Page 1

fPSPD

Instrucrion

Pf

af

Manual

f

3518

PFAFF

INDUSTRIEMASCHINEN

GMBH

KAISERSLAUTERN

Printed

in

Germany

Page 2

Foreword

Pf&Ff

according

some

deviations

mainly

system.

For

this

electrical

the

machine

To

meet

variants,

We

have

a

standard

pocket

the

instruction

automatic

to

to

be

reason

control

certain

but

therefore

service

setter

a

found

they

these

as

customer's

pocket

from

the

box

are

requirements

the

in

the

circuit

supplied

are

setters

of

concentrated

manual

possible.

book

for

are

special

standard

wishes

version.

electro-pneumatic

diagrams

each

machine.

with

there

on

a

somewhat

our

which

For

the

^63

covers

the

and

often

are

only.

are

also

smaller

efforts

as

sewing

the

manufactured

which

These

control

included

They

apply

mechanical

on

many

scale.

compiling

types

machine

service

involve

are

in

to

itself

manual

the

of

for

subclass

publications

because

differs

Should

with

Pfaff

the

slightly

you

the

agency

sewing

have

help

-9OO

only

of

apply

machine

from

any

of

the

responsible

the

kGO

to

the

normal

difficulties

service

for

series

a

certain

fitted

manual

your

Pfaff

may

be

extent,

to

the

Pfaff

Pfaff

which

463,

cannot

please

area.

Industriemaschinen

Kaiserslautern

used.

however,

be

refer

These

35l8

remedied

to,the

GmbH

Page 3

1.

.Introduction

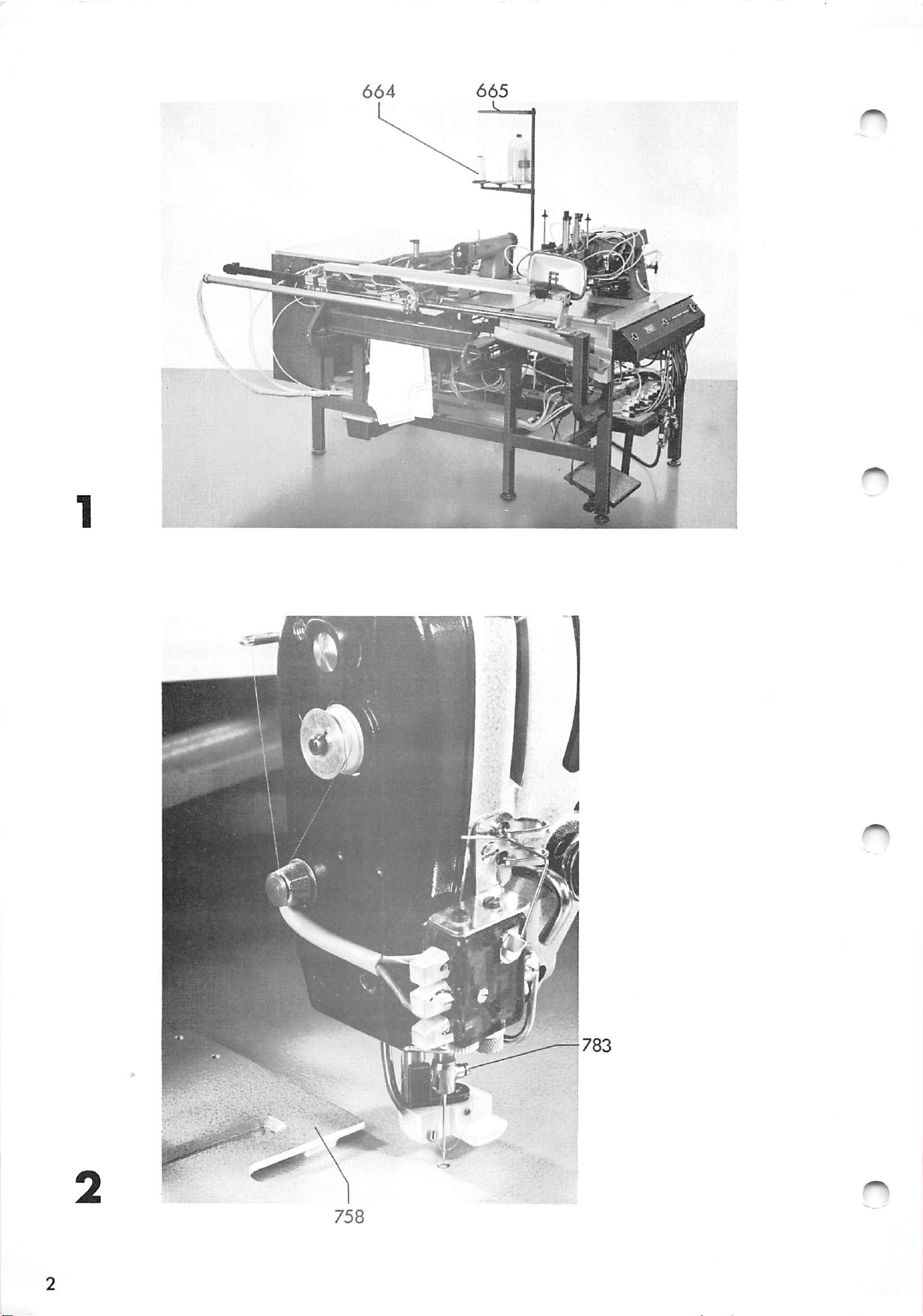

The

with

for

automatic

a

folding

function

date

most

coming

can

only

double-twist

end

of

the

by

condensed

are

possible.

This

instructions

normally

The

with

section

best

the

lockstitch

and

of

the

ofi

into

be

carried

seam

included

means

machine

pocket

sewing

machine

the

use.

thread

are

stitches.

of'.the

and

those

of

setter

sewing

pocket

This

out

is

used.

secured

Various

manual

for

in

the

becoming

is

to

machine,

on

pockets.

are

styles

type

to

operator's

actujiTly

(Fig,

designed

and

of

sewing

satisfaction

The

both

types

contains

the

maintenance

fully

1)

is

ahdiis

The

to

fabrics

operation

beginning

by

a

tack

of

the

work.

conversant

carry

equipped

used

size

accommo

when

and

and

tack

operating

items

out

and

a

the

instructions

sequence.

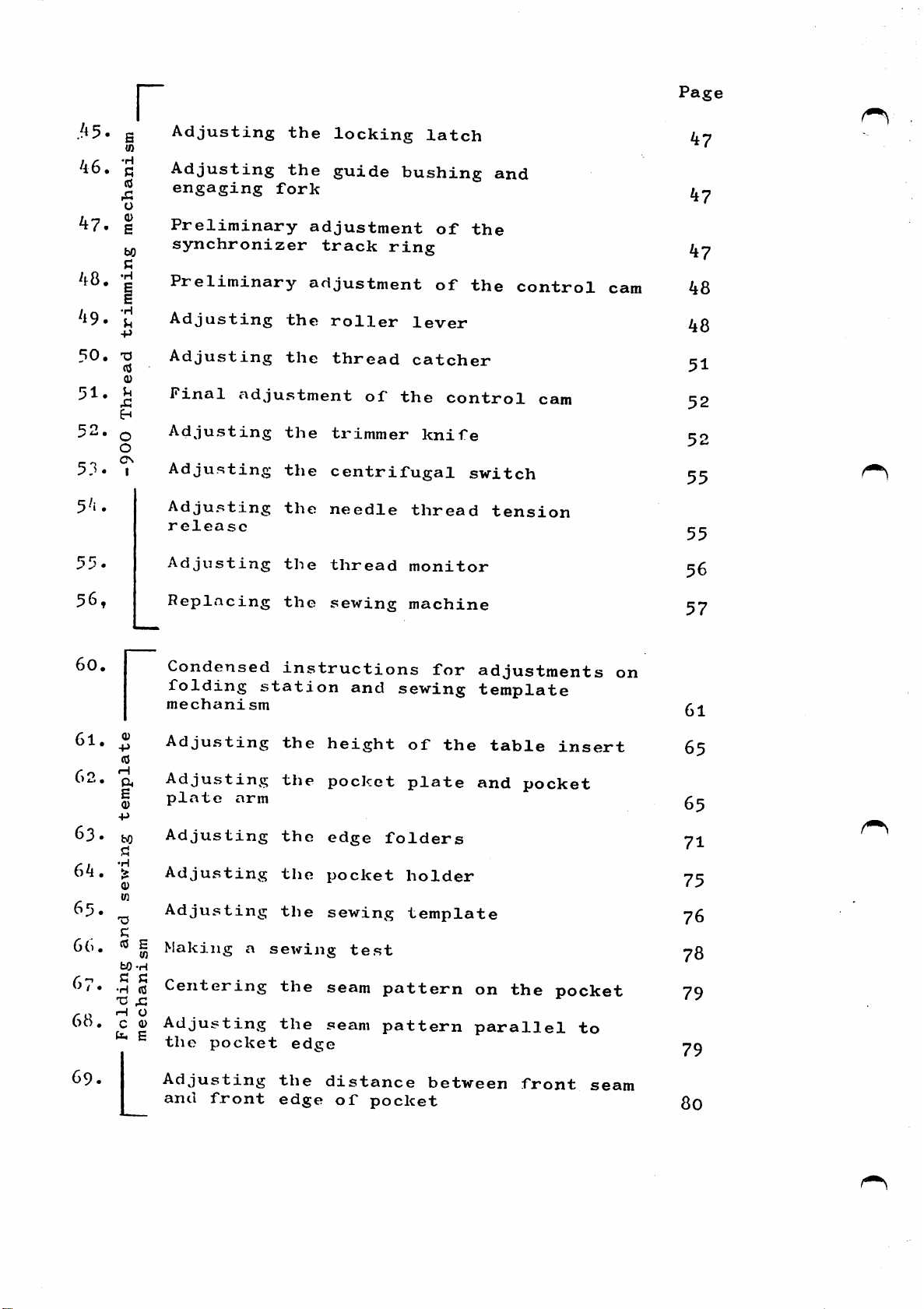

Inserting

The

are

needles

system

sizes

stipulated

Bring

loosen

Push

and

in

turn

template

Re-tighten

80

the

screw

and

the

it

758*

the

to

l^k

needle

needle

new

so

screw

needle

be

needles

90-

783

that

of

used

For

must,

bar

and

needle

783*

each

(Fig,

each

to

remove

the

paragraph

in

the

(e,g,

material

be

the

as

far

long

2)

used.

top

the

sewing

13^

of

needle.

as

groove

R,

it

in

machine

13^

sewn,

its

will

faces

the

kK)

stroke,

given

the

go,

Page 4

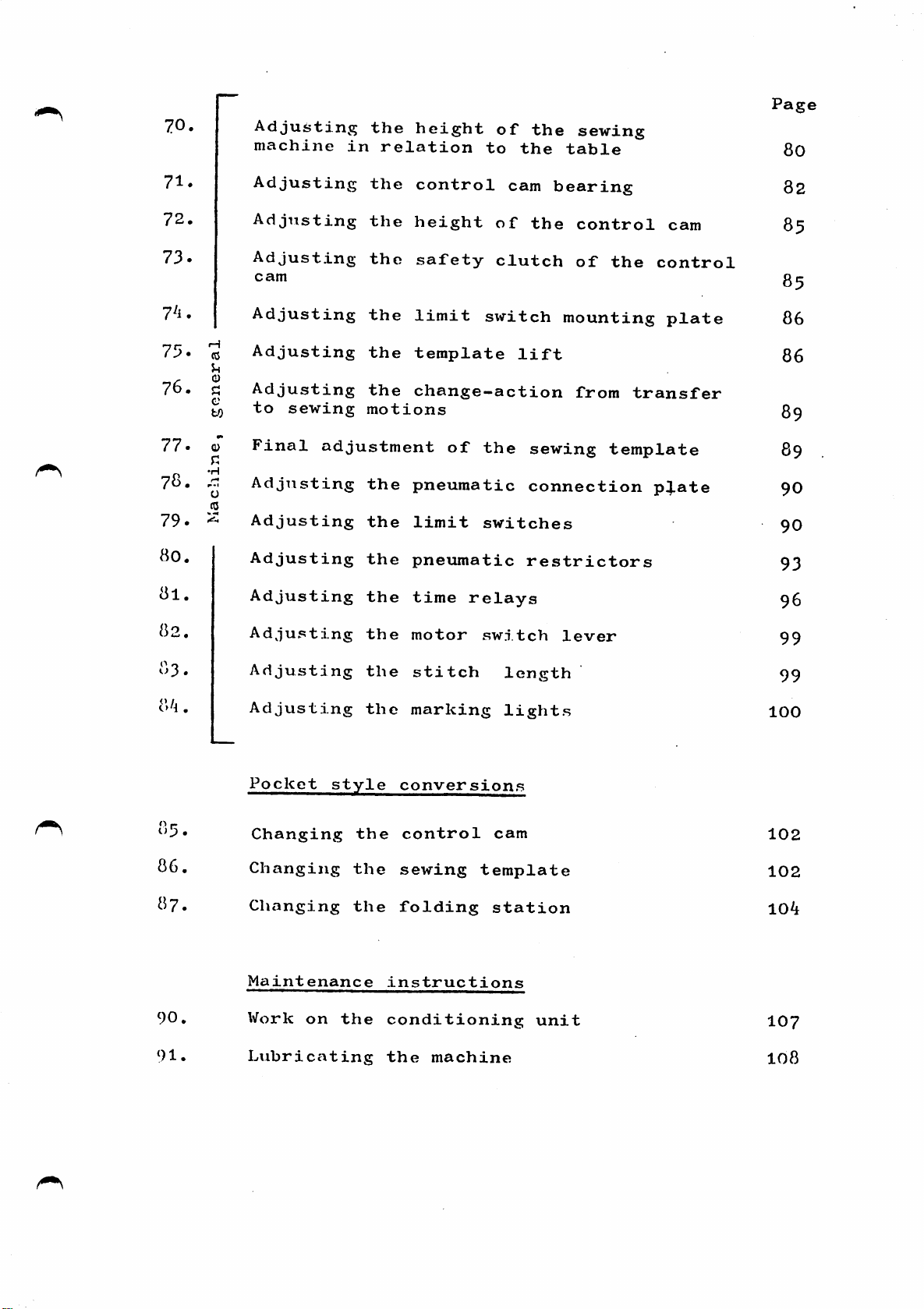

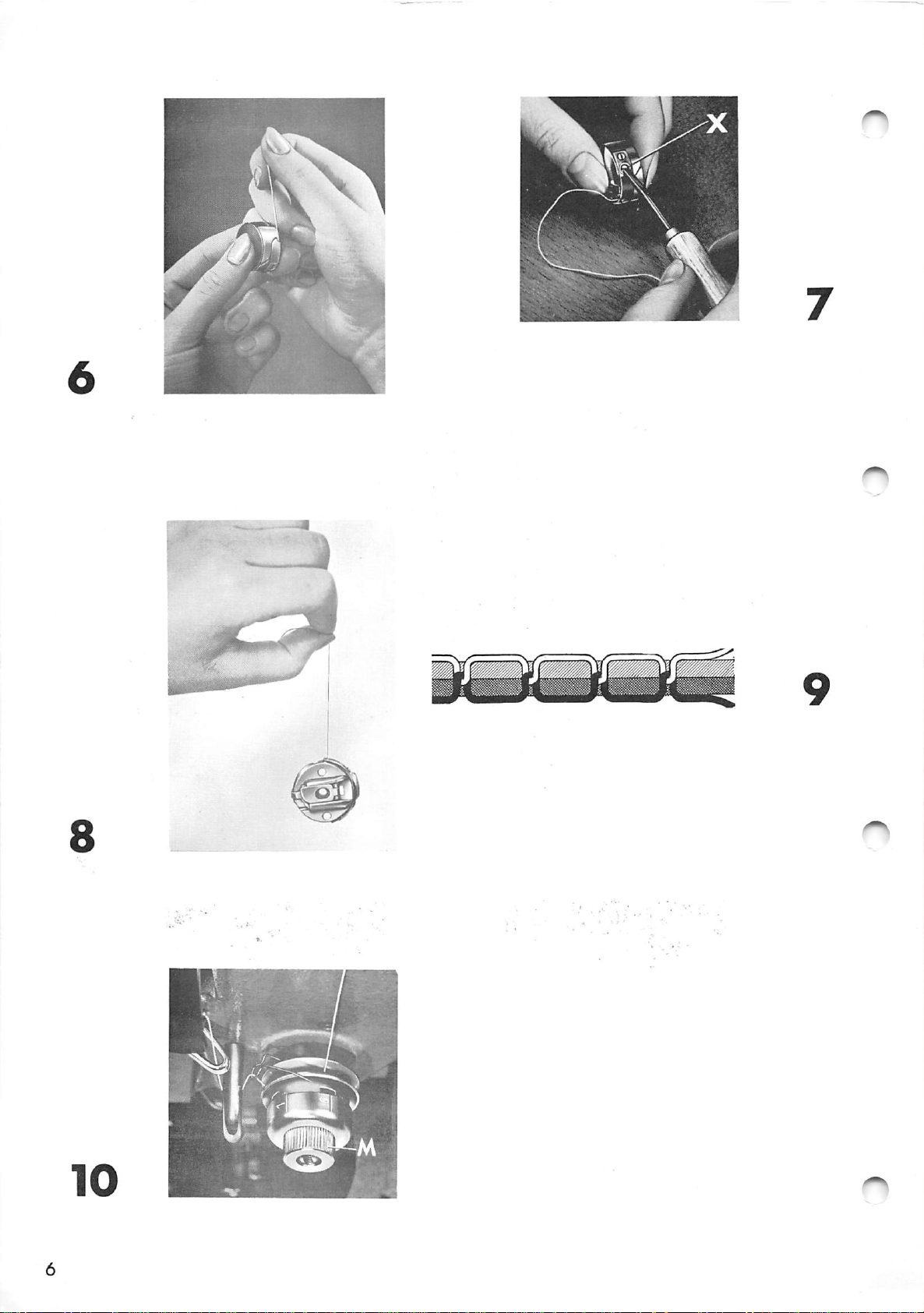

3•

'Threading

the

needle

thread

(Fig.

3)

3.1

Threading

Take

of

the

in

Fig.

of

guide

668

from

guide

of

the

the

thread

wire

thread

needle

Pull

the

needle

machine

the

holes

670

take-up

629

through

from

about

for

thread

1)

667»

below,

and

of

begins

the

in

and

through

Pull

though

lever

through

the

guide

the

3

inches

so

that

sewing.

first

from

the

over

thread

left.

top

the

eye

of

it

time

reel

thread

pin

thread

thread

eye

from

67I

monitor.

672,

thread

does

664,

666

671»

the

so

and

not

between

check

then

right.

that

through

through

pass

guide

to

the

spring

Finally,

unthread

it

through

bracket

three

tension

through

From

it

is

the

the

669i

held

pass

when

holes

the

here,

eye

eye

(665

discs

under

by

the

of

of

the

one

eye

3ead

the

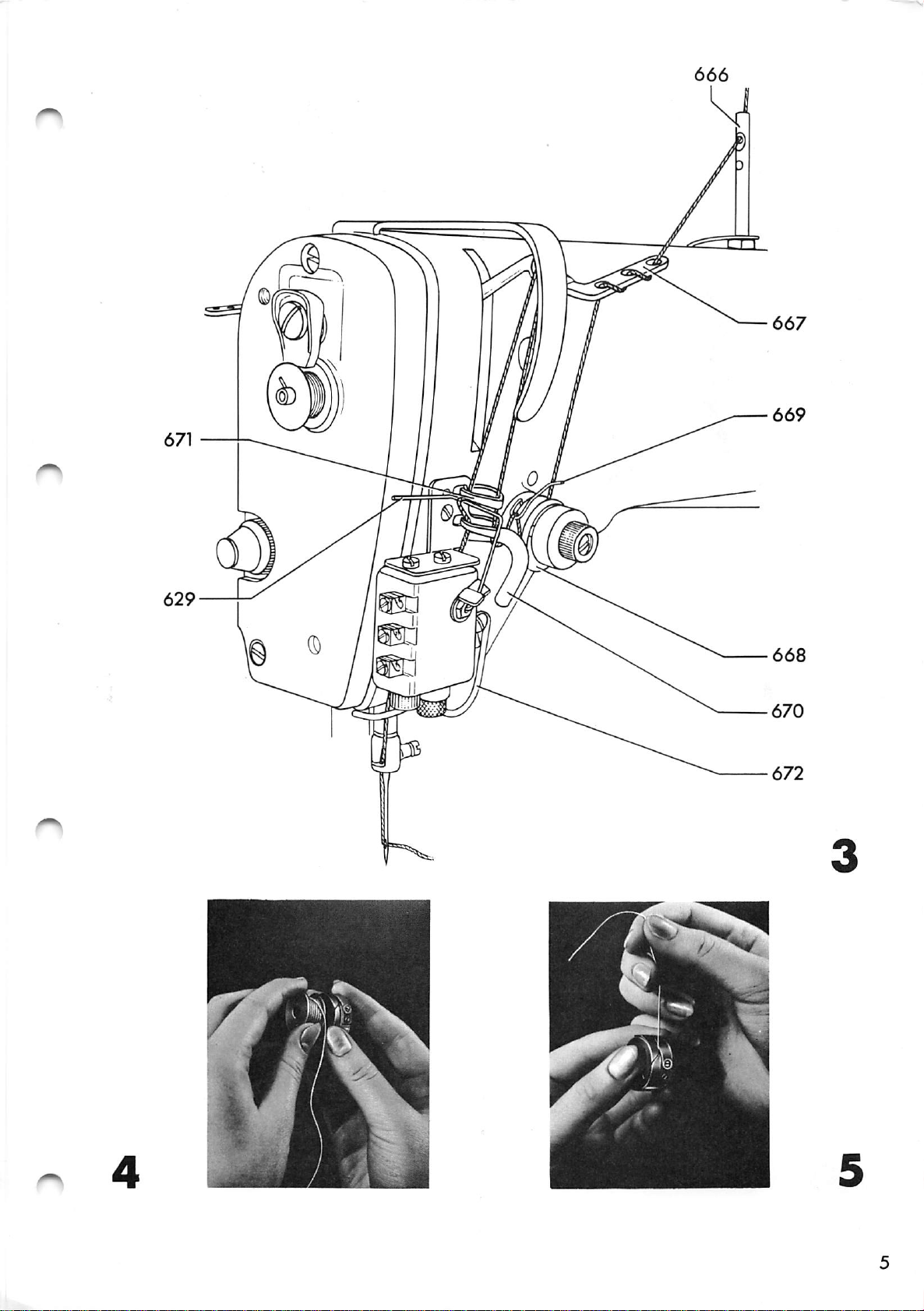

3.2

4.

Thread

Pull

close

old

new

the

sewing

thread

the

to

thread

reel

new

area.

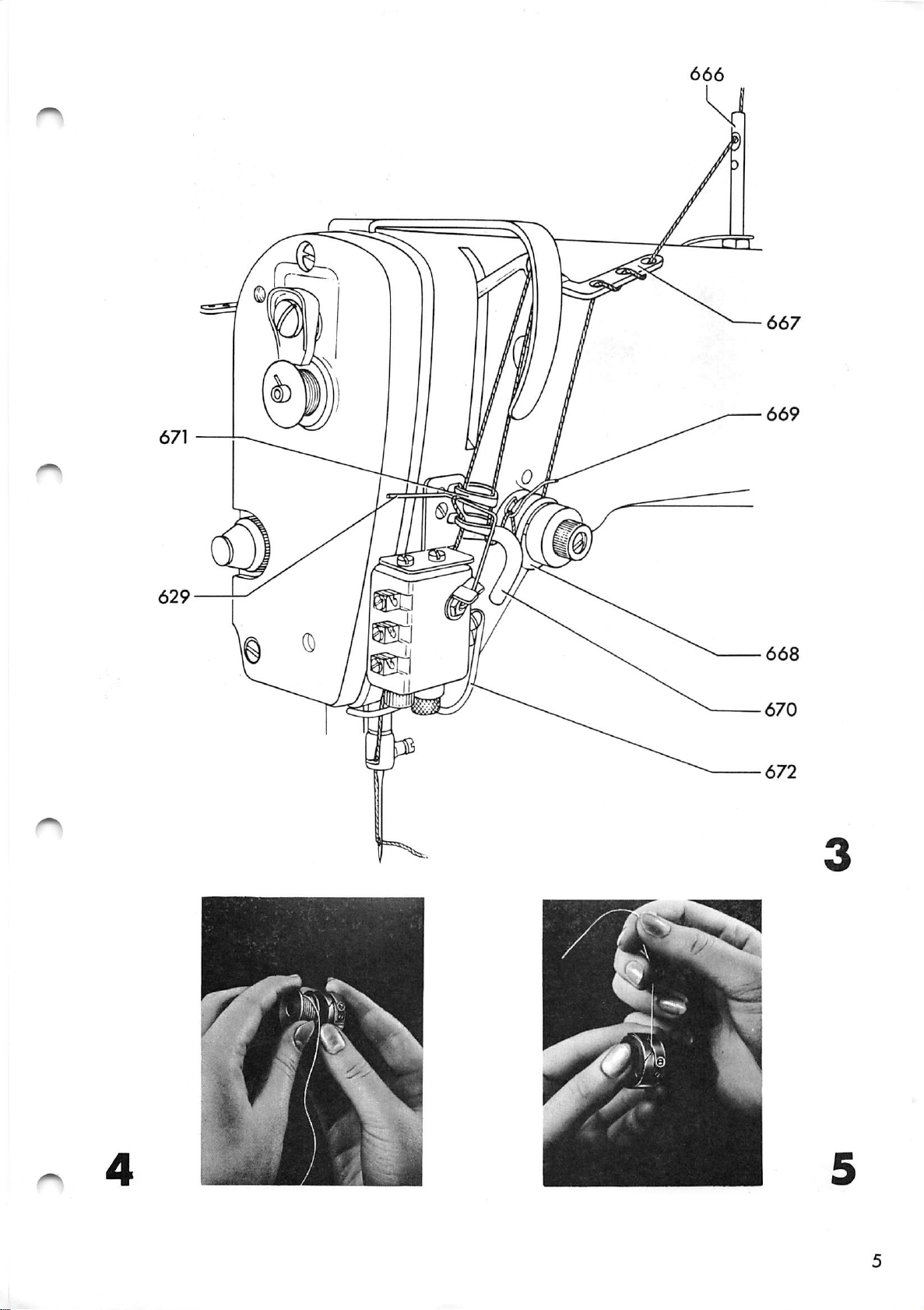

Threading

Insert

clockwise

Pull

tension

Adjust

the

the

the

changing

old

the

on

one

the

the

when

thread

spring

thread

reel

to

the

the

has

Cut

needle.

bobbin

bobbin

tension

stand,

passed

the

the

through

(Figs.

out

on

end

in

thread

by

of

the

of

and

through

end

of

thread

its

case

the

5

and

turning

the

stand.

the

pull

is

6)

needle

new

the

the

(Figs.

so

pulled

slot

screw

Tie

thread,

the

new

that

and

eye

this

old

machine

thread

4,

3^6,

it

(Fig.

under

"X"

and

end

place

thread

turns

4).

(Fig.

to

and

7

the

cut

of

the

and

7)

it

the

the

until

8)

so

that

thread

the

bobbin

(Fig,

8).

case

slowly

drops

when

held

by

the

Page 5

Table

of

contents

Page

INSTRUCTIONS

INSTRUCTIONS

Installing

Adjusting

Pocket

style

FOR

FOR

the

machine

instructions

conversions

THE

THE

OPERATOR

MECHANIC

^6

31

101

Maintenance

Ordering

Lists

and

instructions

control

diagrams

cams

and

sewing

templates

105

111

113

Page 6

INSTRUCTIONS

FOR

OPERATORS

Page 7

♦f

9'

I

Page 8

INSTRUCTIONS

FOR

THE

OPERATOR

Page

10.

11.

12.

1.

2.

3.

k.

5.

6.

7.

8.

9.

Introduction

Inserting

Threading

Threading

Adjusting

Preparing

Loading

Sewing

Setting

bobbin

Winding

Switching

Care

and

the

the

the

the

and

the

the

thread

the

off

maintenance

need.1

needle

bobbin

thread

starting

workpiece

number

bobbin

the

e 3

thread

thread

tensions

the

machine

of

pockets

thread

machine

per

3

k

k

7

7

8

11

l6

17

19

19

13•

Switches

and

buttons

and

their

functions

20

Page 9

LNSTHUCTIONS

FOR

THE

MECHANIC

Page

21.

22.

23.

24.

25.

26.

30.

31.

Installing

Installing

Levelling

Fitting

Oiling

Compressed

Checking

Adjusting

Tools,

Removing

the

the

the

instructions

gauges

the

the

the

reel

air

rotating

sewing

machine

machine

machine

stand

and

and

electrical

other

machine

direction

equipment

connections

27

27

27

28

28

30

33

35

32.

33.

3^.

35.

37. ^

•H

38.1

If)

39.

'lO.

Adjusting

its

Removing

gearcase

Adjusting

Adjusting

S

clearance

Adjusting

Adjusting

Adjusting

Re-fitting

trimming

Regulating

hole

the

needle

the

trimming

cover

the

gear

the

needle

the

needle

the

bobbin

tlie

oil

the

mechanism

the

check

gearcase

hook

in

mechanism

play

rise

bar

case

lubrication

relation

in

the

and

height

opener

valve

cover

to

and

hook

hook-to-needle

and

drive

the

35

36

39

39

^0

'lO

%3

43

kk

Page 10

.^15.

46.

Page

r

Adjusting

t

rG

(0

Adjusting

engaging

the

the

fork

locking

guide

latch

bushing

^7

and

^7

47.

A8.

49. t:

30,

51.

52.

53.

5^1.

55.

56,

60.

61.

62.

63.

6^.

65.

66.

6?.

68.

i

bO

G

I

+>

TJ

(0

0)

rC

o

o

T

0)

+>

(0

rH

a

s

<u

+>

G

•rl

•>

•-

(U

w

73

C

(0 E

fco

G G

•H

-C

H O

C Q)

b E

m

-H

(0

;C

Preliminary

synchronizer

®z^djustment

Adjusting

Adjusting

Final

Adju.sting

adjustment

Adjusting

Adjusting

release

Adjusting

Replacing

Condensed

folding

mechani

Adjusting

Adjusting

plate

Adjusting

Adjusting

Adjusting

Making

arm

a

Centering

Adjusting

the

pocket

the

the

the

the

the

the

the

instructions

station

sm

the

the

the

the

the

sewing

the

the

edge

adjustment

track

roller

thread

of

trimmer

centrifugal

needle

thread

sewing

and

height

pocket

edge

pocket

sewing

test

seam

seam

pattern

ring

lever

catcher

the

knife

thread

monitor

machine

for

sewing

of

plate

folders

holder

template

pattern

of

the

of

the

control

switch

adjustments

template

the

and

on

parallel

control

tension

table

pocket

the

cam

insert

pocket

to

cam

on

k?

k8

A8

51

52

52

55

55

56

57

61

65

65

71

75

76

78

79

79

69.

Adjusting

and

front

the

edge

distance

of

pocket

between

front

seam

L

80

Page 11

70.

Adjusting

machine

in

the

relation

height

to

of

the

the

sewing

table

Page

80

71.

72.

73.

7^1.

75.

76.

77.

7fi.

79.

80.

81.

82.

•H

"o

H

CO

0

rj

C

to

O

r.

r—

(0

Adjusting

Adjusting

Adjusting

cam

Adjusting

Adjusting

Adjusting

to

sewing

Final

Adjusting

Adjusting

Adjusting

Adjusting

Adjusting

adjustment

the

control

the

height

the

safety

the

limit

the

template

the

change-action

motions

the

pneumatic

the

limit

the

pneumatic

the

time

the

motor

of

relays

cam

of

the

clutch

switch

lift

the

sewing

connection

switches

restrictors

switch

bearing

control

of

the

mounting

from

template

lever

cam 85

control

plate

transfer

p4.ate

82

86

86

89

89

90

90

93

96

99

83.

8/i.

'•

86.

87.

90.

91.

Adjusting

Adjusting

Pocket

r

Changing

Changing

Changing

Maintenance

Work

Lvibriediting

on

style

the

the

the

conversions

the

control

the

sewing

the

folding

instructions

conditioning

the

stitch

marking

machine

length

lights

cam

template

station

unit

99

100

102

102

10k

107

108

Page 12

page

95.

lOOo

lot.

102,

103.

Ordering

Information

sowing

Lists

control

templates,

and

Specifications

List

List

Illustrated

of

electrical

of

pneumatic

for

diagrams

parts

cams

ordering

and

sewing

control

templates

cams and

.

equipment

equipment 133

list

112

Ilk

II5

l4l

Page 13

n

/t

Pf

Page 14

0

Page 15

Page 16

^ r1;?t

Page 17

Open

the

the

bobbin

latch

from

of

falling

the

bobbin

out.

case;

Hold

this

the

stops

latch

open,

5•

5.1

insert

the

latch.

you

hear

Ad.lusting

Bobbin

Adjust

"X"

(Fig,

when

Final

to

the

top

and

that

the

it

thread

the

held

adjustment

appearance

bottom

the

threads

bobbin

Press

snap

the

bobbin

7)

by

thread

so

the

case

the

in

tension

thread

that

thread

of

of

threads

are

in

bobbin

place.

tensions

the

the

the

are

interlocked

its

tension

bobbin

(Fig.

tension

seam.

adjusted

case

base,

8),

is

The

lightly

by

case

in

then

turning

slowly

made

tensions

together

the

release

until

screw

drops

according

of

so

middle

the

of

5.2

6,

6.1

the

material

Needle

The

needle

The

For

amount

final

Preparing

Compressed

Before

at

the

of

6

kg/cm

is

adjusted

thread

adjustment

and

starting

supply

2

as

thread

of

air

at

by

tension

tension

starting

connection

shown

tension

the

in

(Fig.

isi-indicated

of

machine

conditioning

turning

Fig,

this

the

and

valve

10)

is

adjusted

tension

machine

always

check

unit

601,

9*

0.2,

on

by

graduations.

see

(Fig,

open

the

The

nut

par,

11)

the

pressure

pressure

"M",

5»1*

valve

Page 18

I-t

the

unit.

The

is

supply

oil

better

and

to

turn

connection

water

levels

the

instead

air

supply

of

conditioning

of

at

on

and

the

conditioning

unit

off

at

0.2

6.2

are

machine

to

drop

water

For

more

Cui'i'ent

Turn

"ON".

The

machine

manual

For

opei'ation

616,

In

the

method

be

dh0cked

is

below

level

details

(Fig.

master

operation.

"AUTO".

following

is

first

switched

the

must

12)

switch

is

in

at

mark

not

see

now

automatic

paragraphs

described.

regular

on.

(see

exceed

par.

602

ready

The

to

oil

arrow

its

12

"l"

to

start,

sequence,

the

intervals

level

in

fig.

mark

(see

"maintenance".

and

press

and

press

manual

when

must

11),

button

is

operation

the

not

and

arrow).

set

button

the

603,

for

7.

7.1

Loading

Marked

The

cuttings,

marked,

60'i,

carried

After

The

pocket

held

facilitate

Lay

the

under

position

plate.

the

workpiece

cuttings

are

positioned

Adjustment

out

by

loading

plate

immediately

re-positioning.

pocket

spring

it

so

on

the

the

blank

clips

that

(Fig.

which

of

cutting,

then

above

(Fig.

13)

the

according

the

marking

mechanic

moves

the

on

the

kk9

and

it

is

13)

location

(see

press

cutting

pocket

against

in

lights

forward

the

of

to

marking

par.

foot

in

plate,

stops

middle

is

8k),

switch

and

order

the

of

pocket

to

down.

push

450,

the

lights

be

7

to

then

is

(Fig.

It

is

it

pocket

12).

Page 19

IBDBQI

Page 20

Page 21

On

striped

or

check

materials

make

sure

that

the

7.2

patterns

This

pocket

the

position

blank

Unmarked

For

unmarked

on

the

tape

then

The

pocket

S

ewing

on

can

be

plate.

is

to

cuttings

surface

(see

positioned

arrow).

cutting

checked

of

be

cuttings

blank

The

the

corrected.

of

according

and

by

operator

cutting

(Fig.

the

The

is

loaded

pocket

means

can

13)

the

positions

table

workpiece

to

as

of

or

with

these

described

blank

the

determine

of

the

black

cuttings

markings.

agree.

winderw

pocket

can

be

adhesive

in

in

whether

marked

are

par.

the

7*1«

S.1

Sewing

\rk\en

and

operated

in

the

workpiece

positioned,

in

Press

pocket

the

press

Press

Folding

descend.

Press

611

out.

manual

the

workpiece.

move

sequence

the

following

buttons

holder

button

button

unit

button

in

cuttings

switches

605

6O6

675»

607

608

610

and

(Fig.

have

and

sequence:

together.

(Fig.

If

correction

"P.HOLD."

"FOLD.

and

table

"FOLDERS":

positioning

13)

been

buttons

l4)

UT."

loaded

This

to

is

(pocket

(folding

insert

edge

pins

are

causes

drop

necessary,

609

folders

612

onto

holder).

unit).

then

move

Press

edge

button

folders

61/

6II

"FOLDERS"

move

out

again.

a

second

time:

11

Page 22

Press

button

607

"FOLD,

UT"

a

second

time:

pocket

pins

in

position

in

place

Press

wards):

to

the

is

set

Press

plate

Press

wards):

to

the

Press

the

holder

retracted.

by

button

the

folding

off

button

moves

button

the

sewing

button

edge

on

at

back

folders,

are

the

the

612

sewing

station.

the

613

6l4

sewing

station.

615

raised

The

folded

workpiece

sewing

"TR.

template

same

"P.PLATE":

to

its

"TR.

FWD".

template

"SEWING":

table

and

pocket

template.

BWD."

The

time.

original

the

insert

the

positioning

is

and

is

held

(transfer

is

transferred

stacker

the

pocket

position.

(transfer,for

is

transferred

sewing

and

now

back

action

action

8.2

After

tion.

Sewing

For

press

After

sewing,

in

working

button

loading

buttons

in

par.

Immediately

next

758

part

cutting

(Fig.

can

automatic

605

8.1

18)

be

is

set

the

the

machine

6I6

"AUTOM".

and

together.

then

proceeds

after

can

be

has

loaded.

off

and

machine

sequence

positioning

The

buttons

picked

picked

the

is

trimming

again

(Fig.

in

automatic

the

operation

automatically.

605

have

up.

As

up

the

in

its

13)

sequence

workpiece,

cycle

been

soon

as

workpiece,

action

starting

described

pressed,

template

the

follows.

posi

first

press

the

next

12

Page 23

Page 24

i

SIIBngBI

Page 25

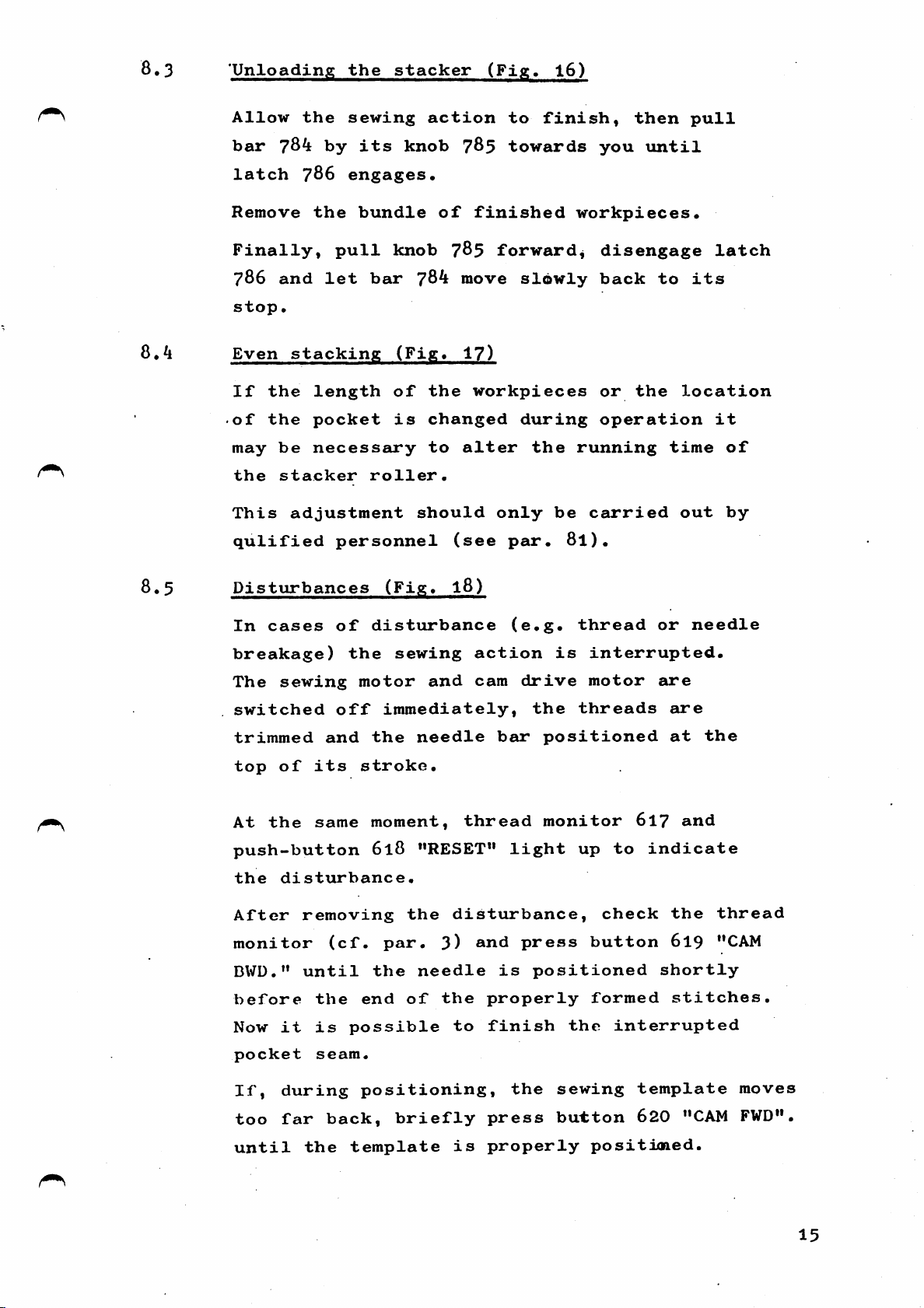

8.3

Unloading

the

stacker

(Fig.

l6)

8.4

Allow

bar

latch

Remove

Finally,

786

and

stop.

Even

If

the

of

the

may

This

the

be

stacker

qulified

the

sewing

by

786

engages.

the

pull

let

stacking

length

pocket

necessary

adjustment

personnel

its

bundle

knob

bar

of

is

roller.

knob

784

(Fig.

should

action

785

of

7^5

move

17)

the

changed

to

alter

(see

to

towards

finished

forward^

slowly

workpieces

during

the

only

par.

finish,

workpieces.

running

be

81).

then

you

tintil

disengage

back

or

the

operation

carried

to

time

out

pull

latch

its

location

it

of

by

8.5

Disturbances

In

cases

breakage)

The

At

sewing

switched

trimmed

top

of

the

and

its

same

push-button

the

disturbance.

After

removing

monitor

BWD."

before

Now

until

the

it

is

of

the

motor

off

stroke.

(cf.

end

possible

(Fig.

disturbance

sewing

and

immediately,

the

needle

moment,

618

"RESET"

the

par.

the

needle

of

3)

the

I8)

(e.g.

action

cam

drive

bar

thread

light

disturbance,

and

press

is

properly

to

finish

thread

is

interrupted.

motor

the

threads

positioned

monitor

up

button

positioned

formed

the

or

617

to

indicate

check

interrupted

needle

are

are

at

and

the

619

shortly

stitches.

the

thread

"CAM

pocket

If,

too

until

seam.

during

far

the

positioning,

back,

template

briefly

is

the

press

properly

sewing

button

positicned.

template

620

"CAM

moves

FWD".

15

Page 26

When

the

sewing

template

is

in

the

correct

position

^•8

8.7

press

continued

Counter

Counter

This

is

quantities

or

week).

To

zero

Stitch

The

desired

of

the

carried

button

(Fig.

621

a

the

length

control

out

to

counts

means

within

counter,

stitch

by

6l8

the

"RESET".

end

l8)

of

cam.

the

of

each

ascertaining

a

certain

press

length

This

mechanic

The

the

cycle.

sewn

period

trip

is

adjustment

sewing

pocket

set

(see

the

(e.g.

622.

on

par.

action

consecutively.

production

per

the

drive

should

be

8^).

is

now

day

motor

9.

Setting

The

be

set

machine

button

We

find

bobbin,

The

To

set

625

by

repeatedly

the

number

number

on

62'i

exact

counter

(leave

set

wheels

the

number

of

counter

switches

"COUNT."

that

depending

up

number

it

number

pockets

623.

off

to

on

has

623,

pressed

pressing

is

at

to

the

of

(Fig®

200

open

pockets

sewn

When

after

pockets

the

to

be

in)

buttons

the

left

per

with

the

folding

12)

material

ascertained

cover

and

right-hand

are

one

counter

lights

can

626,

set

627.

at

bobbin

full

and

be

and

press

the

Make

"0".

up.

sewn

the

number

side

thread

bobbin

expires,

the

by

sure

and

bulb

with

pocket

trial

zeroing

of

all

(Fig.

can

in

one

and

pockets

that

l8)

the

size.

error.

trip

other

16

Page 27

For

each

pocket

sewn,

the

counter

subtracts

10•

10-1

"1".

is

When

trip

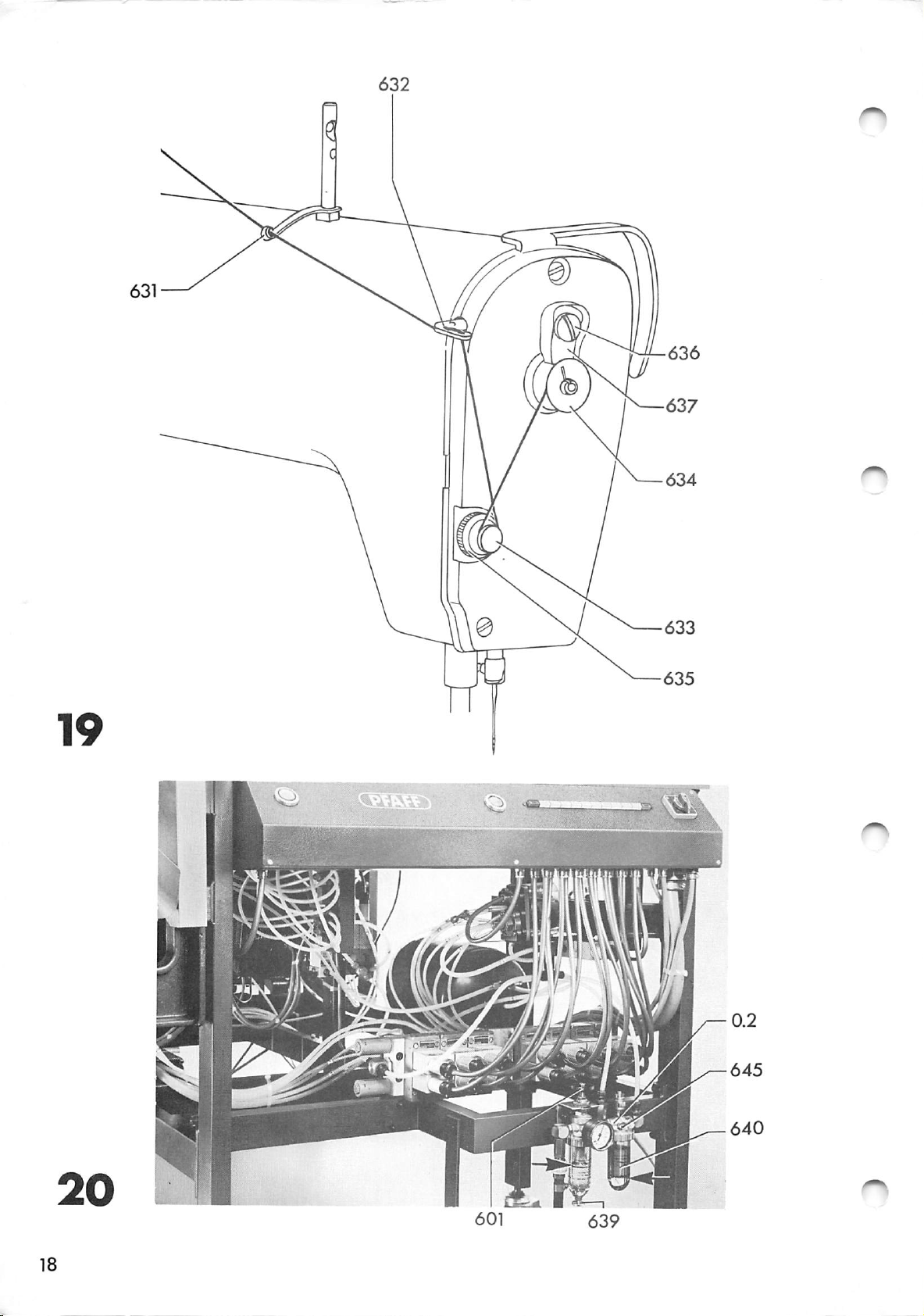

Winding

In

flow

bobbin

Threading

Pass

of

into

632,

thread

When

switched

the

625

order

it

the

the

guide

clockwise

the

bobbin

pressed,

the

to

is

available.

for

thread

top

a

number

coiinter

off

the

has

bobbin

avoid

advisable

bobbin

from

thread

631,

through

around

of

reaches

bobbin

been

the

thread

unterruptions

winding

reel

guide

changed

machine

to

always

bracket

the

tension

times

clockwise

has

(Fig.

664

"0"

to

continues

19)

in

have

(Fig.

through

(665

two

holes

633,

and

be

(see

the

a

I9)

then

around

the

machine

changed*

par.

k)

its

work

full

one

hole

in

Fig.

of

guide

wind

bobbin

and

cycle.

1),

the

10-2

10*

3

634.

Adjusting

The

When

Adjusting

nut

nut

least

winding

635* The

anti-clockwise.

monofil

Tension

runs

even

made

onto

winding

by

possible

633

the

the

thread

or

and

should

the

of

mechanic.

winding

tension

transparent

tension

engaging

middle

the

tension

tension

is

be

adjusted

of

bobbin.

is

increased

threads

should

the

bobbin

the

bobbin.

Adjustment

(Fig.

adjusted

by

be

set.

winder

so

that

19)

on

turning

are

the

This

should

milled

used,

(Fig.

ensures

this

the

19)

thread

be

17

Page 28

Page 29

To

adjust

the

quantity

of

thread

wound,

loosen

screw

For

set

636.

To

downwards.

a

thread

automatically.

•

Switching

When

and

more

it

engage

little.

all

636

lower.

quantity

button

indicator

and

thread

the

If

The

off

638

adjust

set

After

bobbin

you

bobbin

is

the

"OFF"

the

this

adjustment

winder

feel

will

reached,

machine

bulbs

haght

a

resistance,

is

are

lug

higher,

press

now

then

(Fi

g-

pressed,

switched

of

turn

fully

13)

it

the

trip

until

the

trip

for

tighten

turn

is

machine

off.

lug.

less

lug

637

the

the

disengaged

thread

screw

bobbin

set

12.

12.1

Wlienever

thread

pressed

To

completely

switch

Care

Work

If

conditioning

drop

its

To

turns

and

on

the

below

mark

drain

(fig.

a

disturbance

breakage

immediately.

602

to

maintenance

the

conditioning

machine

its

(see

off

20).

switch

"O".

is

unit

mark,

arrows

the

(see

constantly

daily.

water,

par.

off

nor

in

occurs,

8.5)i

the

unit

The

must

Fig.

undo

with

button

machine

in

use

oil

level

the

20).

drain

exception

check

water

tap

turn

638

must

level

639

must

master

the

not

a

of

be

exceed

few

19

Page 30

Screw

in

and

tighten

tap

639

securely.

If

necessary,

12.2

13.

have

Oiling

the

Regularly

with

The

hook

two

the

Switches

Pfaff

quantity

markings

oil

must

mechanic

(Fig.

oil

sewing

be

through

and

21)

the

the

needle

the

(see

of

such

on

buttons

top

following

machine

top

felt

arrow)

oil

that

glass

hole

and

bar,

for

up

ring

the

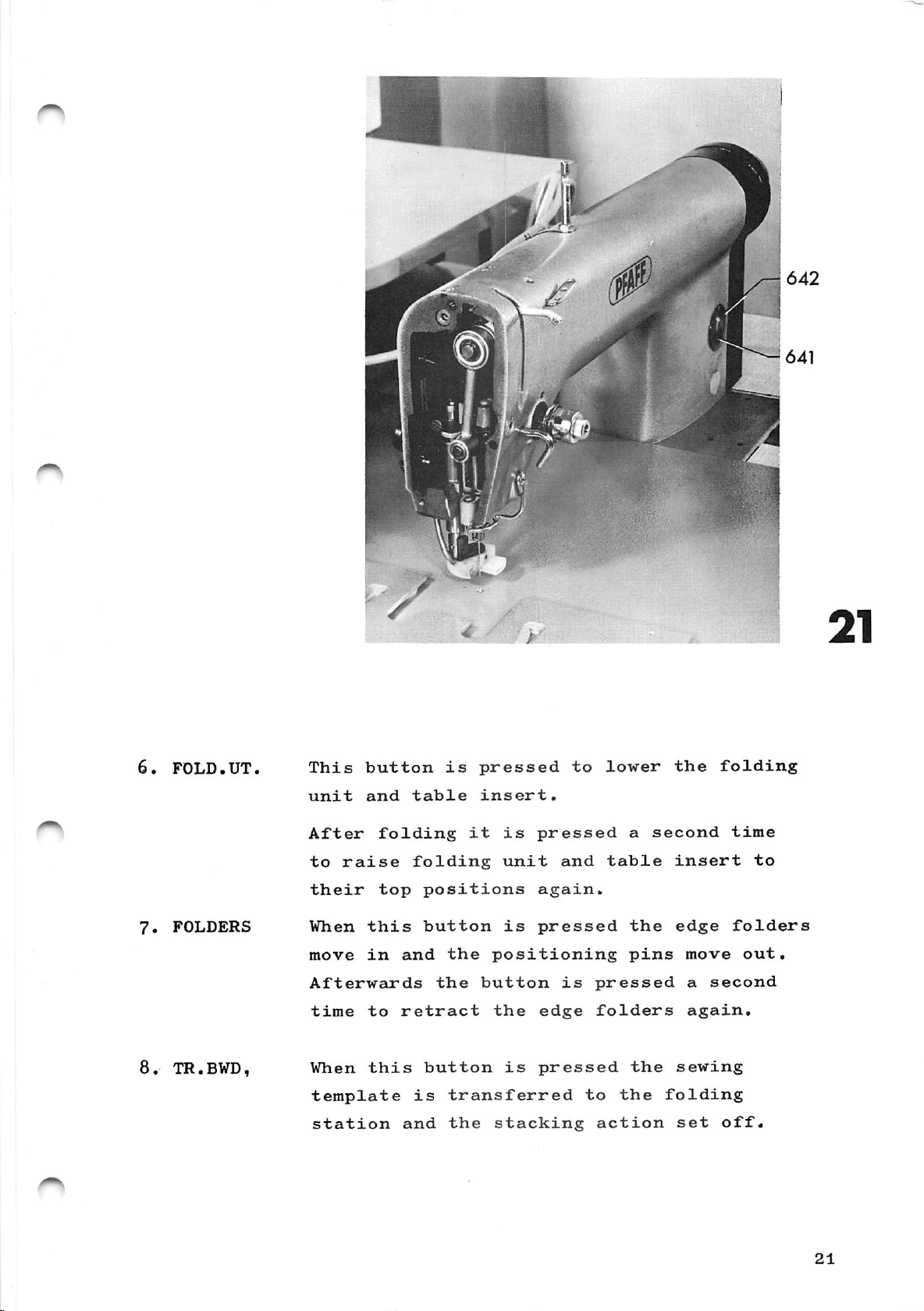

64l.

642.

and

the

oil

points

oil:

bottom

on

lubrication

level

If

their

in

container

on

oilpads

the

presser

of

is

between

necessary,

functions

the

of

the

machine

the

bar

sewing

the

top

6^0,

up

13.1

1.

2.ON

3.

4.

HAND

Manual

0 1

0

operation

Master

switches

at

"1".

When

ready

light.

This

Operated

Vlhen

pocket

switch

this

for

button

these

holder

only

button

operation.

is

to

extend

buttons

for

mains

function

is

pressed

drops

pressed

The

the

are

onto

current.

when

button

for

pocket

pressed

the

this

the

manual

plate

table.

The

switch

machine

has

operation

together

following

a

green

is

set

is

of

the

20

Page 31

/

*

This

unit

button

and

After

to

raise

their

When

move

Afterwards

time

When

this

in

to

this

template

station

table

folding

folding

top

and

retract

is

and

is

it

positions

button

the

the

button

transferred

the

pressed

insert.

is

unit

is

positioning

button

the

is

stacking

to

pressed

and

again.

pressed

is

edge

pressed

lower

table

pressed

folders

to

action

a

the

pins

the

the

the

second

insert

edge

move

a

again.

sewing

folding

set

folding

time

to

folders

out.

second

off.

Page 32

9.

10.

11.

P.PLATE

TR.FWD.

SEWING

Pressed

Pressed

to

the

This

sewing

button

to

to

retract

transfer

station.

sets

off

the

the

the

pocket

sewing

sewing

plate.

template

and

thread

12.

13.

Ik.

15.

16.

P.HOLD.

COUNT,

OFF

CAM

CAM

BWD.

FWD.

trimming

Press,

6051

necessary.

top

position.

Lights

expires.

For

switching

This

has

been

template

If

the

held

pressing

if

when

up

button

button

in

actions.

required,

correction

The

when

The

is

removed,

back

too

long,

this

pocket

the

bobbin

off

pressed

to

marked

button.

after

of

bobbin

then

the

in

order

where

"CAM

correction

pushing

the

holder

thread

has

machine.

after

sewing

BWD,"

workpiece

moves

to

be

a

disturbance

to

move

was

has

is

made

in

to

counter

changed

the

left

been

buttons

is

its

off.

by

22

17.

13-2

1.

RESET

Automatic

0 1

When

template

previous

The

the

operation

sewing

cycle.

Master

switches

at

"1".

a

disturbance

switch

position

buttons,

action

only

for

mains

function

has

changed

this

then

been

by

button

continues

current.

when

removed

means

is

this

to

to

The

switch

and

of

the

be

the

following

the

two

pressed.

end

of

is

set

Page 33

2.

ON

When

this

button

is

pressed

the

machine

is

3.

k.

6.

AUTOM

COUNT.

ready

light.

This

operation.

button

Operated

When

the

these

automatic

Lights

for

operation.

to

buttons

up when

sets

extend

operation

the

the

the

are

bobbin

The

machine

pocket

pressed

sequence

button

thread

for

plate.

together

has

automatic

is

initiated*

counter

a

green

7.

8.

9.

10.

OFF

CAM BWD.

CAM

FWD.

RESET

expires.

For

switching

After

button

point

If

the

held

pressing

When

template

two

previous

pressed.

the

end

removing

until

where

button

in

too

a

disturbance

of

The

sewing

long,

this

position

The

the

bobbin

off

a

the

marked

butifeon.

buttons,

sewing

cycle.

then

the

machine.

disturbance

sewing

was

"CAM

correction

has

been

changed

this

action

has

template

left

by

to

press

off.

BWD."

is

removed

means

button

then

be

changed,

this

reaches

has

made

euid

of

is

continues

been

by

the

to

the

the

be

to

23

Page 34

INSTRUCTIONS

FOR

MECHANICS

Page 35

Installing

the

Machine

Page 36

Page 37

21,

Installing

the

machine

21.1

21.2

21.3

22.

22.1

22.2

Before

transit

to

the

responsible.

Lift

the

possible

to

its

It

may

and

the

Levelling

After

feet

To

When

all

until

check

the

six

installing

damage,

carrier

machine

with

location.

be

necessary

sewing

the

installing

this

machine

feet

its

and

a

machine

machine

frame

use

must

and

off

fork

the

has

the

report

to

to

a

precision

stand

machine

the

its

transit

lift

remove

and

(Fig.

machine

and

table

been

firmly

any

Pfaff

truck,

carry

23)

adjust

levelled

check

complaints

agency

support,

and

the

folding

them

are

horizontal.

spirit

out,

on

the

it

for

carry

separately

its

level.

ground.

if

it

unit

threaded

23.

23.1

23.2

Fitting

Fit

to

the

In

certain

at

other

the

the

supplied

right

locations.

reel

of

cases

stand

reel

the

the

stand

sewing

reel

(Fig.

23)

6'l4

machine.

stand

at

may

its

be

location

fitted

27

Page 38

2.k.

Qilinp;

(Fig.

26)

2h,\

2k.2

2^1.3

Before

must

The

hook

window

6/12.

Check

required,

6'i5

"hbchster

be

level

must

the

and

starting

oiled

The

bar,

the

of

remain

6'i

1.

oil

top

filling

Olstand"

(A.5°E, 50°C)

plug

Compressed

645

and

top

and

felt

The

air

with

and

oil

level

up

part

screw

and

the

machine,

Pfaff

bottom

ring

for

between

oil

in

container

the

(max.

number

it

electrical

sewing

on

the

lubrication

the

is

topped

the

container

oil

in

tight

the

oilpads

presser

following

machine

of

two

markings

up

through

conditioning

6^0

by

up

to

level)

280-1-120

(Fig.

connections

of

the

bar

the

removing

the

with

1^4.

27).

points

oil:

needle

(see

sewing

on

hole

unit.

plug

marking

Ursulin

Replace

(Fig.

arrow)

If

II

2?)

25^1

25-2

25.3

Take

int.

the

of

a

dia.)

compressor,

conditioning

supply.

of

at

Set

the

601

of

Check

with

(Fig.

that

hose

The

least

working

the

to

25)

of

which

supply

7

kg/cm

conditioning

make

sure

indicated

appropriate

will

and

connect

unit

0.2

^ine

.

pressure

that

on

length

withstand

it

and

should

of

6

unit.

the

mains

specification

to

the

have a

kg/cm

and

the

pressure

coupling

compressed

on

voltage

plate

size

(6

0.1

pressure

regulator

coincides

647

mm

of

air

28

Page 39

Page 40

2 3.'!

If

the

in

an

mains

electrical

voltage

earthed

current

socket.

should

failures

is

correct

(The

not

may

insert

fluctuations

he

occur.)

too

the

great,

machine

in

otherwise

plug

the

^

26.

26.1.

26.2

26.3

Checking

Turn

603

sewing

master

"ON".

After

at

fan

direction

as

shown

correct

Turn

master

the

The

machine

pressing

6k8

is

by

reverse

rotating

switch

button

in

the

correct

the

switch

motor

button

motor

arrow

the

602

then

runs

when

poles

602

direction

to

"1"

lights

(Fig,

638

(Fig,

housing.

the

in

Fig.

at

to

"0"

and

fan

20,

the

again.

(Fig.

press

up

27),

2?)

The

turns

If

mains

28)

button

green

"OFF"

rotating

it

is

plug.

and

look

in^r.

the

30

Page 41

Adjusting

Instructions

Page 42

T'oolSi

gauges and

other

equipment

^0^

30.1

General

Set

of

10

mm

Set

of

Set

of

Universal

blades

Adjustable

Hammer,

Brass

drift,

Circ-lip

Metal

Tweezers,

Dottle

rule,

tool

kit

screwdrivers

open-ended

alien

keys,

screwdriver

(watchmaker's

spanner

250-gramme

8

mm

pliers,

of

loctite

elbowed

O.3

original

mm

with

spanners

I.5

to

with

screwdriver)

dia.

x

thick

blades

from 6

6

mm

exchangable

250

mm

Seeger

from

to

2

22

to

mm

30.2

Special

Open-ended

Allen

Universal

C-clamp,

key,

tools

part

spanner,

8

mm

gauge,

No.

part

88O

19

mm

No.

137/00

91-129

6o'l-91

33

Page 43

•.f.

Page 44

31.

JRemoving

the

sewing

machine

(Fig>

35)

31*1

31.2

31.3

31.'1

31.5

Press

602

to

0.1

Move

(Fig.

in

remove

(Fig.

Take

panel

(Fig.

To

630

belt

Disconnect

out

remove

(Fig.

while

button

"0"

27).

the

template

36).

the

27

to

36).

the

28)

plug

plug

I^lug

plug

638

and

piston

five

the

drive

downwards

turning

t!io

65^

635

637

656

"OFF",

di

sconnect

rod

758

together

screws

right

belt,

the

following;

for

Tor

Tor

for

of

and

motor

the

the

the

the

turn

master

airline

cylinder

with

6^9*

and

push

remove

press

take

pulley.

thread

synchronizer,

trimming

carbon

switch

coupling

Z

its

cover

it

clutch

off

monitor,

mechanism,

brush

12

frame

the

holder

and

lever

31.0

31.7

32.

32.1

Disconnect

workpiece

at

their

Cut

guide

mounting.

Adjusting

Fig.

Before

13'it

the

37)

size

couplings.

thread

pin,

adjusting,

the

presser

and

the

80

or

air

between

lift

needle

9c.

tubes

(Z

the

insert

20)

in

for

and

the

sewing

relation

a

needle

trimming

reel

new

stand

machine

to

needle

cooling,

mechanism

and

off

its

hole

System

the

its

35

Page 45

32.2

Remove

Fig.

36.

screws

658

and

take

off

faceplate

659

32.3.

32.^1

32.5

32.6

33.

33«1

Bring

take

662

Turn

the

am

Now

needle

wise

out

(Fig.

eccentric

needle

lengthwise

re-position

direction,

After

662.

Finally,

Screw

securely

Removing

(Fig.

Loosen

take

p 1 iers .

off

the

screw

is

proper

tighten

.

the

38)

nut

circlip

needle

37).

is

in

direction.

in

the

adjustment

in,

but

trimming

63O,

bar

66O

stud

the

the

middle

too.

do

grub

remove

676

to

and

663

middle

needle

not

screw

mechanism

with

the

loosen

with

of

fully

fully

the

the

bottom

a

of

bar

its

661

three

of

grub

screws

screwdriver

the

needle

frame

hole

tighten

tighten

and

and

screws

special

its

so

that

in

the

grub

screw

screw

gearcase

673

circlip

stroke,

661

so

hole

the

cross

screw

66O.

66O

cover

and

and

that

in

^

'^

33.2

33.3

33.'i

Push

synchronizer,

at

Pull

lay

Take

698

the

the

same

tlic

the

out

together

trimming

time.

electrical

trimming

the

twelve

with

pulling

mechanism

mechanism

stud

lead

through

screws

the

foam

carefully

67?

out

aside.

678

and

plastic

of

a

little,

remove

inserts.

towards

its

hole

cover

the

and

36

Page 46

m

i

678

698

37

662

630

r

677

38

37

Page 47

II

686

683

01

mm

687

40

685

38

Page 48

^

3^

• Adjusting; the gear play in the

hook

drive (Fig.

39)

3^.1

3^.2

3'i.3

3^1.^1

3'^.5

3'i , 6

35.

Loosen

the

oil

valve

Loosen

shaft

meshed

Loosen

enough

shaft.

Push

and

bring

stroke.

Move

is

a

needle.

In

this

Adjusting

screw

distributor

68l.

screw

bearing

with

screws

to

the

hook

hook

clearance

position

a

allow

the

shaft

the

679

683

68^

very

685

up

needle

of

needle

and

ring

(Fig.

(Fig,

slight

(one

the

hook

against

bearing

0,'l

fully

pull

bar

mm

rise

oil

by

^0)

and

39)

play.

shown

to

hook

to

68'i

between

tighten

and

tube

turning

turn

until

in

be

both

Fig,

moved

shcift

the

bottom

lengthwise

hook

screw

hook-to-needle

680

out

regulating

eccentric

gears

40)

on

bearing

of

until

tip

683.

of

hook

are

just

its

68'i

its

there

and

35.1

35.2

35,3

clearance

Bring

and

hold

gauge

bottom

Place

needle

and

Pull

wheel

c-clamp

bearing.

position.

tighten

the

(part

needle

c-clamp

bar,

out

carefully

is

(Fig.

needle

the

the

The

2,2-mm

No,

push

its

feeler

in

machine

hO)

bar

91-129

bar

686

it

screw.

in

contact

to

thick

bearing,

(part

up

gauge

sewing

is

the

60'i-9l)

No,

against

with

now

bottom

blade

88O

and

turn

direction

the

in

of

of

the

against

1^7/00)011

the

feeler

the

until

needle

its

needle

its

universal

the

balance

bar

stroke

the

gauge,

the

rise

39

Page 49

35»^

In

it

and

needle,

tip

this

and

position

turning

and

needle.

there

it

adjust

so

is

that

a

clearance

the

sewing

its

tip

of

hook

is

beside

0,1

by

ram

pushing

the

between

35«5

36.

36.1

36.2

36.3

36.After

37•

When

the

finger

case

base,

Adjusting

Loostui

bo

moved.

Txirii

conti'ed

Alter

is

liook

688

Adjusting

the

a

clearance

tip

securely.

setting

68?

screws

balance

behind

the

(see

proper

is

then

the

heiglit

adjustment

the

is

in

place

tighten

needle

688

so

wheel

the

of

of

0.8

encircled

bobbin

correct

bar

tliat

needle

the

mm

case

in

the

height

until

needle

between

view).

tighten

opener

the

the

(see

make

slot

two

needle

the

sure

of

screws

(Fig.

hook

encircled

bar

until

needle

the

(Fig.

bar

two

that

the

685.

^1)

tip

k2)

position

bobbin

can

is

view).

there

eye

screws

just

and

37.1

37-^

37-3

T.nsei'l

opener

Loosen

the

when

After

and

a

screwdriver

689

in

screws

bobbin

case

the machine

correct

remove

the

order

69O

and

opener

is

to

in

adjustment

screwdriver.

in

the

see

adjust

reaches

needle

its

fully

slot

motion

eccentric

its

rise

tighten

of

bobbin

more

far

position.

69I

right

screws

case

clearly.

so

that

position

69O

^0^

'lO

Page 50

\

41

689

690

692

42

41

Page 51

43

0.8mm

689

44

O

1

708

695

42

696

Page 52

37-Loosen

the

shaf

screw

bobbin

t.

case

692

just

opener

enough

to

be

to

turned

allow

on

its

37.3

37.8

37-7

37.8

38.

38.1

Ro-position

there

tip

Bring

position

move

contacts

Turn

still

clearance

is

and

the

the

the

in

bobbin

After

692.

proper

Adjusting

Loosen

rod

695

left.

a

the

bobbin

by

bobbin

the

bobbin

contact

of

case

the

screw

of

the

bobbin

clearance

bobbin

turning

case

opener

case

0.3

and

position

adjustment

oil

694

the

centrifugal

case

with

mm

check

of

of

case

the

base

finger.

opener

between

the

case

0.8

base

opener

balance

it

until

finger

fully

valve

check

opener

mm

until

with

the

switch

between

(Fig.

to

its

v\rheel

lug

there

slot

693

tighten

(Fig.

valve

the

to

so

43).

far

"V"

(F

44)

and

that

then

lug

is

in

ig.

screw

the

its

left

a

the

43).

push

far

38.2

38.3

39.

39.1

Move

ance

rod

In

Refitting

mechanism

check

of

696,

this

Ropl£ice

gasket

tight,

screw

on

1

mm

position

the

(Fig.

cover

if

necessary),

then

machine

valve

between

tighten

7O8

tighten

gearcase

4^)

698

on

support

so

push

the

them

that

cover

turn

there

rod

695

screw

and

gearcase

in

the

down

697.

crosswise.

694.

the

is

a

and

actuating

trimming

(change

screws

clear

finger

Also

43

Page 53

39*2

Insert

676

with

stud

the

677

special

its

hole

pliers.

and

replace

circlip

39*3

39Fully

0 •

^0.1

'

).2

).3

AO.'i

Refit

the

three

brushes

Regulating

Mount

an

d

fit

First

will

Turn

and

from

Lay

go,

on

allow

the

a

cutout

the

machine

seconds.

piece

the

are

tighten

the

a

turn

the

hook.

piece

(stick

of

trimming

screws

correctly

tlie

sew^ing

dri

v e

regulating

then

master

the

of

to

A

thin

paper

screws

hook

machine

belt.

out

machine

white

in

place

run

trace

above

mechanism

673»

making

positioned

673*

lubrication

screw

again

switch,

to

paper

at

top

of

the

on

by

run.until

if

necessary)

speed

oil

hook.

on

a

699

half

press

over

should

sure

stf*nd

the

in

(Fig.

in

a

tlie

the

for

bedplate

that

holder

with

as

turn.

oil

needle

and

about

appear

^16)

far

foot

the

is

two

8l2.

motor

as

switch

emitted

plate

allow

10

on

with

it

the

'1O.5

II

out

screw

tlie

a

amount

little,

in.

of

if

oil

it

is

too

small

is

too

large,

turn

turn

screw

this

699

h h

Page 54

677

697

698

45

676

0

673

673

812

o

46

45

Page 55

47

703

702

0,1

\

mm

701

©

J

o

V

ml

\

\

\

700

o

(S)

f

a

3^

o

xim

•

jr=tx

48

703

46

704

705

Page 56

^5.

Adjusting

the

locking

latch

(Fig.

^7)

^5»1

^15.3

h^.h

^6.

^6.1

Bring

disengage

screws

Re-position

there

lever

In

securely,

When

lever

described

is

this

the

703

Adjusting

(Fig,

With

the

screws

705

to

the

700

a

703

position

trimming

trimming

70'l

be

needle

the

trimming

and

crank

clearance

and

the

should

above

the

guide

just

tiirned

bar

701.

702

crank.

tighten

mechanism

drop

may

have

bushing

mechanism

enough

on

its

to

the

mechanism

on

of

0.1

freely.

to

shaft.

top

its

shaft

mm

screws

is

The

to

repeated.

and

disengaged,

allow

of

its

and

so

between

7OO

and

engaged,

adjustment

engaging

guide

stroke,

loosen

that

locking

7OI

locking

fork

loosen

bushing

46.2

46.3

47.

47.1

47.2

Move

703

between

After

securely.

guide

until

proper

Preliminary

track

With

the

ascending

stroke.

Loo

synchronizer

its

the

balance

sen

shaft.

ring

screws

bushing

there

engaging-fork

is

adjustment

adjustment

(Fig.

trimming

wheel

needle

709

track

705

a

towards

clearance

706

of

49T

mechanism

in

sewing

is

4

mm

just

ring

enough

and

tighten

the

disengaged,

direction

past

710

to

locking

of

0.1

mm

washer

707.

screw

synchronizer

until

the

bottom

to

allow

be

moved

latch

704

turn

on

of

the

its

47

Page 57

k7»3

Move

brush

the

the

is

insulated

track

roughly

ring

surface.

1 mm

so

that

from

the

the

left

inside

carbon

edge

of

^7.^

47.5

'1G.

AG.l

'18.3

Hold

so

from

After

Preliminary

Loosen

cam

n

*

Move

the

stop

of

Bring

and

that

712

cam

the

hold

the

the

correct

screws

the

ring

control

the

balance

the

carbon

end

adjustment

to

be

cam

and

the

713

needle

the

wheel

of

the

adjustment

711

just

moved

laterally

bedplate

to

the

cam.

bar

balance

brush

insulated

on

right

wheel.

to

and

is

fully

of

the

enough

its

so

that

is

the

turn

roughly

shaft.

2.5

and

bottom

track

surface.

tighten

control

to

allow

the

mm.

up

against

ring

17

mm

screw

cam

control

clearance

Then

of

its

710

away

(Fig.

move

the

stroke

709

50)

between

boss

'18.^

^18.5

'19,

^9*1

Turn

points

bedplate.

cam

control

is

Tighten

Adjusting

With

needle

the

roughly

Make

up

against

screws

the

trimming

bar

to

cam

roller

the

712

towards

sure

the

711

mechanism

top

so

the

that

stop

securely.

lever

of

that

the

its

the

front

boss

ring.

(Fig.

disengaged

stroke.

tip

edge

of

51)

of

the

its

of

control

bring

lobe

the

the

iiQ

Page 58

Page 59

•MM

i

IIUUi

52.1

50

52.2

Page 60

Looson

^

715

between

and

SO

roller

screws

that

the

there

inner

716.

7'1^

and

is

surface

re-position

a

clearance

of

control

roller

of

0,5

cam

lever

roin

712

49.4

49.5

49.6

49.7

50•

Now

roller

shaft.

tigliten

ascending

of

its

Pull

go

edge

In

To

must

into

If

49*4

Adjusting

crank

and

of

this

check

be

the

necessary,

and

lever

Turn

needle

stroke.

push

the

position

this,

possible

cam

49-5-

the

the

can

the

717

roller

cam

track.

two

still

balance

bar

downwards

track.

tighten

operate

to

repeat

thread

screws

is

716

easily

the

catcher

71^1

be

turned

wheel

4

mm

as

against

screws

engaging

push

adjustment

far

until

past

(Fig.

so

as

the

7l4

on

fork

the

that

its

the

the

it

outer

securely.

7O6.

roller

in

51)

the

bottom

will

It

paras.

50.1

50.2

50.3

50.4

50.5

With

and

adjust

its

tip

(Fig.

Fully

Position

of

its

Operate

wheel

front

Loosen

catcher

position

the

points

52.1).

tigliten

stroke.

enging

until

position.

screws

719

needle

thread

the

thread

is

finger

plate

to

screws

needle

fork

720

positioned

693

catcher

the

4

706

catcher

and

^s

removed,

middle

7lS«

mm

past

and

turn

shown

719

719

crank

in

laterally

of

the

turn

relation

in

loosen

the

bottom

the

reaches

71?

Fig.

screws

needle.

balance

so

to

52.2.

its

so

that

718

that

51

Page 61

50,6

Finally,

tighten

screws

720

securely.

51.

51*1

51.2

51.3

51.^

51.5

Final

rosition

stroke

Turn

there

of

thread

finger

Loosen

the

distance

off

721

Chock

according

After

adjustment

the

and

the

balance

is

a

693*

screws

and

roller

adjustment

needle

operate

clearance

pul3-off

between

the

lever

to

par.

711

of

engaging

wheel

721

and

catcher

715

49*6.

tighten

the

of

the

mm

in

and

turn

for

control

past

sewing

2 mm

the

control

back

tip

correct

screws

the

fork

between

middle

edge

is

k mm.

cam

bottom

706.

direction

cam

of

adjustment

711

(Fig.

the

of

712

thread

securely.

53)

of

its

until

back

position

until

edge

pull-

52.

52.1

52.2

52.3

Adjusting

Take

If

and

so

to

out

necessary

polish

that

7 nim

surface

Bring

and

re-fit

Adjust

cutting

and

that

catcher.

the

the

screw

its

from

as

edge

the

the

the

cutting

shown

needle

the

knife

trimmer

722

re-grind

cutting

the

knife.

.and

knife

(Fig.

centre

in

bar

so

the

is

knife

edge

Fig.

to

that

needle

the

edge.

line

the

centred

51)

knife,

is

5^^

the

(Fig.

and

Then

at

6f

• 1 •

bottom

clearance

is

a

3*5

over

5^0

remove

remove

bend

distance

its

of

nim

the

the

the

the

supporting

its

between

(F'ig.

thread

knife.

burr

blade

of

stroke

6.5

its

52

Page 62

706

o

pf®

(S)

(JH

o

ii=a

31

693

715

712

Amm

53

3,5mm

i

6,5-7mm

r

54.1

54.2

54.3

53

Page 63

mm

724

723

OJmm

55

703

728

727

56

726

Page 64

The

from

(Fig.

right-hand

the

recessed

5^.3)

edge

edge

of

the

of

knife

the

thread

must

not

catcher

protrude

•

5'2.4

52.5

33.

53.1

53.2

After

The

knife

719

and

thread

of

the

catcher

Adjusting

Loosen

of

centrifugal