with condensate in a time manner.

Operation

CAUTION

NOTICE

at intake pressures < 600 hPa.

NOTICE

NOTICE

Risk of the filter elements becoming blocked with resin!

When pumping gases and vapors with a tendency towards polymerization, the OME filter elements can become resinified.

Observe the corresponding safety devices such as the saturation indicator or pres-

sure relief valve.

NOTICE

Make sure that the return for the operating fluid works.

Operating fluid is only sucked in and returned from an operating pressure of < 800 hPa

and starting from a minimum quantity of operating fluid in the OME.

Long evacuation phases with a high intake pressure should always be followed by

operating phases with a lower operating pressure.

The very smallest of oil particles can only be filtered to a limited degree!

The level of filtering by the filter elements depends on the gas throughput and the particle distribution in the gas flow.

Use the visual saturation indicator as an guide to the degree of saturation of the filter

elements.

13

Maintenance

7 Maintenance

Disclaimer of liability

Pfeiffer Vacuum accepts no liability for personal injury or material damage, losses or operating malfunctions due to improperly performed maintenance. The liability and warranty entitlement expires.

7.1 Draining the operating fluid

If the accumulated operating fluid in the OME is above the top edge of the sight glass 13,

the operating fluid must be drained.

The intervals, at which the operating fluid is drained, depend on the operating conditions.

Operating fluid may contain toxic substances from the pumped media!

Danger of poisoning from the emission of harmful substances from the operating fluid.

Wear suitable protective clothing and respirators.

Dispose of operating fluid according to the local regulations

NOTICE

WARNING

WARNING

Toxic vapours!

Danger of poisoning when igniting and heating synthetic operating fluids (e.g. F4/F5)

above 300 °C.

Observe the application instructions.

Do not allow operating fluid to make contact with tobacco products; observe safety

precautions when handling chemicals.

Check the operating fluid level in the sight glass.

Turn off the vacuum pump, vent to atmospheric pressure and allow to cool.

Ensure that the exhaust line is depressurized.

Screw out the operating fluid drain screw 55; pay attention to the O-ring 64.

Drain off operating fluid.

Separate the operating fluid from the condensate.

– If the drained operating fluid is free of contamination, it can be reused.

Screw in operating fluid drain screw 55; pay attention to O-ring.

Dispose of condensate according to the respectively valid legal requirements.

14

Maintenance

Operating fluid return

line

Due to the automatic operating fluid return, it is not necessary to drain the operating fluid

manually.

However, depending on the process, filtered condensate in the oil sump should occasionally be drained in the OME, since it could enter the operating fluid return to the pump.

NOTICE

Make sure that the return for the operating fluid is working properly.

The operating fluid can only be sucked out and returned when there is a minimum about

of operating fluid in the oil mist eliminator.

If necessary, top up with operating fluid in order to ensure the return of operating fluid

at the start of the evacuation phase.

Pour the operating fluid slowly into the outlet flange of the oil mist eliminator until it

can be seen in the sight-glass.

15

Maintenance

7.2 Changing the filter element

The filter element must be exchanged when the exhaust pressure increases, so that

● the pointer enters the red area of the visual saturation indicator 15 or

● the pressure relief valve inside the OME opens and oil mist exits

Contamination of parts and operating fluid by pumped media is possible.

Poisoning hazard through contact with materials that damage health.

In the case of contamination, carry out appropriate safety precautions in order to pre-

vent danger to health through dangerous substances.

Decontaminate affected parts before carrying out maintenance work.

Danger to health by hazardous substances during maintenance or installation

Depending on the process vacuum pumps, components or operating fluids can be contaminated by toxic, reactive or radioactive substances.

Wear adequate protective equipment during maintenance and repairs or in case of

reinstallation.

WARNING

DANGER

Dismantling

Safely dispose of the materials according to the locally applicable regulations.

45

9

8

7

47

12

14

12

6

65

11

2

3

1

52

51

16

Fig. 6: Changing the filter elements

1Casing

2 Cover

3 Flat seal

6Filter cover

7 Valve casing

8 Compression spring

9 Valve buffer

11 Pressure piece

12 Seal

14 Filter element

Carry out preliminary work as described before.

45 Screws

47 Screws

51 Nut

52 Washer

65 O-ring

Maintenance

Remove the operating fluid return line 27, if installed.

Unscrew screws 45 and remove cover 2 with the filter elements from casing 100, col-

lect remaining operating fluid and clean the parts if necessary;

– pay attention to flat seal 3.

Unfasten nuts 51, remove washer 52, pressure piece 11, O-ring 65 and filter cover 6

being careful with seal 12.

Replace filter elements 14; cleaning is not recommended in most cases.

Dismantling the pressure relief valve

Remove screw 47, dismantle valve casing 7 with the valve buffer 9 and compression

spring 8.

Clean all parts and inspect for wear.

Check the sealed surface of valve buffer 9; replace if necessary.

– When assembling lightly oil valve buffer and ensure the correct seating in the valve

casing 7.

Cleaning Only the filter elements in the C version can be cleaned; the elements in the standard

version must be replaced. The success of the cleaning process depends on the process

medium being used, and should be tested by the user for the specific situation.

WARNING

Explosion hazard

The use of volatile or combustible cleaning agents in vacuum systems can lead to explosive vapour-air mixtures.

After cleaning ventilate and let dry completely.

Clean the filter insert in a solvent bath.

Use blasts of compressed air to expel the cleaning agent from the filter element, and

then dry them.

Assembling Assembling is carried out in reverse order.

Tighten the filter elements at a torque of 3 ... 5 Nm.

– Ensure the correct seating of the seal 12.

Check the pump's ultimate pressure to ensure a leakproof assembly of the operating

fluid return line;

– compare the measurement result with the previously determined ultimate pressure.

Fill in additional operating fluid in OME in order to ensure the return of operating fluid.

17

Maintenance

X

Detail X

35

35.1

38

37

3

100

4

63

142

14

2

2

27

27

25

45

35

36

48

25

28

63

63

67

67

25

28

63

28

67

3

7.3 Cleaning the operating fluid return line

Maintenance intervals depend on the respective process and are recommended as follows.

Check oil for condensate and clean the housing;

– each time the filter of the OME is changed.

Clean and replace possibly the sealing nipple.

– when there is a functional decline in the operating fluid return unit caused by wear

of the sealing nipple.

18

Fig. 7: Cleaning the operating fluid return line

2 Cover

3 Flat seal

4 Connection operating fluid return line

14 Filter element

25 Reducing piece

27 Operating fluid return line

Carry out preliminary work as described before.

Unscrew the screw 48 and remove the clamping plate 36.

Remove floater 35 and cylinder bolt 38.

Check the sealed surface of sealing nipple 37; replace if necessary.

– When assembling lightly oil sealing nipple 37 and ensure the correct seating in the

housing 2.

Clean all parts and inspect for wear.

Assembling is carried out in reverse order.

Check the pump's ultimate pressure to ensure a leakproof assembly of the operating

fluid return line;

– compare the measurement result with the previously determined ultimate pressure.

Fill in additional operating fluid in OME in order to ensure the return of operating fluid.

28 Hollow screw

35 Floater

35.1 Floating support

36 Clamping plate

37 Sealing nipple

38 Cylinder bolt

45 Screws

48 Screw

63 O-ring

67 O-ring

100 Casing

142 Locking screw

8 Service

Service

Pfeiffer Vacuum offers first-class service!

● Fast replacement with exchange products in mint condition

● Advice on the most cost-efficient and quickest solution

Detailed information, addresses and forms at: www.pfeiffer-vacuum.com (Service).

Maintenance and repairs in the Pfeiffer Vacuum ServiceCenter

The following steps are necessary to ensure a fast, smooth servicing process:

Download the forms "Service Request" and "Declaration on Contamination".

Fill out the "Service Request" form and send it by fax or e-mail to your Pfeiffer Vacuum

service address.

Include the confirmation on the service request from Pfeiffer Vacuum with your ship-

ment.

Fill out the declaration on contamination and include it in the shipment (required!).

Drain off operating fluid.

If possible, send pump or unit in the original packaging.

Sending of contaminated pumps or devices

No units will be accepted if they are contaminated with micro-biological, explosive or radioactive substances. “Hazardous substances” are substances and compounds in accordance with the hazardous goods directive (current version). If pumps are contaminated or the declaration on contamination is missing, Pfeiffer Vacuum performs

decontamination at the shipper's expense.

1)

Neutralise the pump by flushing it with nitrogen or dry air.

Close all openings airtight.

Seal the pump or unit in suitable protective film.

Return the pump/unit only in a suitable and sturdy transport container and send it in

Service orders

All service orders are carried out exclusively according to our repair conditions for vacuum units and components.

9 Accessories

Designation OME 40 M

Saturation indicator, optical/electronic for OME 40 M PK 007 308 -T

Oil return unit from OME 40 to Duo 35/65 PK 005 950 -T

while following applicable transport conditions.

1)

Forms under www.pfeiffer-vacuum.com

19

Technical data and dimensions

10 Technical data and dimensions

10.1 Technical data

Parameter OME 40 M/MR OME 40 C/CR

Degree of separation 98 % 98 %

Flange (in) DN 40 flange DN 40 flange

Flange (out) DN 40 ISO-KF DN 40 ISO-KF

Pressure max. (absolute) 1500 hPa 1500 hPa

Exhaust pressure max. Atmosphere Atmosphere

Leak rate < 1 • 10

For Duo 35/65, Duo 35/65 M Duo 35/65 C, Duo 35/65 MC

For pumping speed 35 - 70 m

Capacity 0,7 l 0,7 l

We i g ht 11 k g 11 kg

10.2 Dimensions

-4

Pa m3/s < 1 • 10-4 Pa m3/s

3

/h 35 - 70 m3/h

356

160

350

Fig. 8: OME 40 MR

341

322 46

298

30

142

382

20

11 Spare parts

Please also specify model number of the the rating plate when ordering accessories or

spare parts.

11.1 Spare parts packages

Spare parts package Type No. Model Consisting of

Maintenance kit OME 40 M/MR PK E27 001 -T Standard 3, 12,14, 65

Overhaul kit OME 40 M PK E27 003 -T Standard 3, 9, 12, 13, 14, 60, 62, 63,

Saturation indicator PK 007 307 -T optically 15, 49, 66

Spare parts

OME 40 C/CR PK E27 002 -T C version 3, 12,14, 65

64, 65, 66

OME 40 MR PK E27 004 -T Standard with

return line

OME 40 C PK E27 005 -T C version 3, 9, 12, 13, 14, 60, 62, 63,

OME 40 CR PK E27 006 -T C version with

return line

3, 9, 12, 13, 14, 37, 60, 61,

62, 63, 64, 65, 66, 67

64, 65, 66

3, 9, 12, 13, 14, 37, 60, 61,

62, 63, 64, 65, 66, 67

21

Spare parts

45

9

37

1

3

8

7

12

14

6

11

52

51

12

65

47

54/63

55/64

2

46

57

24

15

60

49

66

1

45

13/62

27

25

63

35

63

67

67

25

28

28

Ansicht/View

A

A

Fig. 9: OME 40 MR

1Casing

2 Cover

3 Flat seal

6Filter cover

7 Valve casing

8 Compression spring

9 Valve buffer

11 Pressure piece

12 Seal

13 Sight glass

14 Filter element

15 Saturation indicator

24 Interchangeable flange

25 Reducing piece

27 Operating fluid return line

28 Hollow screw

35 Float valve

37 Sealing nipple

45 Screws

46 Screw

47 Screws

49 Screw

51 Nut

52 Washer

54 Screw plug

55 Operating fluid drain screw

57 Spring washer

60 O-ring

61 O-ring (previous version, not

shown in the figure)

62 O-ring

63 O-ring

64 O-ring

65 O-ring

66 O-ring

67 O-ring

22

12 Disposal

Disposal

Products or parts thereof (mechanical and electrical components, operating fluids, etc.)

may cause environmental burden.

Safely dispose of the materials according to the locally applicable regulations.

23

VACUUM SOLUTIONS FROM A SINGLE SOURCE

Pfeiffer Vacuum stands for innovative and custom vacuum solutions worldwide,

technological perfection, competent advice and reliable service.

COMPLETE RANGE OF PRODUCTS

From a single component to complex systems:

We are the only supplier of vacuum technology that provides a complete product portfolio.

COMPETENCE IN THEORY AND PRACTICE

Benefit from our know-how and our portfolio of training opportunities!

We support you with your plant layout and provide first-class on-site service worldwide.

Are you looking for a

perfect vacuum solution?

Please contact us:

www.pfeiffer-vacuum.com

Pfeiffer Vacuum GmbH

Headquarters • Germany

T +49 6441 802-0

info@pfeiffer-vacuum.de

Loading...

Loading...