Page 1

Installation

& Operation Manual

Wine Column Refrigeration

Commercial

Model CC24W Series

Model CC24D Series

Residential

Model CR24W Series

Model CR24D Series

Model CC24W-1-4R/CR24W-1-4R Shown

Form No. Z2487

Rev. 11.24.2020

Page 2

Wine Column Refrigeration Installation & Operation Manual

TABLE OF CONTENTS

General Information ................................................................................................................................. 2

Opening/Niche Dimensions ..................................................................................................................... 5

Placement and Alignment of Appliance ................................................................................................. 10

Anti-Tip Bracket ..................................................................................................................................... 11

Installing Door Overlay Panel ................................................................................................................ 13

Door Trim Installation............................................................................................................................. 16

Grill Installation ...................................................................................................................................... 17

Air Filter Installation ............................................................................................................................... 18

PerliQ Digital Control Operation ............................................................................................................ 19

Stainless Steel/Surface Care................................................................................................................. 22

Use and Care Information ..................................................................................................................... 23

Warranty ................................................................................................................................................ 25

GENERAL INFORMATION

Introduction

Congratulations on your purchase of a Perlick

commercial wine column refrigerator. This manual

has been prepared to assist you in the installation

of your column refrigerator and to acquaint you

with its operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer

can provide you with a list of qualied service

agents. For your own protection, never return

merchandise for credit without our approval.

We thank you for selecting a Perlick product

and assure you of our continuing interest in your

satisfaction.

Product Information

Additional product information, such as installation

instructions, Use and Care Guides, Spec Sheets,

CAD Drawings, Compliance Documentation and

product warranty information can be referenced

or downloaded at perlick.com.

Warranty Registration

To register your product, visit our web site at

www.perlick.com. Click on “Commercial”, then

“Resources”, then “Use and Care”, and then

“Warranty Registration Form”. You must complete

and submit this form or the installation date will

revert back to the ship date.

Please record the purchase date and the dealer’s

name, address and telephone number below.

Model Number: ________________________

Serial Number: _________________________

Purchase Date: _______________________

Dealer Name & Address

______________________________________

______________________________________

______________________________________

Phone Number__________________________

NOTE: See page 20 for full warranty details.

Product Identication Plate

Your product information can be found on the

product’s identication plate. The identication

plate is located on the sidewall behind the toe kick

plate. To access the identication plate, simply

remove the toe kick plate (grill). The identication

plate will be adhered to the right sidewall.

Printed in USA 2

Page 3

Wine Column Refrigeration Installation & Operation Manual

DANGER

WARNING

CAUTION

NOTICE

WARNING

CAUTION

CAUTION

SAFETY

PLEASE READ all instructions completely

before attempting to install or operate the unit.

Take particular note of the DANGER, WARNING

an CAUTION information in the manual. The

information is important for the safe and ecient

installation, operation and care of your Perlick unit.

Indicates a hazard that WILL

result in serious injury or

death if precautions are not followed.

IMPORTANT!

Read and understand all information in this manual before attempting the installation.

All electrical work must be performed by a qualied technician and

conform to all applicable state and local codes.

SITE PREPARATION

Indicates a hazard MAY

cause serious injury or

death if precautions are not followed.

Indicates a hazard where

minor injury or product

damage may occur if precautions are not

followed.

Indicates that property

damage may occur if

warnings or instructions are not followed.

Carefully inspect the cabinet

for hidden damage. If

damage is discovered, le your claim immediately

with the transportation company. Perlick is not

responsible for damage in transit.

When moving the unit, be

sure to protect finished

ooring with appropriate material to avoid

damage from moving the appliance.

If unit has been laid on its

back or sides, place unit

upright and allow minimum of 24 hours before

connecting the unit. Failure to do so can aect

the function and performance of the appliance.

This appliance should be installed in a dry,

ventilated indoor location. The ambient

temperature of the location must be between

55°F (13°C) and 100°F (43°C) for optimal

performance.

When fully stocked, Perlick wine column refrigeration is very heavy. To ensure safety and prevent home damage, the load-bearing capacity

of your oor must be 550 lbs for each CC24W

column being installed.

This product must be installed on a level oor

for safety and optimal performance. The base

must be at to ensure anti-tip brackets properly

function and that the refrigeration system is lev-

el. Any walls and surrounding furniture/xtures

need to be securely attached to the oor, wall

studs or concrete prior to installing the column.

To ensure proper performance, the air intake

(toe kick) must not be blocked. Perlick refrigeration is front-breathing, and covering the intake

will cause the system to overheat and fail.

3 Printed in USA

Page 4

Wine Column Refrigeration Installation & Operation Manual

WARNING

CAUTION

CAUTION

DANGER

DANGER

DANGER

DANGER

WARNING

84"

24"

NOTICE

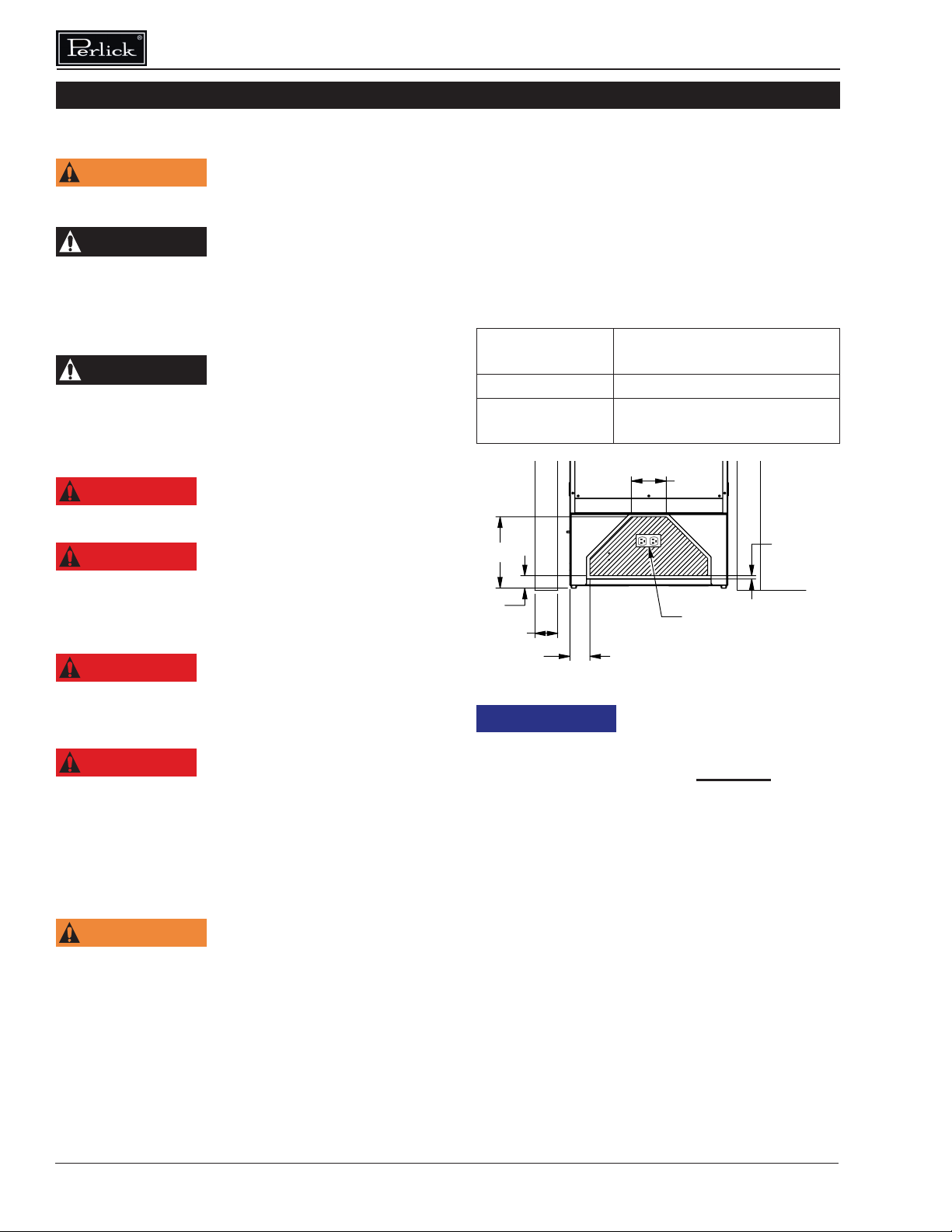

PRIOR TO INSTALLATION

Safety Precautions

Inspect the electrical cord

and plug for damage prior

to plugging the unit in.

If service is necessary,

repair work must be

performed by a Perlick authorized servicer.

Work done by unqualied individuals could

potentially be dangerous and will void the

warranty.

If unit has been laid on its

back or sides, place unit

upright and allow minimum of 24 hours before

connecting power. Failure to follow this

procedure may damage the compressor and

void the warranty.

Do not use or store

flammable liquids (ie;

gasoline) or vapors near the appliance.

Perlick columns are top

heavy. It is important that it

is secured at all times with the door closed

until installed. Install as directed using anti-tip

brackets provided to prevent tipping.

Take special care when

moving to prevent injury.

Installation must comply with all applicable

electrical codes. The electrical supply must be

located within the shaded area of the illustration

below. A separate circuit, servicing only this

appliance, is required. A ground fault circuit

interrupter (GFCI) is not recommended and may

cause interruption of operation. The outlet should

be placed in the hatched area dimensioned below.

Electrical Supply 115V, 60Hz., Phase 1, 3.3

amps

Service Dedicated 15 amp circuit

Power/Cord Type/

Length

NEMA 5-15P w/5’ power cord

5 1/4"

1/2"

3"

ELECTRICAL

4"

3"

OUTLET

LOCATION

Electrical

Serious electrocution

hazard. Electrical

grounding is required. This appliance is

equipped with a 3-prong (grounding) polarized

plug for your protection against possible

shock hazards. Failure to comply with these

electrical guidelines may result in possible

death or serious injury, re or loss of property.

Never use an extension

cord to connect the unit to

the electrical source. Do not use a two-prong

adapter or remove the power cord ground

prong.

This product contains

blown foam insulation

using blowing agent R-611 (Methyl Formate).

The foam in this product does not contain

HFC’s, CFC’s, or HCFC’s.

Printed in USA 4

Page 5

Wine Column Refrigeration Installation & Operation Manual

INSTALLATION

Installation Tools and Materials

• Screwdrivers (standard Phillips.)

• Power Drill

• Drill bits (masonry bits required for concrete

installation)

• Standard socket, wrench and 1/2” socket

• 2’ and 4’ levels

• Material to protect ooring and surrounding

cabinetry

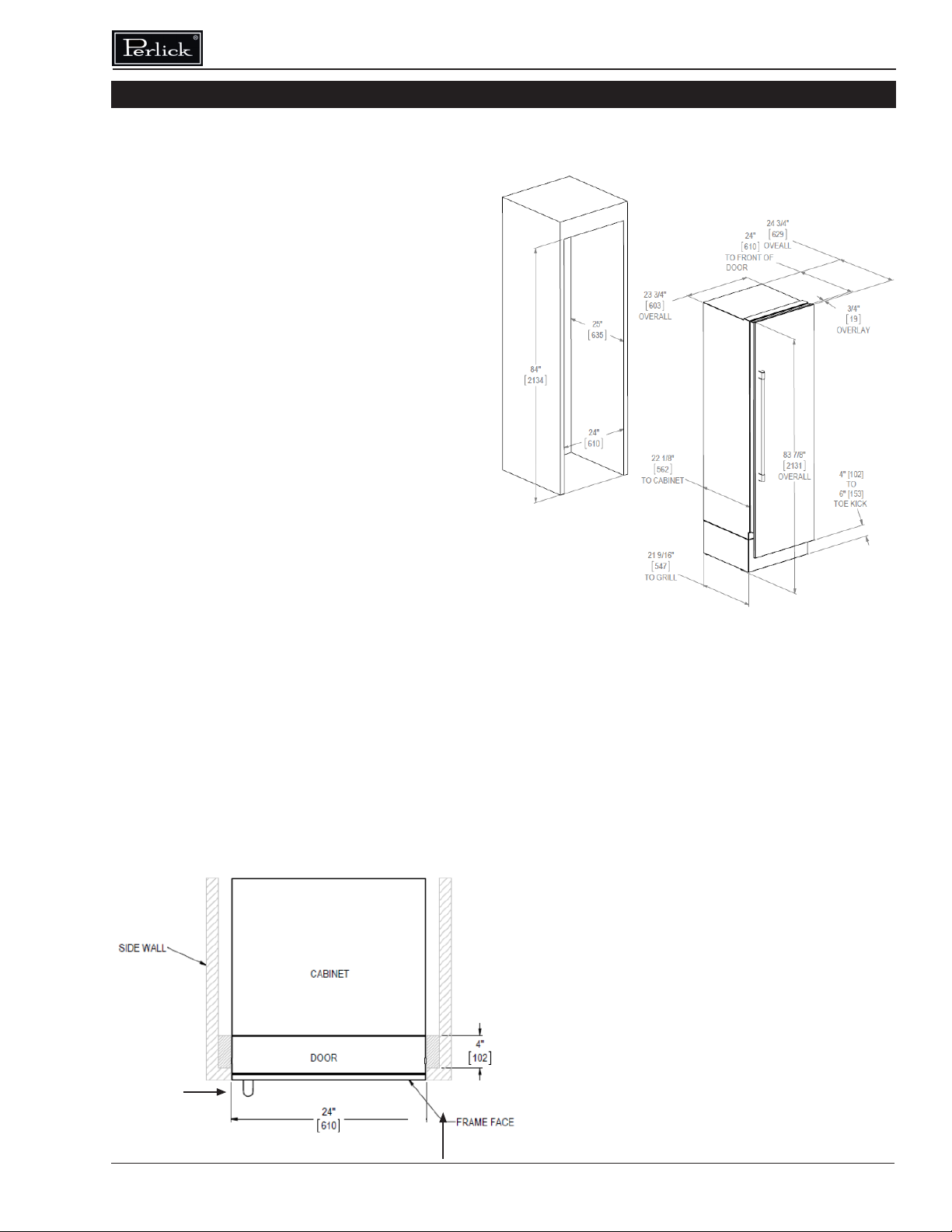

For Built-In Applications

Opening Dimensions

The depth of each Perlick column is 24” (610) to

door face (not including the 3/4” overlay). Allow for

door panel thickness when planning the nished

opening depth. A minimum of 4” (102) nished

return is required on all sides of the opening. See

below for opening dimensions drawing.

It is important that the side walls of the niche are

plumb prior to installation. The minimum thickness

of both the side walls and the top wall must be

5/8” (16). The minimum thickness of the toe kick

panel must be 1/2” (13). A thickness of 3/4” (19)

is recommended.

FACE

Framed cabinets will require additional filler

material behind the face frame for attaching antitip brackets. Refer to the illustration below.

FILLER MATERIAL

5 Printed in USA

Page 6

Wine Column Refrigeration Installation & Operation Manual

INSTALLATION CONTINUED

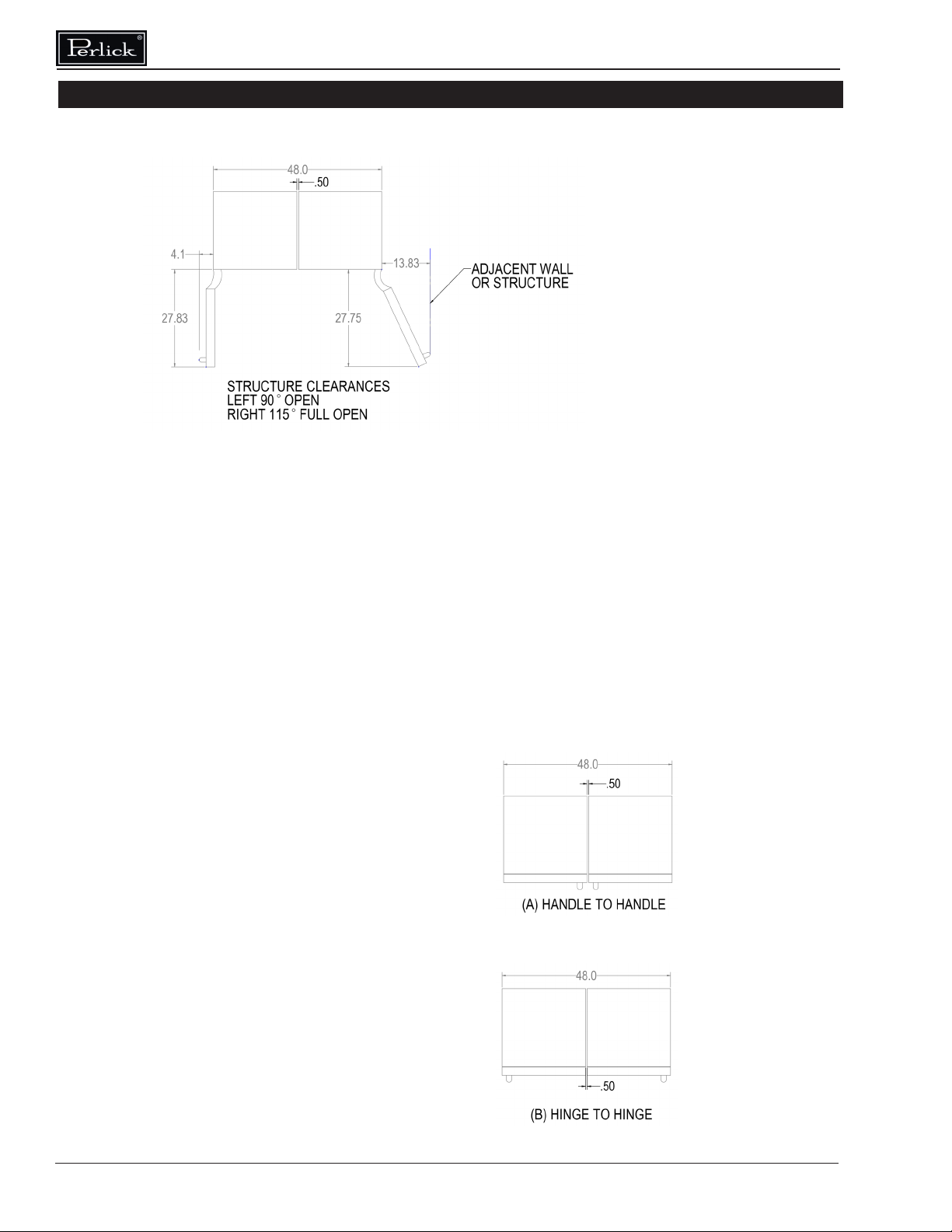

ADJACENT WALL OR STRUCTURE MINIMUM CLEARANCE REQUIREMENTS

WHEN BUILDING INTO STRUCTURE OR NEXT TO ADJACENT WALLS REFERENCE THIS

DRAWING FOR MINIMUM REQUIRED CLEARANCES TO AVOID INTERFERANCE WHEN OPENING

THE DOOR(S).

THE ADJACENT STRUCTURE CLEARANCES INDICATED ARE BASED ON A STANDARD PERLICK

HANDLE INSTALLED ON THE DOOR OVERLAY.

MINIMUM SPACING REQUIRED BETWEEN ADJACENT CABINETS TO AVOID DOOR

SWING INTERFERENCE.

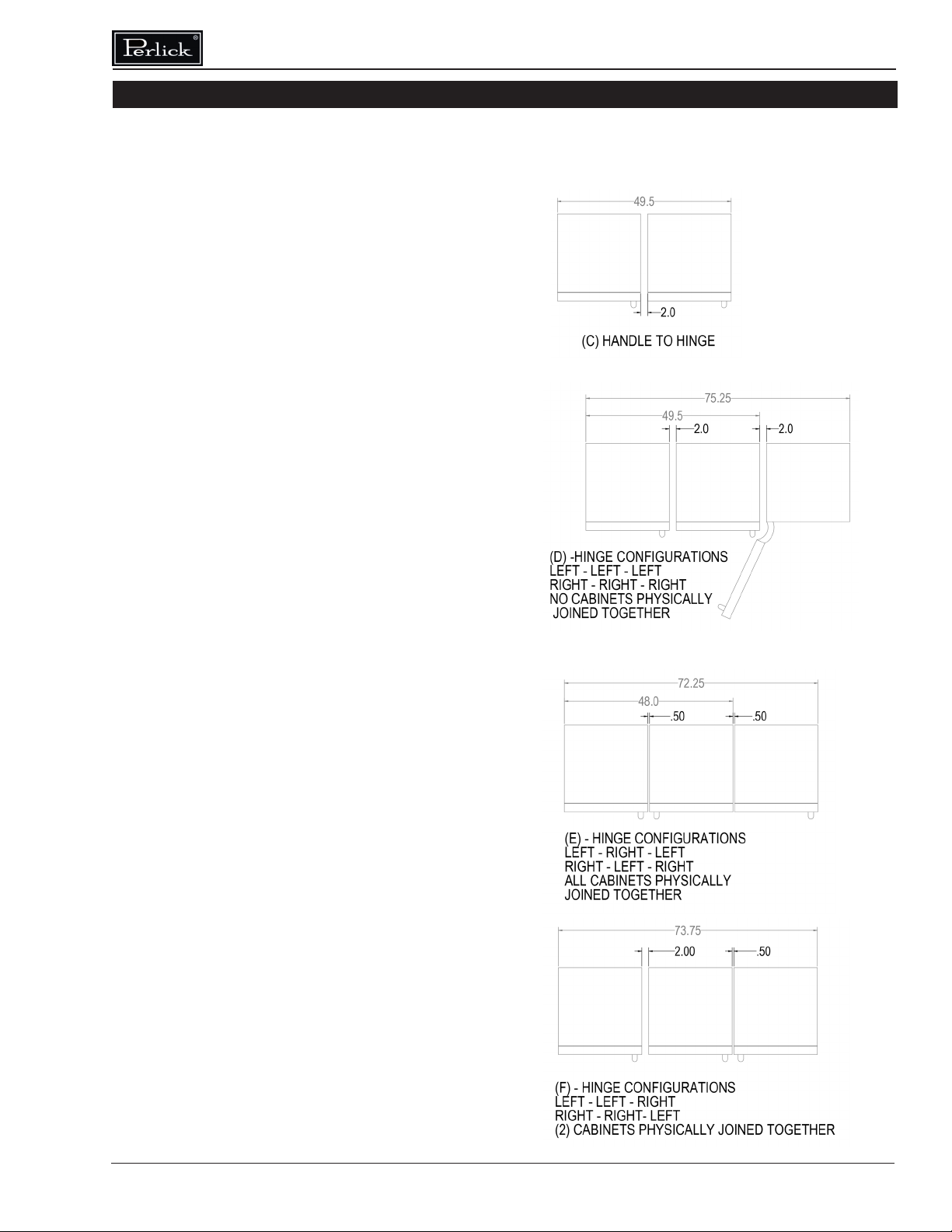

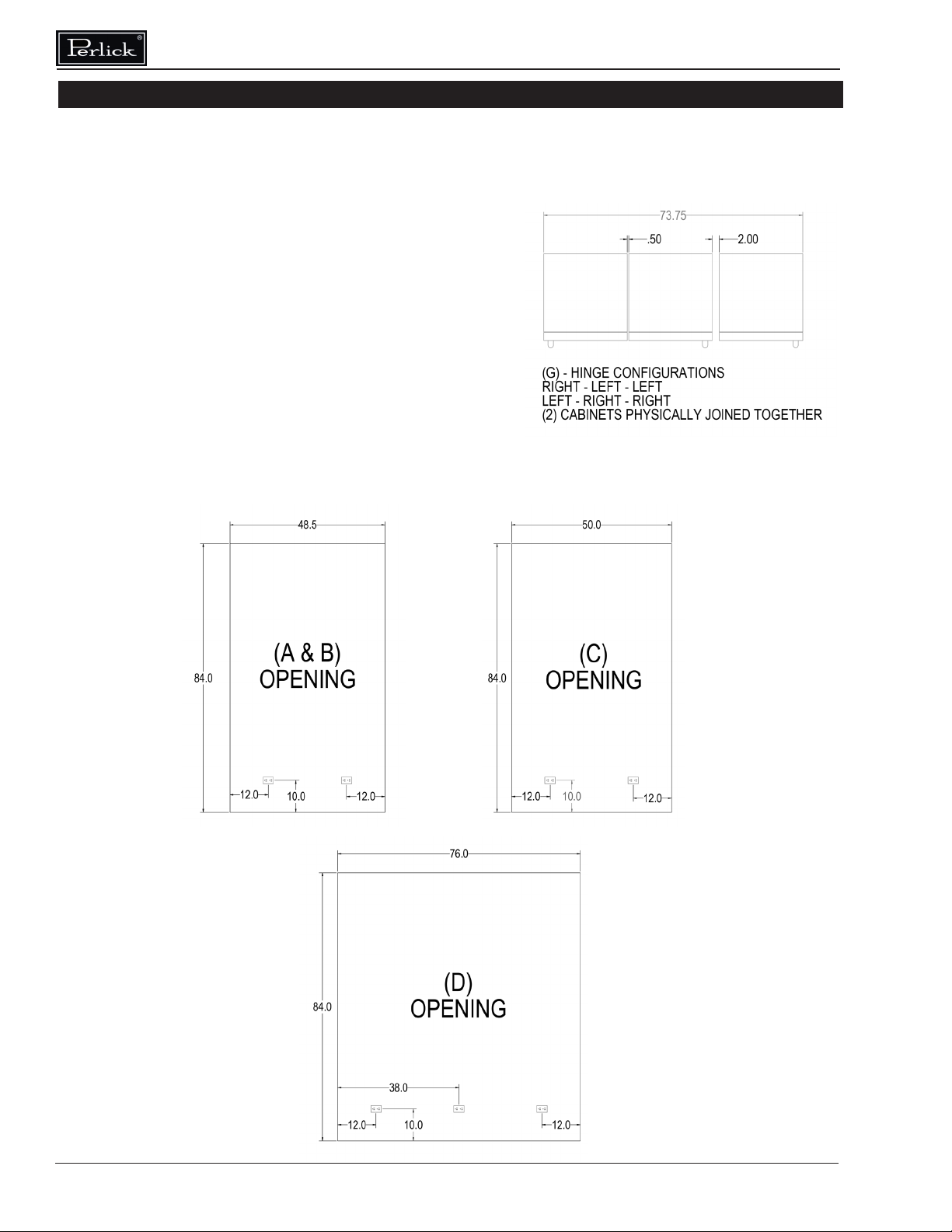

(A) 2 Cabinets HANDLE TO HANDLE.

Refer to (A&B) Opening diagram (page 8) for

nished opening dimensions and outlet locations.

(B) 2 Cabinets HINGE TO HINGE.

Refer to (A&B) Opening diagram (page 8) for

nished opening dimensions and outlet locations.

Printed in USA 6

Page 7

Wine Column Refrigeration Installation & Operation Manual

INSTALLATION CONTINUED

MINIMUM SPACING REQUIRED BETWEEN ADJACENT CABINETS TO AVOID DOOR

SWING INTERFERENCE CONTINUED.

Opening Dimensions

(C) 2 Cabinets HANDLE TO HINGE.

Refer to (C) Opening diagram (page 8) for

nished opening dimensions and outlet locations.

(D) 3 Cabinets with Hinges either all left or all

right.

Refer to (D) Opening diagram (page 8) for

nished opening dimensions and outlet locations.

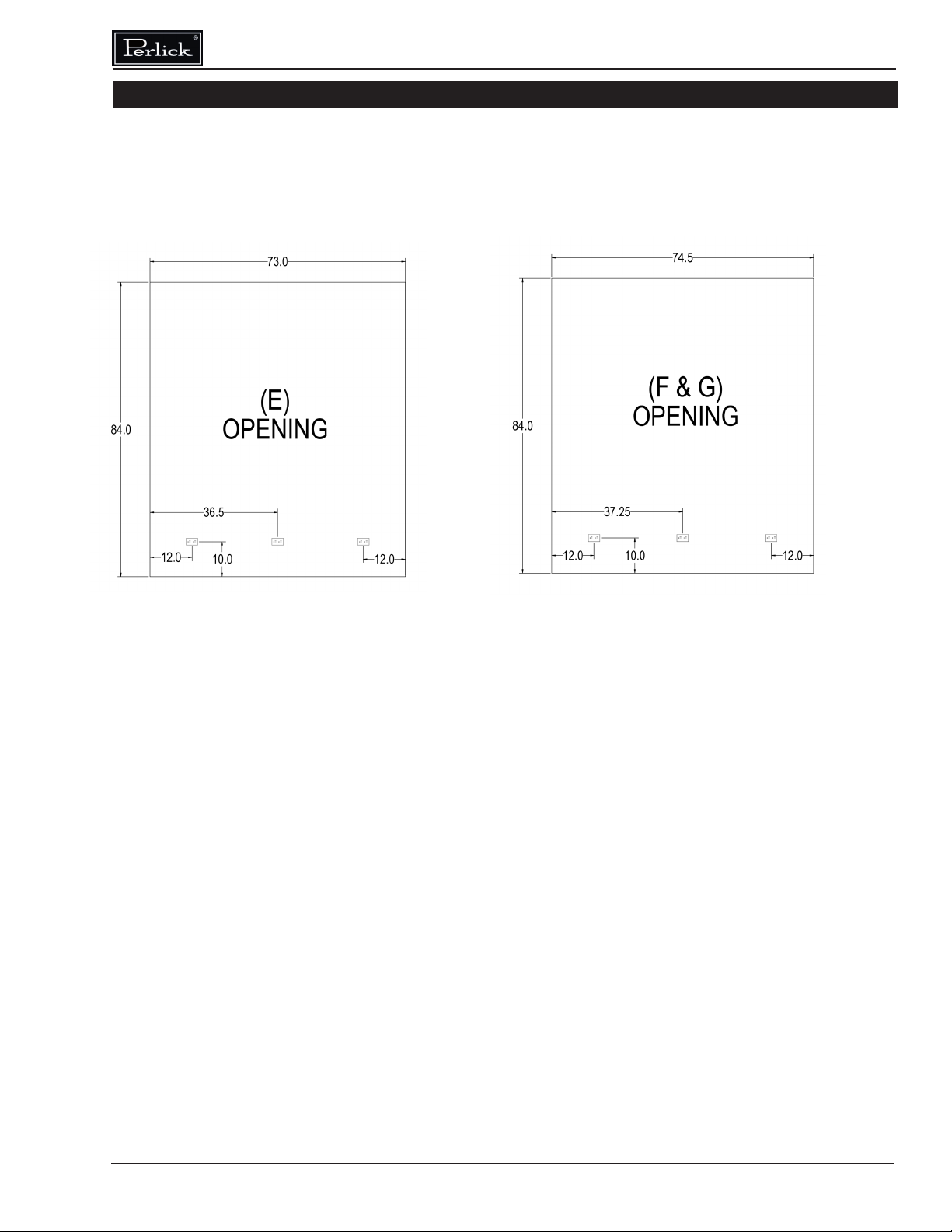

(E) 3 Cabinets with Hinges Left-Right-Left or

Right-Left-Right.

Refer to (E) Opening diagram (page 9) for

nished opening dimensions and outlet locations.

(F) 3 Cabinets with Hinges Left-Left-Right or

Right-Right-Left.

Refer to (F) Opening diagram (page 9) for

nished opening dimensions and outlet locations.

7 Printed in USA

Page 8

Wine Column Refrigeration Installation & Operation Manual

INSTALLATION CONTINUED

MINIMUM SPACING REQUIRED BETWEEN ADJACENT CABINETS TO AVOID DOOR

SWING INTERFERENCE CONTINUED.

(G) 3 Cabinets with Hinges Right-Left-Left or LeftRight-Right.

Refer to (G) Opening diagram (page 9) for nished

opening dimensions and outlet locations.

FINISHED OPENING DIMENSIONS FOR 2 AND 3 UNIT INSTALLATIONS.

Printed in USA 8

Page 9

Wine Column Refrigeration Installation & Operation Manual

INSTALLATION CONTINUED

FINISHED OPENING DIMENSIONS FOR 2 AND 3 UNIT INSTALLATIONS

CONTINUED.

Note:

For installations involving more than 3 cabinets, combine opening dimensions for the openings

which correspond to the combined Hinge and Handle congurations.

9 Printed in USA

Page 10

Wine Column Refrigeration Installation & Operation Manual

CAUTION

WARNING

CAUTION

WARNING

PLACEMENT & ALIGNMENT

Before moving the unit

into position, secure the

door closed and protect any nished ooring.

If the unit has been on its

back, it must stand upright

for a minimum of 24 hours before connecting

power.

Move the unit near the opening. Plug the power

cord into the grounded outlet and roll the unit into

position. Push unit into place.

Leveling

Front and rear leveling legs can be adjusted from

the front once the unit is positioned.

NOTE: Remove grill to access leveling adjustment

access holes.

Once the unit is in position, height adjustment

can be made from the front. Using the hex

driver leveling tool, turn clockwise to raise the

unit or counterclockwise to lower. Refer to the

illustration below.

When the unit is properly leveled, door adjustments

are less likely to be necessary.

Level the unit to the oor,

not surrounding cabinetry.

This could aect the operation of the unit,

such as door closing.

To reduce the possibility

of the unit tipping forward,

the front leveling legs must be in contact with

the oor.

Adjusting front leveling legs.

LEVELING THE UNIT

Adjusting rear leveling legs.

Printed in USA 10

Page 11

Wine Column Refrigeration Installation & Operation Manual

WARNING

CAUTION

ANTI-TIP BRACKET

The anti-tip bracket and supporting hardware

is included with your unit. In the case of dual

installation, each individual unit must be outtted

with the included anti-tip brackets.

For drawings of the anti-tip bracket installation on

integrated unit, see below. For drawings of the

anti-tip bracket installation on freestanding units,

see page 8.

necessary protective devices or apparel when

installing or working with anchors. Anchors

are not recommended for use in lightweight

masonry material such as block or brick, or

for use in new concrete which has not had

sucient time to cure. The use of core drills

is not recommended to drill holes for anchors.

Always wear safety

glasses and use other

Verify there are no

electrical wires or

plumbing in the area which the screws could

penetrate.

Anti-Tip Bracket Installation for Built-In Applications

NOTE: Do not fasten anti-tip brackets to adjacent cabinetry until the cabinet has been leveled.

OUTER FRAME

ANTI-TIP

OUTER FRAME

BRACKETS

ANTI-TIP BRACKETS

INSTALLATION WITH OUTER FRAME

ANTI-TIP BRACKETS

SIDE

ANTI-TIP BRACKETS

INSTALLATION WITH CABINET WALLS

ANTI-TIP

BRACKETS

OUTER FRAME

ANTI-TIP BRACKETS

INSTALLATION WITH OUTER FRAME

DOOR NOT SHOWN

DETAIL P

SCALE 1 : 6

OUTER FRAME

ANTI-TIP

BRACKETS

11 Printed in USA

Page 12

Wine Column Refrigeration Installation & Operation Manual

Anti-Tip Application for Freestanding Applications

NOTE: Cabinet must be leveled before securing to wall

with anti-tip bracket.

Printed in USA 12

Page 13

Wine Column Refrigeration Installation & Operation Manual

CAUTION

1

REV.

DESCRIPTION

DATE

APPROVED

REVISIONS

F

REVISED MTG HOLE LOCATIONS AND COND. AIRFLOW

DIVIDER MTG HOLES

11/8/2017

JMP

E

UPDATED CLIP MTG HOLE LOCATIONS

10/6/2017

JMP

D

REVISED WINDOW SIZE BY INCREASE CUTOUT WIDTH AND

HEIGHT BY 1-1/4" OVERALL

10/5/2017

JMP

C

ADDED HOLES FOR CONDENSER AIR DIVIDER

10/3/2017

JMP

B

UPDATED HOLE PATTERN FOR ADJUSTMENT BRKT

8/25/2017

JMP

A

INITIAL RELEASE

11/8/2016

TEC

2

B

C

1

3

11/28/2016

11/08/2017

JMP

JMP

DIMENSIONS ARE IN INCHES TOLERANCES:

THIS DOCUMENT / PUBLICATION / SOFTWARE / DRAWING CONTAINS PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF THE PERLICK CORPORATION. IT MAY NOT BE REPRODUCED OR TRANSMITTED IN ANY

FORM, ELECTRONIC OR MECHANICAL, INCLUDING PHOTOCOPYING, RECORDING, OR USED IN ANY INFORMATION STORAGE, TRANSMISSION, OR RETRIEVAL SYSTEM, WITHOUT WRITTEN PERMISSION FROM THE PERLICK

CORPORATION. COPYRIGHT 2015 PERLICK CORPORATION. ALL RIGHTS RESERVED.

DRAWN BY:

APPROVED BY:

.0135 THRU

.125:

.004

.1260 THRU

.250:

.005

.2510 THRU

.500:

.006

.5010 THRU

.750:

.008

.7510 THRU

1.000:

.010

1.001 & UP:

.012

BREAK SHARP EDGES - .015 X 45°

RADIUS SHARP FILLETS - .015 TO .031

UNLESS OTHERWISE SPECIFIED:

DATE

SIGNATURES

Milwaukee, Wisconsin

Perlick Corporation

DWG NO.

REFERENCE:

PART NO.

PURCHASE REC.:

TITLE:

1007917

1007917

FOR COLUMN WINE

OVERLAY, WOOD, 4'' TOE KICK

SCALE = 1:10

SHEET 1 OF 4

A

INSTALLING DOOR OVERLAY PANELS

Typical panel dimensions are based on 84”

(2134) nished height with 1/8” (3) reveals.

Template must be adjusted for panels exceed-

ing typical dimensions.

Place the panel face down on a protected work

surface. Attach six clips to the back of overlay in

locations indicated in wood overlay drawing.

Use provided #10 x 1/2” screws to attach clips

to overlay. Overlay then slides onto door face.

Attach overlay to door adjustment brackets using remaining #10 x 1/2” screws. Once mounted, adjust overlay to match adjacent cabinetry.

As the reveal between

cabinets and the unit

decreases, the potential exists for severe

nger pinching if ngers are placed in the

opening when door is closing.

16

"

8

3

14

"

8

3

9

"

1

2

"

4

1

12

"

2

1

36

"

2

1

60

"

2

7

79

"

8

3

6

"

4

11

1

"

16

2

8

3

5

1

"

7

"

4

8

A

3

"

8

3

"

8

3

"

8

3

3

"

8

7

11

"

8

1

" TYP

16

5

19

" TYP

8

3

23

"

4

.136

.136

6

CUTOUT

17" CUTOUT

.500 (4X)

3

4

FOR LOCK OPTIONAL

USE DRILL FIXTURE TO

LOCATE HOLE

5

"

8

60"

.500 (2X)

"

4” Toe Kick Wood Overlay Template Glass Door

3

"

4

OVERLAY CLIP MTG HOLES

DETAIL A

SCALE 1 : 2

MATERIAL:

WOOD

QTY.:

-

FINISH:

1

"

1/2" (6X)

8

3

"

1/2" (6X)

16

HOLES:

13 Printed in USA

Page 14

Wine Column Refrigeration Installation & Operation Manual

CAUTION

CAUTION

INSTALLING DOOR OVERLAY PANELS CONTINUED

Custom Overlay Panels

A custom door panel and handle hardware must

be installed. The thickness of the custom panel

can vary. A minimum 5/8” (16) thick panel is

required, but the thickness can be increased

provided it does not exceed the maximum panel

weight of 65 lbs (29). 3/4” panel is recommended.

Please note that the combined door and overlay

weight cannot exceed 120 lbs (54). The depth of

each model is 24” (610). Allow for panel thickness

when planning the finished opening depth.

Templates for solid and glass door models can

be found on page 9.

As reveals between

cabinetry and the unit

decrease, severe nger pinching can occur

while the door is closing.

The height of the custom door panel can extend

beyond the typical panel height provided it does

not exceed the weight limit listed above.

Do not install a solid

overlay panel onto the

front of a glass door model. Condensation will

form between the glass and the overlay panel,

which will cause damage to custom cabinetry.

Side Panels

Custom panels can be built to customer

specications to match surrounding

cabinetry.

Printed in USA 14

Page 15

Wine Column Refrigeration Installation & Operation Manual

OVERLAY WITH FASTENERS

OVERLAY

DOOR

BRACKET, BOTTOM, OVERLAY

DETAIL G

SCALE 1 : 5

DOOR OVERLAY PANEL ADJUSTMENT

Close the door to make adjustments to align

panels and reveals.

For up-and-down adjustments, turn the height

adjustment screws in the top bracket in and out.

Adjust the screws as needed to achieve an even

reveal on each side of the door overlay.

Once nal adjustments are made to the position

of the door overlay, secure the overlay inplace by

installing the bottom overlay bracket as shown in

BOTTOM OF DOOR illustration below.

HEIGHT ADJUSTMENT

COUNTER CLOCKWISE - UP

CLOCKWISE - DOWN

USE #4 ALLEN KEY

Top Of Door

DETAIL H

SCALE 1 : 6

Bottom Of Door

DOOR

BRACKET, BOTTOM, OVERLAY

*INSTALL BRACKET BOTTOM

OVERLAY TO DOOR AND

OVERLAY

15 Printed in USA

Page 16

Wine Column Refrigeration Installation & Operation Manual

DOOR TRIM

DOOR TRIM INSTALLATION

Once overlay is adjusted, mount the door trim

bracket onto the door adjustment bracket using

the provided screws.

DOOR TRIM

DETAIL J

SCALE 1 : 6

DOOR TRIM

ON

DOOR PANEL

GASKET

FRAME 2

OVERLAY

TEMPATE

CONDENSOR

DIVIDER PANEL

FRAME 1

INSTALLATION STEPS

DOOR TRIM

ON

DOOR PANEL

3.

Printed in USA 16

INSTALL FRAME 1 TO OVERLAY.1.

INSTALL GASKET ONTO FRAME 2.2.

MOUNT FRAME 2 ONTO FRAME 1.

DETAIL K

SCALE 1 : 4

Page 17

Wine Column Refrigeration Installation & Operation Manual

COMPLETION - GRILL INSTALLATION

Install the grill by snapping into latch catches.

GRILL

TOE KICK CLEARANCE

17 Printed in USA

Page 18

Wine Column Refrigeration Installation & Operation Manual

CARBON AIR FILTER (BETA UNITS)

The carbon air filters should be placed on the perforated panel located in the

top-rear of the cabinet.

1. Remove the filter from the plastic bag before installing into the unit. Do not

open or puncture the tyvek bag.

2. To lower the carbon air filter panel, turn the finger screw 1/4 turn.

3. Place the carbon air filter directly onto the panel and fasten securely to the top

with the finger screw.

Note: Wine models require top wine racks to be removed to access panel.

INSTALLING AIR FILTERS

Carbon Air Filter

The carbon air lters should be placed on the

perforated panel located in the top-rear of the

cabinet.

NOTE: The top wine rack will need to be removed

to access the lter.

1. Remove the lter from the plastic bag

before installing into the unit. Do not open or

puncture the tyvek bag.

2. To lower the carbon air lter panel, pull rmly.

3. Place the carbon air lter directly onto

the panel and close panel - push rmly to

engage closure clips.

4. It is recommended that the carbon lter be

replaced every 6 months.

A

CARBON AIR FILTER PANEL

DETAIL A

SCALE 1 : 4

Printed in USA 18

Page 19

Wine Column Refrigeration Installation & Operation Manual

WINE COLUMN DIGITAL CONTROL OPERATION

WINE COLUMN DIGITAL CONTROL OPERATION

The following instructions are for the PerlIQ™ digital

controller in Perlick column wine reserves (models

CC24W and CC24D).

2 3 4 5 6 7 109 12 14 151

1 Wake Button

2 Temperature zone selection (Dual-zone models)

3 White wine temperature setting

4 Red wine temperature setting

5 Cellar temperature setting

6 Temperature adjustment (up and down in 1°

increments)

7 Temperature readout

8 Light adjustment (door open)

9 Light adjustment (door closed)

10 Light intensity adjustment

11 Fahrenheit temperature mode

12 Celsius temperature mode

13 Sabbath mode

14 QuickCool mode

8

Using the Wine Column Control

Upon door opening, the Wake button (1) outline will

illuminate. Once activated, the temperature zone

selection (2), temperature adjustment (6), temperature

readout (7) and settings (15) menu icons will illuminate.

Selecting a Temperature Zone

Perlick’s PerlIQ™ digital controller is preset with

recommended temperature settings for white wine, red

wine and cellaring. Within the presets, you have the

ability to adjust the temperature in 1° increments as you

desire. Because single zone models (CC24W) are one

temperature throughout, there is no zone selection. On

dual zone models (CC24D), press the temperature zone

selection (2) icon to toggle through the zones until desired

zone is illuminated. Single zone models come factory set

to 50°F. Dual zone models come factory set to 60°F in the

top zone and 50°F in the bottom zone.

11 13

15 Settings menu

Top Zone

Bottom Zone

NOTE: Dual Zone Wine Upper compartment temperature

setpoint must always be set at or above the lower

compartment setpoint.

19 Printed in USA

Page 20

Wine Column Refrigeration Installation & Operation Manual

Storing White Wine

Perlick wine columns are preset with expert-

recommended temperature settings for white wine. To

set a zone in dual zone models to this preset, touch the

temperature zone selection icon (2) to illuminate the

zone you’d like to set to white wine temperature, then

choose the white wine temperature setting icon (3) to set.

For single zone models, simply choose the white wine

temperature setting icon (3).

Compartment Sp. Factory Setting Temperature

Range

Any 50°F 40°F - 68°F

To adjust the temperature up

or down, press the temperature

adjustment (6) arrows until desired

temperature is reected in the

temperature readout (7). Double

beep indicates that minimum or

maximum temperature has been

reached. Temperature will ash

twice to indicate new setting.

Cellaring Wine

Perlick wine columns are preset with expert-

recommended temperature settings for cellaring (longterm storage) wine. By choosing the cellar mode, the

entire cabinet will default to 55°F for long-term storage.

For dual zone models, touch the temperature zone

selection icon (2) to illuminate, then choose the Cellar

temperature setting icon (5) to set. For single zone

models, simply choose the Cellar temperature icon (5).

Compartment Sp. Factory Setting Temperature

Range

Any 55°F 40°F - 68°F

To adjust the temperature up

or down, press the temperature

adjustment (6) arrows until desired

temperature is reected in the

temperature readout (7). Double

beep indicates that minimum or

maximum temperature has been

reached. Temperature will ash

twice to indicate new setting.

Storing Red Wine

Perlick wine columns are preset with expert-

recommended temperature settings for red wine. To

set a zone in dual zone models to this preset, touch the

temperature zone selection icon (2) to illuminate the zone

you’d like to set to red wine temperature, then choose the

red wine temperature setting icon (4) to set. For single

zone models, simply choose the red wine temperature

setting icon (4).

Compartment Sp. Factory Setting Temperature

Range

Any 60°F 40°F - 68°F

To adjust the temperature up

or down, press the temperature

adjustment (6) arrows until desired

temperature is reected in the

temperature readout (7). Double

beep indicates that minimum or

maximum temperature has been

reached. Temperature will ash

twice to indicate new setting.

Column Theatre Lighting

Perlick column wine reserves feature an impressive

amount of lighting for clear viewing and display of wine

bottles. Main lighting, which can be changed from white

to blue, runs vertically down the wall, and display lighting

runs horizontally across the ceiling of the unit. Dual zone

models also have display lighting on ceiling of the lower

zone.

Wine models are factory set

to white lighting. To adjust the

brightness of the lighting when the

door is opened, press the up and

down arrows in the light intensity

adjustment icon (4). To change to

blue lighting, continue pressing

the arrows until the control turns

blue in color. To return to white

lighting, continue pressing the

arrows until controls illuminate

white. Icons will ash twice to

conrm color setting.

Printed in USA 20

Page 21

Wine Column Refrigeration Installation & Operation Manual

Changing from Fahrenheit to Celsius scale

The controller is factory set to Fahrenheit scale, but can

easily be changed to read Celsius in the settings menu.

Press the settings menu (15) icon

on the far right. This will illuminate

a cluster of four icons as shown to

the left. To display temperatures in

Celsius, press the Celsius readout

icon (12).

Change will be reected in the

temperature readout (7). The C

will be illuminated to signify the

scale.

Sabbath Mode

All Perlick column refrigeration models have Sabbath

mode capabilities. This allows the user to interact with the

unit without changing the amount of energy it is using. In

this mode, the interior lighting is turned o until user turns

o Sabbath mode.

Press the settings menu (15) icon

on the far right. This will illuminate

a cluster of four icons as shown

to the left. To activate Sabbath

mode, press the Sabbath mode

icon (13).

Quick Cool (Shopping) Mode

The wine column can be set to Quick Cool (shopping)

mode to lower the temperature after loading a large

quantity of product to quickly bring them to the preferred

temperature.

Press the settings menu (15) icon

on the far right. This will illuminate

a cluster of four icons as shown

to the left. To activate Quick Cool

(shopping) mode, press the Quick

Cool (14) icon. This will activate

the mode and the Quick Cool (14)

will remain illuminated until the set

point is achieved.

Showroom Mode

Select Showroom mode for units that are being used

solely for display purposes. Showroom mode has the

user interface fully functional along with the cabinet lights,

however, the refrigeration unit will be shut down.

Press the settings menu (15) icon

on the far left. This will illuminate

a cluster of four icons as shown

to the right. To activate Showroom

mode, press the Sabbath mode

icon (13) and Quick Cool mode

icon (14) simultaneously.

Please note that, when in Sabbath

mode, the Sabbath mode (13)

icon will be the only icon that will

be illuminated (continuously) until

user presses the Sabbath mode

icon to turn the mode o.

21 Printed in USA

Page 22

Wine Column Refrigeration Installation & Operation Manual

STAINLESS STEEL CARE AND CLEANING

Perlick’s stainless steel surfaces are food grade, 304

stainless steel. Stainless steel is a “passive” metal

because it contains other metals like Chromium, Nickel

and Manganese that stablize the atoms. Chromium

provides an invisible lm that covers the steel surface,

acting as a shield agent against corrosion. As long as the

lm is intact and not contaminated, the metal is passive

and stainless. If the passive lm of stainless steel has

been broken, the surface can start to corrode or rust.

Three materials or processes can break down stainless

steel’s passive layer, allowing corrosion to occur.

▪ Mechanical Abrasion This refers to items that will

scratch stainless steel surfaces. Steed pads, wire

brushes and scrapers are prime examples.

▪ Water Water that comes out of the faucet in varying

degrees of hardness. Hard water may leave spots.

When allowed to sit, these deposits will break down

the passive Chromium layer and rust stainless

steel. Other deposits from food preparation must be

promptly removed with an appropriate cleaning agent.

▪ Chlorides Chlorides are found everywhere. They are

in water, food and table salt. Household and industrial

cleaners are the worst oenders.

stainless steel and cause pitting and/or rusting. Clean

frequently to avoid build-up of hard, stubborn stains.

Stainless Steel Exterior Door Cleaning

Keep exterior stainless steel surface pristine by wiping

the door with a damp microber cloth, followed by a dry

polishing chamois. Always follow the grain direction when

cleaning.

BLACK METALLIC SURFACE CARE AND CLEANING

Perlick’s black metallic surface is nished with powder coat.

When properly cared for, powder coating provides a durable,

uniform nish that is resistant to scung, scratching or staining.

The following surfaces are black metallic:

▪ Wine Models Wine Shelf Fronts

To clean the black metallic surface:

1. Carefully remove any loose debris with a damp

sponge.

2. Use a soft cloth and a mild household detergent

solution to remove deposits.

Preventing Stainless Steel Rust

Use non-abrasive tools to clean stainless steel surfaces.

Soft cloths and plastic scouring pads will not harm the

steel’s passive layer.

Clean with polish lines. Some stainless steels have visible

polishing lines or “grain”. When visible lines are present,

always scrub in a motion parallel to the lines. When the

grain cannot be seen, polish in a consistent straight

pattern - not in a circular motion.

Use alkaline, alkaline chlorinated or non-chloride

containing cleaners. While many traditional cleaners are

loaded with chlorides, the industry is providing an everincreasing choice of non-chloride cleaners. If you are not

sure of chloride content in the cleaner being used, contact

your cleaner supplier. If you present cleaner contains

chloride, ask your supplier for an alternative. Avoid

cleaners containing quaternary salt; it also can attack

3. Wipe area with soft cloth and clean water. Dry

thoroughly.

Printed in USA 22

Page 23

Wine Column Refrigeration Installation & Operation Manual

PILASTER

FIXED SLIDER WITH BRACKET

DETAIL N

2

C

1

3

2

B

C

1

SHELF

MOVABLE SLIDER

PILASTER

3. ALIGN FIXED SLIDER WITH MOVING

SLIDER BOTH SIDES, INSERT THE

SLIDER WITH SHELF AND SLIDE IN

FIXED SLIDER WITH BRACKET

INSTALLED SHELFS

INSTALL BOTH LH AND RH SLIDING

2

B

C

1

3

INSTALLED SHELFS

2

B

C

1

WINE STORAGE

Wine Shelving

▪ Prior to making shelf adjustments, clear the shelf of

product. Shelf must be empty prior to changing its

position.

To Remove Wine Shelves

PILASTER

FIXED SLIDER WITH BRACKET

SHELF

1. PULL OPEN THE SHELF

2 PULL OPEN THE SLIDER LEVER

3. REMOVE THE SHELF FROM SLIDER

MOVABLE SLIDER

PILASTER

To Install Wine Shelves

PILASTER

FIXED SLIDER WITH BRACKET

DETAIL N

SCALE 1 : 2

INSTALL SLIDING MOUNTING

1.

BRACKET INTO PILASTER SLOTS.

2.

BRACKETS.

FIXED SLIDER WITH BRACKET

SHELF

DETAIL N

SCALE 1 : 2

4. PULL UP THE SLIDER MOUNTING BRACKET

FROM THE PILASTER SLOTS

5.REMOVE LH AND RH SLIDER BRACKETS.

23 Printed in USA

3. ALIGN FIXED SLIDER WITH MOVING

SLIDER BOTH SIDES, INSERT THE

SLIDER WITH SHELF AND SLIDE IN

MOVABLE SLIDER

PILASTER

Page 24

Wine Column Refrigeration Installation & Operation Manual

CARBON AIR FILTER (BETA UNITS)

The carbon air filters should be placed on the perforated panel located in the

top-rear of the cabinet.

1. Remove the filter from the plastic bag before installing into the unit. Do not

open or puncture the tyvek bag.

2. To lower the carbon air filter panel, turn the finger screw 1/4 turn.

3. Place the carbon air filter directly onto the panel and fasten securely to the top

with the finger screw.

Note: Wine models require top wine racks to be removed to access panel.

AIR FILTRATION SYSTEM

We recommended changing the air lters every 6 months

for optimum performance. Filters can be purchased

through your local authorized Perlick dealer.

Carbon Air Filter

The Carbon air lter removes odor, bacteria and mold

spores from the air.

To remove the Carbon air lter in CC24W and CC24D

Wine units, refer to page 14 - carbon air lter.

A

CARBON AIR FILTER PANEL

DETAIL A

SCALE 1 : 4

Printed in USA 24

Page 25

Wine Column Refrigeration Installation & Operation Manual

WARRANTY

The terms and conditions set forth below

together with those appearing on the face of

the Acknowledgement (the “Order”) constitute

the complete and exclusive agreement between

Perlick Corporation and the Buyer pertaining to

the goods and/or services identied in the Order.

If there is a discrepancy or conict between any

exhibit or supplement to the Order and these

terms and conditions, these terms and conditions

shall control. The Order is intended by Seller and

Buyer to be the complete, exclusive, and nal

statement of their agreement. Any changes to an

Order must be in writing and signed by Perlick

and Buyer.

TERMS NET 30 DAYS

Payment by Visa, MasterCard, American Express

or Discover card accepted or cash in advance

unless prior accommodations have been made

with our Credit Department. Please direct inquiries

for detailed information to our Credit Manager.

All sales, excise, or similar taxes required by

law to be collected or paid by seller shall be in

addition to prices quoted unless an appropriate

Tax Exemption certicate is furnished. All goods

are sold F.O.B. factory. Except for otherwise

provided, Perlick will not be responsible for freight,

transportation, insurance, shipping, storage,

handling, demurrage or similar charges. Invoices

are payable in full in thirty (30) days following

the invoice‚s date of issuance. If by the terms

of sale credit is extended, Perlick reserves the

right to revoke such credit if buyer fails to pay

for any products when due and may demand

payment prior to the commencement of any

further shipment.

WAIVER

Any waiver of strict compliance with the provisions

of an Order must be in writing. No such waiver

shall be construed as a waiver of any other term

or condition except as provided in writing, nor as

a waiver of any subsequent breach of the same

term or condition.

METHOD OF SHIPMENT

All shipments are carefully packed and labeled.

Crates, boxes and cartons used are of approved

weight and strength. Freight rates are based upon

100 pound minimum.

LOST and DAMAGED MERCHANDISE

THE RESPONSIBILITY OF THE PERLICK

CORPORATION CEASES UPON ACCEPTANCE

OF ITS PRODUCTS BY THE CARRIER. Any

damage or loss sustained in shipment is the

carrier’s responsibility. Before giving the carrier

a clean receipt at time of delivery, make sure you

receive every item on the bill and inspect every

carton, crate and box for concealed damage,

i.e., broken boards, crushed or punctured

cartons, torn cardboard. IF ANY ITEMS ARE

SHORT OR DAMAGED, DO NOT ACCEPT THE

SHIPMENT UNLESS THE CARRIER MAKES A

NOTATION OF THIS ON YOUR FREIGHT BILL.

Then request an inspection. Do not destroy the

packing materials. If their agent does not make

an inspection within ve days, advise the carrier

via letter that you notied them regarding the

matter and they have failed to act. You will need

this letter to support your claim. Then le a claim

for your loss. When you give the carrier a clean

receipt, you accept the total responsibility for the

shipment. UPS shipments are insured individually

and UPS will replace all merchandise that is lost

or damaged.

RETURN OF MERCHANDISE

Do not return any merchandise without our

approval. Merchandise returned without a return

merchandise authorization number will not be

accepted at Perlick. Used, discontinued, and

certain custom made items cannot be returned for

credit. These custom items include non-catalog

products (specials) as well as custom assembled

catalog products. Catalog items are designated

as non-returnable on the price list page on which

they appear. Items returned must be in new

condition and packaged in their original carton

or crate. Freight charges must be prepaid on all

return shipments.

25 Printed in USA

Page 26

Wine Column Refrigeration Installation & Operation Manual

When a return is authorized, a credit may be

allowed pending an examination of the returned

goods. The amount of the restocking charge will

depend on the condition of the equipment. The

minimum restocking charge for glass washers,

bottle coolers, frosters, direct draws, cooler

series back bars and accessory parts is 20%.

The minimum restocking charge for custom

series cabinets is 50%. The minimum restocking

charge for un-assembled, freestanding underbar

stainless steel modules is 20%. Assembled under

bar modules are considered custom products

and are not returnable for credit. The restocking

charge on the item returned is either a percentage

of the value of the item or $35.00, whichever is

greater.

ONE YEAR PARTS WARRANTY

Perlick products are guaranteed against defects

in both material and workmanship for a period of

one year from date of sale. Defective parts will be

replaced on a no-charge basis, F.O.B. our factory,

when adjudged defective upon inspection. We are

not responsible for parts damaged by alteration,

unauthorized service, accident or abuse. All costs

associated with replacement, including freight,

labor and/or loss of sales, are the responsibility

of the user..

ONE YEAR LABOR WARRANTY

In addition to Perlick’s one year parts warranty

and ve year compressor warranty, ALL PERLICK

REFRIGERATION SYSTEMS are oered with

a one year labor warranty at no extra charge.

Perlick’s one year labor warranty provides

that Perlick will pay for the cost of any labor to

replace any defective part for up to one year

after installation, subject to the following terms

and conditions:

(A) Parts returned to Perlick shall be returned

freight prepaid and shall be identied with

Perlick’s serial number and return authorization

number.

(B) Improper operation due to voltage variances,

inadequate wiring and physical damage is the

responsibility of the purchaser. They are not

manufacturing defects.

(C) Condenser coils shall be cleaned regularly.

Failure to provide an adequate ow of cooling

air will void this warranty.

(D) Factory-specied maintenance and installation

will be provided by the selling dealer who shall

also be responsible for the installation and setup of these products in accordance with local

plumbing, refrigeration and electrical codes.

Perlick’s one year labor policy applies to the

United States and Canada. IT DOES NOT

APPLY TO REFRIGERATION SYSTEMS

ADDED BY OTHERS (remote systems) or any

part which has been subject to misuse, neglect,

alteration, accident, or to any damage caused

by transportation, ood, re or other acts of God.

Printed in USA 26

Page 27

Wine Column Refrigeration Installation & Operation Manual

27 Printed in USA

Page 28

8300 West Good Hope Road • Milwaukee, WI 53223 •

Toll Free 800.558.5592 • Fax 414.353.7069 • www.perlick.com

Form No. Z2487

Rev. 11.24.2020

Loading...

Loading...