Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

SINGLE DOOR BACK BAR COOLER

MODEL NOS.

CS1DPSP

IMPORTANT INFORMATION

A Warranty card is enclosed that must be filled out

and mailed to the Perlick Corporation in order to register the warranty. If the card is not returned to

Perlick, the warranty period will begin from the date

the equipment is shipped from the factory.

This manual has been prepared to assist you in the

installation of your Single Keg Dispenser and to

acquaint you with its operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer can

provide you with a list of qualified service agents. For

your own protection, never return merchandise for

credit without our approval.

We thank you for selecting a Perlick product and

assure you of our continuing interest in your

satisfaction.

WARNING: When lifting, the full weight of the

cabinet must be supported. Lift from the cabinet

base and not from the top. Improper lifting can

result in severe damage to the cabinet.

Table of Contents

PREPARING THE CABINET FOR USE

Specifications.........................................................2

List of Included Parts.............................................3

Tools Required.......................................................3

Plumbing................................................................3

Electrical................................................................3

Uncrating ...............................................................3

Installing Casters...................................................3

Placing the Cabinet ...............................................3

Leveling the Cabinet ..............................................3

Installing Base Plates............................................3

TEMPERATURE

Refrigeration and Temperature Control.................4

Adjusting the Temperature.....................................4

CLEANING

Cleaning the Cabinet.............................................4

Cleaning the Condenser ........................................4

Condenser.............................................................4

GENERAL INFORMATION

REPLACEMENT PARTS.......................................5

Wiring Diagram......................................................6

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Form No. Z2091A

Rev. 08.03.04

Page 2

Installation and Operating Instructions

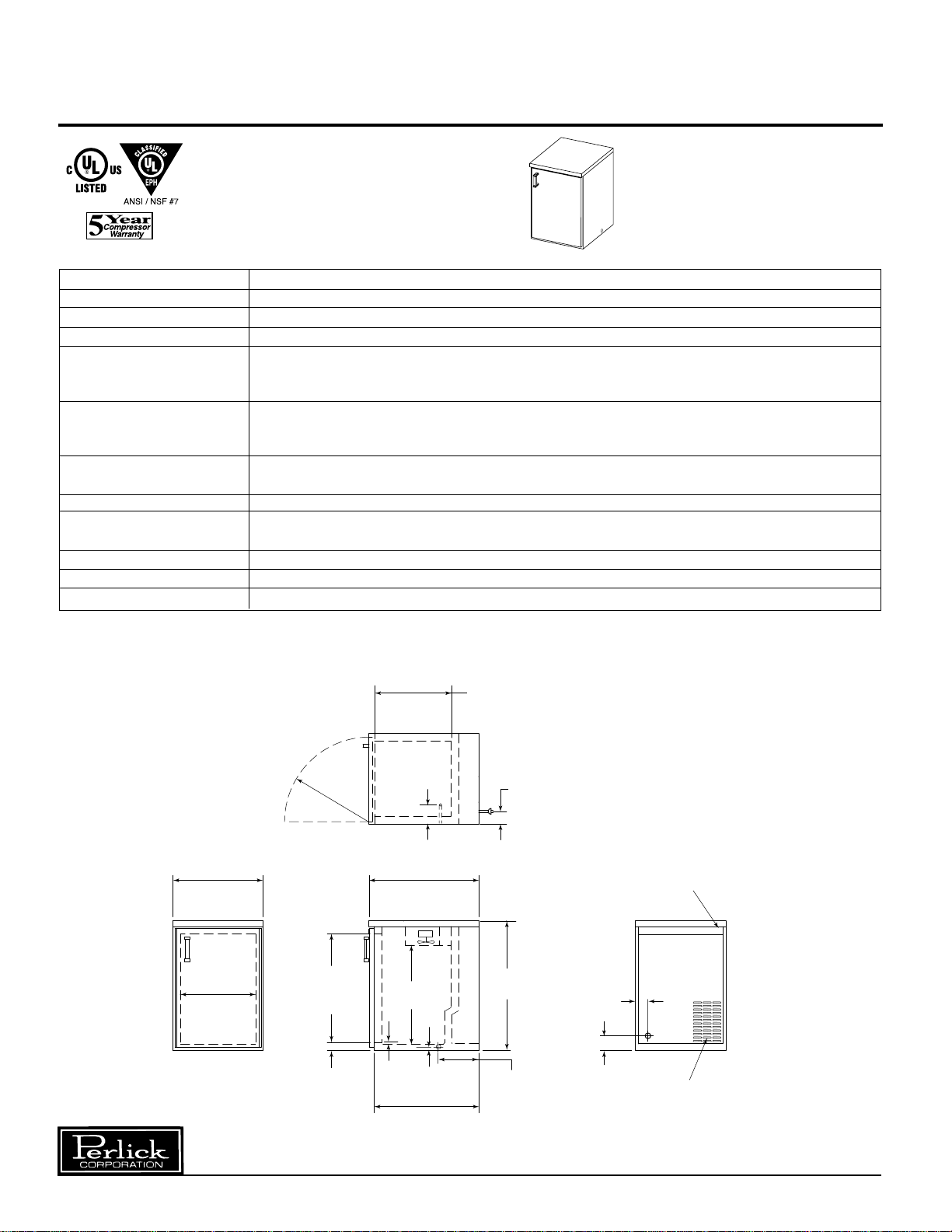

Sizes and Specifications, Single Door Back Bar Cooler

MODEL NOS. CS1DPSP

CONDENSING UNIT H.P.

AMPS 3.2

SHIP WT lbs. (kg) 205 (93)

INTERIOR Door Sill: Reinforced 14 gauge stainless steel sill. Door Pan: High strength polystyrene.

Floor Pan: Stainless steel. Walls & Ceiling: Galvanized steel. Includes pilasters, two shelves and

one (1) mini-flourescent energy efficient light.

EXTERIOR Stainless steel top with square edges. Door, front, back and ends, black texture-painted steel.

Decorative handle and lock. Base is black painted galvanized steel. Full back panel with air gap

vent on top.

REFRIGERATION R-134a capillary tube-type. Aluminum fin and copper tube evaporator coil.

Adjustable temperature control. Self-defrosting.

VENTILATION Two inches of clearance is required behind cabinet for proper air flow.

ELECTRICAL 115 Volt, 60 Hz., 1 Phase AC. Furnished with three prong, six foot rubber cord.

Contact Perlick-Milwaukee for other voltages/frequency requirements.

PLUMBING Floor drain

3

/4” female taper pipe exits out right bottom or right end.

VENTILATION Requires tow inches of clearance at back of cabinet for proper air-flow.

OPTIONALACCESSORIES • Leg Set • Caster Set • Leg & Front Base Plate

1

/6h.p

24"

[610]

20"

[508]

DOOR

OPENING

23" R

[584]

28 11/16"

[729]

OPENING

2 1/4"

[57]

5 11/16" [144]

29 1/8"

[740]

26 1/4"

[666]

1/2"

25/32"

[13]

[20]

27 3/4"

[705]

20 1/4" [514]

BACK TO INSIDE

OF DOOR PAN

3 9/32" [83]

34 7/16"

[875]

10 25/32"

[273]

3 9/32"

[83]

3 29/32"

[99]

CONDENSER

AIR (DISCHARGE)

CONDENSER

AIR (INTAKE)

Form No. Z2091A

Rev. 08.03.04

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

Page 3

Preparing the Cabinet for Use – Single Door Back Bar Cooler

Parts List

■

(2) Shelves.

■

Mini-Flourescent Light.

■

Shelf Clips.

Tools Required

■

#2 Phillips Screwdriver.

■

10” Crescent Wrench.

9

■

/16” Allen Wrench.

3

■

/8” Nut driver.

■

power Drill or Driver (for Leg Installation).

Plumbing

Features a floor drain with a 3⁄4” female pipe thread

connection for disposal of condensate. Remove

bottom or side drain plug with Allen wrench and

3

attach

⁄4” male pipe to external drain.

Electrical

The cabinet must be connected to a separately

fused power source (see electrical specification

plate) and grounded in accordance with National

and Local Electrical Codes. Caution: Do not

attempt to operate the equipment on any other

power source than that listed on the Electrical

Specification plate.

Uncrating and Inspection

Remove all crating material before operating.

Carefully inspect cabinet for hidden damage. If

damage is discovered, file your claim immediately

with the transportation company. Perlick is

not responsible for damage in transit.

Installing Casters

(Optional)

Attach four casters to the cabinet bottom; rigid casters at the rear and swivel casters on the front. Use

1

the supplied

/4”- 20 x 3/4” hex head self-tapping

machine screws.

Placing the Cabinet

Push the cabinet into place using rollers when

necessary. Important: Proper air flow around the

condensing unit is necessary for efficient operation.

Never obstruct the air flow in and out of the

condensing unit. Aminimum of 2” clearance is

required from back.

Leveling the Cabinet

When the cabinet is in place, check installation with

carpenter’s level. When perfectly level, accumulated

water will drain out. Aslight pitch to the drain side

will not harm the cabinet. Water may accumulate if

cabinet is pitched to the opposite side.

Installing Base Plate (Optional)

Attach brackets to cabinet bottom in holes provided.

Use #10 self-drilling hex sheetmetal screws. (See

separate instructions, provided with kit). When

returning cabinet to upright position, be careful not

to bend brackets.

WARNING!

To avoid compressor damage,after returning

cabinet to an upright position, let unit stand for

24 hours before plugging it in and running the unit.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Form No. Z2091A

Rev. 08.03.04

Page 4

General Information – Single Door Back Bar Cooler

Refrigeration and Temperature Control

The Back Bar cabinet is equipped with a heavyduty refrigeration system designed to automatically

maintain a storage temperature of 36-41 degrees F.

The control is factory set at 38 degrees F.

Cleaning the Cabinet

Use a mild detergent and water to clean the inside

and outside of the cabinet. Dry thoroughly. Never

use a scouring pad or abrasive cleanser.

NOTE: An industrial strength, commercial cleaner

can be used to clean the outside of painted

cabinets.

Cleaning the Condenser

Use a long handled, stiff brush to clean the dirt from

the front surface of the condenser. Keeping the

condenser free from dust and dirt will ensure efficient operation.

CAUTION: Do not bend the fins while brushing the

front of the condenser.

Condenser

The condenser (located behind the back cover)

should be inspected every 30 days and cleaned, if

necessary. Failure to keep the condenser clean will

cause a loss in condenser unit efficiency.

Adjusting the temperature

The temperature control is inside the cabinet on

the right-hand side of the evaporator fan panel

assembly. You will need a screwdriver to turn the

adjusting screw. Make small adjustments until the

desired temperature is achieved.

■

Colder Temperatures:

Turn the adjusting screw clockwise (to the right).

■

Warmer Temperatures:

Turn the adjusting screw counterclockwise

(to the left).

In normal operation the condensing unit will run

approximately 16 hours per day. The condenser fan

motor turns off and on with the condensing unit.

The evaporator fan motor runs continuously. The

fan motors are lifetime lubricated and will require

no oiling.

NOTE:

Cabinet Temperatures lower than 34° will not allow

for proper defrosting of the evaporator coil. If

defrosting is necessary, turn the control knob to the

OFF position until coil is defrosted.

Form No. Z2091A

Rev. 08.03.04

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

4

Page 5

Replacement Parts – Single Door Back Bar Cooler

MODEL NOS. CS1DP

Item Description Part #’s

1 Compressor for R134a C22650

2 Condenser fan motor C15240A

3 Condenser fan motor bracket 61289-1

4 Condenser fan blade C6914

5 Condenser fan pan 62209-1

6 Rear panel 62433-1

7 Back panel partition 62131-1

8 Condenser assembly C18634A

9 Condenser panel 62132-1

10 Evaporator fan guard C25400A1

11 Evaporator fan blade - 51⁄2” C14649

12 Evaporator fan motor C15239A

13 Evaporator assembly - complete 62212B

14 Top assembly 62439

15 Temperature control parts kit 57360

16 Right hinged door assembly 64357SRBL

Left hinged door assembly 64357SLBL

17 Door hinge kit, right 63407R

Door hinge kit, left 63407L

18 Magnetic door gasket 62085-1

19 Door sill 60944-1

20 Door handle C31409-1

Parts Not Shown on Drawing

Light, mini-flourecent 57822A

Wiring harness 61346-1

Door lock with keys 57851

Drain line hose kit 57854

14

12

13

11

9

10

6

7

8

5

4

3

2

1

15

16

17

Form No. Z2091A

Rev. 08.03.04

20

19

18

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

5

Page 6

Wiring Diagram – Single Door Back Bar Cooler

EVAPORATOR FAN

POWER CONNECTION

OUTLET

BLACK

WHITE

GREEN

BLACK

WHITE

BLACK

WHITE

THERMOSTAT

BLACK

RED

CONDENSING UNIT

JUNCTION BLOCK

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

6

Form No. Z2091A

Rev. 08.03.04

Loading...

Loading...