Page 1

296-12-18 413/002

Betriebsanleitung engl. 12.94

Instruction manual

3827-2/24

This instruction manual applies to machines from the

following serial numbers onwards:

# 1484416

Page 2

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or in

part, is only permitted with our previous permission and with written reference to the

source.

G.M. PFAFF KAISERSLAUTERN

INDUSTRIEMASCHINEN AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Editing / Illustrations

HAAS-Publikationen GmbH

D-53840 Troisdorf

Page 3

Contents

Contents..................................................................................... Chapter - Page

1 Safety ........................................................................................................ 1 - 1

1.01 Directives ................................................................................................... 1 - 1

1.02 General notes on safety ............................................................................. 1 - 1

1.03 Safety symbols...........................................................................................1 - 2

1.04 Important points for the user ..................................................................... 1 - 3

1.05 Operating and specialist personnel ............................................................ 1 - 3

1.05.01 Operating personnel................................................................................... 1 - 3

1.05.02 Specialist personnel 1 ................................................................................ 1 - 4

1.06 Danger .......................................................................................................1 - 4

2 Proper use.................................................................................................2 - 1

3 Specifications ........................................................................................... 3 - 1

4 Disposal of the machine .......................................................................... 4 - 1

5 Notes on testing in accordance with EN 60204-1 ..................................5 - 1

6 Transport, packaging and storage .......................................................... 6 - 1

6.01 Transport to the customer’s premises ....................................................... 6 - 1

6.02 Transport within the customer’s premises ................................................6 - 1

6.03 Disposal of the packaging .......................................................................... 6 - 1

6.04 Storage....................................................................................................... 6 - 1

7 Explanation of the symbols..................................................................... 7 - 1

8 Operational controls and optical displays..............................................8 - 1

8.01 On/Off switch ............................................................................................ 8 - 1

8.02 Functions of the pedal................................................................................ 8 - 1

8.03 Functions of the knee lever........................................................................ 8 - 1

8.04 Functions of the hand buttons ................................................................... 8 - 2

8.05 Functions of the quick control panel ..........................................................8 - 2

9 Mounting and initial operation................................................................9 - 1

9.01 Mounting.................................................................................................... 9 - 1

9.02 Initial operation...........................................................................................9 - 1

10 Switching the machine on/off ............................................................... 10 - 1

11 Preparation ............................................................................................. 11 - 1

11.01 Inserting the needle ................................................................................. 11 - 1

11.02 Winding the bobbin thread, adjusting the thread tension......................... 11 - 1

11.03 Threading the bobbin case, adjusting the thread tension.........................11 - 2

11.04 Inserting the bobbin case.........................................................................11 - 2

11.05 Threading the needle thread, adjusting the thread tension ...................... 11 - 3

11.06 Pre-selecting the stitch length and fullness .............................................11 - 3

11.07 Adjusting the edge stop ........................................................................... 11 - 4

Page 4

Contents

Contents..................................................................................... Chapter - Page

12 Programming and sewing ..................................................................... 12 - 1

12.01 Semi-automatic operation ........................................................................ 12 - 1

12.02 Automatic operation.................................................................................12 - 3

13 Care and maintenance ........................................................................... 13 - 1

13.01 Cleaning ................................................................................................... 13 - 1

13.02 Lubricating ............................................................................................... 13 - 1

13.03 Checking the air pressure ........................................................................ 13 - 2

14 Adjustment ............................................................................................. 14 - 1

14.01 Tools, gauges and other accessories ....................................................... 14 - 1

14.02 Abbreviations ........................................................................................... 14 - 1

14.03 Check and adjustment aid........................................................................ 14 - 2

14.04 Pre-adjusting the needle height................................................................ 14 - 3

14.05 Centering the needle in the needle hole .................................................. 14 - 4

14.06 Zeroing the bottom feed dog ................................................................... 14 - 5

14.06.01 Adjustment with gearbox housing closed ................................................ 14 - 5

14.06.02 Adjustment with gearbox housing open .................................................. 14 - 6

14.07 Driving motion of the bottom feed dog....................................................14 - 7

14.08 Lifting motion of the bottom feed dog ..................................................... 14 - 8

14.09 Height of the bottom feed dog ................................................................ 14 - 9

14.10 Clearance between presser foot and needle plate...................................14 - 10

14.11 Adjusting the floating foot........................................................................ 14 - 12

14.12 Top feed driving and connecting levers.................................................... 14 - 13

14.13 Zeroing the top feed motion .................................................................... 14 - 14

14.14 Feeding motion of the vibrating presser .................................................. 14 - 16

14.15 Vibrating presser lift ................................................................................. 14 - 17

14.16 Vibrating presser lifting motion ................................................................ 14 - 18

14.17 Position of the vibrating presser .............................................................. 14 - 19

14.18 Synchronizing the vibrating presser .........................................................14 - 20

14.19 Matching forward and reverse stitch lengths........................................... 14 - 21

14.20 Eccentric hook shaft bearing.................................................................... 14 - 22

14.21 Needle rise, final adjustment of needle height and

bobbin case positioning finger.................................................................. 14 - 23

14.22 Height of bobbin case opener .................................................................. 14 - 24

14.23 Position of bobbin case opener................................................................ 14 - 25

14.24 Motion of bobbin case opener .................................................................14 - 26

14.25 Needle thread tension release .................................................................14 - 27

14.26 Thread check spring and thread regulator ................................................ 14 - 28

14.27 Bobbin winder .......................................................................................... 14 - 29

14.28 Position of vibrating presser in relation to presser foot............................ 14 - 30

14.29 Pressure on vibrating presser and presser foot ....................................... 14 - 31

14.30 Limiting the stitch length ......................................................................... 14 - 32

14.31 Lateral position of thread catcher............................................................. 14 - 33

14.32 Point of reversal of needle catcher........................................................... 14 - 34

14.33 Knife.........................................................................................................14 - 35

14.34 Needle thread tension release .................................................................14 - 36

14.35 Synchronizer ............................................................................................ 14 - 37

Page 5

Safety

1 - 1

1 Safety

1

.01 Directives

This machine is constructed in accordance with the European regulations contained in the

conformity and manufacturer’s declarations

In addition to this Instruction Manual, observe also all generally accepted, statutory and

other regulations and legal requirements and all valid environmental protection regulations!

The regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organisations are to be strictly adhered to!

1.02 General notes on safety

● This machine may only be operated by adequately trained operators and only after

having completely read and understood the Instruction Manual!

● All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read

before operating the machine!

● The Danger and Safety Instructions on the machine itself are to be followed!

● This machine may only be used for the purpose for which it is intended and may not be

operated without its safety devices. All Safety Regulations relevant to its operation are to

be adhered to.

● When exchanging sewing tools (e.g. needle, presser foot, needle plate, feed dog or

bobbin), when threading the machine, when leaving the machine unattended and during

maintenance work, the machine is to be separated from the power supply by switching

off the On/Off switch or by removing the plug from the mains!

● Everyday maintenance work is only to be carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualified service staff

or appropriately trained personnel!

● When servicing or carrying out repairs on pneumatic devices, the machine is to be

removed from the compressed air supply! The only exceptions to this are adjustments

and function checks carried out by appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power

supply! Exceptions to this are in accordance with the regulations EN 50110.

● Modifications and alterations to the machine may only be carried out under observance

of all the relevant safety regulations!

● Only spare parts which have been approved by us are to be used for repairs! We

expressly point out that any replacement parts or accessories which are not supplied by

us have not been tested and approved by us. The installation and/or use of any such

products can lead to negative changes in the constructual characteristics of the machine.

We shall not be liable for any damage which may be caused by non-original parts.

Page 6

Safety

1 - 2

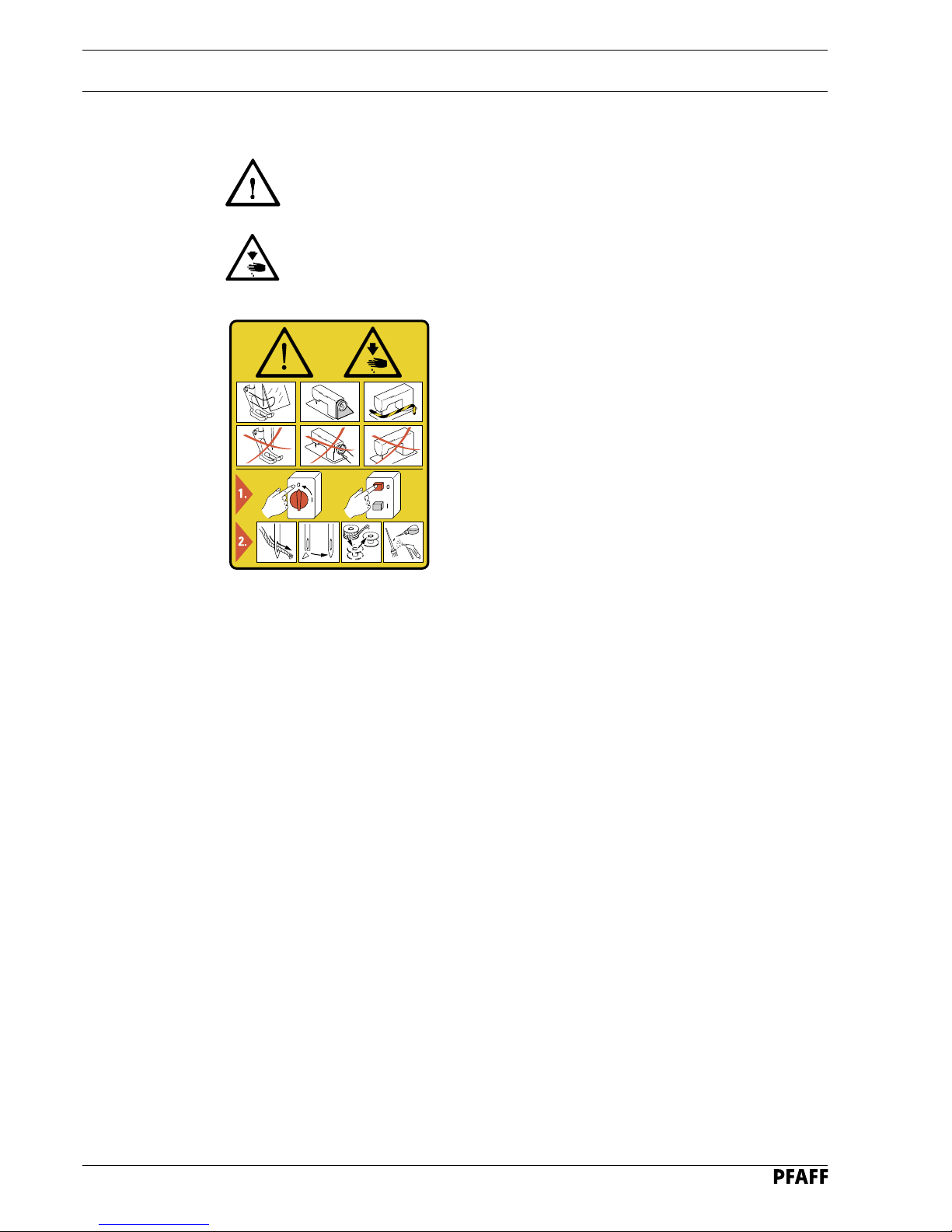

1.03 Safety symbols

Danger!

Points to be observed.

Danger of injury for operating and specialist personnel!

1.04 Important points for the user

● This Instruction Manual is a component part of the machine and must be available to the

operating personnel at all times.

The Instruction Manual must be read before operating the machine for the first time.

● The operating and specialist personnel is to be instructed as to the safety equipment of

the machine and regarding safe work methods.

● It is the duty of the user to only operate the machine in perfect running order.

● It is the obligation of the user to ensure that none of the safety mechanisms are

removed or deactivated.

● It is the obligation of the user to ensure that only authorised persons operate and

work on the machine.

Further information can be obtained at your PFAFF agent.

I

Caution

Do not operate without finger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

Page 7

Safety

1 - 3

1.

05 Operating and specialist personnel

1.05.01 Operating personnel

Operating personnel are persons responsible for the equipping, operating and cleaning of

the machine as well as taking care of faults arising in the sewing area.

The operating personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● never use any working methods which could limit the level of safety in using the

machine!

● not wear loosely fitting clothing or jewellery such as chains or rings!

● also ensure that only authorised persons have access to the potentially dangerous area

around the machine!

● always immediately report to the person responsible any changes in the machine which

may limit its safety!

1.05.02 Specialist personnel

Specialist personnel are persons with a specialist education in the fields of electrics,

electronics and mechanics. They are responsible for the lubrication, maintenance, repair and

adjustment of the machine.

The specialist personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● switch of the On/Off switch before carrying out adjustments or repairs and ensure that it

cannot be switched on again unintentionally!

● never work on parts which are still connected to the power supply! Exceptions are

contained in the regulations EN 50110.

● when servicing or carrying out repairs on pneumatic devices, remove the machine from

the compressed air supply! The only exceptions to this are function checks.

● replace the protective coverings and close the electrical control box after all repairs or

maintenance work!

Page 8

Safety

1 - 4

1.06 Danger

A working area of 1 metre is to be kept free both in front of and behind the

machine while it is in operation so that it is always easily accessible.

Never reach into the sewing area while sewing! Danger of injury by the needle!

Never leave objects on the table or in the needle plate area while adjusting the

machine settings! Objects can become trapped or be slung away! Danger of

injury!

Page 9

Proper use

2 - 1

2 Proper use

The PFAFF 3827 -2/24 is a sewing machine for the closing of side and shoulder seams on

outerwear (e.g. suit jackets, skirt suits, overcoats). The shoulder seams, including bartacks

and application of fullness are produced automatically as mirror images. On the side seams

the fullness to be applied is switched on using a manual switch.

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

Page 10

Specifications

3 Specifications

Sewing machine head:...................................... PFAFF 487 - 706 / 81 - 900 / 99 BS x N3,5

Stitch type:................................................................................................ 301 ( lockstitch )

Model:............................................................................................................................... B

Needle system:........................................................................................................ 134 KK

Needle thickness (Nm):.......................................................................................... 80 - 100

Thread thickness (Nm): ................................................................ max. 60 when synthetic

or comparable thicknesses of other types of thread

Top feed stroke:......................................................................................................... 2 mm

Clearance under the presser foot:.............................................................................. 7 mm

Max. speed: ........................................................................................................ 4800 spm

Max. stitch length: .................................................................................................. 4.5 mm

Sewing motor: ..................................................................................QE 5542-P138SE-Pb5

Maximum motor rpm:................................................................................................. 4000

Working noise level:

Emission at workplace at sewing speed of n = 4000 spm: .......................LpA < 79 dB ( A )

(noise measurement in accordance with DIN 45 635-48-A-1)

Dimensions of machine:

Length:................................................................................................................. 1365 mm

Width: .................................................................................................................... 950 mm

Height: ................................................................................. 1700 mm ( incl. spool holder )

Weight:

Net: .............................................................................................................. approx. 108 kg

Gross: ..........................................................................................................approx. 230 kg

Power supply: ................................................................................................ 230 V ± 10%

50 / 60 Hz, 1 Phase

Power supply frequency: .................................................................................... 50 / 60 Hz

Power input: ................................................................................................... max. 650 VA

Fuse protection: ............................................................................ 1 x 16 A, delayed action

Working air pressure:.................................................................................................. 6 bar

Air consumption:.................................................................................... ~1,6 l / work cycle

3 - 1

Page 11

Disposal of the machine

4 - 1

4 Disposal of the machine

● The proper disposal of the machine is the responsibility of the customer.

● The materials used on the PFAFF 3827 -2/24 are steel, aluminium, brass and various

plastics. The electrical equipment consists of plastics and copper.

● The machine is to be disposed of in accordance with the locally valid environmental

protection regulations.

Special care is to be taken that parts covrered with lubricants are separately

disposed of in accordance with the locally valid environmental protection

regulations!

Page 12

Notes on testing in accordance with EN 60204-1

5 Notes on testing in accordance with EN 60204-1

The PFAFF 3827 -2/24 was tested in accordance with EN 60204-1 before delivery. The

following tests were carried out on the machine:

● Continuous connection of the protective conductor systems

a ) Visual check

b ) Check of the connection of the protective conductor

● Insulation check

● Voltage check

● Function check

5 - 1

Page 13

Transport packaging and storage

6 - 1

6 Transport packaging and storage

6.01 Transport to the customer’s premises

Within Germany, the machine is delivered without packaging. Machines to be exported are

packaged.

6.02 Transport within the customer’s premises

The manufacturer carries no liability for transport within the customer’s premises. Care is to

be taken to transport the machine in an upright position.

6.03 Disposal of the packaging

The packaging of the machine consists of wood, paper, cardboard and VCE fibre. The proper

disposal of the packaging is the responsibility of the customer.

6.04 Storage

The machine can be stored for up to 6 months if not in use. During this time it should be

protected from dust and moisture.

For longer storage the individual parts of the machine, especially the moving parts, should

be protected against corrosion e.g. by a film of oil.

Page 14

Explanation of the symbols

7 Explanation of the symbols

In the following section of this Instruction Manual, certain tasks or important pieces of

information are accentuated by symbols. The symbols used have the following meanings:

Note, information

Operation, adjusting

Programming, preparing, positioning

Cleaning, care

Lubrication, greasing

Servicing, repairing,

adjustment, maintenance

7 - 1

Page 15

Operational controls and optical displays

8 - 1

8 Operational controls and optical displays

8.01 On/Off switch

● Turn the machine on and off by turning

the On/Off switch 1 to „1“ for on and

„0“ for off.

8.02 Functions of the pedal

0 = Machine stop

The position of the presser foot and

needle are dependent on the position

of the switches 1 and 3 on the quick

control panel (see chapter 8.05

Functions of the quick control

panel).

+1= Depends on the position of switch 1

on the quick control panel:

Switch 1 up - presser foot down

Switch 1 down - sew

+2= Sew up to the max. speed in 12

steps.

-1 = Depends on the position of switch 1

on the quick control panel:

Switch 1 down - presser foot up.

-2 = End bartack and trim thread in seam

segment 0 (semi-automatic

operation).

8.03 Functions of the knee lever

● By activating the knee lever 1 the

automatic function is engaged.

1

Fig. 8 - 02

Fig. 8 - 03

+2

+1

0

-2

-1

1

Fig. 8 - 01

Page 16

Operational controls and optical displays

8 - 2

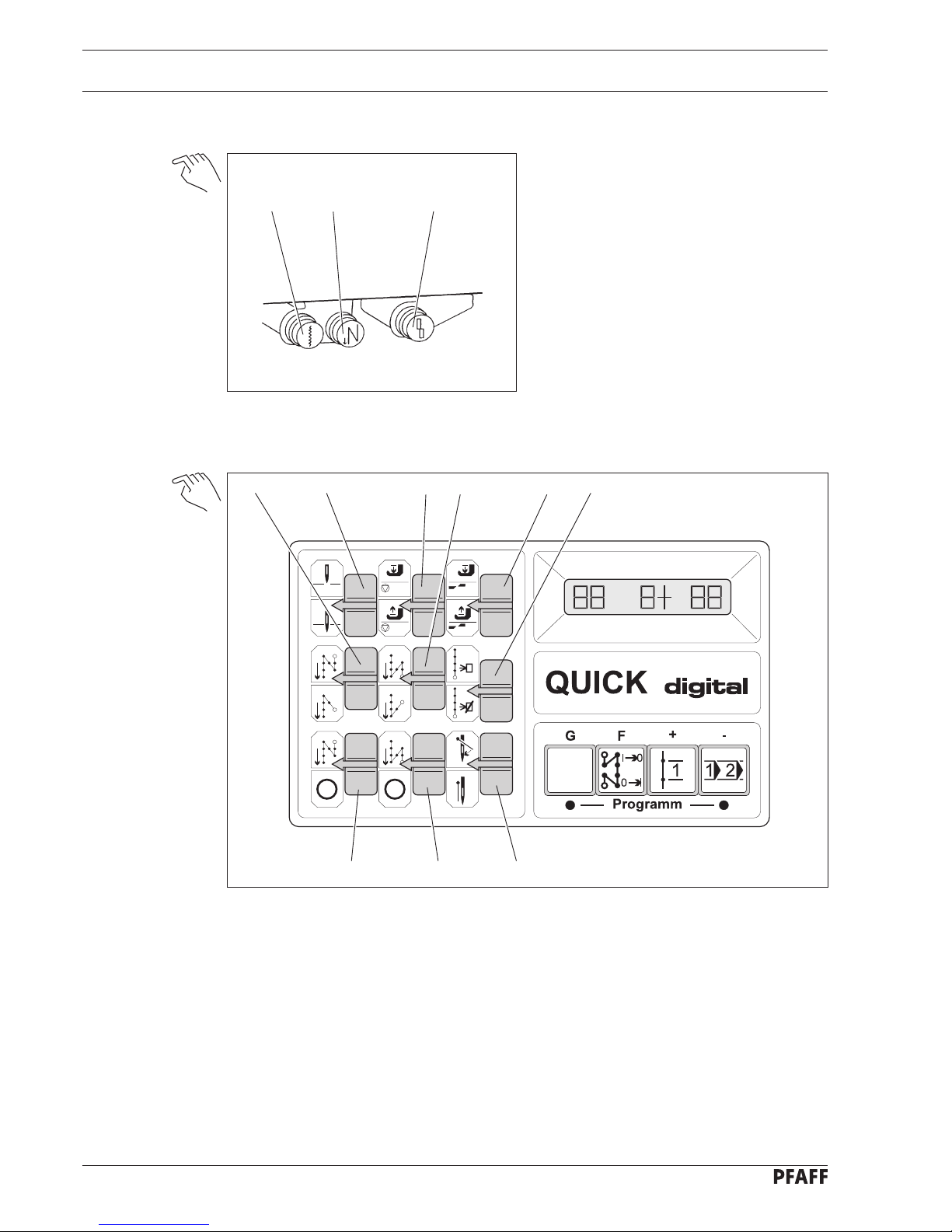

8.04 Functions of the hand buttons

Hand button 1 = Reset; return to semi-

automatic operation.

Hand button 2 = Turn fullness on and

off.

Hand button 3 = Intermediate bartack.

The machine sews

backwards as long as

this button is pressed.

8.05 Functions of the quick control panel

Switch functions

Switch 1 = presser foot up/down with pedal at 0

Switch 2 = presser foot up/down at sewing stop

Switch 3 = needle up/down with pedal at 0

Switch 4 = single/double start bartack

Switch 5 = single/double end bartack

Switch 6 = automatic operation / semi-automatic operation

Switch 7 = start bartack on/off

Switch 8 = end bartack on/off

Switch 9 = thread wiper on/off (no function)

Fig. 8 - 04

2

1

3

Fig. 8 - 05

615234

9

87

Page 17

Operational controls and optical displays

8 - 3

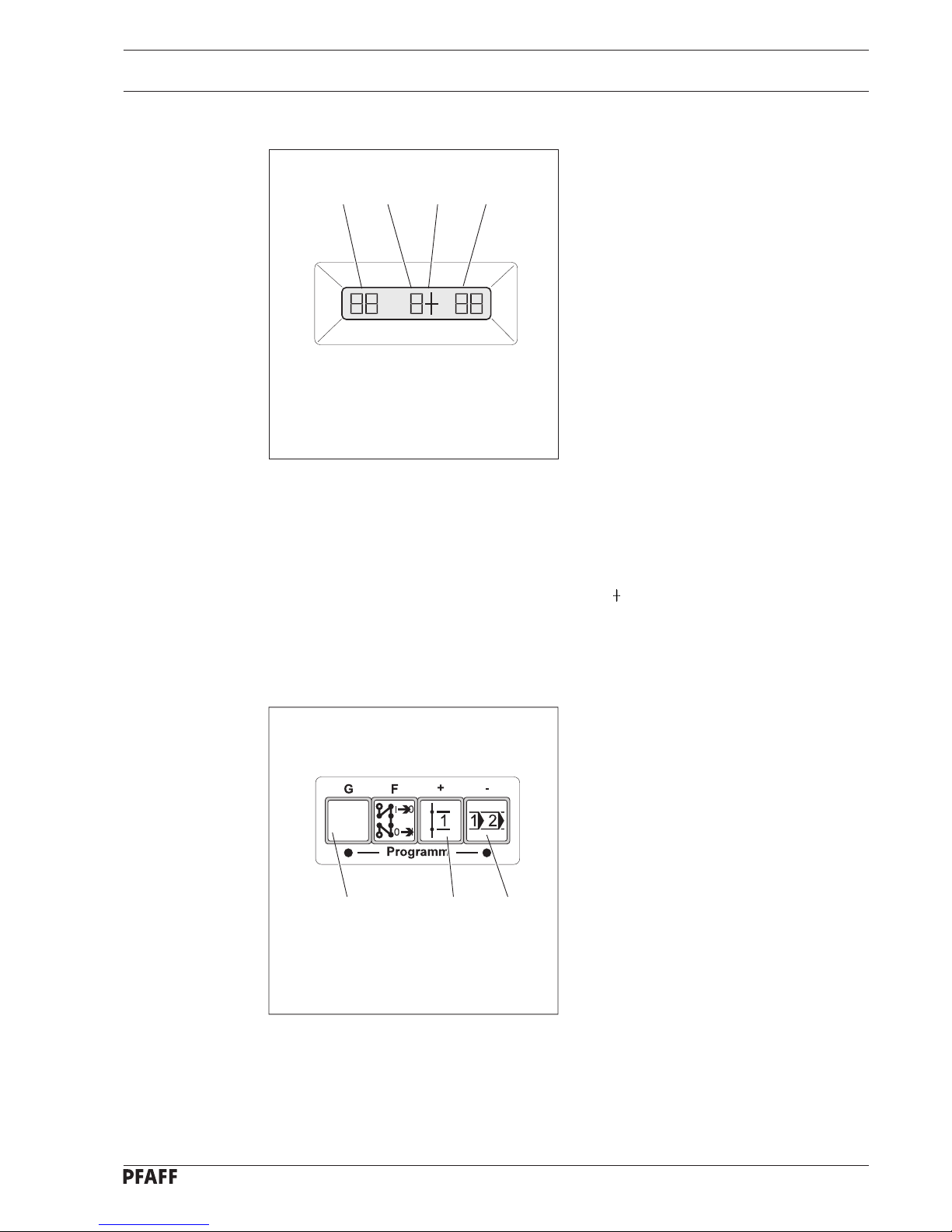

Messages in the display

a = counter value of stitch counter Z1

b = current seam segment:

Seam segment 0 for semi-automatic

operation, seam segments 1- 6 for

automatic operation:

0 = seam segment 0

1 = seam segment 1 of the 1st

shoulder seam

2 = seam segment 2 of the 1st

shoulder seam

seam with fullness

3 = seam segment 3 of the 1st

shoulder seam

4 = seam segment 4 of the 2nd

shoulder seam

5 = seam segment 5 of the 2nd

shoulder seam

seam with fullness

6 = seam segment 6 of the 2nd

shoulder seam

c= for fullness on

d = counter value of stitch counter Z2

Programming buttons on the quick control panel

Button G = positionwise switching to the

stitch counters Z1 and Z2; the

current position blinks in the

display.

Button + = alter selected positions

Button - = alter selected positions

Fig. 8 - 06

G

+

_

ab c

d

Fig. 8 - 07

Page 18

Mounting and initial operation

9 Mounting and initial operation

This machine may only be mounted and put into operation by qualified

specialists! All relevant safety regulations are not to be adhered to!

9.01 Mounting

Connections for electrical and compressed air supplies must be available at the machine’s

location (see chapter 3 Specifications).

A solid, horizontal surface and adequate lighting must also be guaranteed.

9.02 Initial operation

● Check the machine for any possible damage, especially the electrical and pneumatic

leads.

● Clean the machine thoroughly and then oil it (see chapter 13 Maintenance and Care).

● Connect the machine to the power supply.

● Connect the machine to the compressed air supply. The manometer should display an

air pressure level of. 6 bar. Adjust to this value if necessary.

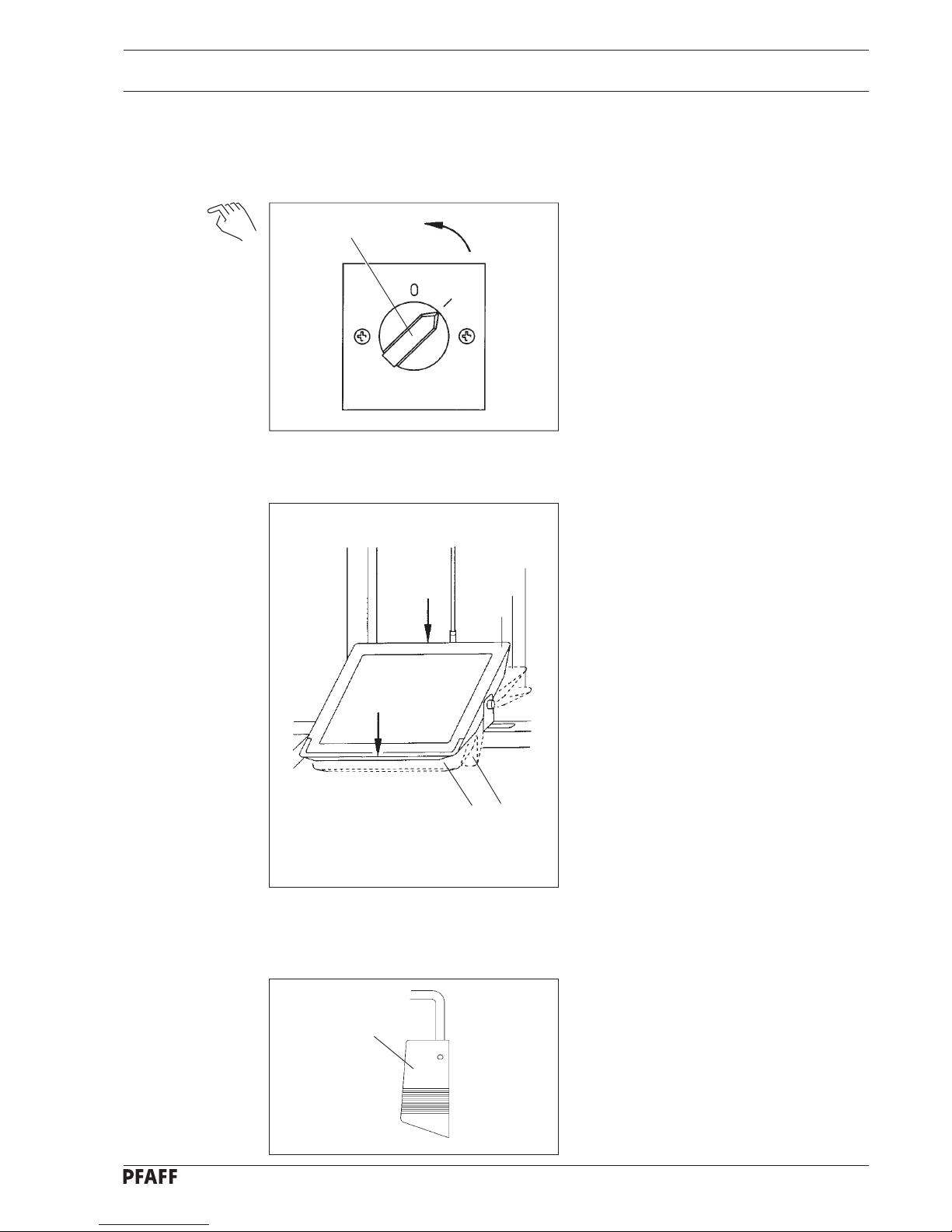

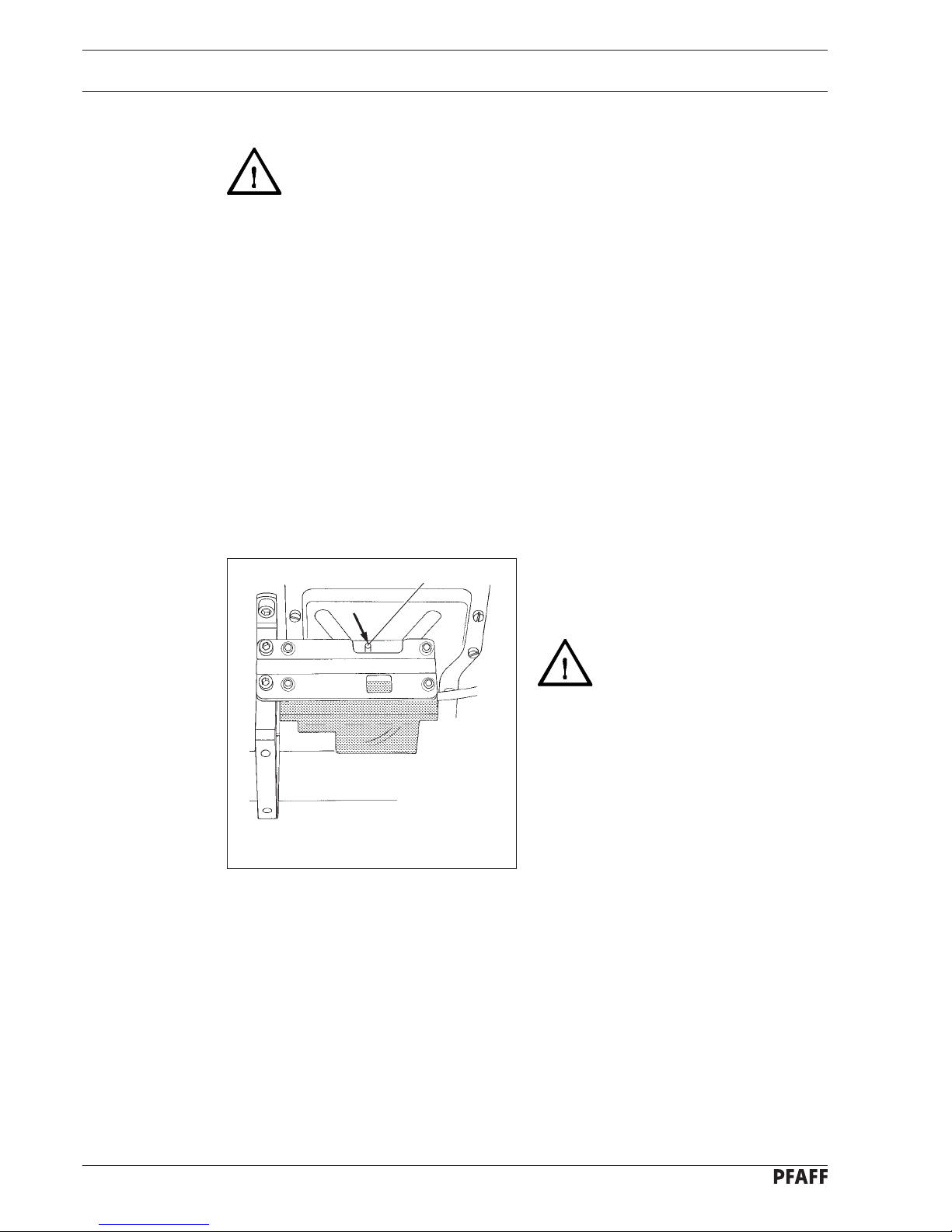

● Before the initial operation remove the

stopper from hole 1.

The stopper serves only to

secure the machine for

transport and must not be used

while sewing!

Abb. 9 - 01

1

9 - 1

Page 19

Switching the machine on/off

10 - 1

10 Switching the machine on/off

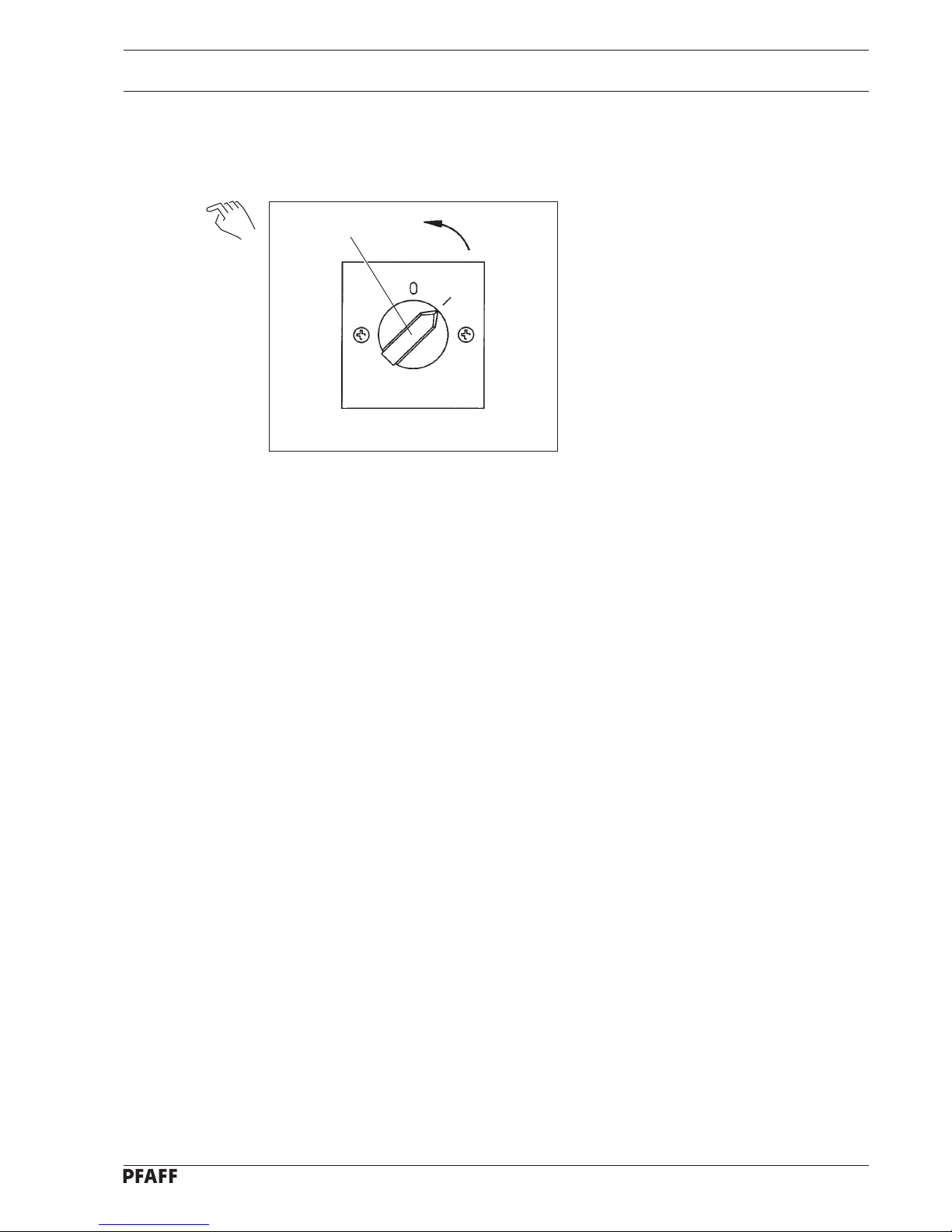

10.01 On/Off switch

● Turn the machine on and off by turning

the on/off switch 1 to „1“ for on and „0“

for off.

Fig. 8 - 01

1

Page 20

Preparation

11 - 1

11 Preparation

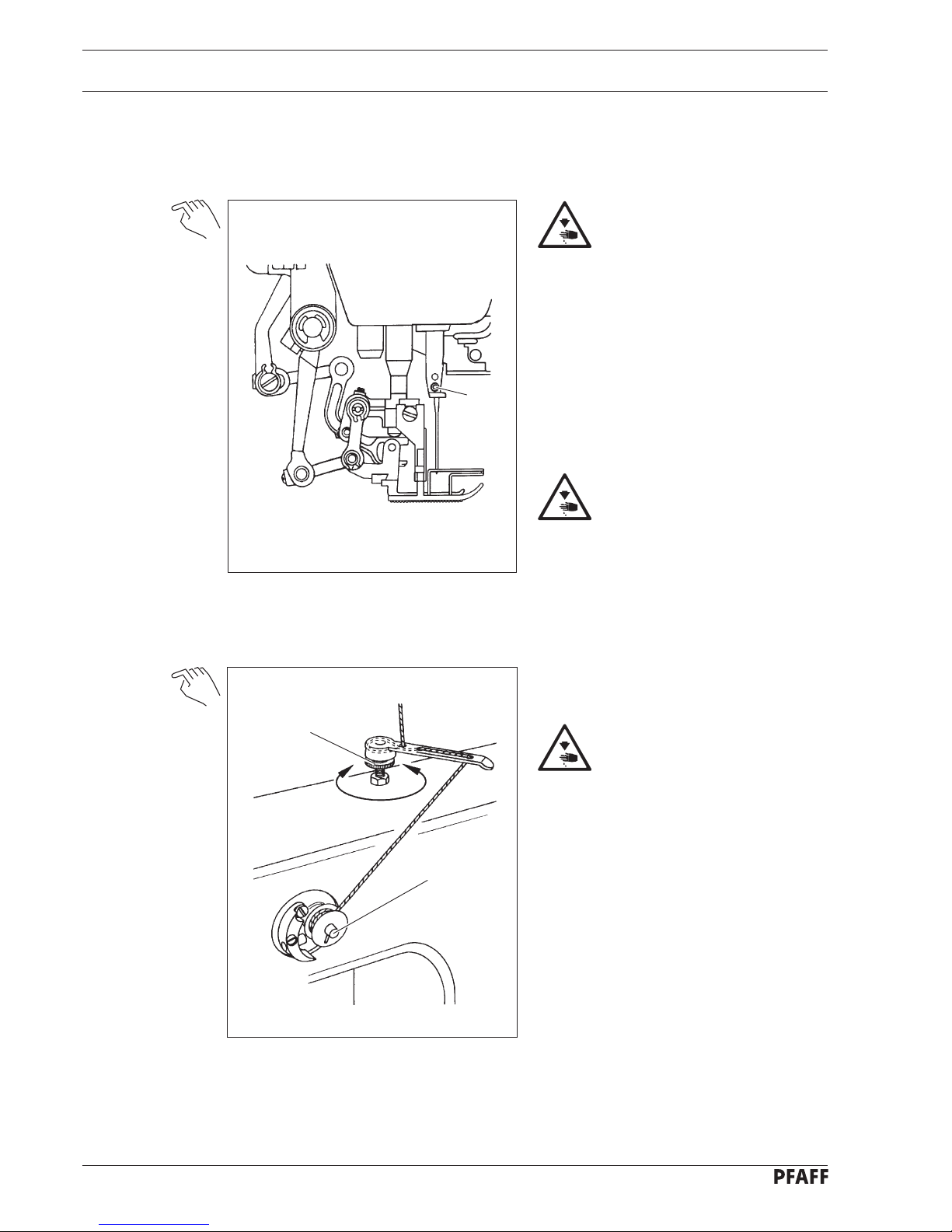

11.01 Inserting the needle

Turn the machine off!

● Bring the needle bar into its highest

position.

● Loosen the needle retaining screw 1.

● Insert the needle 2 as far as possible.

● The long needle-groove must be facing

left when looking in the direction of

sewing.

● Tighten the needle retaining screw 1.

Attention:Needle point and

knife blade! Danger of injury!

11.02 Winding the bobbin thread, adjusting the thread tension

● Set the bobbin winder into gear by

pressing in the bobbin winder spindle 1.

Papidly rotating bobbin!

Danger of Injury!

● Regulate the thread tension by turning

the milled screw 2.

Fig. 11 - 01

1

Fig.11 - 02

+

_

1

2

Page 21

Preparation

11.03 Threading the bobbin case, adjusting the thread tension

Turn the machine off!

● Insert the bobbin into the bobbin case.

● Thread the bobbin case in accordance

with Fig. 11-03.

● Adjust the thread tension by turning

screw 1.

● Use the enclosed tool for this process.

11.04 Inserting the bobbin case

Turn the machine off!

● Remove the bobbin case 1 with the bobbin.

● Change the bobbin (see chapter 11.03 Threading the bobbin case).

● Insert the bobbin case 1 into the bobbin case carrier 2.

11 - 2

Fig. 11 - 03

1

+

5 cm

_

Fig. 11 - 04

1

2

Page 22

Preparation

11 - 3

11.05 Threading the needle thread, adjusting the thread tension

● Thread the needle thread in accordance

with Fig. 11- 05.

● Adjust the needle thread tension by

turning the milled screw 1.

The needle is to be threaded

from left to right!

Do not operate the machine

without the take-up-lever

guard 2! Danger of injury

through the up and down

movement of the take up lever!

11.06 Pre-selecting the stitch length and fullnes

● To adjust the stitch length, move stitch

length controls 1 and 2 together.

● Pre-select fullness with adjustment

lever 3.

Fig. 11 - 05

+

_

6 cm

2

1

Fig. 11 - 06

3

2

1

Page 23

Preparation

11.07 Adjusting the edge stop

● Move the edge stop 1 by turning the milled nut 2.

● To sew without an edge stop 1, swing the lever 3 away.

11 - 4

Fig. 11 - 07

2

3

1

Page 24

Programming and sewing

12 Programming and sewing

With this machine the fullness is applied to the top layer of material. Therefore,

take care to ensure that the workpiece is appropriately inserted.

12.01 Semi-automatic operation

Programming and sewing

To select semi-automatic sewing, switch 6 must be down. During semi-automatic operation

switches 4, 5, 7 and 8 should be up (see Fig. 8 - 05). The positions of switches 1, 2, 3 and 9

can be chosen at your discretion.

Change to programming mode with button G and move to the position of the stitch counter

which have to be altered with button F.

The current position blinks.

Alter the current position with buttons + and -.

Exit from programming mode by pressing button G again.

12 - 1

Fig. 8 - 05

615234

9

87

Page 25

Programming and sewing

Function summary

● Program the stitch counter.

● Insert the workpiece - 1st side seam.

● Sew the start bartack. Trigger the bartack function with the pedal.

● Close the rest of the seam.

● Apply fullness if desired. To do so press the hand button for fullness. The button lights

up. A appears in the display.

● Sew an end bartack at the end of the material. Trigger the bartack function with the

pedal.

● Cut the threads at the end of the seam. Trigger the thread trimming function with the

pedal.

● Start the automatic function by pressing the knee lever with the right knee.

● Insert the workpiece - 1st shoulder seam.

● Close the 1st shoulder seam. The start bartack, fullness and end bartack are completed

automatically one after the other. Seam segments 1 to 3 are shown in the display. When

fullness is being applied a is shown in the display and the fullness button is lit.

● Insert the workpiece - 2nd shoulder seam.

● Close the 2nd shoulder seam. The 2nd shoulder seam is sewn automatically as a mirror

image of the 1st shoulder seam. In the display the seam segments 4 to 6 are shown.

When fullness is being applied a is shown in the display and the fullness button is lit.

After completing seam segments 4 to 6 the seam segment 0 appears in the display.

● Insert the workpiece - 2nd side seam.

● Sew the start bartack.

● Close the seam. Apply fullness if desired.

● Sew the end bartack.

● Trim thread.

12 - 2

Fig. 12 - 01

Activate knee lever

End bartack and

thread trimming

(pedal -2)

1st side seam

with fullness if desired

Start bartack

4

5

6

3

1

2

Seam segments

Seam

segment 0

End bartack and

thread trimming

(pedal -2)

2nd side seam

with fullness if desired

Start bartack

1st and 2nd shoulder seams

Start bartack

Seam with fullness

Automatic

end bartack and

thread trimmer

Seam segments

Page 26

Programming and sewing

12.02 Automatic operation

Function summary

In automatic operation, only shoulder seams can be sewn one after another. See chapter

12.01 Semi-automatic operation for further function summary.

Programming and sewing

To select automatic operation, switch 6 (see Fig. 8 - 05) must be up. For further

programming see chapter 12.01 Semi-automatic operation.

12 - 3

Page 27

Care and maintenance

13 - 1

13 Care and maintenance

Clean the hook and the hook compartment............................................................ daily

Lubricate ........................................................................................................... monthly

Lubricate the top feed joints ............................................................................... weekly

Check the air pressure .......................................................................... daily before use

13.01 Cleaning

Turn the machine off!

● Lay the machine head on its back.

● Clean the hook and the hook compartment daily, more often when in continuous

operation.

● Return the machine head to its upright position with both hands.

Danger of crushing between machine head and table top!

13.02 Lubricating

Turn the machine off!

Only use oil with a mean

viscosity of 10.0 mm2/s at

40°C and a density of 0.847 g/

cm3 at 15°C.

We recommend PFAFF

sewing machine oil.

Part no. 280-1-120 105.

● Lay the machine head on its back.

● Fill the oil reservoir 2 up to the upper

marking 3 through the hole 1.

● Return the machine to its upright position with both hands.

Danger of crushing between machine head and table top!

With the machine working 8 hours a day, the oil reservoir is to be checked once a month

and refilled if necessary.

1

3

2

Fig. 9 - 01

Page 28

Care and maintenance

13 - 2

● The top feed joints are to be given one

drop of oil each, once a week. (see Fig.

13 - 02 - arrows)

13.03 Checking the air pressure

● Check the air pressure at the manometer

before every use of the machine.

● The manometer 1 must show a pressure

of approx. 6 bar.

● Adjust to this value if necessary.

● To do so lift button 2 and turn it until the

manometer shows approx. 6 bar.

When the air pressure is turned off,

condensation drops out of valve 3. Place a

suitable container under the valve!

Fig. 13 - 01

Fig. 13 - 02

3

2

1

Page 29

Adjustment

14 - 1

14 Adjustment

On the PFAFF 487 - 706/.. no c-clamps may be attached to the needle bar as

this would damage the special coating on the needle bar.

All adjustments in these adjustment instructions are based on a completely

installed machine. Covers on the machine which have to be removed and

replaced for checks and adjustment work are not mentioned. The screws and

nuts in brackets are attachments of machine parts which are to be loosened

before making the adjustment and tightened again when the adjustment is

complete.

14.01 Tools, gauges and other accessories

● Screwdrivers with blade width from 2 to 10 mm

● Screwdrivers with blade width from 7 to 14 mm

● Allan keys from 1.5 to 6 mm

● Metal rule, Part No. 08-880 218-00

● Rig pin 5 mm diameter, Part No. 13-030 341-05

● Adjustment gauge, Part No. 61-111 642-19

● Alignment gauge, Part No. 91-069 375-15

● Gauge foot, Part No. 61-111 639-20

● Needles, system 134KK

● Sewing thread and test material

● Hook oil: PFAFF sewing machine oil Part No. 280-1-120 105

mean viscosity of 10.0 mm2/s at 40°C, density 0.847 g/cm3 at 15°C

14.02 Abbreviations

TDC = top dead center

BDC = bottom dead center

Page 30

Adjustment

14 - 2

14.03 Check and adjustment aid

By placing pegs in holes 1 and 3 - 6 the required needle bar positions can be

exactly fixed.

● Turn the handwheel until the needle bar has approximately reached the required position.

● Place the 5 mm rig pin in the appropriate hole and put pressure on it.

● Turn the handwheel forwards and backwards a little until the rig pin moves into the slot

in the crank behind the bearing plate, thus blocking the machine.

Hole 1 = 0.6 mm after the top dead center of the needle bar (0.6 a. TDC)

Hole 3 = 0.6 mm after the bottom dead center of the needle bar (0.6 a. BDC)

Hole 4 = 1.8 mm after the bottom dead center of the needle bar (needle rise)

Hole 5 = Top dead center of the needle bar (TDC)

Hole 6 = 4 mm after the bottom dead center of the needle bar (4 a. BDC)

Fig. 14 - 01

5

1

4

6

3

Page 31

Adjustment

14 - 3

14.04 Pre-adjusting the needle height

Requirement

With the needle bar at its BDC there must be a clearance of approx. 16.5 mm between the

bottom edge of the needle bar and the needle plate.

● Move the needle bar 1 (screws 2) in accordance with the requirement while taking care

to ensure that the needle retaining screw 3 is pointed to the left viewed in the direction

of feed.

3

1

2

5

1

4

6

3

16.5 mm

Fig. 14 - 02

Page 32

Adjustment

14 - 4

14.05 Centering the needle in the needle hole

Requirement

The needle must enter exactly the middle of the needle hole.

● Bring the needle into a position directly over the needle hole.

● Loosen screws 1, 2 and 3.

● Move the needle bar frame 4 into a position according with the requirement in both the

sewing direction and across the sewing direction.

● Tighten screw 3 tightly and screw 2 just a little.

● Using screw 1 pull the guide pin behind screw 1 towards the eye of the needle bar frame

and tighten it.

● Remove the needle.

● Loosen screw 2. Turn the handwheel a few rotations (to avoid any tension that may

exist) and tighten screw 2.

1

4

3

2

Fig. 14 - 03

Page 33

Adjustment

14 - 5

14.06 Zeroing the bottom feed dog

Requirement

With the stitch length set at 0 the bottom feed dog should not move laterally when the

handwheel is turned.

14.06.01 Adjustment with the gearbox housing closed

● Raise the presser foot.

● Turn bush 2 (screw 3) so that the marking 4 is pointing downwards and the edge of the

notched surface is at a 45° angle to the front of the machine.

For the final adjustment see chapter 14.18 Synchronizing the vibrating presser.

● Place a suitable pin or Allan key in hole 5 of the tensioning hoop 6 and hold the shaft 7

still with it.

● Turn the shaft 7 (screw 8) in accordance with the requirement.

56

8

7

45°

Fig. 14 - 04

2

3

4

Page 34

Adjustment

14 - 6

14.06.02 Adjustment with the gearbox housing open

● Raise the presser foot.

● Turn bush 2 (screw 3) so that the marking 4 is pointing downwards and the edge of the

notched surface is at a 45° angle to the front of the machine.

For the final adjustment see chapter 14.18 Synchronizing the vibrating presser.

● Turn the crank 5 (screw 6) in accordance with the requirement.

45°

2

3

6

5

Fig. 14 - 05

4

Page 35

Adjustment

14 - 7

14.07 Driving motion of the bottom feed dog

Requirement

With the largest stitch length set and the needle bar 0.6 mm after the TDC (hole 1) the

bottom feed dog must not move when the crank 3 is turned in the direction of the arrow.

● Turn the feed driving eccentric 1 (screws 2) in accordance with the requirement while

taking care that the notch in the feed driving eccentric is visible.

3

2

1

Fig. 14 - 06

Page 36

Adjustment

14 - 8

14.08 Lifting motion of the bottom feed dog

Requirement

With the stitch length set at 0 and the needle bar at 0.6 mm after the TDC (hole 1) the

bottom feed dog must be at its TDC.

The notch in the feed lifting eccentric 1 must be approx. vertically underneath the middle

of the axle.

● Turn the feed lifting eccentric 1 (screws 2) in accordance with the requirement while

taking care to ensure that there is a little play between the feed lifting eccentric 1 and

the connecting rod behind it.

1

2

Fig. 14 - 07

Page 37

Adjustment

14 - 9

14.09 Height of the bottom feed dog

Requirement

With the stitch length set at „0“ and the needle bar 0.6 mm after its TDC (hole 1) the feed

dog must:

1. be centered in the needle plate cutout, when viewed from the side and from the

direction of feed.

2. be at its upper point of reversal and touching the adjustment gauge along its entire

length.

● Move the feed dog carrier 1 (screw 2) in accordance with requirement 1.

● Allow the presser foot to rest on the gauge.

● Turn eccentric 3 (screw 4) and eccentric 5 (screw 6) in accordance with requirement 2.

Take care that eccentrics 3 and 5 are not turned 180°.

1,16

x

=

x

0,72

Fig. 14 - 08

543

61

2

Page 38

Adjustment

14 - 10

14.10 Clearance between presser foot and needle plate

Requirement

With the presser bar lifter 1 raised there must be a distance of 5 mm between the presser

foot and the needle plate.

● Screw on the gauge foot 13.

● Allow the gauge foot to rest on the needle plate using the presser bar lifter 1.

● Reduce the pressure on the presser bar by loosening the adjusting screw 2 (milled

nut 3).

● Loosen screw 4 and press pin 5 out.

● Swing the connecting joint 6 out of the fork of lever 7.

● Bring the vibrating presser to its highest point by turning the handwheel and raise the

gauge foot.

7

4

5

9

10

6

7

13

8

6

2

3

12

11

1

10

7

Fig.14 - 09

Page 39

Adjustment

14 - 11

● Raise the presser bar 8 and place the 5 mm adjustment gauge underneath the gauge

foot.

● Loosen screw 9 and press the pin out 10.

● Loosen screw 11.

● Position the gauge foot so that its edge is parallel to the needle plate cutout.

● Lower the lifting piece 12 until it comes to rest and tighten screw 11.

Do not mount pins 5 and 10.

Leave screws 4 and 9 loosened for the following adjustment.

Page 40

Adjustment

14 - 12

14.11 Adjusting the floating foot

Requirement

1. With the gauge foot 1 resting on the needle plate, screw 2 must be resting on the stop.

2. With the floating foot 4 resting on the needle plate 5 and the bottom feed dog

underneath the top edge of the needle plate there must be a distance of 0.5 mm

between stop 6 and guide 7.

● Remove the floating foot 4 and replace it with the gauge foot 1.

● Bring the gauge foot 1 to a resting position on the needle plate 5 using the presser bar

lifter 3.

● Adjust screw 2 in accordance with requirement 1.

● Remove the gauge foot 1 and replace it with the floating foot 4.

● Bring the floating foot 4 to a resting position on the needle plate 5 using the presser bar

lifter 3.

● Adjust screw 2 in accordance with requirement 2.

Take care to ensure that the presser foot pressure is stronger than the

pressure of the floating foot spring.

1

0.5 mm

7

6

5

4

3

2

Fig. 14 - 10

Page 41

Adjustment

14 - 13

14.12 Top feed driving and connecting levers

Requirement

All moving parts of the top feed system must move freely and without play.

● Lower the sewing foot using the presser bar lifter 1.

● Loosen screw 2.

● Swing the connecting joint 3 into the fork of lever 4 and insert pin 5. Ensure that the

parts move freely. If necessary adjust lever 4.

● Tighten screw 11.

● Set the stitch length at „0“.

● Center the vibrating presser foot in the presser foot cutout in the direction of sewing and

tighten screw 2.

● Loosen screw 6.

● Align the hole in lever 7 with the hole in lever 8. If necessary move or adjust lever 7.

● Insert pin 9, with its largest eccentricity facing downwards, into the holes of levers 7 and

8 and tighten screw 10.

● Press lever 7 as far as it will go in the direction of feed and tighten screws 6 and 11.

● Adjust the vibrating presser foot laterally so that it is not touching the presser foot

(screw 12).

12

11

6

7

1

8

10

4

2

954 3

Fig. 14 - 11

Page 42

Adjustment

14 - 14

14.13 Zeroing the top feed motion

Requirement

With the stitch length and the top feed set at 0 and with the alignment gauge 8 attached

there should be no movement of the feed driving lever 18 when the handwheel is turned.

7

6

5

12

14

15

17

16

8

13294

18

Fig. 14 - 12

Page 43

Adjustment

14 - 15

● Raise the presser foot.

● Loosen screws 1 and 2.

● Place crank 3 parallel to crank 4 and tighten screw 2.

● Set the stitch length controls 5, 6 and 7 at 0.

● Place the alignment gauge 8 onto the pins 9.

● Turn the handwheel and turn crank 11 (screw 10) so that the vibrating presser foot does

not move.

● Loosen nut 12.

● Move the pull rod 14 up and down several times while moving lever 15 (screw 13) so

that the vibrating presser foot does not move.

● Bring the pull rod 14 to a position where it touches the top of the elongated hole and

tighten nut 12.

● Set the stitch length controls 5,6 and 7 at 3.

● Set crank 16 lengthwise and crosswise against crank 17 and tighten screw 1.

● Remove the alignment gauge 8.

11 10

13

Fig. 14 - 13

Page 44

Adjustment

14 - 16

14.14 Feeding motion of the vibrating presser

Requirement

With the machine set at its longest stitch length and the needle bar positioned 0.6 mm

past its TDC (hole 1) the vibrating presser 3 must not move when crank 4 is moved up and

down.

● Raise the presser foot.

● Turn the feed driving eccentric 1 (screws 2) in accordance with the requirement. Ensure

that the notch (see arrow) is visible.

2

1

4

3

Fig. 14 - 14

Page 45

Adjustment

14 - 17

14.15 Vibrating presser lift

Requirement

With the stitch length set at 0, the presser foot resting on the needle plate and the

vibrating presser at its TDC, there must be the following clearance between the needle

plate and the vibrating presser foot:

● 1.3 mm with the vibrating presser operating behind the needle.

● 2.0 mm with the vibrating presser operating in front of the needle.

● Increase the pressure on screw 1 (nut 2) a little.

● Lower the presser foot until it rests on the needle plate.

● Move the eccentricity of pin 3 (screw 4) towards the needle bar (see arrow).

● Turn the eccentricity of pin 5 (screw 6) downwards.

● Turn the handwheel until the connecting lever 7 is at its rear point of reversal.

● Press the connecting lever 7 (screw 8) to the rear and place the corresponding feeler

gauge (see requirement) between the vibrating presser foot and the needle plate.

● If necessary, re-adjust eccentric pin 5 (screw 6) by turning it accordingly.

8

7

5

6

4

3

1

2

3

4

1.3 mm bzw.

2.0 mm

Fig. 14 - 15

Page 46

Adjustment

14 - 18

14.16 Vibrating presser lifting motion

Requirement

With the stitch length set at 2 and the ascending feed dog at the top edge of the needle

plate, the vibrating presser must be touching the feed dog (see arrow).

● Turn eccentric pin 1 (screw 2) in accordance with the requirement.

2

1

Fig. 14 - 16

Page 47

Adjustment

14 - 19

14.17 Position of the vibrating presser

Requirement

With the bottom feed dog at its top point of reversal the vibrating presser must be parallel

to the bottom feed dog.

● Turn eccentric pin 1 (screw 2) in accordance with the requirement.

2

1

Fig. 14 - 17

Page 48

Adjustment

14 - 20

14.18 Synchronizing the vibrating presser

Requirement

With the stitch-length and vibrating-presser-stroke adjustment levers all at 3 the vibrating

presser and the bottom feed dog must work with the same feed motion when the

handwheel is turned.

● Press the adjustment levers downwards.

● Loosen nut 1.

● Set the adjustment levers 3 at „3“.

● Move the pull rod 2 in the elongated hole in accordance with the requirement and

tighten nut 1.

2

1

3

Fig. 14 - 18

Page 49

Adjustment

14 - 21

14.19 Matching forward and reverse stitch lengths

Requirement

With the stitch length set at „3“ the forward feed must match the reverse feed.

● Turn bush 1 (screw 2) in accordance with the requirement.

Make sure that the eccentricity of the bush 1 is facing downwards.

1

2

Fig. 14 - 19

Page 50

Adjustment

14 - 22

14.20 Eccentric hook shaft bearing

Requirement

1. The notch in bearing 3 (see arrow) must be visible from below.

There must be a slight but still noticeable play between gears 5 and 7.

2. With the hook lightly touching the spin disc 4 and the hook point opposite the center

line of the needle, there must be a clearance of less than 0.1 mm between the hook

point and the clearance cut of the needle.

3. Gear 5 must be flush with gear 7.

● Loosen screw 1 and both screws 2.

● Turn bearing 3 in accordance with requirement 1.

● Set the hook lightly against spin disc 4 and shift bearing 3, without turning it, in

accordance with requirement 2. Tighten screws 1 and 2.

● Position gear 5 (screws 6) in accordance with requirement 3.

5

6

7

3

142

max. 0.1 mm

Fig. 14 - 20

Page 51

Adjustment

14 - 23

14.21 Needle rise, final adjustment of the needle bar height and bobbin case

positioning finger

Requirement

With the needle bar at a position 1.8 mm past its BDC (hole 4):

1. the hook point must be opposite the center line of the needle, and the top edge of the

needle eye must be 0.8 mm below the bottom edge of the sewing hook.

2. There must be a clearance of 0.5 mm between the lug of the positioning finger 3 and

the inside edge of the positioning slot.

● Adjust the hook (screws 1) - without shifting it - and the needle bar (screws 2) - without

twisting it - in accordance with requirement 1.

● Set the lug of positioning finger 3 into the slot in the bobbin case carrier and adjust and

secure it in accordance with requirement 2.

2

1

3

0.5 mm

Fig. 14 - 21

0.8 mm

Page 52

Adjustment

14 - 24

14.22 Height of the bobbin case opener

Requirement

At the left point of reversal of the bobbin case opener 3 the top edge of the bobbin case

opener finger must be 0.5 mm above the bottom edge of the bobbin case cam 4.

● Turn the bobbin case base 1 (screw 2) in accordance with the requirement.

1

2

3

4

0.5 mm

Fig. 14 - 22

Page 53

Adjustment

14 - 25

14.23 Position of bobbin case opener

Requirement

With the bobbin case opener 3 at its left point of reversal:

1. the front edge of the bobbin case opener finger must be approx. 0.6 mm behind the

front edge of the bobbin case cam 7.

2. The bobbin case carrier 6 must be approx. 0.3 mm from the positioning finger 8 and

screw 1 must be touching stop pin 5.

● Loosen screw 1 and then loosen screw 2 so that the bobbin case opener 3 is still just

held in position.

● Adjust the bobbin case opener 3 in accordance with requirement 1.

● Turn the bobbin case opener 3 in accordance with requirement 2 and tighten screw 2.

● Set fixing collar 4 against the bobbin case opener 3 and stop pin 5 and tighten screw 1.

3

2

4

1

5

2

3

7

0.6 mm

0.3 mm

3

6

8

Fig. 14 - 23

Page 54

Adjustment

14 - 26

14.24 Motion of bobbin case opener

Requirement

With the needle bar 1.8 mm past its BDC (hole 4) the bobbin case opener 3 must be at its

right point of reversal.

● Adjust the bobbin case opener eccentric 1 (screws 2) in accordance with the

requirement.

231

Fig. 14 - 24

Page 55

Adjustment

14 - 27

14.25 Needle thread tension release

Requirement

With the presser bar lifter 3 raised the tension discs must be at least 0.5 mm apart.

● Adjust the tension release lever 1 (screw 2) in accordance with the requirement.

● Lower the presser foot onto the needle plate. Now the tension must be fully active.

3

1

2

0.5 mm

Fig. 14 - 25

Page 56

Adjustment

14 - 28

14.26 Thread check spring and thread regulator

Requirement

1. The thread check spring 3 must have finished its stroke by the time the point of the

needle enters the material (stroke approx. 7 mm).

2. The thread regulator 4 must be fixed into the elongated hole so that the thread check

spring 3 moves 1 mm by the time the hook has widened the thread loop to its

maximum.

● Turn the thread tension 1 (screws 2) in accordance with requirement 1.

● Move the thread regulator 4 (screws 5) in accordance with requirement 2.

The stroke of the thread check spring 3 and the position of the thread regulator

4 are dependent on the type of thread and material used and should be

adjusted in accordance with the appearance of the seam.

7 mm

5

2

3

4

1

Fig. 14 - 26

Page 57

Adjustment

14 - 29

14.27 Bobbin winder

Requirement

With the bobbin winder engaged the winder spindle must be driven reliably. With the

bobbin winder disengaged, however, the friction wheel 5 must not touch the drive wheel 1.

The bobbin winder must wind evenly and stop automatically when the thread wound on

the bobbin has reached a point approx. 1 mm below the bobbin rim.

● Switch on the bobbin winder and adjust the drive wheel 1 (screw 2) in accordance with

the requirement.

● Place a bobbin on the winder spindle, thread the machine for bobbin winding and

switch on the bobbin winder.

● To adjust the amount of thread to be wound shift the regulating pin 3 (screw 4) in

accordance with the requirement.

1 mm

512

4

3

Fig. 14 - 27

Page 58

Adjustment

14 - 30

14.28 Position of vibrating presser in relation to presser foot

Requirement

With the presser foot raised by way of the lifting lever and the take up lever is at its top

point of reversal, the teeth of the vibrating presser 3 must not be below the presser foot

shoe 4.

● Turn the eccentric bush 1 (screw 2) in accordance with the requirement.

2

1

34

Fig. 14 - 28

Page 59

Adjustment

14 - 31

14.29 Pressure on vibrating presser and presser foot

Requirement

The proper feeding of the material must be ensured even at top sewing speed. There must

not be any pressure marks on the material.

● Pressure on vibrating pressure - Set regulating screw 1 flush with the top surface of the

machine housing.

● Pressure on presser foot - Turn regulating screw 2 (milled nut 3) until there is a clearance

of approx. 12 mm between the screw shoulder and the machine housing.

If necessary, the pressure on the vibrating presser and the presser foot can be

increased (+) or decreased (-).

+

+

_

1

2

3

_

12 mm

Fig. 14 - 29

Page 60

Adjustment

14 - 32

14.30 Limiting the stitch length

● Loosen screw 1 (accessible through the assembly hole) or screw it out according to the

limit to be set.

● Set the stitch length control lever 2 at the desired maximum stitch length.

● Set the limiting angle 3 from above so that it touches the control lever 2 and secure it (in

the desired position) by tightening screw 1 in either the lower or upper hole.

3

1

2

Fig. 14 - 30

Page 61

Adjustment

14 - 33

14.31 Lateral position of thread catcher

Requirement

The tip of the thread catcher 3 must be pointing at the center line of the needle; if required

however, it can be up to 0.3 mm to the left of this center line.

The thread catcher 3 must move without striking the bobbin case positioning finger 5.

● Disconnect linkage rod 1.

● Set the end of the cylinder plunger 2 flush with the face of nut 3 (nut 4).

● Bring the needle bar to its BDC and position the tip of the catcher 7 in front of the needle

by pushing the pull rod 6 upwards.

● Position the catcher 7 (screws 5) in accordance with the requirement making sure that

the catcher 7 is horizontal.

1

7 65

2

3

4

7

8

Fig. 14 - 31

Page 62

Adjustment

14 - 34

14.32 Point of reversal of thread catcher

Requirement

With the compressed air switched off and the cylinder plunger fully extended by hand

(front point of reversal of the catcher 4) the rear edge of the thread catcher cutout must be

1 to 1.4 mm beyond the front edge of the bobbin case positioning finger.

● Bring the needle bar to its TDC and re-connect the linkage rod 1.

● Bring the ball stud (nut 2) to the middle of the elongated hole.

● Extend the cylinder plunger fully by hand.

● Turn the linkage rod 1 (nuts 3, left and right hand thread!) in accordance with the

requirement.

1

3

2

4

1 - 1.4 mm

Fig. 14 - 32

Page 63

Adjustment

14 - 35

14.33 Knife

Requirement

There must be a clearance of approx. 4 mm between the needle and the cutting edge of

the knife 3.

● Disconnect the linkage rod 1 and bring the needle bar to its BDC.

● Position the catcher 5 directly in front of the needle and move the knife 3 (screw 2) in

accordance with the requirement.

Make sure that the right hand edges of the knife 3 and the catcher 5 are flush (see

arrow).

● Bring the needle bar to its TDC and push the catcher 5 fully forward.

● Place two threads in the cutout of the catcher 5 and carry out a cutting test.

● To correct: position the catcher 5 (screws 4) parallel to the cutting edge while making

sure to observe the requirement described in chapter 14.31 Lateral position of the

thread catcher!

● Place the stop 6 on the right hand bottom edge of the thread catcher 5 and tighten

screws 7.

● Re-connect the linkage rod 1.

2

3

5

4 mm

3

Fig. 14 - 33

4 7

6

1

Page 64

Adjustment

14 - 36

14.34 Needle thread tension release

Requirement

With the thread catcher at its rear point of reversal, finger 3 must be engaged and there

must be a clearance of 0.5 mm between the finger and the control cam 4.

With the tip of the finger 3 at the highest point of cam 4 the tension discs must be at least

0.5 mm apart.

● Fully retract the cylinder plunger 5 by hand.

● By turning screw 7 (nut 6) create a clearance of 0.5 mm between the finger 3 and the

control cam 4.

● Lower the presser foot onto the needle plate using the presser bar lifter.

● Pull the pull rod 2 (screw 1) downwards as far as it will go and secure it into place.

0.5 mm

2

1

0.5 mm

3

7

4

6

5

3

4

Fig. 14 - 34

Page 65

Adjustment

14 - 37

14.35 Synchronizer

Requirement

When stopping sewing, the machine must position itself at approx. 4 mm after the BDC of

the needle bar.

After trimming the thread the machine must position itself in the TDC of the take-up lever.

When pressing the pedal backwards the plunger of the cylinder must extend when the

needle bar is 20 - 22 mm after its BDC.

● For the adjustment see the instruction manual of the motor manufacturer.

Page 66

G.M. PFAFF KAISERSLAUTERN

INDUSTRIEMASCHINEN AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Telefon: (0631) 200-0

Telefax: (0631) 17202

E-Mail: info@pfaff-industrial.com

Gedruckt in der BRD

Printed in Germany

Imprimé en R.F.A.

Impreso en la R.F.A.

Loading...

Loading...