Page 1

Service Manual

1st Release August 2001

Page 2

Page 3

1

Contents 1

Foreword 3

Notes on the sewing machine in relation to environment, handling, cleaning and safety 5

Specifications off PFAFF machines 6

Removing the housing covers 8

Adjustment instructions

Feeding system

1. Adjustment of toothed belt tension 13

2. Adjustment of feed dog in sideways direction on Pfaff 1520 14

3. Adjustment of feed dog in sideways direction on Pfaff 1530-1540 16

4. Adjustment of feed dog height 18

5. Adjustment of presser bar height on Pfaff 1520 19

6. Adjustment of presser bar height on Pfaff 1530-1540 20

7. Adjustment of top feed foot in sewing direction 22

8. Adjustment of top feed foot height 24

9. Adjustment of feed regulator cranks on Pfaff 1520 / 1530 26

10. Adjustment of feed regulator cranks on Pfaff 1540 27

11. Zero point adjustment of stitch length regulator 28

12. Timing of feed motion 30

Automatic utility-stitch unit

13. Replacing the automatic module on Pfaff 1520 - 1530 32

14. Adjustment of the locking disk 34

15. Replacing the zigzag-stitch unit on Pfaff 1520 - 1530 35

16. Basic position of setting eccentric for the sideways needle position 36

17. Adjustment of needle penetration in needle plate slot 37

18. Adjustment of the sideways movement of the needle bar 38

19. Adjustment of the stop for the left needle position 40

20. Adjustment of the feed reversing bar 42

21. Replacing the utility-stitch unit on Pfaff 1540 44

22. Adjustment of the gears in relation to each other 46

23. Replacing the zigzag-stitch unit on Pfaff 1540 47

24. Basic position of setting eccentric for the sideways needle position on Pfaff 1540 48

25. Adjustment of needle penetration in needle plate slot on Pfaff 1540 49

26. Adjustment of the sideways movement of the needle bar on Pfaff 1540 50

27. Adjustment of zigzag stitch penetration in needle plate slot on Pfaff 1540 52

28. Adjustment of the stop for the left needle position on Pfaff 1540 53

Stitch forming parts (sewing hook)

29. Adjustment of needle clearance in needle slot in sewing direction 56

30. Adjustment of hook-to-needle clearance 58

30a. Adjustment of bevel gears 59

31. Sewing hook timing 60

32. Adjustment of needle bar height 62

33. Adjustment of bobbin case position finger 63

Page

Page 4

2

Stitching off

34. Adjustment of needle threader 64

35. Adjustment of bobbin winder stop 66

36. Adjustment of bobbin thread tension 67

37. Adjustment of needle thread tension 68

38. Adjustment of thread check spring stroke 70

39. Adjustment of equal stitch length for left and right buttonhole seams 72

40. Adjustment of equal forward and reverse stitch length 73

(for forward and reverse controlled utility stitches)

41. Making up a sewing sample 74

Repair Instructions

42. Removing and fitting the needle thread tension 75

43. Changing the pressure spring in the handwheel release 76

44. Removing and fitting the sewing hook 78

45. Cleaning and oiling the machine 78

46. Changing the toothed belt 80

47. Adjusting the arm shaft crank 82

48. Changing the bevel gears 84

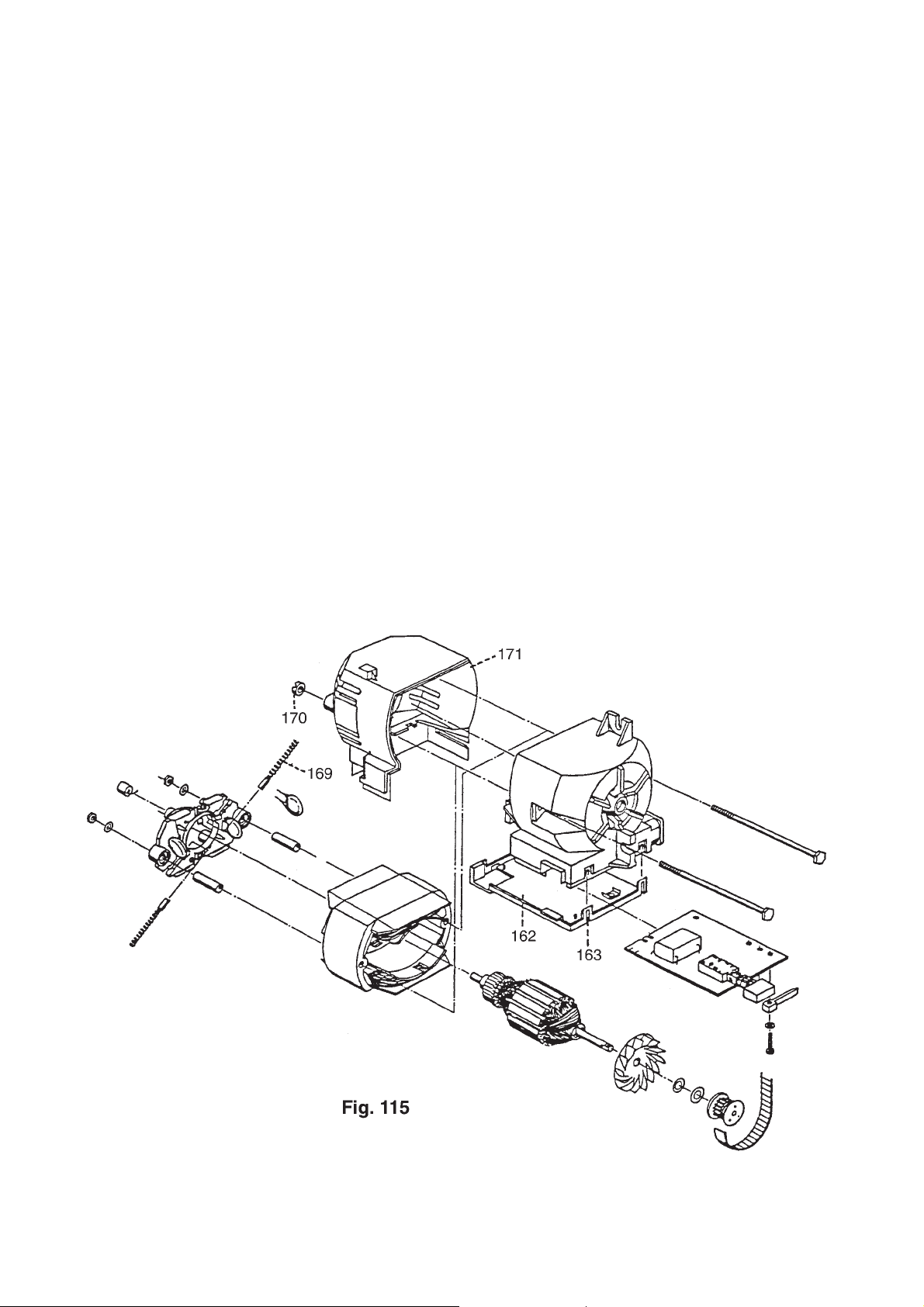

49. Changing the motor 88

50. Changing the motor circuit board on motor types UUS 390 and UUS 393 90

51. Changing the carbon brushes on motor types UUS 390 and UUS 393 91

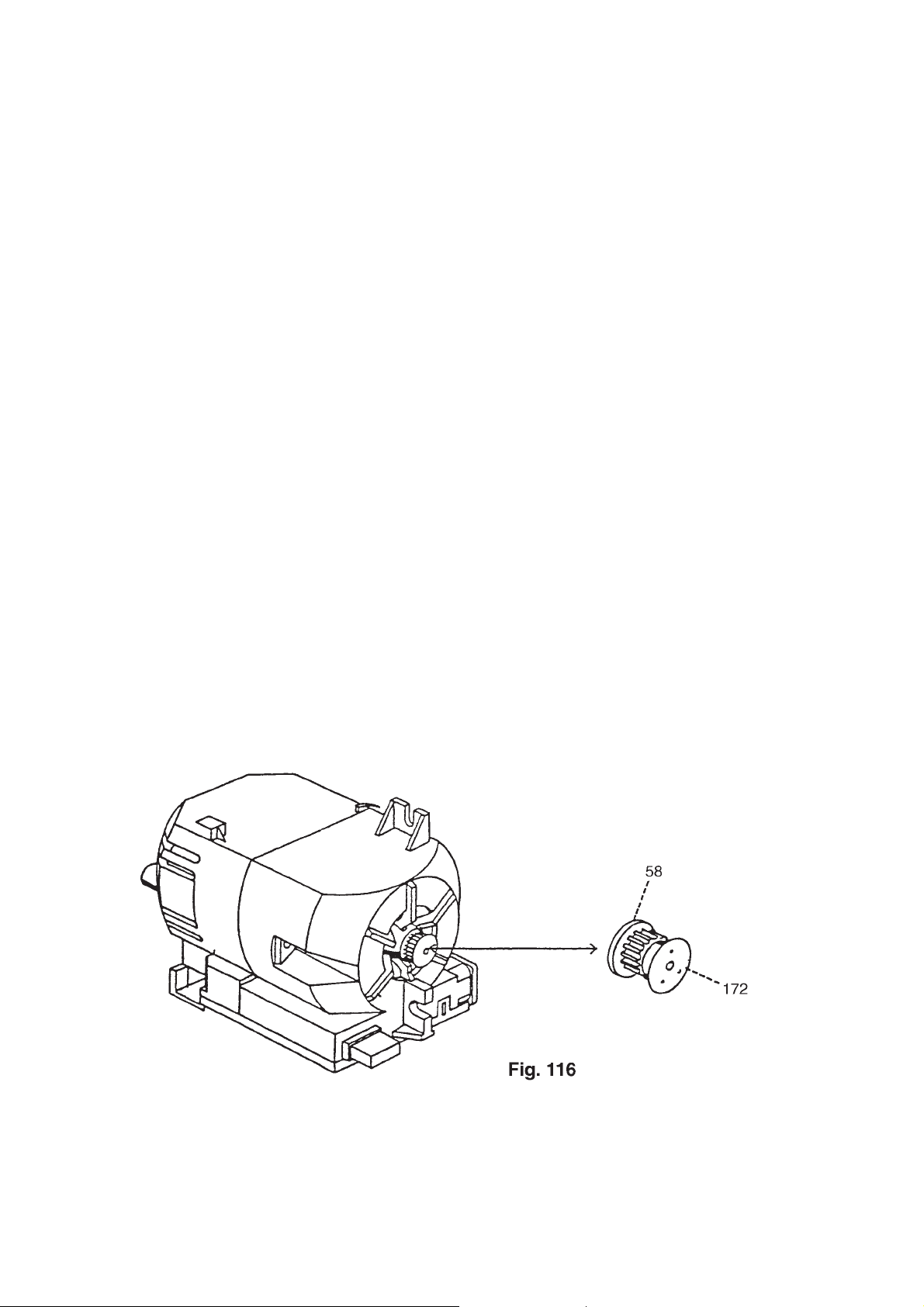

52. Changing the motor pinion 92

53. Changing the motor toothed belt 93

54. Changing the circuit board in foot control AE 010 94

55. Changing the mains connections in foot control AE 010 95

Safety test

56. Electrical safety test 96

57. Electrical safety test with ABB Metrawatt M 5013 96

58. Simulated leakage current measurements of complete motors with ABB Metrawatt M 5013 99

59. Measures required in case of incorrect readings 99

Page 5

3

Foreword

The purpose of this service manual is to assist you in quick and correct repair of the machines.

Adjustments should only be made if the settings deviate from the requirements described in this manual.

When checking or adjusting a machine, always proceed in the order of the worksteps prescribed.

For easier reference, each workstep is identified by a number. Different operational procedures are indicated by a circle or a square.

The indications "left", "right", "top", "bottom", "front" and "back" always refer to the upright machine with

the controls facing the operator.

When assembling dismantled machines, adjust the machine to approximately the right settings.This facilitates the subsequent fine adjustments.

Unless otherwise specified, the handwheel must always be turned forward.

When carrying out maintenance work on live parts or in their proximity, the machine is to be separated

from the power supply by disconnecting the lead cord from the electrical socket.

An electrical safety test must be carried out after all repair work, even if the repair work is of a mechanical

nature.

The required electrical tests for the appliances are laid down in the current EU regulations, EEC directives, and the EMC-law (Standard EN 60335-1/A:96 = ICE 335-1: 91/A1:94, mod).

It is obligatory to perform a safety test in accordance with VDE 0701-1 after repair, modification and

testing of electrical appliances.

Outside Germany there are similar regulations in force which are largely identical with the requirements of

VDE 0701.

It is therefore necessary to consult a specialist when carrying out repairs on electrical appliances.

Page 6

4

For the proper adjustment of the machine, the following gauges and tools are required:

z Needle r ise gauge: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .00-870136-01

z Needle r ise clamp: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .00-870137-01

z Spacer: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63-102600-18

z Adjustment gauge for the bobbin case holder: . . . . . . . . . . . . . . . . . . .00-880133-01

z Presser foot gauge: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63-114690-39

z Ring-shaped open-end spanner 5.5 mm . . . . . . . . . . . . . . . . . . . . . . .43-111010-04

z Torx screwdriver TX 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-434008-40

z Torx screwdriver TX 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-434008-44

z Torx screwdriver TX 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-434008-45

z Torx screwdriver TX 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-434008-46

z Torx screwdriver TX 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-434008-47

z Torx offset screwdriver TX 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-434008-74

z Circlip fitting tool 2.3 short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-437003-20

z Circlip fitting tool 3.2 short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-437003-30

z Circlip fitting tool 4.0 short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-437003-40

z Circlip fitting tool 5.0 short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-437003-50

z Circlip fitting tool 6.0 short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-437003-60

z Circlip fitting tool 10.0 short . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-437003-86

z Spr ing hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .07-437006-00

Subject to design and dimensional modifications.

Page 7

5

Notes on the sewing machine in relation to environment, handling,

cleaning and safety

Environment:

The recommended operating ranges are as follows:

Ambient temperature -10°C to 40°C (50° to 104°F)

Air humidity 20 % to 80 %

This machine is a high-quality electro-mechanical device.It is designed for household purposes and

should always be supervised when in use.

Make sure that it is not subjected to: dust, severe dampness, direct sunlight, static electricity, heat-producing objects, corrosive chemicals or liquids.

To ensure adequate ventilation the machine should be placed unobstructed on a firm, even surface.

Handling:

Always protect the machine from damage caused by hitting or dropping.

Cleaning:

To clean the housing, use a dry, clean, soft, lint free cloth.To remove particularly persistent dir t, use a

soft cloth with a neutral cleansing agent for plastic materials.

Please note!

Do not use any insecticides or chemical products such as petrol (gas) or liquid chemicals to clean the

housing.

Safety:

1. The machine must be put into operation according to the indications on the specification plate.

2. Do not place any objects in the openings on the machine.

3. Do not use the sewing machine if:

- there is visible damage,

- its function is defective,

- it is wet, e.g. with condensation.

4. Do not pull the mains plug out of the socket by its cord.

5. If this appliance is used for another purpose than that intended, or if it is wrongly operated, we cannot

accept any liability for any damage caused.

6. To avoid the risk of electric shock, do not open the machine.There are no par ts inside the machine

which the user can repair.This is solely the responsibility of our qualified service staff.

7. Be sure to use only or iginal PFAFF parts.

Page 8

6

Specifications of PFAFF machines

PFAFF 1540

Electronic free-arm utility stitch machine with 40 sewing programs (push buttons).

A straight stitch program with 15 needle positions.

A zigzag program with 15 needle positions.

A buttonhole program with adjustable width.

37 utility stitches.

High-ohm foot control (cold) with torque raising.

Dual fabric feed.Needle threader.

PFAFF 1530

Electronic free-arm utility stitch machine with 15 sewing programs (program dial).

A straight stitch program with 15 needle positions.

A zigzag program with 15 needle positions.

A buttonhole program with adjustable width.

12 utility stitches.

High-ohm foot control (cold) with torque raising.

Dual fabric feed.

PFAFF 1520

Electronic free-arm utility stitch machine with 15 sewing programs (program dial).

A straight stitch program with 15 needle positions.

A zigzag program with 15 needle positions.

A buttonhole program with adjustable width.

12 utility stitches.

High-ohm foot control (cold) with torque raising.

Detailed specifications of the machines

z Electronic free-ar m utility stitch machine

z Directly controlled automatic utility-stitch unit, step-down ratio 6:1 (1540)

z Program selection by means of a program dial (1520/1530)

z Utility stitch width 5.5 mm

z Stitch length from 0 to 6 mm

z Reverse stitch length from 0 to 3 mm

z High-ohm foot control (cold)

z FM radio and TV screened, approval marking, suppression degree B

z Safety class II with GS test marking

z Master switch for motor.

z Glare-free built-in sewing lamp 230V or 120V 15 W

z Pendulum-type needle bar frame

z Transmission of drive from arm shaft to lower shaft by toothed belt, transmission ratio 1:1

z Power input rating: 90 W when sewing at 950 r.p.m.; 40W when stationary

Page 9

7

z Maintenance-free PFAFF transverse double-rotating hook

z Link take-up lever

z Linkage-type feed regulator

z Dual fabric feed

z Disengageable feed dog

z Needle threader

z Dr ive from motor to handwheel by flat-toothed belt

z 60-1000 stitches per minute

z Sintered metal bear ings

z Oil for sintered metal bearings: BP Energol HLP 46 or HLP 80 No.28-036550-09

z Oil for sewing hook No. 91-129452-91

z Clear wor kspace: 175, 114, 205 mm

z Machine height: 280 mm

z Baseplate dimensions: 390, 155 mm

z Free arm dimensions: 80, 49, 200 mm

z Housing mater ial: lightweight metal

z Weight of sewing head: approx. 8 kg

z Needle system 130/705 H

Additional needle system classifications:

Twin needle Suffix = Zwi

Wing needle Suffix = Wing

Twin hem stitching needle Suffix = Zwi-Ho

Top stitch needle Suffix = N

Stretch needle Suffix = PS

Jeans needle Suffix = J

Possible needle points:

Small ball point Suffix = SES

Medium ball point Suffix = SUK

Large ball point Suffix = SKF

Very pointed round point Suffix = J

Leather point right hand Suffix = LR

Specifications and versions of built-in motors in the PFAFF 1520-1540

Type UUS 390 220-240V 50/60Hz 4500 r.p.m.

No.902-1039-001 27W

Radioscreened according to EN 55014 Safety class II

Type UUS 393 110-120V 50/60Hz 4500 r.p.m.

No.902-1039-003 27W

Radioscreened according to EN 55014 Safety class II

Page 10

8

Removing the housing covers

Note:

Before adjusting or repairing the machine, make sure to remove the housing covers as described

in this manual.

z Disconnect the machine's main plug.

z Remove needle and presser foot.

z Remove detachable work support.

z Remove top cover.

z Switch on bobbin winder.

z Remove the two Torx screws of the housing insert..

z Remove housing insert.

z Lay the machine on its back and remove the four fastening screws of the baseplate.

z Remove baseplate.

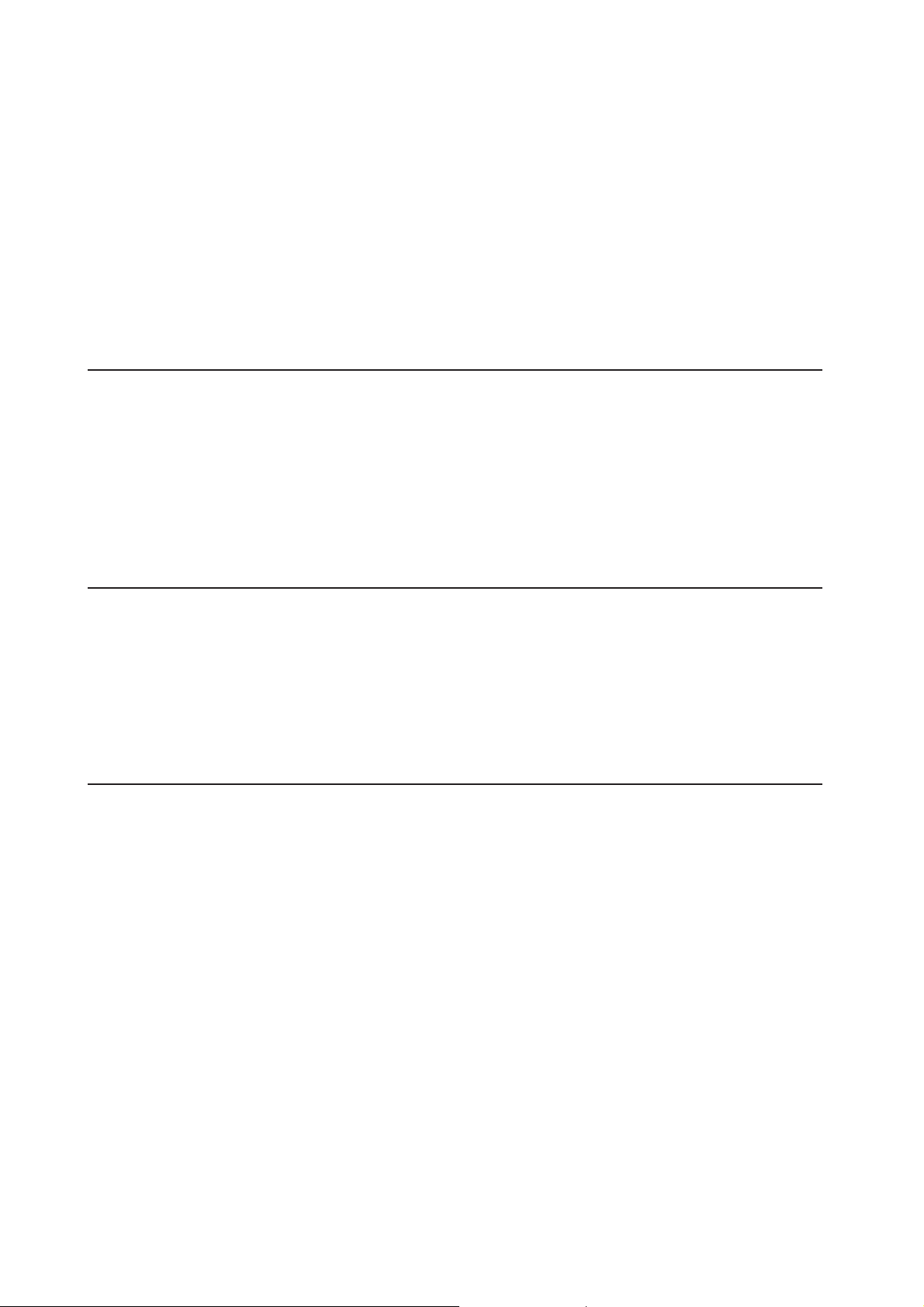

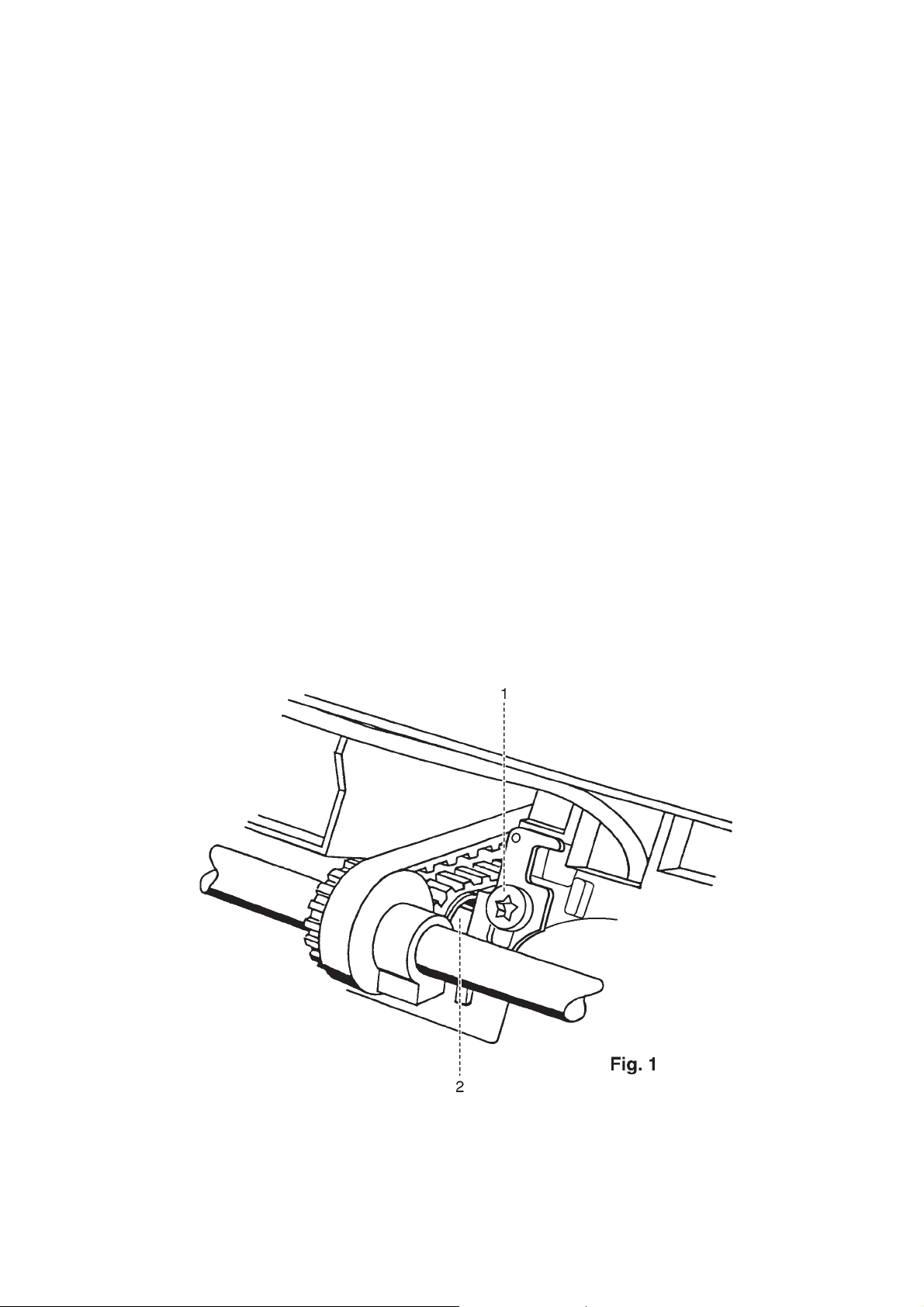

z Remove the two fastening screws 1 of free-arm cover (fig.1).

z Pull the left-hand side of the free-ar m cover a little bit downwards and remove it towards the left.

z Remove needle plate.

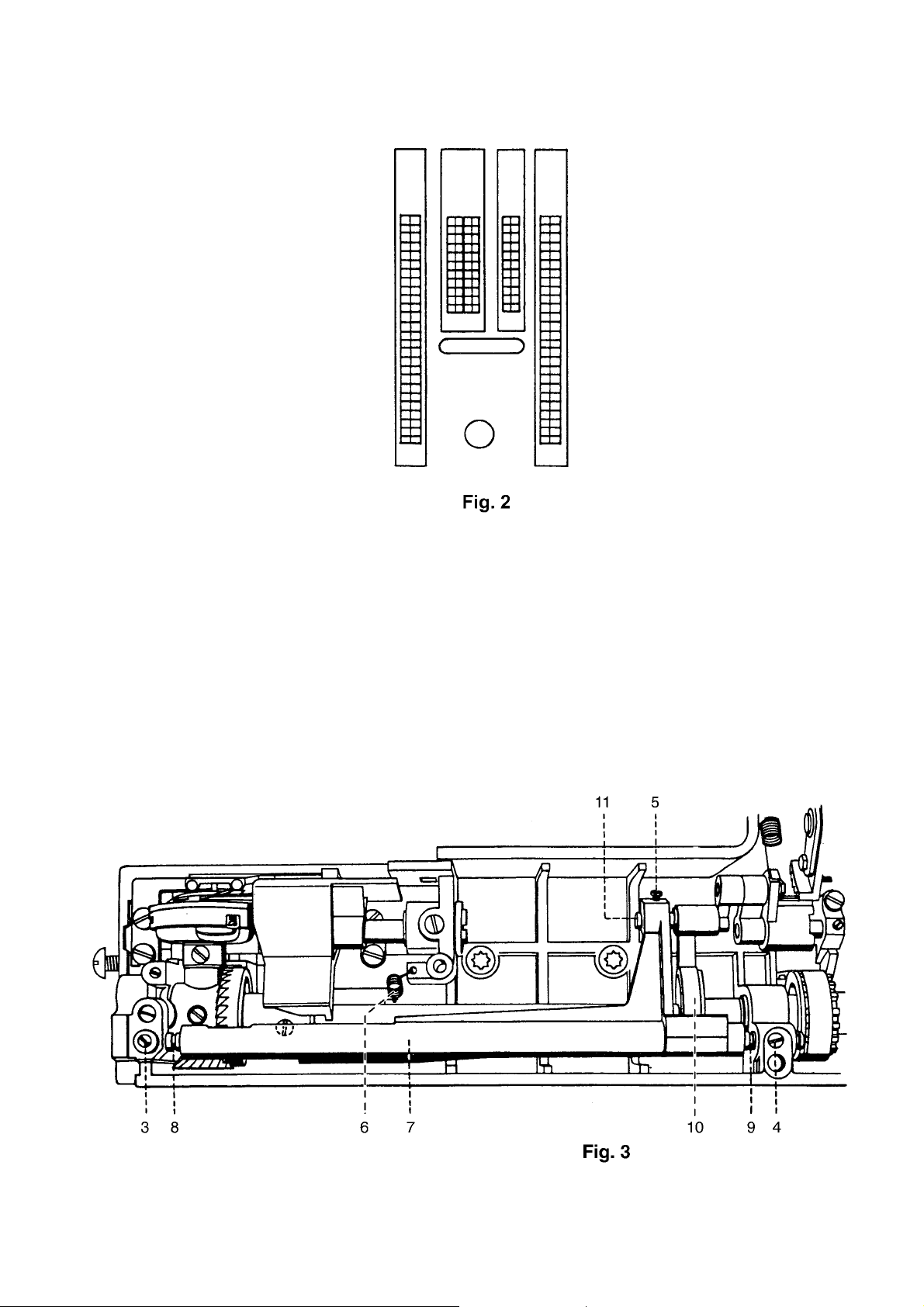

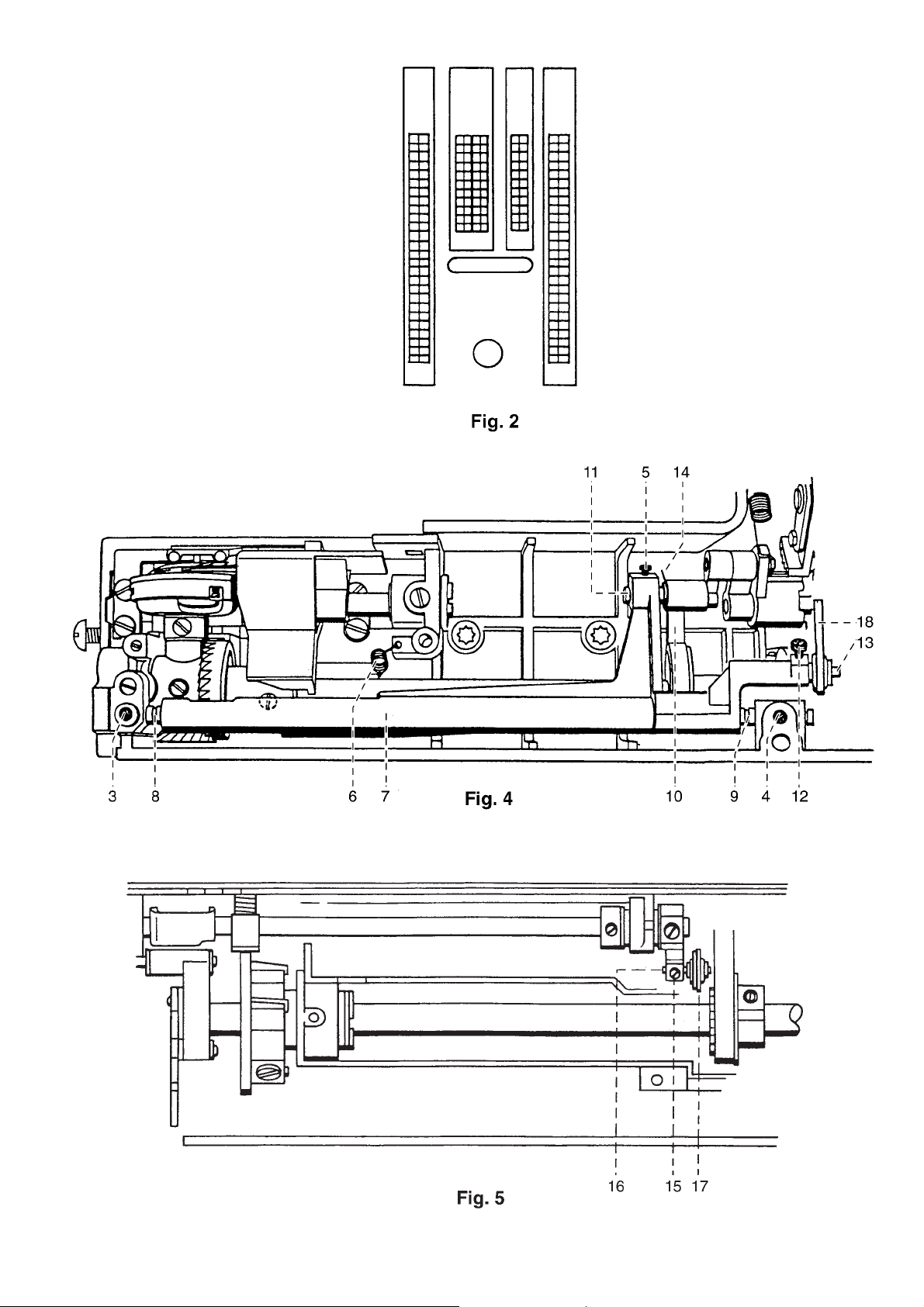

z Remove the two fastening screws 2 of the upper free-arm cover (fig.2).

z Loosen fastening screw 3 of free-arm cover.

z Remove free-arm cover.

Page 11

9

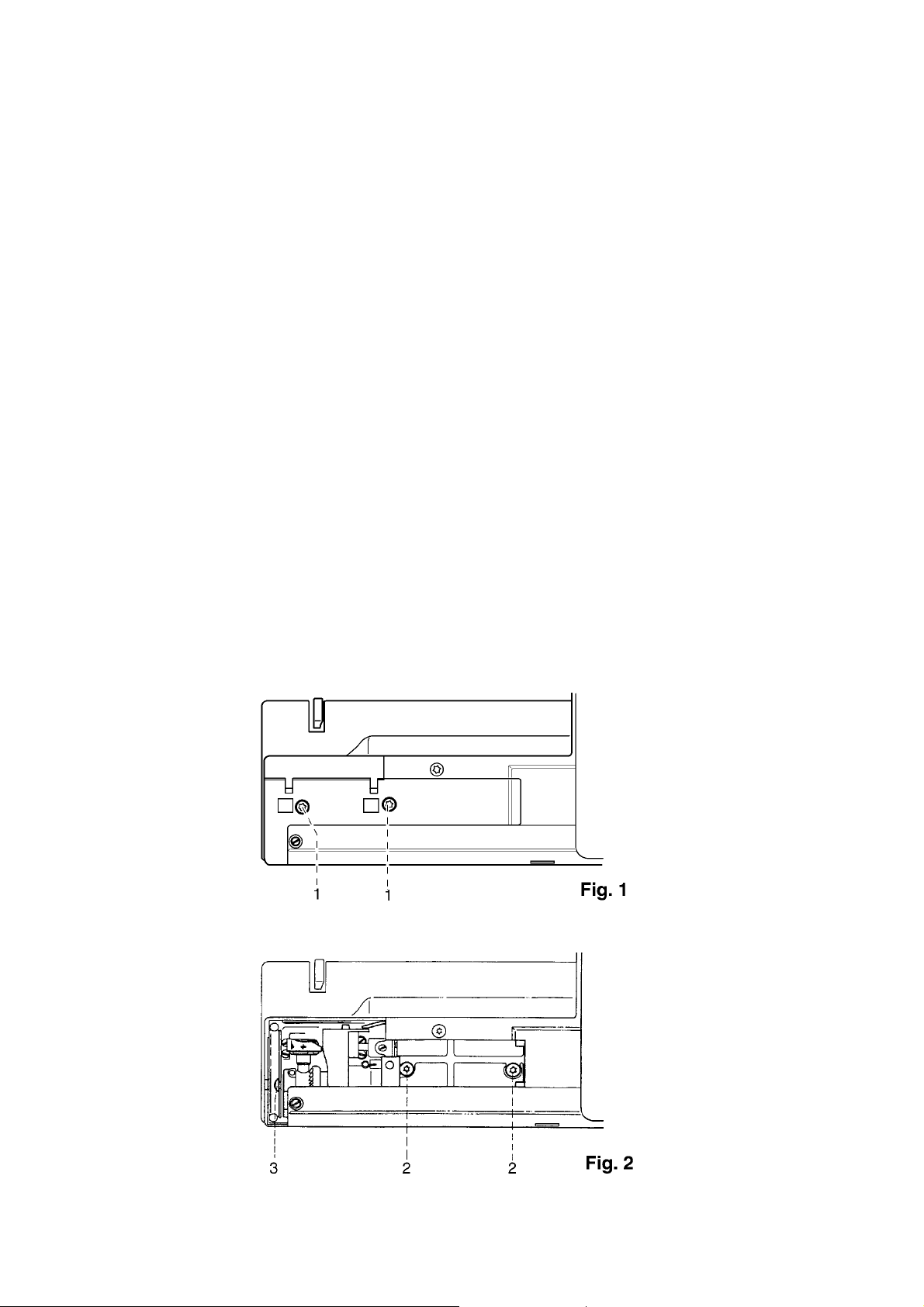

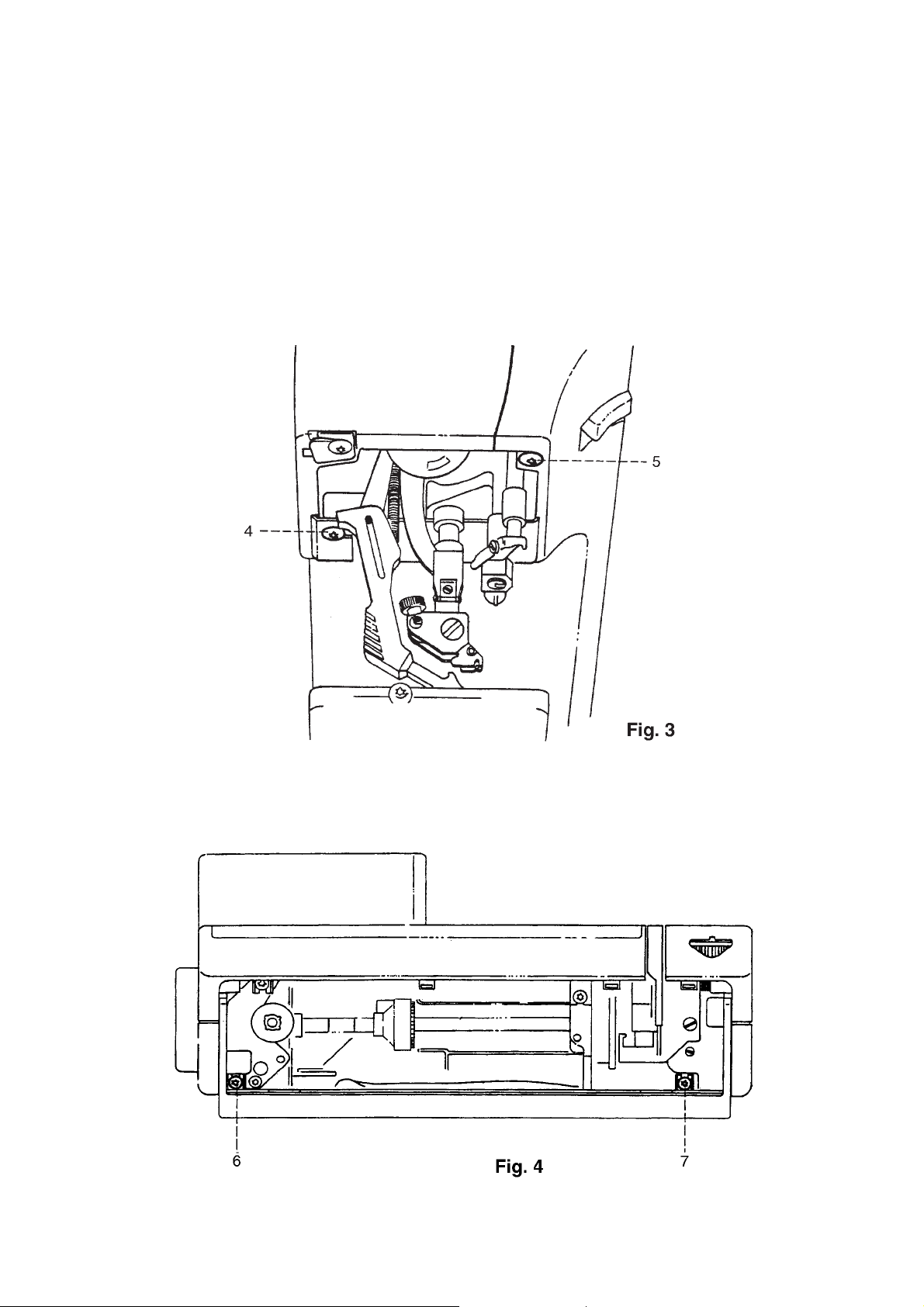

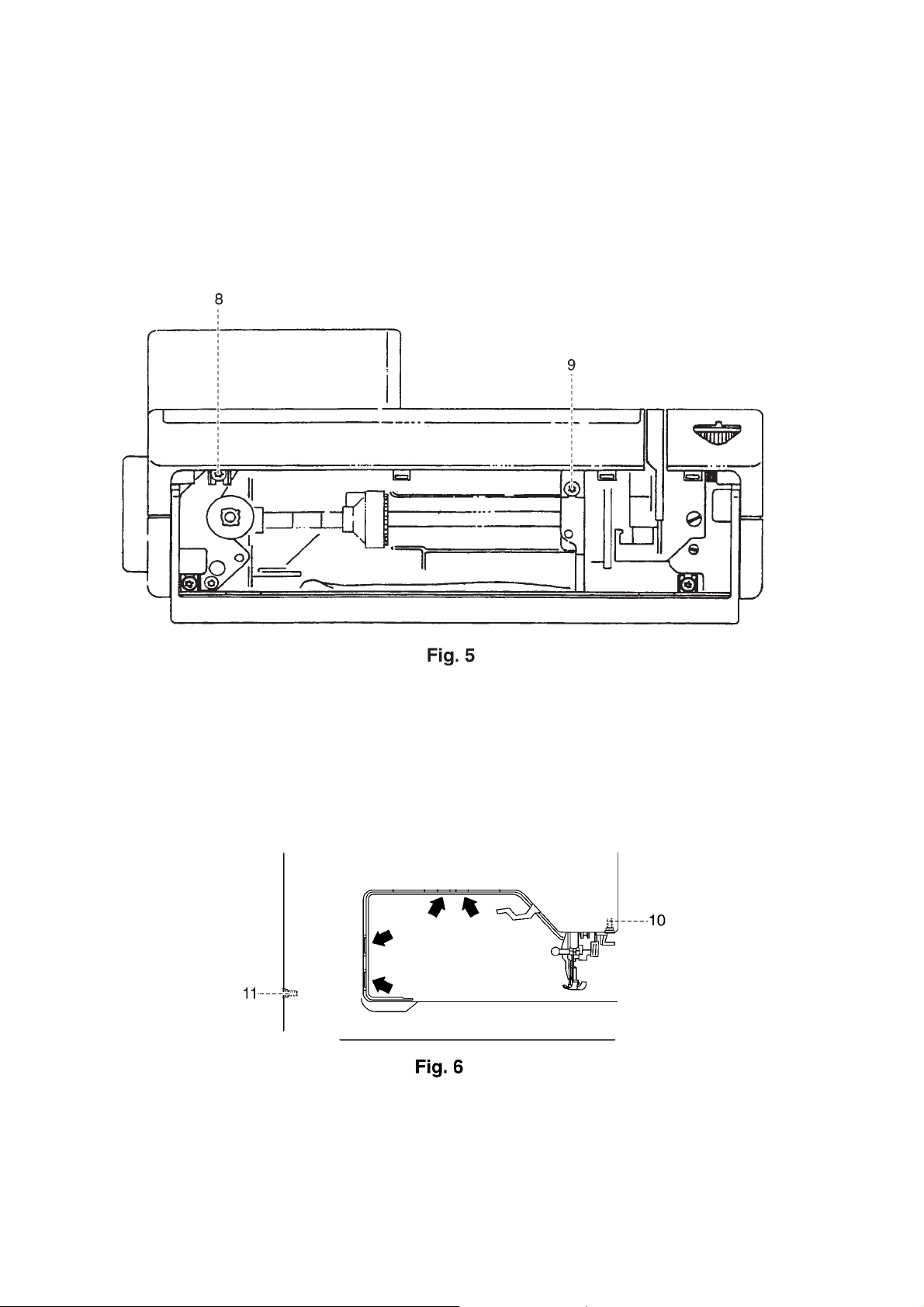

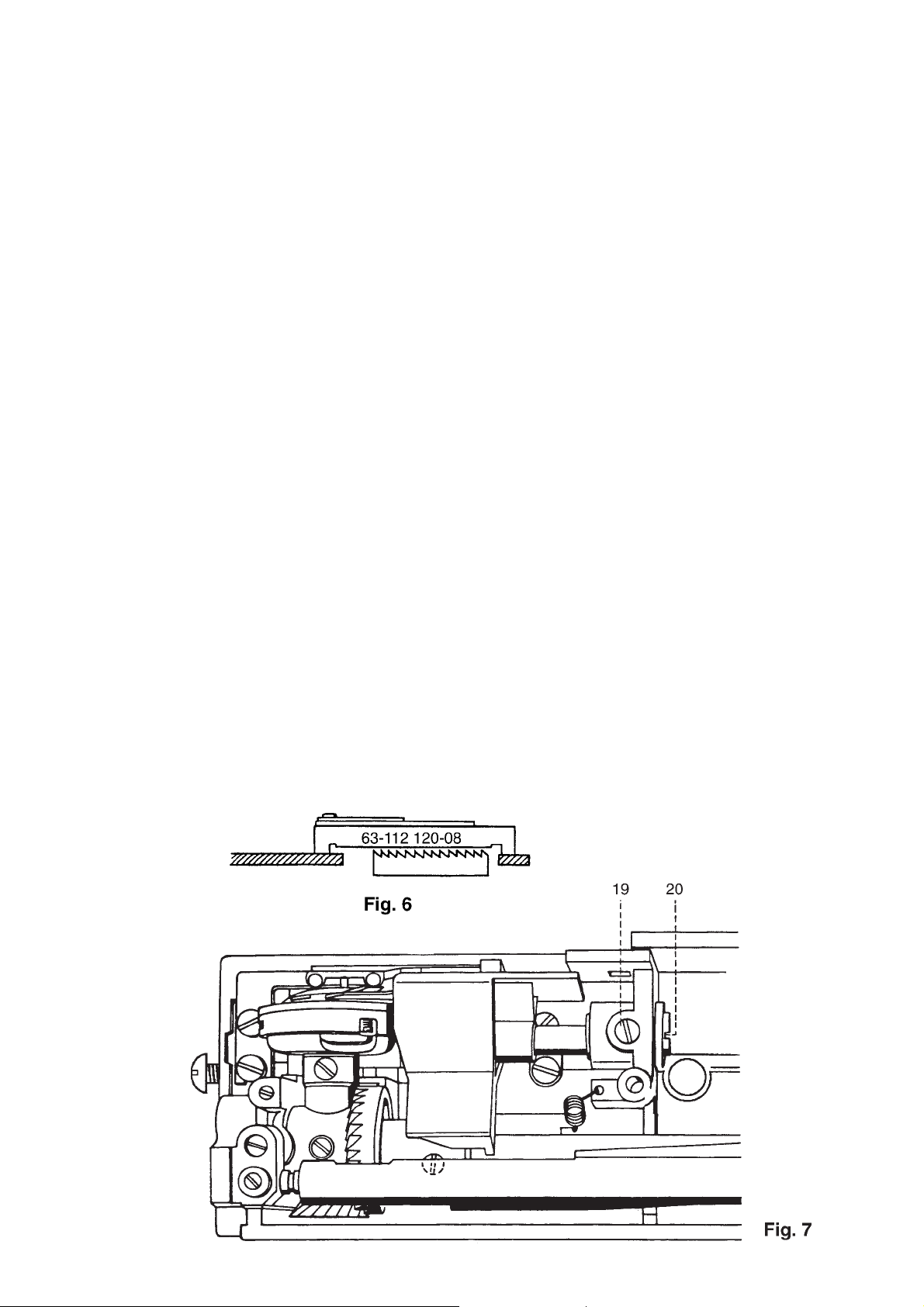

z Loosen the fastening screws 4, 5, 6 and 7 of the rear housing shell (fig. 3 and 4).

z Loosen the snap connections by pressing with your thumb on the spots marked with arrows on

the inner surface of the arm (fig. 5).

z Remove the rear housing shell.

z Remove motor cover.

Page 12

10

z Loosen the fastening screws 8, 9, and 10 of the front housing shell (fig. 5 and 6).

z Remove fastening screws 10 and 11.

Page 13

11

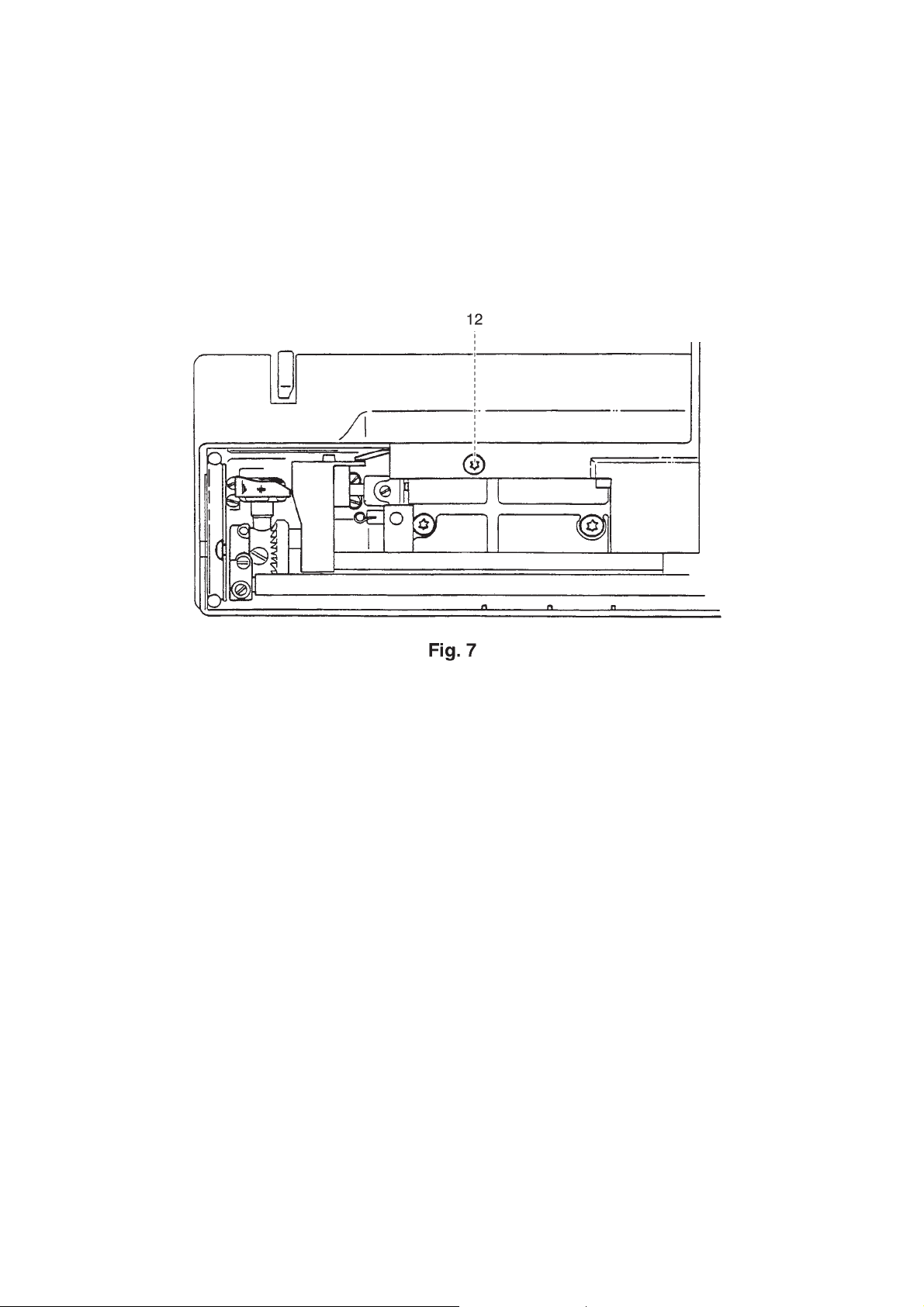

z Remove fastening screw 12 (fig. 7).

z Switch on the top key row of the utility stitch unit.

z Carefully remove the front housing shell by lifting it off.

The assembly must be carried out in reverse order.

Page 14

12

Notes:

Page 15

13

Feeding system

1. Adjustment of the toothed belt tension

Requirement:

The toothed belt must be so taut that the sewing hook has no play in its direction of rotation.

However, it must be possible to turn the machine easily.

Adjustment:

z Loosen screw 1 (fig. 1)

z Re-position tensioning roller 2 with a screwdriver as required.

z Tighten screw 1.

Check:

z Check adjustment according to the "Requirement".

z Press lightly against the middle of the toothed belt (250 g).

The toothed belt should move forward by some 1 to 3 mm.

Page 16

14

2. Adjustment of feed dog in sideways direction on Pfaff 1520

Requirement:

The left and right clearance of the feed dog in the feed slot must be the same (fig.2).

Check:

Carry out a visual check of the feed dog position.

Adjustment:

z Loosen the two screws 3 and 4 (fig. 2a).

z Loosen screw 5.

z Detach spr ing 6.

z Re-position feed-dog driving shaft 7 with the two cylindrical pins 8 and 9 sideways until the feed dog is

centered in the feed slot.

z Fir mly tighten the two screws 3 and 4.

z Push bolt 11 against connecting bar 10.

z Fir mly tighten screw 5.

z Re-attach spr ing 6.

Cross-check:

The feed dog must be exactly in the center of the feed slot.The feed driving shaft must not bind nor have

any play.

Page 17

15

Page 18

16

3. Adjustment of feed dog in sideways direction on Pfaff 1530-1540

Requirement:

The left and right clearance of the feed dog in the feed slot must be the same (fig.3).

Check:

Carry out a visual check of the feed dog position.

Adjustment:

z Lay the machine on its back.

z Loosen screw 12 (fig. 4).

z Remove bolt 13 to the right.

z Loosen screw 5.

z Remove circlip 14.

z Remove bolt 11.

z Loosen both screws 3 and 4.

z Re-position feed-dog driving shaft 7 with the two cylindrical pins 8 and 9 sideways until the feed dog is

centered in the feed slot.

z Fir mly tighten the two screws 3 and 4.

z Detach spr ing 6.

z Remove the needle plate.

z Pull the feed dog forward with one finger and release.

z The complete feed-dog driving shaft 7 must slide lightly back.

z Loosen screw 15 (fig. 5).

z Move the top feed lever forwards and backwards.

z The top feed should move freely without any difficulty (if necessary, remove cause of binding).

z Fit bolt 13 with the washer located to the left of pull-rod 18, and ensure that it is free from play (fig. 4).

z Move the complete top feed lever forwards and backwards.

z Make sure that both top and bottom feed move smoothly and without any difficulty.

z Tighten screw 12 and check once again for ease of operation.

z Move crank pin 16 with pull-rod 17 to the side in such a way that both top and bottom feed can move

easily.

z Tighten screw 15 and check once again for ease of operation.

z Fit bolt 11.

z Insert circlip 14.

z Push bolt 11 against connecting bar 10.

z Tighten screw 5.

z Re-attach spr ing 6.

Cross-check:

The feed dog must be exactly in the center of the feed slot.

Both top and bottom feed must not bind nor have any play.

Page 19

17

Page 20

18

4. Adjustment of feed dog height

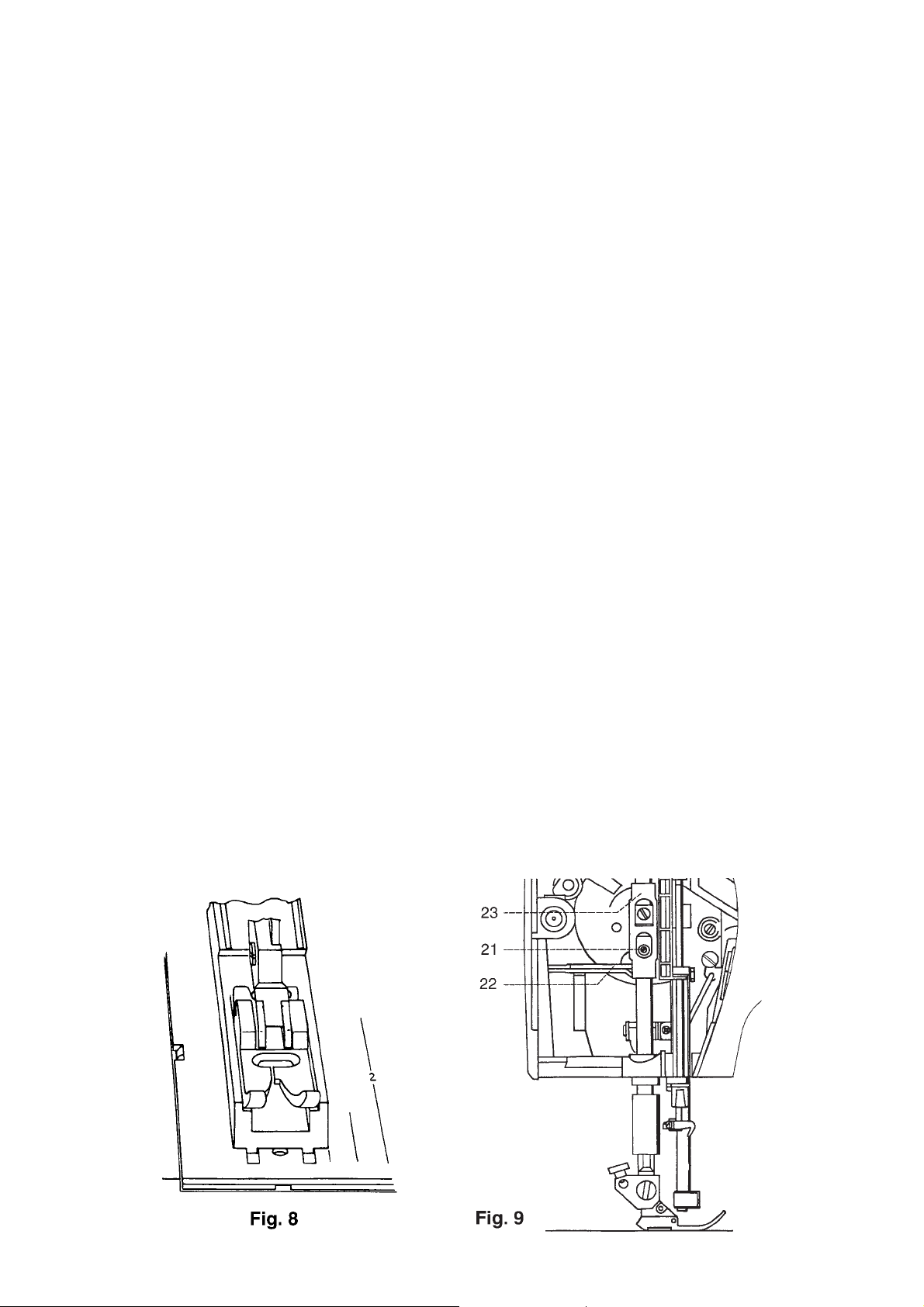

Requirement:

At the highest working position of the feed dog, the tips of the feed dog teeth must protrude above the

needle plate surface by 0.9 mm (fig.6).

Check:

z Remove the needle.

z Remove the presser foot.

z Set the maximum stitch length.

z Place br idge gauge (63-112120-08) over the feed dog onto the needle plate.

z Turn the handwheel until the feed dog has reached its highest working position.

z Carry out a visual check.

z The feed dog must not touch the gauge, but must clear it by 0.1 mm.

Adjustment:

z Loosen screw 19 by just 1/8 of a turn (fig 7).

z Turn eccentric stud 20 until the eccentric is facing the rear part of the housing (basic position)

z Turn the eccentric stud to the left until the feed dog height is properly set.

z Tighten screw 19.

Cross-check

z Turn the handwheel and check the feed dog height at its highest working position.

z Make sure that the feed-dog lowering mechanism neither binds nor hits against anything when the

handwheel is turned.

z Lower feed dog and check the function.

Page 21

19

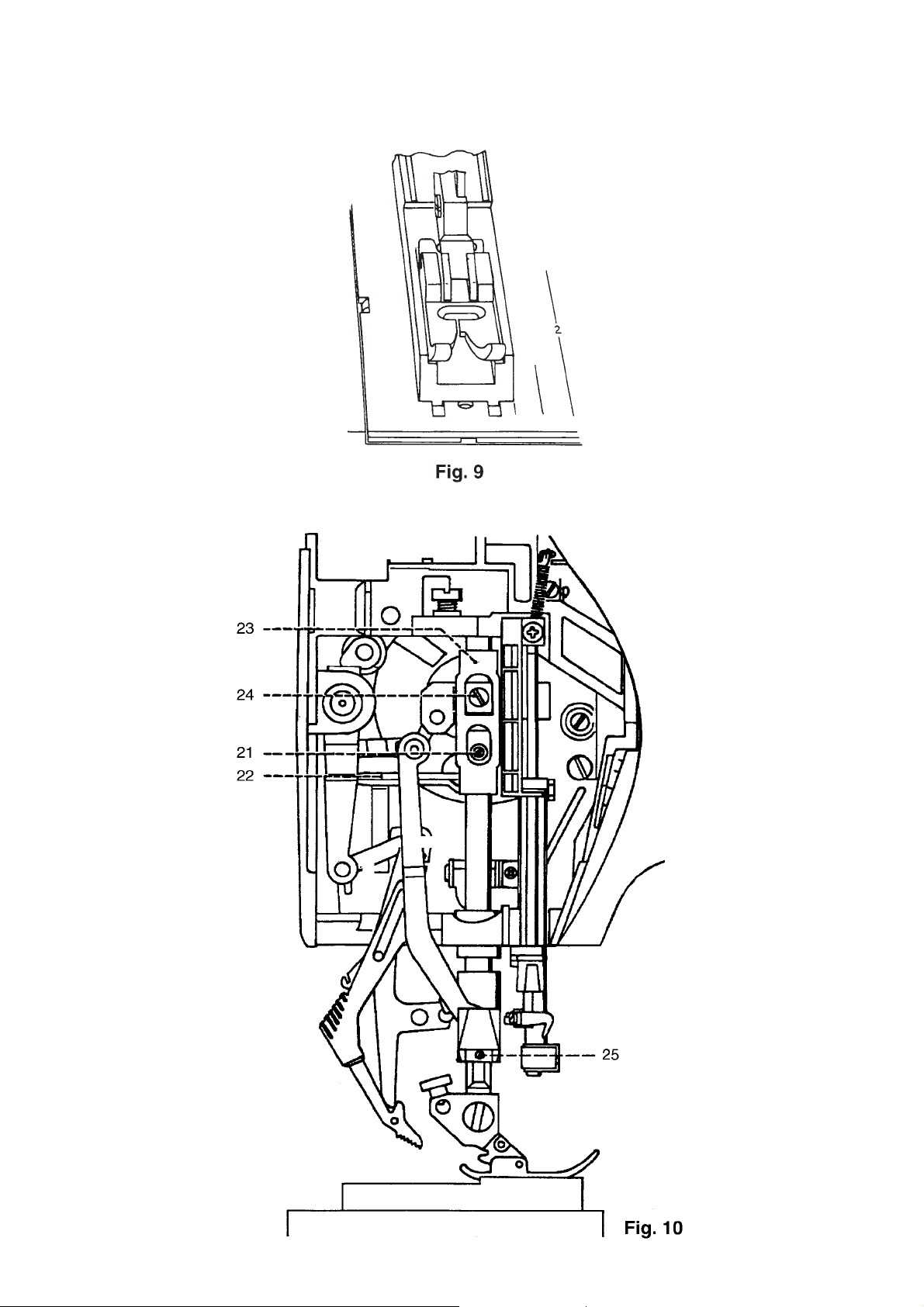

5. Adjustment of presser bar height on Pfaff 1520

Requirement:

With the presser bar lifter raised, there must be a clearance of 8 mm between the needle plate and the

bottom of the zigzag foot.

Check:

z Raise the presser bar lifter.

z Fit the zigzag foot.

z Lower the feed dog.

z Fully raise the presser bar lifter and hold it there fir mly.

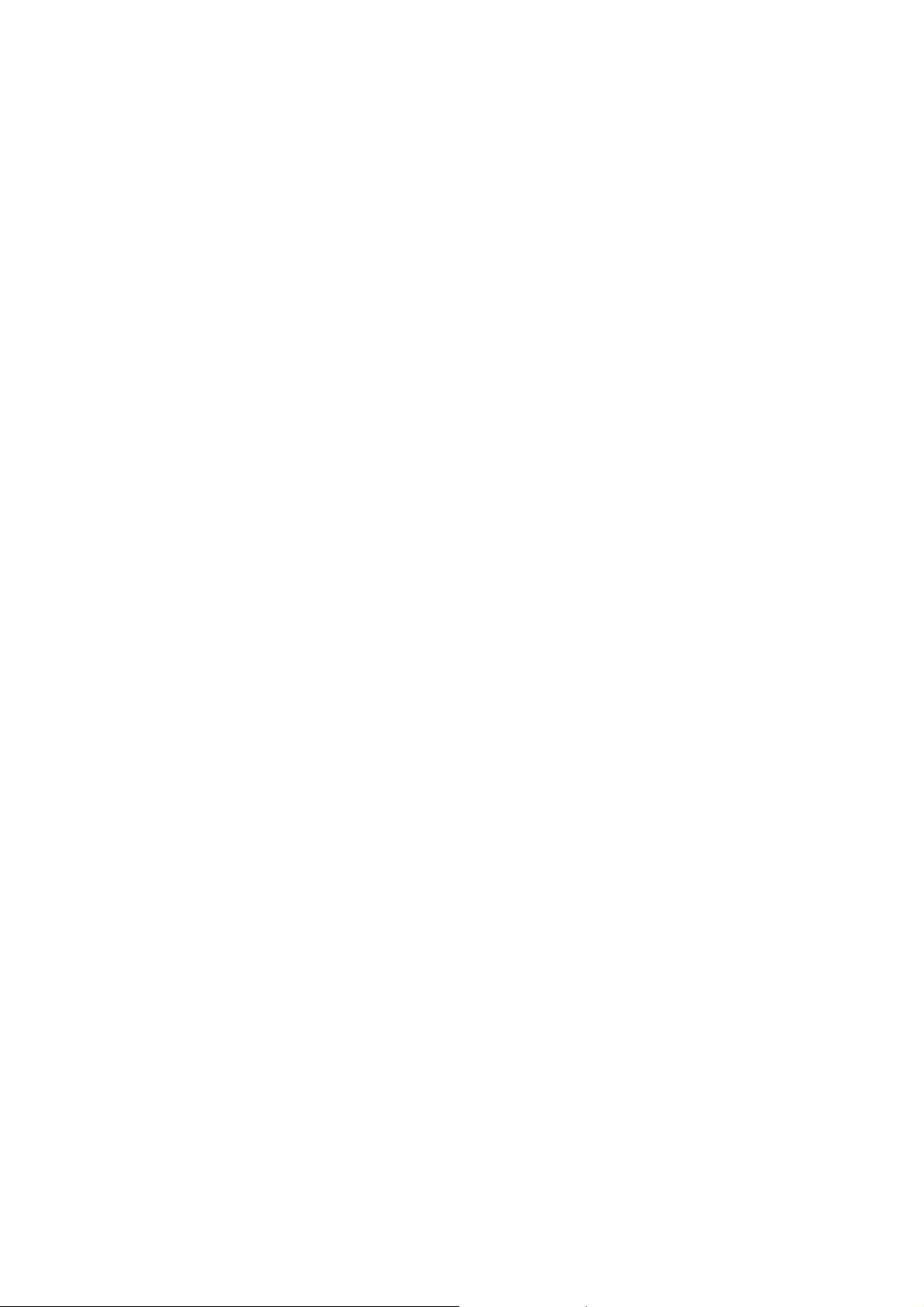

z At the same time, inser t presser foot gauge No. 63-114690-39 from the rear under the zigzag foot and

into the cutouts of the needle plate (fig. 8).

z Lower the presser bar lifter to its normal position again.

The zigzag foot must rest parallel and without play on the presser foot gauge.

However, the presser foot gauge must not lift the zigzag foot, and the needle thread tension release 23

must be without play.

Adjustment:

z Loosen screw 21 (fig. 9)

z With the presser bar lifter raised tur n the zigzag foot until it is parallel to the sides of the presser foot

gauge.

z Use a screwdriver to press presser bar guide 22 firmly downward.

z At the same time, fir mly tighten screw 21.

Cross-check:

z Push the presser bar lifter further upward and release it again.

The zigzag foot must rest parallel and without play on the presser foot gauge.

Needle thread tension release must be without play.The presser bar lifter must be in raised.

Page 22

20

6. Adjustment of presser bar height on Pfaff 1530-1540

Requirement:

With the presser bar lifter raised, there must be a clearance of 8 mm between the needle plate and the

bottom of the zigzag foot.

Check:

z Raise the presser bar lifter.

z Fit the zigzag foot.

z Lower the feed dog.

z Fully raise the presser bar lifter and hold it there fir mly.

z At the same time, inser t presser foot gauge No. 63-114690-39 from the rear under the zigzag foot and

into the cutouts of the needle plate (fig. 9).

z Lower the presser bar lifter to its normal position again.

The zigzag foot must rest parallel and without play on the presser foot gauge.

However, the presser foot gauge must not lift the zigzag foot, and the needle thread tension release 23

must be without play (fig.10).

Adjustment:

z Loosen the three screws 21, 24 and 25.

z With the presser bar lifter raised tur n the zigzag foot until it is parallel to the sides of the presser foot

gauge.

z Use a screwdriver to press presser bar guide 22 firmly downward.

z At the same time, fir mly tighten screw 21.

Cross-check:

z Push the presser bar lifter further upward and release it again.

The zigzag foot must rest parallel and without play on the presser foot gauge.

Needle thread tension release 23 must be without play.The presser bar lifter must be in raised position.

Note:

Tighten the two screws 24 and 25 later, when the top feed foot height is adjusted.

Page 23

21

Page 24

22

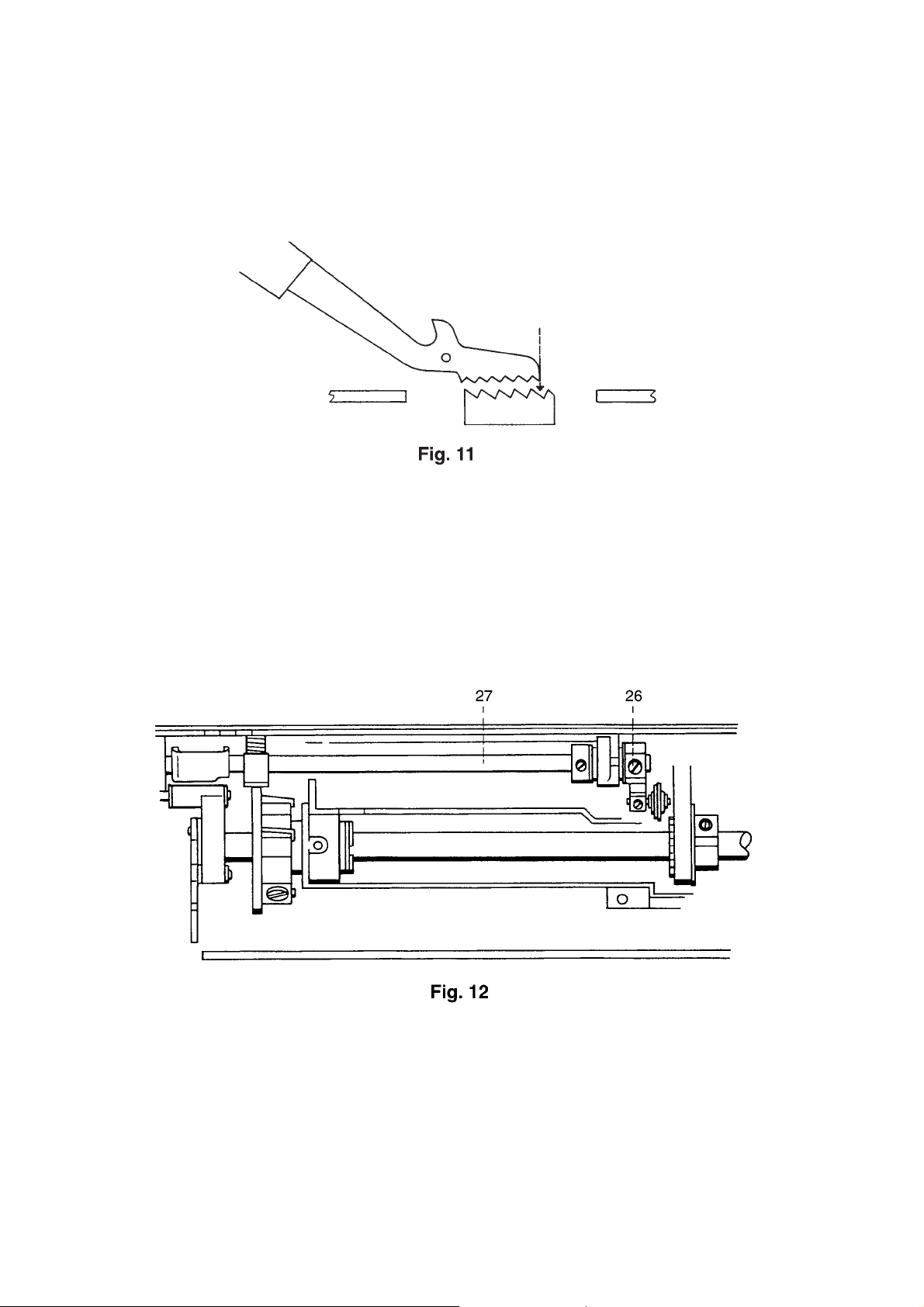

7. Adjustment of top feed foot in sewing direction

Requirement:

The front edge of the top feed foot must be between the first and second tooth point of the center tooth

row of the feed dog (fig.11).

Check:

z Raise the presser bar lifter.

z Remove presser foot & presser foot holder.

z Set the maximum stitch length.

z Engage the top feed foot.

z Turn the handwheel until the rising feed dog is flush with the needle plate surface.

z Lower the presser bar lifter.

z Carry out a visual check.

Adjustment:

z Loosen screw 26 (fig. 12).

z Raise the presser bar lifter until the top feed foot is just resting on top of the feed dog.

z At the same time push the top feed dog to the front or to the rear until its front edge is between the first

and second tooth point of the center tooth row.

z Lower the presser bar lifter.

z Tighten screw 26, making sure that driving shaft 27 has no play.

Cross-check:

z Check as described under "Check".

Page 25

23

Page 26

24

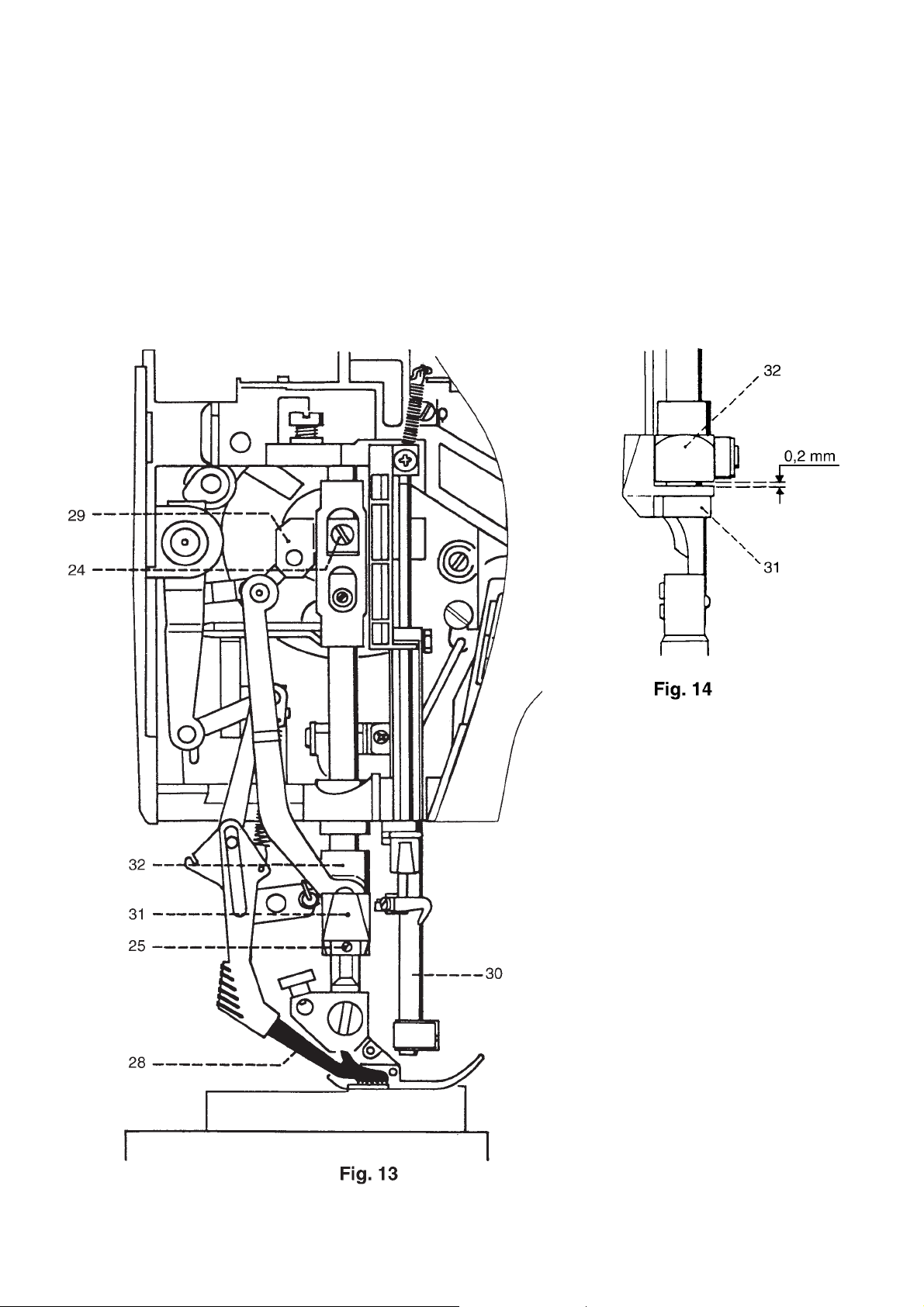

8. Adjustment of top feed foot height

Requirement:

At its highest working position the top feed foot must be 2 mm higher than the lower edge of the zigzag

foot (fig. 13).

Note:

This adjustment must only be carried out when the height of the presser bar is set correctly!

Check:

z Raise the presser bar lifter.

z Fit the zigzag foot.

z Engage the top feed.

z Turn the handwheel until the needle bar is at its lowest position.

Caution: The handwheel must now no longer be turned!

z Lower the feed dog.

z Fully raise the presser bar lifter and hold it in this position.

z At the same time, inser t presser foot gauge No. 63-114690-35 from the rear under the zigzag foot and

into the cutouts of the needle plate.

z Lower the presser bar lifter to its raised position again.

z Press the top feed foot 28 about 2 mm upward against the pressure of the spring and release it.

z Check that the top feed foot rests only lightly on the presser foot gauge and has no play.

Adjustment:

z Loosen screws 24 and 25.

z Push counter bear ing 29 lightly downward until the top feed foot 28 rests lightly on the presser foot

gauge.

z Tighten screw 24 in this position.

Cross-check:

z Check for light resting and freedom of play of the top feed foot on the presser foot gauge as described

under "Check".

Adjusting the guide piece:

z Fully raise the presser bar lifter and hold it in this position.

z Remove the presser foot gauge.

z Lower the presser bar lifter to its raised position again.

z Turn the handwheel until needle bar 30 is in its top position.

Page 27

25

z Set guide piece 31 at a clearance of 0.2 mm from cross head 32 (fig. 14).

z Tighten screw 25.

Cross-check:

z Turn the handwheel and check for clearance of 0.2 mm.

Page 28

26

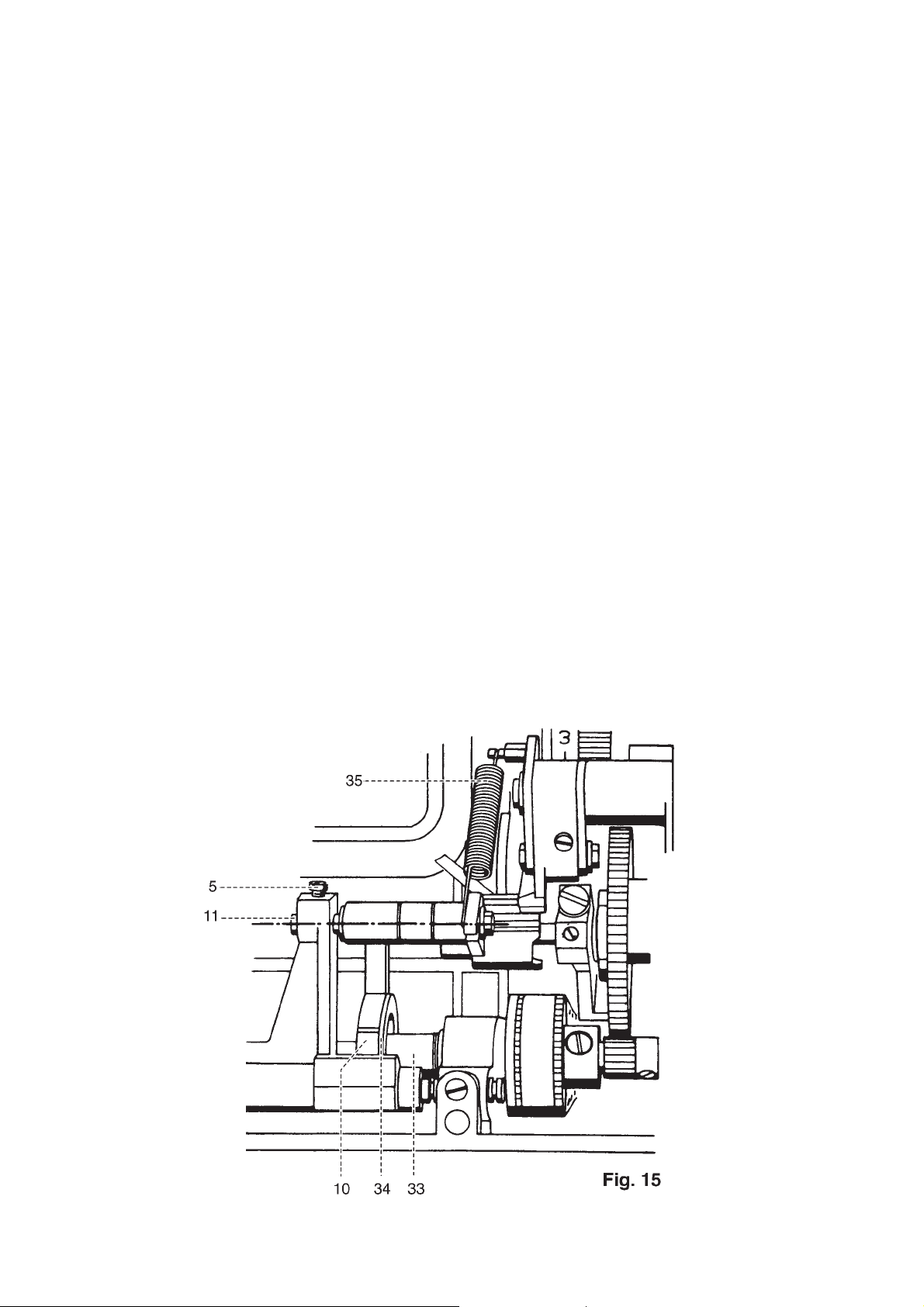

9. Adjustment of feed regulator cranks on Pfaff 1520 / 1530

Requirement:

The feed regulator cranks must not have any axial play.

Check:

Move the feed regulator cranks laterally backwards and forwards (fig. 15).

Adjustment:

z Loosen the two screws 5.

z Push feeding eccentric 33 to the right against the bear ing.

z Push bolt 11 to the r ight until connecting bar 10 is in contact with edge 34 of feeding eccentric 33.

z Tighten the screws 5.

Cross-check:

z Set the stitch length graduated dial to "6".

z Detach spr ing 35.

z Check the joints for easy movement and lack of play.

z Re-attach spr ing 35.

Page 29

27

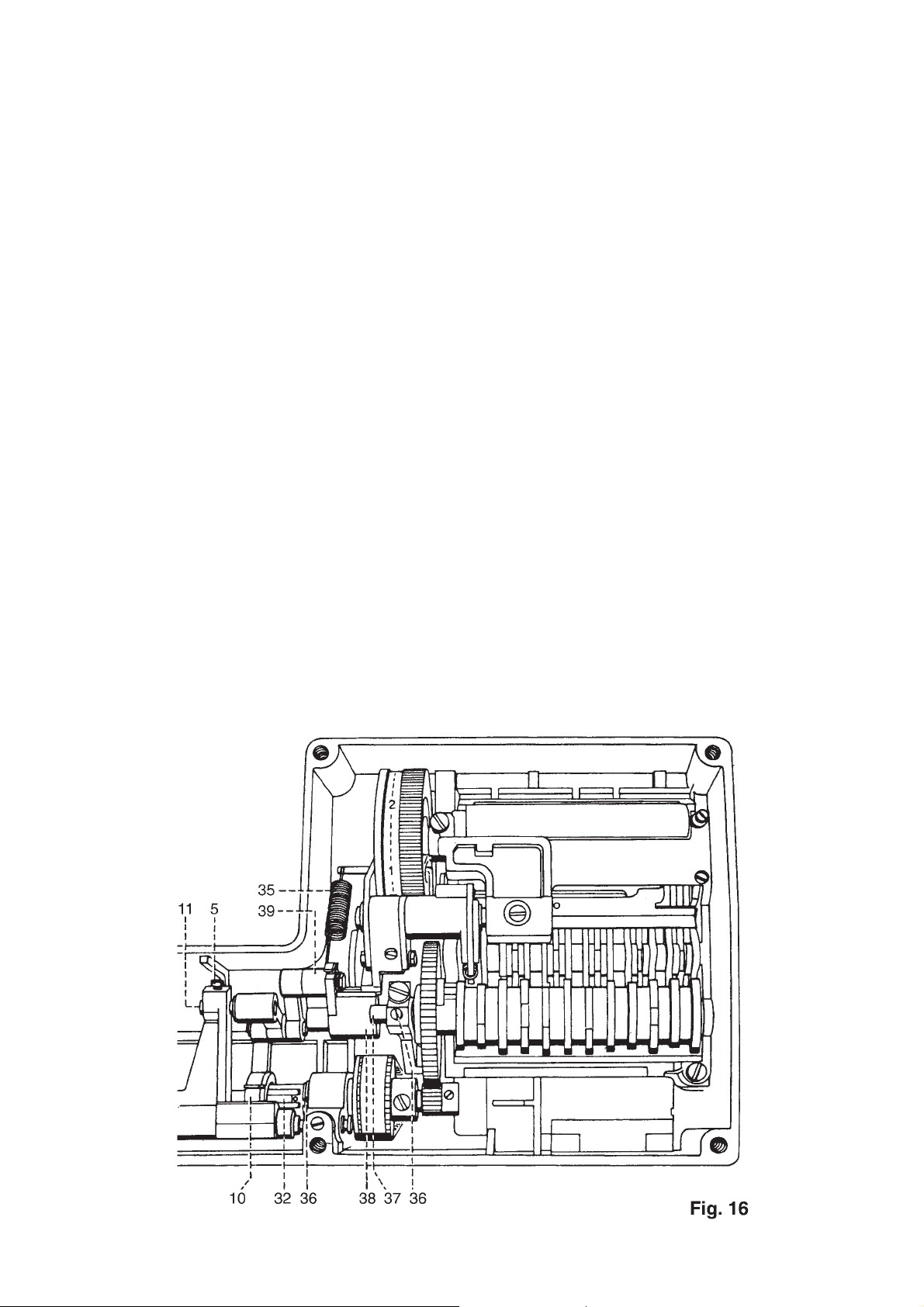

10. Adjustment of feed regulator cranks on Pfaff 1540

Requirement:

The feed regulator cranks must not have any axial play.

Check:

Move the feed regulator cranks laterally backwards and forwards (fig. 16).

Adjustment:

z Loosen the two screws 5 and 36.

z Push feeding eccentric 33 to the right against the bear ing.

z Push bolt 11 to the r ight until connecting bar 10 is in contact with edge 34 of feeding eccentric 33.

z Push the circlip along with shaft 37 and tooth segment 38 along with actuating crank 39 to the left until

no crank or joint has any play anymore.

z Tighten screws 5 and 36.

Cross-check:

z Set the stitch length graduated dial to "6".

z Detach spr ing 35.

z Check the joints for easy movement and lack of play.

z Re-attach spr ing 35.

Page 30

28

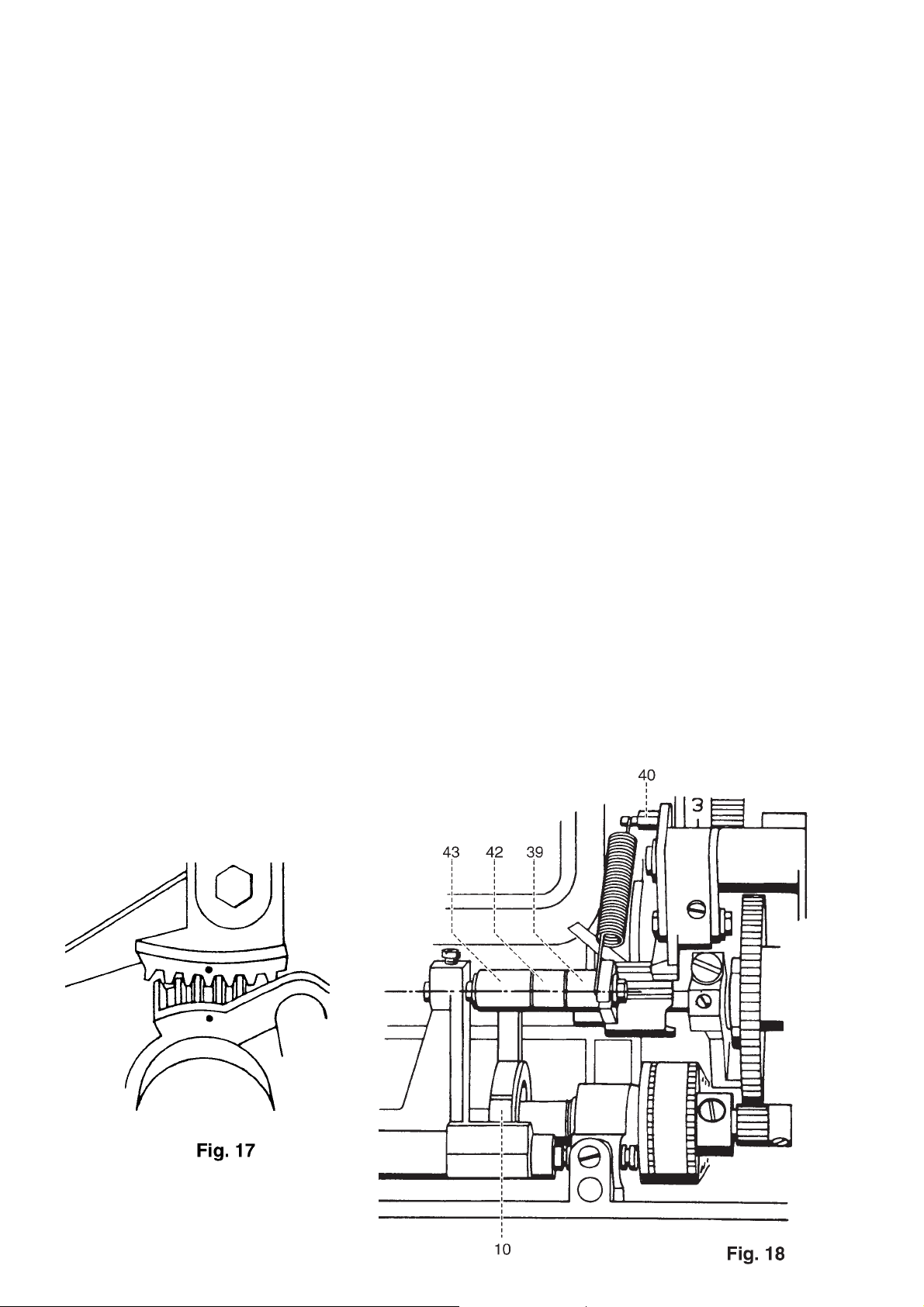

11. Zero point adjustment of stitch length regulator

Requirement:

When the stitch length graduated dial is set to "0", the feed dog should only move up and down.

Check:

z Set the stitch length graduated dial to "0".

z Place a piece of fabric under the presser foot.

z Lower the presser foot.

z Operate the machine.

The fabric must not be fed neither forwards nor backwards.

Precondition 1:

The dot markings on the toothed segments must be diametrically opposite each other (fig. 17).

Precondition 2:

Eccentric 40 must be in its basic position facing upwards (fig.18).

Adjustment:

z Loosen screw 41 with a 5.5 mm spanner.

z Re-position screw 41 until the center lines of the bolts in actuating crank 39 and linkage 42 and rod 43

are level (see dot-dash line).

z Tighten screw 41.

Cross-check:

z As descr ibed under "Check".

Page 31

29

Notes:

Page 32

30

12.Timing of feed motion

Operating sequence:

When the rising needle has cleared the fabric, the feed dog moves up above the needle plate.

The risen feed dog pushes the fabric to the rear. Shortly before the end of the feeding motion, the take-up

lever is in its highest position (t.d.c).

At a stitch length setting of 6 mm the feed dog now pushes another 0.6 mm more to the rear (feeding

stroke).

After completing the feeding movement, the feed dog moves down below the needle plate surface and the

needle enters the fabric.

Underneath the needle plate the feed dog moves back to its basic position.

Requirement:

When the needle bar has moved 2 mm up from its lowest position (b.d.c), the line marks on the edge 34

of feeding eccentric 33 and connection rod 10 must be opposite each other (fig. 19).

Check:

z Remove needle.

z Turn handwheel to set needle bar at its lowest position.

z Apply spacer (63-102600-18) over the needle bar and push it up against the needle bar frame (fig. 20).

z Place the needle-r ise clamp (00-870 137-01) onto the needle bar 30 and secure it lightly.

z Place the 2 mm feeler gauge (00-870 136-01) onto the needle bar with its cutout above the needle-rise

clamp.

z Loosen the needle-r ise clamp and push the 2 mm feeler gauge up against the spacer.

z Tighten the knur led screw of the needle-rise clamp.

z Turn the handwheel back and forth slightly.

z If there is play on the feeler gauge, repeat the above procedure.

z Remove the 2 mm feeler gauge.

z Turn the handwheel in sewing direction until the needle-rise clamp rests on the spacer (fig.21).

z Tilt the machine over backwards.

The line marks on edge 34 of the feeding eccentric 33 and connection rod 10 must now be opposite

each other.

Adjustment:

z If the adjustment is not correct, remove the needle-rise clamp.

z Loosen the three screws 44 in the lower belt gear.

z Re-fit the needle-r ise clamp and repeat the procedure as descr ibed in "Check" until the needle bar has

moved upwards by 2 mm and the needle-rise clamp rests on the spacer (fig. 21).

Page 33

31

z Turn the long drive shaft 45 clockwise until the line marks on edge 34 of feeding eccentric and

connection rod 10 are opposite each other (fig. 19).

Cross-check:

z Turn the handwheel back and forth, until until the needle-rise clamp rests on the spacer.

The line marks must now be opposite each other.

z Tighten all three screws 44 very fir mly.

Page 34

32

Automatic utility-stitch unit

13. Replacing the automatic module on Pfaff 1520 - 1530

Removal:

z Disconnect the machine's mains plug.

z Remove the housing covers as described in this manual.

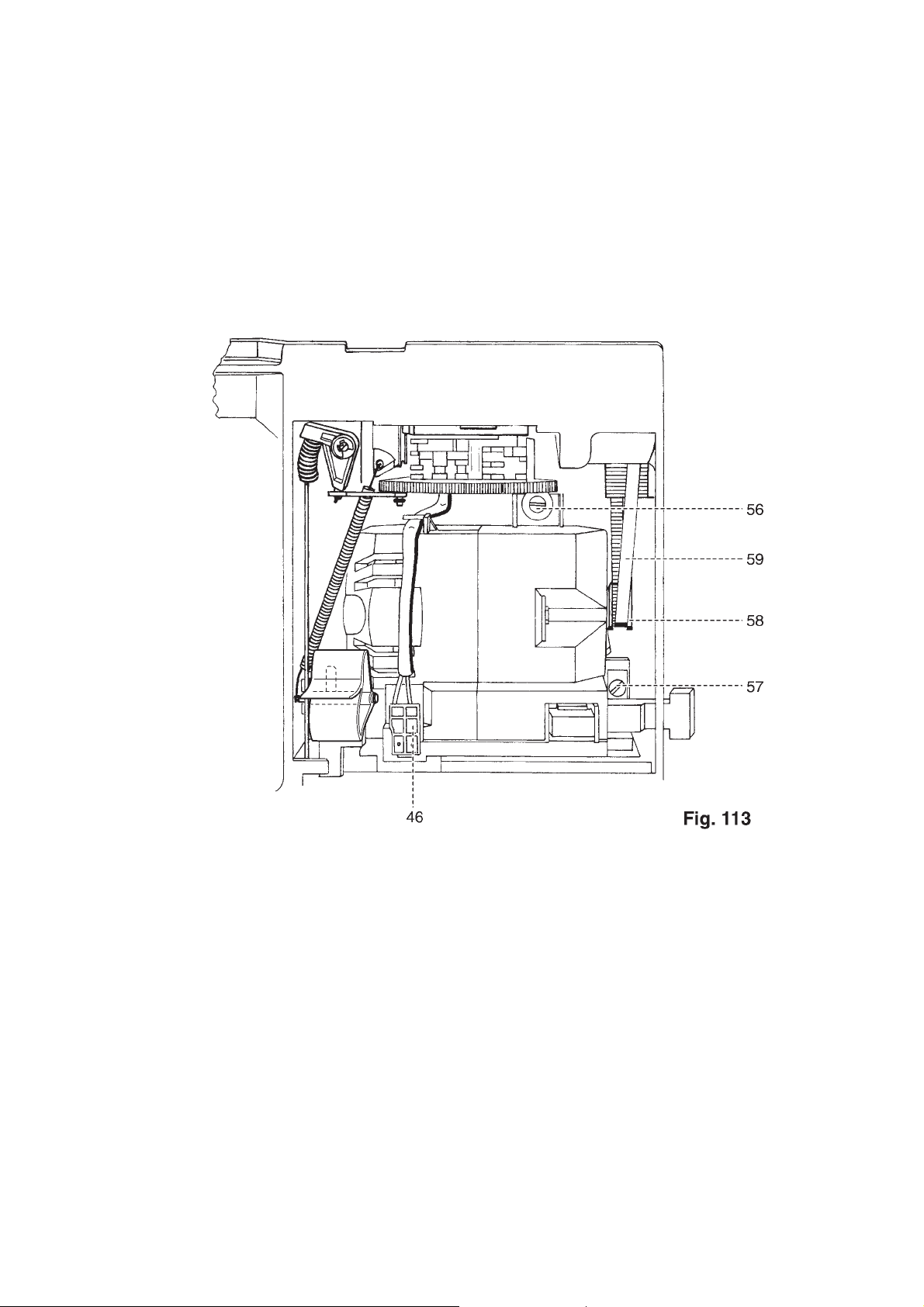

z Disconnect light plug 46 (fig. 22).

z Detach spr ing 47 at the top of the push-lever.

z Loosen screw 48.

z Remove circlip 49.

z Detach connecting lever 50.

z Remove circlip 51.

z Remove reverse button 52 together with bolt 53, connecting rod 54, plastic angle piece 55 and tension

spring 47 (fig. 22).

z Remove screws 56 and 57 and the two washers.

z Remove motor pinion 58 from toothed belt 59 and remove the motor to the front.

z Remove circlip 60 (fig. 23).

z Remove the two screws 61.

z Remove the complete automatic module downwards.

Fitting:

z Loosen the three screws 62 on worm 63.

z Push wor m 63 to the left.

z Insert the module upwards and at the same time insert pin 64 in the eyelet on connecting bar 65.

z Position the automatic unit in such a way that the two screws 61 are located in the center of the slots

and the automatic module, after having been moved forwards, is parallel to the housing.

z Gently tighten screws 61.

z Place circlip 60 onto pin 64.

z Install the motor attaching at the same time the motor pinion 58 to toothed belt 59 (fig. 22).

z Insert the two screws 56 and 57 with their washers and tighten them a little.

z Adjust the toothed belt to its correct setting and tighten screws 56 and 57.

z Insert reverse button 52 complete with bolt 53, connecting rod 54, plastic angle piece 55 and tension

spring 47 and tighten by means of fastening screw 48.

z Refit circlip 51.

z Re-attach connecting lever 50.

z Refit circlip 49.

z Re-attach tension spr ing 47 at the top of the push-lever.

z Reconnect light plug 46.

Page 35

33

Page 36

34

14. Adjustment of the locking disk

Note:

Carry out this adjustment only if compelling reasons exist.

For this adjustment the automatic module has to be removed.

Requirement:

When the automatic module is switched off, lifting pin 66 should be exactly centered in the

groove (fig.24).

Check:

z Set adjustment dial 67 at the dot mar k.

z Move push-lever 68 back and forth.

z Lifting pin 66 should now be exactly centered the groove and should not come into contact with the left

wall of the groove during operation.

Adjustment:

z Loosen screw 69 (Fig. 25).

z Turn adjustment dial 67, until lifting pin 66 is exactly centered in the groove (fig.24).

z Fir mly tighten screw 69 (fig. 25).

Cross-check:

z Move push-lever 68 back and forth and check as described under "Check”

Page 37

35

15. Replacing the zigzag-stitch unit on Pfaff 1520 - 1530

Removal:

z Disconnect the machine's mains plug.

z Remove the housing covers as described in this manual.

z Set stitch width adjustment dial 70 to "0" (fig. 26).

z Remove circlip 71 from connecting rod 72.

z Remove circlip 60.

z Remove connecting rod 65.

z Remove fastening screws 75.

z Carefully remove the zigzag unit from the machine.

Fitting:

z Insert bolt 76 of connecting rod 72 into joint piece 77 of the zigzag unit (fig. 26).

z Fit the zigzag unit in the machine inserting at the same time connecting rod 72 with sliding block 78

into the crank.

z Position the zigzag unit parallel to the arm shaft and gently tighten fastening screws 75.

z Refit circlip 71.

z Insert connecting rod 65.

z Refit circlip 60.

Page 38

36

16. Basic position of setting eccentric for the sideways needle position

Requirement:

In its basic position the setting eccentric must point downwards (fig. 28).

Adjustment:

z Set stitch width adjustment dial 70 to "0" (fig. 27).

z Set needle position adjustment dial 79 to "center".

z Switch the automatic unit to position "E".

z Loosen screw 73 (fig. 28).

z Rotate setting eccentr ic 74 downwards.

z Tighten screw 73.

Note:

When setting eccentric 74 is in its basic position, connecting lever 50 must be parallel to the automatic

unit adjustment dial.

Page 39

37

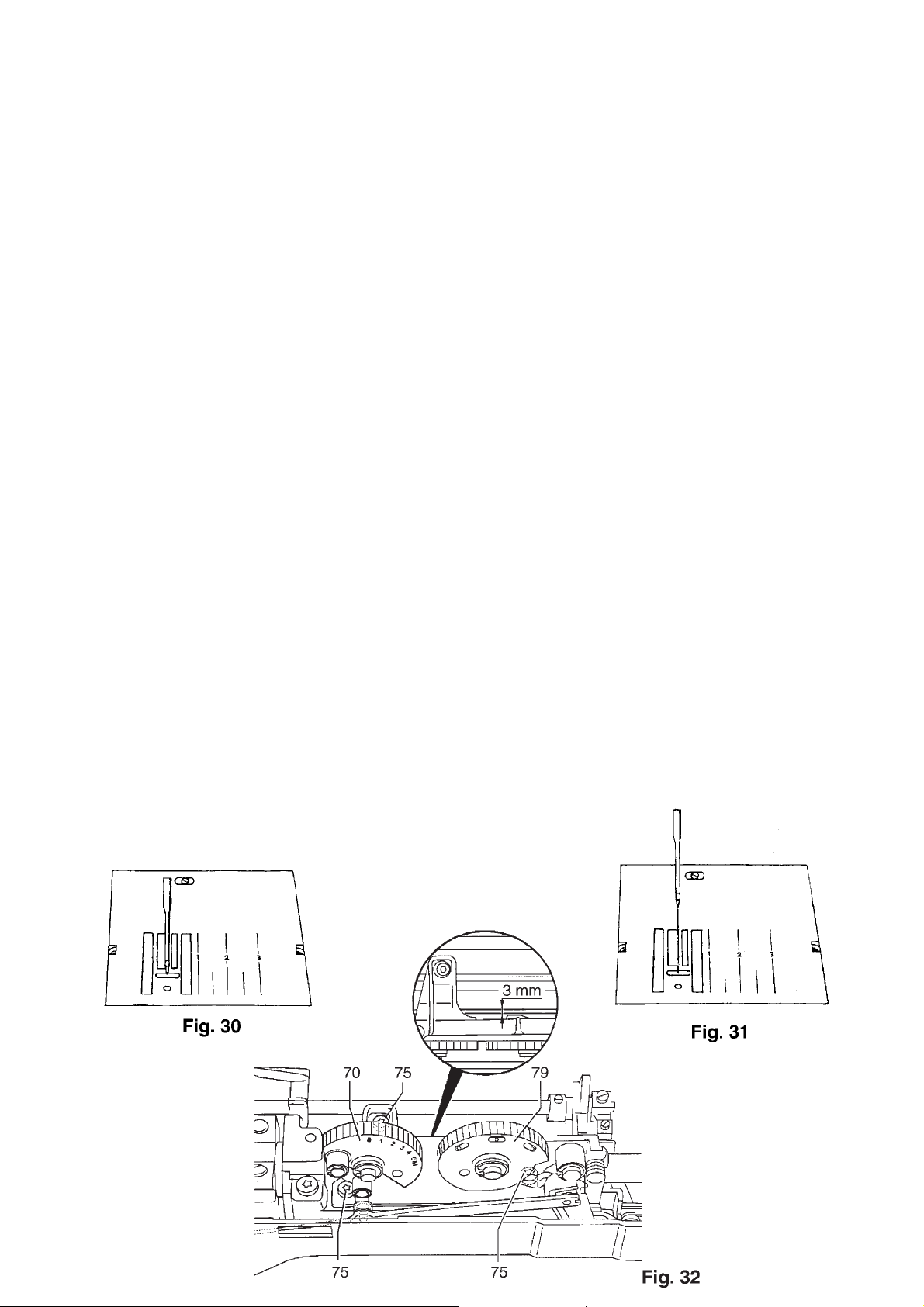

17. Adjustment of needle penetration in needle plate slot

Requirement:

At straight stitch setting with needle position "center" the needle must be exactly in the center of the

needle plate slot (fig. 30).

Check:

z Remove presser foot.

z Insert a new needle.

z Set stitch width adjustment dial 70 to "0" (fig. 32).

z Set needle position adjustment dial 79 to "center".

z Turn the handwheel and check the centered position of the needle.

Adjustment:

z Loosen the three screws 75 on the zigzag-stitch unit by just 1/8 of a turn.

z Turn the handwheel until the needle point is level with the surface of the needle plate (fig.31).

z Move the zigzag-stitch unit to the left or right until the needle is exactly in the center of the needle plate

slot (fig.32).

Note:

The zigzag-stitch unit should now be parallel to the arm shaft and clear it by 3.0 mm.

z Tighten the three screws 75.

Cross-check:

z The needle must be exactly in the center of the needle plate slot.

Page 40

38

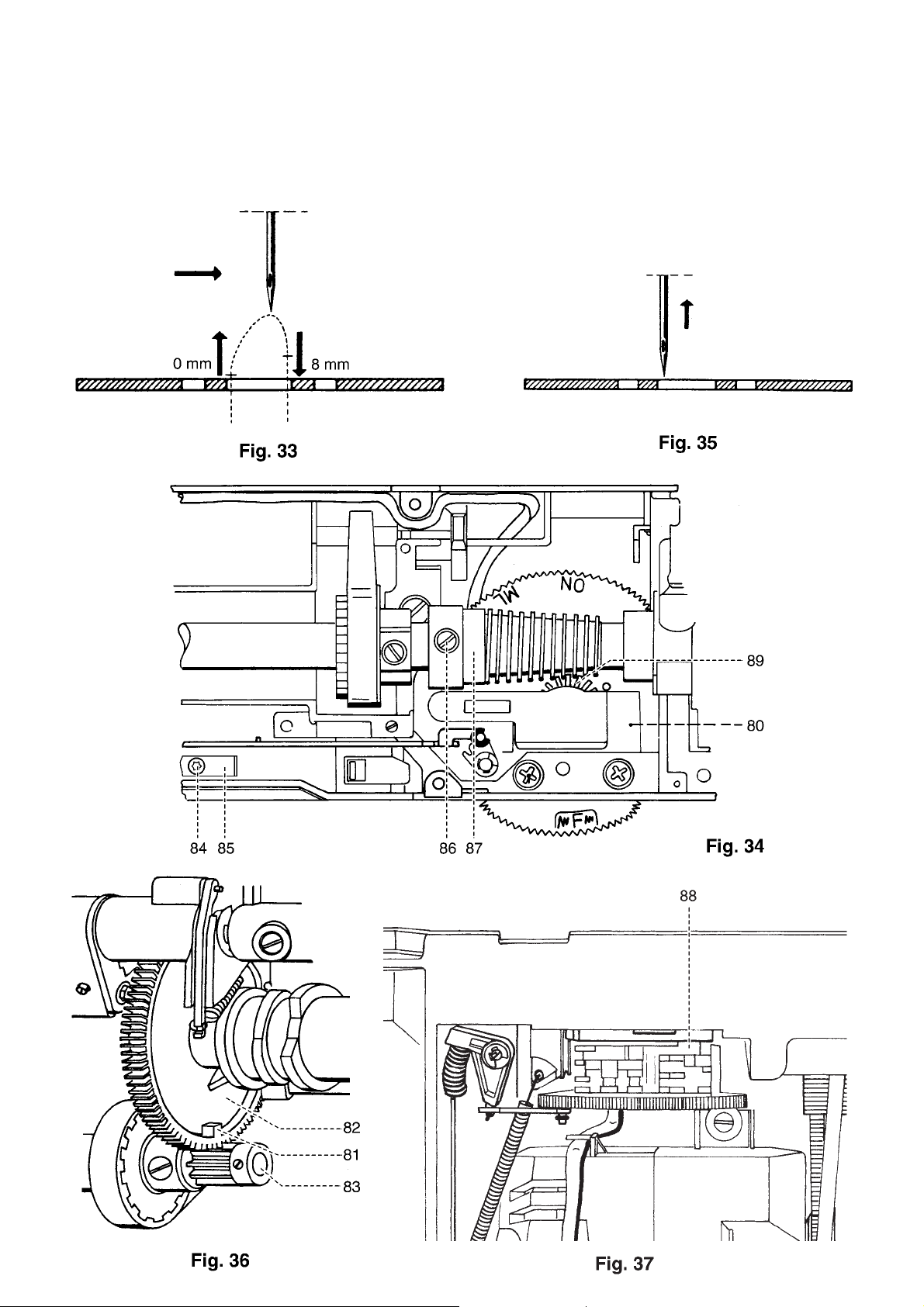

18. Adjustment of the sideways movement of the needle bar

Requirement:

During zigzag sewing operation the sideways movement of the needle should stop above the highest

possible fabric thickness.

The sideways movement of the needle must start when the needle point is leaving the needle plate.

It must be completed before the needle enters the fabric again, approx. 8 mm above the

needle plate (fig. 33).

When hole mark 80 is indicated on the automatic unit bracket (fig.34) and when during a left-hand

zigzag stitch the point of the rising needle is level with the surface of the needle plate (fig. 35), dot

mark 81 on the large gear wheel 82 must be exactly in the center of the small gear wheel 83 (fig. 36).

Check:

z Unscrew the baseplate.

z Set stitch width adjustment dial to the maximum zigzag width.

z Set needle position adjustment dial to "center".

z Set the adjustment dial of the automatic unit to the "E" position.

z Remove presser foot.

z Turn the handwheel in sewing direction until hole mark 80 is indicated on the automatic unit bracket,

the needle rises on the left-hand side and the needle point is positioned exactly on the surface of the

needle plate.

z Check the position of the dot mark on the large gear wheel in relation to the small gear wheel.

z Slowly rotate the handwheel and check the star t of the sideways movement of the needle.

Adjustment:

z Loosen screw 84 on stop 85 for the left-hand needle position.

z Loosen the three fastening screws 86 on worm 87.

z Rotate the handwheel until the point of the r ising needle is level with the surface of the needle plate

(fig. 35).The handwheel must not be rotated any further!

z Turn worm 87 to the front until it is flush with the left-hand side and dot mark 80 is indicated in the

position shown in fig. 34.

z Continue to tur n wor m 87 slowly until the needle begins to move to the right.

z Prevent the stack of cams 88 from rotating by holding it from the front (fig. 37).

z Turn the worm backwards until a little binding can be felt thus making sure that worm 87 and worm

gear 89 have no play (fig. 34).

z Tighten one of the screws 86.

z Check the sideways movement of the needle by rotating the handwheel.

z Check the needle penetration in the needle plate slot.

z If necessary, loosen the two fastening screws 61 on the automatic unit bracket and move the automatic

unit bracket to the left or right, until the needle has the same clearance from the left and right edges of

the needle plate slot.

z Tighten the two fastening screws 61 on the automatic unit bracket.

z Check the setting for sideways needle movement once again and, if necessary, re-adjust.

z Tighten the three fastening screws 86 on worm 87.

Page 41

39

Cross-check:

z As descr ibed under "Check".

Page 42

40

19. Adjustment of the stop for the left needle position

Requirement:

At the widest zigzag stitch setting the crank should rest on the stop.

Check:

z Set stitch width adjustment dial to "5".

z Set needle position adjustment dial to "center".

z Set the adjustment dial on the automatic unit to "E".

z Rotate the handwheel until the needle moves downward on the left side and is at a position of roughly

1 mm above the needle plate.

z Crank 90 should now rest on stop 85.

Adjustment:

z Set stitch width adjustment dial to "5".

z Set needle position adjustment dial to "center".

z Set the adjustment dial on the automatic unit to "E".

z Rotate the hand-wheel until the needle moves downward on the left side and is at a position of roughly

1 mm above the needle plate.

z Push stop 85 against crank 90 (fig. 38).

z Tighten screw 84.

Cross-check:

z As descr ibed under "Check".

Page 43

41

Notes:

Page 44

42

20. Adjustment of the feed reversing bar

Requirement:

At straight stitch or stretch stitch setting there must be a clearance of 0.2 mm between reversing bar 54

and the end of the lever of feeler 91 (fig. 39).

Check:

z Set the adjustment dial for the automatic unit to "E".

z Move the stitch length adjustment dial to the stretch symbol, up to the stop.

z Rotate the handwheel until adjusting crank 39 is positioned fully to the front (fig. 40).

z Move feed reversing bar 54 up and down a little and, at the same time check the 0.2 mm clearance

between reversing bar 54 and the end of the lever of feeler 91 (fig. 39).

Adjustment:

z Loosen screw 73 (fig. 41).

z First tur n setting eccentr ic 74 downwards to its basic position.

z Turn the setting eccentric slightly in a clockwise direction until reversing bar 54 is touching feeler 91.

z Turn the setting eccentric back again until a clearance of 0.2 mm is set.

z Tighten screw 73.

Cross-check:

z Move feed reversing bar 54 gently up and down and check the clearance of 0.2 mm.

z Activate the reverse button at the largest stitch length setting and check the clearance between the

feed reversing bar and the feeler.

Page 45

43

Page 46

44

21. Replacing the utility-stitch unit on Pfaff 1540

Removal:

z Loosen screw 5 (fig. 42).

z Remove circlip 14.

z Remove bolt 11.

z Remove circlip 92.

z Disconnect pull rod 93.

z Detach feed regulator cranks together with connecting rod 10 to the left.

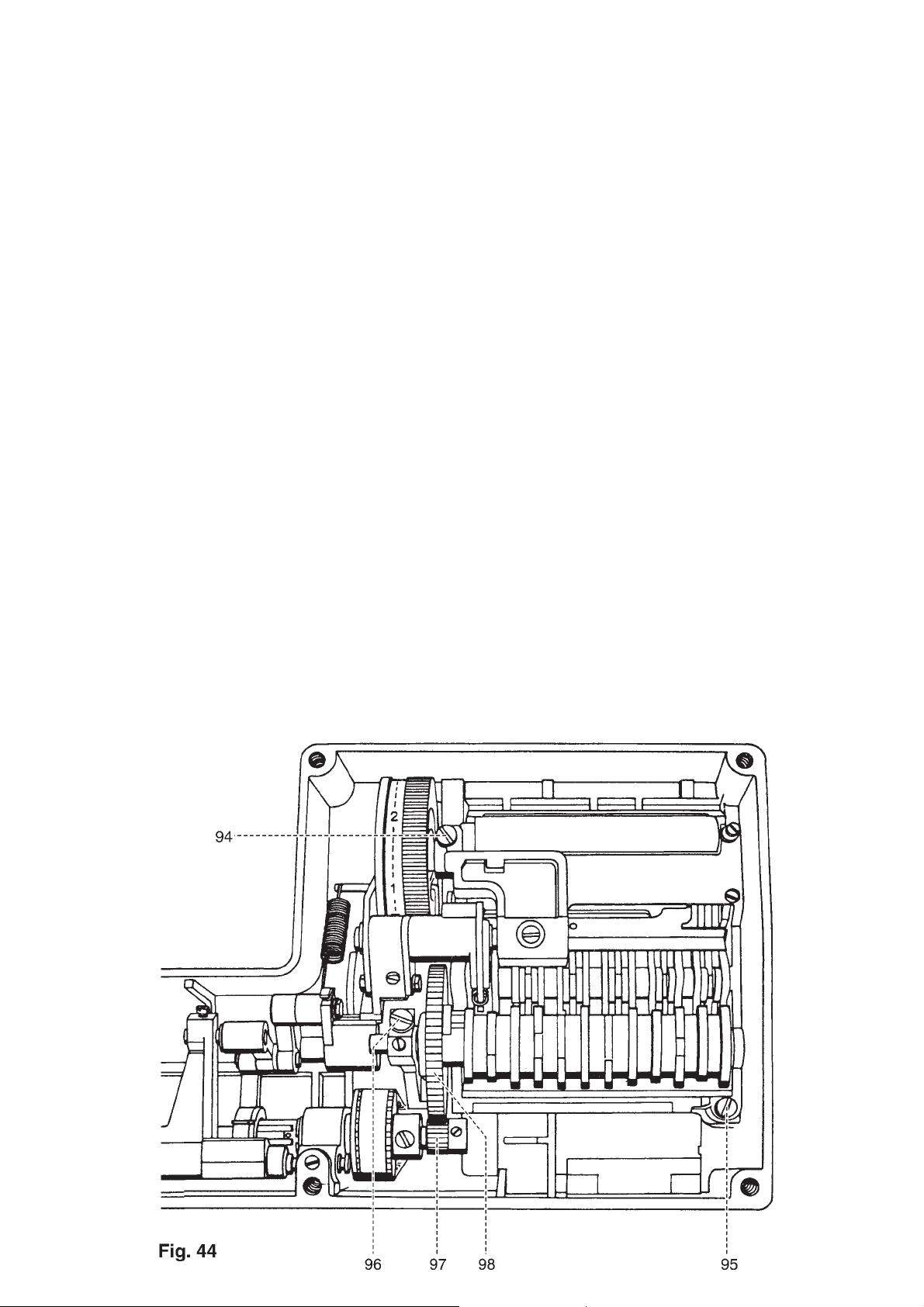

z Loosen the three screws 94, 95 and 96.

z Remove the complete utility-stitch unit downwards.

Note:

Before fitting the automatic unit, make sure that the two dot marks on the toothed segments are exactly

opposite each other (fig. 43).

Fitting:

z Install the utility stitch unit in the machine.

z Insert the two long screws 95 and 96 at the bottom and the shorter screw 94 at the top.Tighten them

lightly (fig. 41).

z Place the feed regulator cranks onto the bolt of actuating crank 10 .

z Insert bolt 11.

z Refit circlip 14.

z Move bolt 11 to the right, until the feed regulator cranks have no sideways play and move easily.

z Tighten screw 5.

z Re-attach pull rod 93.

z Refit circlip 92.

Page 47

45

Page 48

46

22. Adjustment of the gears in relation to each other

Requirement:

The two gears must not have any play, must not bind, and must be parallel to each other.

Check:

z Check for free running by turning the handwheel, check for lack of play by turning the gears back and

forth and carry out a visual check of parallel configuration.

Adjustment:

z Loosen the three screws 94, 95 and 96 and adjust the two gears 97 and 98 so that they are parallel

and have no play (fig. 43).

z Tighten the three screws.

Cross-check:

z As descr ibed under "Check".

z Fir mly tighten screws 94, 95 and 96.

Note:

z The feed regulator cranks must now be adjusted according to section 10 of this manual.

Page 49

47

23. Replacing the zigzag-stitch unit on Pfaff 1540

Removal:

z Disconnect the machine's mains plug.

z Remove the housing covers as described in this manual.

z Set stitch width adjustment dial 70 to "0" (fig. 44).

z Remove circlip 71 from connecting rod 72.

z Remove circlip 92 (fig. 46).

z Detach pull rod 93 and remove it from the top.

z Remove the two circlips 99 (fig. 45).

z Remove plastic angle lever 100 from the front.

z Loosen fastening screws 75 (fig. 45).

z Carefully remove the zigzag-stitch unit from the machine.

Fitting:

z Insert bolt 76 of connecting rod 72 into joint piece 77 on the zigzag-stitch unit (fig. 44).

z Fit the zigzag-stitch unit in the machine inserting at the same time connecting rod 72 with sliding block

78 into the crank.

z Position the zigzag-stitch unit parallel to the arm shaft and gently tighten fastening screws 75.

z Replace circlip 71.

z Insert plastic angle lever 100 together with pull rod 93 (fig. 45).

z Refit the two circlips 99.

z Re-attach pull rod 93 and refit circlip 92 (fig. 46).

Page 50

48

24. Basic position of setting eccentric for the sideways needle position on Pfaff 1540

Requirement:

In its basic position the setting eccentric must point upwards at a position approx.45 degrees towards the

left (fig. 47).

Adjustment:

z Set stitch width adjustment dial 70 to "0" (fig. 47).

z Set needle position adjustment wheel 79 to "center".

z Press straight stitch and zigzag stitch button.

z Loosen screw 73 (fig. 49).

z Rotate setting eccentr ic 74 upwards and 45 degrees to the left.

z Rotate setting eccentr ic 16 to the left and to the right, until the needle is centered in the needle

slot (fig. 48).

z Tighten screw 73.

Page 51

49

25. Adjustment of needle penetration in needle plate slot on Pfaff 1540

Requirement:

At straight stitch setting with needle position "center" the needle must be exactly in the center of the

needle plate slot (fig. 30).

Check:

z Remove presser foot.

z Insert a new needle.

z Set stitch width adjustment dial 70 to "0" (fig. 32).

z Set needle position adjustment dial 79 to "center".

z Press straight stitch and zigzag stitch button on the automatic utility-stitch unit.

z Turn the handwheel and check the centered position of the needle.

Adjustment:

z Loosen the three screws 75 on the zigzag-stitch unit by just 1/8 of a turn.

z Turn the handwheel until the needle point is level with the surface of the needle plate (fig.31).

z Move the zigzag-stitch unit to the left or right until the needle is exactly in the center of the needle plate

slot (fig.32).

Note:

The zigzag-stitch unit should now be parallel to the arm shaft and clear it by 3.0 mm.

z Tighten the three screws 75.

Cross-check:

z The needle must be exactly in the center of the needle plate slot.

Page 52

50

26. Adjustment of the sideways movement of the needle bar on Pfaff 1540

Requirement:

During zigzag sewing operation the sideways movement of the needle should stop above the highest

possible fabric thickness.

The sideways movement of the needle must start when the needle point is leaving the needle plate.

It must be completed before the needle enters the fabric again, approx. 8 mm above the needle

plate (fig. 50).

Check:

z Set stitch width adjustment dial to the maximum zigzag width.

z Set needle position adjustment dial to "center".

z Press zigzag stitch button.

z Remove presser foot.

z Turn the handwheel in sewing direction, until the needle rises on the left-hand side and the needle

point is positioned exactly on the surface of the needle plate (fig.51).

z You can check the start of the sideways movement of the needle by simultaneously touching the back

side of the needle bar frame and the machine head with the index finger of your left hand while turning

the handwheel very slowly with your right hand.

Adjustment:

z Loosen the two screws 101 (fig. 52).

z Turn the handwheel in sewing direction, until the needle rises on the left-hand side and the needle

point is positioned exactly on the surface of the needle plate (fig.51).

z Rotate the large gear 98 in the direction of the arrow until feeler finger 102 (fig. 53) is exactly at the

starting point of rising cam 103.

z Hold the large gear 98 fir mly in this position to prevent it from turning.

z Disengage the small gear 97 by moving it to the right, rotate it until one of the screws 101 is accessible

and then move it fully to the left and re-engage.

z Gently tighten screw 101.

Cross-check:

z Test the needle bar sideways movement as descr ibed under "Check".

z Tighten the two screws 101.

Page 53

51

Page 54

52

27. Adjustment of zigzag stitch penetration in needle plate slot on Pfaff 1540

Requirement:

The widest zigzag stitches must have the same distance to the left and right edges of the needle plate

slot (fig. 54).

Check:

z Remove the presser foot.

z Insert a new needle.

z Set zigzag stitch adjustment dial to "5".

z Set needle position adjustment dial to "center".

z Press zigzag stitch button.

z Turn the handwheel and check the left and the right clearance in the slot.

Adjustment:

z Loosen screw 84 (fig.38) and move stop 85 to the left.

z Loosen screw 73 (fig. 55).

z Rotate setting eccentr ic 74 until the two clearances are equal.

z Tighten screw 73.

Cross-check:

z Turn the handwheel and check the clearances.

Page 55

53

28. Adjustment of the stop for the left needle position on Pfaff 1540

Requirement:

When all push buttons are switched off, the needle must be approx.0.2 mm further left than the widest

zigzag stitch.

The needle must not touch the needle plate.

Check:

z Set stitch width adjustment dial to "5".

z Set needle position adjustment dial to "center".

z Press the zigzag stitch button.

z Rotate the handwheel until the needle moves downward on the left side and is at a position of roughly

1 mm above the needle plate (fig.56).

z Press the button for the buttonhole bartack.

The needle should now move approximately 0.2 mm to the left.

Adjustment:

z Set stitch width adjustment dial to "5".

z Set needle position adjustment dial to "center".

z Press the zigzag stitch button.

z Loosen screw 84 (fig. 38).

z Push stop 85 to a position 0.2 mm from the crank 90.

z Tighten screw 84.

Cross-check:

z Press the zigzag stitch button and the button for the buttonhole bartack alternately and check whether

the needle moves by approx. 0.2 mm without touching the needle plate.

Page 56

54

Stitch forming parts (sewing hook)

Foreword:

The sewing hook adjustment consists basically of the three following adjustments:

z Needle r ise (sewing hook timing)

z Needle bar height

z Hook-to-needle clearance

Needle rise (sewing hook timing):

The needle rise is the movement by which the needle must rise from its lowest position until a thread loop

has formed on the side of the needle on which the scarf is located.

Needle bar height:

The needle bar height must be set in such a way that the sewing hook point can easily enter the thread

loop above the needle eye at straight stitch and zigzag stitch settings.

Hook-to-needle clearance:

The distance of the sewing hook point from the needle must be as small as possible, so that the sewing

hook point does not miss the thread loop.

The sequence of sewing hook adjustments is as follows:

1. Hook-to-needle clearance

2. Bevel gear setting

3. Needle rise (sewing hook timing)

4. Needle bar height

Page 57

55

Shuttles and sewing hook types in lockstitch sewing machines

Oscillating CB

hook and beak shuttle

Horizontal rotary

hook

Large horizontal

rotary hook

Vertical rotary

hook

CB-shuttle complete

Shuttle body

Bobbin case Bobbin

Beak shuttle complete

Bobbin

Hook complete

Hook body

Hook gib Bobbin case base

Bobbin case cap

Bobbin

Hook complete.

Hook body

Hook gib and

needle guard

Bobbin case base

Bobbin case cap

Bobbin

Hook complete

Hook body

Hook gib and

needle guard

Bobbin case base

Bobbin case cap

Bobbin

Page 58

56

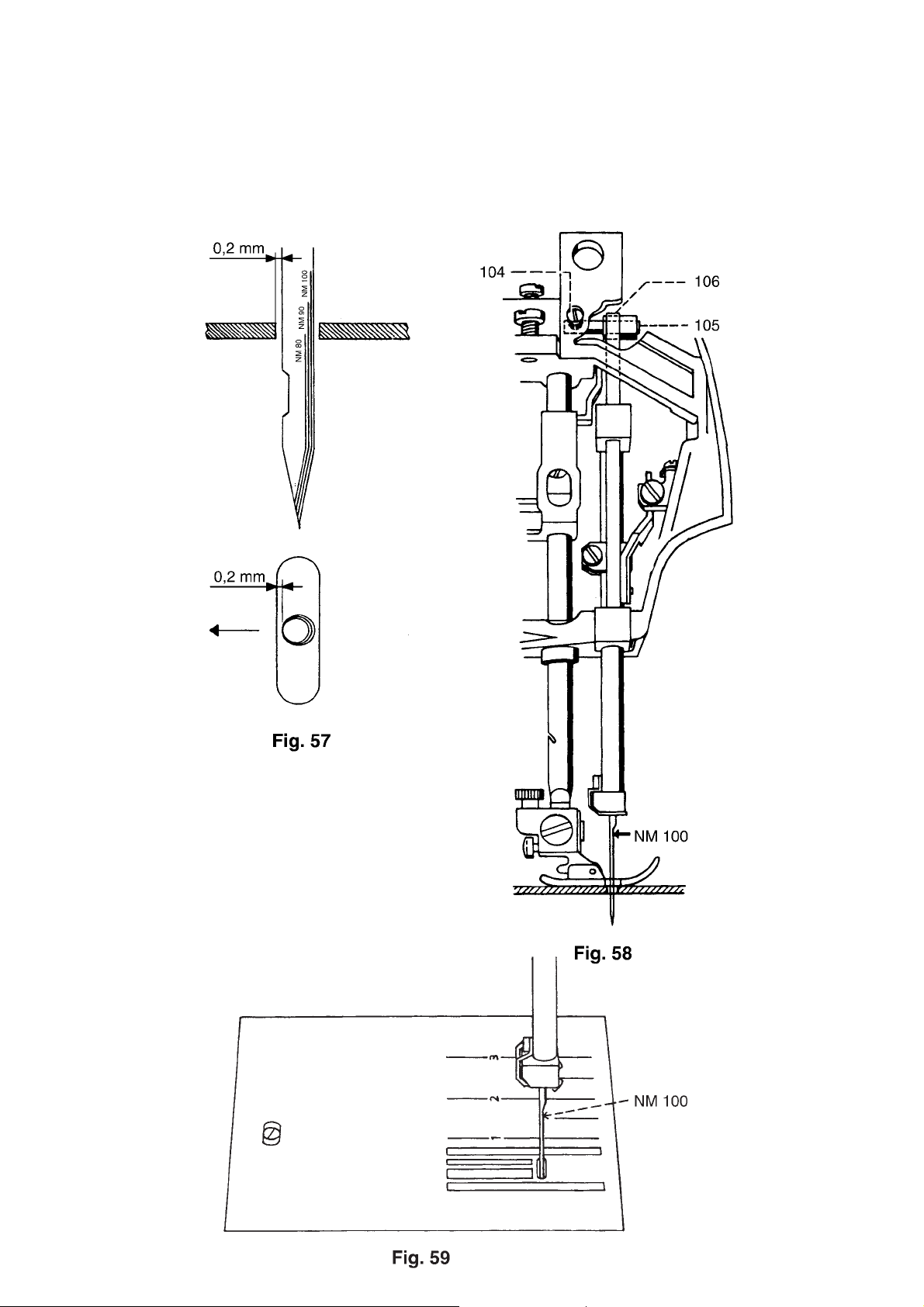

29. Adjustment of needle clearance in needle slot in sewing direction

Requirement:

There must be a clearance of 0.2 mm between the rear edge of the needle shank and the rear edge of

the needle plate slot (fig. 57).

Note:

Since system 130/705 H needles increase in size at the needle front side only, the point of a size 100

needle is positioned exactly in the middle of the needle slot (as seen from front to back), while the point of

a size 80 needle is positioned slightly closer to the rear edge of the needle slot.

Check:

z Insert a new size 100 system 130/705 H needle.

z Press the straight stitch button.

z Attach the zigzag foot.

z Lower the zigzag foot.

z Turn the handwheel until the needle is at its lowest position.The needle must now have the same

distance to the front and rear edges of the needle slot in the presser foot and in the needle plate.

Adjustment of the needle in the needle slot of the presser foot:

z Loosen screw 104 (fig 58)

z Move bolt 105 together with collar and needle bar frame 106 to the front or the rear until the needle is

exactly in the middle of the needle slot in the presser foot.

z Tighten screw 104.

Cross-check:

z Raise the needle by tur ning the handwheel.

z Place a piece of paper under the presser foot and lower the presser foot.

z Turn the handwheel until the needle has reached its lowest position.

z The needle must now have the same clearance to the front and rear edges of the needle slot in the

presser foot.

Important:

The needle bar frame must move must move easily and without binding.

If this is not the case any binding must be removed.

Adjustment of the needle plate:

z Turn the handwheel and raise the needle.

z Remove the zigzag foot.

z Turn the handwheel until the needle has reached its lowest position.

z Turn the setting eccentric until the clearance from the front and rear edge of the needle plate slot is the

same (fig. 59).

Page 59

57

Cross-check

z Carry out a visual check at straight and zigzag stitch settings.

Page 60

58

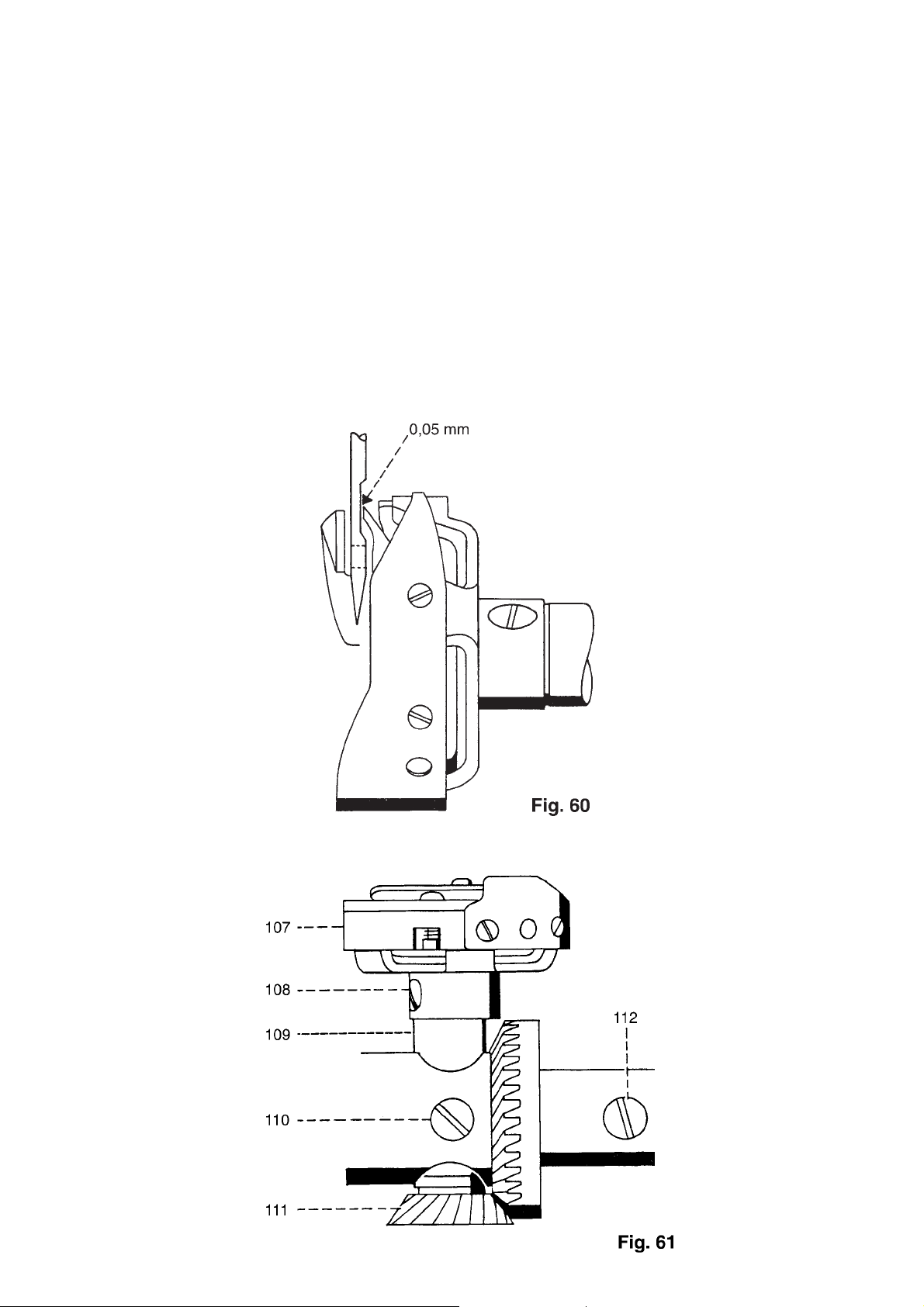

30. Adjustment of hook-to-needle clearance

Requirement:

At the straight stitch setting the clearance between the sewing hook point and the bottom of the scarf in

the needle must be 0.05 mm (fig. 60).

At the widest zigzag stitch setting, the sewing hook point must almost touch the needle.

Check:

z Remove the needle.

z Remove presser foot and needle plate.

z Remove the bobbin case.

z Unscrew the bobbin case position finger.

z Remove sewing hook gib with bobbin case base by unscrewing the three screws.

z Insert a new system 130/705 H, size 80 needle.

z Press the straight stitch button.

z Turn the handwheel until the hook point is exactly opposite the center line of the needle.

z Check the clearance between the hook point and the bottom of the needle scarf.

z Check the axial play of hook 107 to hook shaft bushing 109.

Adjustment:

z If the hook shaft has axial play, loosen the two screws 108 (fig. 61).

z Push bevel gear 111 with the shaft to the front and sewing hook 108 to the rear.

z Tighten the two screws 108.

z Loosen screw 112 in the lifting eccentric by 2 - 3 turns.

z Loosen screw 110 slightly.

z Turn handwheel and sewing hook until the hook point is exactly opposite the center line of the needle

scarf.

z Shift the sewing hook together with hook shaft bushing 109 until the clearance between the sewing

hook point and the bottom of the scarf in the needle is 0.05 mm.

z Tighten screw 110 on the narrow flat of hook bushing.

Note:

The large flat of the hook bushing must face right.

Cross-check:

z Check for free movement of the hook shaft.

z Check the clearance between the hook point and the bottom of the needle scarf once again.

Page 61

59

30a. Adjustment of bevel gears

Requirement:

The bevel gears must move easily and without play.

Adjustment:

z Push bevel gear with lifting eccentric to the left until it rests on bevel gear 38 without play.

z Tighten screw 37 on the surface of the drive shaft.

Check:

z As descr ibed under "Requirement".

Page 62

60

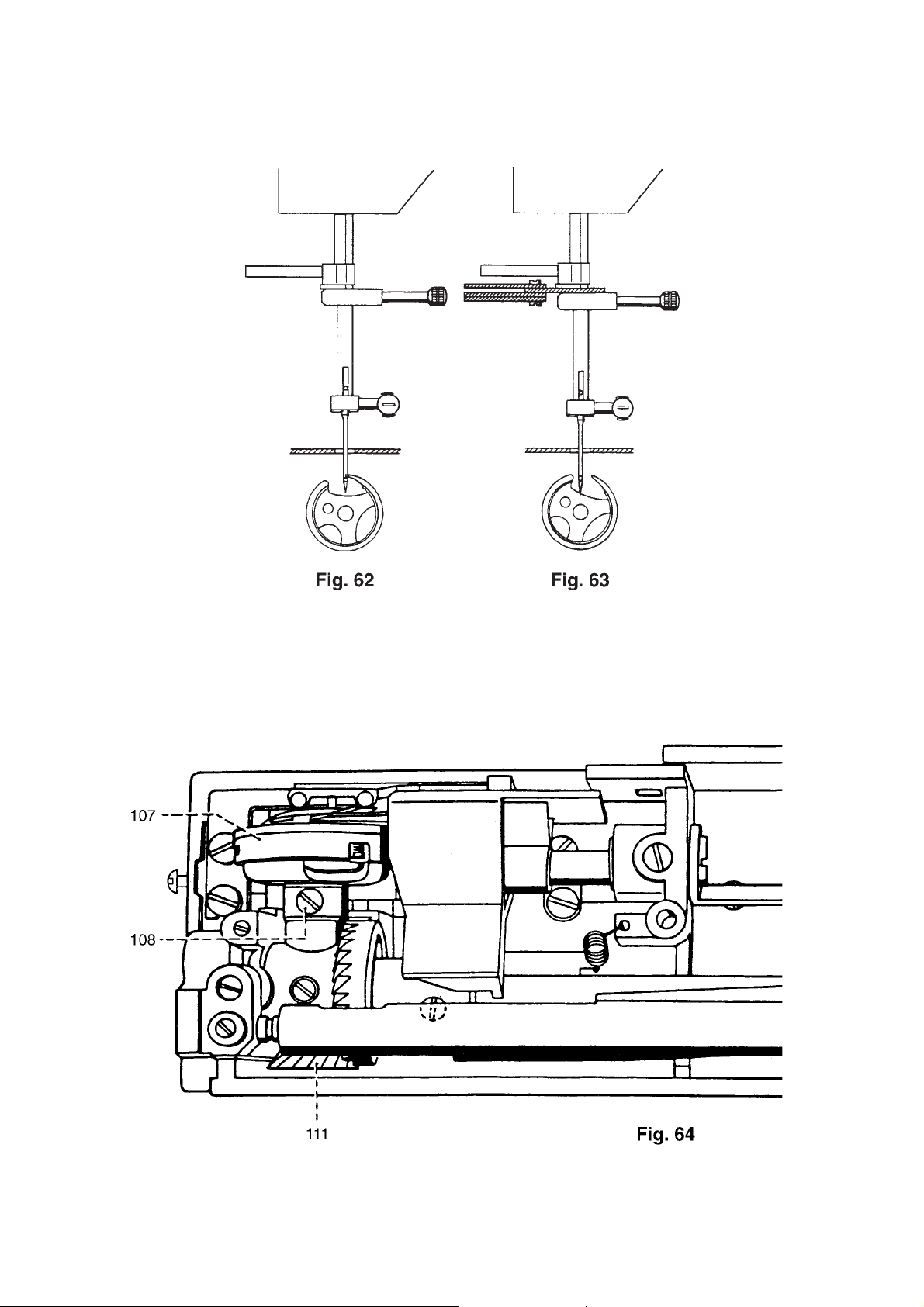

31. Sewing hook timing

Requirement:

When the needle bar has moved 2.2 mm upwards from its lowest position, with the machine set for

straight stitch and center needle position, the sewing hook point must be exactly behind the center line of

the needle (fig. 62).

Check:

z Remove presser foot and needle plate.

z Press the straight stitch button.

z Br ing the needle bar to its lowest position by turning the handwheel.

z Push the spacer (63-102 600-18) onto the top of the needle bar and slide it upwards against the need

le bar frame (fig. 63).

z Push the needle-r ise clamp (00-870 137-01) on the needle bar and tighten it lightly.

z Push the 2.2 mm feeler gauge (00-870 136-01) with its cutout on the needle bar above the needle-rise

clamp.

z Loosen the needle-r ise clamp and push the 2.2 mm feeler gauge upwards against the spacer.

z Tighten the knur led screw on the needle-rise clamp.

z Slightly tur n the handwheel back and forth.

z If there is any play on the feeler gauge, repeat this procedure.

z Remove the 2.2 mm feeler gauge.

z Turn the handwheel in sewing direction until the needle-rise clamp rests on the spacer.

This means that the needle has moved upwards by 2.2 mm to the needle rise position.

The hook point must now be exactly behind the center line of the needle (fig.62).

Adjustment:

z If the setting is not correct, remove the needle-rise clamp.

z Loosen the two screws 108 (fig. 64).

z Refit the needle-r ise clamp and repeat the operation as described under "Check", until the needle bar

has moved 2.2 mm upwards and the needle-rise clamp rests on the spacer.

z Turn the hook until the hook point is exactly behind the center line of the needle.

z Press sewing hook 107 and bevel gear 111 together so that there is no play between them, and tighten

one of screws 108.

Cross-check:

z Slightly tur n the handwheel back and forth until the needle-r ise clamp rests on the spacer (fig. 62).

The hook point must be exactly behind the center line of the needle.

z Remove the needle-rise clamp.

z Check that the hook shaft has no axial play.

z Tighten the two screws 108 very fir mly.

Page 63

61

Page 64

62

32. Adjustment of needle bar height

This machine has a transverse double-rotating hook.

At the right zigzag penetration, the sewing hook reaches the needle a little earlier and at the left penetration a little later than at the center penetration.

As a result of this, the position of sewing hook at the right zigzag penetration is slightly higher above the

needle eye than at the left zigzag-penetration (fig.65).

Requirement:

The clearance between the top edge of the needle eye and the lower edge of the sewing hook point must

be 0.5 mm at the widest left zigzag penetration (fig. 66).

Check:

z Press the button for the widest zigzag stitch.

z Turn the handwheel until the needle rises at the left zigzag stitch and the sewing hook point is exactly

behind the needle center line.

z The clearance between the top edge of the needle eye and the lower edge of the sewing hook point

must be 0.5 mm.

Adjustment:

z Loosen screw 112 just a little (fig. 67).

z Shift needle bar 30 in height, without twisting it, until the clearance of 0.5 mm is set.

z Tighten screw 112.

Cross-check:

z Check the clearance of 0.5 mm.

The needle holder must face exactly square to the right.

Page 65

63

33. Adjustment of bobbin case position finger

Requirement:

The clearance between the position finger and the bottom of the groove in the bobbin case base must be

0.7 mm.

Check:

z It must be possible to inser t clearance gauge (00-880133-01) with ease but without play between the

position finger and the bottom of the groove in the bobbin case base (fig.68).

Adjustment:

z Loosen the two screws 114.

z Insert clearance gauge.

z Press bobbin case position finger 113 against the gauge at an angle of 90 degrees.

z Tighten the two screws 114.

Cross-check:

z As descr ibed under "Check".

Page 66

64

Stitching off

34. Adjustment of needle threader

Requirement:

With the threader lever pushed fully down, prong 115 must pass through in the center between the top

and bottom edge of the needle eye of a size 70 needle (fig.69).

The prong must have the same distance to either side of the walls of the needle eye.

Check:

z Insert a new system 130/705 H, size 70 needle.

z Move the needle bar to its top position by turning the handwheel.

z Push threader lever 116 fully down and swivel it forwards.

z Carry out a visual check.

Height adjustment:

z Disconnect pull-spr ing 117 from above (fig. 71).

z Press threader bracket 118 down and hold it in this position.

z Loosen Phillips screw 119 by just 1/4 of a turn.

z Push threader bracket 123 upward or downward until prong 115 has the same distance from the top

and bottom edge of the needle eye (fig.69).

z Tighten screw 119 in this position.

Cross-check 1:

z Use the button to move threader prong 115 to the rear and to the front again.

z At the same time, carr y out a visual check of the prong height.

Lateral adjustment:

z Use button 116 to tur n the threader prong 115 to the front into the needle eye.

z Loosen screw 120 by just 1/8 of a turn (fig. 70).

z Move prong bracket 121 laterally until prong 115 is precisely centered in the needle eye.

z Tighten screw 120.

Cross-check 2:

z Use the button to move threader prong 115 to the rear and to the front again.

z At the same time, carr y out a visual check of the lateral position of the prong.

z Rotate pull-spr ing 117 by two full turns counter-clockwise and engage it in hook 122 in such a way that

the body of the spring is positioned outwards to the left (fig. 71).

This ensures that the threader is swung automatically backwards.

z Operate the threader button and carry out a visual and functional check.

Page 67

65

Page 68

66

35. Adjustment of bobbin winder stop

Requirement:

The bobbin winder must stop when the thread has reached a level of 1 mm below the bobbin rim.

Check:

z Wind a bobbin and check that the winder stops as required.

Adjustment:

z Loosen screw 123 (fig. 72).

z Position stop 124 to the left for less thread and to right for more thread.

z Tighten screw 123.

Cross-check:

z Wind a bobbin and check that the winder stops as required.

Page 69

67

36. Adjustment of bobbin thread tension

Requirement:

The force required for pulling cotton thread 50/2 or synthetic fiber thread 100/3 off the bobbin must be

approximately 20-25 g.

Check:

z When a threaded bobbin case hangs on its thread, it must not slide downwards by its own weight.

z Upon sharp upward movements of the hand, the thread must run off gradually (fig. 73).

z There must not be any thread waste under the tension spring.

z The tension spr ing must rest evenly and parallel on the bobbin case.

Adjustment:

z Loosen the knur led screw a little and turn it in again until a resistance is felt when the thread is pulled

off.

Cross-check:

z As descr ibed under "Check".

Note:

z Once the bobbin thread tension has been set correctly, tension adjustments should be made only on

the needle thread tension.

Page 70

68

37. Adjustment of needle thread tension

Requirement:

Within the adjusting range from 3 to 5, the interlacing of needle thread and bobbin thread (cotton thread

50/2 or synthetic fiber thread 100/35) must take place approximately in the middle of the fabr ic (fig. 74).

Check:

z Set needle thread tension to "5".

z Press the button for the widest zigzag stitch.

z Set stitch length to "2.0".

z Place a piece of fabric under the zigzag foot and sew.

z Press the button for straight stitch.

z Set stitch length to "2.5".

z Sew with straight stitch.

Adjustment:

z First tur n knur led nut 125 fully to the left (fig. 76).

z Press the button for the widest zigzag stitch.

z Set stitch length to "2.0".

z Sew with zigzag stitch.

z At the same time tur n the knur led nut gradually in clockwise direction, until the interlacing is in the cen-

ter of the fabric (fig. 75).

Cross-check:

z Sew with straight stitch and zigzag stitch as described under "Check".

Page 71

69

Page 72

70

38. Adjustment of thread check spring stroke

The thread check spring prevents the descending needle from piercing the slack needle thread.The

needle thread is slackened by the descending take-up lever.

Requirement:

Thread check spring 126 must keep the needle thread taut at least until the needle point enters the fabric

(fig. 77).

The thread check spring must release the needle thread as soon as the lower edge of the needle eye enters the fabric.

Check:

z Press the straight stitch button.

z Set stitch length to "6.0".

z Place two layers of fabric under the presser foot.

z Sew a few stitches.

z Turn the handwheel and determine the end of the thread check spring stroke.

Correct slackening of the needle thread takes place when it enters the needle eye not tautly but in a

loose curve.

Adjustment:

z Loosen screw 128.

z Turn thread check spring stop sleeve 127 until thread check spring 126 is in the correct position.

z Tighten screw 128.

Cross-check:

z Sew a few stitches and proceed as described under "Check".

Page 73

71

Page 74

72

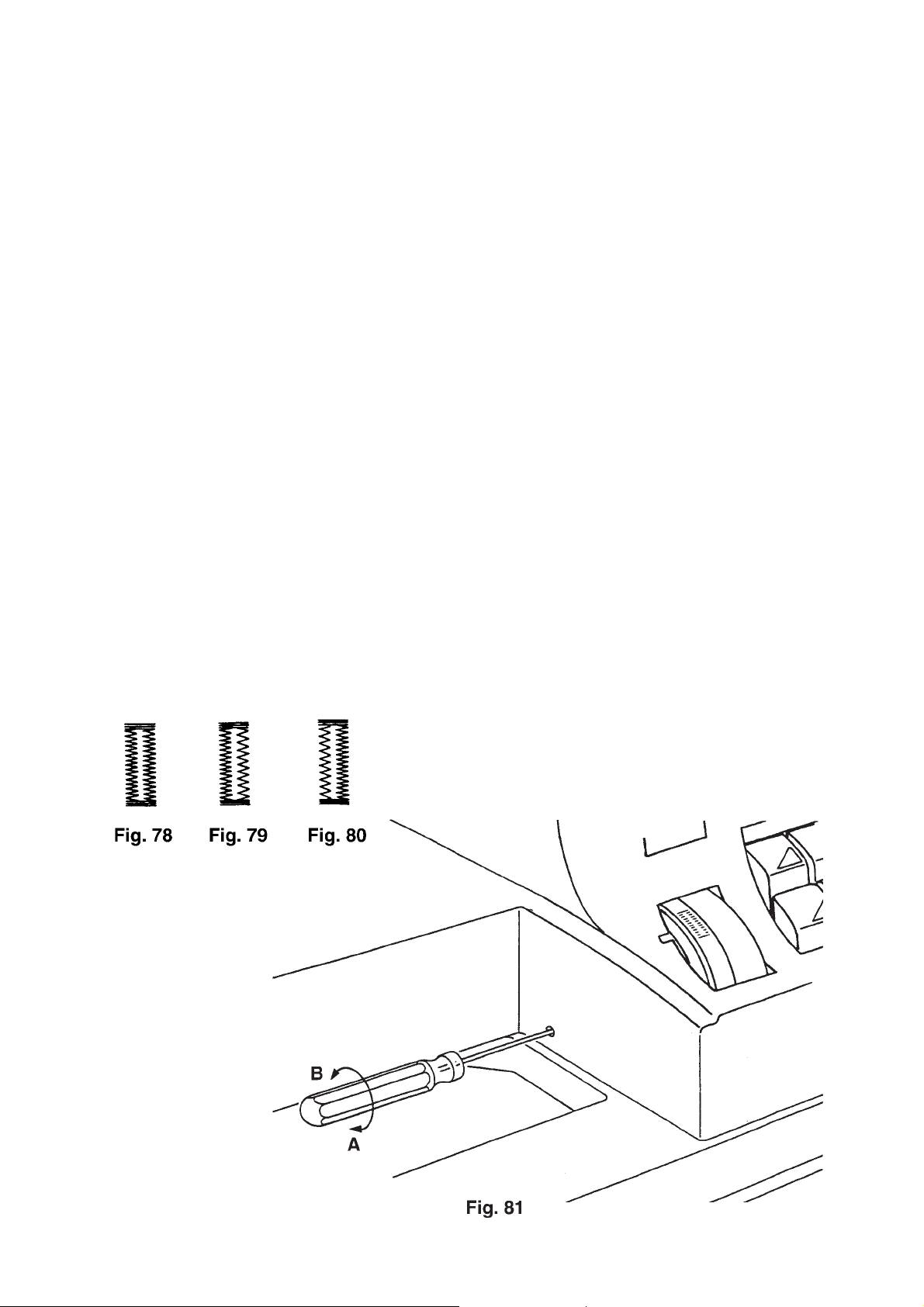

39. Adjustment of equal stitch length for left and right buttonhole seams

Requirement:

The stitch lengths of the left buttonhole seam and of the right buttonhole seam must be the same (fig.78).

Note:

When the correct zero point has been set on the stitch length regulator, the stitch lengths of the buttonhole seams are normally the same (section 11 of this manual).

Check:

z Sew a buttonhole with gimp thread and compare the two stitch lengths.

Adjustment:

z If r ight buttonhole seam has longer stitch length than left one (fig. 79), turn setting eccentr ic slightly to

the front in direction "A" (fig. 81).

z If left buttonhole seam has longer stitch length than right one (fig. 80), tur n setting eccentr ic slightly to

the rear in direction "B" (fig. 81).

Cross-check:

z Sew a buttonhole with gimp thread and check the stitch length.

Page 75

73

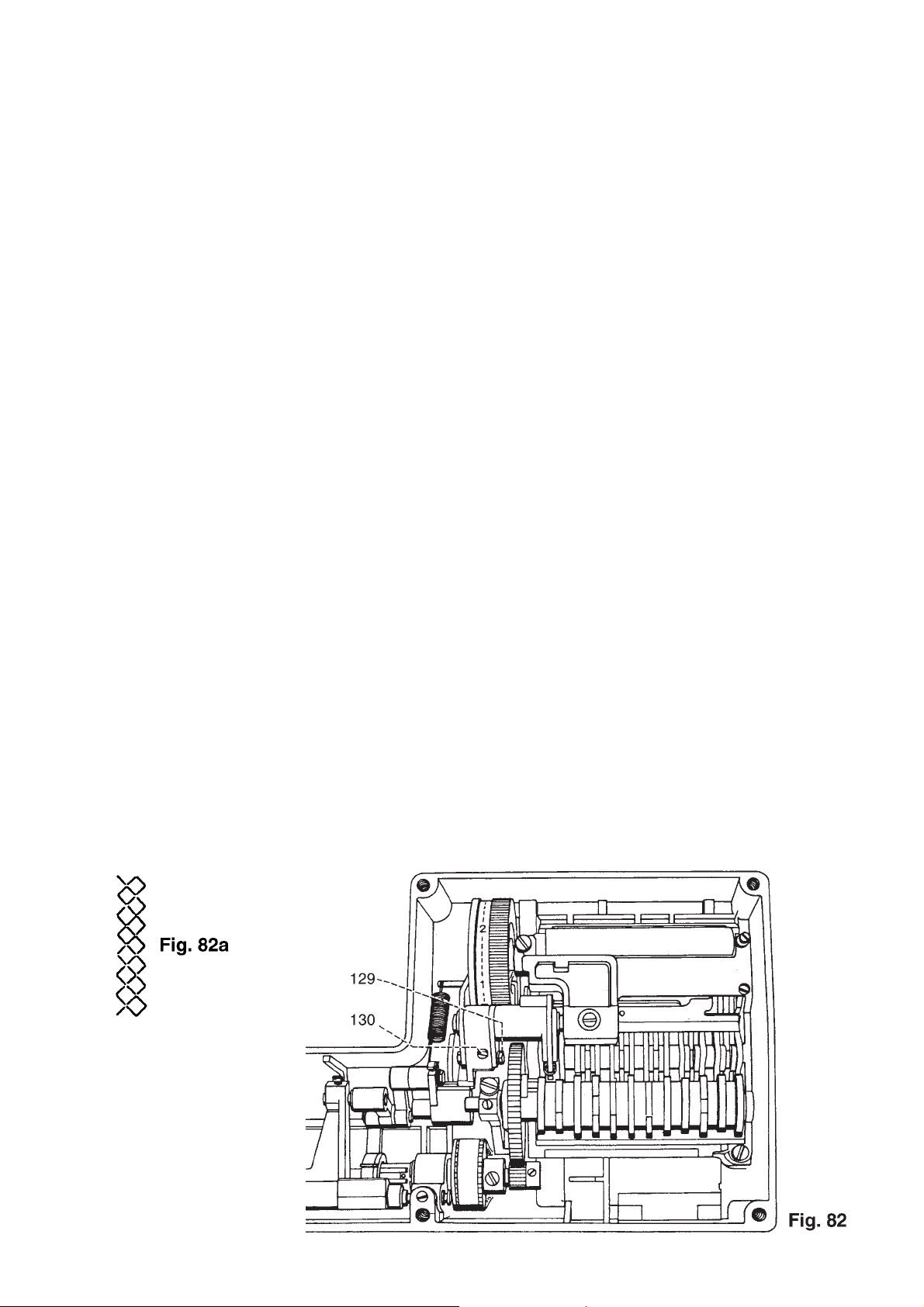

40. Adjustment of equal forward and reverse stitch length

(for forward and reverse controlled utility stitches)

Requirement:

The needle perforations for the honeycomb stitch must always take place in the same penetration holes

for forward and reverse feed (fig. 82).

Check:

z Set the adjustment dial for the stitch length against the stop of the triple stitch symbol.

z Press the button for honeycomb stitching (on Pfaff 1520 /1530 set the automatic unit adjustment dial to

"F").

z Place two layers of linen fabric under the presser foot and sew the honeycomb stitch.

Adjustment:

z Loosen hexagon head screw 129 by just 1/8 of a turn, using a 5.5 mm spanner (fig. 82).

z Loosen screw 130 by approx. 2 turns.

z Tighten screw 129 just a little.

z Sew the honeycomb stitch. The stitch length of the honeycomb stitch should now be a bit too long.

z Loosen screw 129.

z Tighten screw 130 just a little.

z Slightly tighten screw 129.

z Sew the honeycomb stitch and check needle perforations.

z Continue adjusting screws 129 and 130 until the needle enters the same perforations.

z Tighten screw 129 securely.

Cross-check:

Sew the honeycomb stitch and the stretch triple straight stitch and check whether the needle always enters the same perforations.

Page 76

74

41. Making up a sewing sample

When all sewing checks are completed and the machine sews perfectly, a sewing sample is to be made.

This sewing sample should contain the most important stitch patterns that can be sewn on the repaired

machine (fig. 83).

If the customer has any particular requirements, these should be produced on a separate sample.

The following is a sewing sample made on the PFAFF 1540

Stitch program Stitch length Presser foot No.

1 Straight stitch 2.5 Zigzag foot "0"

2 Zigzag stitch 2.0 Zigzag foot "0"

3 Decorative stretch stitch 1.0 Zigzag foot "0"

4 Honeycomb stitch ||| Zigzag foot "0"

5 Stretch triple straight stitch ||| Zigzag foot "0"

6 Stretch triple zigzag stitch ||| Zigzag foot "0"

8 Linen buttonhole approx. 0.3 Buttonhole foot "5"

Page 77

75

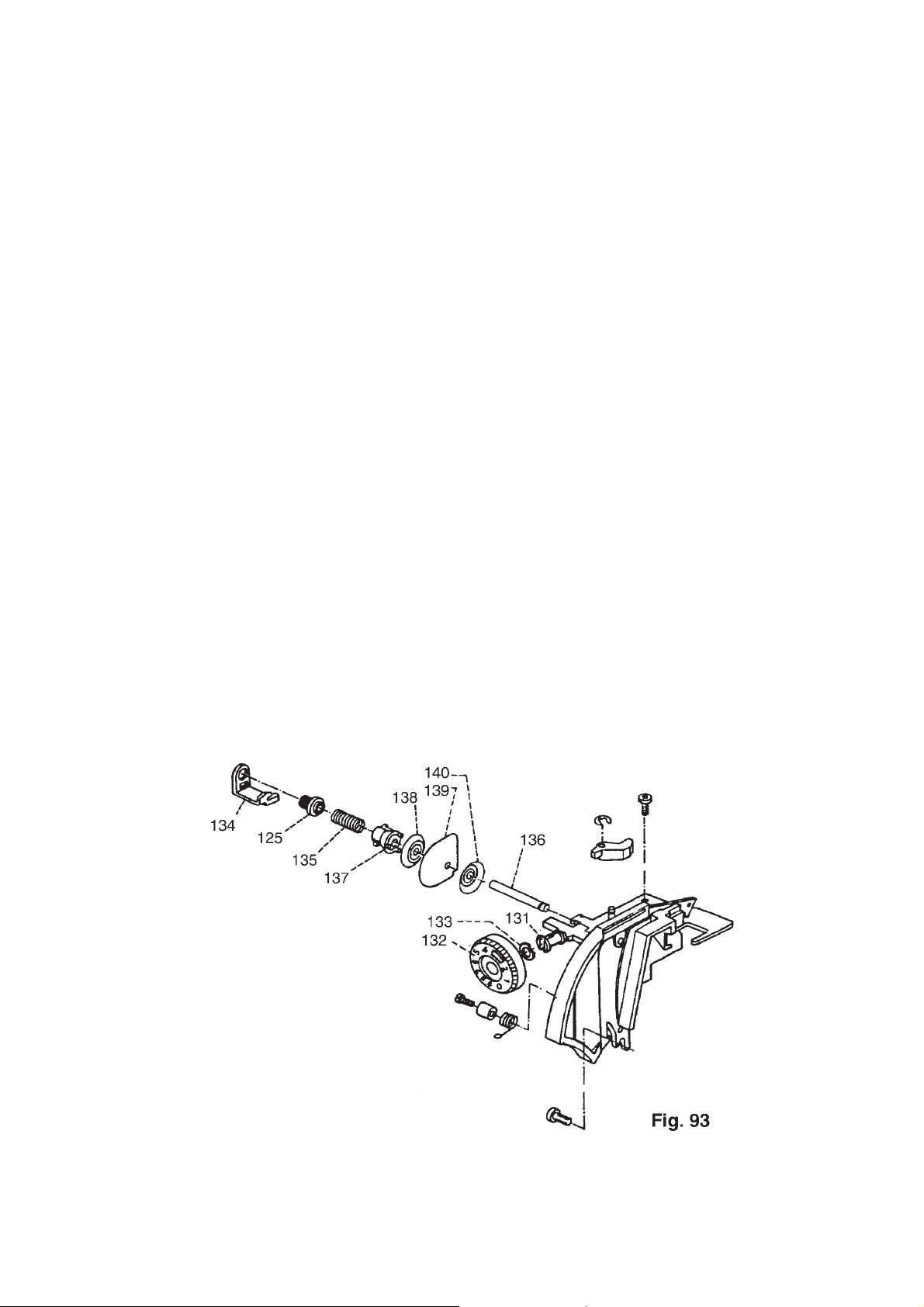

Repair Instructions

42. Removing and fitting the needle thread tension

Removal:

z Remove the needle thread tension.

z Press the two plastic noses 131 together and remove tension dial 132 (fig. 93).

z Remove spring disk 133.

z Turn knurled nut 125 out of guide 134.

z Remove guide 134.

z Remove knurled nut 125 and pressure spring 135.

z Pull out or knock out cemented tension stud 136 complete with pressure piece 137 and the three tensi-

on disks 138, 139 and 140.

Fitting:

z Insert tension stud 136 with the three tension disks and fit pressure piece.

z Cement tension stud into the mounting plate with Onmivit-Rapid.

z Push pressure spr ing 135 and knurled nut 125 onto tension stud 136.

z Insert guide 134 with its right side and fully screw in knurled nut 125.

z Push on adjustment dial 132 making sure that the guide nose is in contact with the outer surface of the

curve.

z Install the needle thread tension.

z Adjust the needle thread tension according to section 35.

Page 78

76

43. Changing the pressure spring in the handwheel release

Removing the handwheel release

z Remove plastic cap 141 using clearance gauge 00-880 133-01 (fig. 94).

z Remove metal screw 142.

z Pull out handwheel release disk 143 and take out pawl 144, clutch piece 145 and pressure spring 146.

Fitting the handwheel release

z Turn handwheel 147 and clutch disk 148 until the hole in the handwheel and the cutout in the clutch

disk are facing downwards (fig.95).

z Place pressure spr ing 146 onto the handwheel boss so that its rear side fits into the guide groove (fig.

96).

z First place clutch piece 145 onto the handwheel boss, then press it towards the back.The pressure

spring is thus placed vertical and the clutch piece is positioned as shown in fig. 97.

z Push the pin of pawl 144 into the hole in such a way that it is positioned as shown in fig. 98.

z Push handwheel release disk 143 with its square mar k 150 facing up into the handwheel (fig. 99).

z In order to be able to lock into the catch, handwheel release disk 143 must be turned counter-clockwi-

se by approx.5 mm.

z Fit metal screw 142 with washer 151.

z Hold handwheel in position and tur n release disk 143 in sewing direction until you hear it snap in place.

z Fit the plastic cap.

z Check the handwheel release by engaging and disengaging it.

Page 79

77

Page 80

78

44. Removing and fitting the sewing hook

Removal:

z Remove the needle.

z Unscrew the presser foot.

z Remove the bobbin case.

z Remove the bobbin case position finger.

z Remove the three screws with springs from behind (fig. 100).

z Remove the bobbin case base with sewing hook gib (fig. 101).

z Turn the sewing hook gib to the left or to the right out of the bobbin case base (fig.102).

z Clean the sewing hook, bobbin case base and hook gib.

Fitting:

z Turn the handwheel until the opening of the sewing hook faces to the left (fig. 103).

z Turn the sewing hook gib to the left into the bobbin case base (fig.104).

z Insert the bobbin case base complete with sewing hook gib into the sewing hook (fig. 105).

z Secure the sewing hook gib from behind with three screws with springs (fig. 100).

z Screw on and adjust the bobbin case position finger.

45. Cleaning and oiling the machine

Note:

The machine is equipped with sintered bearings and components and is therefore maintenance free for

the user.

Only the sewing hook should be lubricated once in a while with normal sewing machine oil.

After repair work, the service engineer should oil the machine with BP Energol HLP 46 or HLP 80 and the

sewing hook with normal sewing machine oil.

Sintered bearings and components must not be cleaned with gasoline, petroleum, kerosene, thinners,

trichlorethylene etc.

Page 81

79

Page 82

80

46. Changing the toothed belt

Removal:

z Disconnect the machine lead cord.

z Remove needle and presser foot.

z Remove detachable work support.

z Remove top cover.

z Switch on bobbin winder.

z Remove the two Torx screws of the housing insert.

z Remove the housing insert.

z Remove the four retaining screws of the baseplate.

z Place the baseplate aside.

z Loosen screw 152 in ar m shaft crank 153 (fig. 106).

z Loosen screw 1 on tensioning roller 2.

z Remove screw 154 on the upper toothed belt sprocket 155.

z Remove the circlip 156 from the arm shaft.

z Moving ar m shaft 157 to the right, remove the toothed belt for the machine and the toothed belt for the

motor 59.

z Loosen the three screws 94, 95 and 96 on the automatic utility-stitch unit.

z Loosen the two screws 101 and remove small gear 97 to the right.

z Move the automatic utility-stitch unit a little to the front and remove toothed belt 158 between the large

gear and the shaft end.

Refitting:

z Insert the new toothed belt 158 for the machine between the large gear and the end of the shaft and

mount it on the lower belt sprocket 159.

z Tighten the three screws 94, 95 and 96 on the automatic utility-stitch unit.

z Pull toothed belt 158 upwards.

z Slide ar m shaft 157 to the left through toothed belt 158 into the left bear ing and ar m shaft crank 153.

z Refit circlip 156 on the ar m shaft.

z Secure the ar m shaft and insert screw 152 in the arm shaft crank.

z Mount toothed belt 158 on the upper belt sprocket 155.

z Insert screw 154 in the upper belt sprocket and firmly tighten.

z Adjust tensioning roller in accordance with section 1.

z Mount toothed belt 59 for the motor on the handwheel.

z Refit small gear 97 on the shaft and gently tighten screws 101.

z Adjust the gears in accordance with section 22.

Page 83

81

Page 84

82

47. Adjusting the arm shaft crank

z Press the straight stitch button.

z Carefully loosen screw 152 on ar m shaft crank 153 just enough to allow the arm shaft crank to be tur-

ned on its shaft (fig. 107).

z Raise the needle bar and insert the needle.

z Fir mly hold ar m shaft crank 153 using the left hand.

z At the same time, tur n the handwheel with your right hand until the feed dog is at the bottom and the

sewing hook point is centered between the feed dog rows.

z Now fir mly hold the handwheel and at the same time tur n ar m shaft crank 153 until the needle bar rea-

ches its lowest position.

z Fit spacer 63-102600-18 on the needle bar.

z Place the needle-r ise clamp 00-870137-01 onto the needle bar and tighten it just a little (fig 109).

z Place the 2.2-mm feeler gauge 00-870136-01 onto the needle bar with its cutout above the needle-rise

clamp.

z Push the needle-r ise clamp and the 2.2-mm feeler gauge up against the spacer.

z Tighten the knur led screw on the needle-rise clamp.

z If there is play on the feeler gauge, repeat the above procedure.

z Remove the 2.2 mm feeler gauge.

z Hold the handwheel and tur n ar m shaft crank 153 in sewing direction until the needle-rise clamp rests

on the spacer.

z The sewing hook point must now be exactly opposite the center line of the rear side of the needle.

z If this is not the case, tur n simultaneously handwheel and arm shaft crank 153 until the sewing hook is

exactly opposite the center line of the rear side of the needle with the clamp resting on the spacer.

z Remove the needle-rise clamp.

z Tighten screw 152 on ar m shaft crank 153 until arm shaft 157 has no play and the needle rise move-

ment is correct.

z To this end, reposition the needle-rise clamp and check.