Page 1

Instruction

book

Pfaff

3516-1/24;

-1/25;

-1/24-928/01;

-1/25-928/01;

-1/28-928/01

No.

29M2-13

097

engl.

HO

97^

Page 2

Contents

Page

1.

2.

3.

4.

5.

6.

7.

8.

9.

General

flaking

Inserting

Winding

Removing

Inserting

Regulating

Inserting

Threading

Regulating

Instructions

the

the

the

the

the

the

the

machine

needle

bobbin

bobbin

bobbin

the

bobbin

bobbin

needle

the

needle

ready

case

case

for

thread

thread

operation

tension

tension

3

3

4

7

7

^

8

8

11

10.

11,

12.

13.

14.

15*

16.

17.

Inserting

Enlarging

Setting

selector

Adjusting

dart

blade

Sewing

Switching

Needle

Machine

and

and

care

and

the

changing

the

off

thread

removing

dart

front

the

depth

machine

breakage

the

the

position

dart

dart

length

stop

blade

of

the

11

12

1

13

13

l4

17

17

o

Page 3

Additional

Instructions

^

18,

18.1.

19•

Additional

Pfaff

3516-1/2^

Threading

with

Additional

Pfaff

new-type

3516-1/24-928/01

instructions

the

needle

thread

instructions

and

-1/25

(Pfaff

monitor)

and

for

for

the

463

the

-1/25-

sewing

head

Page

21

23

928/01

19»1*

2O0

20.1,

21.

Winding

Additional

-1/25

Switching

Additional

the

instructions

and

-1/25-928/01

on

instructions

bobbin

the

start

(Pfaff

for

for

and

the

433

finish

the

Pfaff

sewing

Pfaff

bar

head)

3516

tacks

24

3516-1/28-928/01

Page 4

General

instructions

Page 5

' V

Page 6

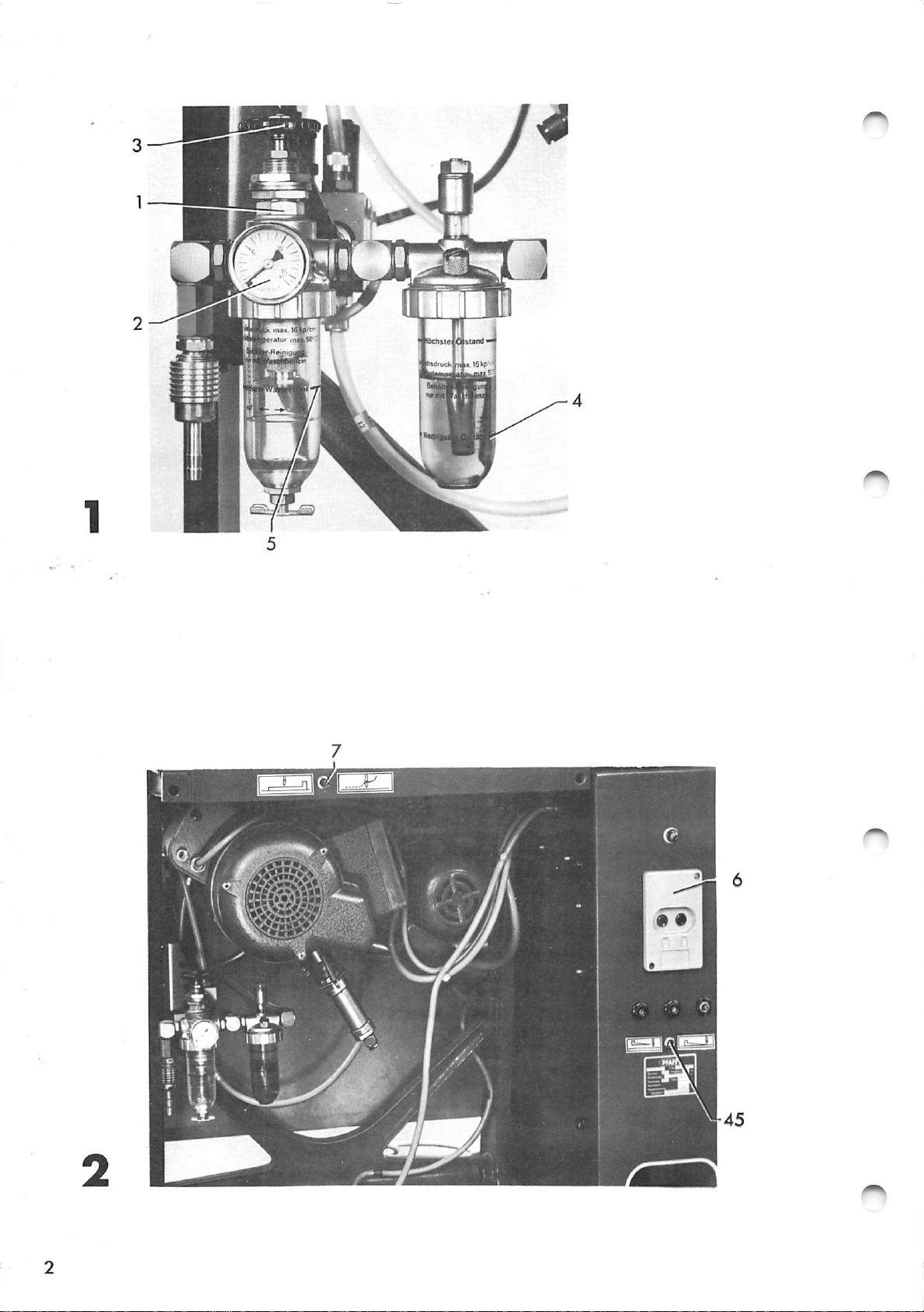

1»

Making

the

machine

ready

for

operation

(Fiia:s«

1

and

2)

1.1.

Compressed

It

is

best

at

the

unit

•

Open

the

ditioning

cates

sary,

valve

a

adjust

3.

V.^henever

check

unit

5.

For

the

lo

and

further

main

valve

unit

working

you

oil

The

the

air

to

line

this

switch

oil

water

details,

(Fig,

switch

rather

at

1

whether

pressure

and

level

level

l)

the

the

main

pressure

on

water

must

please

air

than

presstire

of

the

levels

must

supply

at

line

6

kg/cm

at

pressure

machine,

in

not

drop

not

refer

on

the

conditioning

and

check

gauge

.

make

conditioning

below

rise

to

and

2

If

regulating

above

Section

off

at

indi-

neces

sure

mark

mark

con

to

17

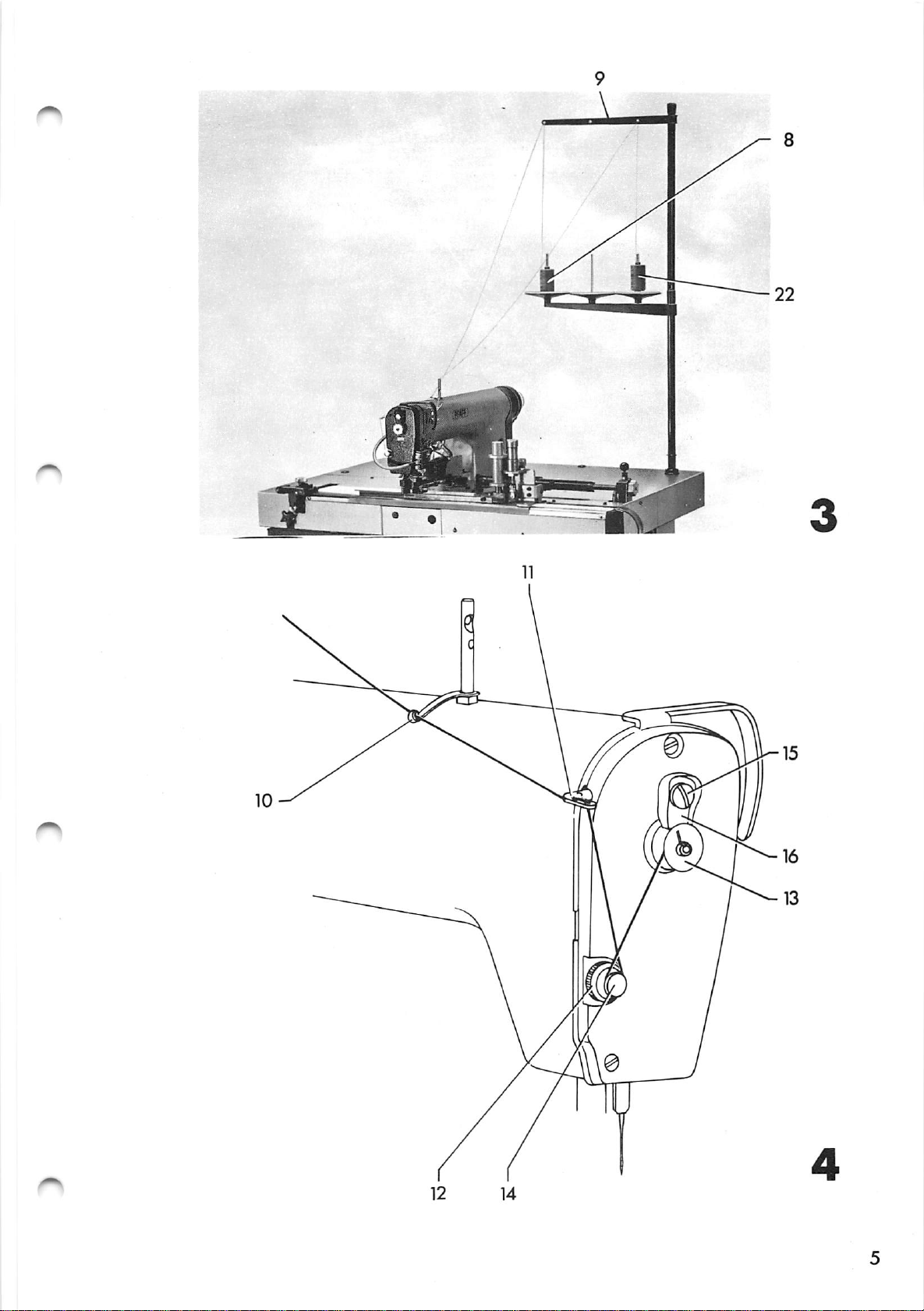

1.2.

2.

"Machine

Electric

Tress

machine

Inserting

Switch

As

a

the

needle

If

a

as

follows:

and

loosen

needle

The

automatic

the

toggle

result,

needle

out

care".

power

is

black

now

the

bar

the

of

the

has

Hold

(Fig.

button

ready

needle

switch

work

raised

already

it

needle

the

dart

between

needle

sewer

2)

of

for

7

holder

to

set

master

operation.

(Fig.

its

been

screw.

holder.

uses

2)

bar

highest

inserted,

thumb

only

switch

to

is

and

Tiieii

System

6.

L-i—^ .

lowered

point.

remove

forefinger

pull

13^

The

and

it

the

kK

needles

When

as

faces

set

it

screw.

in

inserting

will

toward

sizes

go

the

and

a

90f

new

tvirn

front.

1^0

needle,

it

Then

and

so

110.

push

that

tighten

it

its

up

the

long

as

needle

far

groove

Page 7

3•

Winding

In

order

the

to

bobbin

avoid

(Pfaff

unnecessary

^63

sewing

interruptions

head)

of

the

3.1«

3o2.

sewing

available

Important

Pfaff

are

operation

3516-1/?!^-928/01

equipped

Threading

Pass

of

both

tension

bobbin

tlie

the

holes

Regulating

operation

at

note

is

the

thread

upper

of

12.

13.

the

all

with

described

machine

thread

thread

Then

thread

it

times.

a

from

wind

is

advisable

and

different

in

for

spool

9,

through

guide

a

tension

-1/23-928/01

Section

bobbin

(Fig.

11

few

turns

bobbin

guide

and

(Fig.

to

have

winder.

19.

winding

3)

through

clockwise

of

4)

10

thread

a

full

machines

Its

(figs.

a

(Fig.

around

clockwise

hole

^),

bobbin

3

and

through

on

30.

The

thread

disc

l^u

tension,

For

sewing

the

tension

Adjusting

Tension

runs

an

If

out

To

onto

even

adjustment

by

adjust

bobbin,

vertically.

Set

the

tension

Turn

or

counter-clockwise,

monofil

to

and

12

should

the

distribution

a

mechanic.

the

loosen

stop

this

a

starting

middle

is

amount

screw

dog

is

disc

and

minimum.

be

so

of

of

required,

of

15

higher

regulated

cloclcwise

transparent

the

bobbin

adjusted

the

the

this

thread

and

for

bobbin.

thread

adjust

more

by

to

that

will

to

thread,

turning

to

decrease

increase

threads

winder

the

This

on

the

be

be

wound

stop

knurled

it.

reduce

(Fig,

thread

ensures

bobbin.

carried

on

dog

or

the

k)

the

l6

lower

for

screw

Push

If

resistance

The

desired

less

bobbin

15.

down

thread.

stop

winder

amount

is

dog

of

After

l6

felt,

stops

thread

the

adjustment,

to

start

turn

the

automatically

has

been

the

bobbin

wound

bobbin

when

tighten

winder.

slightly.

the

on

the

bobbin.

Page 8

I

I

Page 9

Page 10

^•

Removing

the

bobbin

case

(Fig.

3)

5•

Switch

open

Open

out

of

bin

fall

that

by

Hold

slot

emerges

of

your

case

Inserting

Insert

an

toggle

cover

latch

the

out.

the

the

arrow

the

19

left

by

the

bobbin

bobbin

and

at

switch

17

at

l8

(Fig.

sewing

hand.

its

bobbin

full

when

under

its

rear

the

hook

As

open

bobbin

turns

you

fast

the

7

front

5)

latch,

(Fig.

pull

and

end

(Fig.

and

with

long

into

in

the

pull

tension

20.

of

pull

as

6)

the

10)

the

thumb

you

the

the

direction

thread.

the

spring

toI•••

machine

the

and

hold

bobbin

bobbin

thread

bobbin

forefinger

the

cannot

case

indicated

until

I

and

into

(Fig.

case

bob

so

it

5).

Page 11

6.

he.gulatin.g:

the

bobbin

thread

tension

(Fig.

7)

7 o

Turn

or

The

ance

be

threads

(Fig,

Inserting

Open

bobbin

screw

counter-clockwise,

final

of

balanced

8).

the

between

into

the

against

placcc

Then

tension

the

interlock

the

latch

from

thumb

sewing

the

21

clockwise

finished

properly

bobbin

falling

and

bobbin

close

regulation

in

l8

of

forefinger,

hook

cover

out

case

to

seam.

so

the

case

the

and

to

increase

decrease

Both

that

center

(Fig.

bobbin

of

the

close

until

1?

at

depends

tensions

the

needle

of

3)

case.

case.

insert

the

you

the

it.

the

latch.

hear

front

the

on

Hold

the

thread

the

and

material

This

it

of

appear

should

bobbin

keeps

the

bobbin

Push

snap

the

tension,

the

latch

case

lightly

into

machine.

Threading

Pfaff

Switch

a

result,

for

easy

Important

For

threading

thread

Instructions

Pass

the

hole

thread

the

upper

of

463

toggle

threading.

monitor,

thread

thread

guide

the

sewing

the

note

at

thread

2ko

needle

head

switch

needle

machines

please

the

from

guide

guide

Then

on

?

is

end

spool

23

machines

(Fig,

(Fig,

raised

fitted

refer

of

9

(Figo

and

draw

9)

this

22

the

it

10)

to

with

to

the

booklet.

through

3),

three

into

equipped

to

fr—.

its

highest

a

different

Additional

a

through

holes

thread

with

hole

As

point

of

the

of

retainer

25

(to

do

this,

8

push

the

spring-loaded

sleeve

26

Page 12

Page 13

Page 14

to

the

left

slightly),

from

below

between

tension

under

30

and

"t^ke—up

eyelet

monitor

thread

to

right.

Draw

eye

sewing

In

when

abt.

to

order

using

these

2.k

only.

discs

thread

from

lever

30

so

is

eyelet

2

prevent

begins.

to

threads

27,

regulator

right

31*

that

held

33

inches

unthreading

keep

monofil

through

by

over

to

Lead

finger

and

the

left

the

thread

of

tension

and

thread

one

thread

29,

check

through

through

the

thread

32

of

thread.

the

through

of

the

as

transparent

hole

the

Now

needle

low

of

spring

thread

the

hole

through

thread

pass

the

needle

as

threads,

thread

28,

eyelet

of

thread

it

through

from

needle

when

possible

pass

guide

left

9•

10•

10.1.

10.1.1.

10.1.2.

Regulating

The

needle

ing

nut

cated

The

pearance

Inserting

Insertion

Push

into

Loosen

as

again.

on

final

dart

bracket

far

3^»

a

of

knob

as

the

thread

The

scale.

tension

the

and

removing

blade

36

71

it

will

needle

tension

amount

regulation

finished

35

as

and

go.

with

far

pull

thread

of

seam

the

its

as

bracket

Then

tension

is

regulated

tension

depends

dart

two

it

will

tighten

(see

set

Section

blade

guide

go.

36

the

(Fig.

by

is

on

(Fig.

studs

forward

knob

indi

the

9)

turn

ap

6).

10)

10ol.3*

The

and

machine

length

will

determined

now

sew

by

the

the

dart

dart

at

blade.

the

depth

11

Page 15

10.2,

Removal

10.2,1.

11 •

11.1,

11-1,1,

12.

12.1.

Push

35

Enlarsin.g;

Dart

to

every

unchanged,

lever

forward

blade

bracket

enlarge

dart

37

out

the

35

the

blade

backwards

of

bracket

dart

can

36

dart

depth

be

to

depth

used.

turned

the

Loosen knob 71 and push

distance.

s-etting

Setting

and

Then

changing

tighten

the

and

pull

36.

(FIk,

through

rear.

within

However

bracket

the

knob

dart

dart

10)

This

certain

the

36

again.

length

7^

makes

dart

back

selector

blade

by

length

the

it

limits

required

possible

with

r©mains

(Fig.

11)

-

12.2,

The

hexagonal

with

numbers

Every

To make

selected

blades

To

set

dart

length,

indicated

Changing

owitch

of

master

number

sure

for

are

dart

on

the

switch

dart

1

through

stands

that

every

numbered

length

turn

the

dart

machine

6

length

6

for

a

the

correct

dart

blade

accordingly.

selector

knob

39

blade

off

by

(Fig,

selector

at

its

certain

38

until

is

pushing

13),

right

dart

used,

at

the

at

is

dart

length

all

the

number

the

the

marked

end.

length

dart

correct

top.

red

is

button

12

Page 16

Lift

Swing

ball

the

stud

'lO

rectangular

and

pull

end

knob 39

of

the

towards

hexagonal

the

bar

right.

out

^

13.

of

support

the

right

Push

the

bearing

the

hexagonal

knob

Then

selector

Ad.justing

In

the

depth

stroke

the

Press

39

switch

order

full

front

bracket

toward

of

can

pedal

'il

out

new

on

as

the

to

avoid

length

the

be

edge

43

and

of

bearing

dart

bar

the

the

instructed

front

of

dart

set

of

(Fig#

pull

length

swing

back

left

machine

position

that

its

being

at

four

the

13)

dart

into

again.

in

the

stroke,

sewn,

table.

length

bracket

selector

the

support

and

Section

dart

different

down

into

rectangular

set

12.1.

stop

of

blade

regardless

the

front

to

its

selector

the

'il,

and

the

dart

the

has

end

distances

first

end

dart

to

of

38

left

of

push

length

blade

travel

the

of

from

switch

to

its

•

l4.1.

l4.1.1.

14.1.2.

position.

its

central

and

engage

tive

Care

ficient

its

foremost

slipped

Sewing

Before

toggle

Sewing

Switch

Slip

lustrated

dart

should

space

onto

you

switch

with

toggle

the

This

causes

position.

the

stop

depth.

be

taken,

between

position

the

start

7

dart

switch

workpiece

in

Fig.

blade

sewing,

(Fig.

blade

12,

most

onto

the

Now

suitable

however,

tabletop

to

allow

without

check

13)

at

45

(Fig,

the

and

dart

turn

is

front

dart

press

blade

knob

that

and

the

difficulty.

to

at

I I .

position

13)

pedal

44

for

there

dart

workpiece

make

to

blade

to

(Fig.

the

sure

as

43

move

respec

is

blade

il

(Fig.

to

10)

suf

to

that

in

be

13)

down

dart

pedal

its

number

to

blade

front

is

of

the

moves

released,

position.

times

first

switch

to

to

its

the

dart

This

reposition

position.

central

process

blade

the

position.

again

can

workpiece.

As

be

a

result,

returns

repeated

When

the

the

to

any

13

Page 17

Start

the

machine

by

pushing

pedal

^3

(Fig*

13)

1^,1,6,

1^*2,

down

clamped

strip

dart

Shortly

of

its

is

started,

At

the

bar

reverses

returns

Remove

the

next

pedal

Sewing

as

k7

blade.

travel,

extreme

the

again,

with

far

as

between

and

before

and

to

its

sewn

workpiece

dart

it

work

pulled

the

its

the

right

its

front

part

will

holder

toward

work

speed

bartack

of

direction

position

from

onto

blade

go.

holder

its

the

at

is

the

rear

The

bar

the

reduced,

sewn.

travel,

of

feed,

and

machine,

dart

workpiece

^i6

and

right

bar

reaches

the

the

the

blade

position

off

the

carrier

work

dart

dart

stack

and

is

the

the

sewing

is

depress

end

machine

holder

blade

sewn,

it,

slip

the

1^,2,1,

14.2,2,

15*

Switch

With

cycle

for

However

position

position•

Only

the

the

position),

Switching

When

is

the

sewing

after

work

dart

the

pressed,

toggle

up

the

toggle

to

par,

with

dart

right

the

holder

blade

off

red

the

switch

switch

dart

away,

sewing

bar

return

the

button

machine

14,1,5*

blade

has

machine

of

45

in

blade

does

but

cycle

to

master

(Fig,

this

is

the

at

not

first

has

released

its

(Fig,

is

switched

13)

position,

same

front

return

moves

been

the

starting

13)

switch

to

as

position.

to

completed

workpiece

6

off

the

that

to

its

its

position

(Fig,

instantly.

work

described

front

rear

and

does

(front

13)

14

Page 18

47

46

12

a

13

Page 19

i

m

S"

Page 20

16•

Needle

and

thread

breakage

17•

V;hen

in

the

thread

cycle,

has

completed

(Fig.

Then

13)

insert

Section

instructions

has

been

The

machine

Machine

Conditioning

When

conditioning

The

the

the

oil

water

needle

monitor

however,

to

3,

or

eliminated,

care

machine

level

level

its

a

new

rethread

given

is

unit

unit

must

or

is

now

must

the

^8

not

cycle,

needle,

in

ready

(Fig,

is

every

not

thread

(Fig,

interrupted.

switch

the

Section

switch

for

l^i)

constantly

day.

drop

not

rise

12)

as

needle

toggle

below

breaks,

lights

toggle

instructed

according

9.

After

sewing

in

use,

mark

above

the

up.

When

switch

again.

mark

red

The

the

switch

in

the

7

check

,

and

5*

lamp

sewing

machine

7

to

trouble

to

the

the

17»2.

17*3»

To

drain

three

tighten

If

required,

container

Oiling

There

tion

between

(Fig.

No.

On

28O-I-12O

machines

apply

foam

intervals

Cleaning

turns.

the

should

system

16).

a

plastic

the

drain

50•

the

few

the

water,

When

screw

have

machine

be

so

two

If

required,

equipped

drops

pad

(see

hiachine

enough

that

marks

ikk)

arrows

the

a

through

of

of

open

water

^9

securely

mechanic

(Figs.

oil

the

on

with

oil

the

in

drain

13

oil

oil

top

Pfaff

to

needle

Fig,

has

in

level

up

hole

the

top

and

the

sight

15)*

screw

been

again.

up

16)

the

52.

^63

upper

bar

hook

is

glass

oil

at

'19

drained,

the

lubrica

located

sewing

and

regular

two

oil

51

(Order

lower

to

in

head,

Regularly

of

the

To

get

the

front

remove

sewing

at

the

of

hook

hook,

the

the

with

open

machine.

lint.

a

cover

Clean

soft

the

brush

17

vicinity

every

(Fig.

day.

5)

17

Page 21

o

Additional

Instructions

Page 22

18,

Additional

and

-1/25

instructions

for

the

Pfaff

3516-1/24

l8,l.

Threading

new-type

Switch

Pass

a

then

17.

Make

tainer

sleeve

front

is

right.

Then

the

hole

thread

sure

of

drawn

switch

thread

toggle

thread

of

25

26

wire

through

the

the

the

the

(to

to

toggle

needle

switch

thread

thread

do

the

32

monitor

from

machine

this,

left

of

the

the

svritch 7

(Pfaff

7

(Fig.

the

spool

guide

as

is

drawn

push

slightly),

thread

needle

463

sewing

13)

to

up

on

the

illustrated

into

the

spring-loaded

monitor,

eye

from

(Fig.

I 1**n|

and

thread

thread

passes

13)

head

through

in

in

and

left

to

with

stand,

Fig.

re

to

\

21

Page 23

Page 24

19

•

Additional

and

-1/25-928/01

instructions

for

the

Pfaff

3516-1/2^-928/01

19.1.

19*I*1*

19.1.2.

^

19.1.3.

19.1.^i.

Windinjz;

Pass

hole

then

the

of

thread

illustrated

thread

sure

1.1

loaded

The

kniirled

to

wise,

To

the

(to

thread

decrease

start

spindle

IP

the

bobbin,

the

bobbin

thread

the

thread

the

in

counter-clockwise

thread

do

this,

sleeve

1.2).

tension

disc

to

with

thread

the

increase

the

your

1.3.

bobbin

piles

adjust

from

machine

Fig.

is

slightly

Turn

tension,

it.

thumb

thread

(Pfaff

the

guide

18,

drawn

is

winder,

up

483

spool

on

for

Wind

on

into

push

regulated

this

or

(see

on

one

guide

sewing

up

and

the

thread

bobbin

a

bobbin

thread

few

winding

turns

13.

down

by

turning

disc

counter-clock-

push

clockwise

in

arrow).

side

1.4

of

accordingly.

head)

through

retainer

the

the

the

a

stand,

as

of

Make

spring-

winder

19.2.4.

19.2.

19.2.1.

The

amount

bin

is

adjusting

Threading

Switch

Pass

a

then

19.

Make

tainer

sleeve

front

is

r

the

hole

thread

sure

drawn

ight.

regulated

toggle

thread

of

25

26

of

wire

through

of

stud

the

the

the

(to

to

thread

needle

the

the

by

1.6.

switch

from

thread

machine

thread

do

this,

left

32

of

the

to

be

loosening

(Pfaff

7

(Fig,

the

guide

as

is

drawn

push

slightly),

the

thread

needle

wound

spool

on

illustrated

screw

483

13)

up

the

into

the

monitor,

eye

on

the

1.5

sewing

to

and

thread

spring-loaded

head)

I' "

through

in

thread

passes

from

left

bob

and

^1

stand,

Fig.

re

in

and

to

Then

switch

toggle

switch

7

(Fig.

13)

to

23

Page 25

20.

Additional

and

-l/25-92fi/01

instructions

for

the

Plaff

3516-1/25

20.1.

20.1.1.

20.1.2.

Swiichin.G;

Switch

In

this

the

beginning

Switch

In

this

and

end

on

tlie

toggle

position of

toggle

position

of

switch

of

switch

the

start

the

of

seam

the

the

and

1.7

$eam

1.7

are

finish

to

switch,

only.

IP 1I •

switch,

backtacked.

bartacks

1f~~11

a

the

tack

beginning

(Fi

.

is

made

at

Page 26

PFAFF

INDUSTRIEMASCHINEN

GMBH

r^

KAISERSLAUTERN

Gedrucktinder

Bundesrepublik

Deutschland-PrintedinWest

Germany-ImprimeenR.F^.•Impresoenla

R.F.A.

Loading...

Loading...