Page 1

PFAFF

238

238-0

I

Instruction

and

Service

Book

Manual

R

9030

Page 2

/ hphee ^

(

PFAFF)

238

238-0

High-Speed

Organized

and

transverse

Zigzag

with

instruction

and

Service

Sewing

iink

take-up

rotary

hook

Manuai

Machine

Book

G-MPFAFFAG-KAISERSLAUTERN

BRANCH

Page 3

Foreword

This

Instruction

high-speed

of

answering

on

the

construction,

interested

as

possible.

The

instructions

be

much

appreciated

the

best

serviced

instructions

to

which

by an

affordabetter

you

book

contains

zigzag

all

questions

sewing

machines.

relatedtosewing

function

and

operatortogettoknow

for

mechanics

by all

maintenance

sewing

machine

expert.

as

simpleaspossiblle

We

will

have

understanding.

may

wishtomake.

much

vaiuable

Though

not

exhaustively, it offers sufficient information

operationofthe

her

machine

containedinthe

men

work

satisfactorily

made

every

and

have

We

welcome

Information

intendedasa

various

and

attain

maximum

second

servicing

only

partofthis

our

if it is

efforttorender

included

any

numerous

suggestions

about

Pfaff

238

and

full-scale

textbook

mechanismstoenable

efficiencyasquickly

book

willnodoubt

sewing

machines

employed

the

presentationofthese

properly

since

illustrationsinorder

and

recommendations

238-0

capable

every

even

and

G.M.PFAFF

AG

Page 4

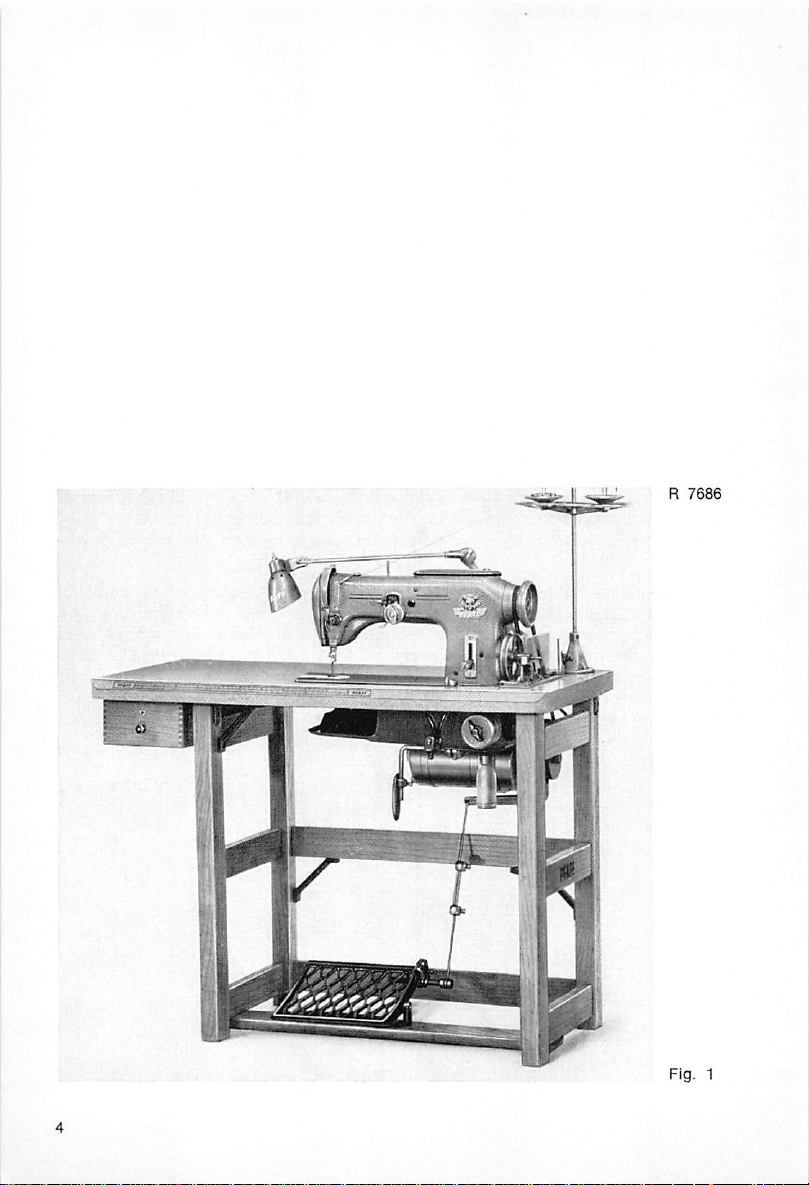

Page 5

Instructions

1.

Brief

Descriptionofthe

The

Pfaff 238

which has been redesigned to match

ward

appearance

for

high-speed

and

Operators

Pfaff

238

zigzag sewing machine Is an Improved version of

our

modern high-speed straight stitchers In out

sewing

performance.

the

Pfaff 138

Like the Pfaff 138, It Is organized with link take-up and transverse rotary sewing hook

which features a special balancing collar In order to

The Pfaff 238 Is supplied in Models A

stitches

The

Model B machines

speedof3,500

If

about

As a

per

Inch.

permissible

desired,

top

s.p.m.

Model B

speedofthe

are

normally fitted for a stitch width of 11/64", or 4.5 mm, and a

machines

'A", or 6.0 mm, and maximum

special

variety,

the

can

Pfaff

width of 5/32" and a sustained

and

machine

be fitted with a

speed

238

can

be

speed

of 3,800 s.p.m.

B for a maximum stitch length of down to 7

depends

of 3,200 s.p.m.

suppliedInModelAforamaximum

ensure

on

special

vibratlonless running.

the

model

and

parts

set

for a stitch width of

the

stitch

width.

top

stitch

2.

Setting

In

power

most

Up

Instanoes,

table

are

the

Machine

the

packed

Pfaff 238 Is

The machine Is driven by a

suit

local

requirements.)

PowerIstransmitted

or

10 mm,

When

and

The

as

mayberequired.

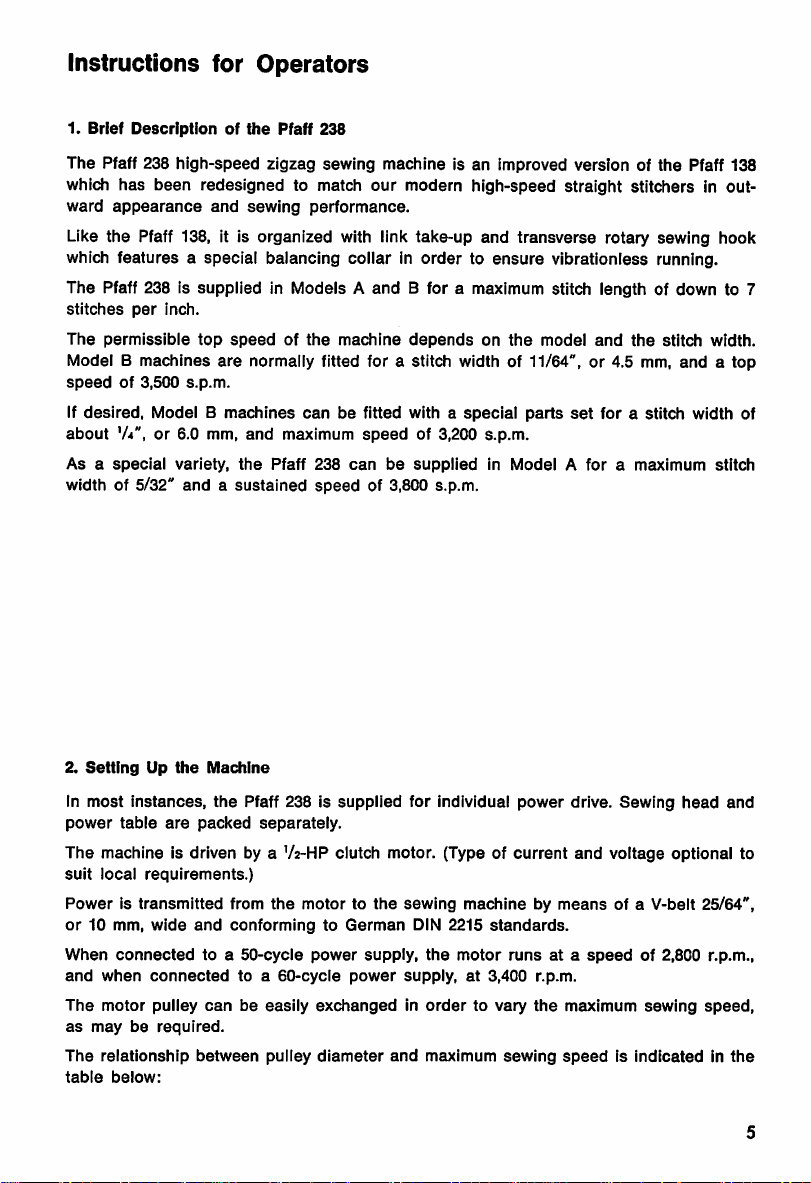

The

table

wide

connected

when

connected

motor

pulley

relationship

below:

from

and

conformingtoGerman

to a

50-cycle

to a

canbeeasily

between

separately.

Va-HP

the

motortothe

power

60-cycle

exchangedInorder

pulley

diameter

supplied

for Individual

power

drive.

Sewing

head

and

clutch motor. (Type of current and voltage optional to

sewing

supply,

power

supply,at3,400 r.p.m.

and

machinebymeans

DIN 2215

the

motor

to vary

maximum

standards.

runsata

the

sewing

of a V-belt 25/64",

speed

of 2,800 r.p.m.,

maximum

speedIsIndicatedInthe

sewing

speed,

Page 6

dm

mm

71

Balance

Whppj

nip.

D

mmdmmm

76

Motor

63 68

Motor

D

mm

Speed

Pulley

16-437

Order

No.

2,800

Dia.

010-55

r.p.m.

Stitches

per

Minute

2,500

dm

mm

-

Motor

Motor

D

mm

-

Speed

Pulley

-

Dia.

Order

No.

3,400

r.p.m.

Stitdies

per

Minute

71

71

71

71

71

71

71

dfn ~

63

67

68

71

mm

mm

mm

mm

76

76

76

76

76

76

76

effective

=

2.48",

=

2.64",

=

2.67",

=

2.79",

dm

- 0

67

71

75

80

85

90 95

95

100

diameter

72

16-437

020-55

76

16-437

030-55

80

16-437

040-55

85

16-437

050-55

90

16-437

060-55

16-437

070-55

16-437

080-55

72

75

76

80

Fig.

2

mm

mm

mm

mm

=

=

=

=

2,600

2,800

3,000

3,200

3,400

3,600

3,800

0 =

2.83",

2.95",

3.00",

3.15",

- - -

- -

-

68

63

67

72

71

76

75

80

80

85

outside

diameter

16-437

010-55

16-437

020-55

16-437

030-55

16-437

040-55

16-437

050-55

85

mm=3,35",

90 mm = 3.54",

95 mm =

100

mm=3.94".

-

-•

3,000

3,200

3,400

3.600

3,800

3.74",

Unpack

lid

that

the

To

lift

For

the

The

this

the

sewing

from

the

box,

support

dust

facilitate

the

adjusting

motor.

and

motor

the

mount

the

the

machineisdispatched

condition.

head

unscrew

machineinthe

the

machineonthe

mountingofthe

and

pull

the

V-belt

tension,

cautiouslytoavoid

the

wood

screws

box.

Cautiously

tablesothatitrestsonthe

V-belt,

slip

belt

onto

the

motor

please

refertothe

without

oil in

damagetothe

which

hold

lift

the

it on

the

pulley.

instructions

the

reservoir

the

machine

machine

and

machine.

cushioned

outofthe

pulley first.

which

must

not

After

rubber

are

removing

wooden

box,

Then

furnished

be

run

wipe

pads.

while

the

blocks

off

slightly

with

in

Page 7

3.

The

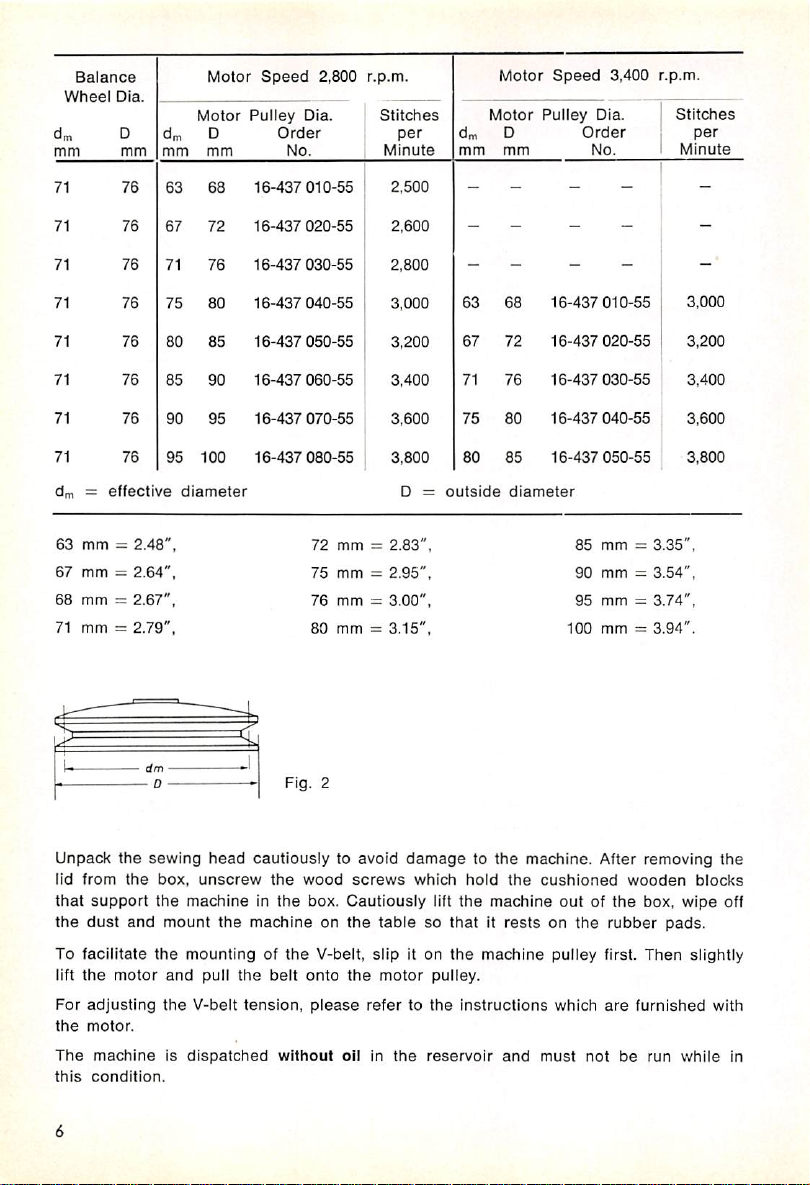

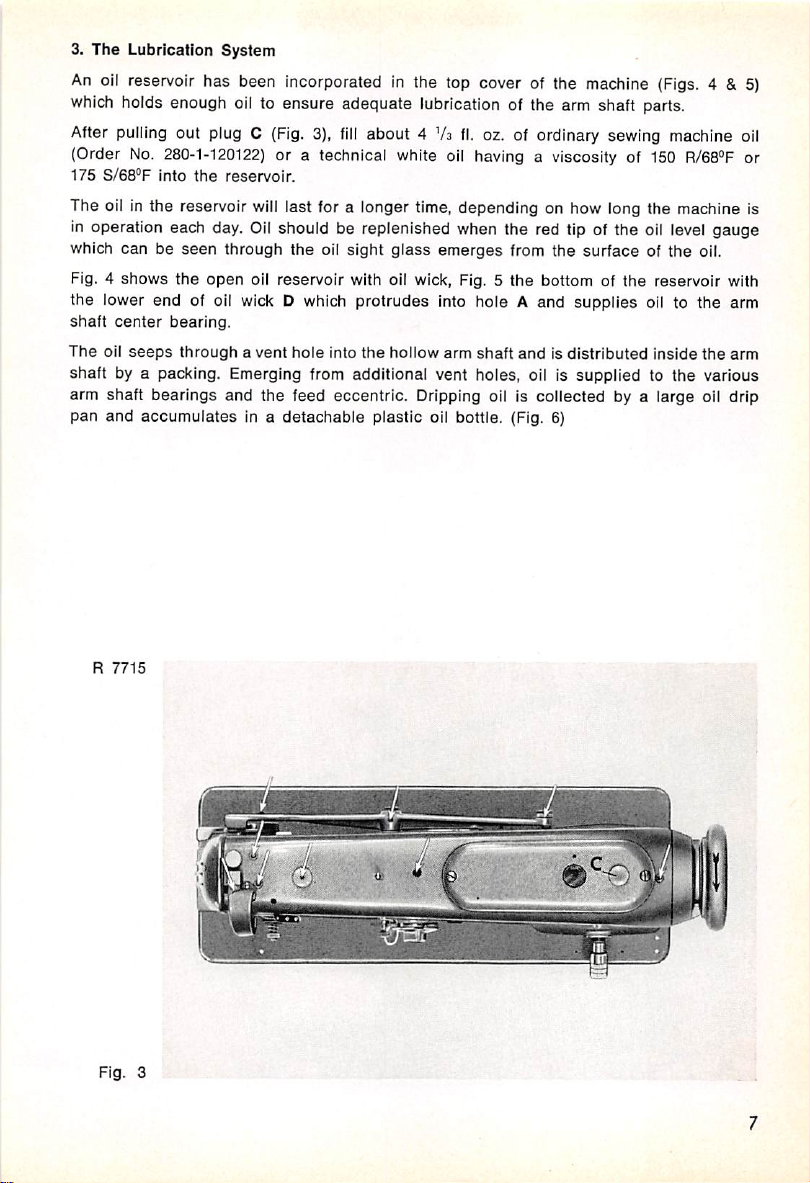

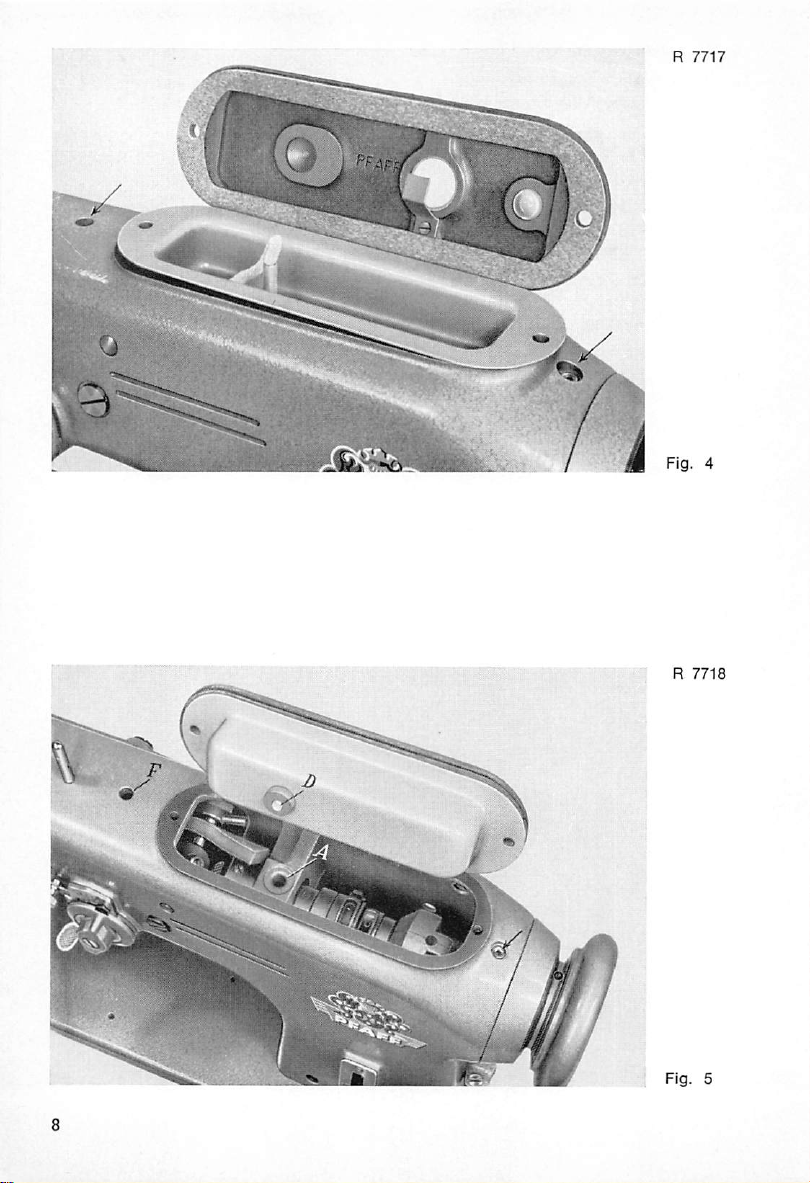

An

Lubrication

oil

reservoir

System

has been

Incorporated

in the top cover of the

machine

(Figs.

4 &5)

which holds enough oil to ensure adequate lubrication of the arm shaft parts.

After pulling out plug C

(Order

No.

280-1-120122)

175

S/es'F

Into

the

The oil in the reservoir

in operation each day.

which can be

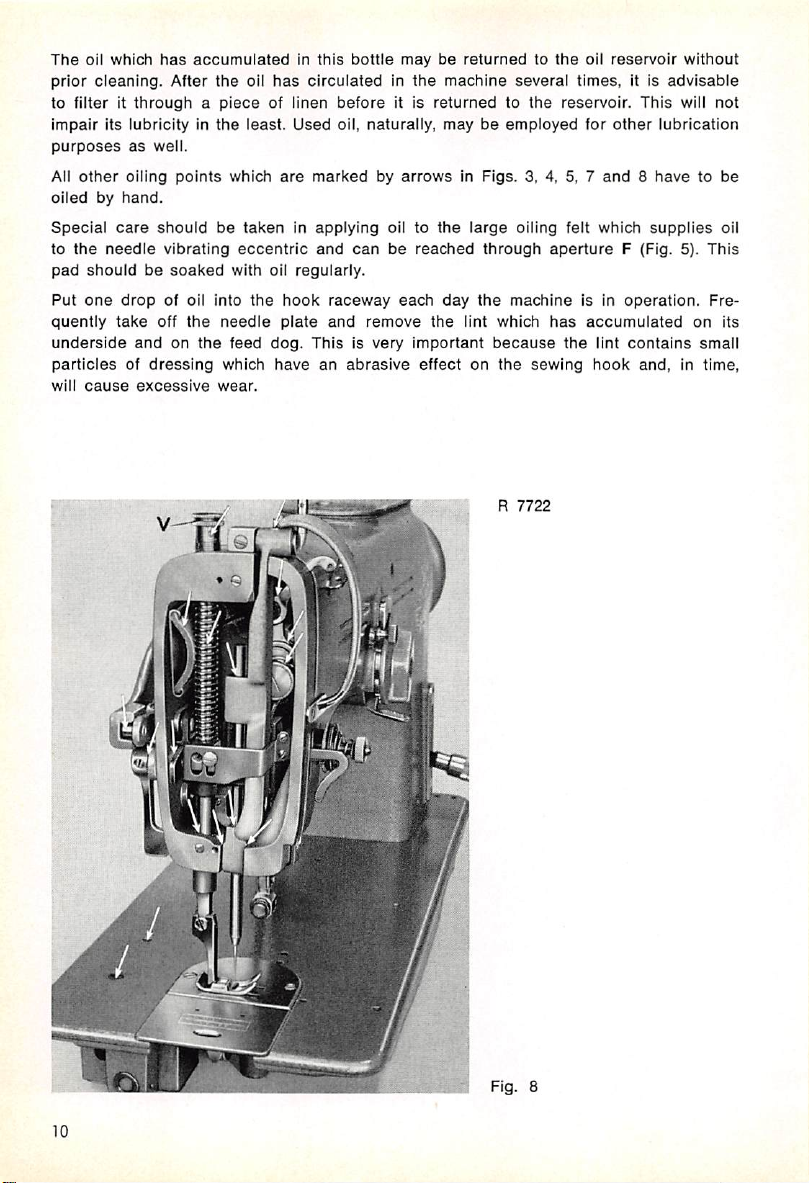

Fig. 4 shows the

the lower end of oil wick D which protrudes into hole A and supplies oil to the arm

shaft

center

The

oil

seeps

seen

open

bearing.

throughavent

(Fig.

3),

fill

about 4Vsfl.

or a technical white oil having a viscosity of 150

reservoir.

will

last for a longer time, depending on how long the ma<^ine is

Oil

should be replenished when the red tip of the oil level gauge

through the oil

sight

glass

oz. of ordinary sewing machine oil

emerges

from the

surface

of the oil.

R/68°F

oil reservoir with oil wick, Fig. 5 the bottom of the reservoir with

hole

into

the

hollow

arm

shaft

andisdistributed

inside

the

arm

shaft by a packing. Emerging from additional vent holes, oil is supplied to the various

arm shaft

pan and

bearings

accumulates

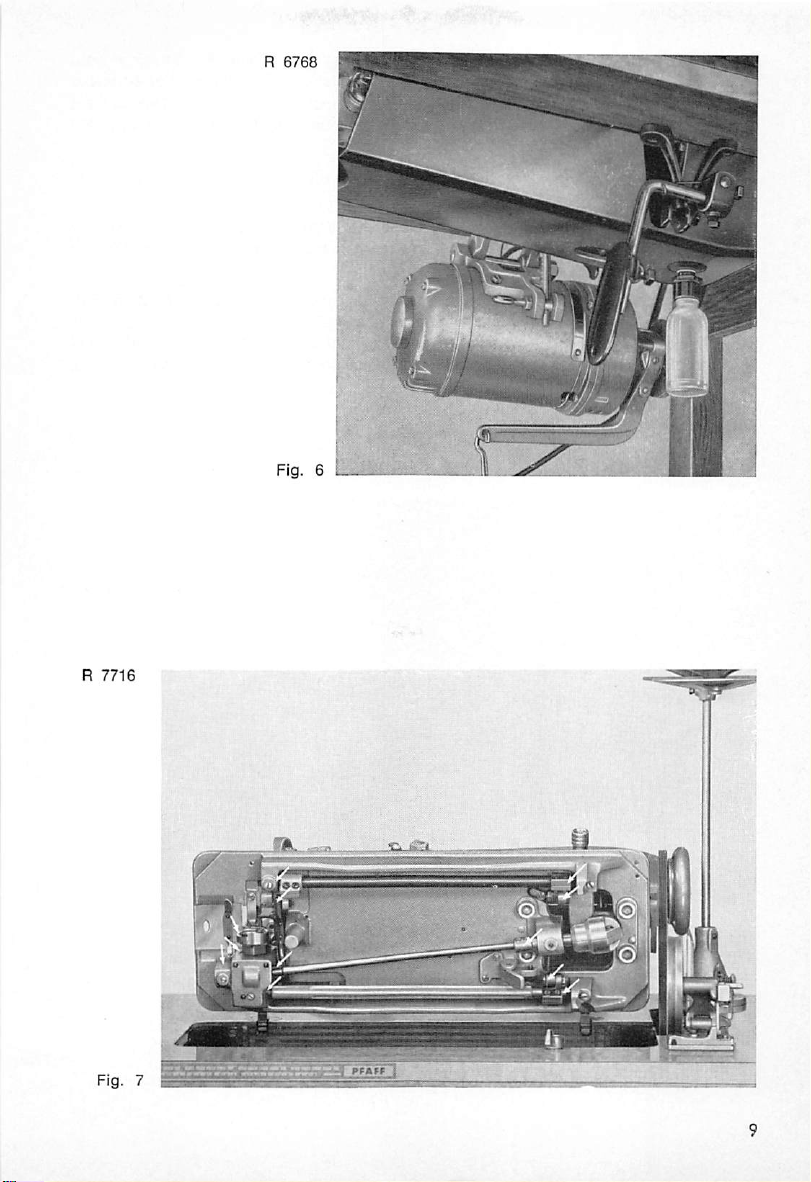

and the feed eccentric. Dripping oil is collected by a large oil drip

in a detachable plastic oil bottle. (Fig. 6)

or

R

Fig.

7715

3

Page 8

Page 9

Page 10

The

oil

which

has

prior

cleaning.

to filter it

Impair

its

purposes

All

other

oiledbyhand.

Special

to

the

needle

pad

shouldbesoaked

Put

one

quently

underside

After

throughapiece

lubricityinthe

as

well.

oiling

points

care

shouldbetakeninapplying

vibrating

drop

of oil

take

off

the

andonthe

particlesofdressing

will

cause

excessive

accumulatedinthis

the

oil

has

circulatedinthe

of linen

least.

Used

which

are

markedbyarrowsinFigs.

with oil

into

needle

feed

which

wear.

eccentric

the

and

regularly.

hook

plate

dog.

Thisisvery

haveanabrasive

bottle

before

oil,

can

raceway

and

maybereturnedtothe

machine

it is

returnedtothe

naturally,

remove

oil to

be

each

the

reached

the

maybeemployed

large

through

day

the

lint

Important

effect

on

several

3, 4, 5, 7

oiling felt

machine

which

because

the

sewing

R

7722

oil

reservoir

times,

it Is

without

advisable

reservoir. This will not

for

other

lubrication

and8havetobe

which

supplies

aperture

has

is in

accumulated

the

lint

hook

F (Fig. 5).

operation.

on

contains

and,intime,

oil

This

Fre

its

small

Fig.

8

10

Page 11

4.

Test-Running

the

Machine

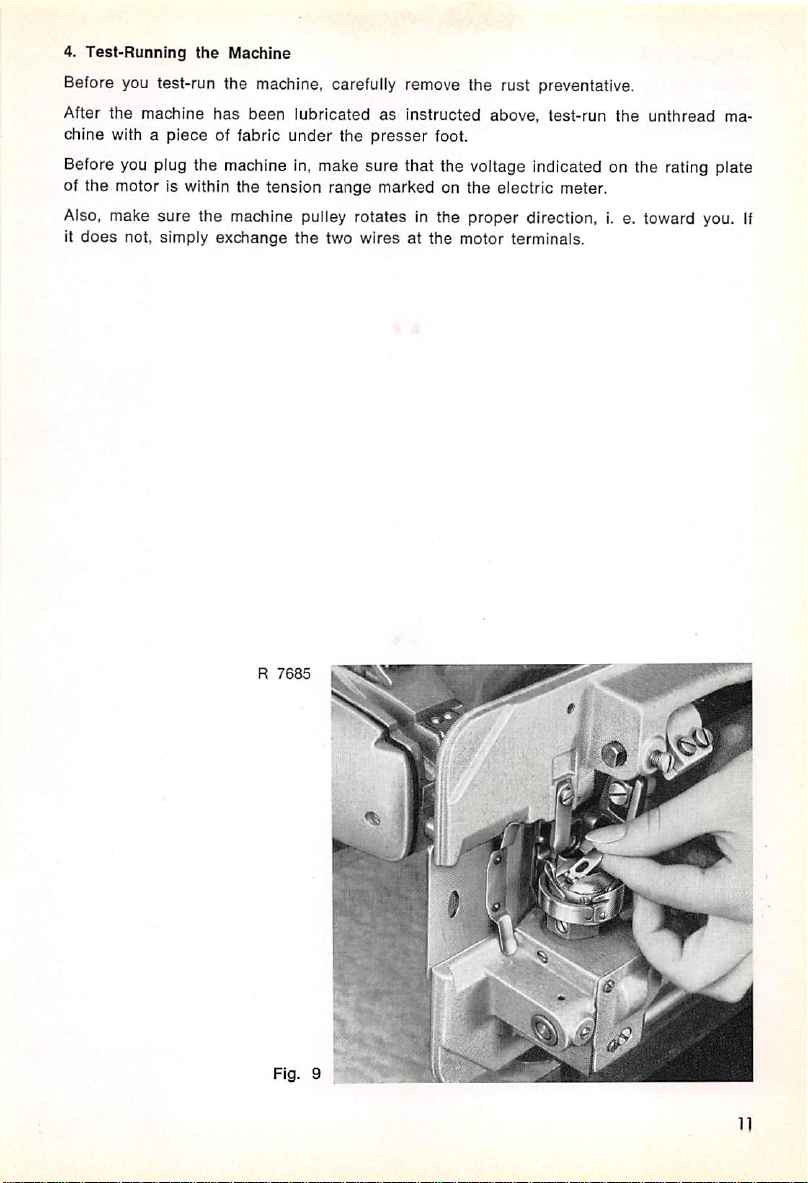

Before you test-run the machine, carefully remove the rust preventative.

After

the

machine

chine with a

Before you plug the machine

piece

has

been

of fabric

lubricatedasinstructed

under

the

presser

In,

make sure that the voltage indicated on the rating plate

foot.

above,

test-run

the

unthread

ma

of the motor is within the tension range marked on the electric meter.

Also, make sure the machine pulley rotates in the proper direction, i. e. toward you. If

it

does

not, simply

exchange

the two wires at the motor terminals.

R

7685

Fig.

9

11

Page 12

5.

Removing

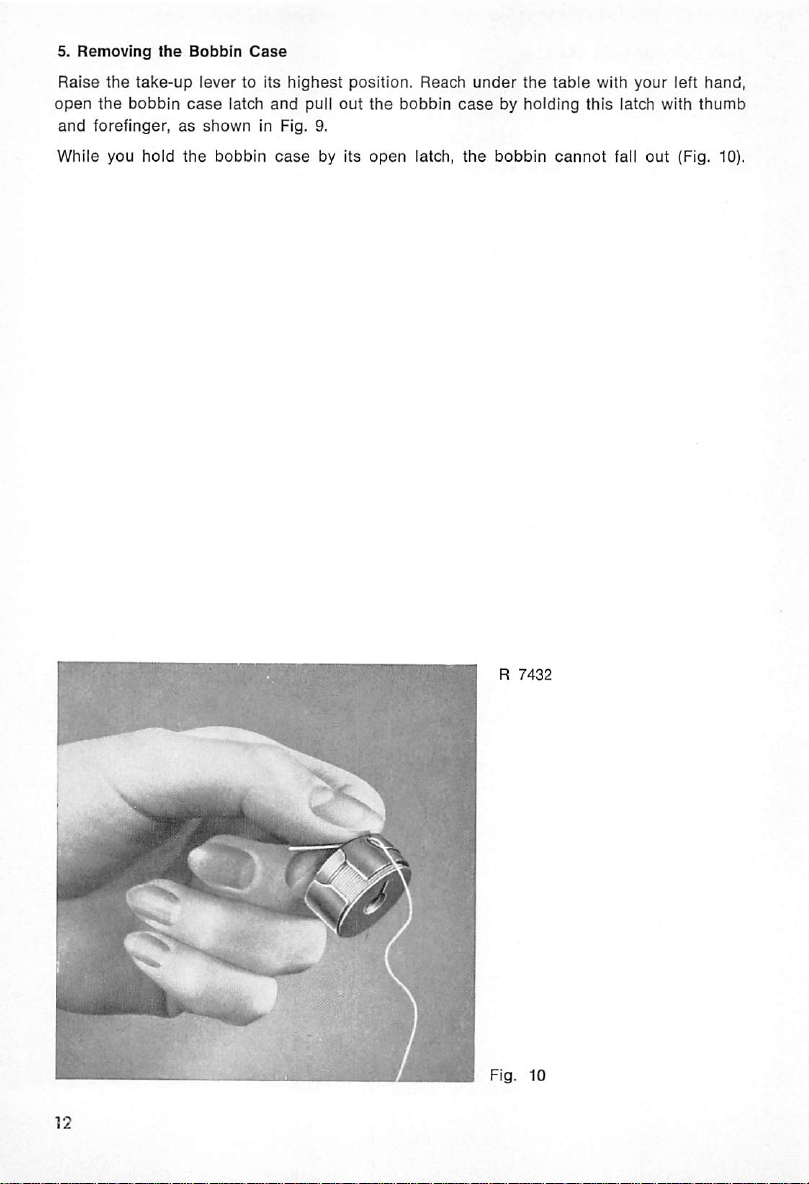

Raise

open

and

forefinger,asshown

While

the

the

you

the

take-up

bobbin

hold

Bobbin

lever

case

the

to its

latch

bobbin

Case

highest

and

in Fig. 9.

case

pull

out

by its

position.

the

open

Reach

bobbin

latch,

under

the

table

casebyholding

the

bobbin

cannot

with

this

your

latch with

fall

out

left

hand,

thumb

(Fig. 10).

R

7432

Fig. 10

Page 13

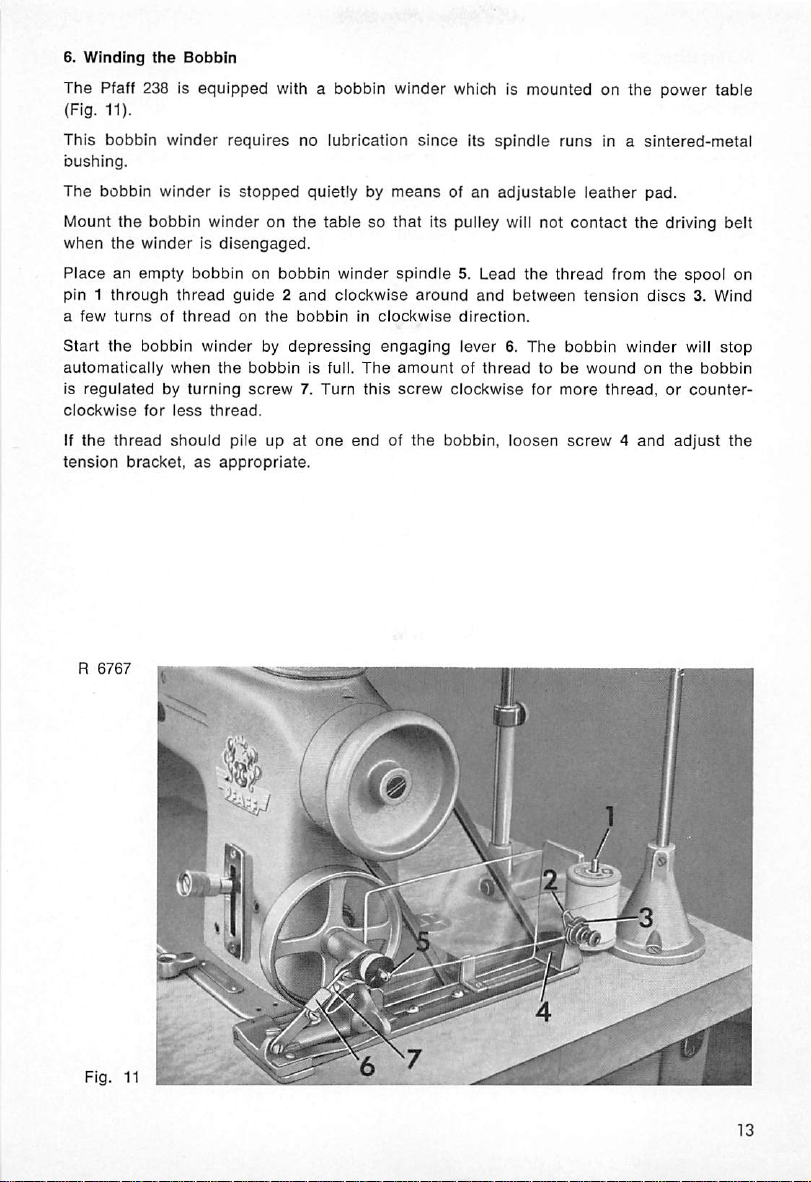

6.

Winding

The

(Fig.

This

bushing.

The

Mount

when

Placeanempty

pin1through

a

few

Start

automatically

is

regulatedbyturning

clockwise

If

the

tension

the

Pfaff 238 is

11).

bobbin

bobbin

winder

winderisstopped

the

bobbin

the

winderisdisengaged.

thread

turns

of

the

bobbin

when

for

less

thread

should

bracket,asappropriate.

Bobbin

equipped

requires

with a bobbin

no

quietly by

winderonthe

bobbinonbobbin

guide2and

thread

on

the

bobbininclockwise

winderbydepressing

the

bobbin

is full.

screw7.Turn

thread.

pile up at

lubrication

tablesothat

winder

clockwise

engaging

The

this

one

endofthe

winder

since

means

which is

of an

its

spindle

adjustable

mountedonthe

its pulley will not

spindle5.Lead

around

direction.

lever6.The

amountofthreadtobe

screw

clockwise

bobbin,

and

the

between

for

loosen

runs

in a

leather

contact

thread

from

tension

bobbin

winder

woundonthe

more

thread,orcounter

screw4and

power

sintered-metal

pad.

the

driving

the

spool

discs3.Wind

will

bobbin

adjust

table

belt

on

stop

the

R

Fig.

6767

m

».

IT

11

^^7

Page 14

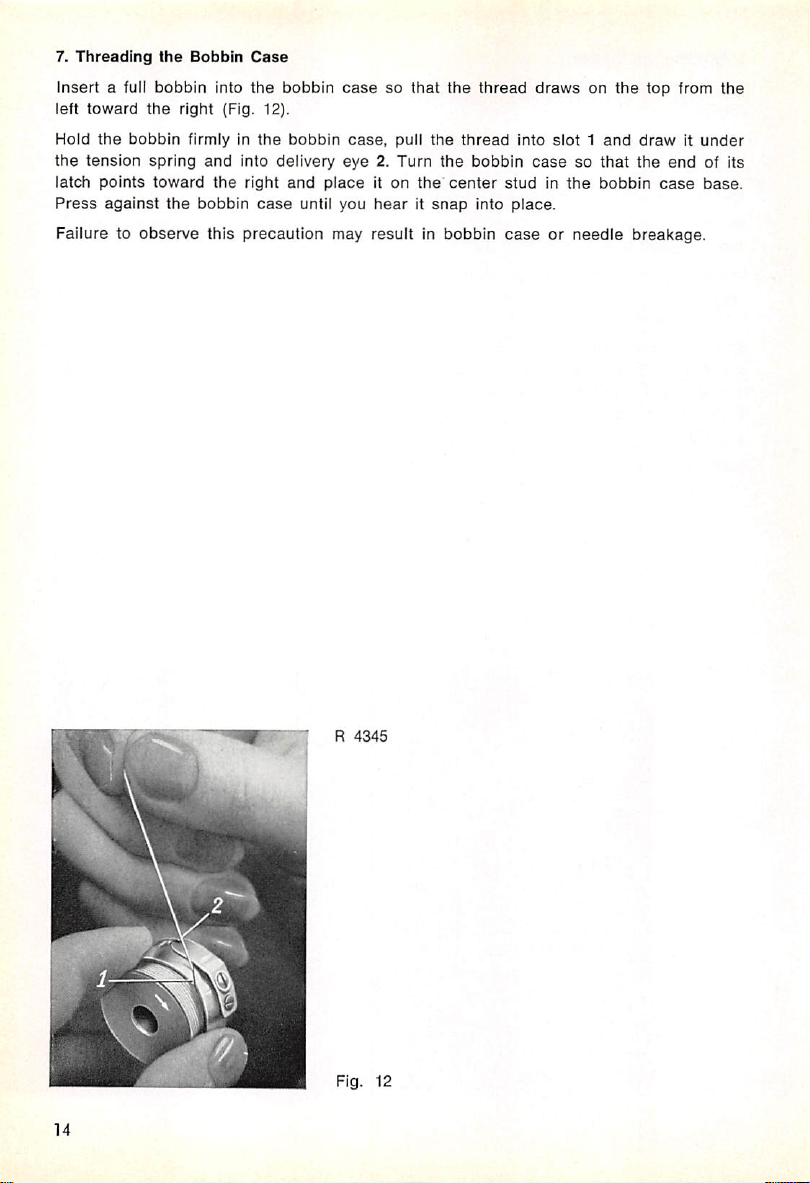

7.

Threading

Insert a full

left

toward

Hoid

the

the

tension

iatch

points

Press

against

Failure to

the

bobbin

the

bobbin

spring

toward

observe

Bobbin

right

firmly in

the

into

(Fig. 12).

and

the

bobbin

Case

the

bobbin

the

bobbin

into delivery

right

and

case

until you

casesothat

case,

eye

2. Turn

placeiton

hearitsnap

puli

this precaution may result in bobbin

the

the

the

the

center

thread

thread

bobbin

studinthe

into

place.

caseorneedle

drawsonthe

into

slot1and

casesothat

top from

drawitunder

the

bobbin

breakage.

end

case

the

of its

base.

R

4345

Fig.

12

14

Page 15

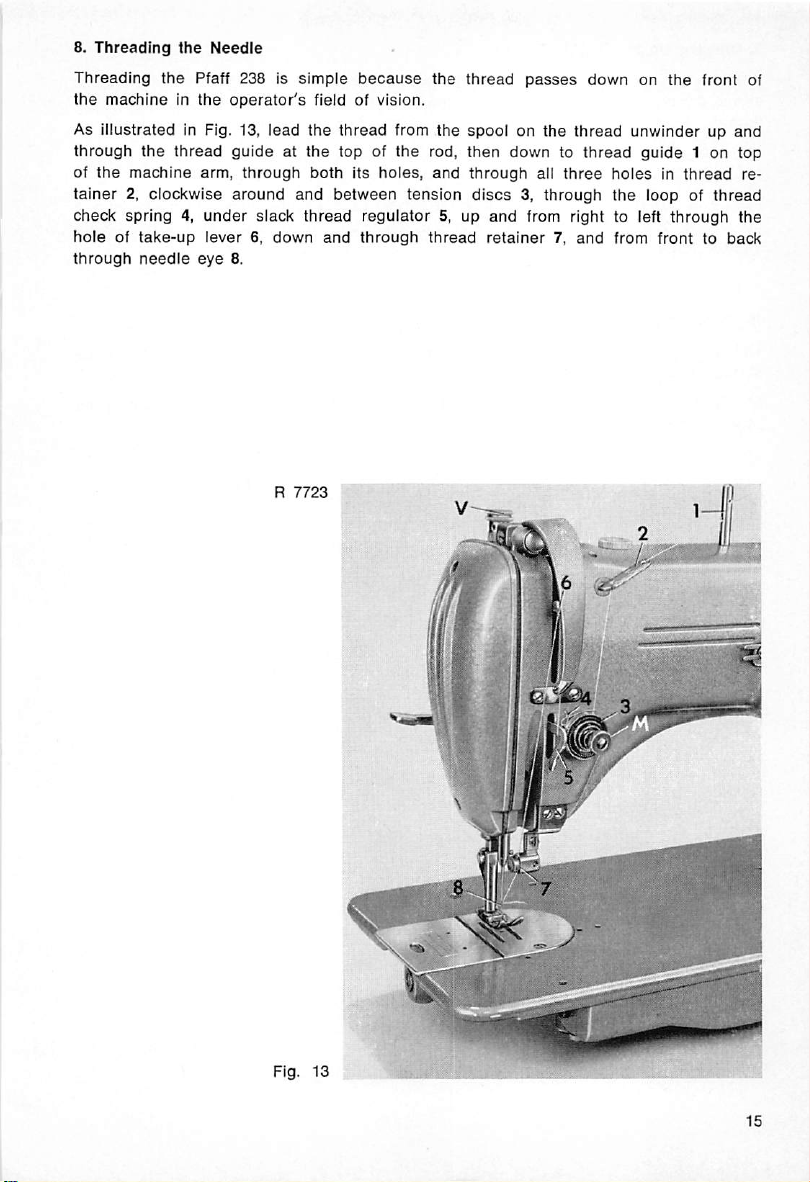

8.

Threading

Threading

the

machineinthe

the

the

Pfaff 238 Is

Needle

operator's

simple

because

field of vision.

the

thread

passes

down on

the

front of

As iiiustrated in Fig. 13, lead the thread from the spool on the thread unwinder up and

through

of

tainer

check

holeoftake-up

through

the

the

machine

2, clockwise

spring4,under

needle

thread

arm,

lever6,down

eye

8.

guideatthe

through

around

slack

R

both

and

thread

7723

top of

its

between

and

the

holes,

tension

regulator

through

rod,

then

and

through

discs3,through

5, up

and

thread

retainer7,and

downtothread

all

three

holesinthread

the

from right to left

guide

loop of

from

1 on top

re

thread

through

fronttoback

the

Fig. 13

Page 16

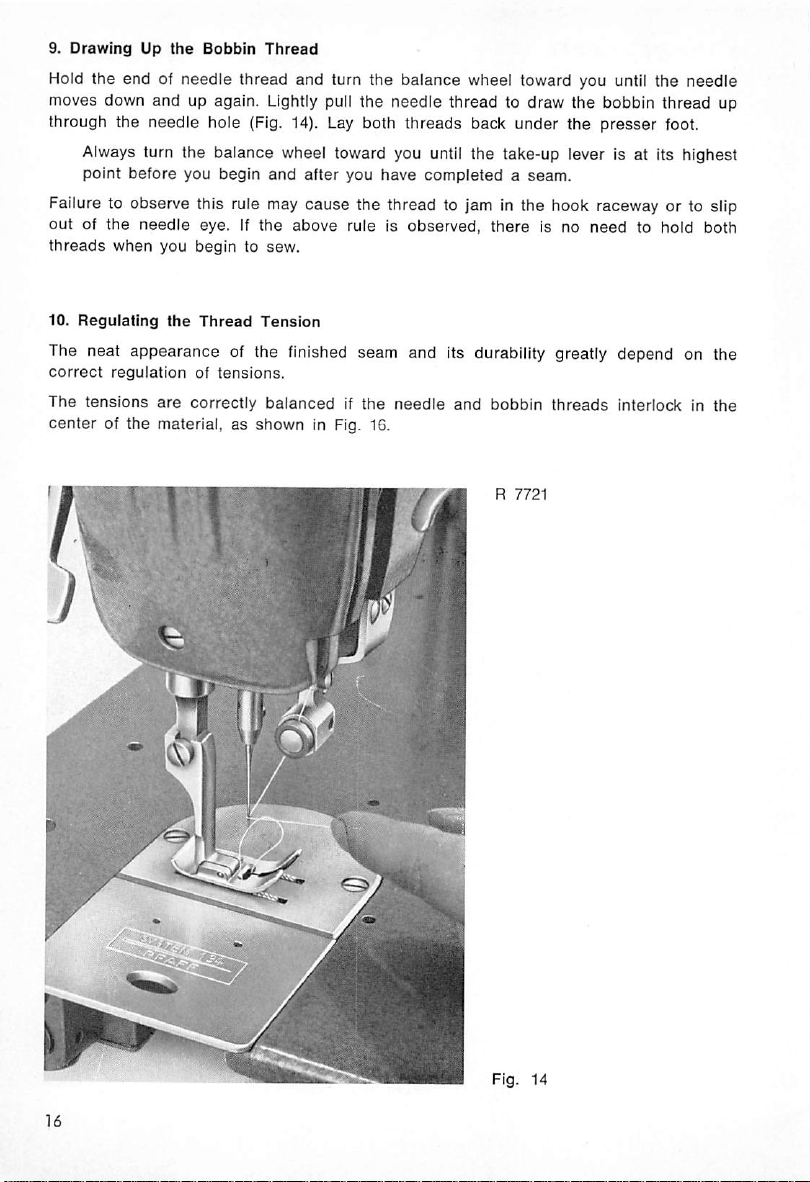

9.

DrawingUpthe

Bobbin

Thread

Hold the end of needle thread and turn the balance wheel toward you until the needle

moves down and up again. Lightly pull the needle thread to draw the bobbin thread up

through the

Always

point

needle

hole (Fig. 14). Lay both

threads

back under the

presser

foot.

turn the balance wheel toward you until the take-up lever is at its highest

before

you

begin

and

after

you

have

completedaseam.

Failure to observe this rule may cause the thread to jam In the hook raceway or to slip

outofthe

threads

10.

Regulating

needle

when you

the

eye. If

begin

Thread

the

to sew.

Tension

above

rule is

observed,

there

is no

need

to hold both

The neat appearance of the finished seam and its durability greatly depend on the

correct

The

centerofthe

regulation

tensions

of

tensions.

are

correctly

balancedifthe

material,asshown

in Fig. 16.

needle

and

bobbin

threads

interlock in

the

Fig. 14

Page 17

The needle thread

ed, by turning it counter-clockwise (Fig. 13).

The bobbin thread tension is regulated by means of the small hook screwdriver. Turn

tension screw z in for more tension, or out, for less tension

The tensions should be regulated according to the material to be sewn. Check to see

that the

the

stitches

stitches

zigzag pattern on the lop and

The grade of thread used plays an important part in obtaining a perfect seam on any

material. Sheer fabrics require a thin and soft thread, whereas stiff and resistant threads,

because of their low resilience, are unsuitable for almost any fabric.

You will

adjustment.

havetohave

are

should

tension

tightly

lieina

a little

is increased by

drawninwithout

straight

experienceinorder

bottom

line,

of the material

turning

tension

puckering

andinzigzag

without

to be

nutM

clockwise,

(Fig.

the

material,instraight

sewing,

should

kinking.

Fig. 15

able

to tell which

15).

and decreas

sewing,

formaperfect

tension

needs

Fig. 16

Fig.

Fig.

17

18

Page 18

In Fig. 17

In Fig. 18

You will

needs

bottom

havetodecide

to be

of

Always lower

is

raised,

it will

11.

Regulating

The

stitch

19).

This

appliestoboth

Turn

this

thumb

The

numerals

The

feed

regulator

action.

When

you

in

reverse.

leased

(Fig. 19).

either

the

upper

either

the

upper

tension

tension

is too tignt, or

is too weak, or

in every individual

adjusted,

the

fabric.

the

particulary when

presser

automatically

the

Stitch

bar

Length

before

release

you

lengthisregulatedbyturning

push

The

straight

nut

right

for

on

the

left of

leverispermanently

the

feed

regulator

lever

will

This

featureisparticularly

shorter

the

return

and

stitches,orleft,

slot

indicate

leverupbeyond

to its

case,ifeither

the

thread

adjust

the

tension.

thumb

zigzag

held

forward

useful

the

lower

tension

the

lower

tension

the

upperorthe

forms small knots or kinks on

the

upper

nut

tension.

S on

the

When

feed

sewing.

for

longer

stitches.

the

stitch

lengthinmillimeters.

downinforward

the

feeding

for

feeding

zero

mark,

position

backtacking.

the

automatically,

too weak.

too tight.

lower

tension

the

presser

regulator

positionbyspring

machine

lever

will

when

top

or

bar

(Fig.

feed

re

•mi

R

7720

Fig. 19

Page 19

12.

Regulating

The

stitch

machine

millimeters.

When

pointer

When

you

makes

the

With

the

about

3/16" or

There

is a

ScrewBservestolock

If

you

set

fixed

and

this, knob G

tacking

wider

zigzag stitch.

gageinnotch

automatically.

Switching from

stitch

width

the

Stitch

widthisregulated

arm

(Fig. 20).

Z is

setonzero,

turn

knob

zigzag

stitch.

zigzag

knobatthe

V4"

(4.5 or 6.0 mm) wide,

small

lug on

the

zigzag

will

notbedisturbedbythe

canbejerkedtozero

the

end

of a

Returnedtothe

R of

straight

can

be

done

Width

by

G to

The

numerals

the

extreme

turning

the

left,

knobGwhichislocatedinthe

on

the

zigzag

scale

machine

the

stitch

left

sews

width

of its

straight.

increases

scale,

dependingonthe

the

undersideofpointerZwhich

this

slideinposition.

knobon2

and

tighten

screwB,for

vibrationsofthe

seam.Bythe

slideSso

when a few

same

middle of

that

the

straight

token,

the

previous

stitches

knobGcanbejerkedtothe

zigzag

stitch

to zigzag stitchingaswellaschanging

while

sewing.

indicate

gradually

the

machine

machine model.

engages

instance,

machine

havetobe

scale,

width

the

will

in a

the

when

sewing.Inspite

pointer

setting

the

stitch length

middieofthe

stitch

width

and

the

machine

make

stitches

notchofslide

stitch

width

made

in back-

left for a

Z will

again

willberestored

and

in

S.

is

of

en

the

R

7719

Fig.

20

Page 20

13.

Setting

LeverHcanbesetinnotch

to

the

With lever H In notch I,

straight

When lever H is

sewing,

With lever H in notch

straight

The

tion, however, raise the needle

Failure to

14.

Regulating

the

Needle

leftorrightofthe

sewing,

and

set

and

swings

sewing,

needle

and

position can be

observe

the

Position

I, IIorIII

needle

plate

the

needleisat

swingstothe

in notch II, the

both

waysinzigzag

III,

the

swingstothe

right in

needleiscenteredinthe

needle

left in

changed

out

of the fabric before you change the needle position.

this precaution may

Pressure

on

the

Material

and

servestomove

slot.

the

extreme

zigzag

stitching.

stitching.

is at

the

extreme right of

zigzag

stitching.

while sewing. When

cause

bending or breaking of

the

needle

left of

the

needle

the

the

machine is not in

from

the

center

needle

plate

slot

plate slot in straight

needle

plate slot in

opera

the

needle.

Smooth feeding and uniform stitching greatly depend on the correct amount of presser

foot

pressure.

a

direct

To increase the pressure for heavier fabrics, turn screw V in, and to

for lightweight materials, turn it

When stitching delicate and

Staggering

resultofincorrect

stitches

pressure

sheer

and

feed

out

markings on

regulation.

(Fig. 13).

the

undersideofthe

ease

fabric

the pressure

fabrics, feed a piece of tissue paper under the mate

are

rial to protect it from the feed points and prevent puckering. This paper can be readiiy

pulled

away

after

sewing

has

been

completed.

in

15.

Selecting

The

Pfaff

Model A machines

sewing

Model B machines

4 mm, longer

materials.

Pfaff 238-115

the

238isfitted

speed,

cording

and

and

Correct

Needle

with

round-shank

use

short System 133

hence

assure

neat

are

equipped

are

available in a number of different point styles to suit various

machines

with System 134 R

use

needles.

needles

seams.

System

which will not tremble, regardless ofthe

130 B

needles

needles

which

with a

are

about

smaller

5/32", or

shank

dia

meter. Pin tucks are made with two System 130 Br and Bl needles which are placed be

tween the needle holder jaws with their flat

tightening the needie

gauge

regulating screw.To make three System 134 RFr RFI

sides

facing,

and

are

secured

in position by

needles

having a flat on the right and left side of the shank, respectively, and two System 134

Rfmc

The

or

0.8

20

needles

number

blade,

mm,

whose

shankisflattened

indicating the

expressedinhundredths

its

sizeIs80.

needle

on

both

sides.

size is identical with

of millimeters.

Thus,ifthe

the

diameter of

diameter

the

needle

of a

shaft,

needle

is

Page 21

The

appearanceofthe

needle,

Lightweight

marks.

When

used

Select

Never

Only

vents

surfaced

synthetic

If an ordinary

thread

fabrics

thick

threadisused

in a thick

the

proper

use

rusty

the

exceptional

thread

needle

threads

and

needle

needle

needles.

breaking.

will

which

needle

seams,werecommend

which

maybeobtained

finished

fabric.

seamIsdependentonthe

shouldbesewn

in a

thin

may

cause

and

thread

quality of

When

overheat

should

that

from

the

operatingatthe

quickly

are

very

overheat

you

useasuperfinished,

us.

with a thin

needle,

needleinordertoprevent

the

thread

skippingofstitches.

sizes

from

the

needle

finish

ensures

high

and

burn

the

sensitivetoheat

when

sewing

correct

is likely to

chart

below:

trouble-free

speedofthe

thread.

and

resistant

Thisisparticularly

fuse

easily.

materials or stitching long

chromium-plated

relationship

ugly

break.

Thin

sewing

Pfaff 238, a

System

between

and

134

needle

thread

pre

rough-

true

needle

of

Needle

100

110

Needle

Size

60

70

80

90

Cotton

130/3

130/4

100/3

100/4

80/3

80/4

70/3-60/3

70/4-60/4

50/3-40/3

50/4-40/4

30/3

30/4

30/6

and

140/3

120/3

100/3

Silk

80/3

70/3

60/3

Thread

Chart

Synthetic

200/3-150/3

140/3-120/3

120/3-100/3

100/3-

80/3

70/3

60/3

Linen

70/3

60/3

50/3

21

Page 22

16.

Changing

(1)

Raise

(2) Loosen

(3) Pull

(4) Insert a new

it will

(5)

Tighten

17.

The

The Pfaff 238 is organized with a System 134 double-revolution,

the

the

out

the

go.

the

Sewing

the

needle

needle

old

Make

needle

Hook

Needle

needle.

needle

sure

bar

set

set

to Its

Into

the

highest

screw,

the

long

screw

point.

using a

small

openingofthe

groove

faces

securely.

screwdriver

needle

toward

you.

clamp

for

this

and

transverse

purpose.

push

it upasfar as

rotary hook

which moves counter-clockwise and is equipped with a special balancing collar to

ensure

vibrationless

runningofthe

machine.

This sewing hook features a welcome improvement over the old-type hook In that its

gib is held In place by one screw instead of the three screws used previously. This

screw

(e in Fig. 21) is located at

small recess in the body of the hook.

the hook, or in

securedbyone

the

two

parts

The springiness of the redesigned gib prevents bobbin

thread

jamming.

case

of thread jamming, is exceedingly simple. Since the hook gib is

screw

and the hook thread guard, or thread pull-off flange, by three,

cannot

possiblybeconfused.

Furthermore,

make it impossible to get at the gib screw.

the

one

end of the hook gib while its

Removal

machine

of the gib for a thorough cleaning of

will

neverbeblocked

All

this

will

other

end

enters

case

breakage

to an

as a result of

extent

which

eliminate the necessity of re

will

moving the hook, resetting the hook shaft and retiming the sewing hook, a job for which

a

mechanic

normally

hastobe

called.

a

Fig.

21

Page 23

18. Pfaff 238-14 for Eyeletting

The Pfaff 238-14 eyeletting machine is supplied in two varieties. Whiie on

238-14/1 the

equipped

Operation of the Pfaff

Put needle position lever H in notch

left in

with

zigzag

work

is turned about the center stud by hand, the

positive

sewing.

rotary

238-14/1

feed.

is exceedingly simple.

III

(Fig.

20) so that the needle swings from right to

Pfaff

the

Pfaff

238-14/2 is

Select a slide with a stud diameter which suits the size of the eyelets you want to

make. Push this slide into the siot of the needle plate and position it so that the needle

will be just inside the groove in the center stud when it

Punch out the hole for the eyelet, using

Make

sure

the

punch

diameterissmailer

one

of the punches suppiied with the machine.

than

the

terial will fit around the stud snugly. Slip the fabric over the

down

evenly

all

around.

Select

the stitch width according to the thickness of

sew

desired. To

work

around

Another

Put

tate

slidesothat

slide

procedure

needle

the

balance

mustberepositioned

This setting affords

the

process.

straight stitches (before sewing the eyelet

eyelet

with a few tying

a neat eyelet, run the machine at a uniform

the

center

stud

evenly.

which maybeappliedisas

position

lever

wheel

thereisa

the

H in

notchIand

until

the

small

clearance

whenever

advantage

needle

that

turn

descends

between

the

stitch width is

the

stitch width

Thus, it is possible to join multiple plies by sewing

seam

stitches

(with knob G

set

descends

center

on the right of its throw.

stud

diametersothat

center

the

material

speed

follows:

knobGto

on

the

the

needle

changed.

the

desired

leftofits

and

canbechanged

with zigzag stitches)

on "O").

stud

and

and

the type of eyelet

while turning the

stitch

throw.

Position

the

center

several

around

the

and

to finish the

the

push it

width.

stud.

times

hole with

ma

Ro

the

The

in

To

prepare

er

foot

The

1

Eyeletting

1

Needle

1 Eyeletting

1 Eyeletting

the machine for eyeletting,exchange the ordinary

for

the

special

set

of organizational parts for

foot

plate

slide,

slide,

needle

No.

41500

No.

42362

w/4 mm -dia.

w/5 mm -dia.

plate

and

subclass

stud.

stud.

eyeletting

No. 42359

No. 42380

-14/1 machines consists of the following:

1 Eyeletting slide, w/6 mm -dia. stud. No. 42361

1

Clamping

1

Punch,3mm

1

Punch,4mm

1

Punch

block

screw

-dia.,

-dia..

No.

No.

799

No.

No.

32424710

41664

41665

foot.

needle

plate and

thepress-

23

Page 24

42359 42360

32424710

ii

42361

799

The

following

1 Eyeletling slide, w/3 mm -dia. stud, No. 42358

1 Eyelelting slide, w/7 mm -dia, stud, No. 46159

1 Eyeletting slide, w/8 mm -dia. stud. No. 46162

1

Punch,

2 mm = 5/64"; 3 mm = 1/8"; 4 mm = 5/32";

5 mm = 3/16": 6 mm = 1/4"; 7

8

mm=5/16".

2 mm

parts

dia.,

will

be supplied on special request:

No.

41663

mm

= 9/32";

Page 25

Operation of the Pfaff

238-14/2

is basically the same as of the Pfaff

238-14/1,

except that

the material is turned about the center stud by a positively driven rotary feed rather

thanbyhand.

The

Pfaff

238-14/2isavailable

Group I for

Group

Ail that is required to

center

studs

II

for

center

studs

change

to exchange the slide with

When

changing

exchanged

few

minutes.

The

mechanical

over

from

in addition. This

setupofthe

in

two

varieties:

of from 5/64" to 15/32" {2-10 mm) dia.

of from 7/16" to 23/32" (11-18 mm) dIa.

the size of the eyelet within

center

stud and the

group

I to

group

conversion

rotary-feed eyeletting unit is illustrated in Fig. 22.

job

presser

II, or vice versa,

canbeperformed

one

of the

ring disc In the eyeletting foot.

the

rotary feed

by every

above

mechanic

groups

has

to be

in a

is

Fig.

22

Page 26

19. Pfaff 238-115 for

Cording

The Pfaff 238-115 is specially fitted for multi-needle decorative stitching and cording

operations. To suit different requirements, this machine is supplied in a number of

varieties equipped with different needle holders, cording plates and cording feet, as

follows:

238-115/1-6

Two

and three-needle ornamental stitching in straight or narrow zigzag

stitch; needle plate slot 3/16" or 1/4" (4.5 or 6.0 mm) wide; needle hold

er

fitted with

double-threaded

screw;

System

130 B

needles.

238-115/1-45 Two or three-needle air cording; needle holder fitted with double-thread

ed

screw;

238-115/1-235

238-115/2-45

System

The

needle

for maximum needle gauges of 1/8", 3/16", and 1/4"

6.0 mm).

Same as

and

238-115/1-45,

130Blneedles.

Two-needle air cording in needle gauges

130Brand

gauge

130 Bl

canbeadjusted

but

fitted

needles.

by turning only

to make

filled

one

screw.

(3.0,

cording: System 130 Br

ranging

from

1/16"

Available

4.5 and

to 1/4"

(1.4 —6.0 mm); needle holder jaws individually adjustable; available for

238-115/2-245

maximum

System

Same as

needles.

needle gauges of 1/8", 3/16", and 1/4"

134 R

needles.

238-115/2-45,

but fitted to make

(3.0,

4.5 and 6.0 mm);

filled

cording; System 134 R

238-115/4-45 Four-needle air cording on gloves, etc.; needle holder fitted with double-

238-115/5

26

threaded screw; four needles

and

are

of

outer

dles

7/32"

and

This

abie

class

needles.

clamped

needles

are

flattened on both sides; over-all width of triple cording 3/16" or

(4.7

134

Rfmh

variety

needle

-6, -45

in position by tightening

are

flattenedonone

or 5.4

mm);

needles.

is supplied on special request

holders

and

for 1, 2

-245

organizations;

are

inserted in slot of needle holder jaws

double-threaded

side,

while

System 134 Rfr and 134

only.

and3needles;

System

canbecombined

130 B or 130 Br

shanksofinner

RFI

or System 134

Fitted

with

screw;

exchange-

and

with

shanks

nee

Rfmc

sub

130 Bl

Page 27

Listed on the opposite

serts

and

cording

four

needle

Since

terial to be

a

certain

plate

the

compositionofthe

sewn,nohard-and-fast

cording

page

are

feet which may be

inserts

and

four

individual

size.

a variety of feed dogs, needle piates,

used

on Pfaff 238-115 machines.

cording

rule

feet

are

standard

parts

sets

dependsonthe

can

be givenasto which

with

each

thicknessofthe

parts

needle

One

machine.

are

piate in

needle

required

piate,

ma

for

Fig. 23 shows the Pfaff 238-115/1-245 fitted with needle plate insert and adjustable needle

holder

Apart

needle

narrow

simply

for filled

from

zigzag

needle

insert

cording

cording

seams.

gauge,ifthe

one

work,

needle

work.

the

For

between

Pfaff 238-115

this

typeofwork,

machine

is tobeused

the

needle

can

alsobeused

it is

holder

set

foranarrow

for

jaws.

for

sewing

single-needle

ornamentai

zigzag

zigzag

stitch

two-

and

stitching,

a

R

Fig.

6365

23

Page 28

Organizational

Parts

for

the

Pfaff 238-115

Needle plate, for 1/8", of 3.0 mm, needle

Feed dog, for 1/8", or 3.0 mm,

Needle

plate, for 3/16", or 4.5 mm,

needle

Feed dog, for 3/16", or 4.5 mm, needle

Needle plate, for 1/4", or 6.0 mm,

Feed dog, for 1/4", or 6.0 mm, needle

gauge

needle

needle

gauge

gauge

gauge

gauge

gauge

Cording slide, w/o ridge

Cording slides, w/ ridges from 1/32" to 9/64", or

0.8 to 3.6 mm

Cording slides, w/

or

0.6to2.4

Cording

mm,

slide

high,insteps

cord

ducts

dia.,insteps

set

screw

of 0.2 mm

from 1/32" to 3/32"

of 0.2 mm

Cording foot, w/ 11 grooves, 0.6 x 0.8 mm,

for 1/8", or 3.0 mm, needle gauge

Cording foot, w/ 11 grooves, 0.8 xl.O mm,

for 1/8", or 3.0 mm, needle

gauge

Cording foot, w/ 9 grooves, 1.0 x 1.2 mm, for

1/8", or 3.0 mm, needle

gauge

Cording foot, w/ 9 grooves, 1.2 x 1.4 mm,

for 3/16", or 4.5 mm, needle gauge

Cording foot, w/ 7 grooves, 1.6 x 1.6 mm, for

3/16", or 4.5 mm, needle gauge

Cording foot, w/ 7 grooves, 2.0 x 1.8 mm, for

3/16", or 4.5 mm, needle gauge

Cording foot, w/ 5 grooves, 2.4 x 2.0 mm, for

3/16", or 4.5 mm, needle

gauge

Cording foot, w/ 5 grooves, 2.8 x 2.4 mm,

for 3/16", or 4.5 mm, needle

gauge

Cording foot, w/ 3 grooves, 3.4 x 2.8 mm, for 1/4"

or

6.0 mm,

needle

gauge

No.

26835

No.

26833

No.

26885

No.

26883

No.

26892

No.

26890

No.

26902

No.

26900

X

heightofridge

No.

26904

X

cord

duct

dia.

No.

564

No.

51263

No.

51265

No.

51267

No.

51269

No.

51271

No.

51273

No.

51275

No.

51277

No.

51279

Cording foot, w/ 3 grooves, 4.5 x 3.2 mm, for

1/4", or 6.0 mm,

28

needle

gauge

No.

51281

Page 29

•AH

miiitniitniitii

t

S>.

Page 30

Page 31

20. Pfaff 238-130 with

Knee-Operated

Stitch Width Control

This machine features a knee-operated stitch

width

control

which

greatly facilitates such

operations as single-needle cording, eyelet embroidery and flat embroidery in the pro

duction of white goods, blouses, etc. (Fig. 24). A

presser

When

foot.

knee pressure is relieved, the stitch

"0" by spring action.

On the Pfaff 238-130 the lug on the underside of pointer 2 fits snugly into notch R of

slide

S (Fig. 20).

be varied by

knee

For

action

this

reason,

while sewing.

screwBmustbeloosened

second

width

control is automatically returned to

treadle

when

serves

the

stitch

to raise the

width

is to

Screw B is tightened to lock the slide for any desired stitch width so that the operator

need not press against the knee lever continuously when sewing satin-stitch seams

with a uniform stitch width

ordinary

attachedtothe

zigzag

sewing, To

presser

throughout,inthis

this

end,

bar.

way,

an ordinary

the

zigzag

Pfaff 238-130

foot with a

canbeused

smooth

sole

for

is

R

Fig.

7213

24

31

Page 32

Satin-stitch

sole

seams

and

permitstosew

If a more prominent

51353

which

has

three

Interesting

H in

from

effects

notch

I, ilorMi,sothat

the

middle.

are

made

with

hinged

bends

without

seam

is to be produced, we recommend to

cord

ductsinfrontofthe

zigzag

compressing

canbeobtainedbyvarying

the

needle

swingstothe

foot No. 51355 which

the

seam.

needle

hole.

the

needle

position,1.e. by

right,tothe

hasarelieved

use

sewing foot No.

putting

left,orboth

lever

ways

Page 33

Page 34

21.

Trouble

Shooting

Machine

Cause:

1.

2.

3.

4.

5.

6.

7.

Skips

incorrect

Wrong

Needle

Needle

Needle

Needle

Needle

8. Hook

9.

Hook

10. Material

11.

Thread

Thread

Cause:

Breaks

1. Any of

2.

Thread

3.

Poororknotty

4.

Thread

5.

Poor-quality

6.

Thread

7.

Burrsorsharp

8.

Thread

Thread

9.

10.

Blunt

Stitches

threading.

needle.

inserted

too

too

bent.

set

set

timed

incorrectly.

fine

for

thick

too

highortoo

too far from

Incorrectly.

tackyorheavily

twisted

the

tension

too

above-mentioned

too

thread

rotten

duetoextremely

thread

jammedInhook

edgesonneedle

snarledupon

check

spring

needle

point.

for

the

the

much.

tight.

used.

used.

spool

timed

thread

thread

needle

dressed.

race.

used.

used.

low.

(correct

conditions

long

plate

pin.

Incorrectly.

clearance

may

and

dry

slot.

.004", or 0.1 mm).

cause

thread

storage.

breakage.

Needle

Cause:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

34

Breaks

Bent

Thread

Hook

Upper

Needle

Needle

Machine

Hook

Needle

Thread

needle

strikes

too

heavy

setting

disturbed

tension

too

deflectedbyhard

bent

because

feeds

while

set

too

closetoneedle.

too

fine

for

snarled

uponspool

hook

point.

for

needle

used.

after

thread

jamming.

tight.

spots

In material.

materialIspushedorpulled.

needleIsdowninmaterial.

the

fabric.

pin.

Page 35

Machine

Cause:

1.

2.

3.

4.

5.

6.

Overheating

Cause:

1.

2. V-belt

3. Full

Feeds

improperly

Feed

dog

set

too

Feed

teeth

too

Feed

dog

unsuitable

Incorrect

pressure

Accumulationsofpacked

Blunt

feed

points.

No

oilInreservoir.

too

tight,

weightofmotor

low.

fine

on

causing

for

for

material.

pulls

the

material.

the

worktobe

lint

excessive

down

between

pressureonarm

V-belt

because

performed.

feed

teeth.

belt

shaft

take-up

bearings.

hanger

has

come

loose.

35

Page 36

Pfaff

238-0

High-Speed

Zigzag

Sewing

Machine

22. Brief

With

for a more efficient high-speed sewing machine. The mechanical setup of the Pfaff

closely resembles that of the job-proven Pfaff

increased

ments:

fvlaintenance-free anti-friction bearings instead of plain bearings at both ends of the arm

shaft, sealed-for-life needle bearings in the take-up lever assembly, wick-lubricated

needle bar bushings, and a separate

sewing

With

en for Pfaff 238

Descriptionofthe

the

introduction

from

3,800to4,500

hook.

of its

Pfaff 238-0

01.

238-0,

s.p.m.

Pfaff

through

wick

has met the

238,

the incorporation of the

and reservoir lubrication system for the

demand

while its sewing speed has been

of the

sewing

following

industry

improve

238-0

the exception of Chapter 3, entitled "The Lubrication System", all instructions giv

applytothe

Pfaff 238-0

also.

R

9401

f"i9- 26

Page 37

23. The Lubrication System of the Pfaff 238-0

From

the

oil

reservoir

the

arm

shaft

center

the

two

needle

bar

tube has

bar

From

necessary.

The

wick

The

wick-fiiied

tube

oii through an oii duct into the hook raceway.

This

are

The bed plate reservoir holds 5 1/3

cation.

reservoir

bined

gasket.

The

oil

The

illustrations on pp. 4-8.

been

bushings.

timetotime,

high

speed

and

reservoir

sewing

piastic

into

the

reservoir

properly

The

and the

with

the

Pfaff

238-0

No.

2801-120122

oiling

points

hookislubricated

oii

lubrication

lubricatedatall

oii

weekly

usesthe

under

the

top

coverofthe

bearing

bushingsinthe

incorporated

check

of the

lubrication

tube

retainer

level

can be

oilbereplenished.Ifnecessary.

or a

which

and

which

the

machine

conducts

ringonthe

system

times.

checked

cleaning

same

technical

have

the

needle

conducts

oii

levelinthe

has

system

from

oiitothe

minimizes

fl.

of the

oii

as the

white

to be

zigzag

bar

madeitnecessarytoincorporateacombination

for

the

the

oii

hook

sewing

oz. of oil

throughanoil

machine.Totop up the

Pfaff

oil

havingaviscosityof150R/68®For175

lubricated

maintenance

machine

mechanisminthe

frame.

For

this

oii

from

the

oii

oii

sight

glass

transverse

reservoir

saddle

hook.

which

238,i.e.

manually

rotary

under

whenceitflows

Centrifugal

and

will

last for several weeks'

sight glass on the

Checking

either

are

oiiissupplied

machine

arm,

not

but

only

purpose,awick-fiiied

reservoirtoboth

and

the

hook.

bed

replenish

plate

the

(Fig.

throughacopper

force

then

flings

ensures

the

markedbyarrows

oil

level

oil,

you

ordinary

that

all

vital

bottom

maybecom

do not lose the

sewing

machine

S/68°F.

also

piastic

needle

oil,

26).

the

parts

lubri

of the

in the

to

to

if

A

37

Page 38

Instructions

24.

Timing

The

functions of

the

balanceofthe

ting

the

stitch to

from

the

time

until

the

needle

the

for

Thread

the

the

the

descending

reaches

Mechanics

Check

thread

needle

desired

thread

the

Spring

check

spring

after

tightness,

take-up

goods.

aretoassist

the

loop

and

in controlling

lever

beginstodraw

has

the

passed

take-up

around

the

slackofthe

the

R

7880

lever in taking up

the

bobbin,Inset

needle

thread

from

the

thread

spool

IjTj^irf J

Fig.

27

Page 39

The downward stroke of the thread check spring is limited by a stop on the tension

barrel and can be adjusted by rotating this barrel, as may be required.

To do this, insert a screwdriver into opening E (Fig. 27), loosen the tension barrel

screw

and, inserting

the

tension

To

adjust

If it

shouldbeimpossibletoturn

screwdriver,

barrel

the

loosen

barrel out of

thread

the

the

is in

check

the

tension

machine

screwdriver

the

correct

spring

barrel

and

slightly

position.

tension,

the

into

the

slotoftension

turn

tension

studinthe

set

screwinopening

loosen

the

tension

set

stud

tension

screw

stud

M, turn

M in

barrel

E (Fig 27),

at its

the

with

rear

the

tension

the

take

the

end. After

latter

aid

tension

set

until

barrel.

of a

the

tension barrel has been replaced in the machine, the stroke of the thread check spring

mustbereadjusted.

R

7887

Fig.

28

39

Page 40

Thread

and

regulator

down

Bysodoing,Itadapts

with

J (Fig. 28) Is

the

presser

barasthe

the

thread

mountedonthe

sewing

consumptiontothe

terial being sewn. As a result of this action,

when

thicker

Thread

setting

the

thread

correlate

spring not only

wards

Once

thread

resortingtotrial-and-error

The

thread

es

the

may be

it will still

portionsofthe

regulator J

the

thread

check

spring

the

thread

takesupthe

perpendicularly.

you

are

familiar with

can

regulator

be

can

regulator

the

material

adjusted

higher

be

adjusted

and

proper

pass

vertically

or lower

tension

amount

functions performed by both the check spring

regulator, you willbeabletomake

methods.

check

spring

is timed correctly If it Is through

goods.

Since

the

take-up

necessarytoIncrease

exertaslight

pull

lever of

the

strokeofthe

on

the

thread

foot

the

under

the

within

barrel

presser

check

after

bar

guide

passes

over

varying

spring

hastotakeupless

the

sewing

foot.

loosening

amountofthread

certain

settings

limits. It Is

so

of thread, but also pulls

the

proper

adjustment

acting

the

Pfaff 238

thread

when

makesarather

check spring

the

needle

collar

and

moves

up

IrregularitiesInthickness.

thicknessesofthe

ma

thread

screw

d (Fig. 28). By

to be controlled by

recommended

that

the

when

right

the

thread

the

away

needle

thread

and

without

check

up

the

reach

long stroke, it

somewhatsothat

enters

the

material.

to

25.

Timing

the

Sewing

Hook

To time the sewing hook correctly, we recommend that you use a needle rise gauge

which

canbeobtained

Begin by removing

(Fig. 20).

Rotate

stroke. Slip both the needle rise

needle

bar,

push

bar

frame,

and

tighten

Then pull out

the

the needle bar frame (Fig. 30). Loosen

and

rotate

the

sewing

needle.

At the

same

time,

between

40

both

parts

fromusunder

the

needle

plate

the

balance

the

gauge

wheel until

clampupagainst

the

clamp

and

cautiously turn the

hook on Its

set

the hookasclose to the needleaspossible, the proper

Order

Nos.

880136/01

and

setting

lever H In notch II

the

needle

has

gauge

(5/64", or 2.0 mm, thick and the clamp onto the

the

gauge

until

screw

securely

(Fig. 29).

balance

set

screws

K and T (Figs. 29 and 30, respectively)

shaft

until Its point Is

and

reached

the

latter

wheel until

opposite

being .004", or 0.1 mm (Fig. 31).

880137/00.

and

knob G on "0"

the

lowest point of Its

contacts

the

clamp

the

center

the

needle

contacts

line of

clearance

the

Page 41

Page 42

26.

To

the

the

Setting

set

the

balance

latter

the

Needle

needle

wheel until

ascends

BaratCorrect

bar at the correct height, turn knob G (Fig. 20) to "4" and rotate

the

on

the

left of its throw.

be positioned .04", or 1.0 mm,

If

adjustmentisrequired,

lower,asmayberequired.

loosen

hook

point is

above

set

Height

the

screw

opposite

Wheninthis

top of

the

m (Fig. 28)

the

needle

and

center

position,

eye {Fig. 31a).

set

the

R

7881

line of

the

needle

the

hook

needle

point

bar

when

should

higher

or

Wmm

Fig.

31a

Fig.

31

42

Page 43

27.

Changing

the

Sewing Hook

1. Remove needle, needle plate, feed dog and bobbin

2.

Loosen

3. Rotate the

4. Pull

5. With

replace

sure

position finger

6.

Time

securely.

7.

Replace

28.

1.

Remove

2.

Take

c (Fig. 28)

Pull

bracket

3.

Remove

bar

eccentric

pull

4.

Take

ing

5.

Rotate

be

6.

Loosen

7.

Loosen

8.

Place

Fig. 34.

it into

out

suppliedatextra

9.

Cautiously

up

hook

set

the

sewing

the

feed

the

there is a

the

feed

Dismantling

face

out

thread

back

complete

will not be

the

needle

out

lever

the

reached

take-up

set

the

Insert

the

screwsKand

balance

hook

dog

set

bobbin

clearance

and

sewing

hookasinstructedinChapter25and

dog

and

the

Thread

cover,

pressure

and

regulating

pull

regulator

outofthe

needle

disturbed.

studa.Then

bar

plastic

plugUon

assembly.

balance

through

crank

screw

P on

barofthe

the

threaded

hollow

hinge

wheel until the feed bar is at its highest point.

off Its

at Its

case

the

bottomofthe

needle

presser

the

presser

J (Fig. 28),

machine.

loosen

frame,

wheel

the

aperture

screw

take-up

pull-off

studofthe

T (Figs. 29

shaft.

highest

point,

push

position finger bracket. As you

of .024 to .036", or 0.6 to 0.9 mm, between the tip of the

position

plate.

Take-up

foot

(with

screw)

screw

and

remove

barupoutofthe

bar

frame

To do this,

screwf(Fig.

enclosing

the

backofthe

until

take-up

Q.

device

endofthe

presser

assemblysothat

on

link

across

take-up

loosen

the

needle

crank

the

backofthe

stud

pull-off

bar

28)

(Fig. 33).

the

link

of its mount. (The pull-off device is available under No. 880141/00 and will be

cost.)

pull

out

the

crank

and

needle

take-up

bar

lever

connecting

assembly,

link.

and

30).

the

slotinthe

and

presser

machine.

guide

set

and

bar,

machine

screw

face

device

and,inthis

including

case

position finger bracket.

new

hook

onto

replace

bobbin

tighten

needle.

bar

spring.

collar

and

the

height

screw

b (Fig. 36)

pull

out

hinge

forward

arm

Q in

machine

sideofthe

through

outofthe

(Fig.

32)

the

needle

arm

machine,asshown

the

way, pull

the

take-up

the

this

case

set

Loosen

presser

settingofthe

studg.This

and

(Fig.

holeinthe

hook

shaft

bracket,

base

make

(Fig. 31).

screwsKand

set

screw

bar

lifting

needle

and

remove

done,

machine.

strip

the

bar

crank

33).

bar,

screw

the

hinge

lever

link,

and

T

lift

can

in

stud

take-

43

Page 44

r 4

m

Page 45

Do

not

apply

force in

removing

the

take-up

lever

assembly

since

all

parts are precision-

engineered and meticulously fitted. Do not tap these parts out of their mount as this

v/ould upset the position of the press-fitted bearing rings.

The boreholes at the lower end of the take-up lever and the upper end of the needle

bar connecting link are fitted with super-finished needle bearings.

Note that end screw L (Fig. 34) must be turned right to loosen it because It

hand

thread.

In stripping

the

thread

take-up

and

needle

bar

assemblies

care

shouldbetaken

has

left-

that

none of the 18 tiny needles gets lost which are contained In each bearing. To facilitate

insertion of the needles into the bearings, put some

the

needles

singly, using a pair of

tweezers.

grease

into the latter and insert

To replace the thread take-up and needle bar assemblies, reverse the above procedure

and

proceed

with

great

care.

R

7882

Fig.

34

Page 46

29.

Adjusting

the

Stitdi

Length

for

Forward

and

Reverse

Sewing

Pfaff 238

less

cause

which

To

screw

just

crankOupwards

In

gulated,asdesired.

machines

whether

the

needle,Inbacktacking

were

change

this

the

N In

the

the

lengthofforward

way,

they

madeinforward

relative

feed

the

stitch

normally

sew

are

forwardorbackward.

sewing.

stitch

lengthsinforward

regulator

slot

stitchesbyturning

for

longer

stitches,ordownwards,

length

relationshipofforward

After

the

adjustment,

settomake

the

end

(Fig. 35),

stitchesofexactly

This

feature

of a

seam,

and

backward

hold

feed

regulator

crank

0 on Its

for

and

tighten

clamping

R

the

same

willbemuch

will

stitch

into

sewing,

leverAsteady

shaft,asappropriate.

shorter

stitches.

backward

screwNsecurely.

5092

stitches

length,

appreciated

the

same

loosen

clamping

canbere

regard

holes

and

be

ad

Turn

Fig.

35

Page 47

30.

Centering

When

correctly In the needle plate slot and.

the

the

machineIsset

Needle

ThrowInthe

for Its

widest

Needle

Plate

zigzag

descending

Slot

stitch,

the

needle

shouldbecentered

on the right and left of Its throw,

should clear both ends of the slot at the same distance. Ifadjustment is required, loosen

pinch screw b (Fig. 36) and turn eccentric stud a in the needle bar frame pitman to

the

right or left,asmay be required.

R

Fig.

7884

f

1

36

47

Page 48

31.

Zeroing

the

Needle

for

Straight

Stitching

When knob G (Fig. 20) is

motion

drop

knob

stitch

exactlyInthe

knob

sure

and

the

machine

the

feed

dog,

G to

"0".

Rotate

into

the

cardboard

same

If

adjustmentisrequired,

steady

and

turn

the

zigzag

regulator

placeapieceofthin

the

spot.

the

set

should

balance

lightly.

slightly

zigzag

stud

on "0",

the

sewaperfectly

wheel

The

needleiszeroed

loosen

regulator

hasnoend

needle

cardboard

forward,

the

set

studtothe

play

and

bar

must

not

make

straight

then

seam.

under

backward,

the

To

sewing

and

check

correctly,ifboth

screw

on

knob

G (Fig. 20),

rightorleft,asappropriate.

tighten

the

set

screw

R

7883

any

sideways

this

foot

and

let

the

punctures

hold

securely.

setting,

turn

needle

are

the

Make

Fig.

37

Page 49

32. Adjusting

the

Needle

Position

Pfaff 238 machines normally are

distance

ting,

from

the zero position both ways (central needle position). To check this set

set

knob G on "0" and put lever H in notchII(Fig. 20). Place a piece of thin card

set

to make zigzag stitches which extend the same

board under the sewing fool and rotate the balance wheel toward you

stitches

ward, then backward, and let the needle,

stitch into the cardboard

equidistant

To adjust, loosen

appropriate.

into

the

from

Then

cardboard

the

set

tighten

lightly.

central

lightly. Flick

The setting is correct if the right and left punctures are

puncture.

knob

G to

descending

"4",

rotate

the

on the right and left of its throw,

screw 1 (Fig. 37) and turn eccentric stud h to the right or left, as

set

screwisecurely.

R

6686

Fig. 38

until

balance

the needle

wheel

for

33.

Adjusting

The

sideways

motion so

and

will

cease

To

check

this setting, flick knob G to "4"

is required,

To

double-check

(Fig. 20) In

when

you

Foracoarse

crank

(Fig.

I (Fig. 38)

tric (Fig. 33)

the

Needle

Throw

motionofthe

that

the

needle

vibrating

rotate

this

notch

turn

knob

adjustment,

33)isvisibleInthe

and

turn

points

whenitagain

the

bevel

setting,

II.

The

settingiscorrectifthe

G to

rotate

the

arm

upward.

needle

bar

mustbetimed

correctlyinrelation

will not begin to vibrate until it

gearonthe

raise

the

right

the

aperture

shaft

bevel

Tighten

the

and

balance

both

reaches

needle

gear

the

goods.

and

watch

the

arm shaft,asmay be required.

bar

to Its

needle

left.

wheel

until

in

the

machine

until

lobe

w of

set

screws

securely

has

risen

needle

vibration. If

highest

bar

set

arm.

point

makesnosideways

screwQon

Loosen

the

needle

after

the

to Its

clearofthe

adjustment

and

set

the

needle

set

screwskand

vibrating

adjustment.

vertical

goods

lever

motion

bar

eccen

H

49

Page 50

Contents

Instructions

1.

Brief

Setting

2.

The

3.

4.

Test-Running

5.

Removing

6.

Winding

7.

Threading

8.

Threading

Drawing

9.

Regulating

10.

Regulating

11.

Regulating

12.

Setting

13.

14. Regulating

15.

Selecting

16.

Changing

17.

The

18. Pfaff 238-14

19. Pfaff 238-115

20.

Pfaff

21.

Trouble

for

Descriptionofthe

Up

Lubrication

the

the

Up

the

the

Sewing

238-130

Shooting

Operators

the

the

Bobbin

Bobbin

the

Bobbin

the

Needle

the

the

Thread

the

the

Stitch

Needle

the

Correct

the

Needle

Hook

for

for

with

Pfaff

Machine

System

Machine

Case

Case

Bobbin

Tension

Stitch

Width

Position

Pressure

Needle

Eyeletting

Cording

Knee-Operated

Thread

Length

on

238

the

Material 20

Stitch

Width

Control

Page

5

5

7

11

12

13

14

15

16

16

18

19

20

20

22

22

23

26

31

34

Pfaff 238-0

22.

Brief

Descriptionofthe

23.

The

Lubrication

Instructions

24.

Timing

Timing

25.

26.

Setting

27.

Changing

Dismantling

28.

29. Adjusting

30.

Centering

31. Zeroing

32. Adjusting

33. Adjusting

High-Speed

for

the

Thread

the

the

the

the

the

the

the

the

Zigzag

Systemofthe

Mechanics

Check

Sewing

Needle

the

Hook

BaratCorrect

Sewing

Thread

Hook

Stitch Length for Forward

Needle

Needle

Needle

for

Needle

Throw in

Straight

Position 49

Throw 49

Sewing

Machine

Pfaff 238-0

Pfaff

238-0

Spring

Height 42

Take-up

and

the

Needle

Reverse

Plate

Slot

Sewing

....

Stitching 48

36

37

38

40

43

43

46

47

51-

Page 51

ST

(ptur

No. 9497 engl. P 368 Printed In

f

Germany

Loading...

Loading...