Page 1

-20/02

3538

INSTRUCTION MANUAL

-30/02

This instruction manual applies to machines

from the following serial numbers onwards: 2 804 345

and software version 0437/001.

296-12-19 292/002

Instruction Manual engl. 10.15

Page 2

This instruction manual applies to all models and subclasses listed in Chapter 3

Technical Data.

The adjustment manual for the machine can be downloaded at no charge under

www.pfaff-industrial.de/de/service-support/downloads/technical.

As an alternative to the Internet download, the adjustment manual can also be

ordered under order no. 296-12-19 293/002.

Reprinting, reproduction and/or translation of PFAFF instruction manuals (including parts

thereof) is only permitted with our prior agreement and citation of the source.

PFAFF Industriesysteme

und Maschinen GmbH

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Table of Contents

Contents ..................................................................................................Page

1 Safety .................................................................................................................................... 5

1.01 Directives ............................................................................................................................... 5

1.02 General safety instructions ....................................................................................................5

1.03 Safety symbols ...................................................................................................................... 6

1.04 Special points of attention for the owner-operator ................................................................6

1.05 Operating personnel and technical staff ................................................................................7

1.05.01 Operating personnel .............................................................................................................. 7

1.05.02 Technical staff ........................................................................................................................ 7

1.06 Danger warnings ....................................................................................................................8

2 Proper Use ............................................................................................................................9

3 Technical Data

................................................................................................................. 10

3.01 PFAFF 3538 ......................................................................................................................... 10

4 Disposal of the Machine .................................................................................................... 11

5 Transport, Packaging and Storage ...................................................................................12

5.01 Transport to the customer’s premises ................................................................................ 12

5.02 Transport within the customer’s premises .......................................................................... 12

5.03 Disposal of the packaging materials .................................................................................... 12

5.04 Storage ................................................................................................................................ 12

6 Work Symbols ....................................................................................................................13

7 Operating Controls ............................................................................................................14

7.01 Main switch ........................................................................................................................ 14

7.02 Light barrier ..........................................................................................................................14

7.03 Stop button .......................................................................................................................... 15

7.04 Control panel ........................................................................................................................16

7.04.01 Symbols on the display ........................................................................................................ 17

7.04.02 Plus/minus keys ................................................................................................................... 17

7.04.03 Function keys ....................................................................................................................... 18

8 Set-up and Initial Commissioning ....................................................................................20

8.01 Set-up .................................................................................................................................. 20

8.01.01 Aligning the machine .......................................................................................................... 20

8.01.02 Mounting the reel stand ...................................................................................................... 21

8.02 Connecting the plug-in connections and ground cable ........................................................22

8.03 Initial start-up ....................................................................................................................... 23

8.04 Switching the machine on/off ............................................................................................. 23

Page 4

Table of Contents

Contents ..................................................................................................Page

9 Set-up .................................................................................................................................. 24

9.01 Inserting the needle ............................................................................................................. 24

9.02 Threading the needle / adjusting the needle thread ............................................................ 25

10 Input .................................................................................................................................... 26

10.01 Sewing – automatic mode ...................................................................................................27

10.02 Sewing – Unit with cutter and rack ......................................................................................28

10.03 Input mode .......................................................................................................................... 29

10.04 Input mode ..........................................................................................................................31

10.09 Parameter list ....................................................................................................................... 32

10.10 Error messages .................................................................................................................... 36

11 Maintenance and Care .......................................................................................................38

11.01 Maintenance intervals .......................................................................................................... 38

11.02 Cleaning the machine .......................................................................................................... 38

11.03 Checking / topping up the oil level of the oil tank for the front parts ................................... 39

11.04 Checking / topping up the oil level of the gear mechanism ................................................. 40

11.05 Checking / setting the air pressure ......................................................................................41

11.06 Emptying / cleaning the maintenance unit’s water tank ...................................................... 41

12 Wearing Parts .....................................................................................................................42

Page 5

Safety

1 Safety

1

.01 Directives

The machine was built in compliance with the European regulations specifi ed in the declara-

tion of conformity and declaration of incorporation.

As a supplement to this instruction manual, please also observe the generally applicable, le-

gal and other regulations and legislation – also in the country of use – and the valid environ-

mental protection regulations! Always comply with the locally applicable regulations of the

professional associations and other supervisory authorities!

1.02 General safety instructions

The machine may only be operated after you have become acquainted with the associ-

ated instruction manual and only by operating personnel who have received appropriate

training!

Always read the safety instructions and the instruction manual of the motor manufactur-

er before starting up the machine!

Always follow the hazard and safety instructions attached to the machine!

The machine may only be operated for its intended purpose and only with the associated

safety covers, while adhering to all the relevant safety requirements.

The machine must always be disconnected from the power supply by pressing the main

switch or pulling out the mains plug when sewing tools are replaced (such as the needle,

sewing foot, needle plate, feed dog etc.) and when threading, leaving the workstation, or

performing maintenance!

The daily maintenance work may only be carried out by suitably qualifi ed personnel!

Repairs and special maintenance work may only be carried out by technical staff or peo-

ple with appropriate training!

Unless otherwise stated, the machine must be isolated from the power supply and pneu-

matic supplies before any servicing work or repairs are performed! The only permitted

exceptions are for adjustment work and functional tests by appropriately trained techni-

cal staff!

Work on electrical equipment may only be carried out by qualifi ed technical staff!

Work on parts and equipment under voltage is not permitted!

Exceptions are regulated by the EN 50110 standards.

Modifi cations and changes to the machine may only be made in compliance with all of

the relevant safety requirements!

Only those replacement parts approved by us for usage may be used for repairs! We

warn you expressly that spare parts and accessories that are not supplied by us are also

not tested and approved by us.

Fitting or using these products may therefore have negative effects on features which

depend on the machine design. We are not liable for any damage caused by the use of

non-Pfaff parts.

5

Page 6

Safety

1.03 Safety symbols

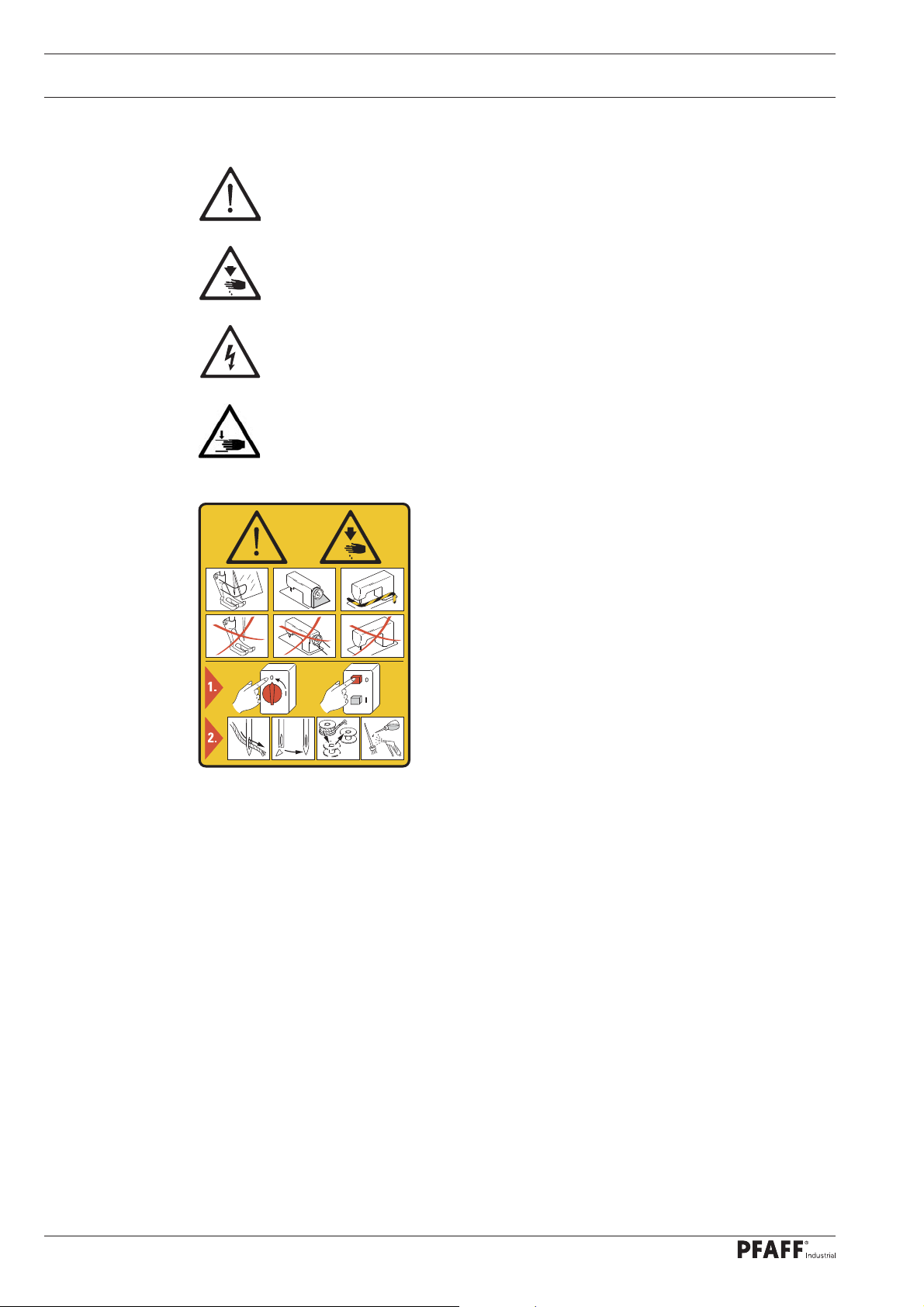

Hazard point!

Special points of attention.

Risk of injury to operating personnel or technical staff!

Electric voltage!

Danger to operating personnel or technical staff.

Danger of hands being crushed!

Caution!

Do not operate without fi nger guard and safety covers!

Turn off the main switch before threading, changing the

bobbin or needle, cleaning etc!

I

1.04 Special points of attention for the owner-operator

This instruction manual is a part of the machine and must be made available to the oper-

ating personnel at all times. The instruction manual must have been read before the ini-

tial start-up.

The operating personnel and technical staff must be instructed about the machine’s safe-

ty covers and about safe working methods.

The owner-operator may only operate the machine in a fl awless condition.

The owner-operator must ensure that no safety covers are removed or disabled.

The owner-operator must ensure that only authorised persons work on the machine.

Additional information can be requested from the responsible sales centre.

6

Page 7

Safety

1.05 Operating personnel and technical staff

1

.05.01 Operating personnel

Operating personnel are persons responsible for equipping, operating and cleaning the ma-

chine and for fault clearance in the sewing area.

The operating personnel are obligated to comply with the following points:

The safety instructions provided in the instruction manual must be followed for all work!

Any work method jeopardising machine safety must be refrained from!

Tight-fi tting clothing must be worn. The wearing of jewellery such as chains and rings is

prohibited!

Care must be taken to ensure that no unauthorised persons are located in the machine’s

hazard zone!

Any changes occurring on the machine which impair its safety must be reported to the

owner-operator immediately!

1.05.02 Technical staff

Technical staff are persons with technical training in electricity/electronics and mechanics.

They are responsible for lubricating, servicing, repairing and adjusting the machine.

The technical staff are obligated to comply with the following points:

The safety instructions provided in the instruction manual must be followed for all work!

Turn off the main switch before starting any adjustment or repair work and secure it

against reactivation!

Working on live parts and equipment is prohibited!

Exceptions are regulated by the EN 50110 standards.

Unless otherwise stated, the machine must be isolated from the power supply and pneu-

matic supplies before any servicing work or repairs are performed!

Exceptions are permitted solely for function tests.

Reattach the safety covers following repair and maintenance work!

7

Page 8

Safety

1.06 Danger warnings

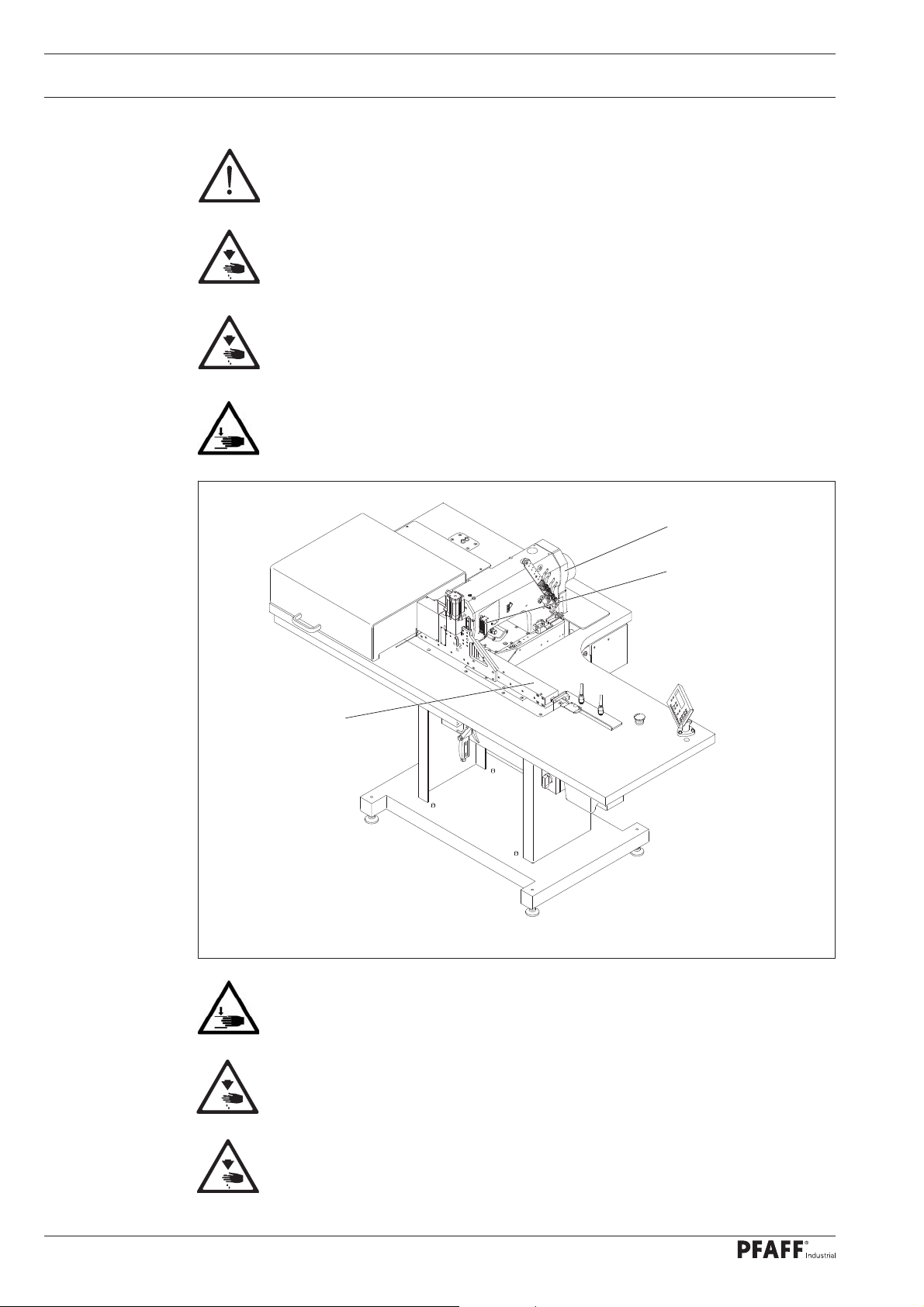

A work area of 1 m must be kept around the machine during operation to en-

sure unobstructed access at all times.

Do not reach into the needle range during the sewing operation!

Risk of injury from the needle!

Do not allow any objects to be placed on the table during the adjustment work!

The objects could become jammed or be slung away!

Risk of injury from parts fl ying around!

Danger of hands being crushed!

3

Fig. 1 - 01

2

1

Do not operate the machine without the protective cover 1!

Risk of injury from the feed band!

Do not operate the machine without the take-up lever guard 2!

Risk of injury due to movement of the take-up lever!

Do not operate the machine without the belt guard 3!

Risk of injury due to the rotating driving belt!

8

Page 9

2 Proper Use

The PFAFF 3538 is a sewing machine for effi ciently hemming pocket openings.

Proper Use

Any usage not approved by the manufacturer is deemed misuse! The manufac-

turer shall assume no liability for damage caused by misuse! Proper use also

includes compliance with the operating, maintenance, adjustment and repair

measures specifi ed by the manufacturer!

9

Page 10

Technical Data

3 Technical Data

3

.01 PFAFF 3538

Stitch type: ....................................................................................................... 401 (chainstitch)

Design B: ......................................................... for the machining of medium-weight materials

Design C: ...........................................................for the machining of medium-heavy materials

Needle thickness: ........................................................................................................ 80 – 140

Needle system: ................................................................................................................ 62x57

Thread thickness max. ........................................................................................................ 11/3

Speed max.: ................................................................................................. 4000 stitches/min.

Stitch length max: ..........................................................................................................4.5 mm

Noise data:

Noise emission level at workplace with a sewing speed of n = 2400 min-1: ...... LpA = 75 dB(A)

(Noise measurement in accordance with DIN 45 635-48-A-1,ISO 11204, ISO 3744,

ISO 4871)

Motor data: ................................................................................. see motor instruction manual

Air consumption per switching cycle: ...........................................................................0.146 Nl

Net weight of sewing head with stand: ............................................................. approx. 308 kg

Gross weight of sewing head with stand: ......................................................... approx. 521 kg

Subject to alterations

KpA = 2.5 dB

10

Page 11

Disposal of the Machine

4 Disposal of the Machine

It is up to the customer to dispose of the machine properly.

The materials used for the machine include steel, aluminium, brass and various plastics.

The electrical equipment consists of plastics and copper.

The machine must be disposed of in accordance with the locally valid environmental pro-

tection regulations, with a specialised company being contracted if necessary.

Please ensure that parts coated with lubricants are disposed of separately in ac-

cordance with the locally valid environmental protection regulations!

11

Page 12

Transport, Packaging and Storage

5 Transport, Packaging and Storage

5

.01 Transport to the customer’s premises

All machines are completely packed for delivery.

5.02 Transport within the customer’s premises

The manufacturer assumes no liability for transport within the customer’s premises or to

the individual usage sites. Please ensure that the machines are only transported in a vertical

position.

5.03 Disposal of the packaging materials

The packaging materials of these machines consists of paper, cardboard and VCI fl eece. It is

up to the customer to dispose of the packaging properly.

5.04 Storage

The machine can be stored for up to 6 months when not in use. It must then be protected

from dirt and moisture. For longer storage periods, the machine’s single components,

especially its sliding surfaces, must be protected against corrosion, e.g. by an oil fi lm.

12

Page 13

Work Symbols

6 Work Symbols

Activities to be performed or important information in this instruction manual are empha-

sised by symbols. The symbols used have the following meaning:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

13

Page 14

Operating Controls

7 Operating Controls

7

.01 Main switch

1

Turning the main switch 1 switches the

machine on and off.

Fig. 7 - 01

7.02 Light barrier

The LED in the light barrier indicates the

following status:

– LED lights up green = Reception indica-

tor (If there is no sewing material below

it).

– LED fl ashes green or yellow = Setting

aid/soiling indicator.

– LED lights up yellow = Output indicator

(if there is no sewing material below it).

14

Fig. 7 - 02

Page 15

Operating Controls

7.03 Stop button

Press the stop button:

Machine and feed band stop.

Release the stop button:

Press the F4 key on the control panel to

start the machine or insert new pocket

blanks.

1

Fig. 7 - 03

15

Page 16

Operating Controls

7.04 Control panel

The control panel is used to display and access machine functions for set-up and sewing, to

enter parameter values and to read error messages and service settings.

1

3500 1 3,5 2000

2

Fig. 7 - 04

F1

F2

F3

F4

0

0

0

0

0

0

The control panel has the following operating and display controls:

The display 1 comprises a two-line alphanumeric LCD display with 16 characters per line

and is used to display the corresponding information and selection parameters.

The plus/minus keys 2 are used for selecting or altering the functions and parameters

shown on the display.

The function keys 3 are used for turning the corresponding function on and off.

Switched-on functions are each indicated by the lit LED.

3

16

Page 17

Operating Controls

7.04.01 Symbols on the display

In addition to clear texts and set values, the following symbols appear on the display.

Symbol Function

Current program number

Piece counter

Speed

Stitch length

SD memory card

Machine memory

Enter

7.04.02 Plus/minus keys

The corresponding set values are selected and altered using the appropriate plus-minus

keys. At the same time the set value shown above is changed slowly at fi rst by pressing

and holding the corresponding plus or minus key. If the key is held pressed for longer, the

set value changes more quickly.

3500 1 3,5 2000

Fig. 7 - 05

F1

F2

F3

F4

0

0

0

0

0

0

Plus/minus keys

+

The displayed values can be increased or decreased using the respective key on the display

–

17

Page 18

Operating Controls

7.04.03 Function keys

If a function is on, this is always indicated by the correspondingly lit LED. Detailed explana-

tion of functions:

Thread machine

The sewing head is moved back so that the machine can be threaded.

The thread tension is opened when threading.

This key corresponds to number 1 when entering the code number.

Chain cutter on/off (with subclasses 2 and 3).

The chain is separated at the start and end of the pocket during the sewing operation.

This key corresponds to number 2 when entering the code number.

Stacker on/off (with subclass 3)

The sewn pockets are automatically stacked during the sewing operation if the cover of

the stacker is closed.

This key corresponds to number 3 when entering the code number.

Label feeder on/off (with subclass 4).

This key corresponds to number 4 when entering the code number.

Fill the unit

The unit is fi lled after pressing the key. FILL 3538 appears on the display.

Now pocket blanks must be fed in until the unit is completely fi lled. The unit is fi lled

when the length entered in parameter 503 is reached. If the unit is fi lled, it automatically

switched to the sewing operation.

This key corresponds to number 5 when entering the code number.

Sew until the unit is empty (with subclasses 2 and 3)

The unit sews until all pocket blanks are sewn after pressing the key.

EMPTY 3538 appears on the display. The unit automatically switches to ready for sewing

when the unit sews until it is empty.

This key corresponds to number 6 when entering the code number.

F1

F1 key

This key is reserved for special functions.

This key corresponds to number 7 when entering the code number.

18

F2

F3

F2 key

This key is reserved for special functions.

This key corresponds to number 8 when entering the code number.

F3 key

This key is reserved for special functions.

This key corresponds to number 9 when entering the code number.

Page 19

Operating Controls

F4

F4 key

The unit continues to sew after the "Remove fabric" message although there is still mate-

rial under the initial light barrier.

Scroll

If this key is pressed, the input menus on the display are scrolled through.

TE key

The machine changes from sewing mode to stitch input mode if this key is pressed.

Piece counter / counter

0

0

0

0

0

0

These keys can be used to switch between the piece counter and the counter. If the re-

spective function is switched on, a menu appears to set the counter to a preset, variable

value when pressing the key.

Coded via parameters 811 and 812.

The piece counter key corresponds to number 0 when entering the code number.

Separate chain (with subclasses 2 and 3)

The chain cutter is activated once after pressing the key.

Raise/lower band feed

This is raised if the band feed is lowered and lowered if the band feed is raised. Coded

via parameter 813.

Raise/lower presser foot

This is raised if the presser foot is lowered and lowered if the presser foot is raised. Coded via parameter 813.

Band feed forwards

The band feed moves forward while the key is pressed.

Coded via parameter 813.

Band feed backwards

If the band feed is raised, the band feed moves backwards while the key is pressed.

Coded via parameter 813.

19

Page 20

Set-up and Initial Commissioning

8 Set-up and Initial Commissioning

The machine may only be set up and started up by qualifi ed personnel! All of

the relevant safety regulations must always be complied with in this process!

Adequate stability of the stand must be guaranteed, even during the sewing

operations.

8.01 Set-up

Suitable electrical and pneumatic supply connections must be provided at the erection site,

see Chapter 3 Technical Data.

The erection site must have a fi rm and level subsurface and adequate lighting.

The table top is lowered for packaging purposes.

The adjustment of the table height is described below.

8.01.01 Aligning the machine

20

1

Fig. 8 - 01

Loosen the adjustable feet 1.

Align the machine horizontally by turning the levelling feet.

All four levelling feet must sit fi rmly on the ground.

Tighten the lock nuts on the levelling feet 1.

1

1

Page 21

8.01.02 Mounting the reel stand

Fig. 8 - 02

Set-up and Initial Commissioning

Assemble the reel stand as shown in

Fig. 8 - 02.

Then insert the stand into the hole in the

table top and secure it with the enclosed

nuts.

21

Page 22

Set-up and Initial Commissioning

8.02 Connecting the plug-in connections and ground cable

ACHTUNG

ATTENTION

Vertauschungsgefahr

Danger of exchange

SSI

X1/B

X11/B

Sollwertgeber

Ausgänge

Eingänge

X13

X5

RS 232/1

X1/A

CAN-BUS

X11/A

X15

Fadenwächter

Motor

X8

1

E

3

5

4

D

Fig. 8 - 03

SM1

X4/B

X4/A

2

SM2

X3

B

Insert all plugs on the control box 2 in accordance with their designation.

Insert the “motor” into the bushing X 3 and the bushing X 8.

Caution!

Plugging in the connector incorrectly can damage the control unit!

Attach the following ground cables in order to discharge static electricity:

Securely attach the ground cable from the sewing head 1 to ground point A.

Securely attach the ground cable from the control point 8 to ground point B.

Securely attach the ground cable from the main switch 3 to ground point C.

D

C

B

A

22

Securely attach the ground cable from the stand 4 to ground point D

Securely attach the ground cable 5 from the motor to ground point E

Page 23

8.03 Initial start-up

Set-up and Initial Commissioning

Inspect the machine and in particular the

electric lines and pneumatic connecting

hoses for possible damage.

Remove the stopper 1 from the oil tank

2

1

2. The stopper serves solely for transit

support and may not be used during the

sewing operations.

Clean the machine thoroughly and then

oil it, see Chapter 10 Maintenance and

Care.

Have technical staff check whether the

machine’s motor may be operated at the

existing mains voltage.

Fig. 8 - 04

Never operate the machine if there are any differences.

Before the initial commissioning, have technical staff verify that parameter 201

(machine class) is set to “1”.

The machine must only be connected to a grounded socket!

Connect the machine to the compressed air system. The manometer should display a

pressure of around 6 bar. Set this value, if possible (see Chapter 10.04 Monitoring/adjust-

ing air pressure).

8.04 Switching the machine on/off

Switch the machine on, see Chapter 7.01 Main switch.

23

Page 24

Set-up

9 Set-up

9.01 Inserting the needle

Observe and comply with all regulations and instructions in this instruction

manual.

Pay particular attention to all safety regulations!

All set-up work may only be carried out by appropriately instructed personnel.

Disconnect the machine from the electricity mains for all set-up work by operat-

ing the main switch or by removing the mains plug!

Switch off the machine!

Risk of injury due to accidental

machine start-up!

Only use needles of the system

intended for the machine, see

Chapter 3 Technical Data!

2

Fig. 9 - 01

Approach the thread-in position (see

1

1

2

P. 18)

Bring the needle bar to the top position

and loosen screw 1.

Insert needle 2 up to the stop (while do-

ing so, the long needle groove must

point to the right).

Tighten the screws 1.

24

Page 25

Set-up

9.02 Threading the needle / adjusting the needle thread

1

Fig. 9 - 02

Switch off the machine!

Risk of injury due to accidental machine start-up!

Thread the needle as shown in Fig. 9-02.

Adjust the needle thread tension by turning the knurled thumb screw 1.

25

Page 26

Input

10 Input

3500 1 3,5 2000

F4

0

0

0

0

0

0

F1

Fig. 10 - 01

F2

F3

The following appear on the display (from the left):

Max. speed (e.g. 3500 revolutions per minute), it can be changed using the correspond-

ing plus/minus key. Coded via parameter 809.

Stitch length (e.g. 3.5 mm), it can be changed using the corresponding plus/minus key.

The electronically set stitch length here must be identical to the mechanically set stitch

length on the sewing head.

The following procedure should be observed to set the stitch length:

1. Set the mechanical stitch length on the sewing head.

2. Enter the electronic stitch length.

3. Feed in the pocket blank(s) and check the stitch quality.

4. Change the mechanical and/or electronic stitch length if the sewn pocket blank

is too fl at. Coded via parameter 810.

Piece counter or counter (e.g. 20000). Coded via parameters 811 and 812.

26

The function of the other keys is explained in the “Operating Controls” chapter. The sewing

cycle is started by inserting pocket blanks.

ERROR 6 appears if the sewing head is not in the sewing position after switch-

ing on the unit. The outputs to raise the band feed and move the sewing head

are not switched on (valves stay depressurised) and the user must manually

move the sewing head to the sewing position.

Page 27

Input

10.01 Sewing – automatic mode

The following work steps assume that the sewing preparations listed in the

“Set-up” chapter have been carried out thoroughly and the machine has been

programmed according to the order.

Turn on the machine at the main switch and wait for it to be ready for operation.

Press the presser foot key and raise the presser foot.

Lay the top edge of the pocket blank at the stop.

Slide the pocket blank to the left under the Plexiglas cover.

Light barrier detects the start of the pocket blank.

Feed band takes hold of the pocket blank.

Feed band moves the pocket blank to the left into the pleating attachment.

Pleating attachment folds over the top edge.

Feed band moves the folded pocket blank into the sewing position.

Top edge seam is sewn.

Pocket blank is transported out of the sewing area.

The following keys are switched on in automatic mode, see Fig. 10-02

3500 1 3,5 2000

F1

F2

F3

F4

0

0

0

0

0

0

Fig. 10 - 02

27

Page 28

Input

10.02 Sewing – Unit with cutter and rack

In contrast to the basic machine described in 10.01, the “Plus” machine sepa-

rates the pocket blanks after hemming with a cutter. An integrated extraction

device removes the loose threads during the cutting process and collects them

in a container under the work table. The individual pocket blanks are automati-

cally fanned out with an automatic racking device and placed on a round table.

Turn on the machine at the main switch and wait for it to be ready for operation.

Press the presser foot key and raise the presser foot.

Lay the top edge of the pocket blank at the stop.

Slide the pocket blank to the left under the Plexiglas cover.

Light barrier detects the start of the pocket blank.

Feed band moves the pocket blank to the left into the pleating attachment.

Pleating attachment folds over the top edge.

Feed band moves the folded pocket blank into the sewing position.

Top edge seam is sewn.

Pocket blank is transported out of the sewing area.

Light barrier triggers the “Cutting” process.

Pneumatically operated blade separates the continuing seam.

Feed band transports the pocket blank to the rack.

Rack moves back and opens the passage downwards.

Pocket blank falls down onto the round table.

Pneumatic cylinder switches the round table one step further.

Rack moves forward and closes the passage.

Unit is ready for the next pocket blank.

The blanks can be removed when the round table is full.

28

Page 29

Input

10.03 Input mode

Select the function group

No

500

F4

0

0

0

0

0

0

F1

Fig. 10 - 03

F2

F3

The desired function group must be selected using the allocated plus/minus key after chang-

ing to input mode.

Select the function group or function with the corresponding plus/minus key.

+

The upper key is + and the lower key is -.

–

The selected function group is taken over by pressing the plus/minus key under the En-

ter symbol and the machine jumps to the “Enter parameter” status after entering the code.

This display does not appear if the access code has already been entered or the function

group is not code protected.

If the TE key is pressed, the machine changes to production mode (LED off).

29

Page 30

Input

The following function groups are available:

Group Function Access rights (factory setting)

100 Operator level free

200 Mechanic level coded

300 Sewing drive positions coded

400 Times coded

500 Counter and speeds coded

600 Service coded

700 Sewing motor coded

800 Access rights coded

Access rights for the individual function groups and for the functions accessible via the keys

can be changed in the function group 800. The access code for coded functions can also be

changed (status on delivery: 3819). Coded functions can only be accessed after entering the

code. Specifi c keys as interpreted as numeric keys for input purposes (see the “Operating

Controls” chapter).

30

Page 31

Input

10.04 Input mode

Enter parameters

No

505

Fig. 10 - 04

VAL

16,4

F1

F2

F3

0

0

0

The display shows the selected parameter number on the left and the associated parameter value further to the right. Parameter 505, the clearance from the chain cutter sensor to

the chain cutter has been selected in the example above. The displayed parameter value is

16.4 mm.

The values above can be changed using the plus/minus keys. The parameter values are tak-

+

en over by advancing to another parameter number.

–

F4

0

0

0

If the TE key is pressed, the values are also taken over and the machine switches to sewing

mode.

31

Page 32

Input

10.09 Parameter list

Function group 100: Operator level

101 Display software version (0437/xxx)

102 Display motor control software version

103 Key beeper (I = OFF, II = ON)

104 Needle thread monitor (I = OFF, II = ON)

105 Bobbin thread monitor (I = OFF, II = ON)

106 Display serial number of machine

Function group 200: Mechanic level

201 Subclass(x)

202 Label feeder attached (I = OFF, II = ON)

203 Band feed acceleration (200; 50 – 999)

204 Band feed braking (250; 50 – 999)

205 Maximum stitch length when sewing in 1/10 mm

206 Switching frequency from fi ne step to full step

(2,3)

207

1: 3538-1/01 (Basic)

2: 3538-1/02 (with chain cutter)

3: 3538-1/03 (with chain cutter and stacker)

(4.0; 2.0 – 8.0)

(375; 0 – 2000)

Automatic extraction (I = OFF, II = ON)

Function group 300: Positions

301

302

303

Reference position (needle at top edge of needle plate)

Position of cover-thread carrier t.d.c. (153, 0 – 191)

Position of needle at bottom position (81, 0 – 191)

Function group 400: Times (0.01 – 2.00 s)

401 Holdoff time after initial light barrier (0.01 s)

402 Switching time for needle head to move to thread-in

position (A7) (1.00 s)

403 Wait period after sensor when sewing head in sewing

position (A7) (0.10 s)

404 Switching time to raise/lower band feed (A6) (0.85 s)

405 Switching time of presser foot upwards (A10)

(0.20 s)

406 Switching time of presser foot downwards (A10)

(0.20 s)

407 Needle thread monitor hide stitches (3, 0 – 9)

408 Bobbin thread monitor hide stitches (3, 0 – 9)

(2,3)

409

Chain cutter switch-on time (A8) (0.01 s)

32

Page 33

Input

(2,3)

410

411

412

413

414

415

416

417

418

(3)

(3)

(3)

(3)

(3)

(3)

(3)

(3)

Chain cutter travel time downwards (A8) (0.01 s)

Switching time of stacker downwards (A12) (0.01 s)

Switching time of stacker upwards (A12) (0.01 s)

Switching time of stacker to the right (A13) (0.01 s)

Switching time of stacker to the left (A13) (0.19 s)

Switching time to open stacker (A14) (0.28 s)

Switching time to close stacker (A14) (0.17 s)

Switching time to turn stacker (A4) (0.01 s)

Switching time to hold pocket (A3) (0.01 s)

Function group 500: Counter, speeds and clearances

501 Soft start stitches (0; 0-15) soft start speed (1500; 0 –

4500 rpm)

502 Stop clearance (55.0; 0 – 999.9)

503 Length when fi lling machine (370; 0 – 9999)

504 Speed of band feed in a manual process (like a sewing

head speed with a stitch length of 4 mm)

(2000, 10 – 4000)

(2.3)

505

Clearance of chain cutter sensor to the chain cutter

(16.4; 0 – 999.9)

(2.3)

506

Clearance of start of pocket to the chain cutter

(3.0; 0 – 999.9)

(2.3)

507

Clearance of end of pocket to the chain cutter

(3.0; 0 – 999.9)

(3)

508

Clearance of stacker sensor to the stacker

(90.0; 0 – 999.9)

Function group 600: Service

601 Band feed stepping motor process (X: individual steps,

XX: continuously forwards or backwards while the key

is pressed)

602 Inputs: 0123456789ABCDEF

0: free (E1 – X5.1)

1: free (E2 – X5.2)

2: free (E3 – X5.3)

3: free (E4 – X5.4)

4: free (E5 – X5.5)

5: free (E6 – X5.14)

6: free (E7 – X5.15)

7: Needle thread monitor (option) (E8 – X5.16)

8: Bobbin thread monitor (option) (E9 – X5.9)

33

Page 34

Input

9: Stacker cover (E10 – X5.10) (3)

A: Feed band stop (E11 – X5:11)

B: Stop switch (break contact) (E12 – X5.12)

C: Sewing head in sewing position (E13 – X5.13)

D: Stacker light barrier (E14 – X5.8) (3)

E: Chain cutter light barrier (E15 – X5.6) (2.3)

F: Initial light barrier (E16 – X5.7)

603 Outputs:

1: free (X13.1 and X13.2)

2: free (X13.3 and X13.4)

3: Presser foot (X13.5) ( 1: top, 0: bottom)

4: Raise band feed (X13.6) (1: top)

5: Lower band feed (X13.7) (1: bottom)

6: Sewing head sewing position (X13.8)

7: Sewing head thread-in position (X13.9)

8: Open thread tension (X13.10)

9: Extraction (X13.11) ( 1: on, 0: off) (2.3)

10: Stacker left/right (X13.12) ( 1: left, 0: right) (3)

11: Stacker down (X13.13) ( 1: bottom, 0: top) (3)

12: Open stacker (X13.25) ( 1: open, 0: closed) (3)

13: Hold pocket (X13.24) (3)

14: Turn stacker (X13.16) (3)

15: Chain cutter (X13.17) ( 1: on, 0: off) (2,3)

16: Sewing motor running (X13.18) ( 1: running, 0: at a

standstill)

604 Turn sewing motor in sewing direction

605 Run cold start

3

606

Run stacking process

34

Function group 700: Sewing motor

701 P-section speed regulator (10)

702 I-section speed regulator (50)

703 P-section position controller (20)

704 D-section position controller (30)

705 Time for position controller (25)

706 P-section position controller for rest brake (25)

707 D-section position controller for rest brake (15)

708 Maximum torque for rest brake (0)

709 Minimum machine speed (6)

710 Maximum machine speed (4500)

Page 35

Input

711 Maximum motor speed (68)

712 Positioning speed (25)

713 Acceleration ramp (35)

714 Braking ramp (30)

715 Reference position (43)

716 Dead man time (40)

717 Motor starting current (7)

718 Anti-rank fi lter (3)

719 Rotation direction assignment (1)

720 Positioning technique

(1 – time-optimised; 2 – path-optimised)

Function group 800: Access rights

801 Access rights for function group 100*

802 Access rights for function group 200*

803 Access rights for function group 300*

804 Access rights for function group 400*

805 Access rights for function group 500*

806 Access rights for function group 600*

807 Access rights for function group 700*

808 Access rights for function group 800*

809 Access rights for maximum key speed*

810 Access rights for stitch length keys*

811 Access rights for piece counter key*

812 Access rights for counter key*

813 Access rights for direct functions* (band forwards, band

backwards, raise band, presser foot up/down and chain

cutter)

821 Enter access code (in status on delivery: 3538)

* 0 – free, 1 – blocked with a code

35

Page 36

Error

10.10 Error messages

Error code Description

Error 1 System error

Error 2 Sewing motor ERROR 2/BB/xxx

BB = 20: Deadman

xxx = sewing motor control

unit error (see Motor errors)

Error 3 Ramp memory too small

Error 4 free

Error 5 Stacker not ready(3)

Error 6 Sewing head sewing position/thread-in position

Error 7 Stepping motor movement

Error 8 Needle thread monitor

Error 9 Bobbin thread monitor

Error 11 Stepping motor step frequency too high

Error 21 Power supply unit overloaded (24 V)

Error 22 Mains voltage

Error 23 Power supply 24 V too low

10: Speed

0B: StopX

0A: Reset stitch counter

09: Write parameters

05: Position t.d.c. by shortest route

03: Position t.d.c. in reverse

02: Position t.d.c. forwards

30: Timeout for increasing speed

31: Timeout from uncertain positioning

32: Timeout from deadman command

33: Timeout for deleting errors

34: Timeout for emergency stop

35: Timeout for writing parameters

36: Timeout for resetting stitch counter

37: Timeout for stop command after x stitches

38: Timeout for initialisation

39: Establishing contact when turned on

(sensor monitoring)

1. Ramp X not ready

2. Ramp Y not ready

3. Time monitoring

36

Page 37

Error

Motor errors

Error code Description

33 Invalid parameter value

35 Communication error

36 Init. not ready

37 Command overrun

64 Mains off during initialisation

65 Excess current directly after mains on

66 Short circuit

68 Excess current during operation

70 Motor blocked

71 No incremental plug

74 Incremental encoder missing for transmission/

reduction

173 Motor blocked in 1st stitch

175 Internal starting error

222 Dead man monitoring

3737

Page 38

Maintenance and Care

11 Maintenance and Care

11

.01 Maintenance intervals

Cleaning the hook area .............................daily, several times during continuous operation

Cleaning the complete machine ............................................................................... weekly

Machine oil level .................................................................................. daily, before start-up

Checking / setting the air pressure ...................................................................... as needed

Cleaning the maintenance unit air fi lter ............................................................... as needed

These maintenance intervals are based on an average running time of a single

shift production shop. Shorter maintenance intervals are recommended for in-

creased running times.

11.02 Cleaning the machine

The required cleaning cycle for the machine depends on the following factors:

Single or multi-shift operation

Dust formation caused by the workpieces

Optimal cleaning instructions can therefore only be determined on a case-by-case basis.

Disconnect the machine from the electricity mains for all cleaning work by shut-

ting off the main switch or removing the mains plug! Risk of injury due to acci-

dental machine start-up!

The following tasks are recommended during a single shift operation to avoid operational er-

rors:

Open the hook area cover.

Clean the hook area daily, more frequently during continuous operation.

Close the gripper area cover!

Only operate the machine when the hook room cover is closed!

Risk of injury due to moving parts!

38

Page 39

Maintenance and Care

11.03 Checking / topping up the oil level of the oil tank for the front parts

2

max.

min.

1

Fig. 11 - 01

Check the oil level before every start-up.

The oil level must not drop below the “min.” marking or rise above the “max.”

marking.

The oil level must always be visible in the sight glass 1.

Add oil to the container through the hole 2 as needed

Only use oil with a centre viscosity of 22.0 mm

0.865 g/cm3 at 15 °C.

We recommend PFAFF sewing machine oil part no. 280-1-120 144.

2

/s at 40 °C and a density of

39

Page 40

Maintenance and Care

11.04 Checking / topping up the oil level of the gear mechanism

Fig. 11 - 02

2

1

Switch off the machine!

Risk of injury due to accidental machine start-up!

Open the side cover and check the oil level before every machine start-up.

The oil level must always be visible in the sight glass 1 (if no air bubble is visi-

ble, then the oil level is too high.)

Remove the screw 2 as needed and add only enough oil for an air bubble to remain

visible.

Replace the screw 2.

Only use oil with a centre viscosity of 22.0 mm

0.865 g/cm3 at 15 °C.

2

/s at 40 °C and a density of

40

We recommend PFAFF sewing machine oil part no. 280-1-120 144.

Page 41

Maintenance and Care

11.05 Checking / setting the air pressure

Check the air pressure on the manome-

2

ter 1 before every start-up.

The manometer 1 must show a pressure

of 6 bar.

Adjust this value if needed.

Pull up the button 2 for this and turn it

out of position accordingly.

1

Fig. 11 - 03

11.06 Emptying / cleaning the maintenance unit’s water tank

Switch the machine off.

Detach the compressed air

tube on the maintenance unit.

Empty the water tank

The water tank 1 empties itself auto-

matically after the compressed air tube

for the maintenance unit has been removed.

Clean the fi lter

2

Unscrew the water tank 1 and take out

the fi lter 2.

Clean the fi lter with compressed air or

1

Fig. 11 - 04

isopropyl alcohol, part number 95-665

735-91.

Screw in the fi lter 2 and screw on the

water tank 1.

41

Page 42

Wearing Parts

12 Wearing Parts

11-173 174-15

This list shows the most important wearing parts.

A detailed parts list for the complete machine can be downloaded at www.

pfaff-industrial.de/de/service-support/downloads/technical. As an

alternative to the Internet download, the parts list can also be requested as a

hard copy under order no. 296-12-19 292.

11-108 171-15 (2x)

91-264 154-25 (2x)

11-108 171-15 (2x)

11-174 089-15

11-174 089-15 (4x)

System 62 x 57

11-174 173-25

11-330 082-15 (2x)

91-172 843-05 (2x)

91-000 250-15

42

95-353 031-05

95-353 171-05 (4x)

95-353 030-05

91-293 154-91 (XB1)

91-293 155-91 (XB5)

91-293 156-91(XB6)

91-293 157-91(XB7)

91-292 930-91(XB8)

91-292 934-91

Page 43

Notes

Page 44

PFAFF Industriesysteme

und Maschinen GmbH

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Telefon: +49 - 6301 3205 - 0

Telefax: +49 - 6301 3205 - 1386

E-mail: info@pfaff-industrial.com

Gedruckt in der BRD / Printed in Germany / Imprimé en la R.F.A. / Impreso en la R.F.A

© PFAFF is the exclusive trademark of VSM Group AB I PFAFF Industriesysteme und Maschinen GmbH is an authorized licensee of the PFAFF trademark.

Loading...

Loading...