Page 1

3586-2/02

Instruction Manual

This instruction manual applies to machines from the

following serial numbers onwards:

# 2721352

296-12-18 937/002

Betriebsanleitung engl. 01.06

Page 2

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or in

part, is only permitted with our previous permission and with written reference to the

source.

PFAFF Industrie Maschinen AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Page 3

Table of contents

Contents ..........................................................................................Chapter

Register 01

Safety........................................................................................................................... 1

Register 02

Proper use.................................................................................................................... 2

Specifications ............................................................................................................... 3

Disposal of the machine............................................................................................... 4

Transport, packaging and storage ................................................................................ 5

Explanation of the symbols .......................................................................................... 6

Register 03

Controls ....................................................................................................................... 7

Register 04

Mounting and commissioning the machine ................................................................. 8

Register 05

Preparation ................................................................................................................... 9

Register 06

Sewing ....................................................................................................................... 10

Input mode functions ................................................................................................. 11

Register 07

Care and maintenance ............................................................................................... 12

Adjustment ................................................................................................................ 13

Register 08

Controller ................................................................................................................... 14

Circuit diagrams ......................................................................................................... 15

Register 09

Parts list .........................................................................................................................

Register 10

Miscellaneous ................................................................................................................

Page 4

Page 5

Register 01

Contents ...............................................................................Chapter - Page

1 Safety ...................................................................................................... 1- 1

1.01 Directives ...................................................................................................................1- 1

1.02 General notes on safety ............................................................................................. 1 -1

1.03 Safety symbols .......................................................................................................... 1 - 2

1.04 Important points for the user ..................................................................................... 1 - 2

1.05 Operating and specialist personnel ............................................................................ 1 - 3

1.05.01 Operating personnel................................................................................................... 1 - 3

1.05.02 Specialist personnel ................................................................................................... 1 - 3

1.06 Danger .......................................................................................................................1 - 4

Page 6

Safety

1 Safety

1

1.02 General notes on safety

.01 Directives

This machine was built in accordance with the European regulations stated in the Conformity

and Manufacturer’s Declaration.

In addition to this Instruction Manual, also observe all generally accepted, statutory and other

regulations and legal requirements - also those of the country in which the machine will be

operated - and all valid environmental protection regulations!

Applicable local regulations of the social insurance society for occupational accidents or other

supervisory organizations are to be strictly adhered to!

● This machine must only be operated by adequately trained operators and only after

having completely read and understood the Instruction Manual!

● All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read

before operating the machine!

● The danger and safety notices fixed on the machine must be observed and must remain

attached.

● Do not remove attached safety devices or set them out of action

● This machine must only be used for the purpose for which it is intended and must not be

operated without its safety devices. All applicable safety regulations must be observed.

● When replacing sewing tools (such as e.g. needles, sewing foot etc.), when threading the

machine, leaving the workplace and during maintenance work, the machine must be

disconnected by operating the on/off switch, or by removing the mains plug!

● Daily maintenance work must only be carried out by appropriately trained personnel!

● For maintenance and repair work on pneumatic equipment, the machine must be

disconnected from the pneumatic supply system! Exceptions are adjustment work and

function tests which are carried out by appropriately trained staff.

● Repair work and special maintenance work must only be carried out by specialists or

appropriately trained personnel!

● Work on electrical equipment must only be carried out by appropriately trained specialist

personnel!

1 - 1

● Work is not permitted on parts and equipment which are connected to the power supply!

Exceptions to this are contained in the regulations EN 50110.

● Modifications and alterations to the machine must only be carried out pursuant to all

relevant safety regulations!

● Only spare parts which have been approved by us are to be used for repairs! We

expressly point out that any replacement parts or accessories not supplied by us have not

been tested and approved by us. The installation and/or use of any such products may

result in negative changes to the constructional characteristics of the machine. We are

not liable for any damage which may be caused by non-original parts.

Page 7

1.03 Safety symbols

Danger!

Points to be observed!

Danger of injury to operating and specialist personnel!

Safety

Caution

Do not operate without finger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

I

1.04 Important points for the user

● This Instruction Manual is a component part of the machine and must be available to the

operating personnel at all times.

The Instruction Manual must be read before operating the machine for the first time.

● The operating and specialist personnel is to be instructed on the safety equipment of the

machine and regarding safe work methods.

● It is the duty of the user to only operate the machine in perfect running order.

● It is the obligation of the user to ensure that none of the safety mechanisms are removed

or deactivated.

● It is the obligation of the user to ensure that only authorized persons operate and work on

the machine.

Further information can be obtained at the point of sale.

1 - 2

Page 8

Safety

1.05 Operating and specialist personnel

1

.05.01 Operating personnel

Operating personnel are persons responsible for the preparation, operating and cleaning of

the machine as well as taking care of problems arising in the sewing area.

The operating personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● never use any working methods which could reduce the level of safety in using the

machine!

● not wear loosely fitting clothing or jewelery such as chains or rings!

● also ensure that only authorized persons have access to the potentially dangerous area

around the machine!

● always immediately report to the user any changes in the machine which may reduce

its level of safety!

1.05.02 Specialist personnel

Specialist personnel are persons who have completed expert education/training in the fields

of electrics, electronics and mechanics. They are responsible for the lubrication,

maintenance, repair and adjustment of the machine.

The specialist personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● switch off the On/Off switch before carrying out adjustments or repairs and ensure that it

cannot be switched on again unintentionally!

● never work on parts and devices which are still connected to the power supply! The only

exceptions to this directive are found in the regulations EN 50110.

● replace the protective coverings and close the electrical control box after all repairs or

maintenance work!

1 - 3

Page 9

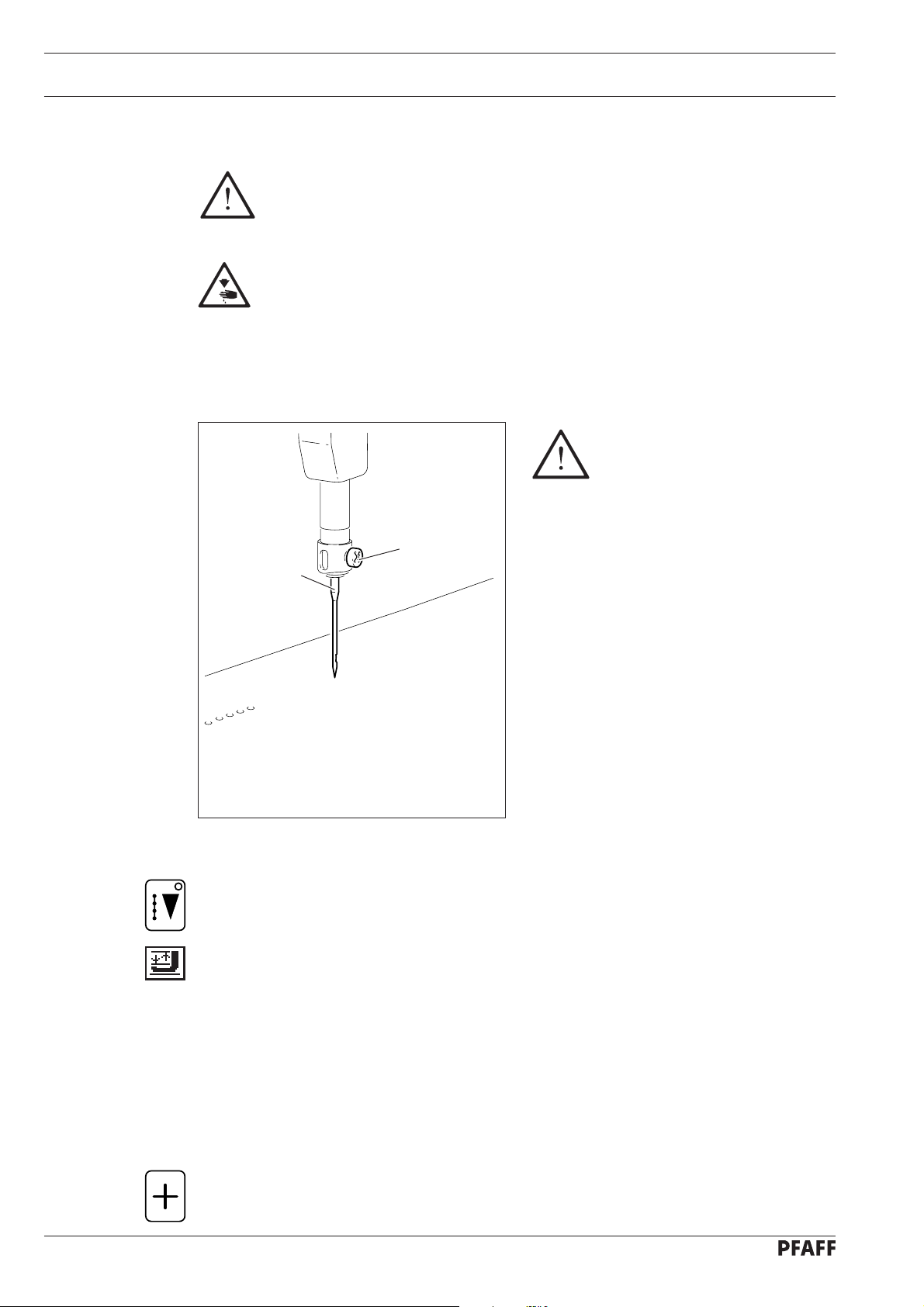

1.06 Danger

75-001

Safety

A working area of 1 meter is to be kept free both in front of and behind the

machine while it is in operation, so that it is always easily accessible.

Never reach into the sewing area while sewing!

Danger of injury by the needle!

Never leave objects on the table while adjusting the machine settings! Objects

can become trapped or be slung away!

Danger of injury by hurled objects!

1

Fig. 1 - 01

3

2

Do not operate the machine without its take-up lever guard 1!

Danger of injury due to the motion of the take-up lever!

Do not place fingers under the pressure bar 2!

Danger of crushing by the descending pressure bar 2!

Do not operate the machine without machine cover 3!

Danger of injury from moving parts!

1 - 4

Page 10

Safety

1 - 5

Page 11

Register 02

Contents ............................................................................... Chapter - Page

2 Proper use ................................................................................................ 2- 1

3 Specifications ........................................................................................... 3- 1

4 Disposal of the machine ............................................................................. 4- 1

5 Transport, packaging and storage ................................................................ 5- 1

5.01 Transport to the customer’s premises ....................................................................... 5 - 1

5.02 Transport within the customer’s premises ................................................................. 5 - 1

5.03 Disposal of the packaging .......................................................................................... 5 - 1

5.04 Storage ......................................................................................................................5- 1

6 Explanation of the symbols ......................................................................... 6- 1

Page 12

Proper use

2 Proper use

The PFAFF 3586-2/02

without basting stitch.

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine! The

appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

is a mechanised sewing unit for sewing darts and pleats with or

2 - 1

Page 13

Specifications

3 Specifications

Stitch type: .................................................................................................................... 301

Max. sewing speed: .......................................................................................... 4500 s.p.m.

Stitch length: ................................................................................................... 1.0 - 3.0 mm

Basting stitch length ....................................................................................... 6.0 - 9.0 mm

(This value is calculated automatically and cannot be set)

Needle system: ........................................................................................................ 134 KK

Needle size (Nm) in 1/100 mm: ...............................................................................80 - 100

Dart length: ....................................................................................................... 9 - 250 mm

Dart depth:

Up to a dart length of 80 mm ................................................................................... 30 mm

From a dart length over 80 mm................................................................................ 37 mm

Pleat length: ...................................................................................................... 9 - 250 mm

Pleat depth: ......................................................................................................... 3 - 70 mm

Working height: ........................................................................................... 760 - 1140 mm

▲

Motor speed: ........................................................................................... 200 - 4500 r.p.m.

Power requirement: .................................................................................. approx. 1200 VA

Connection voltage: .................................................................................. 230 V, 50 -60 Hz

Min. working pressure: ............................................................................................... 6 bar

Noise data:

Emission sound level at the workplace at a speed of 4500 spm: ......................... 81 dB(A)

(Noise measurement in acc. with DIN 45 635-48-A-1, ISO 11204, ISO 3744, ISO 4871)

Machine dimensions:

Length: ................................................................................................................. 1250 mm

Width: .................................................................................................................... 850 mm

Height (without reel stand): ....................................................................... 1040 - 1420 mm

Weight: ..................................................................................................................... 135 kg

▲

Subject to alteration

■

KpA = 2,5 dB

■

3 - 1

Page 14

Disposal of machine

4 Disposal of machine

● The proper disposal of the machine is the responsibility of the customer.

● The materials used in the machines are steel, aluminium, brass and various plastics.

The electrical equipment consists of plastics and copper.

● The machine is to be disposed of in accordance with the locally valid environmental

protection regulations. If necessary, a specialist is to be commissioned.

Special care is to be taken that parts soiled with lubricants are separately

disposed of in accordance with the locally valid pollution control regulations!

4 - 1

Page 15

Transportation, packing and storage

5 Transportation, packing and storage

.01 Transportation to customer's premises

5

All machines are delivered completely packed.

5.02 Transportation inside the customer's premises

The manufacturer cannot be made liable for transportation inside the customer's premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fibre. Proper dis-

posal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but it

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a film of oil.

5 - 1

Page 16

Explanation of the symbols

6 Explanation of the symbols

In this Instruction Manual, tasks to be carried out and important information are drawn to

your attention by symbols. The symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Servicing, repairing, adjustment, maintenance

(only to be carried out by specialist personnel)

6 - 1

Page 17

Register 03

Contents ...............................................................................Chapter - Page

7 Control elements ...................................................................................................... 7 - 1

7.01 On/off switch ............................................................................................................. 7 - 1

7.02 Disk drive ...................................................................................................................7- 1

7.03 Graphics control panel................................................................................................ 7 - 2

7.03.01 Display ....................................................................................................................... 7 - 2

7.03.02 Operational mode keys .............................................................................................. 7 - 3

7.03.03 Function keys .............................................................................................................7- 3

7.03.04 Number keys.............................................................................................................. 7- 3

7.04 Bundle clamp switch (optional)................................................................................... 7 - 4

Page 18

Control elements

7 Control elements

7.01 On/off switch

● By turning switch 1 the machine’s power

supply is switched on or off.

1

Fig. 7 - 01

7.02 Disk drive

-002

● Disk drive 1 can be used to read in

sewing programs and operating

software.

1

7 - 1

Fig. 7 - 02

50-003

Page 19

7.03 Graphics control panel

The graphics control panel 1 consists of the display screen and 2 key zones.

Control elements

1

Esc

Clear

Fig. 7 - 03

7.03.01 Display

In its basic condition the displays on the screen are divided into 3 part sections:

Status bar

The status bar is in the upper section of the display. Here, up to 5 pictograms with their

corresponding values can be displayed (see Chapter 10.01 Status bar).

Text field

The text field is in the middle section of the screen. Here, messages can be displayed in 2

lines.

Pictogram bar

The pictogram bar is found at the bottom of the display. The functions of the symbols, which

appear here, can be called up using the

symbol displayed on a dark background.

1 2

3

4 5 6 7 9 0

number keys.number keys.

number keys. Active functions are shown by a

number keys.number keys.

8

Enter

When creating or modifying seam programs, the different seam types are

shown graphically on the display.

7 - 2

Page 20

Control elements

5

0

7.03.02 Operational mode keys

By pressing the corresponding key, two different modes of operation can be selected.

The selected mode of operation is indicated by a diode.

SEWING

INPUT

mode

mode

7.03.03 Function keys

Arrow keys

- To move to another menu page

- To position the cursor when entering several values in one line

- To select the next program within a sequence program

Plus/Minus keys

- To select sign for input values

- To raise and lower input values

Esc-key

Esc

- Interruption of inputs without taking over the input value

- Return to superordinate menu functions

(right/left)

Clear key

Clear

- To reset the input value to 0

Enter

Enter key

- To confirm an input value

- To acknowledge an error after an error message

7.03.04 Number keys

1

Below the display there is a row of number keys (1-0).

Depending on the operating mode, these keys have the following functions:

- Executing a function illustrated by the symbol of the corresponding key

- Entering of numerical values

- Selecting functions or menu levels

3

2

9

4

6

8

7

7 - 3

Page 21

7.04 Bundle clamp switch (optional)

Control elements

Fig. 7 - 04

1

● The bundle clamp can be opened or

closed with switch 1.

The bundle clamp is not part of

the standard equipment of the

machine.

50-002

7 - 4

Page 22

Control elements

7 - 5

Page 23

Register 04

Contents ...............................................................................Chapter - Page

8 Installation and commissioning .............................................................................. 8 - 1

8.01 Installation .................................................................................................................. 8 - 1

8.01.01 Adjusting the table height .......................................................................................... 8 - 1

8.01.02 Assembling and fitting the reel stand ......................................................................... 8 - 2

8.01.03 Fitting the bundle clamp (optional) ............................................................................. 8 - 2

8.02 Commissioning .......................................................................................................... 8 - 3

8.03 Switching the machine on/off .................................................................................... 8 - 3

Page 24

Installation and commissioning

8 Installation and commissioning

The machine must only be installed and commissioned by qualified personnel!

All relevant safety regulations must be observed!

8.01 Installation

The site where the machine is installed must be provided with power connections

(see Chapter 3, Specifications).

It must be ensured that the standing surface of the machine site is firm and horizontal, and

that sufficient lighting is provided for.

For packing and transportation reasons the table top is in the lowered position.

The table height is adjusted as described below.

8.01.01 Adjusting the table height

1

1

1

1

8 - 1

50-005

Fig. 8 - 01

● Loosen screws 1 and adjust table to required height.

● Well tighten screws 1 again.

Page 25

Installation and commissioning

8.01.02 Assembling and fitting the reel stand

● Assemble the reel stand as shown in

Fig. 8-02.

Fig. 8 - 02

8.01.03 Fitting the bundle clamp (optional)

4

3

3

50-004

21

Fig. 8 - 03

● Insert bundle clamp with square bar 1

● Tighten screws 3.

● Plug in plug 4.

into the guide unit 2.

8 - 2

Page 26

Installation and commissioning

8.02 Commissioning

● Clean the entire machine thoroughly and check the electrical leads and pneumatic

connection lines for any damage.

● Check whether the machine can be operated with the available mains connection (see

Chapter 3 Specifications).

If there are any irregularities, do not operate the machine under any circumstances!

● Have specialists connect the machine to the mains.

● Oil the machine, or fill in oil (see Chapter 12 Care and Maintenance).

● Connect the machine to the compressed air system.

The manometer must display a pressure of 6 bar

If necessary, set to the correct value (see Chapter 12.05 Checking/regulating air

pressure).

..

.

..

8.03 Switching the machine on/off

● Switch the machine on or off, see Chapter 7.01 On/off switch.

Before commissioning the machine, it is advisable to check the zero points, see

Chapter 13.08.06 Zero points of the drive units for X- and Y-axis.

8 - 3

Page 27

Register 05

Contents ...............................................................................Chapter - Page

9 Preparation ............................................................................................................... 9- 1

9.01 Inserting the needle ................................................................................................... 9 - 1

9.02 Threading the needle thread /adjusting the needle thread tension ............................. 9 - 2

9.03 Winding the bobbin thread, adjusting the thread tension ........................................... 9 - 3

9.04 Changing the bobbin / adjusting the bobbin thread tension ........................................ 9 - 4

9.05 Adjusting the height of the sewing foot ..................................................................... 9 - 5

9.06 Selecting a language .................................................................................................. 9 - 5

9.07 Selecting a seam program ......................................................................................... 9 - 6

Page 28

Preparation

9 Preparation

9.01 Inserting the needle

All regulations and instructions in this Instruction Manual are to be observed!

Special attention is to be paid to the safety regulations!

All preparation work is only to be carried out by appropriately trained personnel.

Before all preparation work, the machine is to be separated from the electricity

supply by removing the plug from the mains or switching off the On/Off

switch!

Only use system 134 KK

needles!

1

2

Fig. 9 - 01

● Switch on the machine, see Chapter 8.03 Switching the machine on/off.

● Select SEWING

● Select Threading aid

The pressure bar moves out of the needle area, the sewing foot is lowered and the

sewing start is locked.

mode.

function (number key 5).

75-003

9 - 1

● Loosen screw 1 and remove needle 2.

● Insert the new needle so that the long needle groove is facing forwards.

● Tighten screw 1.

● Press the Plus key.

The machine is ready for operation again.

Page 29

Preparation

75-004

9.02 Threading the needle thread /adjusting the needle thread tension

1

Fig. 9 - 02

● Switch on the machine, see Chapter 8.03 Switching the machine on/off.

● Select SEWING

mode.

+

-

● Select Threading aid function (number key 5).

The pressure bar moves out of the needle area, the sewing foot is lowered and the

sewing start is locked.

● Thread needle thread as shown in Fig. 9-02.

● Adjust the needle thread tension by turning the adjustment wheel 1.

● Press the Plus key.

The machine is ready for operation again.

9 - 2

Page 30

Preparation

9.03 Winding the bobbin thread, adjusting the thread tension

4

3

Fig. 9 - 03

-

+

6

1

2

5

● Place the empty bobbin 1 onto the bobbin winder spindle 2.

● Thread the thread in accordance with Fig. 09-03 and wind it a few times around bobbin 1

in an anti-clockwise direction.

● Switch the bobbin winder on by pushing the bobbin winder spindle 2 and lever 3

simultaneously.

The bobbin is wound during sewing.

● The tension of the thread on bobbin 1 can be adjusted using milled screw 4.

● The bobbin winder stops automatically when bobbin 1 is full.

If the thread is wound irregularly:

● Loosen nut 5.

● Turn thread guide 6 accordingly.

● Tighten nut 5.

9 - 3

Page 31

9.04 Changing the bobbin / adjusting the bobbin thread tension

1

2

Preparation

5 cm

3

4

50-009

-

+

Fig. 9 - 04

● Switch on the machine, see Chapter 8.03 Switching the machine on/off.

● Select SEWING

● Select Threading aid function (number key 5).

The pressure bar moves out of the needle area, the sewing foot is lowered and the

sewing start is locked.

● Open flap 1.

● Raise latch 2

mode.

and remove the bobbin case 3

together with the bobbin.

50-008

● Insert the filled bobbin into the bobbin case 3

the arrow when the thread is pulled out.

● Through the slot pull the thread under the spring as shown in Fig. 9-04.

● Adjust the bobbin thread tension by turning screw 4.

● Raise latch 2 and insert the bobbin case 3

● Release latch 2

● Close flap 1.

● Press the Plus key.

The machine is ready for operation again.

and press the bobbin case into the hook until you feel it lock into place.

so that the bobbin turns in the direction of

together with the bobbin in the hook.

9 - 4

Page 32

Preparation

9.05 Adjusting the height of the sewing foot

The sewing foot height is

adjusted correctly when the

sewing foot is positioned

(suspended) slightly above the

workpiece.

3

Fig. 9 - 05

9.06 Selecting a language

● Select INPUT mode by pressing the respective key.

Depending on the setting and configuration of the machine the displayed status

bar may differ from the following example.

2

● Loosen counter screw 1 and adjust the

presser foot 3

by turning milled screw 2.

● Tighten counter screw 1 again.

to the material thickness

1

75-005

100 100 50.5 5000

1 2

● Select the input menu function (number key 0).

● Select the SWITCH FUNCTIONS function with number key 3.

3

● Select the LANGUAGES function with number key 2.

2

to

1

● Select the desired language with the number keys 1 - 5:

4

● The language selected is assumed immediately once the corresponding number has been

3

4 5 6 7 9 0

1= 3= 5=

2= 4 =

entered.

D

8

F

E

Enter

Esc

Clear

bdf

9 - 5

Page 33

9.07 Selecting a seam program

Preparation

1

Enter

bis

● Switch on the machine and select INPUT

Depending on the setting and configuration of the machine, in particular the

status bar may differ from the following example.

100 100 50.5 5000

1 2

● Using the Program number selection (number key 1) or Sequence number selection

0

● Using the number keys select a previously entered seam program.

● Complete selection with Enter.

3

4 5 6 7 9 0

(number key 2) function, select the required menu.

Seam programs can be transferred from a disk to the machine memory. To do

so the READ / WRITE PROGRAM function must be selected (see Chapter

11.05 Functions in INPUT mode).

8

mode.

Enter

Esc

Clear

bdf

The CREATE/MODIFY PROGRAM function (see Chapter 11.05 Functions in

INPUT mode) is used to create a seam program on the graphics control panel.

9 - 6

Page 34

Preparation

9 - 7

Page 35

Register 06

Contents ...............................................................................Chapter - Page

10 Sewing .................................................................................................................... 10 - 1

10.01 Status bar .................................................................................................................10- 1

10.02 Automatic Program Start ......................................................................................... 10 - 2

10.03 Manual Program Start .............................................................................................. 10 - 3

10.04 Sequence program ................................................................................................... 10 - 4

10.05 Error messages ........................................................................................................ 10 - 5

10.06 Program interruption ................................................................................................ 10 - 5

11 Input ........................................................................................................................ 11 - 1

11.01 Summary of the functions in the INPUT mode ........................................................ 11 - 1

11.02 Summary of the functions in the input menu ........................................................... 11 - 2

11.03 Summary of the service functions ........................................................................... 11 - 3

11.04 Selecting functions from the menu .......................................................................... 11 - 4

11.05 Functions in the INPUT mode .................................................................................. 11 - 6

11.06 Input of seam programs ........................................................................................... 11 - 17

11.07 Examples for entering seam programs .................................................................... 11 - 24

11.07.01 Straight dart ............................................................................................................. 11 - 24

11.07.02 Curved pleat ............................................................................................................. 11 - 26

11.08 CREATE/MODIFY FREE PROGRAMS ...................................................................... 11 - 29

11.08.01 Program structure .................................................................................................... 11 -29

11.08.02 Entering the free programming function .................................................................. 11 - 29

11.08.03 Status bar in initial state (free programming)............................................................ 11 - 31

11.08.04 Summary of the functions in the initial state (free programming) ............................ 11 - 32

11.08.05 Explanation of the functions in the initial state (free programming) ......................... 11 - 33

11.08.06 Summary of the Insert functions ............................................................................. 11 - 36

11.08.07 Explanation of the insert functions ........................................................................... 11 - 37

11.08.08 An example for entering a free program .................................................................. 11 - 40

11.09 Installing operating programs ................................................................................... 11 - 46

11.09.01 Booting for software updates .................................................................................. 11 - 46

11.09.02 Booting after changing the basic control unit ........................................................... 11 - 47

Page 36

Sewing

10 Sewing

In the SEWING mode functions are available for production and production preparation. By

pressing the corresponding key on the graphics control panel, the operational mode can be

selected.

Before production begins, following work steps must be carried out:

● Prepare the machine, see Chapter 9 Preparation.

● Select SEWING

● Insert the workpiece and start the program sequence.

Information and functions of the graphics control panel are listed below and explained.

mode.

In the SEWING mode, the program sequence can be started either

automatically or manually, the differences are explained below in Chapters

10.02 Automatic Program Start and 10.03 Manual Program Start.

10.01 Status bar

In the upper section of the display screen information is shown about the current machine

status. For this purpose symbols are displayed with corresponding values.

100 100 20.5 5000

1 2

Explanation of the status bar symbols.

Program number

The number of the current program appears after the symbol for the program number.

No symbol appears for standard programs.

In the case of sequence programs

method (automatic or manual) appears after the symbol.

Seam length

The value for the seam length of the selected seam program appears after this symbol.

3

1

AUT

4 5 6 7 9 0

8

the corresponding sequence number and the move-on

Enter

Esc

Clear

bdf

10 - 1

Depth

The value for the programmed depth of the selected seam program appears after this

symbol.

Piece counter

The actual number of pieces is shown after this symbol.

Page 37

10.02 Automatic Program Start

In the case of an automatic program start, the program sequence begins as soon as the

loading table with the workpiece is moved forward.

Starting position of the machine

Sewing

to

100 100 20.5 0

BOBBIN 0 / 10000

1 2

Explanation of the symbols in the pictogram bar:

Automatic program start

The pictogram indicates that the program starts automatically.

If the Manual program start

function, see Chapter 10.03 Manual program start

Starting position

This is a direct function to bring the machine into its starting position.

Sewing foot up/down, threading aid

This is a direct function for raising or lowering the sewing foot. At the same time the

pressure bar is switched on or off and if necessary moved into the threading position.

Depth correction dependent on the material

The depth specified in the seam program is corrected according to the function selected.

The maximum value for the depth correction can be set in the input mode under the Sewing

head functions

the selected depth correction appears on a dark background.

3

4 5 6 7 9 0

(number key 4)

function, see Chapter 11.05 Functions in the INPUT mode. The symbol for

8

(number key 1)

function is selected, the machine switches over to this

(number key 5)

Enter

..

.

..

(number keys 6 – 0)

Esc

Clear

bdf

The depth correction value is reduced by 100%

The depth correction value is reduced by 50%

The specified depth remains unchanged.

The depth correction value is increased by 50% of the specified depth.

The depth correction value is increased by 100% of the specified depth.

of the specified depth.

of the specified depth.

10 - 2

Page 38

Sewing

10.03 Manual Program Start

In the case of a manual program start, the program sequence is started by selecting the

Start Start

Start function on the graphics control panel after the loading table has been moved forward.

Start Start

Starting position of the machine

to

100 100 20.5 0

BOBBIN 0 / 10000

1 2

3

4 5 6 7 9 0

8

Enter

Esc

Clear

bdf

Explanation of the symbols in the pictogram bar:

Manual program start

(number key 1)

The pictogram indicates that the program has been started manually.

If the Automatic program start

function is selected, the machine switches over to this

function, see Chapter 10.02 Automatic program start.

Starting position

(number key 4)

This is a direct function to bring the machine into its starting position.

Sewing foot up/down, threading aid

(number key 5)

This is a direct function for raising or lowering the sewing foot. At the same time the

pressure bar is switched on or off and if necessary moved into the threading position.

Depth correction dependent on the material

(number keys 6 – 0)

See Chapter 10.02 Automatic program start.

Loading table moved forward

100 100 20.5 5000

BOBBIN 2500 / 10000

1 2

3

4 5 6 7 9 0

8

Enter

Esc

Clear

bdf

Explanation of the symbols changed in the pictogram bar:

Start

(number key 1)

Direct function to start the program sequence.

Step-by-step forwards

(number key 2)

With this function the seam pattern can be traced forwards step by step.

10 - 3

Page 39

Machine running

Sewing

100 100 20.5 5000

BOBBIN 2500 / 10000

1 2

3

4 5 6 7 9 0

8

Enter

Explanation of the symbols in the pictogram bar:

Stop (number key 1)

Direct function to stop the entire program sequence

(see Chapter 10.06 Program interruption

Depth correction dependent on the material

))

)

))

(number keys 6 – 0)

See Chapter 10.02 Automatic program start.

Intermediate machine stop

100 100 20.5 0

BOBBIN 0 / 10000

1 2

3

4 5 6 7 9 0

8

Enter

Esc

Clear

bdf

Esc

Clear

bdf

Explanation of the symbols in the pictogram bar:

Start

(number key 1)

Direct function to continue the program sequence.

Step-by-step forwards

With this function the seam pattern can be traced forwards step by step.

Starting position

(number key 4)

This is a direct function to bring the machine into its starting position.

Increase insertion depth

The insertion depth for this seam can be increased or reduced.

10.04 Sequence program

In sequence programs separate programs can be combined and saved under one program

number. The selection of a sequence program and the move-on method can be recognised

by the corresponding symbol in the status bar.

100 100 20.5 0

100 | 190 | 105

1

AUT

(number key 2)

(number key 9) / Reduce insertion depth

Esc

BOBBIN 0 / 10000

Clear

(number key 0)

1 2

3

4 5 6 7 9 0

8

Enter

The sequence consists of the programs 100, 190 and 105.

bdf

10 - 4

Page 40

Sewing

1

AUT

Automatic switching to next sequence

The separate programs of the sequence are processed automatically after each other. The

program number displayed on a dark background shows which part must be inserted next.

1

MAN

Manual switching to next sequence

The current program of a sequence is processed until another program is selected from the

sequence.

Within the sequence the program is selected with the arrow keys.

The program number displayed on a dark background shows which program has been

currently selected.

10.05 Error messages

If an error message occurs, text and pictogram bars in the display are written over. An error

message can be caused by incorrect settings, defective elements or seam programs, as well

as by overload conditions.

● Before machine operation can continue, the error must be corrected.

How to correct the error:

Enter

● Press Enter to move back to an incorrect input.

● Correct the input.

10.06 Program interruption

A program sequence can be interrupted by activating the Stop function on the graphics

control panel.

100 100 20.5 0

100 | 190 | 105

1 2

Explanation of the symbols in the pictogram bar:

Start

(number key 1)

Direct function to continue the program sequence.

Step-by-step forwards

With this function the seam pattern can be traced forwards or backwards step by step.

Combined with the Start

Start

function is pressed in addition to the activated Step-by-step

Starting position

This is a direct function to bring the machine into its starting position.

1

AUT

3

4 5 6 7 9 0

(number key 2) / Step-by-step backwards

function, the seam pattern sequence runs automatically when the

(number key 4)

BOBBIN 0 / 10000

8

Enter

Esc

Clear

bdf

(number key 3)

……

…function.

……

10 - 5

Sewing foot up / down, threading aid

(number key 5)

This is a direct function for raising or lowering the sewing foot. At the same time the

pressure bar is switched on or off and if necessary moved into the threading position.

Depth correction dependent on the material

(number keys 6 – 0)

See Chapter 10.02 Automatic program start.

Page 41

11 Input

This chapter lists and describes the functions in the INPUT mode. This operational mode

includes the functions for program management, language selection, machine setting and

configuration, as well as for service and adjustment work. However this chapter does not

describe how to create a seam program. For information on how to create seam programs

please refer to the relevant instruction manual.

11.01 Summary of the functions in the INPUT mode

INPUT

mode

Program number selection

Sequence program number selection

Modify selected program

Create program

Input

1 - DART 1

2 - DART 2

3 - PLEAT 1

4 - PLEAT 2

5 - BASTING STITCH

Create / modify free program

Enter seam parameters

1 - STARTTACK

2 - STITCH CONDENSING SEAM START

3 - ENDTACK

4 - STITCH CONDENSING SEAM END

5 - ANGLE SEAM END

6 - BASTING STITCH

Bobbin thread functions

1 - RESET STITCH COUNTER

2 - BOBBIN THREAD PRESELECT

Sewing head functions

1 - MAXIMUM SPEED

2 - SPEED TACK / REDUCTION

3 - SPEED BASTING STITCH

4 - INTERMITTENT STOP

5 - MAX. DEPTH CORRECTION

Input menu (see Chapter 11.02 Summary of the functions in the input menu)

1 - PROGRAM MANAGEMENT

2 - COUNTER

3 - SWITCH FUNCTIONS

4 - TIMES

5 - SERVICE (SEE CHAPTER 11.03 SUMMARY OF THE SERVICE FUNCTIONS)

11 - 1

Page 42

Input

11.02 Summary of the functions in the input menu

INPUT

mode

Input menu

1 - PROGRAM MANAGEMENT 1 - DIRECTORY 1 - DIRECTORY OF MEMORY

2 - READ/WRITE PROGRAM 1 - READ ONE PROGRAM FROM DISK

3 - DELETE PROGRAM 1 - DELETE ONE PROGRAM IN MEMORY

4 - FORMAT DISK

2 - DIRECTORY OF DISK

2 - READ ALL PROGRAMS FROM DISK

3 - WRITE ONE PROGRAM ON DISK

4 - WRITE ALL PROGRAMS ON DISK

2 - DELETE ALL PROGRAMS IN MEMORY

3 - DELETE ONE PROGRAM ON DISK

4 - DELETE ALL PROGRAMS ON DISK

2 - COUNTERS 1 - RESET PIECE COUNTER

2 - THREAD MONITOR 1 - SUPPRESSED STITCHES NEEDLE

THREAD MONITOR

2 - REACTION TIME THREAD MONITOR

3 - NUMBER OF SLOW START - STITCHES

4 - CARRIAGE START (NIS)

5 - START FOR THREAD TRIMMING

3 - SWITCH FUNCTIONS 1 - THREAD MONITOR 1 - NEEDLE THREAD MONITOR

2 - BOBBIN THREAD MONITOR

2 - LANGUAGE SELECTION 1 - GERMAN

2 - ENGLISH

3 - FRENCH

4 - SPANISH

5 - TURKISH

3 - LOCK/RELEASE FUNCTIONS

4 - OTHER FUNCTIONS 1 - MOVE TAKE - OVER

2 - THREADING POSITION

4 - TIMES 11 - AIR BLAST TIME

5 - SERVICE (SEE CHAPTER 11.03 SUMMARY OF SERVICE FUNCTIONS)

11 - 2

Page 43

11.03 Summary of the service functions

INPUT

mode

Input menu

5 - SERVICE

1 - SEWING DRIVE FUNCTIONS 1 - TURN SEWING MOTOR

2 - STEPPING MOTOR FUNCTIONS 1 - STEPPING MOTOR 1, SMX

3 - INPUTS / OUTPUTS

Input

2 - THREAD TRIMMING PROCEDURE

3 - CUTTING SPEED - PRESELECT

2 - STEPPING MOTOR 2, SMY

3 - STEPPING MOTOR 3, SMD

4 - ADJUST ZERO POINTS 1 - CARRIAGE POSITION

2 - DEPTH

3 - NEEDLE POSITION

4 - CORRECTION VALUE START POINT

5 - ADJUSTMENTS READ/WRITE 1 - READ MACHINE DATA FROM DISK

2 - WRITE MACHINE DATA TO DISK

3 - READ ZERO POINTS FROM DISK

4 - WRITE ZERO POINTS TO DISK

6 - OTHER FUNCTIONS 1 - CARRY OUT COLD START

2 - DISPLAY SOFTWARE STATUS

3 - CONTRAST SETTING OF DISPLAY

4 - CHANGE CODE NUMBER

5 - INSTALL OPERATING SYSTEM

The service functions are explained in Chapter 11.05 Functions in the INPUT

mode.

11 - 3

Page 44

Input

11.04 Selecting functions from the menu

An example is designed to show how to move about within menu levels.

Contrast setting of display:

● By pressing the corresponding key, select INPUT

mode

(LED in key lights up)

100 100 50.5 5000

1 2

● Select input menu

1 - PROGRAM MANAGEMENT .....

2 - COUNTER .....

3 - SWITCH FUNCTIONS .....

4 - TIMES .....

5 - SERVICE .....

1 2

● By pressing number key 5, call up the SERVICE function.

5

1 - SEWING DRIVE FUNCTIONS .....

2 - STEPPING MOTOR FUNCTIONS .....

3 - DISPLAY INPUTS / OUTPUTS

4 - ADJUST ZERO POINT .....

5 - ADJUSTMENTS READ/WRITE .....

6 - OTHER FUNCTIONS .....

3

4 5 6 7 9 0

function (press number key 0)

3

4 5 6 7 9 0

8

8

Enter

Enter

Esc

Clear

bdf

Esc

Clear

bdf

Esc

Clear

1 2

● With number key 6 select OTHER FUNCTIONS.

6

1 - CARRY OUT COLD START

2 - DISPLAY SOFTWARE STATUS

3 - CONTRAST SETTING OF DISPLAY

4 - CHANGE CODE NUMBER

5 - INSTALL OPERATING SYSTEM

1 2

3

5

8

● Insert the code number (standard setting: 3586) using the number keys.

6

CODE NUMBER?

3586

[ PERMISSIBLE 0000 - 9999 ]

1 2

3

4 5 6 7 9 0

3

4 5 6 7 9 0

3

4 5 6 7 9 0

8

8

8

Enter

Enter

Enter

bdf

Esc

Clear

bdf

Esc

Clear

bdf

11 - 4

Page 45

Input

Enter

Enter

● Confirm code input with Enter.

● Select the CONTRAST SETTING OF DISPLAY function (number key 3)

3

CONTRAST SETTING

ADJUST WITH +, - KEYS

1 2

3

4 5 6 7 9 0

8

Enter

Esc

Clear

The contrast setting is changed immediately when the key is pressed and does

not have to be confirmed with Enter. On no account may the contrast be

reduced to such an extent that it is no longer possible to read the display!

● The contrast can be changed as required using the plus/minus keys.

● Press Enter

to exit the function.

bdf

Summary of the function selections

INPUT

mode

0

Input menu

function

(number key 0)

1 - PROGRAM MANAGEMENT

2 - COUNTER

3 - SWITCH FUNCTIONS

4 - TIMES

5

5 - SERVICE

1 - SEWING DRIVE FUNCTIONS

2 - STEPPING MOTOR FUNCTIONS

3 - DISPLAY INPUTS / OUTPUTS

4 - ADJUST ZERO POINT

5 - ADJUSTMENTS READ/WRITE

6

6 - OTHER FUNCTIONS

1 - CARRY OUT COLD START

2 - DISPLAY SOFTWARE STATUS

3

3 - CONTRAST SETTING OF DISPLAY

4 - CHANGE CODE NUMBER

5 - INSTALL OPERATING SYSTEM

11 - 5

Page 46

Input

11.05 Functions in the INPUT mode

Initial state in the INPUT

100 100 50.5 5000

1 2

1

AUT

3

4 5 6 7 9 0

mode

Esc

Clear

8

Enter

bdf

Explanation of the functions:

Program number selection

(number key 1)

This function is for the selection of the desired program number.

Sequence program number selection

(number key 2)

With this function it is possible to select the sequence program number, the method of

moving the sequence forward and the sequence. When a sequence program number is

selected, the sequence saved under this number is displayed.

Create / modify current program

(number key 4)

With this function it is possible to create or modify the currently selected program using the

graphics control panel.

Create / modify program

(number key 5)

Using the graphics control panel with this function seam programs can be created or

modified, the seam pattern and the corresponding program number are selected after the

function has been called up, see Chapter 11.06 Entering seam programs

Create / modify free program

(number key 6)

..

.

..

With this function free seam programs can be created or modified on the machine, see

Chapter 11.07 Create / modify free program

..

.

..

Seam parameters (number key 7)

This function opens a menu for entering seam parameters:

1 - STARTTACK

2 - STITCH CONDENSING SEAM START

3 - ENDTACK

4 - STITCH CONDENSING SEAM END

4 - ANGLE SEAM END

5 - BASTING STITCH

1 2

1

3

4 5 6 7 9 0

STARTTACK

8

Enter

Esc

Clear

bdf

With this function the number of stitches for the start backtack can be entered.

11 - 6

STITCH CONDENSING SEAM START

2

With this function the stitch length and number of condensed stitches at the seam

start can be entered.

ENDTACK

3

With this function the number of stitches for the end backtack can be entered.

Page 47

STITCH CONDENSING SEAM END

4

With this function the stitch length and number of condensed stitches at the send of

the seam can be entered.

ANGLE SEAM END

5

With this function the number of stitches and angle at the seam end can be entered.

BASTING STITCH

With this function the stitch length and number of stitches at the beginning and end of

6

the seam can be entered.

Input

Bobbin thread functions

(number key 8)

This function opens a menu for the selection of various bobbin thread functions:

1 - RESET STITCH COUNTER

2 - BOBBIN - THREAD PRESELECT 10000 STITCHES

1 2

1

3

4 5 6 7 9 0

RESET STITCH COUNTER

8

Enter

Esc

Clear

bdf

This function resets the stitch counter to "0", e.g. after an unplanned bobbin change.

BOBBIN THREAD PRESELECT

This function is used to enter the number of stitches, after which the machine stops

2

automatically for a bobbin change.

Sewing head functions

(number key 9)

The function opens a menu for the selection of various sewing head functions:

1 - MAXIMUM SPEED 4500 RPM

2 - SPEED TACK / REDUCTION 4500 RPM

3 - SPEED BASTING STITCH 1000 RPM

4 - INTERMITTENT STOP ON

5 - MAX: DEPTH CORRECTION 0.5 MM

1 2

1

3

4 5 6 7 9 0

MAXIMUM SPEED

8

Enter

Esc

Clear

bdf

This function is for entering the maximum speed

SPEED TACK / REDUCTION

2

This function is for entering the reduced speed for backtacking stitches at the beginning

and end of the seam.

SPEED BASTING STITCH

3

This function is for entering the speed of the basting stitch.

INTERMITTENT STOP

4

With this function the sequence interruption after loading the workpiece (for manual

depth correction) can be switched on or off.

11 - 7

Page 48

Input

MAX: DEPTH CORRECTION

5

With this function the value for the maximum depth correction can be entered. The indi-

vidual intermediate values are calculated automatically.

Input menu

(number key 0)

This function opens a menu for selecting various functions from other menu levels

1 - PROGRAM MANAGEMENT .....

2 - COUNTER .....

3 - SWITCH FUNCTIONS .....

4 - TIMES .....

5 - SERVICE .....

1 2

1

3

4 5 6 7 9 0

8

PROGRAM MANAGEMENT

Enter

Esc

Clear

bdf

This function opens a menu for organizing seam programs:

1 - DIRECTORY .....

2 - READ/WRITE PROGRAM .....

3 - DELETE PROGRAM .....

4 - FORMAT DISK

1 2

1

3

4 5 6 7 9 0

DIRECTORY

8

Enter

Esc

Clear

bdf

This function opens a menu with functions for listing the directories of the memory:

1 - DIRECTORY OF MEMORY

2 - DIRECTORY OF DISK

1 2

1

3

4 5 6 7 9 0

DIRECTORY OF MEMORY

8

Enter

This function displays the contents of the machine memory.

DIRECTORY OF DISK

2

Displays the contents of a disk. Program numbers valid for this machine are

displayed.

READ/WRITE PROGRAM

2

This functions opens a menu for transferring seam programs:

1 - READ ONE PROGRAM FROM DISK

2 - READ ALL PROGRAMS FROM DISK

3 - WRITE ONE PROGRAM ON DISK

4 - WRITE ALL PROGRAMS ON DISK

Esc

Clear

bdf

Esc

Clear

11 - 8

1 2

3

4 5 6 7 9 0

8

Enter

bdf

Page 49

3

READ ONE PROGRAM FROM DISK

1

A selected program is read from a disk into the machine memory.

READ ALL PROGRAMS FROM DISK

2

All the programs on a disk are read into the machine memory.

WRITE ONE PROGRAM ON DISK

3

A selected program is written from the machine memory onto a disk.

WRITE ALL PROGRAMS ON DISK

4

All programs from the machine memory are written onto a disk.

DELETE PROGRAMS

The function opens a menu for deleting seam programs:

Input

1 - DELETE ONE PROGRAM IN MEMORY

2 - DELETE ALL PROGRAMS IN MEMORY

3 - DELETE ONE PROGRAM ON DISK

4 - DELETE ALL PROGRAMS ON DISK

1 2

1

3

4 5 6 7 9 0

DELETE ONE PROGRAM IN MEMORY

A selected program is deleted in the machine memory.

DELETE ALL PROGRAMS IN MEMORY

2

All the programs in the machine memory are deleted.

DELETE ONE PROGRAM ON DISK

3

A selected program is deleted on a disk.

DELETE ALL PROGRAMS ON DISK

4

All the programs on a disk are deleted.

FORMAT DISK

4

Formats a disk and names it "K3586".

Esc

Clear

8

Enter

bdf

When you format a disk, all files on the disk are deleted!

11 - 9

Page 50

Input

COUNTER

2

This function opens a menu for customizing the counters:

1 - RESET PIECE COUNTER

2 - THREAD MONITOR .....

3 - NUMBER OF SLOW START - STITCHES 2 STITCHES

4 - CARRIAGE START (NIS) 90°

5 - START FOR THREAD TRIMMING 200°

1 2

1

3

4 5 6 7 9 0

RESET PIECE COUNTER

8

Enter

Esc

Clear

bdf

With this function the piece counter is set at "0" for the daily production.

THREAD MONITOR

2

The function opens a menu for changing the thread monitor counters:

1 - SUPPRESSED STITCHES NEEDLE THREAD MONITOR: 5STITCHES

2 - REACTION TIME NEEDLE THREAD MONITOR: 2

1 2

1

3

4 5 6 7 9 0

8

SUPPRESSED STITCHES NEEDLE THREAD MONITOR

Enter

Esc

Clear

Changes the number of stitches, for which the needle thread monitor is not

active during sewing.

bdf

REACTION TIME, NEEDLE THREAD MONITOR

2

With this function the sensitivity of the needle thread monitor is changed

(1 = quick reaction, max. sensitivity).

NUMBER OF SLOW START - STITCHES

3

Changes the number of stitches, which are to be sewn at reduced speed when

sewing on a section of the workpiece.

CARRIAGE START (NIS)

4

This function changes the time for starting the motors of the carriage drive.

(° = degrees after t.d.c. needle bar).

START FOR THREAD TRIMMING

5

Changes the time at which the impulse to start thread trimming is sent to the

thread trimming valve (º = degrees after t.d.c. needle bar).

11 - 10

Page 51

3

SWITCH FUNCTIONS

3

This function opens a menu for switching machine functions on or off.

Input

1 - THREAD MONITOR .....

2 - LANGUAGE SELECTION .....

3 - LOCK/RELEASE FUNCTIONS

4 - OTHER FUNCTIONS .....

1 2

1

3

4 5 6 7 9 0

THREAD MONITOR

8

Enter

This function opens a menu for selecting thread monitors:

1 - NEEDLE THREAD MONITOR ON

2 - BOBBIN THREAD MONITOR ON

1 2

1

3

4 5 6 7 9 0

8

NEEDLE THREAD MONITOR

With this function the needle thread monitor is switched on or off.

BOBBIN THREAD MONITOR

2

This function counts the stitches.

Esc

Clear

Enter

bdf

Esc

Clear

bdf

LANGUAGE SELECTION

2

This function opens a menu for the selection of the languages displayed (see

Chapter 9.06 Language selection):

1 - GERMAN

2 - ENGLISH

3 - FRENCH

4 - SPANISH

1 2

3

4 5 6 7 9 0

8

Enter

Esc

Clear

bdf

LOCK/RELEASE FUNCTIONS

With this function all functions in the INPUT mode can be released, secured with

a code number and made accessible to authorized personnel only by means of a

key.

A table with the code numbers of the individual functions can be found in Chapter

14.03.01 Tables for lock/release functions.

11 - 11

Page 52

Input

OTHER FUNCTIONS

4

This function opens a menu for switching the other functions on or off.

1 - MOVE TAKE OVER

2 - THREADING POSITION

1 2

1

3

4 5 6 7 9 0

MOVE TAKE OVER

8

When this function is switched on, the material take over is moved

automatically by a certain amount during the sewing cycle.

THREADING POSITION

2

When the threading aid function is switched on, the pressure bar is moved.

TIMES

4

This function opens a menu for altering the time settings.

AIR BLAST TIME

1

This function is used to set the duration of the air blast for blasting out the material

at the end of the seam.

Enter

Esc

Clear

bdf

11 - 12

Page 53

SERVICE

5

This functions opens a menu for selecting the service functions:

Input

1 - SEWING DRIVE FUNCTIONS .....

2 - STEPPING MOTOR FUNCTIONS .....

3 - DISPLAY INPUTS/OUTPUTS

4 - ADJUST ZERO POINT .....

5 - ADJUSTMENTS READ/WRITE .....

6 - OTHER FUNCTIONS .....

1 2

1

3

4 5 6 7 9 0

SEWING DRIVE FUNCTIONS

8

Enter

This function opens a menu for checking the sewing motor:

1 - TURN SEWING MOTOR

2 - THREAD TRIMMING PROCEDURE

3 - CUTTING SPEED - PRESELECT 200 RPM

1 2

3

4 5 6 7 9 0

8

Before activating the following functions, make sure that the

needle can enter the needle hole without any problem!

TURN SEWING MOTOR

1

With his function the sewing motor can be started and stopped again. The

speed can be pre - selected or even altered during running, using the plus/

minus keys.

Esc

Clear

Enter

bdf

Esc

Clear

bdf

THREAD TRIMMING PROCEDURE

2

This function starts the thread trimming procedure.

CUTTING SPEED - PRESELECT

3

This function preselects the positioning speed for thread cutting.

STEPPING MOTOR FUNCTIONS

2

This function opens a menu for moving the stepping motors:

1 - STEPPING MOTOR 1 (X)

2 - STEPPING MOTOR 2 (Y)

3 - STEPPING MOTOR 3 (D)

1 2

3

4 5 6 7 9 0

8

Before activating the following functions, make sure that the carriage

drive can move freely!

STEPPING MOTOR 1 (X)

1

This function moves stepping motor 1 (X - axis).

Enter

Esc

Clear

bdf

11 - 13

Page 54

Input

STEPPING MOTOR 2 (Y)

2

This function moves stepping motor 2 (Y - axis).

STEPPING MOTOR 3 (D)

3

This function moves stepping motor 2 (depth).

DISPLAY INPUTS/OUTPUTS

3

After this function has been selected, the states of inputs and outputs are

displayed: 1 = Input actuated / output switched

0 = Input not actuated / output not switched

NODE 1 (A??) : 1 - - - - - - 8 9 - - - - - - 16

INPUTS : 00101101 10101000

OUTPUTS : 00000100 00100000

1 2

3

4 5 6 7 9 0

8

With this function (number key 0) a menu is opened, in which outputs

can be set or reset. The required output is selected with a code number.

A signal is given for any errors occurring. In the case of outputs equipped

with a transmitter for sending a response signal, the response time is

measured and displayed.

There is a table of the inputs and outputs with code numbers in Chapter

14.03 Tables.

ADJUST ZERO POINT

4

This function opens a menu for adjusting the zero points

1 - CARRIAGE POSITION

2 - DEPTH

3 - NEEDLE POSITION

4 - CORRECTION VALUE START POINT 1.0 mm

Enter

Esc

Clear

bdf

Esc

Clear

11 - 14

1 2

1

3

4 5 6 7 9 0

CARRIAGE POSITION

8

Enter

bdf

With this function the basic position of the carriage can be set.

DEPTH

2

With this function the distance between material take over and pressure bar

can be set.

NEEDLE POSITION

3

This function sets the position "TDC needle bar".

CORRECTION VALUE START POINT

4

With this function it is possible to correct the seam starting point in X -

direction.

Page 55

6

ADJUSTMENTS READ/WRITE

5

After this function has been called up, a menu is opened for entering or copying

machine data:

Input

1 - READ MACHINE DATA FROM DISK

2 - WRITE MACHINE DATA TO DISK

3 - READ CONF./ZERO POINTS FROM DISK

4 - WRITE CONF./ZERO POINTS TO DISK

1 2

1

3

4 5 6 7 9 0

8

READ MACHINE DATA FROM DISK

Enter

Esc

Clear

bdf

With this function it is possible to read machine data (file name: MDAT)

which is saved on a disk, into the machine memory (e.g. after a cold start).

WRITE MACHINE DATA TO DISK

2

With this function the data for the machine setting (file name: MDAT) can be

written on to a disk.

There is a table of transferable machine data in the service manual for this

machine.

READ CONFIGURATION/ZERO POINTS FROM DISK

3

With this function it is possible to read the machine configuration and the

zero points (file name: KONF), which are saved on a disk, into the machine

memory (e.g. after a master reset).

WRITE CONFIGURATION/ZERO POINTS TO DISK

4

With this function it is possible to write the machine configuration and the

zero points (file name: KONF) on to a disk.

OTHER FUNCTIONS

This function opens a menu with various other functions:

1 - CARRY OUT COLD START

2 - DISPLAY SOFTWARE STATUS

3 - CONTRAST SETTING OF DISPLAY

4 - CHANGE CODE NUMBER

5 - INSTALL OPERATING SYSTEM

1 2

1

3

4 5 6 7 9 0

CARRY OUT COLD START

8

Enter

Esc

Clear

bdf

With this function a cold start can be carried out.

During this procedure all settings, except the zero point settings and the

machine configuration, are returned to the initial load status; all programs in

the machine memory are deleted.

DISPLAY SOFTWARE STATUS

2

After this function has been selected, the part numbers of the machine

software and the software versions of various controllers are displayed.

11 - 15

Page 56

Input

CONTRAST SETTING OF DISPLAY

3

Under no circumstances may the display be adjusted to such an

extent, that it is no longer possible to read the display.

With this function the contrast setting of the display can be altered.

CHANGE CODE NUMBER

4

After a cold start, this number is 3586. This function allows you to select your

own code number from 0000 - 9999.

Functions secured by a code number can only be selected with

the respective code.

INSTALL OPERATING SYSTEM

5

With this function, after the boot disk K3586BOOT1 has been inserted, the

operating software is loaded for a software update, see Chapter 11.09

Installing operating programs.

11 - 16

Page 57

11.06 Input of seam programs

Seam programs can be created or modified with the graphics control panel, using the

Create/Modify program

corresponding program number can be selected.

The selection of the seam type depends on the additional seam requirements:

Starttack pre - set pre - set pre - set pre - set

Stitch condensing optional optional optional optional

seam start

End tack not possible not possible pre - set not possible

Stitch condensing automatic automatic optional automatic

seam end

function. After the function has been selected, the seam type and

DART 1 DART 2 PLEAT 1 PLEAT 2

Input

Angle seam end automatic automatic not possible not possible

Basting stitch not possible not possible optional optional

Basic status of the seam program input

1 - DART 1

2 - DART 2

3 - PLEAT 1

4 - PLEAT 2

5 - BASTING STITCH

1 2

3

4 5 6 7 9 0

8

Enter

Esc

Clear

bdf

● After the required seam type has been selected (number keys 1 to 5), the program

number must be entered.

Use the arrow keys

to enter the program number or stitch length in the basic

pattern of each seam type.

11 - 17

Page 58

Input

DART 1

1

With this function the corresponding seam type can be programmed.

Program numbers 100 - 199 are allocated to the seam type "Dart 1"

➞

➞

:

2

1

+

3

-

4

1: 10.0 2: 100 3: +0

100 2.2

4: 0

Esc

Clear

1 2

1

3

Number key 1

4 5 6 7 9 0

8

Enter

bdf

Press this number key to enter the value for dart depth.

Number key 2

2

Press this number key to enter the value for dart length.

Number key 3

3

Press this number key to enter the value for curve.

Number key 4

4

Press this key to enter the value for shifting the starting point.

Starttack / stitch condensing seam start

(number key 8)

With this function it is possible to define the type of seam starttack. By pressing a

key it is possible to select either a tack or stitch condensation at the beginning of

the seam.

11 - 18

Page 59

2

3

6

5

DART 2

2

With this function the corresponding seam type can be programmed.

Program numbers 200 - 299 are allocated to the seam type "Dart 2"

➞

➞

:

2

+

1

3

6

+

-

5

7

-

4

1: 10.0 2: 100 5: +0

3:10.0 4:50 6:+0

200 2.2

7: 0

Input

Esc

Clear

1 2

1

3

Number key 1

4 5 6 7 9 0

8

Enter

bdf

Press this number key to enter the value for dart depth.

Number key 2

Press this number key to enter the value for dart length.

Number key 3

Press this number key to enter the value for depth at waist.

Number key 4

4

Press this number key to enter the value for length at waist.

Number key 5 / number key 6

Press these number keys to enter the values for curve.

Number key 7

7

Press this key to enter the value for shifting the starting point.

Starttack / stitch condensing seam start

(number key 8)

With this function it is possible to define the type of seam starttack. By pressing a

key it is possible to select either a tack or stitch condensation at the beginning of

the seam.

11 - 19

Page 60

Input

PLEAT 1

3

With this function the corresponding seam type can be programmed.

Program numbers 300 - 399 are allocated to the seam type "Pleat 1".

➞

➞

:

2

1

3

+

4

-

5

1: 10.0 2: 40 4: +0

3: 20.0 5: 0

300 2.2

Clear

Esc

1 2

1

3

Number key 1

4 5 6 7 9 0

8

Enter

bdf

Press this number key to enter the value for pleat depth.

Number key 2

2

Press this number key to enter the value for pleat length.

Number key 3

3

Press this number key to enter the value for depth at hip.

Number key 4

4

Press this number key to enter the value for curve.

Number key 5

5

Press this key to enter the value for shifting the starting point.

Starttack / stitch condensing seam start

(number key 8)

With this function it is possible to define the type of seam starttack. By pressing a

key it is possible to select either a tack or stitch condensation at the beginning of

the seam.

End tack / Stitch condensing seam end

(number key 9)

With this function it is possible to define the type of seam end tack. By pressing a

key it is possible to select either a tack or stitch condensation at the end of the

seam.

Basting stitch

(number key 0)

With this function it is possible to attach a basting stitch.

(The symbol for the currently selected type of basting stitch is always displayed).

➞

➞

:

300 2.2

8

Enter

Esc

Clear

bdf

1 2

2

1

3

4 5 6 7 9 0

1: 50 2: 140

11 - 20

Page 61

Input

The depth of the basting stitch corresponds to the depth of the pleat at the hip.

The beginning, end and type of basting stitch can be defined with the following

functions.

Number key 1

1

After pressing this key, the value for the basting stitch start can be entered.

Number key 2

2

After pressing this key, the value for the basting stitch end can be entered.

Basting stitch type

(number key 0)

After pressing this key it is possible to select two different types of basting

stitches. The symbol for the currently selected basting stitch type is

displayed.

PLEAT 2

4

With this function the corresponding seam type can be programmed.

Program numbers 400 - 499 are allocated to the seam type "Pleat 2".

➞

➞

:

2

1

1 2

1

3

+

6

9

-

4

3

Number key 1

5

+

7

-

1: 20.0 2: 50 6: +0

3: 20.0 4: 40 7: +0

5: 10.0 9: 0

4 5 6 7 9 0

400 2.2

8

Clear

Enter

Press this number key to enter the value for pleat depth.

Esc

bdf

Number key 2

2

Press this number key to enter the value for pleat length.

Number key 3

3

Press this number key to enter the value for depth at hip.

Number key 4

4

Press this number key to enter the value for length at hip.

Number key 5

5