Page 1

select

1520

1530

1540

Instruction manual

Page 2

1

2

3

4

5

6

78

9

10

11

12

13

14

15

16

18

17

19

20

21

22

23

24

25

26

27

28

29

Page 3

Parts of your select sewing machine

1 Connection socket “foot control with main cord”

2 Main switch

3 Handwheel release disk

4 Handwheel

5 Bobbin winder

6 Lid with stitches

7 Extra spool holder

8 Spool holder with spool cap

9 Take-up lever

10 Needle thread tension dial

11 Threading path

12 Thread cutter

13 Needle threader (1540)

14 Presser foot holder with presser foot

15 Removable accessory tray

16 Base plate

17 IDT System / Integrated Dual Feed (1540/1530)

18 Needle holder with fi xing screw

19 Presser foot lifter

20 Button for “reverse sewing”

21 Stitch length dial

22 Stitch selection 1540

23 Carrying handle

24 Stitch selection 1530 & 1520

25 Thread guide

26 Sewing lamp (max. 15 watt)

27 Stitch width dial

28 Needle position dial

29 Needle plate

Page 4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

For the United States only

When you use an electrical appliance, basic safety precautions should always be adhered to as follows:

Read all instructions before using this sewing machine.

DANGER To reduce the risk of electric shock:

1. The sewing machine should never be left unattended when plugged in. Always unplug this appliance

from the electric outlet immediately after using and before cleaning it.

2. Always unplug before relamping. Replace bulb with same type rated 15 Watts.

3. Do not reach for a sewing machine that has fallen into water. Unplug immediately.

4. Do not place or store a sewing machine where it can fall or be pulled into a tub or sink. Do not place in or

drop into water or other liquid.

WARNING To reduce the risk of burns, fi re , electric shock, or injury to persons:

5. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or

near children.

6. Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

7. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or dropped into water. Return the appliance to the nearest authorized dealer

or service center for examination, repair, electrical or

mechanical adjustment.

8. Never operate the sewing machine with any air opening blocked. Keep ventilation openings of the sewing

machine and foot control free from the accumulation of lint, dust, and loose cloth.

9. Never drop or insert any object into any opening.

10. Do not use outdoors.

11. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

12. To disconnect, turn all controls to off (“O”) position, then remove plug, not the cord.

13. Never operate on a soft surface such as a bed or couch where the air openings may be blocked.

14. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

15. Keep fi ngers away from all moving parts. Special care is required around the sewing machine needle.

16. Always use the proper needle plate. The wrong plate can cause the needle to break.

17. Do not use bent or blunt needles. Use needles recommended by the manufacturer only.

18. Do not pull or push fabric while stitching. It may defl ect the needle, causing it to break.

19. Switch the sewing machine off (“O”) when making any adjustments in the needle area, such as threading

needle, changing needle, threading bobbin, or changing presser foot, etc.

20. Always unplug sewing machine from the electric outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

21. Hold plug when rewinding into cord reel. Do not allow plug to whip when rewinding.

Please also observe the general safety notes on opposite page.

This sewing machine is designed and manufactured for HOUSEHOLD use only

SAVE THESE INSTRUCTIONS

Page 6

Introduction

Accessories and needles 55-56

Accessory tray 3

Appliqué 51

Appliqué foot 62

Bias-tape binder 61

Blind stitch 25

Bobbin case 8-9

Buttonholes 33, 51

Changing the needle plate 68

Changing the needle 15

Cleaning and oiling 68

Closed overlock stitch 29

Cording foot 62

Covering stitch 30-31

Darning with the elastic stitch 38

Darning with the straight stitch 37

Darning 37-38

Decorative sewing 47-54

Drawing up the bobbin thread 12

Dropping the feed dog 15

Elastic stitch 27

Elastic stitches 26-29

Electrical connection 2

Embroidering with a dense

zigzag stitch 48-51

Eyelet embroidery 52

Feather stitch 30

Felling foot 59

Free arm 3

Fringe foot 63

Gathering foot 59

Gathering with elastic thread 36

Gathering with the straight stitch 36

General information on sewing 23

Handwheel release disk 4

Hemming with the twin needle 35

Hemstitch seam 54

Honeycomb stitch 27

Inserting lace 43

Integrated Dual feed / IDT 14

Left needle position 16

Main switch 2

Maintenance and

trouble-shooting 67-70

Monograms 48

Needle table 64-65

Needle thread tension 15,23

Needle threader 11

Non-elastic stitches 24-25

Oiling the sewing machine 68

Open overlock stitch 28

Optional accessories 58-66

Overlock stitches 28-29

Patchwork quilt 53

Pennant stitch 31

Placing sewing thread on

spool holder 5

Practical sewing 21-44

Presser foot lifter 13

Pullover stitch 29

Pushbutton controls 18

Contents

Page 7

Introduction

Quilt and patchwork foot 63

Quilting 53, 63

Removable accessory tray 3

Removing the presser foot 13

Repairing tears 38

Reverse sewing 17

Richelieu 52

Right needle position 16

Ruffl er 61

Selecting needle position 16

Selecting stitch width 16

Serging with blindstitch and

overlock stitch 25, 28-29

Serging with zigzag stitch 24

Setting stretch stitches 17-19

Setting utility stitches 17-19

Sewing light 69

Sewing on buttons 34

Sewing on patches 38

Sewing on zippers 40-41

Sewing table Introduction

Shirring foot 79

Shell-edging 44

Smocking 35

Special accessories table 58

Stabilizing edges 42

Standard buttonhole 33

Standard buttonhole with gimp thread 33

Stitch density 17

Stitch length adjustment dial 17

Stitch selection dial 19

Straight stitch 24

Stretch triple straight stitch 26

Stretch triple zigzag stitch 26

Tapering 49-51

Thread tension 15

Thread cutter 12

Threading the upper thread 10

Top feed (Integrated

Dual Feed) 14

Top-stitching 23

Trouble-shooting 70

Twin needle 11, 35

Utility stitch table Introduction

Winding from the second

spool holder 6

Winding the bobbin 4-7

Winding through the needle 7

Zigzag stitch 24

Page 8

Introduction

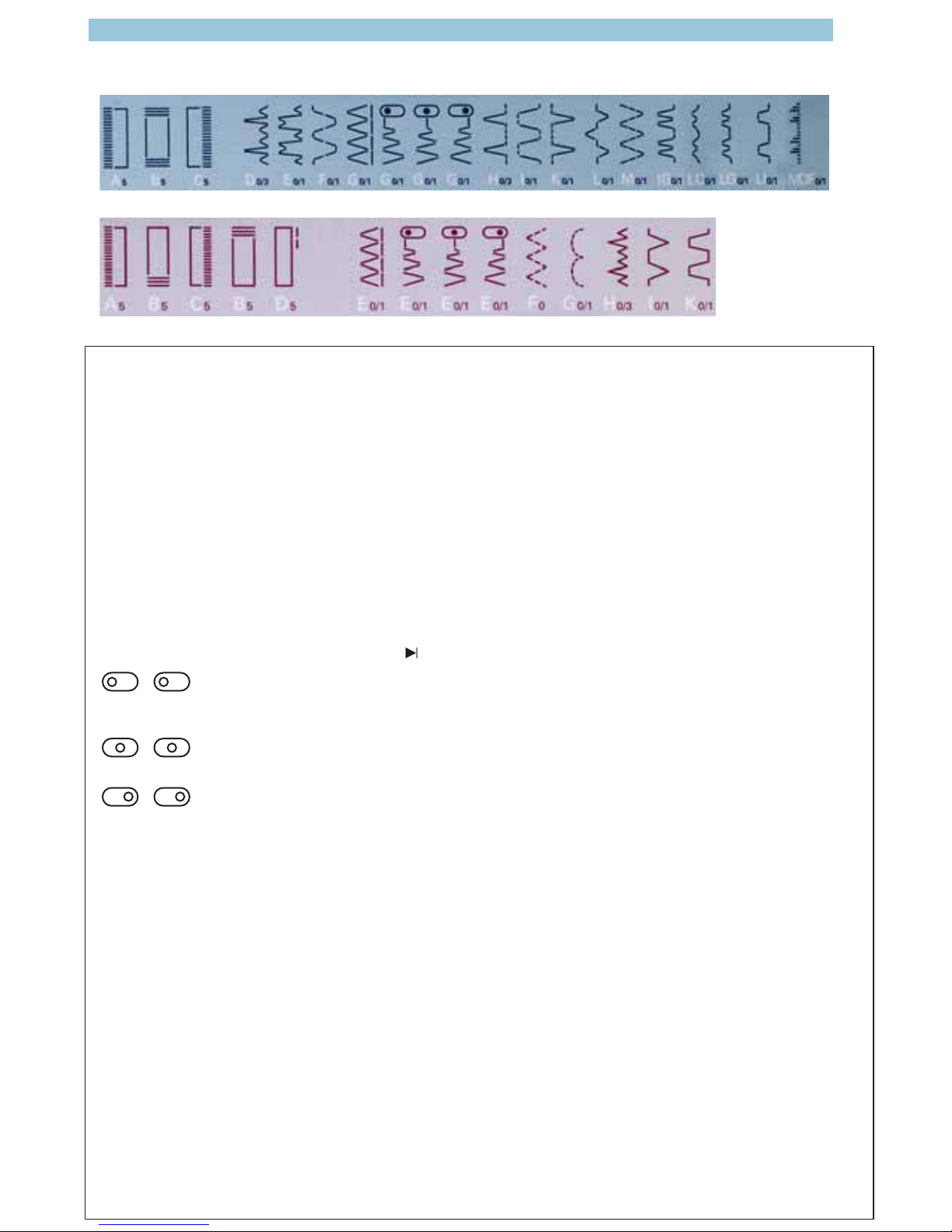

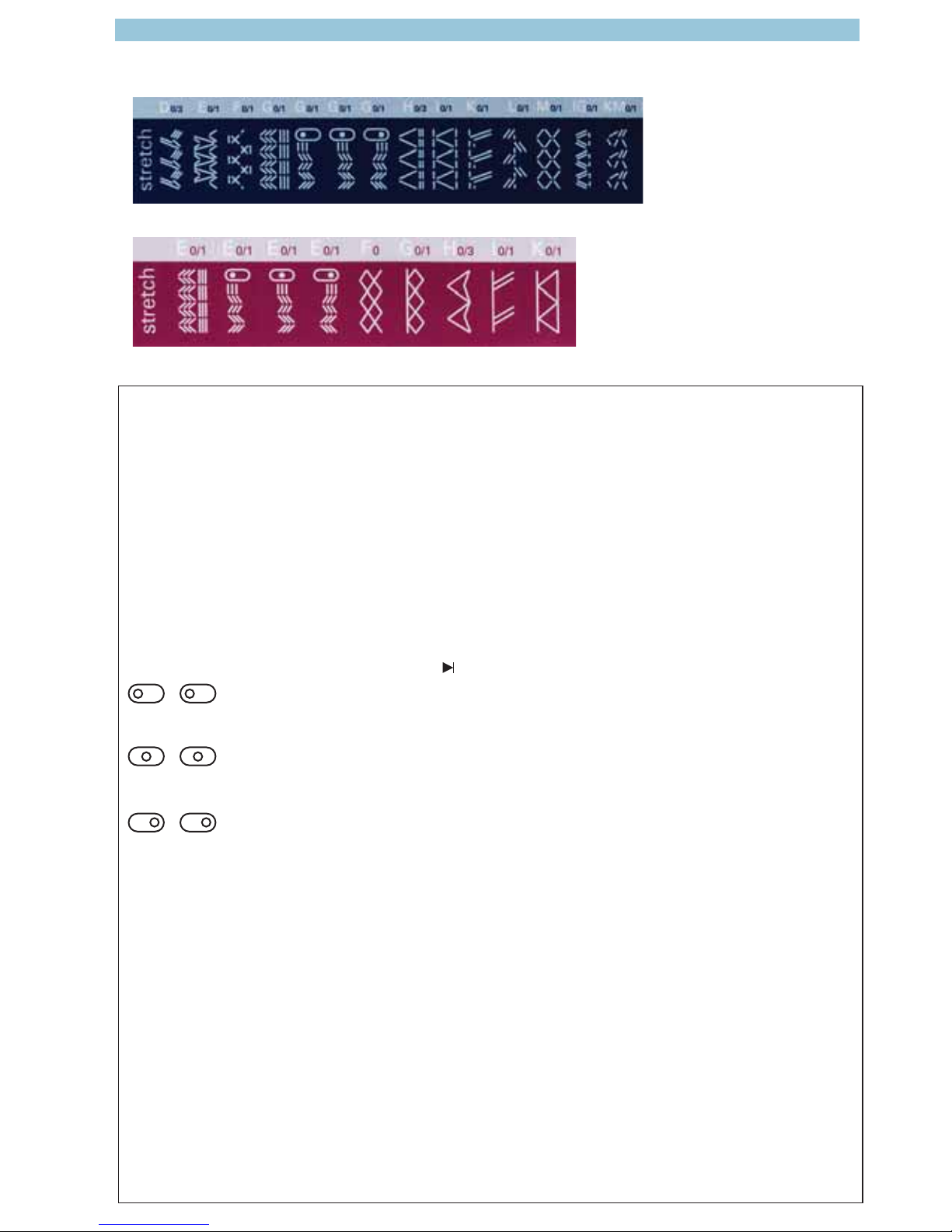

Stitch table (non-elastic stitches)

select 1540

select 1530 & select 1520

Stitch Description Application

1540 1530/1520

A/B/C A/B/C

Buttonhole Standard buttonhole for blouses or be linens

D H Blind stitch with zigzag For invisible hemming with simultaneous

(elastic) seam/overcasting. Especially for stretch material

E – Greek stitch with zigzag A traditional decorative stitch e.g. for towel borders

F – Scallop stitch A traditional decorative stitch e.g. for embroidering

blouses or table linens

G E Straight stitch, For all straight stitching and top 15 needle positions stitching work up to 6 mm

Stitch width dial set at 0

Zigzag stitch, For serging and appliqué. Also suitable for

15 needle positions, stitch tapering, eyelet embroidery and cording work

width dial set at 0.5 – 5

Left needle position Straight stitch: For all sewing and top-stitching

(for straight stitch operations which require a left needle position.

and zigzag stitch) Zigzag stitch: For serging, appliqué and tapering.

Center needle position Straight stitch: For most sewing and top-stitching

operations. Zigzag for most zigzag operations.

Right needle position For all sewing and top-stitching operations which

(for straight stitch require a right needle position. Zigzag stitch:

and zigzag stitch) For serging, appliqué, tapering and cording work

H – Blind stitch For invisible hemming on sturdier

materials

I – Greek stitch, wide A traditional decorative stitch

K I Shell-edging stitch For decorative hem edges on light fabrics

e.g. lingerie

L – Fancy elastic stitch For fl at overlapped seams

M F Elastic stitch For overcasting, sewing on elastic, darning tears

and inserting patches

IG – Viennese stitch Decorative stitch e.g. for household textiles

LC – Emperor stitch, narrow A dainty decorative stitch

LG – Emperor stitch, wide A dainty decorative stitch

LI K Greek stitch, narrow A traditional decorative stitch

MDF – Decorative stitch A traditional decorative stitch

– G Decorative stitch Decorative stitch e.g. for quilting

Page 9

Introduction

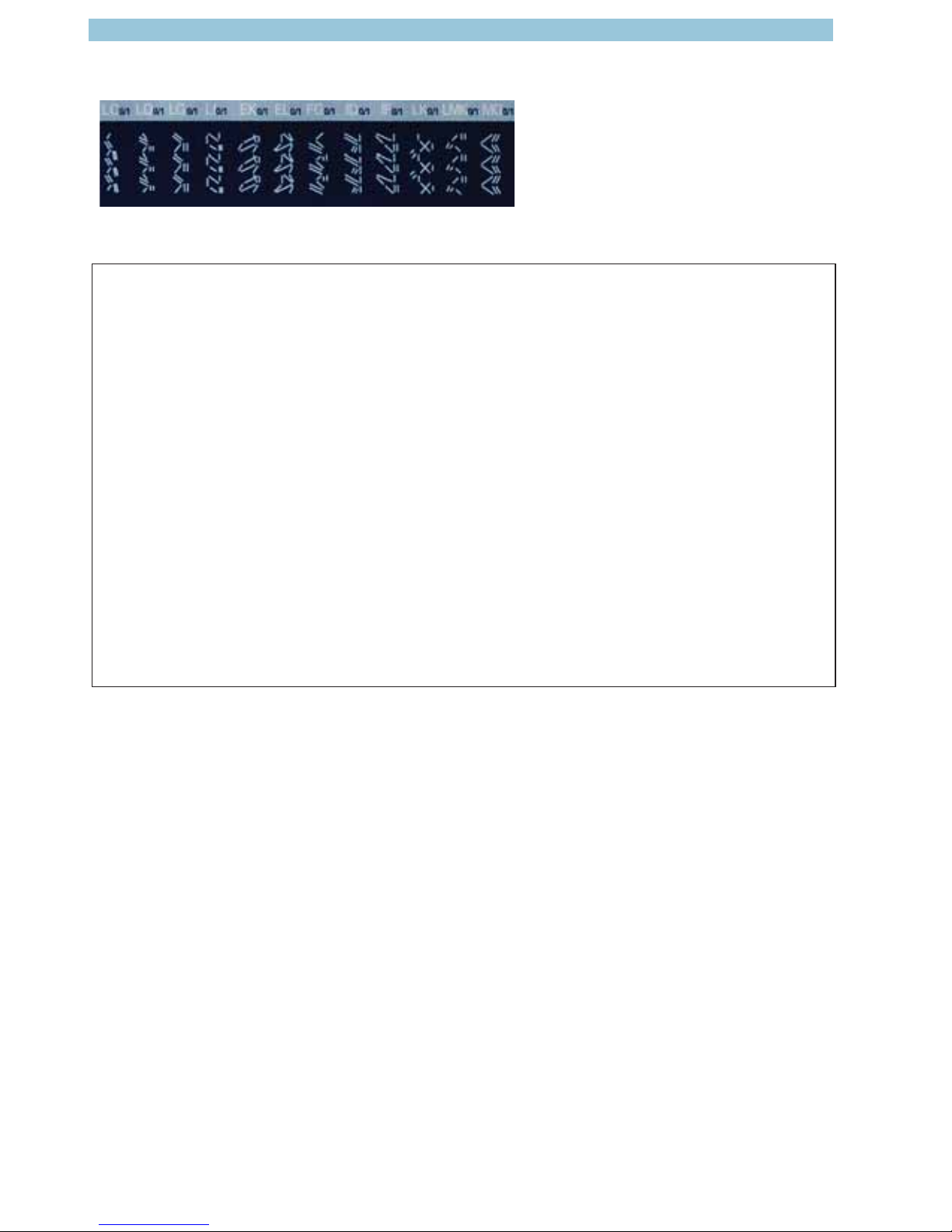

select 1540

select 1530 & select 1520

Stitch table (stretch stitches)

Stitch Description Application

1540 1530/1520

D – Peacock’s eye stitch Elastic closing and serging seam. The material

must be turned by 180 degrees

E – Cover stitch For top-stitching and overstitching stretch

materials, e.g. cuffs, hems and panels

F – Herringbone stitch A decorative stitch for top-stitching or whip stitching hems, e.g. pajamas and sweatsuits

G E Stretch triple straight stitch, For stretch seams, e.g. inside seams as well as

15 needle positions seams on sportswear and workwear

Stretch triple zigzag stitch, For sewing elastic bands on elastic materials or

15 needle positions seams on stretch materials

Stitch width knob 0.5 – 5

Left needle position For elastic seams which require a left needle

(for stretch triple straight position

and zigzag stitches)

Center needle position For elastic seams which require a center needle

(for stretch triple straight and position

zigzag stitches)

Right needle position For elastic seams which require a right needle

(for stretch triple straight position

and zigzag stitches)

H – Pullover stitch Elastic closing and serging seams for jersey.

The material must be turned by 180 degrees

I K Closed overlock stitch A closing and serging seam for materials which

fray easily

K I Open overlock stitch A closing and serging seam for sturdy materials

or materials which do not fray easily

L – Feather stitch For joining two fi nished edges with a gap between,

e.g. hemstitching. Also for crazy quilting

M F Honeycomb stitch For sewing on elastic thread, overstitching terry

cloth seams and for ornamental hem seams.

IG – Penant stitch A decorative stitch also used as a covering stitch

KM – Cord stitch A loose decorative stitch

– G Heavy open overlock stitch A closing and serging seam on heavy materials

– H Decorative stitch Embellishment

Page 10

Introduction

select 1540

Stitch table (stretch stitches)

Stitch Description Application

1540 1530/1520

LC – Dutch stitch, narrow A decorative stitch, e.g. for household textiles

LD – Dutch stitch A decorative stitch, e.g. for household textiles

LG – Border stitch A decorative stitch, e.g. for traditional embroidery

LI – Weaving stitch An ornamental stitch, e.g. for bath accessories

EK – Spiral stitch A decorative stitch, e.g. for household textiles

EL – Diagonal coverstitch For top-stitching and overstitching stretch

materials, i.e. cuffs, hems and panels

FG – Turkish stitch with zigzag A top-stitching seam for patchwork and quilting

ID – Branch stitch A decorative elastic stitch, e.g. for sportswear

IF – Floss stitch For whip-stitching hems, e.g. on pajamas and

sweatsuits. The material must be turned by 180

degrees

LK – Diagonal stitch An elastic decorative stitch

LMK – Triangle stitch A decorative, elastic stitch

MG – Florentine stitch A stretch, decorative stitch

Page 11

1

Operate your Pfaff select

Operate your Pfaff select

Electrical connection 2

Removable accessory tray 3

Bobbins 4-7

Bobbin case 8-9

Threading the needle 10

Needle threader 11

Pulling up the bobbin thread 12

Presser foot lifter 13

Thread cutter 12

Changing the presser foot 13

IDT System/Integrated Dual Feed 14

Changing the needle 15

Needle thread tension 15

Lowering the feed dog 15

Stitch width dial 16

Needle position dial 16

Reverse sewing 17

Stitch length dial 17

Stitch selection 18-19

Page 12

2

220 V

120 V

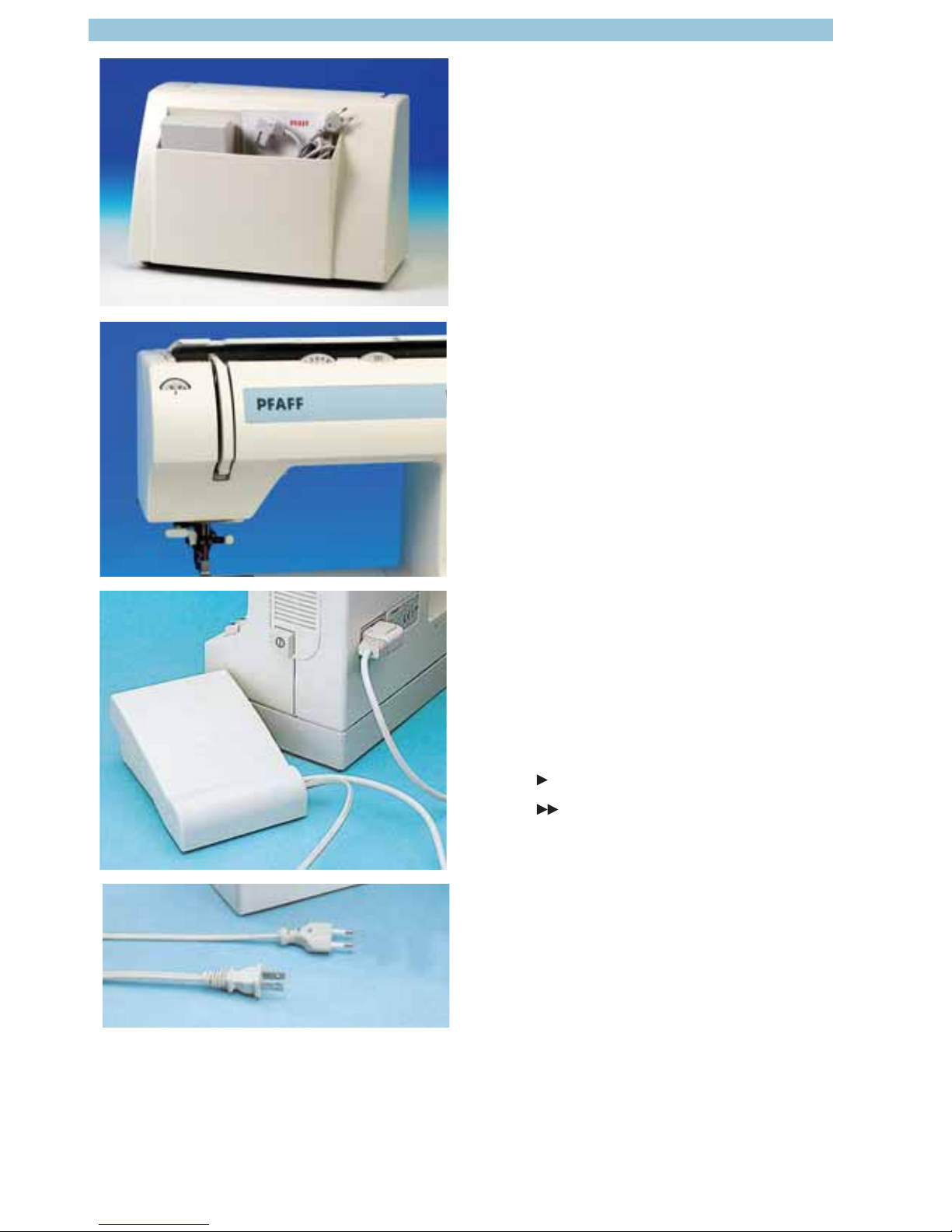

Operate your Pfaff select

Carrying-case

Place the cords, foot control and instruction

book in the compartment of the carrying-case

Top cover

Open the folding cover (6) upwards

The stitches of the sewing machine are

illustrated on the inside of the top cover.

Connecting the foot control

Connect the plug of the foot control to the

connecting socket (1) of the sewing machine

and to the wall socket. The sewing speed is

regulated by pressing the foot control.

Additionally, you can regulate the sewing

speed by moving the slide on the front part of

the foot control.

Position

= half speed

Position

= full speed

For this sewing machine, a foot controller typ

AW 0253 or AE 013 must to be used.

Main switch

When the main switch (2) is switched on, the

sewing lamp lights up.

The sewing machine is now ready to use.

This appliance has a polarized plug (one blade

wider than the other). To reduce the risk of

electric shock, this plug is intended to fi t in a

polarized outlet only one way. If the plug does

not fi t fully in the outlet, reverse the plug. If it still

does not fi t, contact a qualifi ed electrician to

install the proper outlet. Do not modify the plug

in any way.

Page 13

3

Operate your Pfaff select

Accessory tray

Your Pfaff select sewing machine has a

removable accessory tray (15) which is also

used as an extended work support.

Model 1540, has a special removable

accessory organizer. The enclosed accessories

are numbered. Sort the enclosed accessories

into the corresponding sections of the

accessory organizer.

Using the free arm

In order to sew with the free arm, you must

remove the accessory tray. Using both hands,

swing the accessory tray (15) to the left and lift

it out of the hole.

When replacing the removable accessory tray

to its proper position, ensure that it is fl ush with

the free arm of the sewing machine.

Page 14

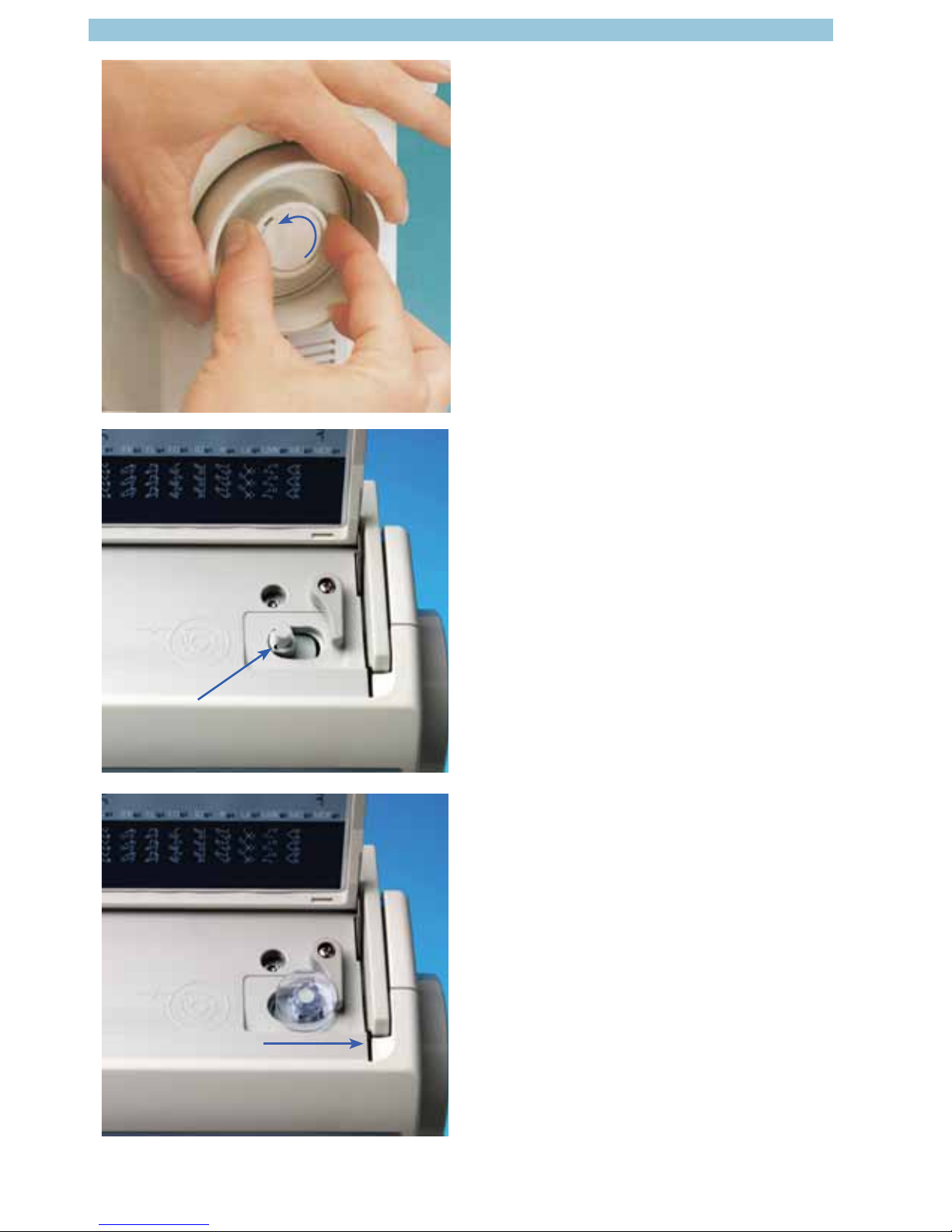

4

Operate your Pfaff select

Preparing the machine

for bobbin winding

Hold the handwheel (4) fi rmly and turn the

handwheel release disc (3) until it stops in the

direction of the arrow. This stops the needle

from moving while the machine is winding the

bobbin.

Placing the bobbin

Switch off the main switch (2)

Place the empty bobbin so that the black pin of

the bobbin winder (5) snaps into the slot of the

bobbin.

Push the bobbin to the right

Note: The bobbin can only be wound when it is

moved fully to the right.

Page 15

5

A

B

D

Operate your Pfaff select

Winding the bobbin

from the spool holder

Place the sewing thread on the spool holder

(8). To guarantee free movement of the thread

and to give additional hold to the thread spool,

fi t a spool cap corresponding to the size of the

thread spool

Threading

Place the thread into guide A and pull it through

opening B and to the right under the hook D.

Wind the thread clockwise a few times around

in the bobbin.

Switch on the main switch

Hold the end of the thread fi rmly and press

the foot control. The winding action will stop

automatically as soon as the bobbin is full.

Cut the thread, push the bobbin to the left and

remove it.

Don’t forget:

Turn the handwheel release disk (3) fully back

again. Then turn the handwheel (4) towards

you until it snaps into place.

Page 16

6

B

C

D

Operate your Pfaff select

Winding from the second spool holder

Push the second spool holder (7) into its

hole and place a spool of thread with the

corresponding spool cap on it.

Threading

Place the thread into guide C and pull it

through opening B to the right under hook D.

Wind the thread clockwise a few times around

the bobbin.

Switch on the main switch

Hold the end of thread fi rmly and press the

the foot control. The winding action will stop

automatically as soon as the bobbin is full.

Cut the thread, push the bobbin to the left and

remove it.

Don’t forget:

Turn the handwheel release disk (3) fully back

again. Then turn the handwheel (4) towards

you until it snaps into place.

TIP: If the machine is already threaded, you

can easily wind thread from the second spool

holder without having to unthread the machine.

Page 17

7

D

Operate your Pfaff select

Winding through the needle

Even if the machine has been completely

threaded, you can still wind the bobbin.

Raise presser foot lifter (19). Pass the

needle thread through the presser foot and

downwards; then through the right threading

slot (11) and upwards.

Now, pull the thread into the take-up lever

from left to right (9). The take-up lever must be

positioned at its very top.

Pass the thread to the right under the guide

hook D. Then wind the thread several times

around the bobbin. Press the foot control and

winding the bobbin.

Don’t forget:

Make sure to stop the needle from moving

while winding the bobbin (see page 4).

Page 18

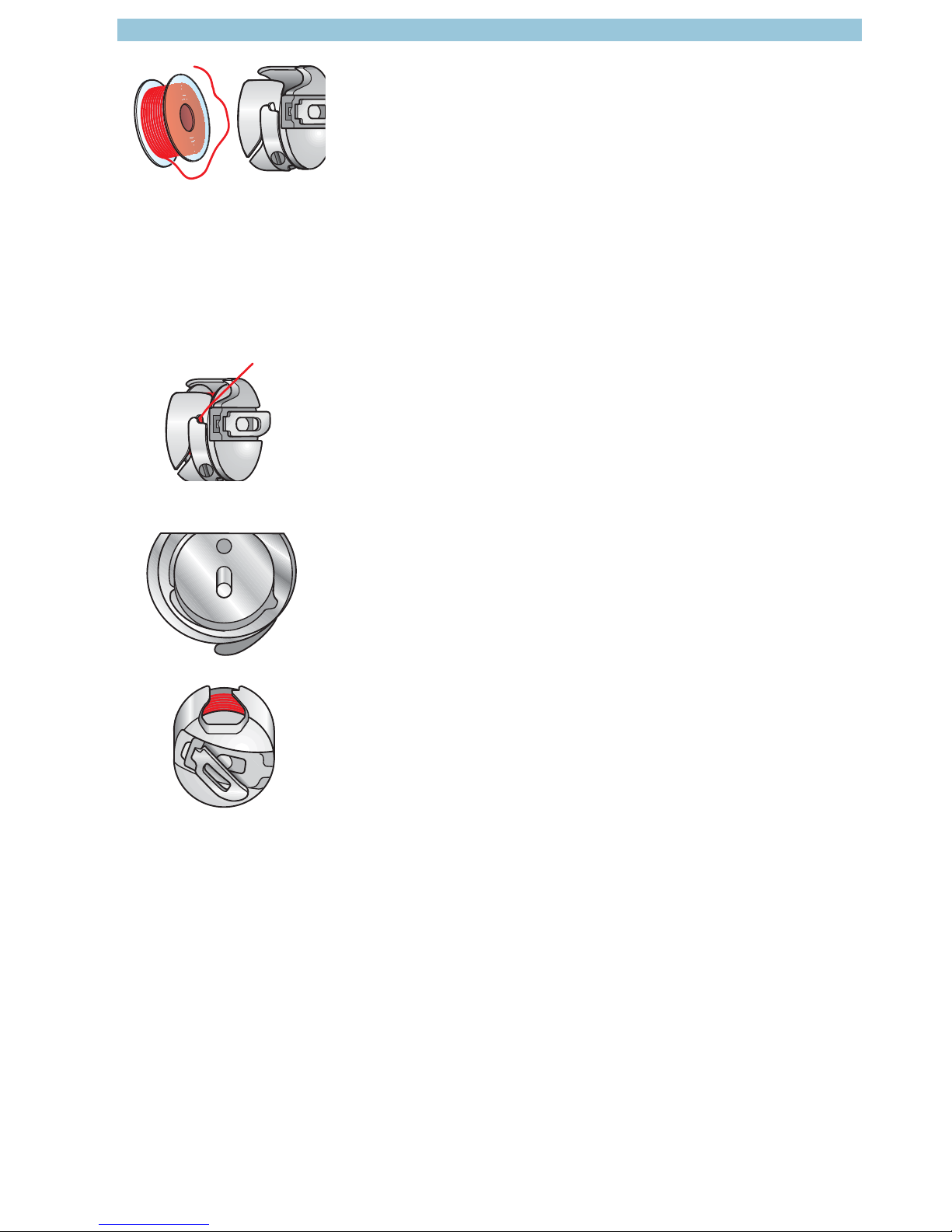

8

Operate your Pfaff select

Bobbin Case/Hook Cover

Switch off the main switch

Hold the side of the bobbin case/hook cover

and open it towards you.

Removing the bobbin case

Raise the bobbin case lever and pull out the

bobbin case. Release the lever and remove

the empty bobbin.

Thread tension

To ensure perfect sewing and a durable seam,

the top and bottom thread-tensions must be

well adjusted to each other and the threads

must be interlaced between the two fabric

pieces. The interlacing should be visible from

the underside of the material only when sewing

decorative seams, buttonholes and darning.

Page 19

9

Operate your Pfaff select

Inserting the bobbin

Insert the full bobbin into the bobbin case. In

doing so, pull the thread sideways through slot

A, then under the tension plate B until it rests in

the opening (see arrow).

Check: When you look at the bobbin and pull

the thread, the bobbin must turn clockwise.

Inserting the bobbin case

Lift lever F and slide the bobbin case onto the

hook pin D as far as it will go. Opening E of the

bobbin case must face upwards.

Check: Pull the bobbin thread sharply. The

bobbin case must not fall out of the hook.

Page 20

10

D

A

E

Operate your Pfaff select

Threading the needle thread

Switch off the main switch

Raise the presser foot lifter (19) and turn the

handwheel until the take-up lever (9) has

moved to the top. Place the thread on the

spool holder (8) and fi t the corresponding

spool cap.

Now, using both hands, pull the thread into

guide A and under thread guide hook D. Pass

the thread through the lefthand threading slot

(11) and downwards. Pull the thread around

stop E into the righthand threading slot and

upwards to the take-up lever (9).

The thread must be pulled into the take up

lever (9) from left to right and downwards

again in the righthand threading slot. Finally,

pass the thread from the side behind one of

the two thread guides (25).

To thread the needle, place the thread from

front to back through the needle eye.

To thread the needle using the needle

threader (Model 1540), please refer to the

next page.

Page 21

11

A

A

B

Operate your Pfaff select

Needle threader (Model 1540)

To make threading the needle easier and

quicker, you have been provided with the

PFAFF needle threader (13). Lower the presser

foot. Turn the handwheel until the needle is at

its highest position. Place the needle thread

under hook A and hold it taut. Move the needle

threader fully downwards and turn it towards

the needle so that the small hook B goes

through the needle eye. Place the thread into

the hook from below.

Turn the needle threader towards the rear,

releasing the thread carefully, and allow the

threader to move upwards. You can now pull

the thread through the needle eye.

Threading the twin needle

Insert the twin needle.

Fit the second spool holder and place one

spool of thread on each holder.

In the left threading slot (11) you will fi nd

tension disk A. During threading, make sure

that you pass one thread left and one thread

right over tension disk A.

Carry on threading in the usual way, but make

sure the threads are not twisted with each

other.

Pull the threads right and left into thread guide

(25) and thread the needles.

Note: You cannot use the needle threader for a

twin needle (Model 1540).

Page 22

12

Operate your Pfaff select

Drawing up the bobbin thread

Turn off the main switch

Raise the presser foot. Hold the needle thread

and turn the handwheel towards you until

the needle is at the top again and the bobbin

thread has formed a loop. Pull the needle

thread to draw up the bobbin thread.

Bobbin thread

Close the bobbin case/hook cover and pull the

thread under the presser foot to the left.

Thread cutter

Pull the threads from the back to the front

over the thread cutter (12).

Page 23

13

Operate your Pfaff select

Presser foot lifter

The presser foot is raised or lowered with the

presser foot lifter (19).

Removing the presser foot

Turn off the main switch

Position the needle at its highest point

Press the presser foot upwards at the front and

downwards at the back at the same time so

that it disengages from the presser foot holder

(14)

Engaging the presser foot

Place the presser foot under the presser foot

holder (14) so that when the presser foot lifter

(19) is lowered, the pins of the foot engage in

the presser foot holder.

Check: Please check that the presser foot is

properly engaged by raising the presser foot

lifter.

Page 24

14

Operate your Pfaff select

The Intigrated dual feed/IDT System (Models

1530 and 1540)

PFAFF offers the ideal solution for sewing

diffi cult materials: the intigrated dual feed. This

system feeds the material from the top and

bottom simultaneously as is done in industrial

sewing machines. The fabric is fed precisely.

When sewing light or diffi cult materials such as

silk and rayon fabrics, the dual feed prevents

seam puckering.

Engaging the Intigrated Dual feed

(Models 1530, 1540)

Important! For all sewing jobs with the top

feed, only use sewing feet with cutout at the

back.

Raise the presser foot. Then push the top

feed (17) downwards until it snaps into place.

Disengaging the Intigrated Dual Feed

Hold the dual feed with two fi ngers at the

marked places. Push the top feed (17) down a

little and out to the rear, and let it move slowly

upwards.

The even feeding action also ensures perfect

matching of checked and striped fabrics.

Page 25

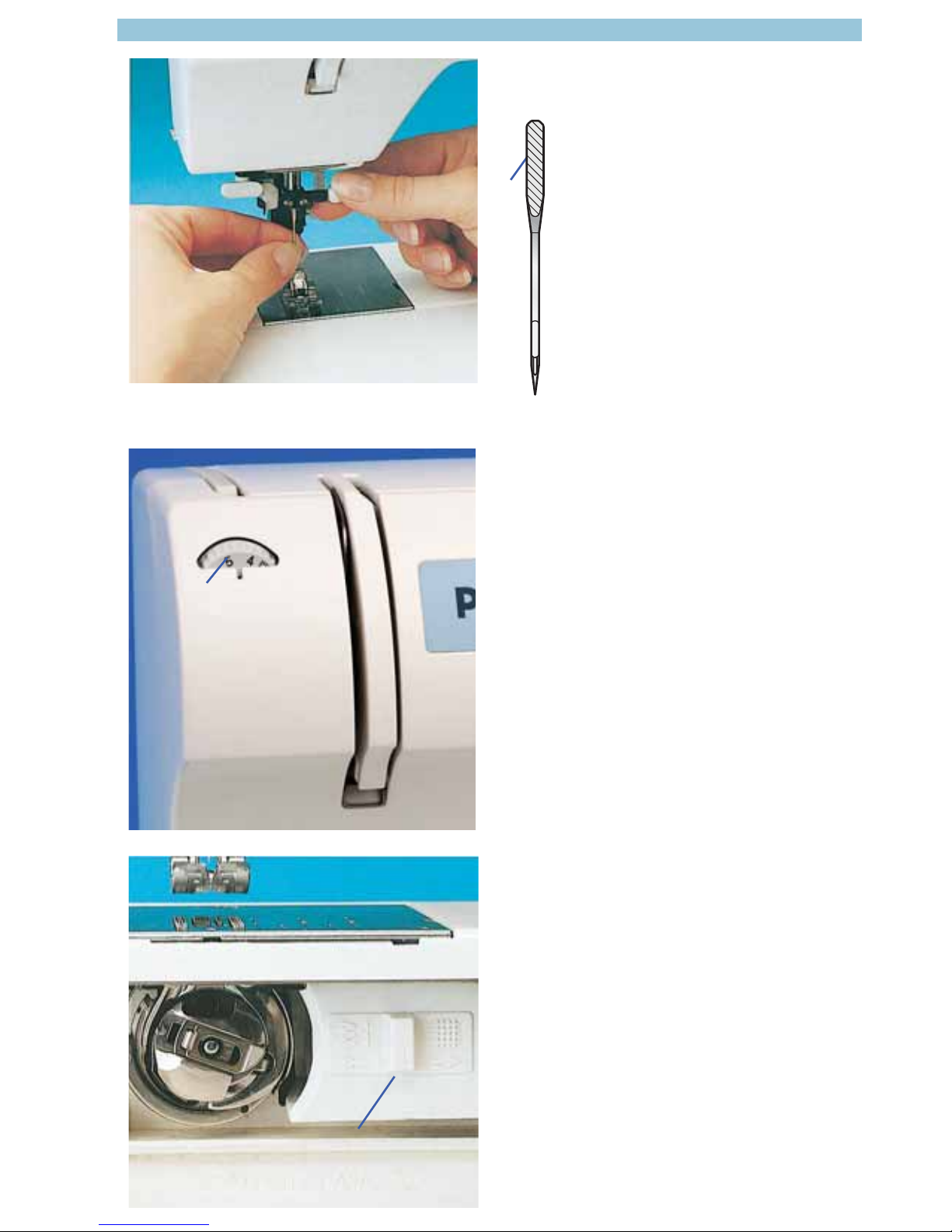

15

A

A

A

Operate your Pfaff select

Changing the needle

Switch off the main switch

To remove: Lower the presser foot

and move the needle to its highest

point. Now loosen the fi xing screw

(18) and pull the needle downwards.

To insert: The fl at side A of the needle

must face to the rear. Lower the

presser foot and insert the needle,

pushing it up as far as it goes. Hold

the needle and tighten the fi xing screw

(18) fi rmly.

Setting the needle thread tension

Set the required needle thread tension (10)

with the help of the mark A.

The normal setting for sewing is 4 to 5.

For embroidering, darning and buttonhole set

the tension between 2 and 3.

Dropping the feed dog

For certain sewing work, e.g. darning the feed

dog has to be dropped. To do this, open the

bobbin case/hook cover and move slide A fully

to the right. Now the feed dog is dropped.

Page 26

16

Operate your Pfaff select

Stitch width dial

The stitch width can be adjusted with this dial

(27). When selecting the width, the needle

must not be in the material.

Basic setting: Turn the stitch width knob (27) to

the symbol

(maximum stitch width).

Exception: Straight stitch is sewn with stitch

width 0.

In chapter “Utility stitches and practical sewing”

(pages 21-44), you will fi nd recommendations

in the tables for the stitch width selection of

individual stitches. During sewing you can also

change the stitch width.

Needle position dial

In the center needle position

, 14

additional needle positions can be selected

by turning the needle positioning dial (28) in

increments to the left or right. The furthest

needle position to the left

can be

achieved by turning the dial(28) as far as it will

go to the right. The furthest needle position

to the right can be achieved by turning

the dial as far as it will go the left. When the

position of the needle is being changed, the

needle must not be in the material.

Note: If you have selected the right needle

position, you can now use the width dial (27) to

increase or reduce the width of the left side of

the stitch. The reverse applies also for needle

position to the left (see page 49).

Page 27

17

Operate your Pfaff select

Reverse sewing

The machine sews in reverse only as long as

the reverse sewing button (20) is pressed.

Stitch length adjustment dial

With the stitch length adjustment dial (21) you

can adjust the stitch length between 0 and 6

mm by turning the point marking on the button

to the required length.

Between the numbers 0 and 1 you will fi nd the

“buttonhole” symbol. This area is the optimum

stitch density for sewing buttonholes and

embroidering.

The further you turn the dial to 0, the higher the

density of the stitch.

To sew stretch stitches (dark background), you

must turn the stitch length adjustment dial (21)

as far as it will go in the grey area.

Page 28

18

B

B

B

Operate your Pfaff select

Utility stitches

Each stitch has been given a letter that you can

fi nd on the push button controls. By pressing

the correct button, the stitch is selected and the

machine is ready to sew. Button B releases the

buttons that have been activated.

Under the lid (6) you will fi nd the stitch

table with all the utility stitches and stitch

combinations.

Stretch stitches

All the stitches with a colored background are

stretch stitches, i.e. they are suitable for stretch

material. Press the selected button down and

turn the stitch length dial (21) as far as it will go

in the grey area.

Button B releases the button that have already

been activated.

Utility and stretch stitch combinations

By pushing two or several buttons you can

create combinations in the utility stitch range.

The stitch length dial can either be in the

normal sewing range or in the stretch range.

All the stitch combinations are illustrated on the

stitch table in the lid. You can release buttons

that are already activated with button B.

Stitch selection, push button controls – select 1540

Page 29

19

24

A

21

Operate your Pfaff select

Stitch selection, stitch dial – select 1530, 1520

Utility stitches

Each stitch is identifi ed by a letter. The stitches

and their corresponding letters are shown on

the inside of the lid, a chart is also found in the

Introduction chapter.

Turn the dial (24) until the corresponding letter

is positioned below mark A.

Stretch stitches

All the stitches with a colored background are

stretch stitches, i.e. they are suitable for stretch

material.

Turn the dial (24) until the corresponding letter

is positioned below mark A.

Turn the stitch length dial (21) as far as it will

go in the grey area.

Page 30

20

Operate your Pfaff select

Page 31

21

Utility stitches and practical sewing

Utility stitches

and practical sewing

Sewing chart 22

General sewing aids 23

Non-elastic stitches 24-25

Elastic stitches 26-27

Overlock stitches 28-29

Covering stitches 30-31

Buttonhole 32-33

Button sewing 34

Hemming with the twin needle 35

Smocking 35

Gathering 36

Darning 37-38

Sewing on zippers 39-41

Stabilizing edges 42

Sewing lace 43

Shell edging 44

Page 32

22

1540

1530

1520

Utility stitches and practical sewing

Explanation of the sewing chart

The following charts show the recommended

settings for each stitch or technique.

These charts also provide you with further

instructions that are necessary when sewing

the selected stitches.

The choice of the sewing foot, the setting

of the needle thread tension and whether

the sewing is carried out with the top feed

switched on or off.

Always use the “center” needle position

if not otherwise specifi ced in the

instructions.

stitch

stitch

Stitch number

Stitch width in mm

Stitch length in mm

Dual feed on =

off =

Thread tension

Presser foot number

Page 33

23

A

B

Utility stitches and practical sewing

Needle thread tension

To ensure perfect sewing results, the needle

and bobbin thread tensions must be perfectly

tuned to each other . The normal setting for

utility stitches is in the range of 4-5.

Check the tension with a wide zigzag stitch.

The threads must be interlaced between the

two fabric pieces.

If the needle thread tension is too high the

threads are interlaced above the top fabric.

If the needle thread tension is too low, the

threads are interlaced below the lower fabric.

The adjustment of the needle thread tension is

described on page 15 and the bobbin thread

tension on page 8.

Topstitching

Straight stitch G (1540)/E (1530, 1520) can be

sewn using any of 15 various needle positions

in such a way that you can always guide the

sewing foot along the fabric edge for topstitching work. The top-stitch needle position is

determined by the needle position dial. If you

wish to top-stitch farther from the fabric edge,

simply guide the fabric along the guide marks

on the needle plate or use the edge guide

(standard accessory No.8). The edge guide is

inserted into hole A and is secured with fi xing

screw B.

Sewing aid for thick seams

To ensure a consistent feed when beginning

sewing at a thick seam, we recommend

supporting the presser foot on a piece of fabric

of the same height as the workpiece

Too high tension

Too low tension

Perfect tension

Page 34

24

B

A

C

1540

1530

1520

1540

1530

1520

Utility stitches and practical sewing

Straight stitch

Stitch G/E is the basic straight stitch. The stitch

length can be increased up to 6 mm if required.

It is easier to do some sewing jobs by changing

the needle position, e.g. top-stitching a collar

or sewing in a zipper. You can select up to 15

different needle positions (see page 16).

Please ensure that the needle is at its highest

position when adjusting the needle position.

Zigzag stitch

In addition to overlock stitching, zigzag

stitch G, stitch width 5

, is also suitable for

overcasting various materials. In this case,

the material should only be positioned halfway

under the sewing foot.

When overcasting the edge, make sure the

needle goes into the material and over the

edge alternately.

The width for overcasting can be reduced up

to 2 mm.

For overcasting diffi cult materials, blind stitch

foot No. 3 is very useful. When sewing, the

thread lies over pin C, thus preventing curling

of the fabric edge. In this way you can sew

beautiful smooth seams.

The raw edge must be guided along edge

guide B. You can adjust this edge guide with

adjusting screw A.

Important: When the blind stitch foot is used

for overcasting with the zigzag stitch, select

the right needle position. Choose a stitch width

in the range of 3-5 mm (do not use any other

needle position).

stitch

G

E

E

0

0

0

2,5

2,5

2,5

3-5

3-5

3-5

0/1

0/1

0/1

stitch

G

E

E

2-

2-

2-

1-2

1-2

1-2

3-5

3-5

3-5

0/1

0/1

0/1

Page 35

25

B

A

1540

1530

1520

Utility stitches and practical sewing

Remember!

When blind stitching, if you select a needle

position other than right,

and stitch width

other than 5, make sure the needle does not

strike the bar of presser foot 3.

If the stitches are visible on the right side,

adjust edge guide B by turning adjusting screw

A.

Use the needle position

and the width

dial (27) to regulate the penetration of the

needle in the crease.

Stitch H (1540)

Stitch D (1540), stitch H (1530/1520)

Blind stitch (Model 1540)

Blind stitch H is best suited for invisible hems;

sewing by hand is no longer necessary.

• Serge the edge of the hem

• Fold the edge inwards by the hem width.

• Now unfold the hem again so that the hem

edge protrudes by about 1 cm

• Place the fabric under the sewing foot so

that the crease line runs along edge guide

B.

• Using the needle positioning knob 28,

select the needle position to the right

.

• When the needle enters the crease line, it

must only pick up one fi ber of the fabric.

Blind stitch (elastic)

Stitch D (1540) or H (1530/1520) is a blind

stitch for woven or elastic materials. The hem

is sewn and overcast at the same time.

stitch

H/D

- /H

- /H

5-

5-

5-

1-2

1-2

1-2

3-5

3-5

3-5

0/3

0/3

0/3

Page 36

26

1540

1530

1520

1540

1530

1520

Utility stitches and practical sewing

Stretch triple straight stitch

This stitch is used for sewing all seams where

great strength is needed, e.g. inside trouser

seams.

Turn the stitch length dial away from you as far

as it will go for the longest stitch length.

Stretch triple zigzag stitch

The stretch triple zigzag stitch is a highly

elastic and decorative seam which is very

suitable for hems on T-shirts and underwear.

• Serge the edge of the hem.

• Fold the hem inwards at the required width.

• Topstitch the hem from the right side.

select

G

E

E

0

0

0

Stretch

Stretch

Stretch

3-5

3-5

3-5

0/1

0/1

0/1

select

G

E

E

3-5

3-5

3-5

Stretch

Stretch

Stretch

3-5

3-5

3-5

0/1

0/1

0/1

Page 37

27

1540

1530

1520

1540

1530

1520

Utility stitches and practical sewing

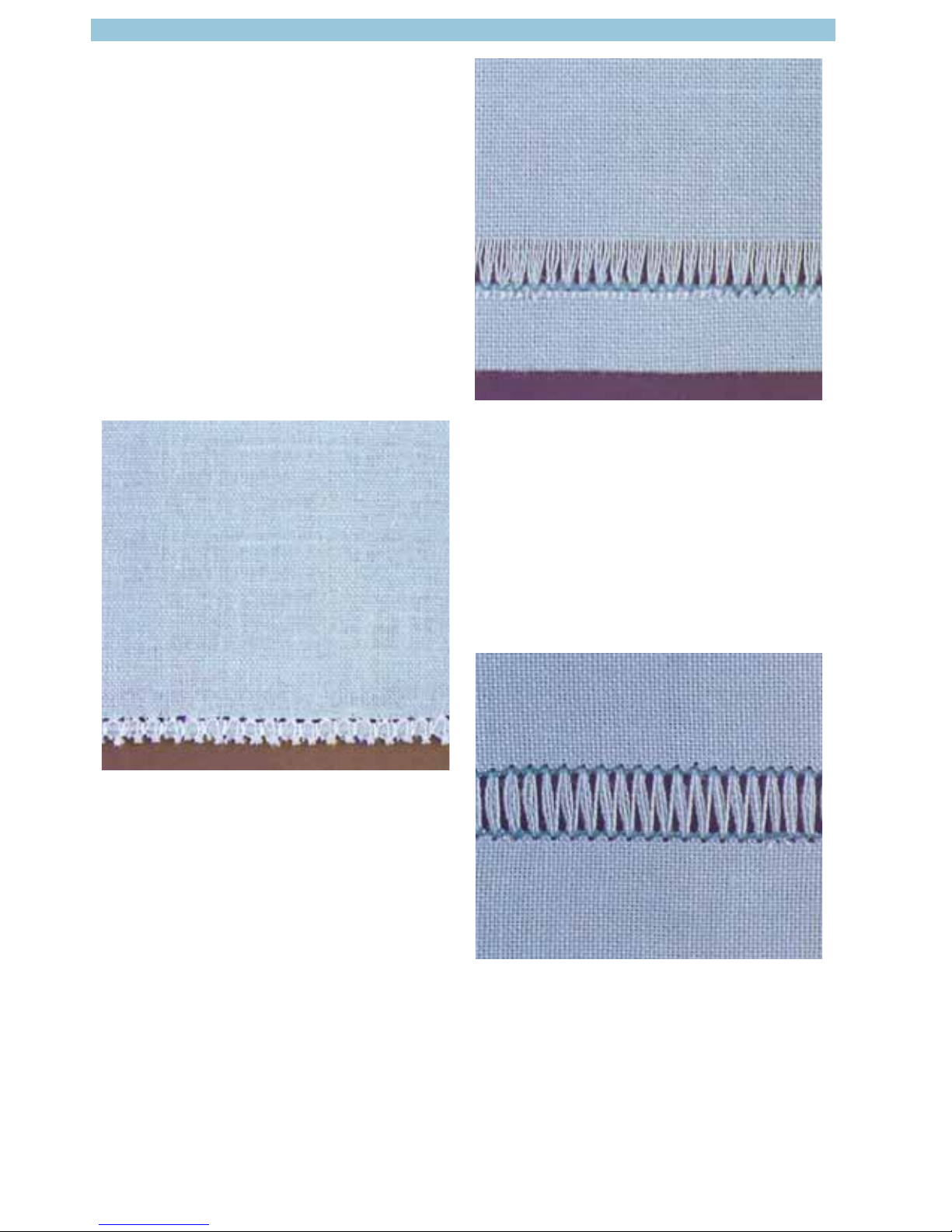

Honeycomb stitch

The honeycomb stitch is an elastic and

decorative hem which is particularly suitable for

hems on T-shirts and childrens clothes.

• Fold the hem over double and overstitch it.

Elastic stitch

Because of its high elasticity, this stitch can be

used for sewing elastic on swimwear, skirts or

lingerie.

• Mark elastic and fabric in quarters.

• Pin elastic to fabric at quarter markings.

• Place fabric and elastic under sewing foot.

• Stretch elastic to fi t the fabric. Begin

sewing.

Note: When stretching elastic, make sure to

stretch from the front and back of the sewing

foot.

select

M

F

F

5-

5-

5-

1-2,5

1-2,5

1-2,5

3-5

3-5

3-5

0/1

0/1

0/1

select

M

F

F

5-

5-

5-

Stretch

Stretch

Stretch

3-5

3-5

3-5

0/1

0/1

0/1

Page 38

28

1540

1530

1520

Utility stitches and practical sewing

What is an overlock stitch?

For elastic materials and knits, the select

models offer overlock stitches which sew

two fabric layers together and overcast

simultaneously. They are more elastic than

normal seams, very durable and quickly sewn.

Tip: We recommend using blind stitch foot

No. 3 when sewing overlock seams. It guides

particularly well and prevents the seam from

puckering even on wide seams.

Open overlock stitch

With this stitch, thicker materials and fabrics

which do not fray too much can be sewn

together perfectly.

TIP: Make sure that the needle sews to the

right of the material just over the edge and not

in it.

stitch

K

I

I

5-

5-

5-

Stretch

Stretch

Stretch

3-5

3-5

3-5

0/3

0/3

0/3

Page 39

29

1540

1530

1520

1540

1530

1520

Utility stitches and practical sewing

Closed overlock stitch

The closed overlock stitch is perfect for sewing

jersey knits. You can also sew sleeve cuffs and

knit collars which are well-sewn and longlasting.

TIP: Ensure that the sleeve cuff is stretched

while it is being sewn.

Remember!

When overlocking, if you select a needle

position other than center,

and stitch

width other than 5 , make sure the needle

does not strike the bar of sewing foot 3.

Pullover stitch (Model 1540)

This stitch is suitable for open-knit fabrics.

Fashion-knit garment sections can also be

joined effortlessly with this stitch. Make sure

that the material is fed to the right of the

needle, not to the left.

TIP: To prevent the seam from stretching while

sewing, it is advisable to add a woolen thread

under light tension.

stitch

I

K

K

5-

5-

5-

Stretch

Stretch

Stretch

3-5

3-5

3-5

0/3

0/3

0/3

stitch

H

–

–

5-

–

–

Stretch

–

–

3-5

–

–

0/1

–

–

Page 40

30

1540

1530

1520

Utility stitches and practical sewing

What is a covering stitch?

You can use the following stitches for sewing a

fl at covering seam. This produces a so called

“fl atlock effect” which lends a professional look

to collar plackets or raglan seams.

The covering stitches are only available on

select 1540.

Feather stitch (Model 1540)

With the feather stitch you can sew highly

elastic materials with an effect similar to that of

hem stitching, e.g. lingerie.

• Serge the fabric edges and baste them

over.

• Lay the edges to be sewn underneath the

pressing foot with a distance between the

edges of about 3 mm.

• Stitch from the face side, ensuring that the

needle perforates the material both right

and left.

stitch

L

–

–

5-

–

–

Stretch

–

–

3-5

–

–

0/1

–

–

Page 41

31

1540

1530

1520

1540

1530

1520

Utility stitches and practical sewing

Fancy elastic stitch (Model 1540)

The fancy elastic stitch is very useful for

materials that require a fl at seam, e.g. terry

cloth and fl eece.

• Place the two fabric edges so that they

overlap by about 2 cm and overstitch each

edge with fancy elastic stitch.

Pennant stitch (Model 1540)

The pennant stitch is one of the many types

of covering stitches. Since it can be stretched

it is particularly suitable for overstitching the

bands on elastic materials, e.g. sweatshirts or

sportswear.

• Sew the band onto the part with an overlock

stitch (see pgs 28,29)

• The seam allowance can now be

overstitched from the right side of the fabric.

Make sure that the needle enters in the

shadow of the seam.

stitch

L

–

–

5-

–

–

1-2

–

–

3-5

–

–

0/1

–

–

stitch

IG

–

–

5-

–

–

Stretch

–

–

3-5

–

–

0/1

–

–

Page 42

32

h

3-5

3-5

3-5

1540

1530

1520

Utility stitches and practical sewing

Buttonholes

Sewing buttonholes is very easy with all the

models with pushbutton controls since the

fabric does not have to be turned.

Buttonholes are generally sewn onto a piece of

doubled fabric. However, for some materials,

e.g. silk, organza and viscose, it is necessary

to use stabilizer to prevent the material from

contracting while sewing.

To produce beautiful seams, embroidering

or darning threads are ideally suited to this

purpose.

Mark the starting point of the buttonhole either

with a magic pen or dress pin, and always sew

a sample buttonhole fi rst.

Note: Before starting any buttonhole, always

push the guide of the buttonhole foot fully to

the front, i.e. so that the red arrow is at the

fi rst red mark. The red marks are arranged at

an interval of 0.5 cm. They are a guide when

determining the length of the buttonhole.

1540 – Standard buttonhole

• Insert the buttonhole foot and slide the foot

forward as far as it will go.

• Select stitch 1 (C) and sew the right side of

the buttonhole to the required length. Clip

the top thread after a few stitches.

• Select stitch 2 (B) and hold the button down

as you sew a few bartacks.

• Select stitch 3 (A) and sew the left side of

the buttonhole until it matches the previous

side in length.

• Select stitch 4 (B) and hold the button down

as you sew a few bartacks.

• Release button B and sew a couple stitches

to secure your buttonhole.

• Carefully cut open your buttonhole with

scissors or a seam rippper.

Tip: If you would like to sew very fi ne

buttonholes, you can reduce the buttonhole

width with the stitch width dial (27) down to

approx. 3 mm. Use the center needle position

.

CBA

-

-

stitch

5-

–

–

0/1

–

–

Page 43

33

B

A

1540

1530

1520

Utility stitches and practical sewing

1520/1530 – Standard buttonhole

• Insert the buttonhole foot and slide the foot

forward as far as it will go.

• Select stitch A. Sew the left side of the

buttonhole to the required length. Clip the

top thread after a few stitches.

• Select stitch B and sew a few bartacks

while holding the fabric securely.

• Select stitch C. Sew the right side of the

buttonhole until it matches the previous side

in length.

• Select stitch B and sew a few bartacks

while holding the fabric securely.

• Select stitch D. Secure the buttonhole by

sewing a few stitches.

• Carfully cut open your buttonhole with

scissors or a seam ripper.

Tip: If you would like to sew very fi ne

buttonholes, you can reduce the buttonhole

width with the stitch width dial (27) down to

approx. 3 mm. Use the center needle position

.

Standard buttonhole with gimp thread

To sew especially durable buttonholes,

on heavy fabrics, knits or sportswear, we

recommend using a gimp thread.

On knits the gimp thread is particularly

important to prevent the buttonhole from

stretching.

• Lay the gimp thread over the rear

protrusion A and pass the thread ends

underneath the presser foot towards the

front.

• Clamp the threads to the left and right of

protrusion B.

• Slide the buttonhole runner as far forwards

as possible and sew the buttonhole as

described for your select model.

• Pull the loop of the gimp thread into the

buttonhole and cut the threads.

Carfully cut open your buttonhole with scissors

or a seam ripper.

stitch

–

ABC

ABC

–

5-

5-

–

0/1

0/1

Page 44

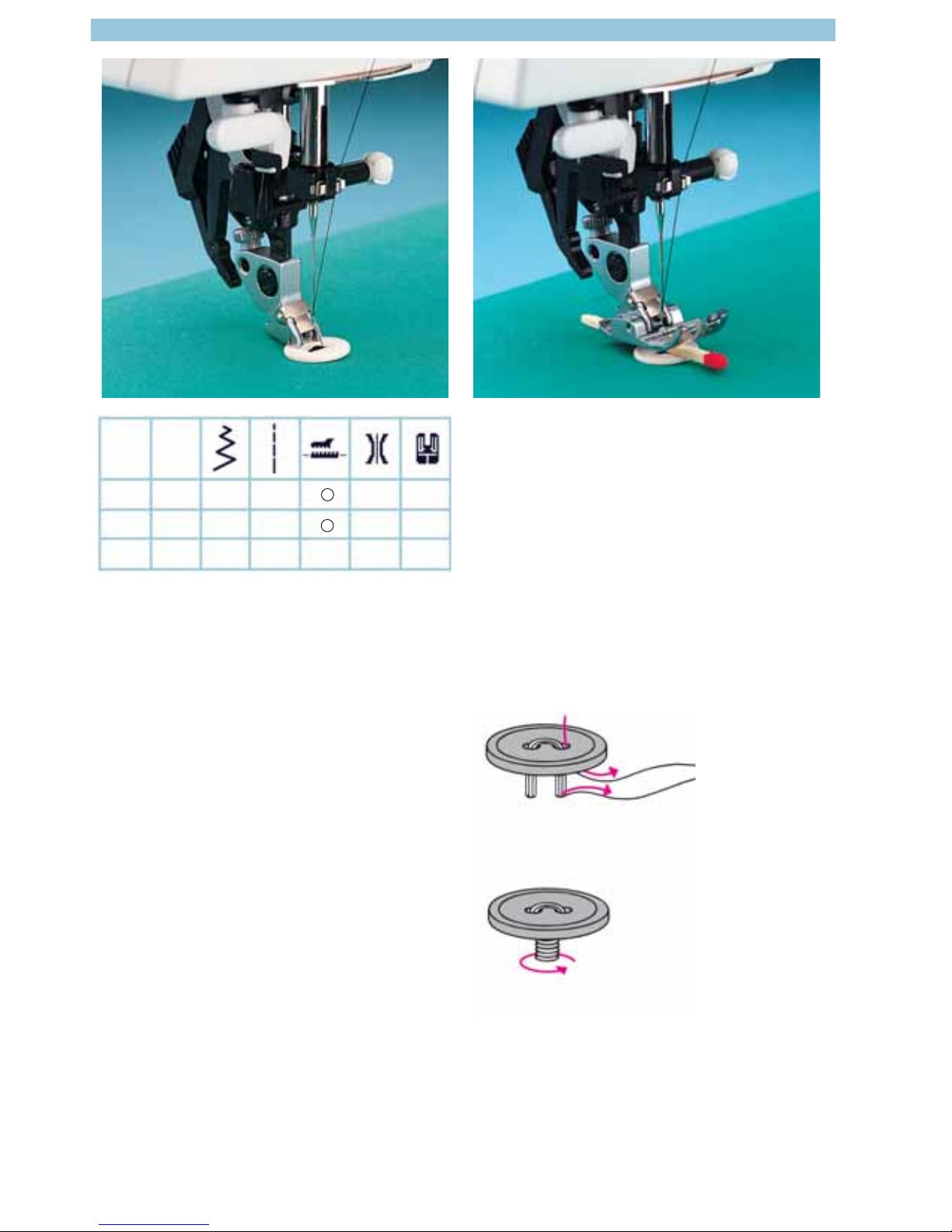

34

1540

1530

1520

Utility stitches and practical sewing

Sewing on buttons

With zigzag stitch G/E (stitch width 4 mm) you

can sew on two- and four-hole buttons.

• Remove the sewing foot and lower the feed

dog

• Turn the handwheel towards you and move

the button in such a way that the needle

enters the left hole in the button

• Now lower the presser foot lifter; this holds

the button off the blade.

• Sew on the button. Take care to ensure that

the needle also enters the right-hand hole in

the button.

Securing

• Select straight stitch by turning the width

dial (27) to 0.

• Change the needle position with the needle

position dial (28) so that the needle enters

one of the two holes.

• Sew a few securing stitches.

Sewing on buttons with shanks

Insert the sewing foot

• Place a match between the holes of the

button and sew it on as described to the left.

• Remove the match and pull the fabric and

the button apart.

• Wrap the shank you have just created with

sewing thread and knot it. (See illustrations

below)

stitch

G

E

E

4

4

4

–

–

–

2-3

2-3

2-3

–

–

–

Page 45

35

1540

1530

1520

1540

1530

1520

Utility stitches and practical sewing

Hemming with the twin needle

Use the twin needle to make beatiful topstitch

seams.

Using the twin needle you can add a

professional touch to hems on stretch materials

such as T-shirts, knitted articles or cycling

shorts both quickly and easily.

Twin needles are available in different widths.

The traditional width for topstitching is 4 mm.

To prevent the needle from striking the needle

plate, you must make sure that you select the

center needle position .

• First fold and iron the width of fabric desired

for the hem.

• Then topstitch the hem from the right side.

• Finally, cut the protruding hem edge back to

the seam.

Use only a stretch needle when sewing stretch

material!

Tip: On diffi cult materials such as ribbed knitwear it is advisable to baste the hem before

topstitching it.

On page 11 you will fi nd a description of how to

thread the twin needle.

Smocking effect with elastic threads

Fine, light fabrics such as Batist, rayon and silk

are particularly suitable for beautiful smocking

work. For smocking work with the elastic

thread, you should use an additional bobbin

case and wind the bobbin by hand with the

elastic thread. As the elastic thread is much

stronger than the normal bobbin thread, the

tension of the bobbin case must be set at very

low.

Don’t forget, the higher the bobbin thread

tension, the more intense the gathering effect.

• Sew a test seam to determine the level of

gather.

• Mark the fi rst line on the right side of the

fabric and sew along it.

• Each additional seam can be sewn at a

presser foot’s width from the fi rst row.

• When sewing several seams next to one

another, you must stretch the fabric to its

original length when sewing the subsequent

seams. Otherwise, the gather will be

irregular.

• Knot the threads at the beginning and end

of the seam on the reverse side.

stitch

G

E

E

0

0

0

3

3

3

3-5

3-5

3-5

0/1

0/1

0/1

stitch

G

E

E

0

0

0

3-4

3-4

3-4

3-5

3-5

3-5

0/1

0/1

0/1

Page 46

36

1540

1530

1520

1540

1530

1520

Utility stitches and practical sewing

Gathering with the straight stitch

Using a straight stitch, you can gather sleeves,

skirts and valances with a stitch length of 6

mm. To ensure consistent gathering you should

sew two or three rows of gathering.

• Mark the fi rst line on the right side of the

fabric and sew along it. Allow the threads to

extend approx. 10 – 20 cm.

• Each subsequent seam can be sewn one

presser foot width from the last.

• Gather the piece of fabric by pulling the

bobbin thread. You determine the amount of

gather by how much you pull the thread.

• Finally, the thread ends are knotted to

secure the gather.

Gathering with elastic thread

Sleeve and waist seams can be gathered by

sewing over an elastic thread.

• Mark the fi rst gathering seam on the

reverse side of the fabric.

• Sew a few stitches using stitch M/F. Leave

the needle in the fabric. The needle must

be in the center of the presser foot. Raise

the presser foot and lay the elastic thread

around the needle.

• Lower the presser foot and sew a few

stitches. Then pull the elastic thread evenly

at both ends.

• Determine the amount of gather by the

amount you pull the threads.

• The gather can also be altered after sewing

by pulling the ends of the elastic threads.

• Finally, knot the threads and elastic.

Tip: The cording foot (special accessory) is

particularly suitable for gathering. Due to its

guide grooves the elastic is fed evenly during

the sewing process.

stitch

G

E

E

0

0

0

6

6

6

3-5

3-5

3-5

0/1

0/1

0/1

stitch

M

F

F

5-

5-

5-

Stretch

Stretch

Stretch

3-5

3-5

3-5

0/1

0/1

0/1

Page 47

37

D

C

G

F

E

A

B

1540

1530

1520

Utility stitches and practical sewing

Darning with the straight stitch

Insert the darning foot:

Loosen screw D. Set the needle at its highest

point and push the pin of the darning foot fully

into the hole C of the sewing foot holder. When

doing this, the guide fork G should position

itself around the presser bar. The lever E must

be behind the fi xing screw F. Now tighten

screw D.

Darning position:

Lower the presser-foot lifter (A) while pushing

it lightly to the rear. This snaps the presser foot

lifter into a notch (B) on the back side of the

sewing machine into the darning position.

• Place the darning work in the darning hoop.

• Drop the feed dog.

• Pull up the bobbin thread and hold the

threads when you start sewing.

• Darn the damaged area by guiding

the fabric back and forth evenly in the

prescribed direction while ensuring that

each line ends with a small curve. This

helps to avoid the fabric ripping again.

• When you have fi nished sewing the

damaged area, rotate the fabric again.

You determine the stitch length yourself by

moving the fabric back and forth.

Tip: If you move the fabric too slowly, small

knots will appear on the reverse side of the

fabric.

stitch

G

E

E

0

0

0

–

–

–

2-3

2-3

2-3

6

Optional

Optional

Page 48

38

1540

1530

1520

Utility stitches and practical sewing

Darning with the elastic stitch

Darning with the elastic stitch is especially

suitable for repairing damaged areas.

• Sew over the damaged area in rows until it

is well covered. Take care to ensure that the

rows overlap.

Sewing on patches

To cover larger holes is it necessary to sew a

new piece of fabric onto the damaged area.

• Baste the new piece of fabric onto the

damaged area of the face side of the fabric.

• Sew over the fabric edges with the elastic

stitch.

• Now cut the damaged area back to the

seam from the reverse side of the fabric.

Repairing tears

On tears, frayed edges or small holes it is

useful to lay a piece of material under the

reverse side of the fabric. The underlayed

fabric reinforces the workpiece and ensures

perfect repair.

• Lay a piece of fabric underneath the

damaged fabric. It must be a little larger

than the damaged area.

• Now sew over the damaged area.

• Cut the under layed piece of material back

to the seam.

stitch

M

F

F

5-

5-

5-

0,2-1,5

0,2-1,5

0,2-1,5

3-5

3-5

3-5

0/1

0/1

0/1

Page 49

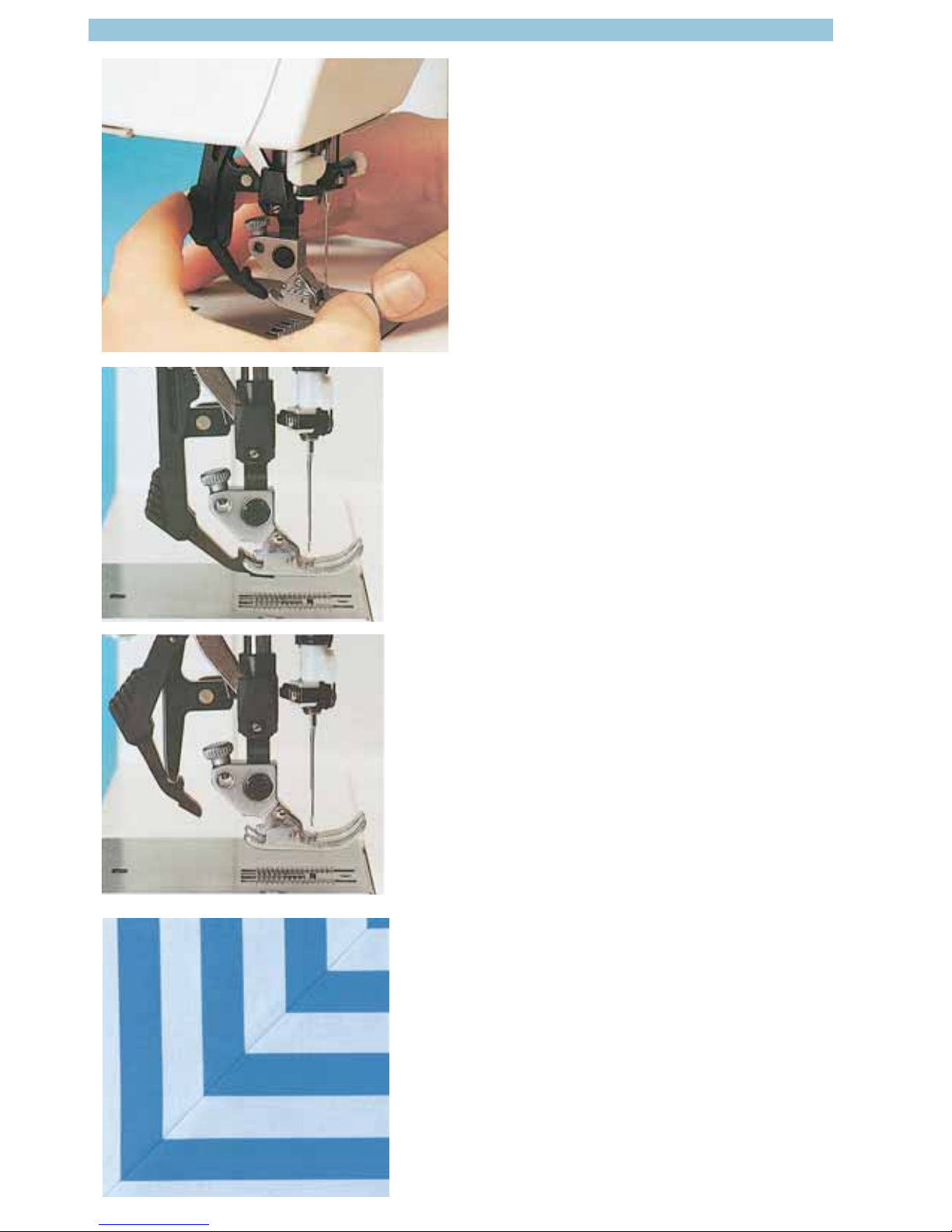

39

1540

1530

1520

Utility stitches and practical sewing

Sewing on zippers

There are various methods of sewing on

zippers. For skirts, we recommend the fully

concealed zipper, for men’s and ladies’

trousers the semi concealed zipper. Various

zippers are available. We recommend using a

metal zipper for strong fabrics such as denim.

For all other materials we recommend a plastic

zipper.

It is important for all types of zippers to sew

very close to the edge of the teeth of the

zipper. This is why it is possible to insert the

zipper foot either on the right or the left of the

presser foot holder.

Additionally, you can set the needle so that it

enters close to the edge of the zipper teeth by

using one of the 15 available needle positions.

If the foot is engaged to the right, the needle

must only be moved to the right. If the foot is

engaged left, the needle must only be moved

to the left.

Left presser foot position

Right presser

foot position

stitch

G

E

E

0

0

0

3

3

3

3-5

3-5

3-5

4

4

4

Page 50

40

Utility stitches and practical sewing

Fully concealed, sew-in zipper

• Insert the zipper foot on the right side.

• Baste in the zipper and lay it underneath the

presser foot so that the teeth of the zipper

run alongside the foot.

• Stitch in half of the zipper, leave the needle

in the fabric, raise the presser foot and

close the zipper.

• Now you can continue sewing the seam up

to the end of the zipper and sew the cross

seam.

• Sew the second half of the zipper parallel at

the same distance.

• Stop after the fi rst half and leave the needle

in the fabric. Raise the presser foot and

open the zipper.

• Now you can fi nish sewing the seam.

Page 51

41

Utility stitches and practical sewing

The trouser zipper

• Iron the seam allowances, taking care to

ensure that the underlap extends by about

4 mm.

• Baste the zipper under the underlap so that

the teeth are visible.

• Insert the zipper foot on the right side and

move the needle to the right needle position

.

• Stitch along the edge of the zipper.

• Just before the end of the seam, open the

zipper and fi nish sewing the seam.

• Close the zipper and baste the overlap

evenly to the other half of the zipper.

• Then sew through the basted seam.

Tip: To achieve a perfect seam, we

recommend using the edge guide.

Page 52

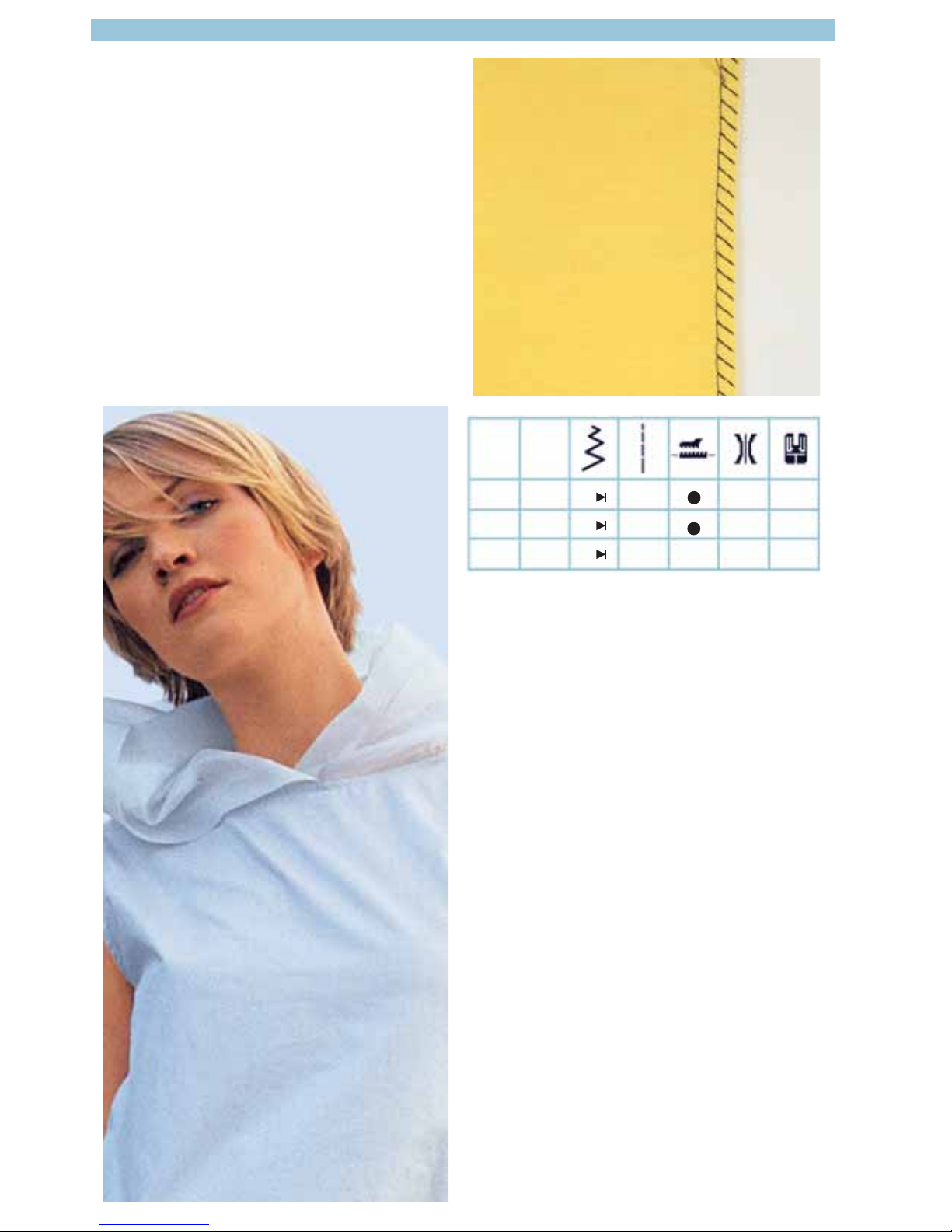

42

1540

1530

1520

Utility stitches and practical sewing

Stabilizing edges

With the hemmer you can hem blouses, silk

scarves and valances with ease, without

having to pre-iron the fabric edges. The

hemming prevents the edges from fraying and

a clean, durable edge is the result.

• Fold the beginning of the fabric edge over

twice (approx. 2 mm)

• Lay the folded fabric edge underneath the

hemmer and sew a few stitches.

• Leave the needle in the fabric, raise the

presser foot and insert the fabric into the

hemmer foot scroll.

• Lower the presser foot and guide the fabric

evenly into the hemmer.

Take care to ensure that the fabric does not

run under the right half of the presser foot.

Tip: On silk, viscose and chiffon fabrics, the

roll hem is particularly attractive with a zigzag

stitch

stitch

G

E

E

0

0

0

3

3

3

3-5

3-5

3-5

7

Optional

Optional

Page 53

43

1540

1530

1520

Utility stitches and practical sewing

Attaching lace

You can beautify and remodel home textiles

with the desired suitable lace as often as you

like.

Here’s how it’s done:

• First serge the cut edges.

• Sew the lace onto the face side of the fabric

up to the fi rst corner.

• Fold the corner and sew over it diagonally.

• Sew the following sides in the same way.

Inserting lace

You can achieve a beautiful effect by inserting

lace, e.g. on babywear and children’s clothing.

• First the lace is basted onto the right side of

the fabric.

• Sew on both sides of the lace at a narrow

margin.

• The fabric underneath the lace is cut down

the middle and ironed to the side.

• Sew over both edges of the lace with a

small, dense, zigzag stitch (stitch width 2-4

mm).

• Cut back the extra fabric.

stitch

G

E

E

0

0

0

2,5

2,5

2,5

3-5

3-5

3-5

0/1

0/1

0/1

Page 54

44

1540

1530

1520

Utility stitches and practical sewing

Shell-edging

Shell-edging is especially attractive on thin,

soft fabrics such as silk and viscose.

It is often used as an edging on lingerie.

The higher the needle thread tension, the

deeper the shell edge feed.

• Serge the fabric edge and iron the seam

allowance to the left.

• Take care that the fabric only runs half

underneath the presser foot while sewing.

This intensifi es the effect of the shelledging.

Tip: By sewing a colored woollen thread into

the seam you strengthen the shell-edge while

also creating an attractive contrast in the seam.

A fi ne fabric of another color can also be used

instead of a woollen thread.

select

K

I

I

4,5

4,5

4,5

1,5

1,5

1,5

4-5

4-5

4-5

0/1

0/1

0/1

Page 55

45

Decorative sewing and embroidery techniques

Decorative sewing and

embroidery techniques

Sewing table for decorative sewing 46

Decorative stitches 47

Monograms 48

Embroidering with the

dense zigzag stitch/Tapering 49-51

Appliqué 51

Richelieu 52

Eyelet embroidery 52

Patchwork quilt 53

Hemstitching 54

Page 56

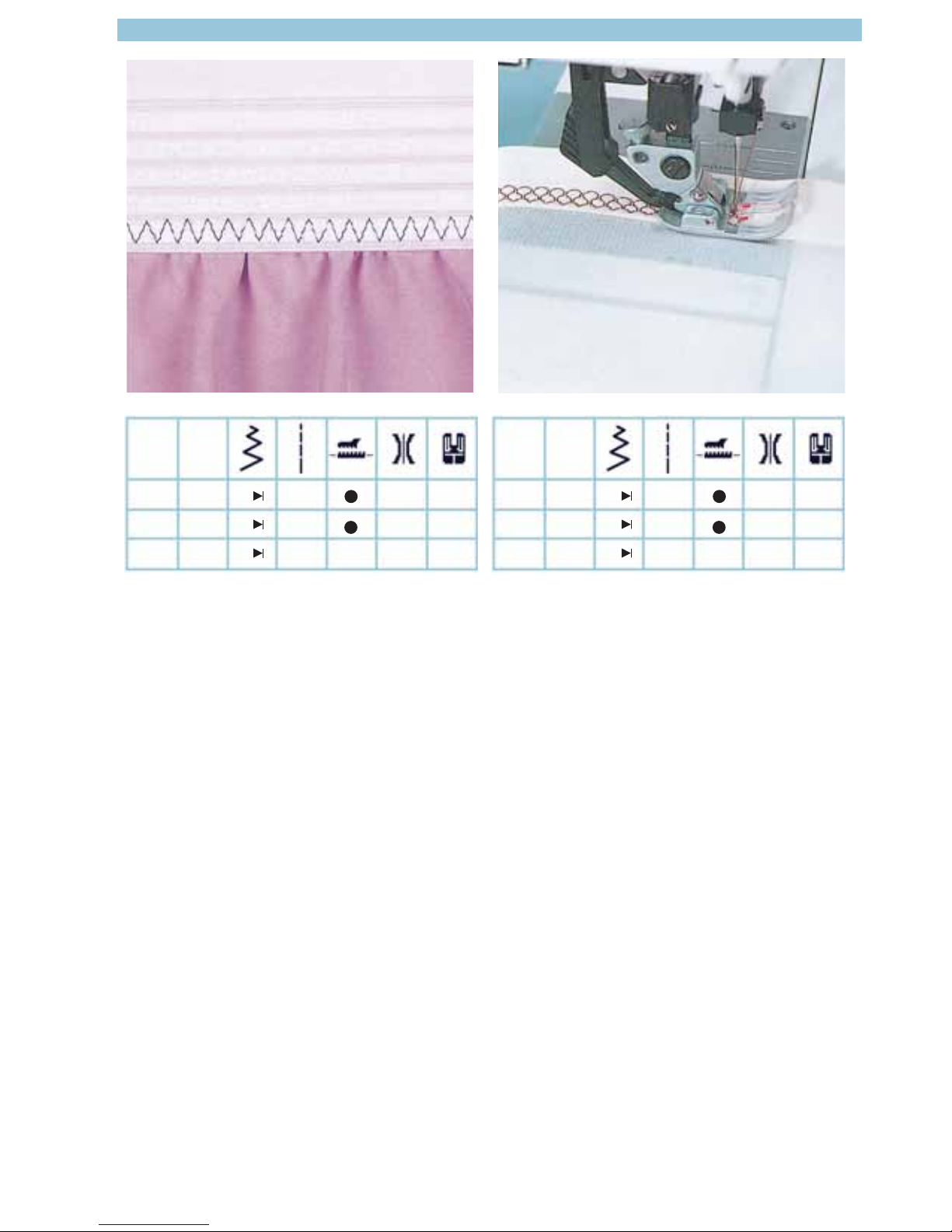

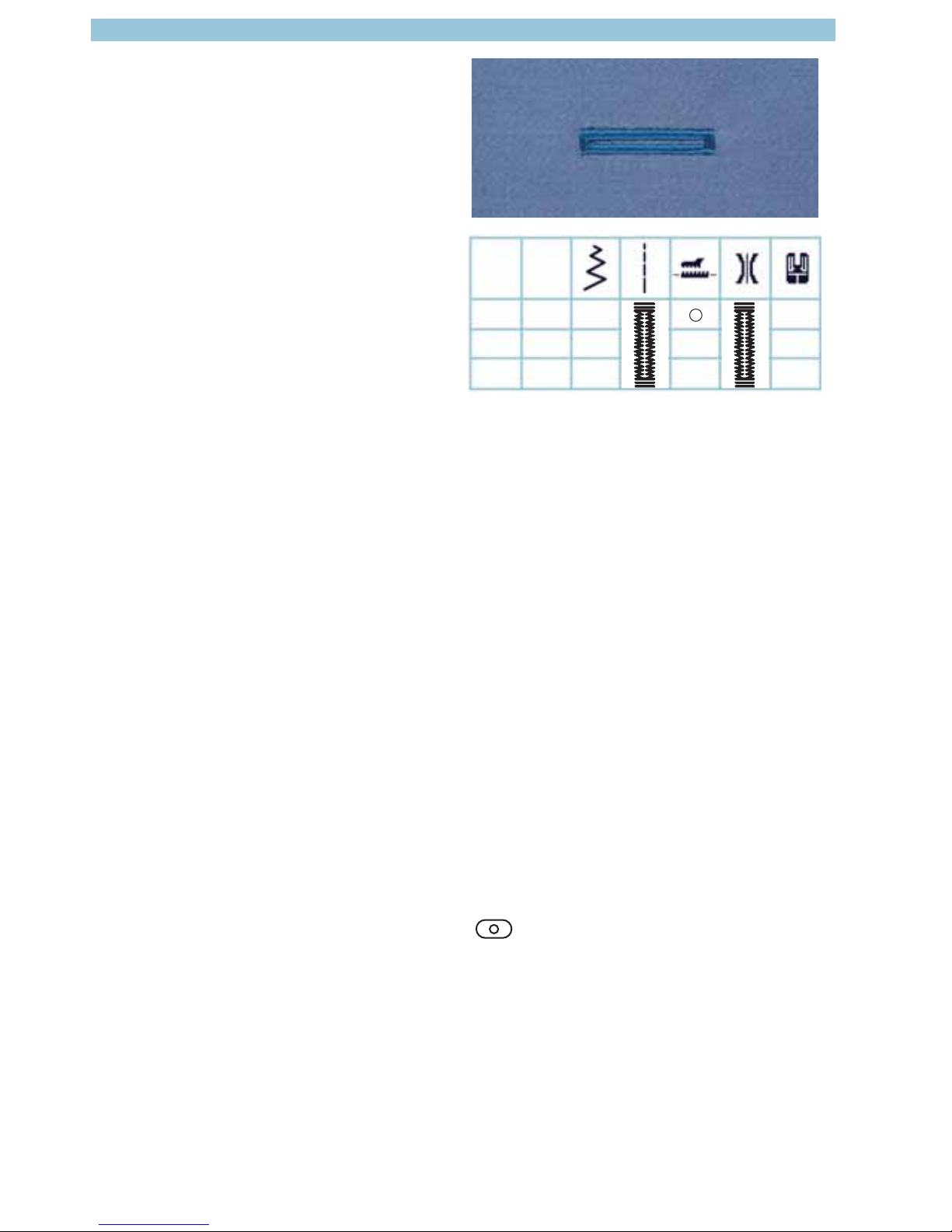

46

1540

1530

1520

Decorative sewing and embroidery techniques

Decorative stitches

To enhance home textiles or garments, you

can produce decorations by selecting different

stitches, using different thread/fabric colors or

vary length and width of the stitches.

For decorative stitches we recommend using

special embroidery threads which are available

from your Pfaff dealer. Use stabilizer under

the fabric to be decorated. This prevents the

material from pulling. Use a magic pen or

marking chalk to mark a line for your fi rst row

of stitching.

The following recommendations apply to all

samples on the following pages.

The stitch length and stitch width can be varied

as required.

Always use the center needle position

if

not otherwise indicated

stitch

-

-

-

5-

5-

5-

0,5-1

0,5-1

0,5-1

2-3

2-3

2-3

stitch

Stitch number

Stitch width in mm

Stitch length in mm

Dual feed on =

off =

Thread tension

Presser foot number

Page 57

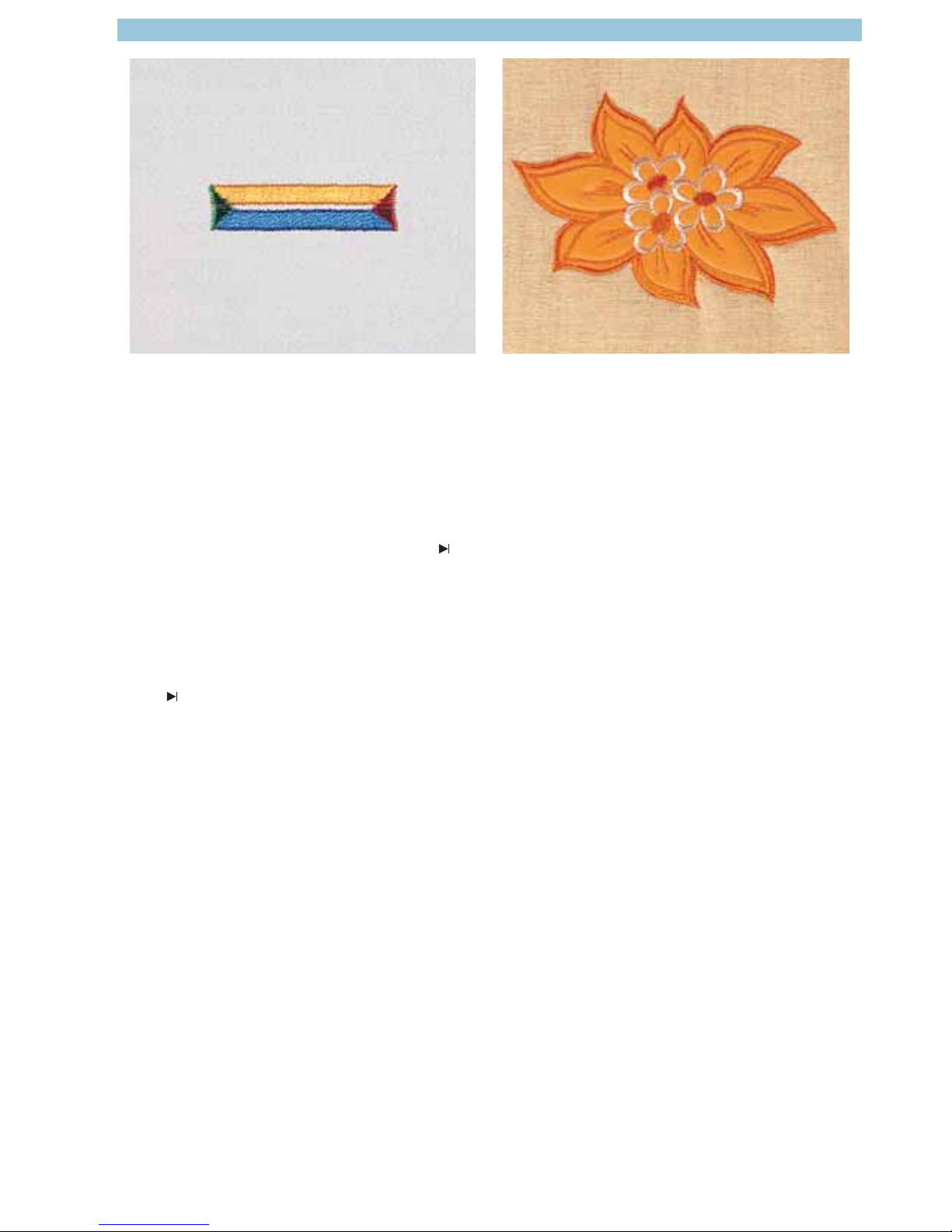

47

Decorative sewing and embroidery techniques

Borders with a combination of stitches

(only on select 1540)

By combining different stitches as desired you

can easily achieve embroidery effects. This

is a simple and pleasing way to embellish

tablecloths and garments.

• Place appropriate stabilizer under the fabric.

• Mark the center with tailor’s chalk.

• Begin with the combination M/G Stretch,

stitch width 5

. Embroider along the

marked line.Then turn the fabric and

embroider back down the border in reverse.

• Sew close to the fi rst border with the

combination L/K Stretch stitch width

5

.

• I/F Stretch, stitch width 5

, completes

the border. Embroider one row. Then turn

the material and embroider back down the

border in reverse.

Combinations with colored thread

(only on select 1540)

An additional effect can be produced with

different colored thread. Multi-colored thread

was used for the middle border in this example.

You can purchase it in a great variety of

shades from your PFAFF dealer.

• Place appropriate stabilizer under the fabric.

• Mark the middle with tailor’s chalk.

• Begin with the stitch H Stretch, stitch width

5

. Embroider along the marked line. Then

turn the fabric and embroider back down the

border in reverse.

• Sew close to the fi rst border with the stitch

I/G Stretch, stitch width

2-4 mm.

• F/G Stretch, stitch width 3-4 mm completes

the border.

Page 58

48

Decorative sewing and embroidery techniques

Monograms

Whether working with stretch or woven fabric,

with the help of the darning foot and the stitch

G (1540), E (1530/1520), stitch width 2.5-5

,

you can embroider initials of your own design.

Sewing this way without a set pattern does,

however, require a little practice.

• Draw the initials onto the fabric with an

invisible-ink marker.

• Drop the feed dog. Insert the darning foot

and bring it into darning position (see page

37).

• Place stabilizer under the fabric.

• Hoop the fabric in an embroidery hoop and

embroider using the zigzag stitch.

• Tie off the threads and remove the

stabilizer.

Tip: By sewing quickly and moving the material

slowly, you will achieve dense stitches.

When embroidering on terry-cloth, the

monogram must fi rst be sewn with a narrow

zigzag stitch and then stitched again with a

wider zigzag stitch. In this way the terry-cloth

loops are completely covered.

Embroidering block letters is somewhat easier.

Here the feed dog is not dropped which means

that free sewing is no longer necessary. You

can simply sew along the lines with stitch G

(1540), E (1530/1520), stitch width 2.5-5

.

• Place stabilizer under the fabric.

• Before sewing, draw the monogram onto

the fabric.

• Sew along the lines you have sketched

using the zigzag stitch.

Page 59

49

Decorative sewing and embroidery techniques

Uneven embroidering

• Place stabilizer under the fabric.

• Set needle thread tension to “buttonhole”,

select zigzag stitch G (1540), E (1530/

1520), set stitch length to “buttonhole” and

select the center needle position

.

• Increase or decrease the width of the stitch

using the width dial (27).

Note: If you selected the right or left needle

position, the stitch width will only change in one

direction.

Embroidering with

a dense zigzag stitch/Tapering

Tapering is easy with your select sewing

machine. By adjusting the width of this dense

zigzag stitch you can create interesting

embroidery.

Even embroidering

• Place stabilizer under the fabric.

• Set needle thread tension to “buttonhole”,

select zigzag stitch G (1540), E (1530/

1520), set stitch length to “buttonhole” and

select the center needle position.

• Turn the width dial (27) smoothly and

consistently from 0 to 5

mm and back

again to 0 while sewing at a constant speed

through the procedure.

Note: If you selected the right or left needle

position, the stitch width will only change in one

direction.

Page 60

50

Decorative sewing and embroidery techniques

Floral embroidery

For this fl ower arrangement, only a dense

zigzag stitch was used in combination with the

variable stitch width and the various needle

positions.

• Place stabilizer under the fabric.

• Draw the contures of a fl ower motif with a

self-erasing textile pen.

• Set needle thread tension to “buttonhole”,

select zigzag stitch G (1540), E (1530/

1520), set stitch length to “buttonhole”.

• Flowers:

Select center needle position

and

embroider individual petals. Adjust the stitch

width with the width dial (34) during sewing

according to the contures of the fl ower .

• Leaves:

Select right needle position

and

embroider half of the leaf. Vary the stitch

width using the width dial (27). Turn the

handwheel towards you after fi nishing

the fi rst half of the leaf until the needle is

positioned in the material.

• Turn the material 180 degrees and

embroider the other half of the leaf

Embroidering corners

By changing the stitch width during sewing

of dense zigzag stitches you can embroider

corners with 45 degree angles.

• Set needle thread tension to “buttonhole”,

zigzag stitch G (1540), E (1530/1520), set

stitch length to “buttonhole” and stitch width

5 mm.

• Select right needle position

and embroider a straight line.

• Embroider corner:

After the needle has penetrated the material

to the right, reduce the stitch width using the

width dial (27) by 0.5 mm to 4.5 mm. Sew

a stitch.

• Reduce the width once again by 0.5 mm

and sew a stitch. Continue in this manner

until the stitch width is 0.5 mm.

• Turn the handwheel towards you until the

needle penetrates the material. Turn the

material 90 degrees and sew a stitch.

• Increase the width by 0.5 mm to 1.0 mm.

Sew one stitch.

• Increase the width by 0.5 mm again and

sew one stitch. Continue in this manner until

the initial width is achieved. Now embroider

a straight line.

If the corner is to continue in the opposite

direction, use the outermost left needle position

.

Page 61

51

Decorative sewing and embroidery techniques

Decorative buttonhole

This buttonhole is a beautiful alternative to the

traditional buttonhole (see page 32-33). Since

you determine the width of the buttonhole

seam, the buttonhole can have a width of up

to 10 mm.

• Sew two buttonhole seams about 1 mm

apart using a dense zigzag stitch (stitch G

(1540), E (1530/1520), stitch width 3-5

mm). The needle thread tension is set to

“buttonhole”.

• Select the right needle position and sew

over both ends of the buttonhole seam with

a triangle. To do this, turn the stitch width

dial (27) during sewing constantly from 0 to

5

and back to 0. The top of the triangle

should meet the middle of both buttonhole

seams.

Appliqué

Appliqués are quickly made and always produce

a beautiful fancy effect. By using different

materials and patterns you can

sew many different variations. You can make a

perfect, densely stitched seam with the appliqué

foot (special accessories), because it has a

special cutout on the

underside for the buttonhole seam. Use a fusible

backing fabric to iron the appliqué onto the

material, making it easier for you to appliqué.

• Insert the appliqué foot in the sewing

machine.

• Transfer your drafted pattern to the face side,

smooth side, of the fusible backing fabric.

Remember that e.g. letters have to be drawn

as a mirror image.

• Now iron the backing fabric onto the

appplqué material. Cut the motif out and pull

the paper off.

• Place and iron on the appliqué parts on the

base material.

• Sew over a appliqué material edges with

the dense zigzag, stitch G (1540), E (1530/

1520), stitch width 2-4 mm, stitch length

“buttonhole”. The needle thread tension is in

the “buttonhole” area. Make sure the needle

stitches over the outer edge so that no

fraying occurs later.

Tip: For appliqué pieces which are pointed

at the ends, you can make the zigzag stitch

narrower using the width dial (27) so that the

ends are pointed.

Page 62

52

Decorative sewing and embroidery techniques

Richelieu

This especially artistic form of eyelet and insert

embroidery is easy to sew with your sewing

machine.

• Using a magic marker, draw your motif onto

the right side of the fabric.

• Then place two layers of water-soluble

stabilizer underneath the fabric to be

embroidered and hoop both the fabric and

the stabilizer into an embroidery hoop.

• Insert decorative embroidery foot number 1.

• To lend more durability to the embroidery,

sew all of the contours twice using the

straight stitch (stitch length approx. 1 mm).

• Then carefully cut out the fabric 2 mm next

to the contour from the areas which are to

be hollow. The stabilizer must not move.

• Embroider the contours with a dense zigzag

stitch.

• Finally, simply dissolve the stabilizer fl eece

in cold water and your one-of-a-kind design

is fi nished.

Eyelet embroidery

Traditional eyelet embroidery which previously

had to be made laboriously by hand can now be

made quite easily with

the help of an eyelet plate (special accessory).

This is very effective on blouses, bed or table

linen. Use utility stitches such as the zigzag

stitch, blind stitch, or elastic stitch. .

For classic eyelet embroidery, use stitch G

(1540), E (1530/1520), with a stitch width 3-5

mm.

• Remove the presser foot. Set the presser

bar lifter at the darning position (see page

37).

• Place the eyelet plate on the needle plate,

making sure pin A fi ts in the middle cutout of

the needle plate. Then push the plate down

at the front.

• Place the marked fabric taut in an

embroidery hoop. Cut one or two of the

fabric threads and push the fabric over the

pin in the eyelet plate. The fabric must fi t

snugly around the pin.

• Draw up the bobbin thread and hold it for

the fi rst few stitches.

• Stitch around the cut with the selected

stitch. It is important to turn the fabric slowly

and evenly. The stitches should be very

close to each other.

• Afterwards secure with straight stitch.

Page 63

53

Decorative sewing and embroidery techniques

Patchwork quilt

Patchwork and quilting are traditional

handicraft techniques which were originally

used by North American pioneer women to

make use of left-over fabric. Over the years it

has developed into a creative hobby.

Traditionally patchwork was sewn by hand.

Today your creative ideas can be realized in

a much shorter time with your select sewing

machine.

A patchwork quilt consists of three layers

of fabric, two layers of fabric with a layer of

batting sandwiched between. Many pieces of

fabric are joined together in patterns to form

the top layer of the quilt. This is tacked to a

middle layer of polyester or cotton batting and

a backing layer.

The quilt and patchwork foot (special

accessory – see page 63) is particularly

helpful for sewing patchwork and quilting. The

distance of the needle to the outer edge of the

foot is 1/4 inch (6 mm) and 1/8 inch (3 mm) to

the inner edge.

And this is how it’s done:

• Cut the pieces necessary for your quilt top,

making sure to include a seam allowance of

1/4 inch (6 mm).

• Sew the pieces together as required by the

block chosen. These squares will then be

sewn together and will form the top of the

quilt.

• Baste the fi nished top of the quilt onto the

batting and the bottom quilt layer.

• Use your Pfaff select model to sew all

layers together. Work from the inside of

the quilt out. Use a straight stitch for long

seams. Use stitches such as FG or L stretch