Page 1

418

438

838

PFAFF

Service

innovation

Manual,

madebyPFAFF

Page 2

Contents

1

Preparations for adjusting

2 Centring the needle in

Setting

the

3

Stitch

4

4.1

Zeroing

4.2

Stitch

4.3

Limiting

Adjustung

4.4

Adjusting

5

Adjusting

6

7

Needle position "left, centre, right"

8 Adjusting

Adjusting

9

Zeroing

10

10.1

Adjustment with

10.2

Adjustment

Adjusting

11

12

Bottom

Tensloning

13

14

Adjusting

Preliminary adjustment of

15

16

Oil distributor ring

Hook timing

17

18

Final

Bobbin

19

19.1

Position of bobbin

19.2

Timing

Adjusting

20

21

Clearance

22

Feed

Oil

23

24

Tension

25

Lubrication of

Hook

26

27

Knee

28

Knee lever play

Bobbin

29

30

Thread

Presser

31

Annex

32

Needle

33 Left,

34

Needle

stabilizing rod parallel to the

width

control

the

needle

width

the

the

the

the

the

the

the

for straight stitching 8

scale

maximum stitch width

locking

needleinthe

needle

needle

stitch length

bottom

feed

closed

with

open

the

bottom

feed

liftingmotion

the

driving belt in

the

hook bearing bracket

and

hook-to-needle

adjustmentofneedle

case

opener

case

the

bobbin

slack

between

height

case

thread

presser

mechanism

dog

check

the

valve

release

zigzag

lubrication

lever

stroke

limitation

winder

check

spring

foot

pressure

for

machines

vibration

center

and

position

right

lever

the

needle hole (in sewing direction) 5

needle

bar

lever

needle

hole (sideways)

throw

position lever

scale

ring

gearcase

gearcase

feed

driving motion

the

gearcase

needle

bar height

clearance

bar

height

opener

opener

control

foot

and

needle

eccentric

and

thread

regulator

equipped

needle

positions

with

zigzag

control

-716/..

Page

2

6

8

9

10

11

12

13

14

16

25

18

18

19

20

21+22

23

24

25

26

27

28

29

29+30

31

32

33

34+35

36

37+38

39

40

41

42

43

44

44

45

46+47

48+49

Page 3

Notesonsafe

machine

operation:

The machine must only be usedfor the purpose It

When

converting Itto another version, allvalid safety rules

has

been designed for.

mustbefollowed.

Service and repair workmust only be performed byqualifiedpersaonel.

Workon liveparts Is not permitted, apartfrom exceptions according to

Service manual

418 438

418-716/.. 438-716/..

For

the

separate

Important

Donot use a C-clamp on the needlebar of Pfaff

Its special coating. Make

chinesInoperation forthe firsttime orwhich

For shipping

and

838. ItIstherefore

the

machine

418,438,838

appliesto the following versions:

adjustment of automatic fancy-stltch

manuals.

note

sure

you

check

purposes

for

the

oilis drained from

necessarytofill

the

first

time.Astickeronthe

this housing with 75 c.c. of oil

mechanism

418,438

the

hook lubrication

have

been

the

needle

machine

-718/01

and

Idlefor a longer period (I.e. 1or 2 months).

vibrating eccentric housingof the

arm

servesasa

DIN

57105

and VDE0105.

838

838-716/..

and

thread trimmer -900/..

there

838 machinesasthiswould damage

system

(see

Section 27) on ma

Raff

(see

Section26) before operating

reminder.

418,438

are

When the machine Is given a general overhaul put about 2 c.c.of piniongrease, with a dripping point of

160°C, inthe bevel-gear

grease

canbeobtained

case

of the hook. We recommend you use Molykote-Longtherm 00. This

from us

under

No. 280-1-120 199.

Tools,

gauges

and

other

1

setofscrewdrivers

1

set

of alien

1

setofwrenches

with2to10mm

keys

from 1.5 to 6 mm

with

openings

1 wrench with 27-mm-wlde

1

metal

ruler

accessories

opening

required

wide

for

blades

from 7 to 14 mm wide

adjusting

the

machines

1 cylindrical pin (5 mm dia.), No. 13-030 341-05

1

feed

dog

gauge,

No. 91-129

1 hook bearing bracket

1

wrapperofsystem

2

strips

of white

paper

1 rollof

Sewing

adhesive

thread

and

tape

testing

438

gauge.

needles

material

995-05

No. 91-129

996-05

Page 4

1

Preparations

for

adjusting

Note:

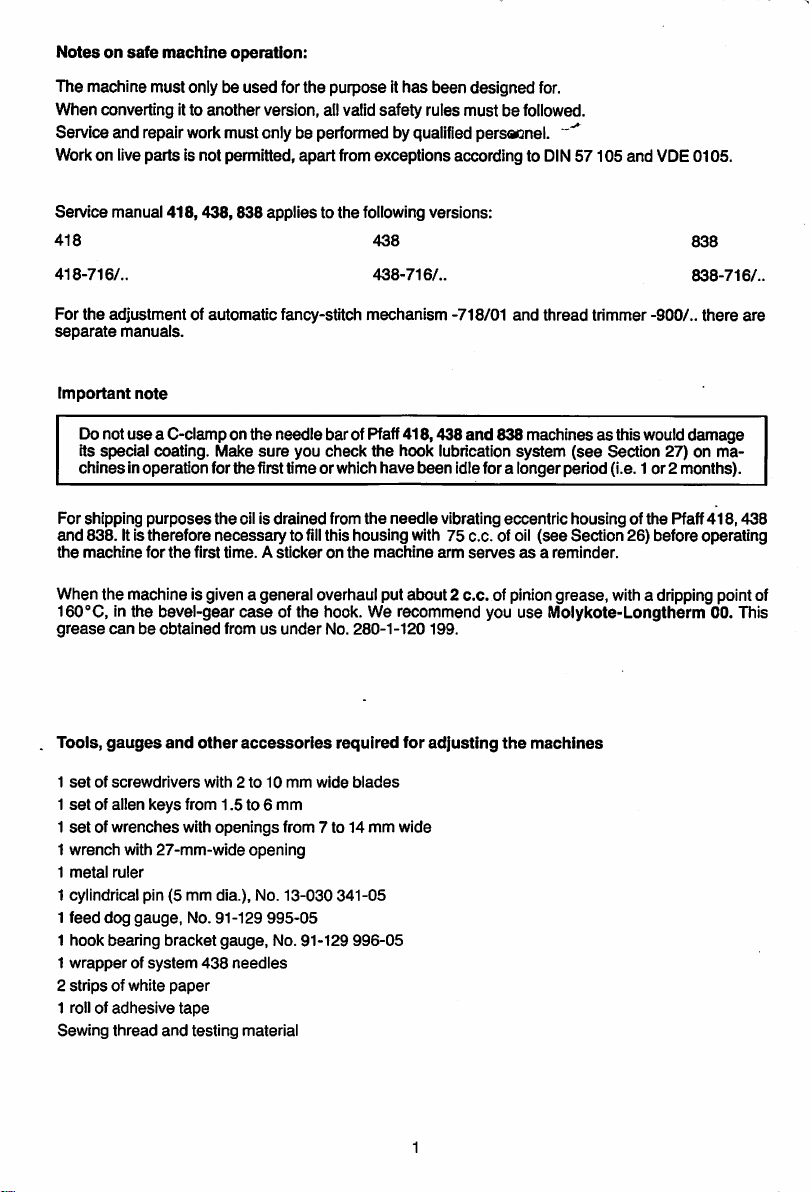

To allow the machine to be blocked with

bearing plate (Fig.1.0.1.)

has

four holes.

the

needle

baratthe

required position

Afterpositioning themeedlebar as requiredpush the pinintothe appropriatehole

it

enters

the

recess

behind the bearing plate, thus blocking the machine.

5mrn

the

until

1.0.1

Page 5

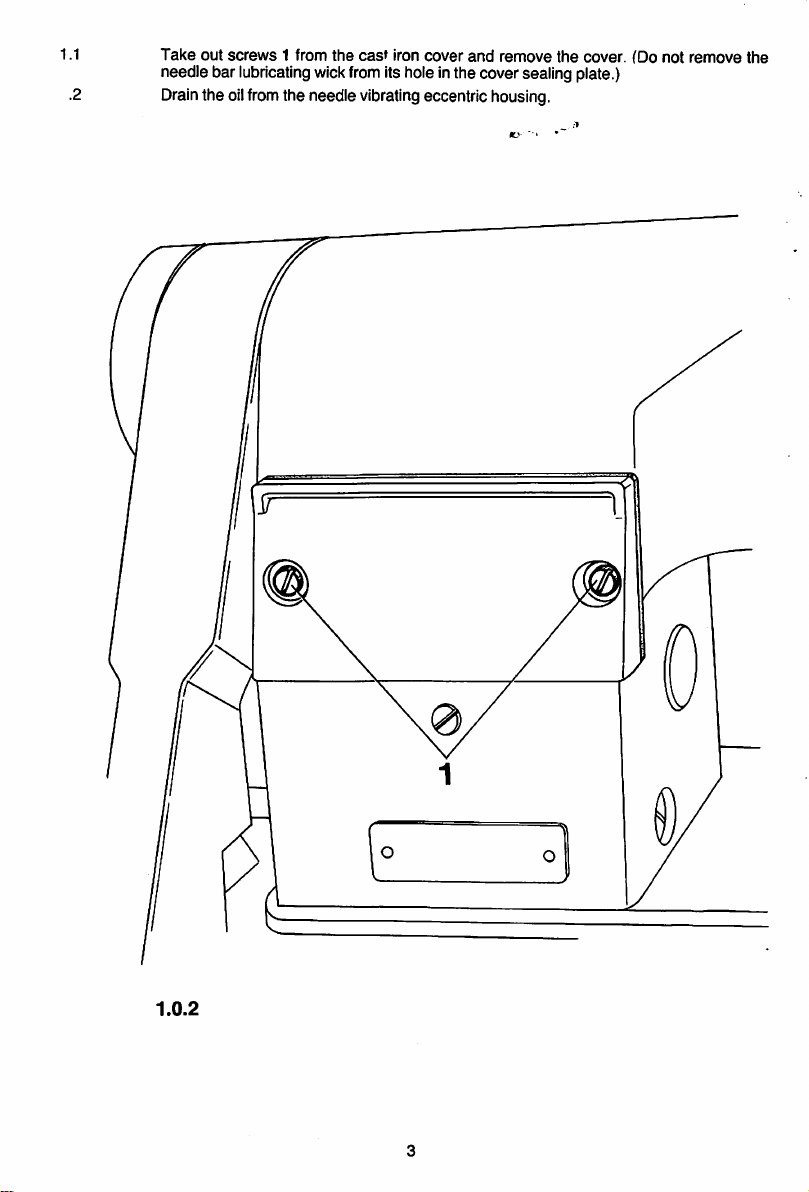

1-1

Take

out

screws

1 from

the

cast

iron

cover

and

needle bar lubricating wickfromits hole inthe coversealing plate.)

remove

.2 Drainthe oilfromthe needle vibratingeccentric housing.

the

cover. (Do not

remove

the

1.0.2

Page 6

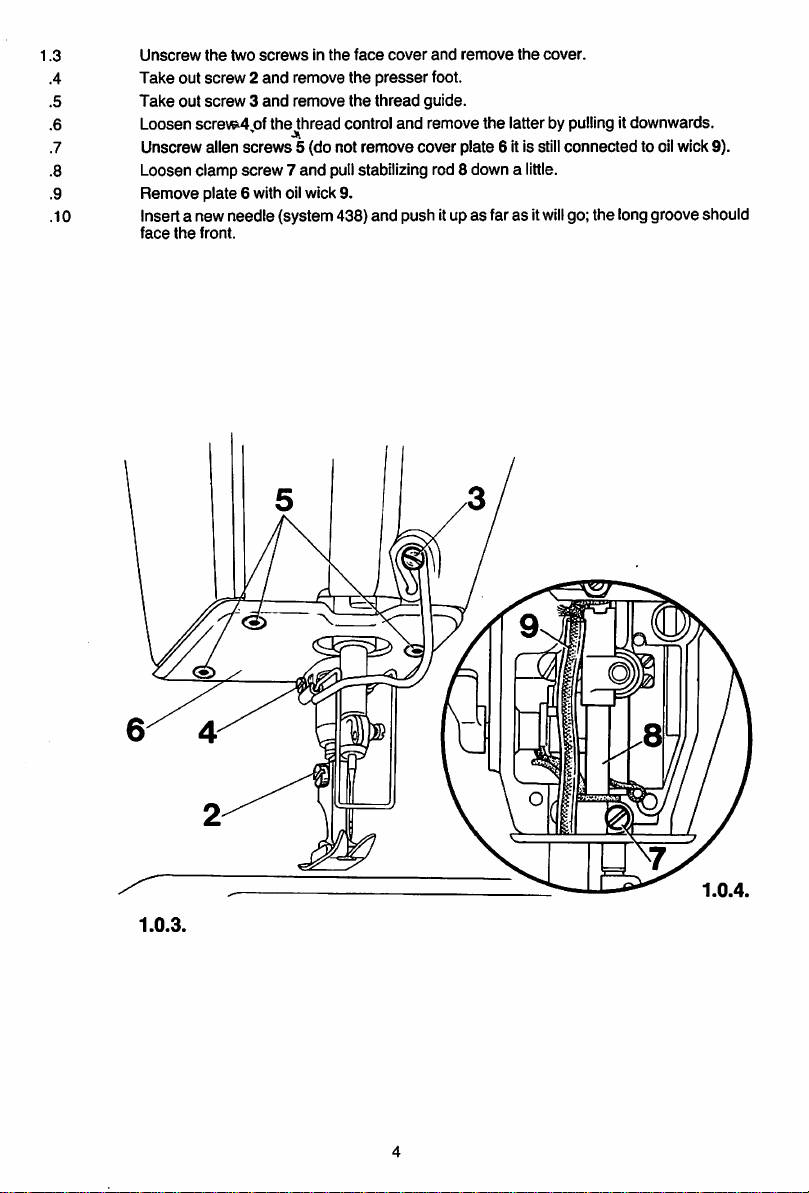

1.3

.4

.5

.6

.7 Unscrew alien screws 5 (do not remove cover plate 6 it is stillconnected to oilwick 9).

.8 Loosen clamp screw7 and pullstabilizing rod 8 down a

.9

.10 Insert a new needle (system 438) and push itup as faras it

Unscrew

Take

out

Take

out

Loosen

Remove

face

the

the

two

screwsinthe

screw2and

screw3and

screv^jof

plate 6 with oilwick 9.

front.

remove the

remove

thejthread

face

cover

presser

the

thread guide.

control

and

and

remove

foot.

remove

the

cover.

the

latterbypullingitdownwards.

little.

will

go; the longgroove should

1.0.3.

1.0.4.

Page 7

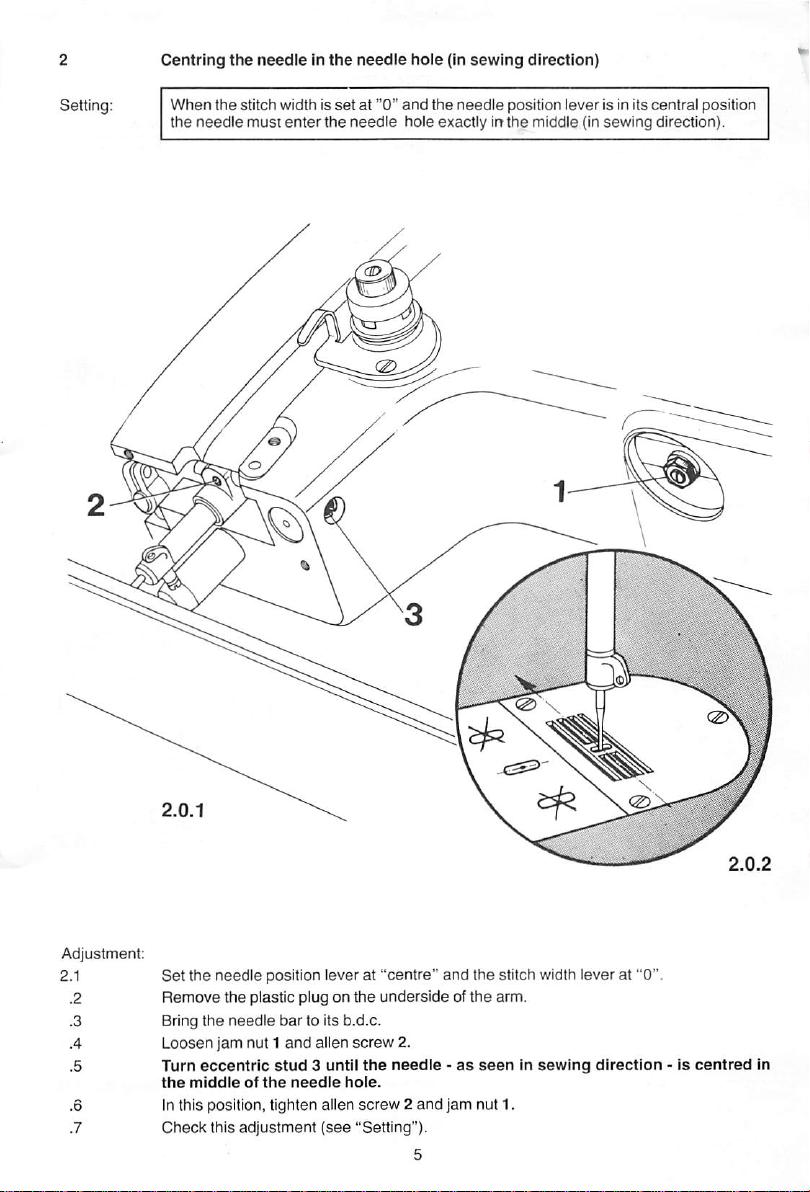

Centring

When

the

needle

the

needleInthe

the

stitch width is

must

enter

the

set

needle

at "0"

needle

hole

and

the

hole

exactlyinthe

(in

needle

sewing

direction)

position lever is in its central position

middle (in

sewing

direction).

1

2

3

4 L(

5

6

7 C

S'

R

B

Ti

th

In

Page 8

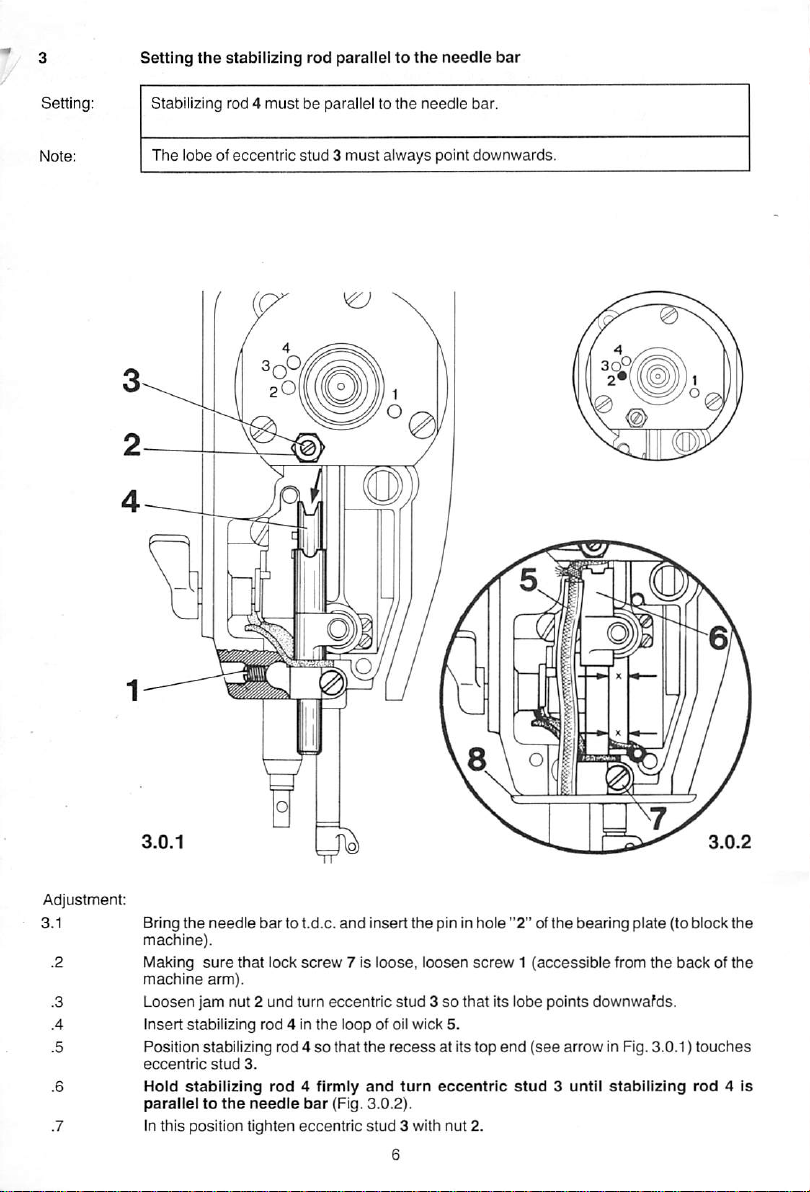

Setting

the

stabilizing

rod

paralleltothe

needle

bar

Setting: Stabilizing rod 4

The

lobe of eccentric

must

be parallel to

stud3must

the

needle

bar.

always point downwards.

Adjustment:

Bring

the

needle

3.1

sure

arm).

bartot.d.c.

that

lock

machine).

lulaking

machine

Loosen

jam nut 2 und turn eccentric

Insert

stabilizing rod 4 in

Position stabilizing rod 4sothat

eccentric

Hold

paralleltothe

In

stabilizing

this

position

stud

3.

rod

needle

tighten

and

screw

7 Is

the

loop of oil wick 5.

4 firmly

bar

(Fig.

eccentric

Insert

loose,

the

and

3.0.2).

stud

recess

the

pin In

loosen

stud3so

at Itstop

turn

eccentric

3 with nut 2.

hole

"2"ofthe

screw1(accessible

bearing

from

plate

the

that Its lobe points downwafds.

end

(see

arrow in Fig. 3.0.1)

stud

3 until

stabilizing

(to block

backofthe

touches

rod

4 Is

the

Page 9

3.8 Tocheck thatitis parailelto the needle bar firstpullstabilizing rod4 downand then push

it up againasfarasit

necessary

•9

Making sure that stabilizing rod 4 is still in contact witheccentric stud 3 tighten clamp

screw

turn eccentric

7 securely.

will

go, making

stud

3 accordingly).

sure

that guide 6

does

not move to the

side

.10 Remove the cylindricalpin from the hole inthe bearing plate.

.11 Bring

.12

the

machine

Screw

on coverplate 8.

needle

arm.

bar

to b.d.c.

and

tighten

screw

1 which is

accessible

from

the

backofthe

(if

Page 10

4

4.1

Stitch

Zeroing

width

the

control

needle

for

straight

stitching

Setting:

When

the

stitch

width

controlissetat"0"

the

needle

bar

must

not

movetothe

side.

4.0.1

Adjustment:

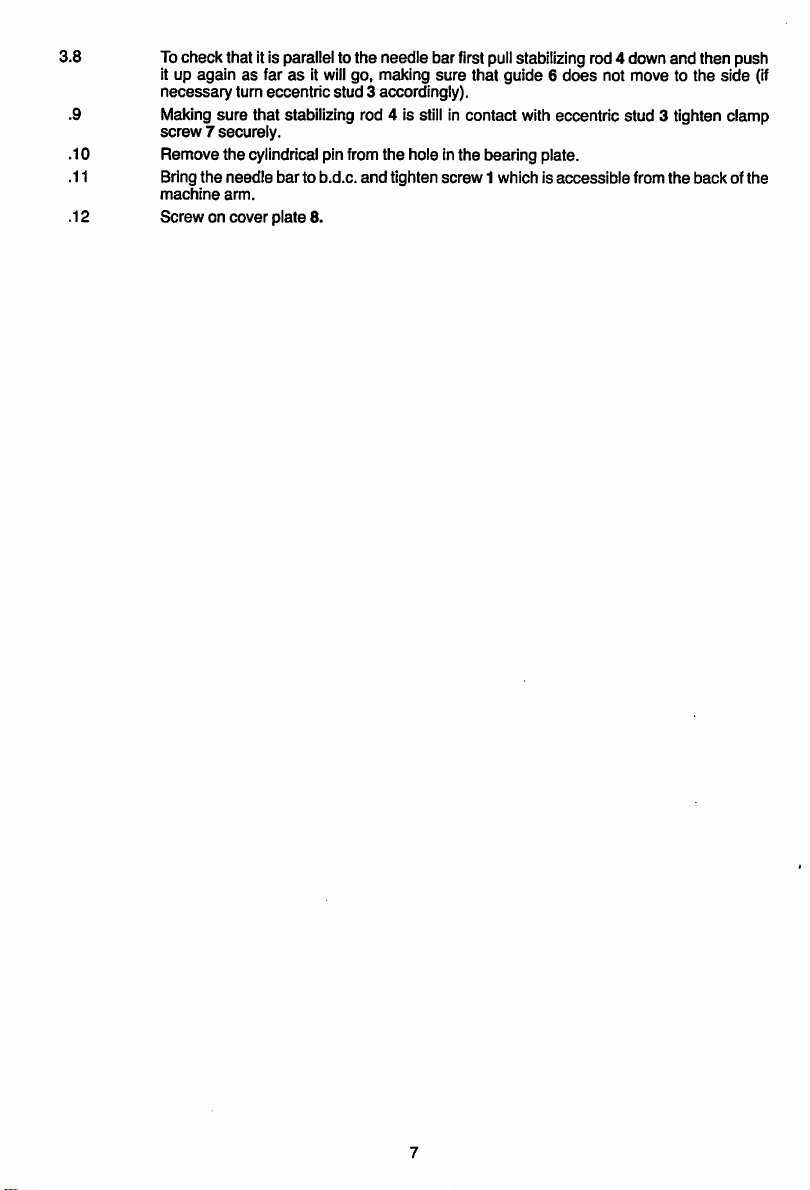

4.1.1

.2

.3 Loosen clamp screw 4 and letlockinglever 5 move back

.4 In this position, tighten

.5 Move stitch widthlever 6 to the rightasfarasit

.6 Turnon the masterswitch and let the machine runslowly. Move

.7 Inthis positionpush screw 2 to the rightasfarasit

Set

needle position lever 1 at its central position.

Loosen

the

screws2and

left until

the

3.

needle

clamp

bar

screw

stops

4.

swinging

until

will

go (i.e.towards "0").

sideways.

will

go and tighten it.

itsspring isrelaxed.

stitch

width lever 6 to

.8 Check this adjustment (see "Setting").

.9

.

10

Switch

off

Screw3is

master

still

switch.

loose.

8

Page 11

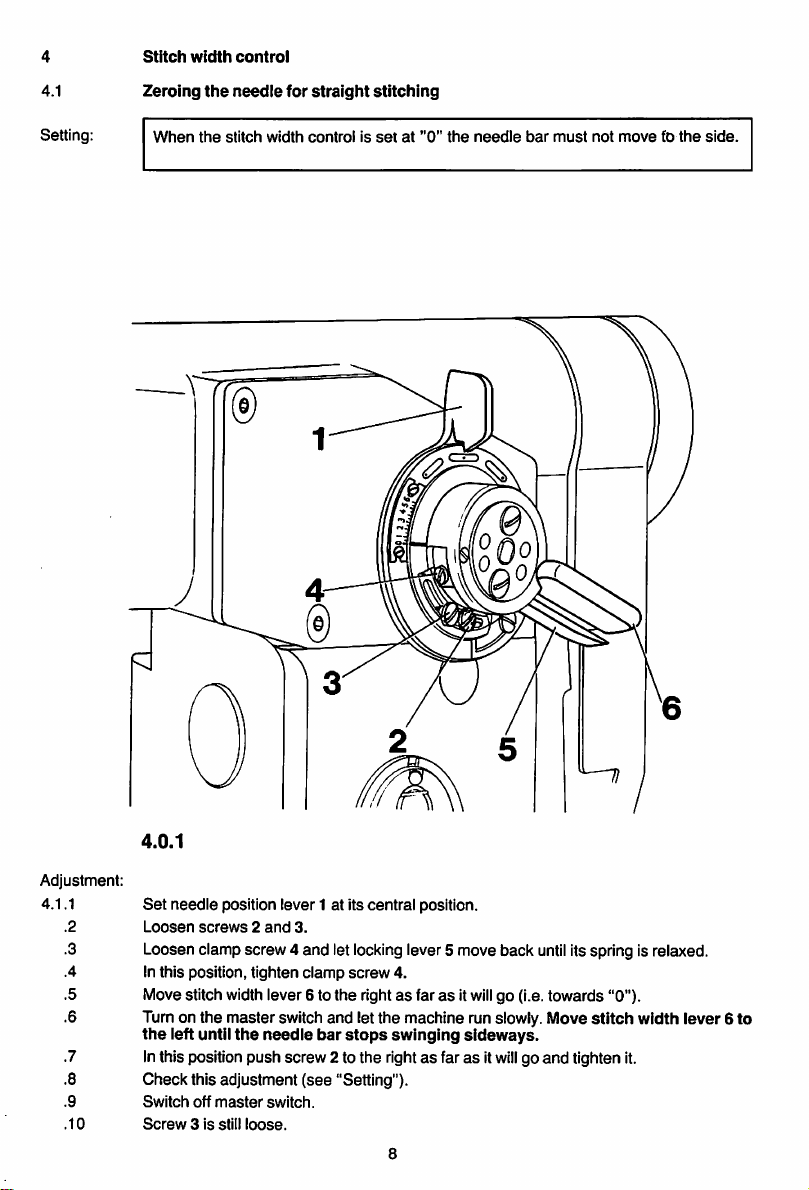

4.2

Stitch

width

scaie

Setting:

When

the

stitch width control is

mustbeopposite

mark

3 of

the

setat"0"

the

stitch width lever.

zero

markonthe

stitch width

scale

4.0.2

Adjustment:

4.2.1

.2

.3

.4

.5

Movestitch

Loosen

Adjust

ieverl.

screws

the

width

lever1 to the rightas faras it

2.

stitch

width

in this position tighten both

Check

this adjustment

(see

scale

screws

"Setting").

untii

will

go.

the

zero

markisopposite

mark

3 of

stitch

2.

9

width

Page 12

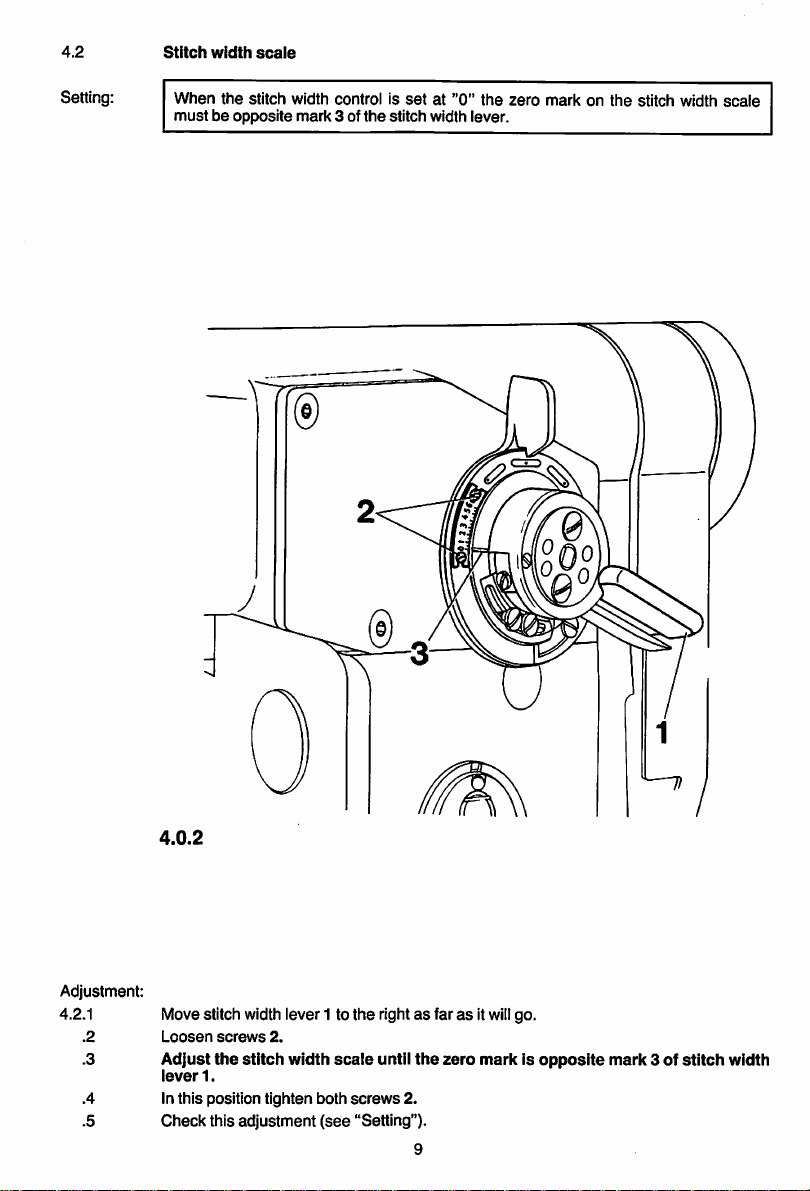

4.3

Setting:

Limiting

When

the

oppositethe

the

maximum

maximum

maximum

stitch

width

stitch width is

stitch

width

set,

mark

2 of

markonthe stitch

the

stitch width lever

width

scale.

must

be

4.0.3

Adjustment:

4.3.1

Note:

Move

stitch

width

width

markonthe

Inthis position move

as

itwillgo

and

tighten it.

lever1to

stitch

stop

the

left

until

width

scale.

screw

3 which limitsthe maximum stitch width upwardsasfar

mark2is

opposite

Iffor certain sewing operationsthe machine is equippedwith a

smaller

than

the

widest

to the width ofthe

Check

this

adjustment

stitch width indicated on

needle

hole rather than the graduation mark on

(see

"Setting").

10

the

scale,

limit

needle

the

the

the

stitch width

maximum

plate

whose

according

stitch width scale.

stitch

hole Is

Page 13

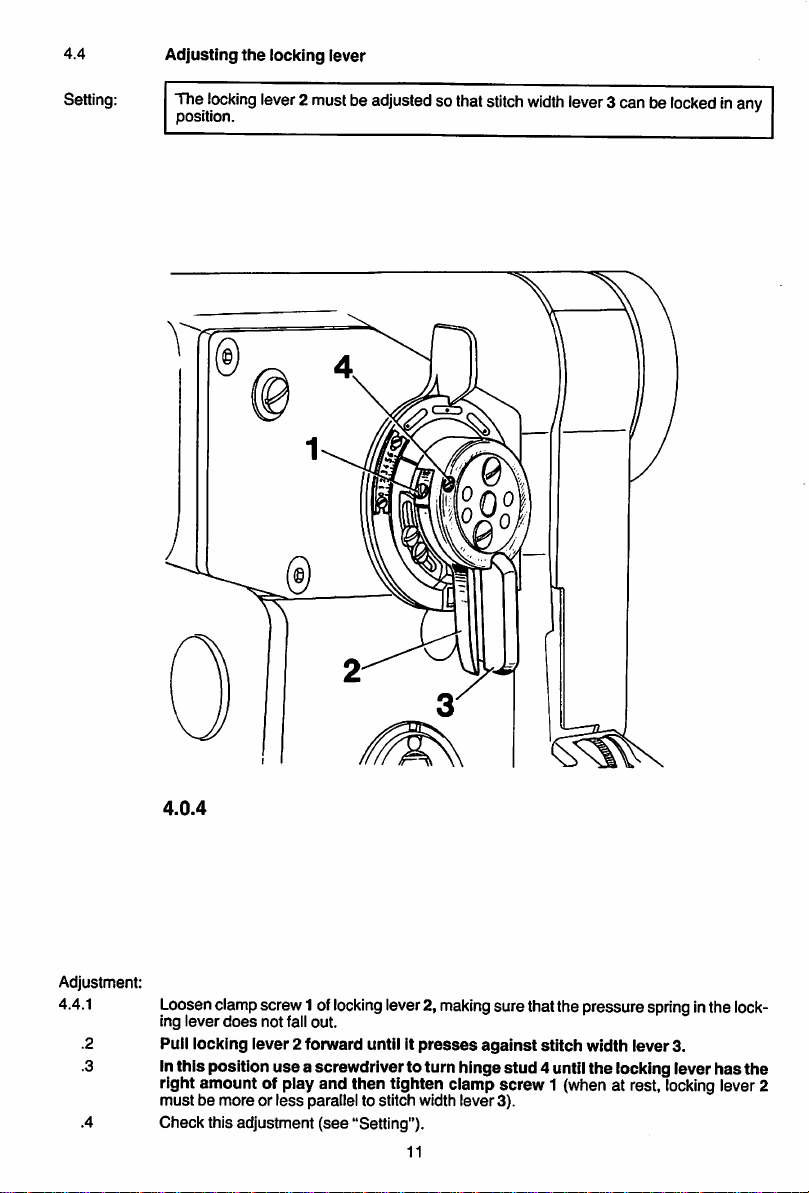

4.4

Setting:

Adjusting

The

locking

position.

the

locking lever

lever2mustbeadjusted

sothat

stitch

width

lever

3can be

locked

inany

4.0.4

Adjustment:

4.4.1

.2

.3

.4

Loosenclampscrew1 of

ing

lever

does

not fall out.

Pull locking lever2 forward until it

In

this

position

locking

lever2,

presses

use

a screwdriverto turn hinge

making

sure thatthe pressurespringinthe

against

stitch width lever3.

stud

4 until

the

locking lever

right amount of play and then tighten clamp screw 1 (when at rest,

mustbemoreorless

Check this adjustment

parallel to stitch width

(see

"Setting").

11

lever

3).

locking

lock

has

lever2

the

Page 14

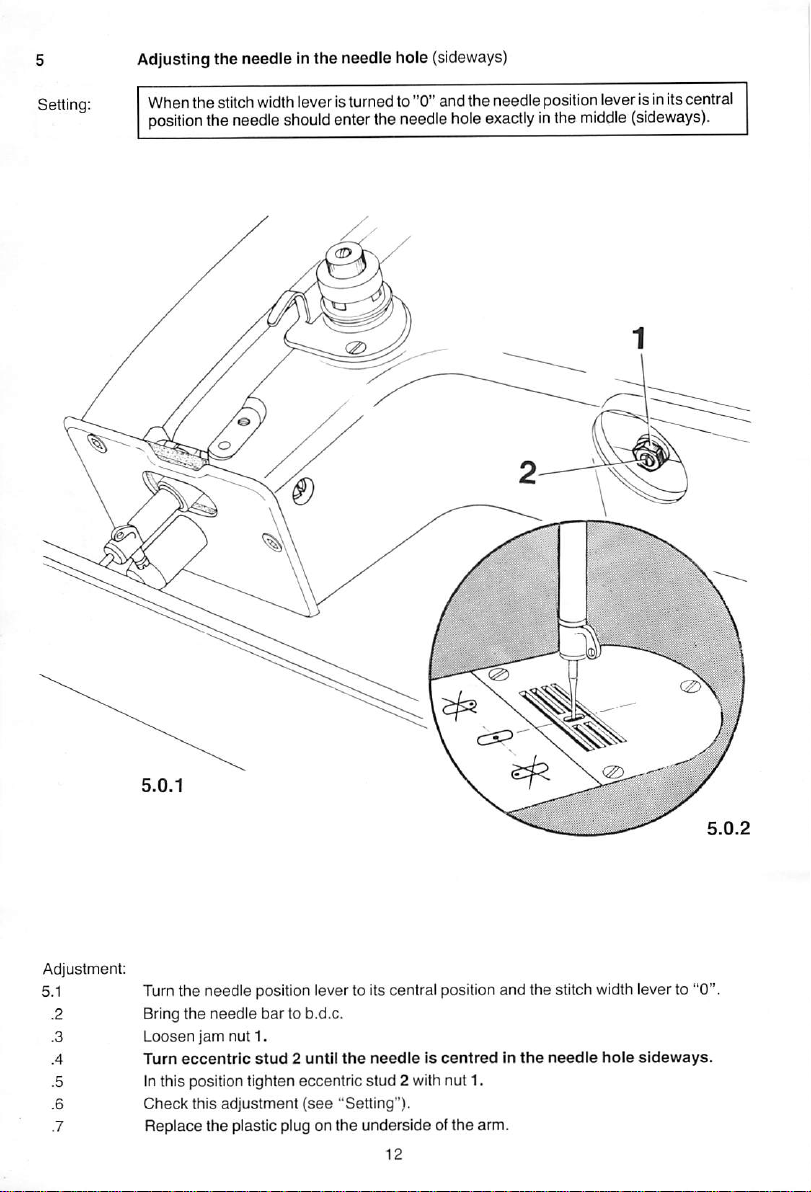

Adjustingthe needle Inthe needle hole

When the stitch widthlever isturned to"0" and the needie position leveris initscentral

position

the

needie

shouid

enter

the

(sideways)

needle

hole

exactlyinthe

middle

(sideways).

m

I

Adjustment:

5.1

Turnthe needie positioniever to its central positionand the stitch widthleverto "0'

Bring the

Loosen

Turn

Inthis position tighten eccentric

Check

Replace

needle

jam

nut 1.

eccentric

this

adjustment

the

plastic plug on the

bar

to b.d.c.

stud2until

(see

the

needleIscentredInthe

stud

2 with nut 1.

"Setting").

undersideofthe

arm.

needle

hole

sideways.

Page 15

6

Adjusting

the

needle

throw

Setting:

Whenthe

in

hole

2) it

needle

must

bar

risesfrom the bottom position on the rightofits throw to t.d.c. (pin

not

movetothe

side

when

the

stitch width

leverismovedtoand

coAmm

fro.

6.0.1

Adjustment:

.1

.2

.3

.4

.5

.6

.7

.8

Loosen screws1 ofzigzag eccentric2 justenough toallow the eccentricto be turned on

its

shaft

against

strong

resistance.

Bring

the

needle

bar

from the bottom position on

the

right of its throw to t.d.c.

Insert cylindrical pin in hole "2" ofthe bearing plate (to blockthe machine).

Moveeccentric 2 sidewayson itsshaft untilthereis a clearance of about 5 mm between it

and

the

rightwall of the casting.

Turn

eccentric2on

width

leverismovedtoand

Check

this

adjustment

Remove

Screws1are

cylindrical pin from hole "2"ofthe bearing plate.

still

its

(see

loose.

shaft

fro.

"Setting").

(See

until

Fig. 8.0.1.).

the

needle

13

bar

stops

vibrating

when

the

stitch

Page 16

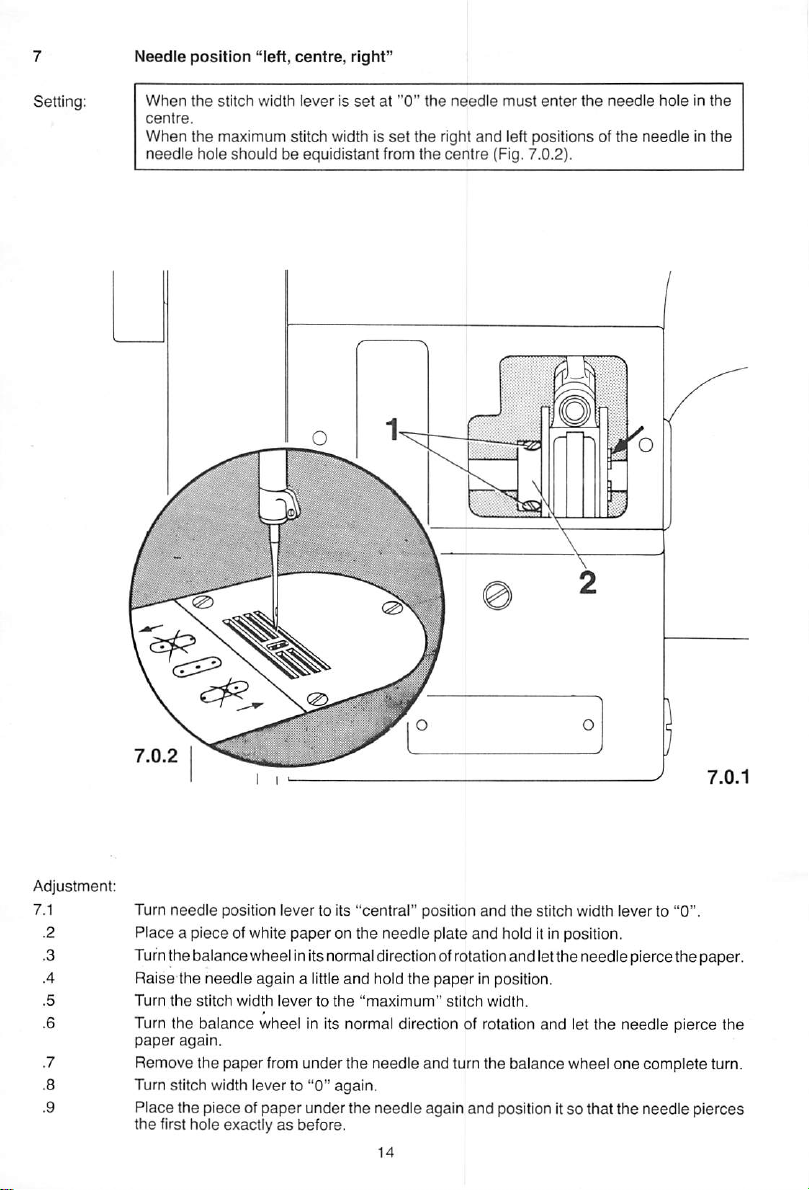

Needle

position

When

the

centre.

When

needle

stitch

the maximum stitch width is

hole should be equidistant from the

"left,

centre,

width

leverissetat"0"

right"

set

the

the

needle

right

centre

must

and

left positions of

(Fig. 7.0.2).

enter

the

needle

the

needleInthe

holeinthe

Turn

needle

position lever to its "central" position

and

the stitch width lever to "0".

Place a piece ofwhite paperon the needle plate and hold itinposition.

Turnthe balance wheel initsnormal direction of rotationand letthe needlepierce the paper.

Raise

the

needle

again

a little

and

Turn

the

stitch

width

levertothe

hold the

"maximum"

paper

stitch

in position.

width.

Turn the balance wheel in its normal direction of rotation and let the needle pierce the

paper

again.

Remove

the

paper

from

under

the

needle

and turn the

balance

wheel

one

complete

Turn stitch width leverto "0" again.

Place the piece of paper under the needle again and position itso that the needle pierces

the first hole exactlyasbefore.

turn.

Page 17

7.10

.11 Move

Making

mum"

and

needle

punctures

that

the

sure

that

the

needle

let

the

vibrating

needle

point is not in

pierce

the

eccentric

paper

2 in

the

again.

the

directionInwhich

mustbemovedinordertoobtainasymmetrical

eccentricisnot

rotatedinthe

process.

.12 Inthis positiontighten screws1 and pushthe circlip

eccentric.

.13 Checkthis adjustment

(see

"Setting").

paper, turn

(see

the

stitch width lever to "maxi

the

two

outer

stitch

pattern;

make

needle

sure

arrow inFig. 7.0.1) up against the

15

Page 18

8

Adjusting

the

needle

position

lever

Setting:

The leftand rightthrows of the needle must be the same both at the widest stitch

setting and at the leftand rightneedle positions.

8.0.1

Adjustment:

8.1

Loosen

screws1and

2.

Tum needle position lever 3 to Its"central" position

mum"

stitch

width.

and

stitch width lever 4to the "maxi

Tum the balance wheel in its normal direction of rotation untilthe descending needle is

positioned

.4

.5

.6

.7

Place a piece ofwhite paperoverthe needle holeand fixitin positionwithadhesive tape.

Turnthe balance wheel Insewing direction untilthe needle pierces the paper.

Turnthe balance wheel inthe oppositedirection and let the needlepierce the paperagain.

Turnstitch widthlever 4 to "0" and push needle position lever 3to the right untilthe point

above

the

left

endofthe

needle

hole.

ofthe needle Ispositioned exactly above the hole last made Inthe paper.

.8

.9

.10

.11

position

In

Push needle position lever 3 to the leftuntilthe point ofthe needle Is positioned exactly

above

the lefthole Inthe paper.

In

this

position

Check this adjustment

push

screw2against

push

screw1against

(see

"Setting").

16

its

stop

and

tighten

it firmly.

its

stop

and

tighten

it firmly.

this

Page 19

9

Adjusting

the

stitch

length

scale

ring

Setting:

When the stitch iength is

graduation

mark

4.

set

at "0" the "0" mark on scale ring 3 must be inline with

Adjustment:

as

9.1

Turn miiied wheel 1

moves

downwards.

.2

.3

Loosen

screw2and

mark

4.

Inthis position tighten

farasit willgoin

turn

scale

ring3so

screw

2.

the

direction in which

that

the

figure

17

the

reverse-feed

"0" is in line with

control

graduation

Page 20

10

Zeroing

the

bottom

feed

Setting:

10.1

When

the

baiance

stitch iength is

wheeiisturned.

Adjustment with

closed

((t

set

at "0"

gearcase.

1/

the

feed

dog

must

not

move

fonward

when

the

10.0.1

Adjustment:

10.1.1

.2

.4

.5

Loosen

clamp

screw

4 of

actuating

Place

a 27-mmwrench on hexagon torsion nut 6

position.

Keep

feed

Hold

against

Check

rotating

dog

the

the

stops

balance

moving

wheel

forward.

wrench in this position and, making

the

casting, tighten

this

adjustment

(see

clamp

"Setting").

crank

and

screw

18

5.

turn

4.

and

the

wrenchonthe

sure

the

thus

hoid actuating shaft 7 firmlyin

torsion

nut

actuating crank 5

and

until

circlip 8

the

are

Page 21

10.2

Adjustment with

open

gearcase.

10.0.2

Adjustment:

10.2.1

.2

.3

Remove the

outofthe

Set

stitch length at

To

makeiteasiertosee

feed

Loosen

resistance.

Turn

driver

rock

the

and

gearcase

gearcase).

shaft

clamp

balance

thus

crank

screw

wheel

the

In this position tighten

Check

this

adjustment

cover on the underside of the machine (collect any oilwhich runs

"0".

when

the

feed

1.

2 just

enough

andatthe

feed

dogiscompletely

clamp

screw

(see

"Setting").

dog is motionless insert a srewdriver in the slot of

to allow

same

time

crank

turn

3 to be

feed

turned

shaft

on its

crank3until

shaft

motionless.

2.

19

the

against

screw

Page 22

11

Adjusting

the

bottom

feed

driving

motion

Setting: When the machine is

beyond

control is

its

t.d.c.

operated.

(pin in hole 4)

set

for its longest stitch

the

feed dog

and

must

the

needle

not move

bar

is positioned 1 mm

when

the

reverse-feed

11.0.1

Adjustment:

11.1 Turn the shaft to

make

screws 1 offeed driving eccentric 2 accessible and loosen them

just enough for the eccentric to be turned againststrong resistance.

.2 Turnthe balance wheel untilthe needle baris positioned 1 mmbeyond itst.d.c.

.3 Insertthe cylindrical pininhole 4 ofthe bearing plate (to blockthe machine).

.4

.5 Move

.6 Inthis position,makingsure that the feed

Set

the machinefor itslongest stitch.

the

the

is

tighten

reverse-feed control up

notchonthe

completely

motionless.

oneofthe

eccentricisvisible

screws

1.

and

and

down

and

the

driving

turn feed driving eccentric 2 until

screwdriverinfeed

rock

eccentric is not moved along the shaft,

shaft

crank

.7 Remove the cylindricalpin from the hole ofthe bearing plate.

.8 Tighten

.9 Checkthis

-10

Remove

the

other

adjustment

the

screwdriver

screw

1.

(see

from

"Setting").

feed

rock

20

shaft

crank

3.

3

Page 23

12

Bottom

feed

lifting

motion

12.1

Setting;

On

Cl.

418

and

438

When thestitch length is

t.d.c.

(pin in hole 4)

set

at "0" and the needlebar is positioned1.0 mm

the

feed

dog

must

be at its

td.c.

beyond

its

12.0.1

Adjustment:

Set

the

12.1.1

.2 Loosen

.3 Turn

.4 Insert

.5 Tomake iteasierto recognise the

.6

.7 Inthis position, making

stitch length at "0".

screws

the

balance

the

cylindricalpin in hole "4" ofthe bearing plate (to block

crank

3.

Turn

feed

lifting

crank3isatits

tighten

the

accessible

1 infeed liftingeccentric 2.

wheel until

eccentric2on

b.d.c.

the

needle

dead

Its

(see

arrow in Rg. 12.0.1.).

sure

that feed

screw

1.

bar

centre positioninserta screwdriverintheslotof

shaft

lifting

is positioned

until

the

screwdriverInfeed

eccentric 2

1.0mmbeyond

the

does

not move along the shaft,

its

machine).

.8 Remove the cylindrical pinfrom the hole ofthe bearing plate.

.9 Tighten

.10

Check

the

this

adjustment

second

screw

(see

1.

"Setting").

21

t.d.c.

lifting

lifting

shaft

Page 24

12.2

OnCI.838

Setting: Whenthe stitchlengthis set at "0" and the needle bar is positioned1.0 mm

t.d.c.

(pin in hole 4)

the

feed dog

must

be at its t.d.c.

beyond

Its

12.0.2

Adjustment:

12.2.1

.2

.3 Turnthe balance wheel untilthe needle par is positioned 1.0 mm

Set

the stitch length at "0".

Loosen

screws

1 in

feed

lifting

eccentric

2.

beyond

its Ld.c.

.4 Insert the cylindricalpin in hole "4" ofthe bearing plate (to block the machine).

.5 Turn

.6 Inthis position, tighten

.7 Remove

.8

Tighten

feed

lifting

eccentric2on

the

the

cylindricalpin from the hole ofthe bearing plate.

the

second

screw

its

accessible

1.

shaft

screw

until

the

feed

dog

is at

its

Ld.c.

1.

.9 Check this adjustment (see"Setting").

22

Page 25

13

Tensioning

the

driving

beltinthe

gearcase

Setting:

The driving beit must be tensioned so that the

machine

does

not

bind.

gears

have no backlash, but the

o

O

13.0.1

Adjustment:

Loosen

screw

sure

the

not

this

1.

driving

that

eccentric

bind.

adjustment

gear

3.

eccentric

bushingsothat

screw

1.

(see"Setting").

bushing

23

2 is not moved,

the

gears

have no

the

tension

backiash

middie of

the

driving beit by

but

the

13.1

.2

Move eccentric bushing 2 until the driving belt is positioned in

case

opener

Making

turning

does

Inthis position tighten

Check

the

bobbin

machine

Page 26

14

Setting:

Adjusting

The

hook

bearing

the

hook

shaft

bracket

bearing

must

gauge.

contact

bracket

both

the

vertical

and

horlzontai

surfacesofthe

14.0.1

hook

14.0.2

Adjustment:

14.1

.2

.3

.4

.5

Remove bed slide, needle plate, feed dog and bobbin

Loosen clamp screw 1

Loosen,the two hook

and

swing the bobbin

set

screws and remove the sewing hook fromits shaft.

case

case

opener

position finger.

to the right.

Loosen alien screw 2 on the bedplate and releasethe taper keyofhook bearing bracket 3

underneath this screw bytapping the head ofthe alienscrew

Screwonthe

hook bearing bracket

gaugesothat on Ci.

438

lightly

witha hammer.

and

838

machines

438-439and onCi.418 machinesnumber418-419can be read fromthe front(Fig.14.0.1).

By

turning

with both

In this position tighten alien

Unscrew

and

moving

the

vertical

and

remove the hook bearing bracketgauge.

hook

and

bearing

horizontal

screw

2.

24

bracket3bring

surfacesofthe

the

hook

shaft

into

hook bearing bracket gauge.

number

contact

Page 27

15

Preliminary

adjustmentofneedle

bar

height

Setting:

When

between

the

needle

needle point

bar

is at t.d.c. (pin in hole "2")

and

needle

plate.

there

mustbeclearance

of 19

mm

15.0.1

Adjustment:

Bring

15.1

the needle bar to

Place

the

.2

.3

.4

Loosen

Adjust

19 mm

.5

.6

Inthis position tighten

Remove

needle

screws

the

needle

between

the

needle

t.d.'c.

plate in the

1 in

the

needle

bar

.vertically - without

needle

point

screws

plate again.

and insertthe cylindrical pinin hole "2" ofthe bearing plate.

needle

plate cutout.

bar

and

1.

connecting

needle

25

stud.

turning

plate.

it - untii

there

is a

clearance

15.0.2

of

Page 28

16 Oil

distributor

ring

Setting: When the hook is incontact with the oildistributor ring there must be a clearanceof

0.2-0.3 mm

between

the hook point

and

the middle of the

clearance

cut of the

needle

(Fig. 16.0.2).

16.0.1

Adjustment:

16.1

.2

.3

.4

.5

.6

.7

Set the stitch

Place

width

leverat "0" and the needle positionlever at itscentral position.

the sewing hook on the hook shaft.

Bringthe needlebar toa position2 mm beyond b.d.c. but make sure the needle

strike

the

sewing hook.

Loosen

screw

1 of oil distributor ring 2.

Making

sure

that

the

butor

ring

and

the

hook

point and the middle of the clearance cut of the needle

hook is up

In this position tighten

Check this adjustment

screw

(see

until

thereisa

1.

"Setting").

against

the

oil distributor ring, movethe oil distri

clearanceof0.2-0.3mmbetween

26

(Fig.

16.0.2).

does

the

16.0.2

not

hook

Page 29

17

Hook

timing,

hook-to

needie

ciearance

and

bobbin

case

position

finger

Setting:

Withthe

needle

needle

position lever InItscentral position, the stitch width lever at "0"

bar

at a position 2 mm beyond b.d.c. (pin In hole "1") the hook point

and

the

must

be exactly oppositethe centre lineofthe needle. Also,Inthisposition, there should bea

clearanceofabt.

0.1mmbetween

hook

point

and

needle.

17.0.1

Adjustment:

17.1

.2

.3

.4.

.5

.6

.7

.8

Bring

the needle bar to a position 2.0 mm beyond b.d.c., makingsure that the needle

does

not strike the sewing hook. Blockthe machineInthis position byinserting the pin In

hole

"1" of

the

bearing plate.

Set

the stitch width lever at "0" and the needle position lever at Itscentral position.

Turnthe sewinghook on Itsshaft

until

Itspoint Isopposite the centre line ofthe needle.

Adjustthe hookiateraiiy,howeverwithoutturning it, untiithere isa ciearanceof 0.1

mm

between

Inthis position, tighten the accessible hook

Screwonthe

bobbin

the

bobbin

Pull

the pinoutofthe holeInthe bearingplateand tightenthe second hookset screw1.

Check this adjustment

case

its

bobbin

base

case

point

and

base.

and

the

needie.

case

position fingersothat

that

(see

thereisa

"Setting").

clearanceof0.5mmbetween

27

set

screw 1.

it is positioned in

its

the

front

slotofthe

edge

and

Page 30

18

Final

adjustmentofneedle

bar

height

Setting;

Withthe stitch width lever at "0", the needle position lever at its left position and the

hook point positioned exactlyopposite the needle, the bottom

must

be positioned 0.5 mm

above

the

top of the

needle

eye.

edge

ofthe hook point

18.0.1

Adjustment:

18.1

.2

.3

.4

Set the stitch widthlever at "0" and the needle positionlever to itsleftposition.

Turn the balance wheel untilthe hook point is exactly opposite the needle.

Loosen bothclamp screws 1 of the needle bar connecting stud.

Push

the

needle

bar

up or

down

until

the

hook

pointis

topofthe

needle

eye.

Inthis position, tighten bothscrews1, making

28

sure

positioned

that the needlebar

0.5 mm

has

not

18.0.2

above

been

V

the

tumed.

Page 31

19

19.1

Bobbin

case

opener

Positionofbobbin

(not on 838)

case

opener

Setting:

There

must be a

bobbin

case

between

case

base

between

the bobbin

clearance

base

(Fig.19.0.3). Furthermore,

the

top of

(Fig.19.0.2). And, finally,

the right

side

case

opener

19.0.2

of abt. 0.8 mm

the

bobbin

ofthe bobbin

is at its left point of reversal (Fig.19.0.4).

R

case

position finger

case

there

slot

between

there

must

should

and

the bobbin

bobbin

be a

and

the

be a

clearanceofabt.

case

case

opener

clearanceofabt.

inner

edgeofthe

position finger

finger

0.5

0.3

and

mm

bobbin

mm

when

19.0.3

19.0.4

Adjustment:

19.1.1

Turn bobbin

.2

Push

screw

tance.

Loosen alien

case

opener

finger 1sothatitcontacts

the

opener

finger against clamp crank 2 located underneath and tighten clamp

3 just sufficiently to allow

screw

4 of the eccentric bobbin

the

the

opener

finger to be turned on Its shaft

case

opener

29

right

bushing.

sideofthe

bobbin

against

19.0.1

case

slot.

resis

Page 32

19.1.4 Turn

the

the

eccentric

bobbin

of

(Fig. 19.0.2).

.5

Adjust

the

bushinginheight

0.8mmbetween

(Fig. 19.0.3).

.6 Inthis position, tighten alien

.7 Turn the

.8

.9 Inthis position tighten

Turn

base,

case

clamp

balance

the

opener

until

thereisa

slot

and

the

crank2underneath.

.10 Check this adjustment

o

bushing

case

opener

until

thereisclearanceofabt.

finger

without

bobbin

case

opener

screw

4.

wheel to bring the bobbin

fingeronits

clearanceofabt.

bobbin

clamp

(see

19.0.2

shaft,

case

position

screw

"Setting").

3, making

and

the

inner

turning

finger

and

case

opener

making

sure

0.3mmbetween

finger

(Fig. 19.0.4).

sure

0.5 mm

edgeofthe

it until

there

the

is a

edgeofthe

to its leftpoint ofreversal.

it still

contacts

the

right

the

bobbin

case

between

bobbin

the

case

clearanceofabt.

bobbin

case

the

bobbin

sideofthe

opener

still

bobbin

contacts

top

base

base

case

19.0.3

19.0.4

30

19.0.1

Page 33

19.2

Timing

the

bobbin

case

opener

Setting:

When the needlebar is at a position2.0 mm

beyond

finger must be at its right pointof reversal(Fig. 19.0.6).

b.d.c. (pininhole "1") the opener

€)

19.0.6

Adjustment:

Loosen

the

three

screws

19.2.1

1 of bobbin

.2

.3

.4

Tighten the central

against

resistance.

Bring

the

pin in

needle

hole

screw

bar

"1" (to block

1 just sufficiently to allow eccentric 2 to be turned on its shaft

to a position

the

To facilitate determining the

slot of

the

clampofopener

Turn

opener

eccentric

2 until

machine).

finger 3.

case

opener

eccentric

2.0mmbeyond

exact

point of reversal insert a small screwdriver in the

opener

finger

3 isatits

b.d.c.

2.

and,

in this position,

right

pointofreversai

(Fig. 19.0.6).

Pull

the

pin out of

Tighten the central

Pull

the

screwdriverout of

ment

(see

the

"Setting").

holeinthe

screw

bearing

1 first, thenthe two outer

the

clamp

31

slot of

plate.

the

bobbin

screws

case

1.

opener

and

check

this

O

19.0.5

insert

adjust

1—

the

Page 34

20

Adjusting

the

slack

thread

control

Setting:

When the needle bar is at b.d.c. the bottom

be inline with

20.0.2

the

top

edgeofthe

hole in

edge

the

ofthe slack thread control wire must

threadguide(Rg. 20.0.2).

Adjustment:

20.1

.2

.3

Push

slack

thread

control wire 1 on

the

needle

position of

top

edgeonthe

bar

Bring

Adjust

the

with

the

the

bedplate.

Inthis position tighten

Check this adjustment

to b.d.c.

slack

screw

(see

bushing2and

thread

holeinthe

3.

"Setting").

control

thread

32

hold it inposition.

wire 1sothat

guide,

and

make

its

bottom

sureitis

edge

set

Is In line

parallel

20.0.1

to

Page 35

21

Clearance

between

presser

foot

and

needle

plate

Setting:

When the

presser

presser

foot

21.0.1

bar lifter is raised there must be a clearance of 7 mm between

and

needle

plate.

Adjustment:

21.1

Screw on feed dog, needle plate and bed slide.

Making

sure

central position, raise the

that the stitch width lever is at "0" and the needle position lever is in its

presser

bar

lifter.

Replace the presser foot and lower it onto the needle plate by means of the presser

bar

lifter.

.4

Reduce the pressureofthe presser bar by turning out regulatingscrew 1 untilthe presser

foot is pressed againstthe needle plate onlyslightly.

.5

.6

.7

.8

.9

.10

Push the 7-mm-thick part of the

under

the

hinge of the

presser

Loosen clamp screw 2 of the

Tum

the

balance

wheel

Adjust

the

holeofthe

in

this

position

screw

2.

Check

this

position of

presser

adjustment

push

the

foot.

the

(see

lifting

until

the

presser

lifting

"Setting").

gauge

under the presser foot from behind so that it is

foot.

bracket and raise the presserbar

needleisdowninthe

footsothat

bracket

downasfarasit willgoand

33

the

needle

needle is

lifter.

holeofthe

centred

presser

exactly in

tighten

foot.

the

clamp

Page 36

22

22.1

Feed

On

Ci.

dog

418

height

and

438

Setting:

Withthe stitch

hole"4") the

entire

length (Fig. 22.0.3).

set

at "0" and the needle bar at a position 1.0 mm

feed

dog

mustbecentred

Inits slots

and

contactthe

beyond

gauge

td.c.

(pinin

throughoutIts

22.0.2

Adjustment:

22.1.1

Bringthe needle bar to a position.1.0 mm

the

bearing plate (to block

.2

.3

.4

.5

.6

clamp

the

screws1and

gauge

under

the

Loosen

Place

edge

is flush with

Lowerthe presserbar lifterto rest the

Push the feed bar upwards, centre the feed dog inthe needleplate slots and holditin this

position.

Tumfeed

lifting

crank 3

the

machine).

2.

the

presser

edgeofthe

until

needle

the feed dog contacts the gauge and tighten

beyond

footsothat its

plate.

presser

foot on the gauge.

t.d.c. and insertthe pinInhole "4"of

recess

faces

downwards

and

damp

just lightly.

.7

.8

Turn

tact

eccentric

with

bushing5underfeed

the

gauge

throughout Its entirelength and tightenclampscrew 2 lightlytoo.

rock

shaft

crank

4 until

the

feed

dog

Is in

Tightenclampscrews 1and 2,makingsure the feed dog iststillin contactwiththe gauge

throughout its entire length.

.9

.10

Raise the presserfoot

out of

the

hole in

lifter,

the

bearing plate.

removethe gaugefromunder the presserfootand pullthe pin

Check this adjustment (see "Setting").

34

22.0.1

Itsfront

screw 1

con

Page 37

22.2

On

Cl.

838

Setting:

With

the

hole "4")

stitch

the

teethofthe

set

at "0"

and

the

needle bar at a position 1.0 mm

feed

dog

must

be 1mmabove

the

beyond

needle

plate.

td.c.

(pinin

Adjustment:

22.2.1

Bring

the needle bar to a position1.0 mm beyond

td.c.

and insertthe pininhole "4" of

the bearing plate (toblockthe machine).

.2

.3

.4

.5 In

Loosen

Lift

presser

Turn

eccentric

this

position, tighten

screw

1.

foot by

2 until

means

the

screw

ofthe

lifting

teethofthe

1.

lever.

feed

dog

are

1 mm

above

the

needle

.6 Take the pinout of the hole inthe bearing plate.

.7 Check this adjustment

(see

"Setting").

35

plate.

Page 38

23

Oil

check

valve

Setting:

Note:

There should be a

clearanceof1.0mmbetween

actuating rod 2 of the centrifugal

governor and push rod3 ofthe oilcheck valve (Fig.23.0.2).

If

the

machine

case

with abt. 130 c.c. of Pfaff

has

been

in operation for a longer time, it is

sewing

machine

recommendedtofill

oil No.

280-1-120144

the

having a

gear-

mean

viscosityof22.0 mm^/sat 40°Cand adensityof0.865 g/cm^at 15°Cbeforethe gearcase

cover

is closed.

91-168384-05,

The

two oil

shouldbereplaced

pads,

1

which

too.

are

available

under

Nos.

91-168383-05

and

p

b

23.0.2

Adjustment:

23.1

.2

.3

.4

.5

.6

.7

.8

.9

Loosen

screw1of

Push

actuating

Press

push

Reposition

rod2and

In this position tighten

Place

the

its

Clean

Replace

Check

oil

smallest

the

the

this

rod 2 to

rod 3 into oil

oil

check

push

rod

padinthe

cutout.

gasket

face on the

gearcase

adjustment

the

oil

check

valve.

the

leftasfarasitwill

check

valve 4 until a

valve

4 until

3 (Fig. 23.0.2).

screw

1.

gearcasesothat

gearcase

cover

and

tighten

(see

"Setting").

there

36

go.

resistance

Is a

clearanceof1.0mmbetween

the

vertical fin in

and

the

gasket

screws

of the

crosswise.

is felt.

the

gearcase

gearcase

actuating

is positioned in

cover.

23.0.1

Page 39

24

Tension

release

mechanism

(Thisadjustment procedure

trimmer.)

does

not

applyto machines equipped withsubcl. -900 thread

Setting-

When the presser bar lifteris raised both tension discs should be at least0.5 mm apart

(Fig. 24.0.2).

Q)

24.0.1

Adjustment:

24.1 Take out

.2 Lowerthe presser footontothe needle plate bymeans ofthe presser bar

.3 Loosenclampscrew 1 of

itwillgo.

.4 Bring

the

the

needle

four

screws

bartob.d.c.

of the arm

lifting

rear

cover

and

swing the

cover

out to

levercrank2 and pushtheconnecting roddownas faras

the

lifter.

.5 Raise the presserfoot and placethe feed dog gauge under the foot withits recess up.

.6 Lowerthe presser foot intothe recessof the gauge.

.7

Loosen

screw

3 of

tension

release

cam

37

4.

24.0.2

right.

Page 40

24.8

.10

.11

.12

.13

.14

.15

Adjust

tension

release

cam

4 on Its

tension

.9

Swing up

In

tighten

this

release

the

presser

position,

screw

3.

pin

push

5.

bar

tension

lifter until a

release

resistance

cam

shaftsothat

is feit.

4 up

it is

positioned

against

tension

exactly

release

opposite

pin 5

and

Remove the feed dog gauge from under the presser foot and lowerthe presser foot onto

the

needle

plate again.

Tightenclampscrew 1, makingsure thatretainingring6onthe

lifting

shaft isstiilincontact

withthe face side of the machine and crank 2 contactsthe casting.

Check this adjustment

Screwonthe

The

arm

face

rear

cover remains swung out.

cover.

(see

"Setting").

0

24.0.1

38

24.0.2

Page 41

25 Lubrication of

zigzag

eccentric

25.1

Note:

Fill

the zigzag eccentric housing with abt. 75 c.c. of oil.

Only

and a densityof 0.865

25.2 Clean the

.3

cover.

Screw

on the cover, making

the

hole of

use

Pfaff

sewing machineoil

gW

gasket

face on the coverof the zigzag eccentric housing and the

the

sealer

sure

plate.

having

a mean

viscosity

at 15°C(No.280-1-120144).

that the

needle

bar lubricating wickis stillpositioned in

of 22.0

mm^/s

gasket

at 40°C

ofthis

39

Page 42

26

Hook

lubrication

Setting:

Afterthe machine

appear

on a piece of

has

paper

i

run at full

placed

[m

speed

overthe

for

about

ten

seconds,

a fine trace of oilshould

needleplate cutout abovethe hookraceway.

0

26.0.1

Adjustment:

26.1

.2

.3

.4

.5

.6

Checkthe

22.0

upper

Tuminregulatingscrew1 oftheoilcheckvalveas faras it

a

turn.

Switchonthe

oil

level

mm®/sat40°C

mark. We recommend Pfaff sewing machine oil No. 280-1-120144.

machine

anda

and

density

runitfor

of0.865

about

and,ifnecessary,topupthe

reservoir

g/cm^at15°C

one

minute.

with

oil

with

until

the

oil

level

will

go,and then backabout half

a mean

isin

Remove needle plate and feed dog and take the needle out of the needle bar.

Placea piece ofwhite paperover the needle plate cutout and holditthere.

Letthe machine runabout ten seconds. Thencheck to

see

ifa finetrace ofoilhas appear

viscosity

line

ed onthe paper opposite the hook raceway.

.7

.8

.9

.10

If

too

much

turnitout

oil is emitted,

somewhat.

turn

regulating

screw

Check thisadjustment (see "Setting").

Replace and screwon feed dog and needle plate.

Replace

the

needleinthe

needle

bar.

40

line

littie;orif

too

little oil Is

with

the

emitted

of

Page 43

27

Setting:

Knee

When

plate

lever

the

knee

by a little

stroke

more

limitation

lever is fully

than

7.0mmand

((

operated,

the

the

presser

presser

foot mustbe lifted from the

bar

lifter

must

drop

by its

own

needle

weight.

27.0.1

Adjustment:

27.1

.2

.3

.4

Placethe feed dog

Lowerthe

Loosen

Move

presser

Hold

back

Remove the feed dog

Check

presser

locknut 1

the

knee

foot

must

the

knee

outbyone

this

adjustment

and

levertothe

leveratthis

turn,

gauge

under the

presser

footso that Its

foot onto the feed dog gauge.

turn

stop

screw2out

notbelifted off

right

position

and

lock It In

gauge

from

(see

"Setting").

under

until a

the

and

place

41

a few turns.

noticeable

gauge.

turn

with locknut 1.

the

presser

stop

recess

resistance

screw

2 Inasfarasit will

foot.

faces the needleplate.

Is felt;

however

go,

J

the

then

Page 44

28

Knee

lever

play

Setting:

There

mustbea noticeable

when

the

knee

A

db

0

leveris

f

amount

operated

of play

just lightly.

between

0

nut 2

and

forked connection 3

28.0.1

Adjustment:

28.1

.2

.3

.4

Loosen

locknut1of

Turn in

nut

nection3when

Lock nut 2 in place by tightening locknut 1.

Check this adjustment

2 until

the

nut

there

knee

2.

is a

(see

noticeable

lever is

"Setting").

operated

42

amount

just

of play

lightly.

betweenitand

forked

con

Page 45

Bobbin

winder

When

the

bobbin winder is

the bobbin winder is

wheel

2.

The

bobbin winder

has

reached

a point abt. 1 mm below its rim (Fig. 29.0.2).

engaged,

disengaged,

must

stop

the

winderspindle must be driven reliably;

however, friction wheel 3

automatically

when

the

thread

must

not

wound on

contact

the

when

drive

bobbin

Raise

the

presser

bar

lifterand

Loosen

both

screws

1 in

Set

drive

driven

wheel2so

reliably

when

be driven by drivewheel 2

Tighten

both

screws

1.

Place a bobbinon the winder spindle, thread the machine for bobbin winding,

bobbin

winder

and

start

Loosen

screw

4 of

stop

If

the

bobbinistoo

full

enough,

After

the

adjustment,

If

the

thread

accordingly.

Check

this

adjustment

full,

pushittoward

tighten

piles upon

Finally, replace the arm

engage

drive

wheel

2.

closetofriction

the

bobbin

winderisengaged,

when

the

the

machine.

latch 5.

push

regulating

the

left.

screw

4.

one

sideofthe

{see

"Setting").

rear

cover

with

the bobbin winder.

wheel3that

bobbin

winderisdisengaged.

stud6toward

bobbin, adjust the

the

four

screws

the

bobbin

but

thread

winder

that

friction wheel 3 will

the

right, if

guide

spindle

the

bobbinIsnot

on the

engage

machine

29.0.2

will

be

not

the

arm

Page 46

30

Thread

check

spring

and

thread

regulator

Setting:

Note:

The

stroke of the thread

needie

reaches

the

check

materiai (abt. 7.0 mm stroke).

spring must be completed when the point of

the

Special sewing operations may make Itnecessary to choosea longer or shorter stroke.

30.0.2

30.0.1

Adjustment:

30.1

Loosen both screws 1 ofthread tension piate 2 just sufficiently to allowthe tension barrel

to be turned inthis plate.

Turn tension barrel 3 until the stroke of the thread checkspring amountsto abt.

7.0

mm

inthis position,tighten bothscrews 1 ofthread tension plate 2 evenly.

Check this adjustment

(see

"Setting").

Loosen both screws4 of thread regulator 5.

Push

the

thread

regulatorupas

Inthis

position,

tightenbothscrews 4. (The

on the type of thread and

pearanceofthe.seam).

Screw

on thread guide 6.

31

Presser

foot

pressure

31.1 Threadthe machine,place a piece of

foot

onto

it.

material

farasIt will

go.

position

ofthethread regulator isdependent

used and should be adjusted

fabric

underthe presser footand

according

lower

the presser

.2 Turninregulatingscrew 1 (Fig.21.0.1) untilproper feedingofthe materiai isensuredeven

at

top

speed.

44

to the ap

Page 47

Annex

32

for

machines

Needle

equipped

vibration

with

zigzag

control

-716/..

Setting:

The

sideways

motion of the

terial. (Check with

the

needle

machine

bar

should

set

at its widest zigzag stitch.)

cease

when the

needle

enters

the ma

32.0.1

Adjustment:

32.1

Unscrew

pullthe needle

.2

.3

.4

Set

Loosen

Turn

when

Inthis position,tighten the two

ner

Check this adjustment

the

stitch width

the

needle

the

wall

and

the

two

needle

cast-iron

vibration

needle

coverofthe

bar

lubricating wick out of its hole in the cover sealing plate.

leveratthe

screws

1 of

cam3so

enters

the

vibrating

(see

needle

widest

gear

2.

that

material.

gear

cam3the

"Setting").

vibrating

zigzag

the

needle

set

screws 1, making sure

stitch.

bar

cam

has

right inner wallsothat they

45

housing, making

completed

sure

Its

sideways

gear

2 contactsthe leftin

havenoend

you do not

motion

play.

Page 48

33

Left,

center

and

right

needle

positions

Setting:

With the machine

set

at its widest zigzag stitch, the right and left needle punctures

should be equidistant from the central needle puncture (Fig. 33.0.2).

33.0.1

Adjustment:

33.1

.2

.3

Movestitchwidthlever 1 (Fig.33.0.1) to the widestzigzag stitch.

Place a piece ofwhite paper on the needle plate and holdit there.

Tum

the

balance

wheel

in its normal direction of rotation

and

let

the

needle

stitches of a complete pattern.

.4

.5

.6

Hold

the paper fast and tumthe balancewheel

positioned a little

Set

needle

Tumthe balancewheelInits

above

the paper.

position lever 2 at "center" and stitch width lever 1 at "0".

normal

until

the

point

directionofrotation

ofthe ascendingneedleis

until

the needle

point

pierces the paper. This needle puncture should be centered between the two outer

punctures

If

itis

(Fig. 33.0.2)

not,

takeoutthe

four

alien

screws3ofthe

stitch

width

regulator

plate

(Fig.

and remove the plate by pullingitforward.

46

stitch all

again

33.0.1)

Page 49

33.8 Loosen lockout 4 (Fig. 33.0.3).

.9 Replace the stitch width regulator plate and

.10 Loosen

.11 Turn eccentric bushing 6

.12

screw

"Setting" is

Tighten

screw

5 (Fig. 33.0.4).

obtained.

5.

uritii

a symmetrical stitch patternasdescribed

.13 Again unscrew the stitch width regulator plate.

.14 Tighten lockout 4 while retaining

.15 Clean

the

stitch width regulatorplate

screw

and

apply sealing compound and screw the plate down.

.16

Check

this adjustment

(see

"Setting").

secure

itin position with two

5 witha screwdriver.

the

surface

contactingthe machine arm casting,

screws

under

only.

33.0.4

33.0.3

47

Page 50

34

34.1

Needle

Fixing

position

the

left

lever

needle

position

Setting:

The

straight-stitch punctures in the left

needle puncture

made

at maximum stitch width.

needle

position should coincide with

the

left

Adjustment:

34.1.1

.1.2

.1.3

.1.4

.1.5

Loosen needle position

Set needle

Turn

left of

the

its

position

balance

throw

andatbottom

limiting

screws 1 and 2.

lever3 at"center"and stitch

wheel

in its normal direction of rotation until

dead

center.

width

lever4 atthewidestzigzagstitch.

the

needle

is at

the

Moveneedle position lever 3 graduallytoward the leftwhileconstantly actuating stitch

width lever 4 untilthe needle

Inthisposition, push stopscrew1 upas faras it

screw2loose

however.

does

not move any more.

48

will

go andtightenitsecurely.Leavestop

34.0.1

extreme

Page 51

34.2 Fixingthe right needle

potion

Setting:

The straight-stitch puncture in the right needle position should coincide with the

right

needle

puncture

made

at maximum stitch width.

34.2.1 Set needle positionlever3 at"center" and stitchwidthlever 4 at the widestzigzag stitch.

.2

Turn

extreme

the

balance

rightofIts

wheelInIts

throw

andatbottom

normal

directionofrotation

dead

center.

until

the

needleisat

the

.3 Move needle position lever 3 gradually toward the right whileconstantly actuating stitch

width lever 4 untilthe needle doe's not move any more.

.4 Inthis position,

.5

Check

this adjustment

push

stop

(see

screw

"Setting").

2 to

the

leftasfarasit willgoand

tighten itsecurely.

49

Page 52

r

PFAFF

Sr-

%

^ .

Pfaff,

D-6750

'-i:

296-!2-i26i.i

Innovation

Koisersioutern. Postfoch

modebyPFAFF

3020/3040.

Telefox (0631) 17202

Telefon (0631)

2000.

Telex

45753

Loading...

Loading...