Page 1

1571

1574

INSTRUCTION MANUAL

1591

1593

This instruction manual applies to machines

from the serial number # 7 265 636 onwards.

296-12-19 225/002

Instruction Manual engl. 03.17

Page 2

This instruction manual applies to all models and subclasses listed in chapter 3

Technical Data.

The adjustment manual for the machine can be downloaded at no charge

under www. pfaff-industrial.de/de/service-support/downloads/technical.

As an alternative to the Internet download, the adjustment manual can also

be ordered as a hard copy under order no. 296-12-19 226/002.

Reprinting, reproduction and/or translation of PFAFF instruction manuals

(including parts thereof) is only permitted with our prior agreement and

citation of the source.

PFAFF Industriesysteme

und Maschinen GmbH

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Table of Contents

Contents ..................................................................................Page

1 Safety .................................................................................................................................... 6

1.01 Directives ............................................................................................................................... 6

1.02 General safety instructions ....................................................................................................6

1.03 Safety symbols ...................................................................................................................... 7

1.04 Special points of attention for the owner-operator ................................................................7

1.05 Operating personnel and technical staff ................................................................................8

1.05.01 Operating personnel .............................................................................................................. 8

1.05.02 Technical staff ........................................................................................................................ 8

1.06 Danger warnings ....................................................................................................................9

2 Proper Use .......................................................................................................................... 10

3 Technical Data

.................................................................................................................11

3.01 PFAFF 1571 ......................................................................................................................... 11

3.02 PFAFF 1574 ......................................................................................................................... 12

3.03 PFAFF 1591 ......................................................................................................................... 13

3.04 PFAFF 1593 .......................................................................................................................... 14

4 Disposal of the Machine .................................................................................................... 15

5 Transport, Packaging and Storage .................................................................................... 16

5.01 Transport to the customer's premises ................................................................................ 16

5.02 Transport within the customer's premises .......................................................................... 16

5.03 Disposal of the packaging materials .................................................................................... 16

5.04 Storage ................................................................................................................................ 16

6 Work Symbols .................................................................................................................... 17

7 Operating Controls ............................................................................................................18

7.01 Main switch ......................................................................................................................... 18

7.02 Keys on the machine head .................................................................................................. 18

7.03 Bobbin thread monitoring using the stitch count ................................................................. 19

7.04 Pedal .................................................................................................................................... 19

7.05 Hand lever to raise the roller presser ................................................................................... 20

7.06 Swivelling out the roller presser ..........................................................................................20

7.07 Knee switch ......................................................................................................................... 21

7.08 Knee lever ............................................................................................................................ 21

7.09 Edge trimmer -725/04 for PFAFF 1571 ................................................................................22

7.10 Edge trimmer -725/04 for PFAFF 1574 and 1591 ................................................................23

7.11 Control panel ........................................................................................................................ 24

7.11.01 What appears on the display ............................................................................................... 24

7.11.02 +/- keys ................................................................................................................................ 25

7.11.03 Function keys ....................................................................................................................... 25

Page 4

Table of Contents

Contents ..................................................................................Page

8 Set-up and Initial Commissioning .................................................................................... 27

8.01 Set-up .................................................................................................................................. 27

8.01.01 Setting the table height ....................................................................................................... 27

8.01.02 Inserting the sewing machine into the stand ...................................................................... 28

8.01.03 Assembling the anti-tipping device ......................................................................................29

8.02 Mounting the fl ange motor .................................................................................................. 29

8.02.01 Mounting the fl ange motor on the bearing plate ................................................................. 29

8.02.02 Mounting the fl ange motor on the machine ........................................................................ 30

8.02.03 Mounting the machine cover ............................................................................................... 30

8.02.04 Connecting the plug-in connections and ground cable ........................................................ 31

8.02.07 Mounting the fl ange motor belt guard ................................................................................. 36

8.02.08 Connecting the safety switch .............................................................................................. 36

8.03 Assembling the reel stand ................................................................................................... 37

8.04 Initial start-up ....................................................................................................................... 38

8.05 Switching the machine on / off ............................................................................................ 38

9 Set-up .................................................................................................................................. 39

9.01 Inserting the needle ............................................................................................................ 39

9.02 Winding the bobbin thread, adjusting the thread tension .................................................... 40

9.03 Removing / inserting the bobbin case ................................................................................. 41

9.04 Inserting the bobbin case / adjusting the bobbin thread tension ......................................... 41

9.05 Threading the needle thread / adjusting the needle thread tension

(with the PFAFF 1571; 1591 and 1593) .................................................................................... 42

9.06 Threading the needle thread / adjusting the needle thread tension (with the PFAFF 1574) ...43

9.07 Adjusting the stitch length ................................................................................................... 44

9.07.01 Entering the sealing speed .................................................................................................. 44

9.07.02 Entering a second stitch length or fullness .......................................................................... 44

9.08 Entering the start and end backtacks .................................................................................. 45

9.09 Entering/changing the template code .................................................................................. 46

9.10 Setting the bobbin stitch counter ....................................................................................... 48

9.11 Inserting and removing the SD memory card ..................................................................... 49

10 Sewing ................................................................................................................................ 50

10.01 Manual sewing .................................................................................................................... 50

10.02 Programmed sewing ........................................................................................................... 51

10.03 Program interrupt ................................................................................................................. 53

10.04 Error messages .................................................................................................................... 53

11 Input .................................................................................................................................... 54

11.01 Input mode .......................................................................................................................... 54

11.01.01 Overview of the functions in input mode ............................................................................ 54

11.01.02 Overview of the seam program input .................................................................................. 54

11.02 Seam program input variants ............................................................................................... 56

11.03 Changing available seam programs ..................................................................................... 57

11.04 Deleting seam programs .....................................................................................................60

Page 5

Table of Contents

Contents ..................................................................................Page

11.05 Examples for seam programming ........................................................................................ 61

11.05.01 Example for seam program input ........................................................................................ 61

11.05.02 Examples for seam program input via teach-in .................................................................... 67

11.05 Program management .........................................................................................................71

11.06.01 Calling up program management ......................................................................................... 71

11.06.02 Displaying programs in the machine memory ..................................................................... 72

11.06.03 Displaying programs and the machine data on the SD memory card .................................. 73

11.06.04 Copying programs and machine data onto the SD memory card ........................................ 74

11.06.05 Copying programs and machine data in the machine memory ........................................... 75

11.06.06 Deleting programs in the machine memory ........................................................................ 76

11.06.07 Deleting programs and machine data on the SD memory card ........................................... 77

11.06.08 Formatting the SD memory card ......................................................................................... 78

11.07 Parameter settings ..............................................................................................................79

11.07.01 Overview of parameter functions ........................................................................................ 79

11.07.02 Example of a parameter entry ............................................................................................. 80

11.07.03 Parameter list for control P320 and P321 ............................................................................ 81

11.08 Error messages and description .......................................................................................... 85

11.09 Warning messages .............................................................................................................. 85

12 Maintenance and Care ....................................................................................................... 86

12.01 Maintenance intervals .......................................................................................................... 86

12.02 Cleaning the machine .......................................................................................................... 86

12.03 Oiling the hook ..................................................................................................................... 87

12.04 Oil reservoir for hook lubrication .......................................................................................... 87

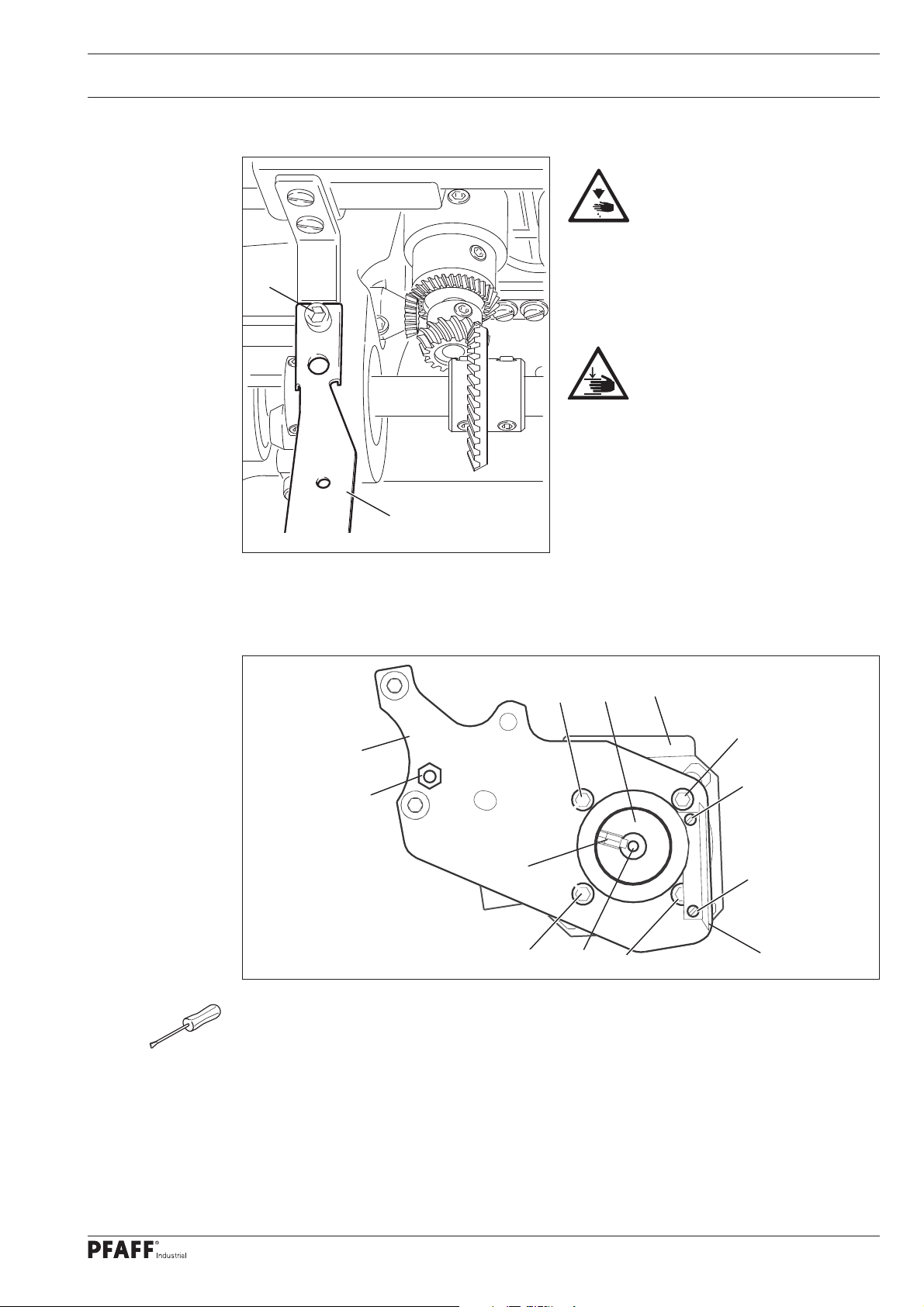

12.05 Lubricating the bevel gears .................................................................................................. 88

12.06 Topping up the thread lubrication oil reservoir ..................................................................... 89

12.07 Lubricating the roller presser drive gear mechanism (only at ø 25 mm and ø 35 mm) ........ 89

13 Table Top ............................................................................................................................. 90

13.01 Tilt base ............................................................................................................................... 90

13.02 Table top cutout ................................................................................................................... 91

14 Wearing Parts ..................................................................................................................... 92

Page 6

Safety

1 Safety

1

1.02 General safety instructions

.01 Directives

The machine was built in compliance with the European regulations specifi ed in the declara-

tion of conformity and declaration of incorporation.

As a supplement to this instruction manual, please also observe the generally applicable, le-

gal and other regulations and legislation – also in the country of use – and the valid environ-

mental protection regulations! Always comply with the locally applicable regulations of the

professional associations and other supervisory authorities!

The machine may only be operated after you have become acquainted with the

associated instruction manual and only by operating personnel who have received

appropriate training!

Always read the safety instructions and the instruction manual of the motor manufacturer

before starting up the machine!

Always follow the hazard and safety instructions attached to the machine!

The machine may only be operated for its intended purpose and only with the associated

safety covers, while adhering to all the relevant safety requirements.

The machine must always be disconnected from the power supply by pressing the main

switch or pulling out the mains plug when sewing tools are replaced (such as the needle,

sewing foot, needle plate and bobbin) and when threading, leaving the workstation, or

performing maintenance!

The daily maintenance work may only be carried out by suitably qualifi ed personnel!

Repairs and special maintenance work may only be carried out by technical staff or

people with appropriate training!

Work on electrical equipment may only be carried out by qualifi ed technical staff!

Work on parts and equipment under voltage is not permitted!

Exceptions are regulated by the EN 50110 standards.

Modifi cations and changes to the machine may only be made in compliance with all of

the relevant safety requirements!

Only the replacement parts approved by us for usage may be used for repairs! We warn

you expressly that spare parts and accessories that are not supplied by us are also not

tested and approved by us.

Fitting or using these products may therefore have negative effects on features which

depend on the machine design. We are not liable for any damage caused by the use of

non-Pfaff parts.

6

Page 7

Safety

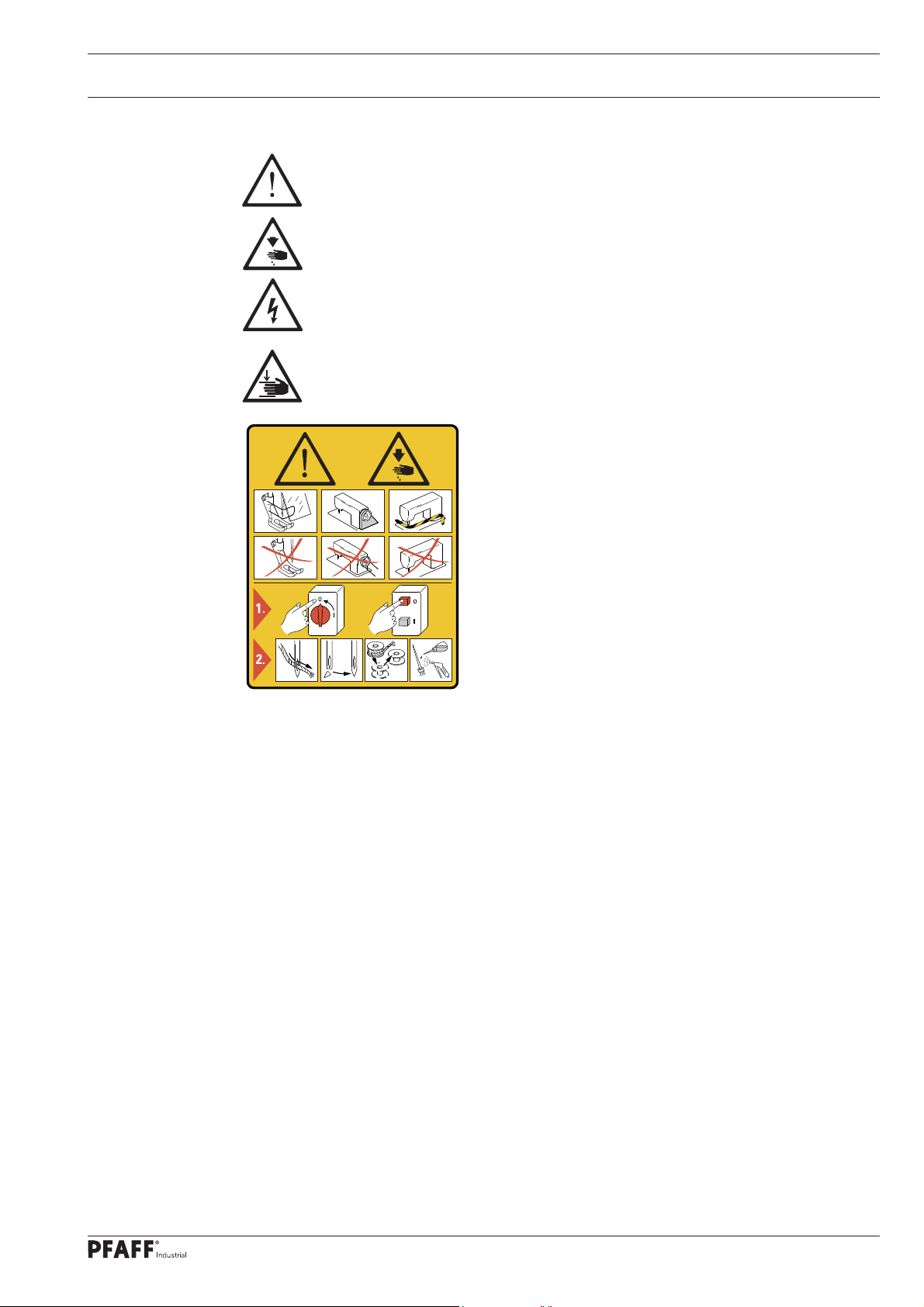

1.03 Safety symbols

Hazard point!

Special points of attention.

Risk of injury to operating personnel or technical staff!

Electric voltage!

Danger to operating personnel or technical staff

Danger of hands being crushed!

Danger to operating personnel or technical staff

Caution!

Do not operate without fi nger guard and safety covers!

Turn off the main switch before threading, changing the

bobbin or needle, cleaning, etc.!

I

1.04 Special points of attention for the owner-operator

This instruction manual is a part of the machine and must be made available to the oper-

ating personnel at all times. The instruction manual must have been read before the initial

start-up.

The operating personnel and technical staff must be instructed about the machine's safe-

ty covers and about safe working methods.

The owner-operator may only operate the machine in a fl awless condition.

The owner-operator must ensure that no safety covers are removed or disabled.

The owner-operator must ensure that only authorised persons work on the machine.

Additional information can be requested from the responsible sales centre.

7

Page 8

Safety

1.05 Operating personnel and technical staff

1

.05.01 Operating personnel

Operating personnel are persons responsible for equipping, operating and cleaning the

machine and for fault clearance in the sewing area.

The operating personnel are obligated to comply with the following points:

The safety instructions provided in the instruction manual must be followed for all work!

Any work method jeopardising machine safety must be refrained from!

Tight-fi tting clothing must be worn. The wearing of jewellery such as chains and rings is

prohibited!

Care must be taken to ensure that no unauthorised persons are located in the machine's

hazard zone!

Any changes occurring on the machine which impair its safety must be reported to the

owner-operator immediately!

1.05.02 Technical staff

Technical staff are persons with technical training in electricity/electronics and mechanics.

They are responsible for lubricating, servicing, repairing and adjusting the machine.

The technical staff are obligated to comply with the following points:

The safety instructions provided in the instruction manual must be followed for all work!

Turn off the main switch and secure it against reactivation before starting any adjustment

and repair work!

Never work on live parts and equipment!

Exceptions are regulated by the EN 50110 standards.

Reattach the safety covers following repair and maintenance work!

8

Page 9

Safety

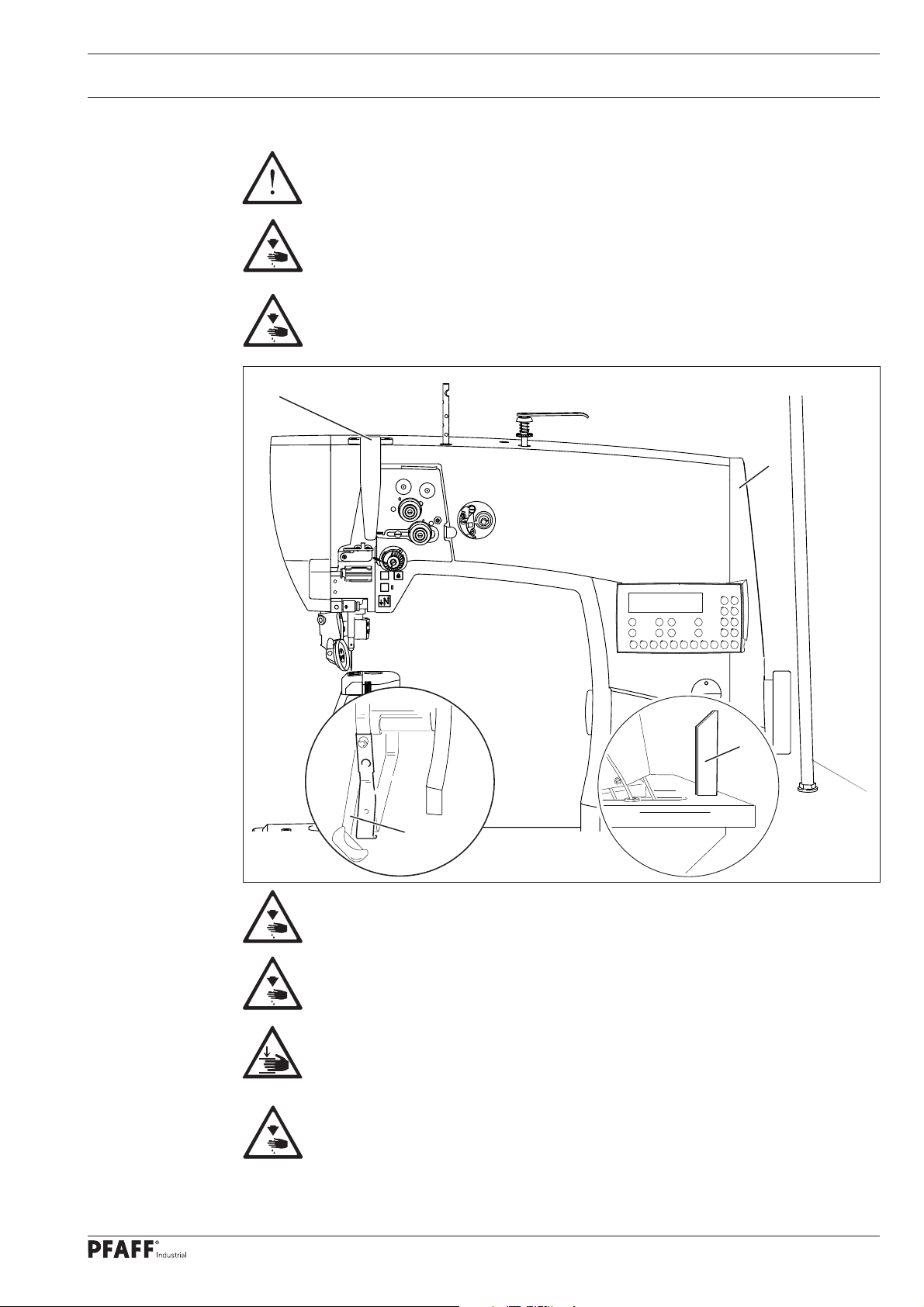

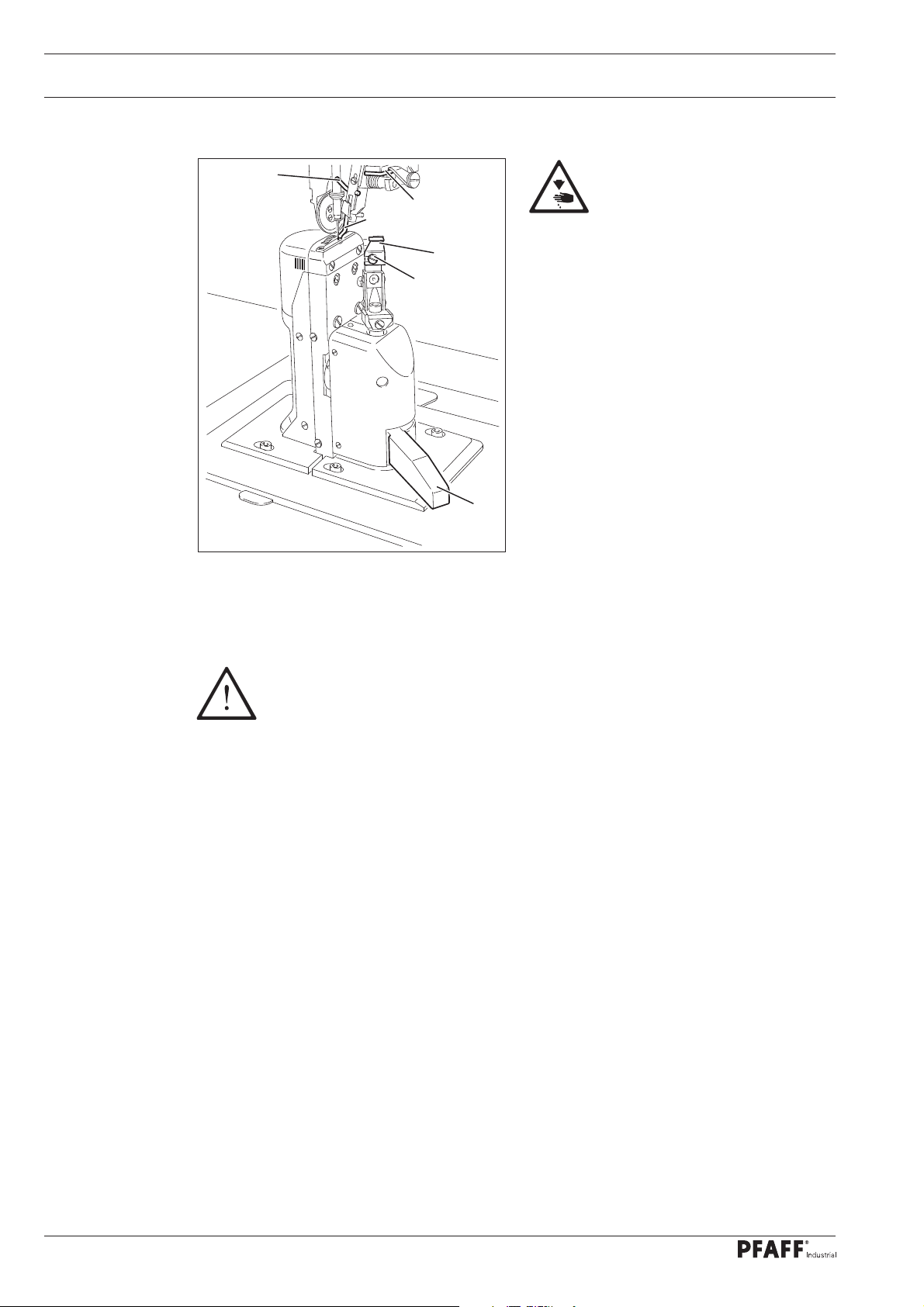

1.06 Danger warnings

A work area of 1 m must be kept free in front of and behind the machine to

ensure unobstructed access at all times.

Do not reach into the needle range during the sewing operation!

Risk of injury from the needle!

Do not allow any objects to be placed on the table during the adjustment work!

The objects could become jammed or be slung away!

Risk of injury from parts fl ying around!

1

2

Fig. 1 - 01

4

4

3

Do not operate the machine without the take-up lever guard 1!

Risk of injury due to the motion of the take-up lever!

Do not operate the machine without the belt guard 2!

Risk of injury due to the rotating driving belt!

Do not operate the machine without the anti-tipping device 3!

Risk of injury by crushing between the sewing head and the table top!

Do not operate the machine without the support 4! Risk of damage due to the

top-heavy sewing head!

Machine can tip over backwards when moving it!

9

Page 10

Proper Use

2 Proper Use

The PFAFF 1571 is a single needle post-bed high-speed seamer (post is positioned to the

left of the needle) with forwards- and backwards-moving feed wheel and roller presser plus

feed-synchronised needle.

The PFAFF 1574 is a two-needle post-bed high-speed seamer with forwards- and

backwards-moving feed wheel and roller presser.

The PFAFF 1591 is a single needle post-bed high-speed seamer (post is positioned to the

right of the needle) with forwards- and backwards-moving feed wheel and roller presser plus

feed-synchronised needle.

The PFAFF 1593 is a single needle post-bed high-speed seamer (post is positioned to the

right of the needle) with forwards- and backwards-moving feed wheel and roller presser.

The machines are used to create double lock stitch seams in the leather and upholstery

industries.

Any usage not approved by the manufacturer is deemed misuse!

The manufacturer shall assume no liability for damage caused by misuse!

Proper use also includes compliance with the operating, maintenance,

adjustment and repair measures specifi ed by the manufacturer!

10

Page 11

Technical Data

3 Technical Data

3

.01 PFAFF 1571

Stitch type: .........................................................................................................301 (lockstitch)

Needle system: .................................................................................................................... 134

Model BN7: ...................................................... for the machining of medium-weight materials

Model CN7: ........................................................for the machining of medium-heavy materials

Needle size in 1/100 mm:

Model BN7: ................................................................................................................... 90 - 110

Model CN7: ................................................................................................................. 120 - 150

Stitch length max: ..........................................................................................................7.0 mm

Speed max.:

Model BN7 ................................................................................................. 3500 stitches/min

Model CN7 ................................................................................................. 2000 stitches/min

Trimming margin (for -725/..) .................................................................................0.8 - 2.5 mm

Cutting speed (for -725/..) .................................................................................. 2800 cuts/min.

Clearance beneath the roller presser for dia. 30 mm: ......................................................7 mm

Clearance beneath the roller presser for dia. 25 mm and dia. 35 mm: ...........................12 mm

Passage width: .............................................................................................................245 mm

Clearance height: ..........................................................................................................115 mm

Post height ....................................................................................................................180 mm

Bed plate dimensions: ............................................................................................... 518 x 177

Sewing head dimensions

Length: ............................................................................................................. approx. 562 mm

Width: .............................................................................................................. approx. 250 mm

Height (above table): ........................................................................................ approx. 505 mm

Motor data: ..................................................................................see motor specifi cation plate

Noise data

(Noise measurement in accordance with DIN 45 635-48-A-1,ISO 11204, ISO 3744, ISO 4871)

Model B:

Emissions sound pressure level in the workplace at n = 2800 min-1: ............... LpA = 80 dB(A)

Model C:

-1

Emissions sound pressure level in the workplace at n = 1600 min

: .............. LpA = 74 dB(A )

Net weight of sewing head: ................................................................................ approx. 64 kg

Gross weight of sewing head: ............................................................................. approx. 74 kg

Subject to alterations.

Depending on the material, workstep and stitch length.

KpA = 2,5 dB

11

Page 12

Technical Data

3.02 PFAFF 1574

Stitch type: .........................................................................................................301 (lockstitch)

Needle system: ............................................................................................................... 134-35

Model BN5: ...................................................... for the machining of medium-weight materials

Model CN5: ........................................................for the machining of medium-heavy materials

Needle size in 1/100 mm:

Model BN5: ................................................................................................................... 90 - 110

Model CN5: ................................................................................................................. 120 - 150

Stitch length max: ..........................................................................................................5.0 mm

Speed max.:

Model BN5 ................................................................................................. 3000 stitches/min

Model CN5 ................................................................................................. 2000 stitches/min

Trimming margin (for -725/..) .................................................................................0.8 - 2.5 mm

Cutting speed (for -725/..) .................................................................................. 2800 cuts/min.

Clearance beneath the roller presser for dia. 30 mm: ......................................................7 mm

Clearance beneath the roller presser for dia. 25 mm and dia. 35 mm: ...........................12 mm

Passage width: .............................................................................................................245 mm

Clearance height: ..........................................................................................................115 mm

Post height ....................................................................................................................180 mm

Bed plate dimensions: ............................................................................................... 518 x 177

Sewing head dimensions

Length: ............................................................................................................. approx. 562 mm

Width: .............................................................................................................. approx. 250 mm

Height (above table): ........................................................................................ approx. 505 mm

Motor data: ..................................................................................see motor specifi cation plate

Noise data

(Noise measurement in accordance with DIN 45 635-48-A-1,ISO 11204, ISO 3744, ISO 4871)

Model B:

Emissions sound pressure level in the workplace at n = 2800 min-1: ............... LpA = 81 dB(A)

Model C:

-1

Emissions sound pressure level in the workplace at n = 1600 min

: .............. LpA = 74 dB(A )

12

Net weight of sewing head: ................................................................................ approx. 68 kg

Gross weight of sewing head: ............................................................................. approx. 78 kg

Subject to alterations.

Depending on the material, workstep and stitch length.

KpA = 2,5 dB

Page 13

Technical Data

3.03 PFAFF 1591

Stitch type: .........................................................................................................301 (lockstitch)

Needle system: .................................................................................................................... 134

Model BN7: ...................................................... for the machining of medium-weight materials

Model CN7: ........................................................for the machining of medium-heavy materials

Needle size in 1/100 mm:

Model BN7: .................................................................................................................... 90 -110

Model CN7: ................................................................................................................. 120 - 150

Stitch length max ...........................................................................................................7.0 mm

Speed max.:

Model BN7 ................................................................................................. 3500 stitches/min

Model CN7 ................................................................................................. 2000 stitches/min

Trimming margin (for -725/..) .................................................................................0.8 - 2.5 mm

Cutting speed (for -725/..) .................................................................................. 2800 cuts/min.

Clearance beneath the roller presser for dia. 30 mm: ......................................................7 mm

Clearance beneath the roller presser for dia. 25 mm and dia. 35 mm: ...........................12 mm

Passage width: .............................................................................................................245 mm

Clearance height: ..........................................................................................................115 mm

Post height ....................................................................................................................180 mm

Bed plate dimensions: ............................................................................................... 518 x 177

Sewing head dimensions

Length: ............................................................................................................. approx. 562 mm

Width: .............................................................................................................. approx. 250 mm

Height (above table): ........................................................................................ approx. 505 mm

Motor data: ..................................................................................see motor specifi cation plate

Noise data

(Noise measurement in accordance with DIN 45 635-48-A-1,ISO 11204, ISO 3744, ISO 4871)

Model B:

Emissions sound pressure level in the workplace at n = 2800 min-1: ............... LpA = 80 dB(A)

Model C:

Emissions sound pressure level in the workplace at n = 1600 min-1: .............. LpA = 74 dB(A )

Net weight of sewing head: ................................................................................ approx. 64 kg

Gross weight of sewing head: ............................................................................. approx. 74 kg

Subject to alterations.

Depending on the material, workstep and stitch length.

KpA = 2,5 dB

13

Page 14

Technical Data

3.04 PFAFF 1593

Stitch type: .........................................................................................................301 (lockstitch)

Needle system: .................................................................................................................... 134

Model BN5: ...................................................... for the machining of medium-weight materials

Needle size in 1/100 mm:

Model BN5: .................................................................................................................... 90 -110

Stitch length max ...........................................................................................................5.0 mm

Speed max.:

Model BN5 ................................................................................................. 3500 stitches/min

Clearance beneath the roller presser for dia. 30 mm: ......................................................7 mm

Clearance beneath the roller presser for dia. 25 mm and dia. 35 mm: ...........................12 mm

Passage width: .............................................................................................................245 mm

Clearance height: ..........................................................................................................115 mm

Post height ....................................................................................................................180 mm

Bed plate dimensions: ............................................................................................... 518 x 177

Sewing head dimensions

Length: ............................................................................................................. approx. 562 mm

Width: .............................................................................................................. approx. 250 mm

Height (above table): ........................................................................................ approx. 505 mm

Motor data: ..................................................................................see motor specifi cation plate

Noise data

(Noise measurement in accordance with DIN 45 635-48-A-1,ISO 11204, ISO 3744, ISO 4871)

Emissions sound pressure level in the workplace at n = 2800 min-1: ..............LpA = 80 dB(A))

Net weight of sewing head: ................................................................................ approx. 64 kg

Gross weight of sewing head: ............................................................................. approx. 74 kg

Subject to alterations.

Depending on the material, workstep and stitch length.

KpA = 2,5 dB

14

Page 15

Disposal of the Machine

4 Disposal of the Machine

It is up to the customer to dispose of the machine properly.

The materials used for the machine include steel, aluminium, brass and various plastics.

The electrical equipment consists of plastics and copper.

The machine must be disposed of in accordance with the locally valid environmental

protection regulations, with a specialised company being contracted if necessary.

Please ensure that parts coated with lubricants are disposed of separately in

accordance with the locally valid environmental protection regulations!

15

Page 16

Transport, Packaging and Storage

5 Transport, Packaging and Storage

5

.01 Transport to the customer's premises

All machines are completely packed for delivery.

5.02 Transport within the customer's premises

The manufacturer assumes no liability for transport within the customer's premises or to

the individual usage sites. Please ensure that the machines are only transported in a vertical

position.

5.03 Disposal of the packaging materials

The packaging materials of these machines consists of paper, cardboard and VCI fl eece. It is

up to the customer to dispose of the packaging properly.

5.04 Storage

The machine can be stored for up to 6 months when not in use. It must then be protected

from dirt and moisture. For longer storage periods, the machine's single components,

especially its sliding surfaces, must be protected against corrosion, e.g. by an oil fi lm.

16

Page 17

Work Symbols

6 Work Symbols

Activities to be performed or important information in this instruction manual are

emphasised by symbols. The symbols used have the following meaning:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

17

Page 18

Operating Controls

7 Operating Controls

7

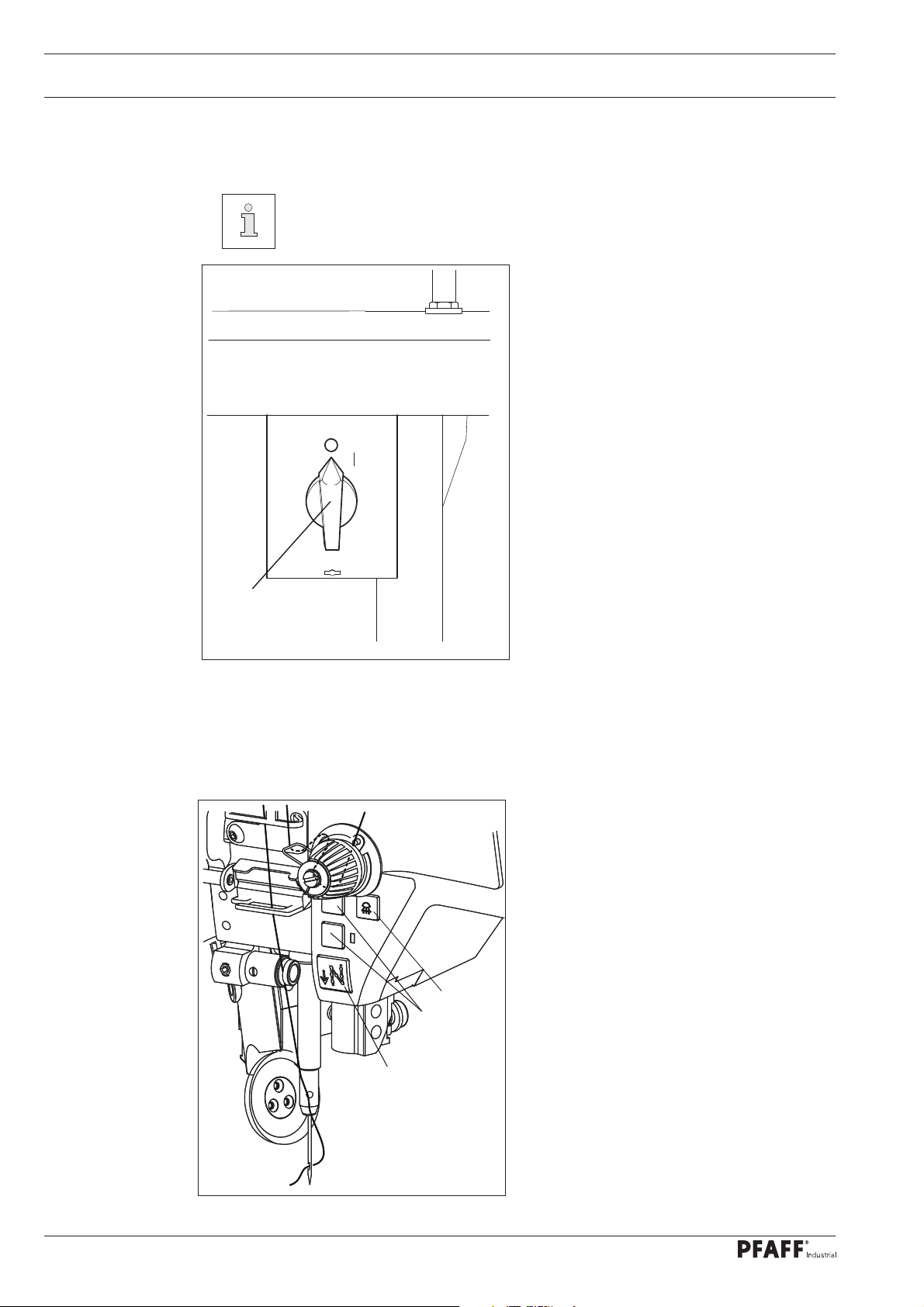

.01 Main switch

Before switching on the machine, raise the take-up lever as far as possible.

Turning the main switch 1 switches the ma-

chine on and off.

1

Fig. 7 - 01

7.02 Keys on the machine head

The machine sews backwards as long as

the key 1 is pressed during the sewing

operation.

The keys 2 can be assigned functions us-

ing parameters “203” and “204”. (See

chapter 15.07 Parameter settings).

The sewing lamp integrated on the ma-

chine head is switched on and off with

3

the key 3.

2

18

1

Fig. 7 - 02

Page 19

Operating Controls

7.03 Bobbin thread monitoring using the stitch count

The diode 1 fl ashes on reaching the

predefi ned stitch count.

The stitch count re-starts after trimming

the thread and changing the bobbin.

For presetting the stitch count

please refer to chapter 9.11 Set-

ting the bobbin stitch counter.

1

Fig. 7 - 03

7.04 Pedal

With the main switch turned on

0 = Neutral position

0

+1

+ 1 = Sewing

- 1 = Raise roller presser

- 2 = Trim thread

Other pedal functions can be

set through the programming,

see chapter 10 Sewing.

-1

Fig. 7 - 04

-2

19

Page 20

Operating Controls

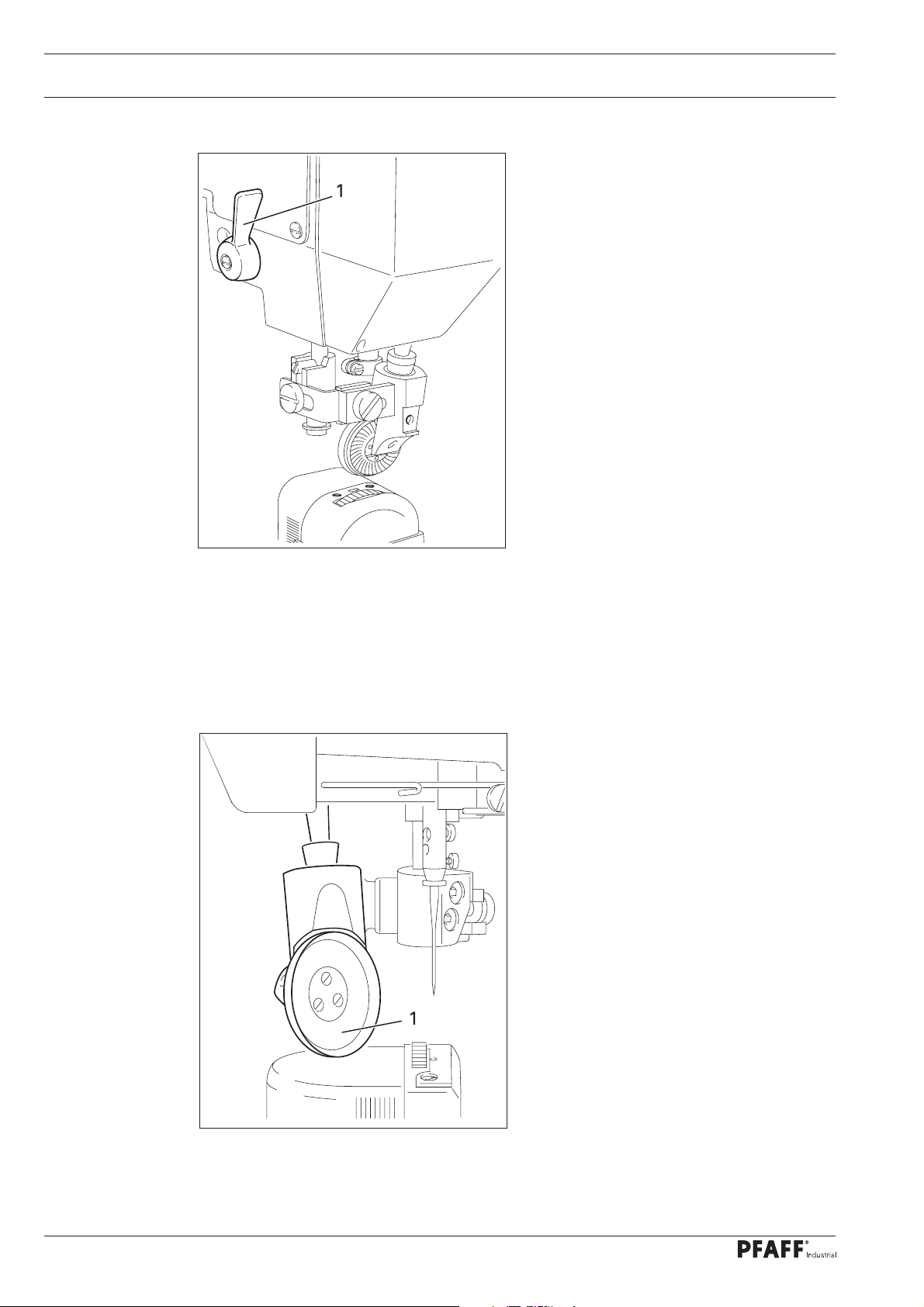

7.05 Hand lever to raise the roller presser

Turning the hand lever 1 raises the roller

presser.

Fig. 7 - 05

7.06 Swivelling out the roller presser

The roller presser 1 can be swivelled out

by gently pulling downwards when the

roller presser is in the raised position.

20

Fig. 7 - 06

Page 21

Operating Controls

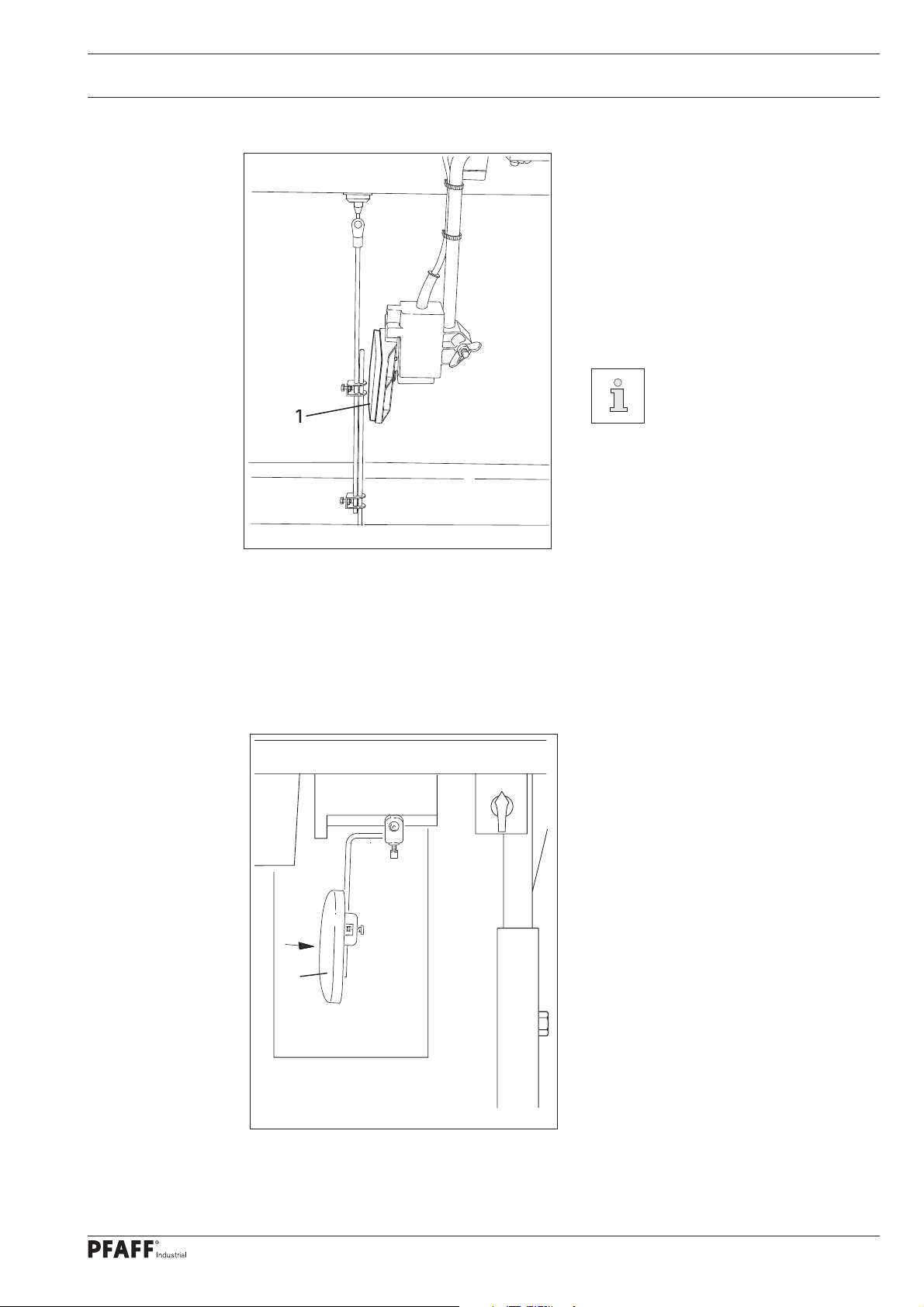

7.07 Knee switch

It is possible to choose between 2

predefi ned fullnesses or 2 stitch lengths

in manual sewing by pressing the knee

switch 1.

It is possible to move to the next seam

zones in programmed sewing by using

the knee switch 1.

The function of the knee

switch 1 must be activated on

the control panel, see chapter

10 Sewing.

Fig. 7 - 07

7.08 Knee lever

1

Pressing the knee lever 1 in the direction

shown by the arrow raises the roller

presser.

Fig. 7 - 08

21

Page 22

Operating Controls

7.09 Edge trimmer -725/04 for PFAFF 1571

Fig. 7 - 09

3

4

2

6

5

1

Switching on the knife drive:

Swivel the lever 1 backwards; the knife

moves to the operating position.

Switching off the knife drive:

Press the lever 1; the knife swivels away

backwards.

Switching on the edge guide:

Swing in the edge guide 2 by hand and

press the lever 3; the edge guide 2

moves to the operating position.

Switching off the edge guide:

Raise the edge guide 2 and allow it

to engage; the edge guide 2 is out of

operation.

Raise the lever 4; the edge guide swivels

away backwards.

Do not reach into the knife

during operation! Risk of injury!

Replacing knives:

The work described below may only be carried out by technical staff or people

with appropriate training!

Switch the machine off.

Release the screw 5 and remove the knife 6.

Insert a new knife and gently tighten the screw 5.

Adjust the knife as described in chapter 15.05.05 Knife movement of the adjustment

manual and tighten the screw 5.

22

Page 23

Operating Controls

7.10 Edge trimmer -725/04 for PFAFF 1574 and 1591

3

4

2

7

6

5

1

Fig. 7 - 10

Do not reach into the knife during operation! Risk of injury!

Switching on the knife drive:

Swivel the lever 1 backwards; the knife moves to the operating position.

Switching off the knife drive:

Press the lever 1; the knife swivels away backwards.

Switching on the edge guide:

Swing in the edge guide 2 by hand and press the lever 3; the edge guide 2 moves to the

operating position.

Switching off the edge guide:

Raise the edge guide 2 and allow it to engage; the edge guide 2 is out of operation.

Raise the lever 4; the edge guide swivels away backwards.

Replacing knives:

The work described below may only be carried out by technical staff or people

with appropriate training!

Switch the machine off.

Release the screw 5 and remove the knife 6.

Insert a new knife and slide it fully towards the needle plate insert 7.

Gently tighten the screw 5.

Adjust the knife as described in chapter 15.05.07 Knife position of the adjustment

manual and tighten the screw 5.

23

Page 24

Operating Controls

7.11 Control panel

Machine functions for set-up and sewing, to enter parameters and service settings are

displayed and called up via the control panel.

1

Fig. 7 - 11

3

2

The control panel consists of the following operating and display controls:

The display 1 comprises a two-line alphanumeric LCD display with 16 characters per

line and is used to display relevant information and the selection of parameters.

The +/- keys 2 are used to select or change the functions and parameters displayed.

The function keys 3 are used to switch the relevant function on or off. Switched-on

functions are each indicated by an illuminated LED lamp.

7.11.01 What appears on the display

Besides the texts and setting values, the following symbols are shown on the display.

The symbols appear solely in programmed sewing mode, see chapter 10.02 Programmed

sewing.

.

Current program number

P

Current seam section

Seam input via "teach-in"

T

DEL

Deleting a program

Stitch count in the current seam zone

24

Maximum speed in the current seam zone

Stitch length (feed motion) for the roller presser

Stitch length (feed motion) for the feed wheel

Page 25

Operating Controls

7.11.02 +/- keys

A B C D

3 3 3 3

Setting values (e.g. input of backtack stitches) are selected and changed using the

respective +/- keys. Pressing and holding the corresponding +/- key will slowly change the

number value shown above the key. The change to the number value will be made quicker if

the +/- key is held for a longer period of time.

7.11.03 Function keys

An active function is always indicated by a corresponding illuminated LED lamp.

Detailed functional description: Start backtack

Start backtack

The seam lock at seam start (start backtack) is turned on or off by pressing this key. The

number of start backtack forward stitches (A) or backward stitches (B) can be changed

in manual sewing by pressing the respective key underneath. Reset the corresponding

partial seam stitch count to zero to convert from double backtack to single backtack.

End backtack

The seam lock at seam end (end backtack) is turned on or off by pressing this key.

The number of start reverse stitches (C) or forward stitches (D) can be changed in

manual sewing by pressing the respective +/- key underneath. Reset the corresponding

partial seam stitch count to zero to convert from double backtack to single backtack.

Needle position up after sewing stop

The “needle position up after sewing stop” function is turned on or off by pressing this

key. If this function is on, the needle moves to top dead centre when sewing stops.

Foot position after stop

The "foot position up after sewing stop" function is turned on or off by pressing this key.

If this function is on, the sewing foot is raised when sewing stops.

Foot position after thread trimming

The "foot position up after thread trimming" function is turned on or off by pressing this

key. If this function is on, the sewing foot is raised after the thread has been trimmed.

Thread trimming

The "thread trimming" function is switched on or off by pressing this key.

25

Page 26

Operating Controls

Speed

With this key, a maximum speed for each seam zone can be defi ned which is only

activated in the corresponding seam zone.

Reverse sewing (only for programmed sewing)

If this key is pressed, the reverse sewing function is switched on or off.

Program interrupt

The automatic processing of a sewing program is interrupted by pressing this key.

The stitch count is switched off and a few processes vary.

Stop

The machine stops automatically at the seam zone end in programmed sewing when the

function is turned on.

Photo cell

The corresponding function is switched on and off by pressing this key. If this function is

on, the machine moves to the next seam zone via the photo cell.

Stitch count (only for programmed sewing)

The corresponding function is switched on and off by pressing this key. If this function

is on, the machine moves to the next seam zone after sewing the number of stitches

entered.

TE/speed

If this key is pressed once, the speed limit for the programmed sewing mode is

activated.

If this key is pressed twice (within 5 seconds) the machine changes from sewing mode

to input mode.

Scroll

If this key is pressed, the input menus on the display are scrolled through.

PM / mode

If this key is pressed, the programmed sewing function is switched on or off.

The program-specifi c parameters are shown in the alphanumeric part of the display.

F1

If this key is pressed, the placed stitch position is switched on or off when sewing begins.

The corresponding needle position is set using the key and by turning the handwheel.

F2

No function is assigned.

F3

The corresponding function is switched on and off by pressing this key. If this function

is on, the machine moves to the next seam zone by using the knee switch.

26

F4

If this key is pressed, the next backtack is not stitched. If this key is pressed twice,

the next two backtacks are not stitched.

Page 27

Set-up and Initial Commissioning

8 Set-up and Initial Commissioning

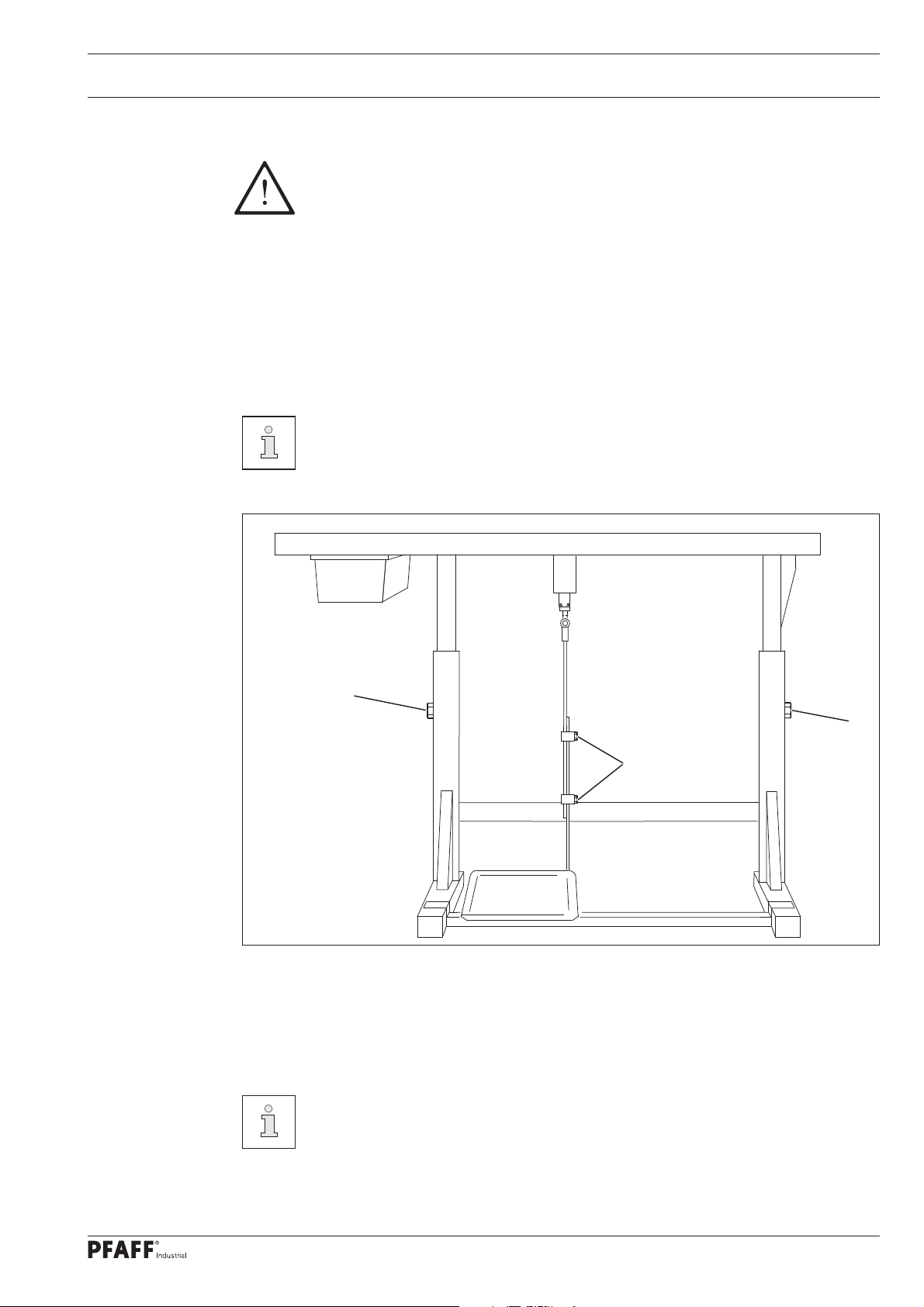

The machine may only be set up and started up by qualifi ed personnel! All of

the relevant safety regulations must always be complied with in this process!

If the machine was delivered without a table, then the stand and the table top

provided must safely support the weight of the machine and its motor.

Adequate stability of the stand must be guaranteed, even during the sewing

operations.

8.01 Set-up

Suitable electrical supply connections must be provided at the erection site, see chapter 3

Technical Data. The erection site must also have a fi rm and level subsurface and adequate

lighting.

The table top is lowered for packaging purposes.

The adjustment of the table height is described below.

8.01.01 Setting the table height

1

2

Fig. 8 - 01

The stand must have all four feet fi rmly on the ground to make sure it is positioned

securely.

Loosen the screws 1 and 2.

Move the table top to the desired working height by pulling it out and pushing it in and

align the table top horizontally.

Adjust the stand on both sides evenly to prevent it tilting.

1

Firmly tighten the screws 1.

Adjust and tighten the desired pedal position on the screws 2.

27

Page 28

Set-up and Initial Commissioning

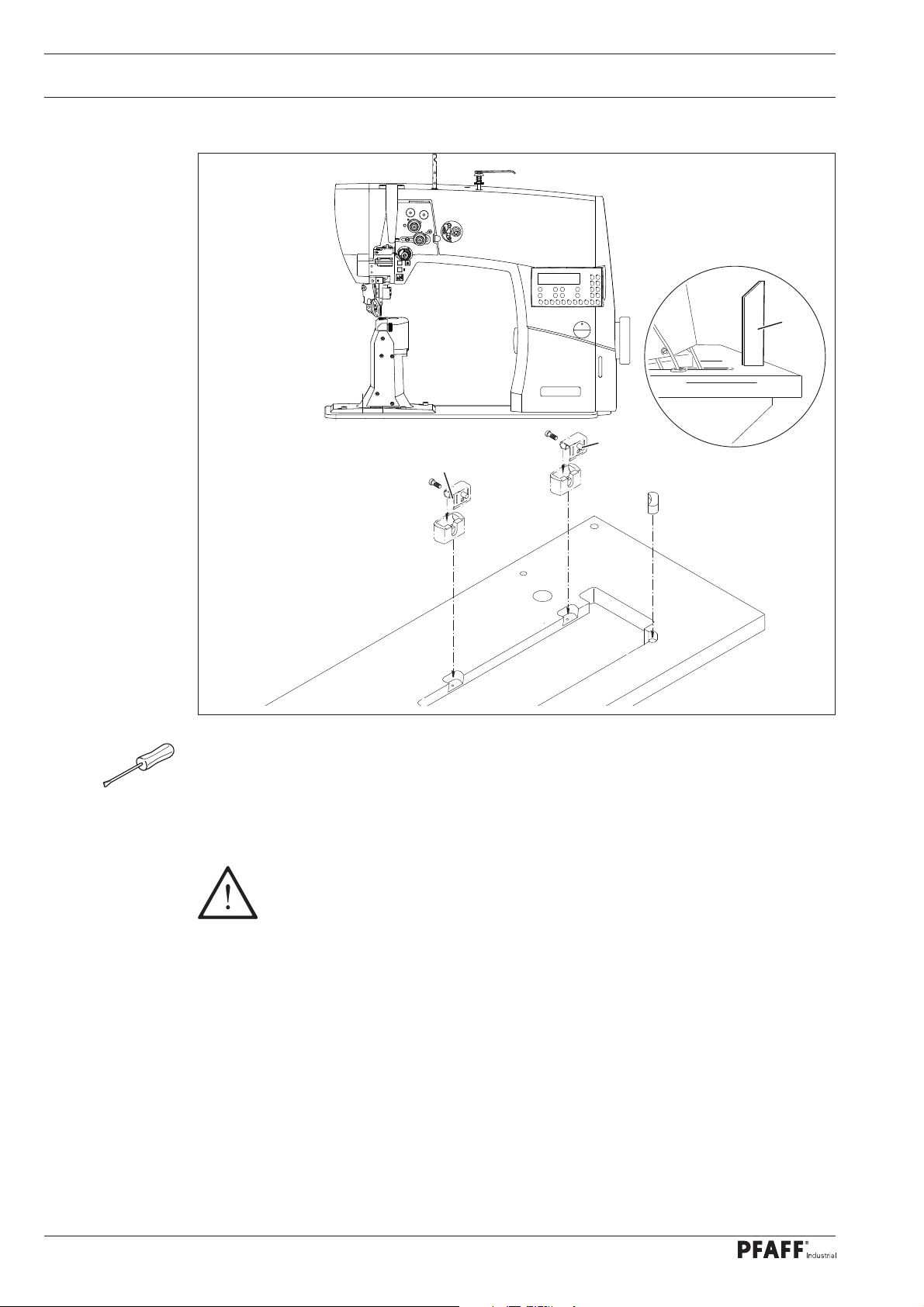

8.01.02 Inserting the sewing machine into the stand

2

4

1

1

Fig. 8 - 02

The hinges 1 are screwed to the sewing head base plate.

Insert the sewing machine into the table top.

Insert the sewing head support 2 into the table top hole.

Do not operate the machine without the support 2! Risk of damage due to the

top-heavy sewing head!

Machine can tip over backwards when moving it!

28

Page 29

Set-up and Initial Commissioning

.01.03 Assembling the anti-tipping device

8

2

1

Fig. 8 - 03

Switch off the machine!

Risk of injury due to accidental

machine start-up!

Screw on the anti-tipping device 1 includ-

ed in the accessories with the screw 2.

Do not operate the machine

without the anti-tipping device 1!

Risk of injury by crushing

between the sewing head and

the table top!

8.02 Mounting the fl ange motor

8

.02.01 Mounting the fl ange motor on the bearing plate

3

1

9

8

Fig. 8 - 04

Fix the bearing plate 1 onto the motor 2 using the screws 3, as shown in fi g. 8-04.

Remove the wedge from the motor shaft 4.

3

4

7

2

3

6

6

3

5

Attach the angle bracket 5 with the screws 6.

Mount the toothed belt wheel 7 onto the motor shaft 4 so that the screw 8 is positioned

with the lug in the motor shaft slot 4.

Screw the threaded pins 9 into the bearing plate 1.

29

Page 30

Set-up and Initial Commissioning

8.02.02 Mounting the fl ange motor on the machine

2

Use the screw 3 and 4 to fi x the bearing

plate 1 of the motor 2 to the machine

housing (tighten the screws 3 and 4

slightly).

4

1

Fig. 8 - 05

3

8.02.03 Mounting the machine cover

2

1

4

Use the screws 2 (2x) and the screws 4

(3x) to fasten the cover 1 to the housing.

Place the cover 3 on the cover 1 and

fasten with the screws 4 (3x).

3

4

30

Fig. 8 - 06

Page 31

Set-up and Initial Commissioning

8.02.04 Connecting the plug-in connections and ground cable

B

4

1

0

3

4

D

C

D

B

A

2

E

M

Fig. 8 - 07

Insert all connectors on the control box 2 in accordance with their designation.

Caution

Inserting the connector incorrectly can damage the control unit!

Attach the following ground cables in order to discharge static electricity

Securely attach the ground cable from the sewing head 1 to ground point A.

Securely attach the ground cable from the control point B to ground point B.

Securely attach the ground cable from the main switch 3 to ground point C.

Securely attach the ground cable from the stand 4 to ground point D.

Securely attach the ground cable from the motor cable M to ground point E.

31

Page 32

Set-up and Initial Commissioning

8.02.05 Fitting the toothed belt / home position of the machine drive with the

PFAFF 1571; 1591 and 1593

Switch the machine on

2.5 2.5

2 x

No

Press the TE/Speed key twice to call up the input mode.

NO VAL

101 II

Select the parameter group “600” by pressing the corresponding +/- key.

NO

600

Confi rm the selection by pressing the corresponding +/- key.

Enter the template code, see chapter 9.10 Entering/changing the template code.

32

NO

603 8

Select the parameter group “603” by pressing the corresponding +/- key.

Turn the motor shaft by hand until the display shows the value "8”.

Turn the handwheel in the direction of rotation until the needle point (approaching from

above) is on the upper edge of the needle plate.

Lay on the toothed belt 1 while making sure that both the motor shaft 4 (Fig. 8 - 08) and

the machine are not twisted.

Page 33

Set-up and Initial Commissioning

3

3

Fig. 8 - 08

Fit the toothed belt 1

Pivot the motor bearing plate 2 so that the toothed belt 1 is taut.

Tighten the screws 3 in this position.

Turn the handwheel in the direction of rotation until the needle point (approaching

from above) is on the upper edge of the needle plate. ± 2 increments are permitted as

a tolerance.

Complete the adjustment of the sewing motor by pressing the TE/SPEED key.

1

2

4

33

Page 34

Set-up and Initial Commissioning

8.02.06 Fitting the toothed belt / home position of the machine drive with the

PFAFF 1574

Fit the toothed belt 1 (Fig. 8 - 08).

Pivot the motor bearing plate 2 so that the toothed belt 1 is taut.

Tighten the screws 3 in this position.

10

9

8

Slide the synchroniser 8 onto the shaft so

that the position fi nger 9 is positioned in

the synchroniser groove (see arrow).

Gently tighten the screws 10.

Plug the adapter cable 11 into the

bushing X 3 on the control unit.

Connect the synchroniser 12 to connector

S.

Connect the motor to connector R.

Connect the ground cable 13 to the

housing.

Fig. 8 - 09

11

13

X8

12

X3

S

R

34

Fig. 8 - 10

Page 35

Switch the machine on

Set-up and Initial Commissioning

2 x

No

2.5 2.5

Press the TE/Speed key twice to call up the input mode.

NO VAL

101 II

Select the parameter group “600” by pressing the corresponding +/- key.

NO

600

Confi rm the selection by pressing the corresponding +/- key.

Enter the template code, see chapter 9.10 Entering/changing the template code.

NO

603

Select the parameter group “603” by pressing the corresponding +/- key.

NO

603

Turn the machine one revolution by pressing the corresponding +/- key.

Check the needle bar position.

Loosen the synchroniser screws 10, hold the synchroniser shaft tightly and turn the hand-

wheel in the direction of rotation until the needle point (approaching from above) is on

the upper edge of the needle plate.

Tighten the synchroniser screws.

Turn the machine one revolution again by pressing the corresponding +/- key again and check the

setting - repeat the setting process if necessary.

Complete the adjustment of the sewing motor by pressing the TE/Speed key.

35

Page 36

Set-up and Initial Commissioning

8.02.07 Mounting the fl ange motor belt guard

1

Attach the belt guard 1 with the screws

2 and 3.

2

3

Fig. 8 - 11

8.02.08 Connecting the safety switch

2

Plug in the connector 1 of the safety

switch 2 as shown in Fig. 8 - 12.

If the sewing head is tilted

back, the safety switch

activates the start inhibitor,

preventing the machine starting

up if the main switch is turned

on.

36

1

Fig. 8 - 12

Page 37

Set-up and Initial Commissioning

8.02.09 Checking the start inhibitor function

STOP

2.5 2.5

Switch on the machine at the main switch and move the sewing head.

The error message “STOP” must appear on the control panel.

If this message does not appear, check the switch 2 setting.

The machine is ready for operation again after righting the sewing head.

8.03 Assembling the reel stand

Fig. 8 - 13

Assemble the reel stand as shown in the

adjacent illustration.

Then insert the stand into the hole in the

table top and secure it with the enclosed

nuts.

37

Page 38

Set-up and Initial Commissioning

8.04 Initial start-up

Inspect the machine for any damage, particularly the electric cables.

Clean the machine thoroughly and then oil it, see also chapter 12 Maintenance and

Care.

Arrange for technical staff to check whether the machine's motor may be operated at the

existing mains voltage and whether it is connected properly.

Never operate the machine if there are any differences.

The machine must only be connected to a grounded socket!

Arrange for the home position of the machine drive to be verifi ed by certifi ed

technicians before the initial start-up! Have these settings carried out where

required.

8.05 Switching the machine on / off

Switch the machine on (see chapter 7.01 Main switch).

38

Page 39

Set-up

9 Set-up

Observe and comply with all regulations and instructions in this instruction

manual.

Pay particular attention to all safety regulations!

All set-up work may only be carried out by appropriately instructed personnel.

Disconnect the machine from the electricity mains for all set-up work by operat-

ing the main switch or by removing the mains plug!

9.01 Inserting the needle

1

3

Fig. 9 - 01

Switch off the machine!

Risk of injury due to accidental machine start-up!

Only use needles of the system intended for the machine, see chapter 3

Technical Data!

PFAFF 1571; 1591 and 1593

Raise and fold out the roller presser 3

1

1

2

2

3

Fig. 9 - 02

PFAFF 1574

Raise and fold out the roller presser 3

Bring the needle bar to the top posi-

tion.

Loosen the screw 1 and insert the

needle 2 until you feel it stop. The

long groove must point to the right

with the PFAFF 1571 and to the left

with the PFAFF 1591 and 1593.

Tighten the screw 1.

Bring the needle bar to the top position.

Loosen the screws 1 and insert the nee-

dles 2 until you feel them stop. The long

groove of the left needle must point to

the right and that of the right needle

must point to the left.

Tighten the screws 1.

39

Page 40

Set-up

9.02 Winding the bobbin thread, adjusting the thread tension

7

4

1

6

5

3

9

2

8

Fig. 9 -03

Fit the empty bobbin 1 onto the bobbin winder spindle 2 with the rest thread chamber on

the outside.

Thread in the thread as shown in Fig. 9 - 03 and wind it round the bobbin 1 a few times in

an anti-clockwise direction.

Switch on the bobbin winder by pressing the bobbin winder spindle 2 and the lever 3

simultaneously.

40

The bobbin fi lls up during sewing.

If the machine is only run for bobbin winding (without sewing), a bobbin case

must be fi tted in the hook!

Otherwise a jammed thread may damage the hook!

The tension of the thread on the bobbin 1 can be adjusted with the knurled thumb screw 4.

The bobbin winder stops automatically when the bobbin 1 is suffi ciently full.

Remove the fi lled bobbin 1 and cut the thread with the knife 5.

The fi ll amount of the bobbin 1 can be adjusted with the pin 8 (loosen the screw 9 and

tighten it again) if the thread is wound unevenly:

Loosen the nut 6.

Turn the thread guide 7 accordingly.

Tighten the nut 6.

Page 41

Set-up

9.03 Removing / inserting the bobbin case

Fig. 9 -04

1

2

Removing the bobbin case:

Bring the take-up lever to its top position

Open the post cover, raise the lever 1

and remove the bobbin case 2.

Inserting the bobbin case:

Press the bobbin case 2 until you feel it

snap into the bobbin case base.

Move the lever 1 and close the post cov-

er.

Do not operate the machine with an open post cover!

Risk of injury due to moving parts!

Switch off the machine!

Risk of injury due to accidental

machine start-up!

9.04 Inserting the bobbin case / adjusting the bobbin thread tension

Switch off the machine!

Risk of injury due to accidental

machine start-up!

1

5 cm

+

Insert the bobbin as shown in Fig. 9 - 05.

When the thread is drawn off, the bobbin

must turn in the direction shown by the

arrows.

Adjust the thread tension by turning the

screw 1.

-

Fig. 9 -05

41

Page 42

Set-up

9.05 Threading the needle thread / adjusting the needle thread tension

(with the PFAFF 1571; 1591 and 1593)

1

+

Fig. 9 - 06

-

Switch off the machine!

Risk of injury due to accidental machine start-up!

42

Thread the needle thread as shown in Fig. 9 - 06. Please ensure that the PFAFF 1571

needle is threaded from right to left and that of the PFAFF 1591;1593 is threaded from

left to right.

Adjust the needle thread tension by turning the knurled thumb screw 1.

Page 43

Set-up

9.06 Threading the needle thread / adjusting the needle thread tension

(with the PFAFF 1574)

2

1

+

Fig. 9 - 07

-

+

-

Switch off the machine!

Risk of injury due to accidental machine start-up!

Thread the needle thread as shown in Fig. 9 - 07. Please ensure that the right needle is

threaded from the left and the left needle is threaded from the right.

Adjust the needle thread tension by turning the knurled thumb screw 1 (right needle or 2

left needles).

43

Page 44

Set-up

9.07 Adjusting the stitch length

9.07.01 Entering the sealing speed

The stitch length is defi ned by setting the feed motion of the roller presser and feed wheel.

For the incorporation of fullness, the feed motion on the roller presser must be larger or

smaller than the feed motion on the feed wheel.

Switch the machine on.

Once the machine is switched on, the current stitch length values for the roller presser

and feed wheel are shown in the display.

2.5 2.5

Set the stitch length (feed motion) for the roller presser by pressing the

corresponding +/- key.

Set the stitch length (feed motion) for the feed wheel by pressing the corresponding

+/- key.

9.07.02 Entering a second stitch length or fullness

Using the PM key, a second stitch length or fullness setting can be made in addition to the

standard stitch length. Switching between both settings is carried out in programmed sew-

ing by pressing the knee switch.

2

1 1 2.5 2.5

Switch machine on.

Press the PM key to enter programmed sewing (LED lamp lights up).

Select the program number (1 or 2) by pressing the corresponding +/- key.

Sew 1 - 2 stitches and press the knee switch, see also chapter 7.07 Knee switch.

44

Set the stitch length (feed motion) for the roller presser by pressing the

corresponding +/- key.

Set the stitch length (feed motion) for the feed wheel by pressing the corresponding +/-

key.

Page 45

Set-up

9.08 Entering the start and end backtacks

Switch machine on.

2.5 2.5

Set the corresponding function by pressing the start backtack and/or the end backtack

keys. (LED lamp lights up)

Switch to the input menu for the start and end backtacks by pressing the scroll key.

A B C D

3 3 3 3

C

A

B

D

Select the desired value for the number of start backtack forward switches (A) by press-

ing the corresponding +/- key.

Select the desired value for the number of start backtack reverse stitches (B) by pressing

the corresponding +/- key.

Select the desired value for the number of end backtack reverse stitches (C) by pressing

the corresponding +/- key.

Select the desired value for the number of end backtack forward stitches (D) by pressing

the corresponding (+/- key.

The input menu for the stitch length is called up again by pressing the scroll key.

45

Page 46

Set-up

9.09 Entering/changing the template code

Switch machine on.

2.5 2.5

2 x

No

Press the TE/Speed key twice to call up the input mode.

NO VAL

101 II

Select the parameter group “800” by pressing the corresponding +/- key.

NO

800

Confi rm the selection by pressing the corresponding +/- key.

CODE: 1500

46

0

1

Enter the template code by pressing the corresponding keys (the factory setting is code

“1500”, see also chapter 7.11.03 Function keys.

Conclude the input of the template code by pressing the corresponding +/- key.

The code input remains saved until the machine is switched off by the

main switch. Provided that the machine is not turned off, all parameters

can be accessed without re-entering the template code.

5

Page 47

Set-up

NO VAL

801 0

No

Select the parameter “810” by pressing the corresponding +/- key.

810 1500

Confi rm the selection by pressing the corresponding +/- key.

CODE: 1500

0

2

1

3 4 5

6

7 8

9

Enter the template code by pressing the corresponding keys, see also chapter 7.11.03

Function keys.

End the input by pressing the TE/SPEED key. The newly entered template code is saved

and the sewing mode is called up.

Provided that the machine is not turned off, all parameters can be

accessed without having to repeatedly enter the template code. Do not

forget the code. Protected functions cannot be called up without the

corresponding code! Please contact PFAFF customer service centre in this

case.

47

Page 48

Set-up

9.10 Setting the bobbin stitch counter

Switch machine on.

2.5 2.5

2 x

No

VAL

Press the TE/Speed key twice to call up the input mode (LED lamp lights up).

NO VAL

101 II

Select the parameter group “105” by pressing the corresponding +/- key.

NO VAL

105 1000

Set the number of stitches that can be sewn with a bobbin by pressing the correspond-

ing +/- keys.

End the input by pressing the TE/Speed key. The entered value is saved and the sewing

mode is called up.

48

The stitch count function can only be activated when parameter “104” is

set to “1”.

Page 49

Set-up

9.11 Inserting and removing the SD memory card

Insert the SD card

1

Open the cover 1.

Insert the SD card 2 into the card slot

with the label facing forwards.

2

2 GB

max.

Close the cover 1 again.

Only use FAT 16 format

memory cards.

Remove the SD card

Open the cover 1.

3

Fig. 9 - 08

Adjusting the slide 3 makes it possible to activate ("LOCK" position) or

deactivate the write protection function on the SD memory card. The write

protection function must be deactivated to store, edit or delete data on

the SD memory card.

Press gently on the corner of the SD

memory card 2 - the SD card will be

ejected.

Close the cover 1 again.

The SD card must be kept for future boot processes.

The SD card is not a default confi guration.

49

Page 50

Sewing

10 Sewing

10.01 Manual sewing

In sewing mode all settings relevant for the sewing operation are shown in the display.

Functions can be switched on or off by pressing the key, values for start and end backtacks

or placed stitch can be altered directly.

A difference is made between manual sewing and programmed sewing in this mode.

The “PM” key is used to switch between manual sewing (LED lamp off) and programmed

sewing (LED lamp on).

Fixed programs are set under the program numbers 1-2. The program numbers 3-99 can be

assigned freely programmable seams.

After the machine has been switched on and manual sewing has been selected by pressing

the PM key, the display appears for entering the stitch length, see also chapter 9.07 Setting

the stitch length.

2.5 2.5

If the backtack function is switched on, the display appears for entering the backtack values,

see also chapter 9.08 Entering the start and end backtacks.

Pressing the scroll key switches between the displays.

A B C D

3 3 3 3

For other functions during manual sewing, see also chapter 7.11 .03 Function keys:

50

Backtack suppression Raise roller presser on/off

Start backtack on/off

End backtack on/off Thread trimming on/off

Raise needle position on/off

Sewing is carried out using the pedal function, see also chapter 7.04 Pedal.

Raise roller presser after seam end on/

off

Page 51

Sewing

10.02 Programmed sewing

In programmed sewing a difference is made between fi xed programs (program numbers 1

and 2) and freely programmable sewing programs (program numbers 3-99).

The fi xed programs are are used for the quick and easy production of seams with different

number of stitches or fullness. The respective 2 or 3 seam zones are switched using the

knee switch function, see also chapter 7.07 Knee switch.

The fi xed programs are also designed as running programs and can be concluded by the

pedal function, see also chapter 7.04 Pedal.

The freely programmable sewing programs (program numbers 3 to 99) can be entered,

altered or deleted if necessary, see chapter 11 Input.

After the machine has been switched on (chapter 7.01 Main switch) and the programmed

sewing mode key has been selected with the PM key, the display appears for selecting the

program number, seam zone and stitch length.

2

1 1 2.5 2.5

If other functions are switched on, for example backtack functions, maximum seam

zone speed or stitch count, the scroll key can be used to switch between other menu

displays, for example, for entering the values in the corresponding seam zone and stitch

count.

The number of backtack stitches is set in manual sewing mode, see chapter

9.08 Entering the start and end backtacks. The values entered apply to all

seam programs.

2

1 1 1300 134

Entering the values is carried out by pressing the corresponding +/- key.

51

Page 52

Sewing

For other functions in programmed sewing, see also chapter 7.11 .03 Function keys:

Place stitch position on/off Thread trimming on/off

Knee switch function on/off Seam zone speed on/off

Backtack suppression on/off Reverse sewing direction on/off

Start backtack on/off Program interrupt

End backtack on/off Programmed stop on/off

Raise needle position on/off Photo cell on/off

Raise roller presser on/off Stitch count on/off

Raise roller presser after

thread trimming on/off

Sewing is carried out using the pedal functions, see chapter 7.04 Pedal.

If multiple seam zones belong to a seam program, the individual seam zones

are automatically processed one after the other.

52

Page 53

Sewing

10.03 Program interrupt

If the course of a seam program is interrupted (e.g. a broken thread), the program interrupt

function must be called up.

The seam program course is interrupted after pressing the program interrupt key.

Sewing can continue manually and the values for the stitch length from the current seam

program are taken over.

2

5 1 2.5 2.5

The corresponding +/- key can be used to select the seam zone, in which the seam

program should be continued.

By pressing the program interrupt key again, the machine moves into the selected

seam zone and the programmed sewing function is continued.

10.04 Error messages

When a fault occurs, the display shows "ERROR" together with an error code, as shown

in the following example. In addition, the LED in the memory card slot lights up red

(see arrow). An error message can be caused by the incorrect set up, faulty elements or

overloading.

ERROR: 9

Correct the error.

Confi rm the error correction if required by pressing the TE/Speed key.

The LED in the memory card slot lights up yellow (see arrow).

For a description of errors see chapter 11 .07 Error codes and descriptions.

53

Page 54

Input

11 Input

This chapter describes the input mode functions and how to enter seam programs.

11 .01 Input mode

When the machine is in its initial state, it is possible to enter the parameters and the

corresponding values directly in the control unit. The functions information, photo cell and

service can be called up.

11.01.01 Overview of the functions in input mode

The input mode is called up by pressing the TE/Speed key twice.

2 x

A difference is made between parameter inputs and seam program inputs within the input

mode.

The PM key is used to enter into the seam program input after calling up the input mode.

11.01.02 Overview of the seam program input

Call up seam program input

Select program number (corresponding +/- key)

Select input variants

P

Seam program input/ alteration

Confi rm selection (Enter)

Seam zone

Stitch length (feed motion) roller presser

Stitch length (feed motion) feed wheel

Scroll (only when the following functions are turned on)

Seam zone

Max. speed

Stitch number

Placed stitch position

Scroll (only when the following functions are turned on)

Seam zone

Start backtack forward stitches

A

Start backtack backward stitches

B

Start backtack speed

54

Scroll (only when the following functions are turned on)

Seam zone

End backtack backward stitches

C

End backtack forward stitches

D

End backtack speed

Page 55

Input

Scroll

Seam zone

INS

Insert seam zone

Delete seam zone

DEL

END

Last seam zone selection

Input variant

T

Seam input via teach-in

Confi rm selection (Enter)

Seam zone

Stitch length (feed motion) roller presser

Stitch length (feed motion) feed wheel

Scroll (only when the following functions are turned on)

Seam zone

Max. speed

Placed stitch position

Scroll (only when the following functions are turned on)

Seam zone

Start backtack forward stitches

A

Start backtack backward stitches

B

Start backtack speed

Scroll (only when the following functions are turned on)

Seam zone

End backtack backward stitches

C

End backtack forward stitches

D

End backtack speed

After operation of pedal

Seam zone

Stitch number sewn

Last seam zone selection

END

Select input variants

DEL