Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

CUSTOM BACK BAR CABINET — SELF CONTAINED AND REMOTE

MODEL NOS.

BS Series

BR Series

BS Series

IMPORTANT INFORMATION

To register your product, visit our web site at

(www.perlick.com). Click on “Commercial”, then

“Service”. You will see the link to “Warranty

Registration Form”. You must complete and submit

this form or the installation date will revert back to

the ship Date.

This manual has been prepared to assist you in the

installation of your Cabinet and to acquaint you with

its operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer can

provide you with a list of qualified service agents. For

your own protection, never return merchandise for

credit without our approval.

We thank you for selecting a Perlick product and

assure you of our continuing interest in your

satisfaction.

BR Series

Table of Contents

PREPARING THE CABINET

Specifications .....................................................2,3

List of Included Parts .............................................

Tools Required ......................................................

Plumbing ................................................................4

Electrical ................................................................

Uncrating and Inspection .......................................

Placing the Cabinet ...............................................4

Leveling the Cabinet ..............................................4

Installing Casters or Legs .....................................

Installing the Base Plate ........................................

Refrigeration and Temperature Control .................

Cleaning the Cabinet .............................................5

Cleaning Stainless Steel .......................................5

Replacement Parts ................................................

Reversing Door Hinge ...........................................

Wiring Diagram ......................................................8

4

4

4

4

4

4

5

6

7

WARNING: When lifting, the full weight of the

cabinet must be supported. Lift from the cabinet

base and not from the top. Improper lifting can

result in severe damage to the cabinet.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Form No. Z2278

Rev. 05.06.10

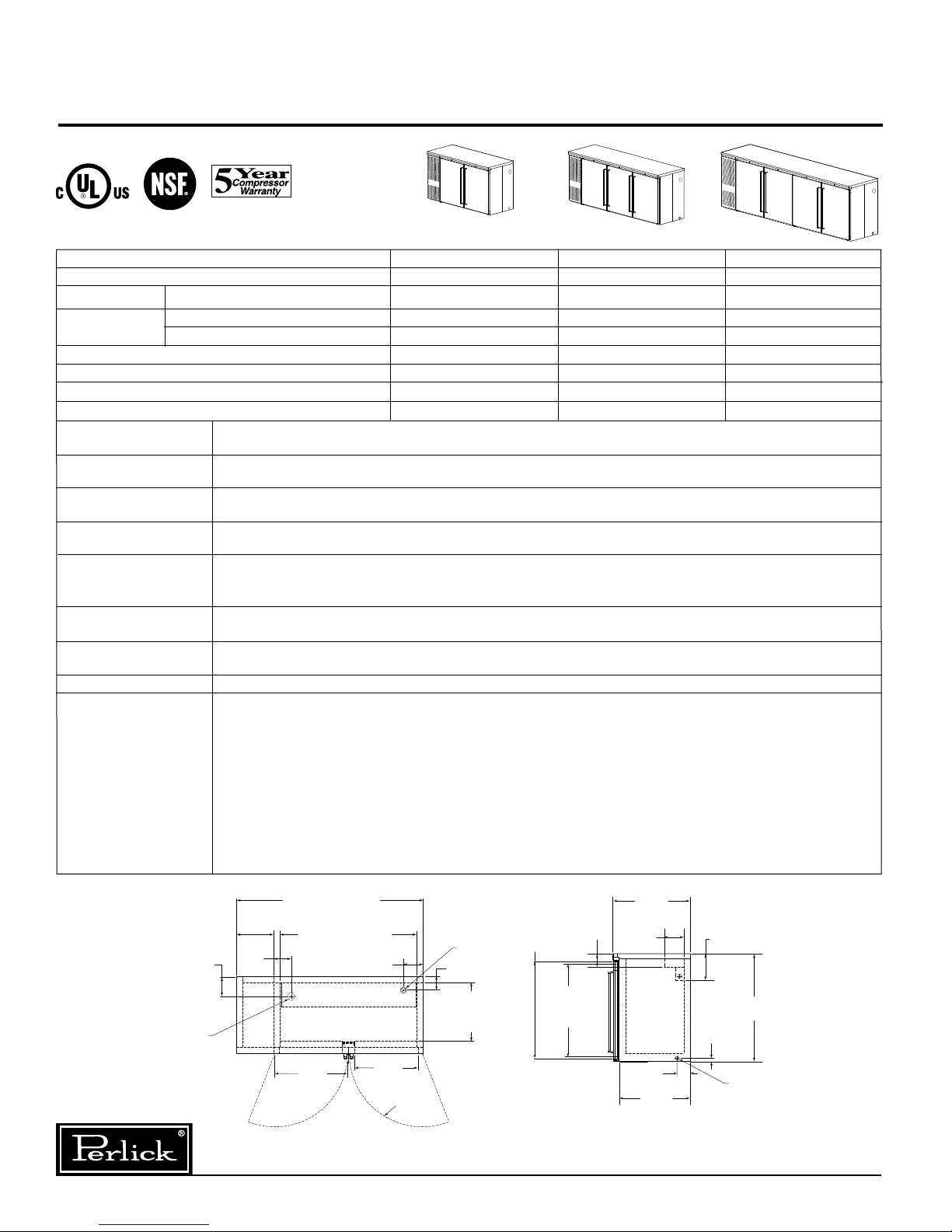

Page 2

108” [2743] 4 DOOR

84” [2134] 3 DOOR

60” [1524] 2 DOOR

92” [2337] 4 DOOR

68” [1727] 3 DOOR

44” [1118] 2 DOOR

12”

[305]

5 1/8”

[130]

6 5/16”

[161]

4 1/4”

[107]

“NOTE B”

“NOTE A”

18 3/4” [476]

BACK LINER

TO INSIDE OF

DOOR SILL

19 7/8”

[505]

DOOR

OPENING

23 1/2”

[597]

DOOR

OPTIONAL

FLOOR

ACCESS

KIT 2”

NOTE A: 3/4” NPT DRAIN EXIT

NOTE B: 1” NPS DRAIN ACCESS

6 3/16”

[157]

24 3/4”

[629]

7 3/4”

[197]

34 1/2”

[876]

1 1/8”

[29]

7 3/16”

[182]

22 3/4”

[578]

4 3/16”

[106]

6 3/8”

[163]

31 1/4”

[794]

DOOR

HEIGHT

27 7/16”

[697]

DOOR

OPENING

R23 1/2”

Installation and Operating Instructions

Sizes and Specifications, Custom Back Bar Cabinets – Self Contained

MODEL NOS. BS60 BS84 BS108

NUMBER OF DOORS 2 Door 3 Door 4 Door

CABINET Length 60” (1524) 84” (2134) 108” (2743)

DIMENSIONS Depth 24

(mm) Height 34

CASE CAPACITY

(based on 12oz. Long Neck bottle) 15 24 32

CONDENSING UNIT H.P. 1

RUNNING LOAD –AMPS 6.3 8.1 8.3

SHIP WT. Lbs. (kg.) 380 (172) 490 (222) 630 (286)

INTERIOR

Door sill: High strength polyethylene. Door pan and ceiling: High strength polystyrene. Floor pan and

Walls: Stainless steel. Includes pilasters, (2) vinyl coated shelves and floor rack per door, and interior lights.

EXTERIOR

grille finishes

Front, back, top and sides stainless steel. Bottom galvanized steel. See optional accessories for door and

DOOR HINGING Stainless steel hinges with standard locations as illustrated. For special hinging specify

hinge locations starting from left to right. Field reversible.

DOOR HARDWARE

Door handles: Choice of full length stainless steel, classic 6” black vinyl wrapped pull or top mounted

stainless steel pull tab. Lock finish:

REFRIGERATION R-134a capillary tube-type. Aluminum fin and copper tube evaporator, epoxy coated coil. Adjustable

temperature control. Self-defrosting. Pull-out condensing unit for service and cleaning.

Compressor left, standard.

ELECTRICAL 115V, 60Hz., 1 phase AC. Furnished with 3-prong, 6 foot NEMA5-15 PC cord. Contact Perlick for other

voltage/frequency requirements.

PLUMBING Evaporator condensate is removed automatically. Optional floor drain with

right end or 1” NPS out bottom come plugged from factory.

INSULATION Foamed-in-place polyurethane, 2” walls, 1

OPTIONAL

ACCESSORIES &

MODIFICATIONS

• Leg set

• Beer dispensing tapping kit

• Laminated top

• Laminated ends

• Compressor right

• Brass hardware

(classic & full length only)

• Caster sets

• Base plates

• Floor access kit

3

/4” (629) 243/4” (629) 243/4” (629)

1

/2” (876) 341/2” (876) 341/2” (876)

/4 1/3 1/3

chrome

3

/4” NPT at

1

/2” top.

Door finishes

Black vinyl coated

Stainless steel

Customer choice of laminate

Painted in color of choice

Grille finishes

Black vinyl coated

Stainless steel

Customer choice of laminate

Painted in color of choice

Prepared for field lamination

Glass door with black vinyl

coated frame

Glass door with stainless

steel frame

Glass door with laminated frame

Form No. Z2278

Rev. 05.06.10

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

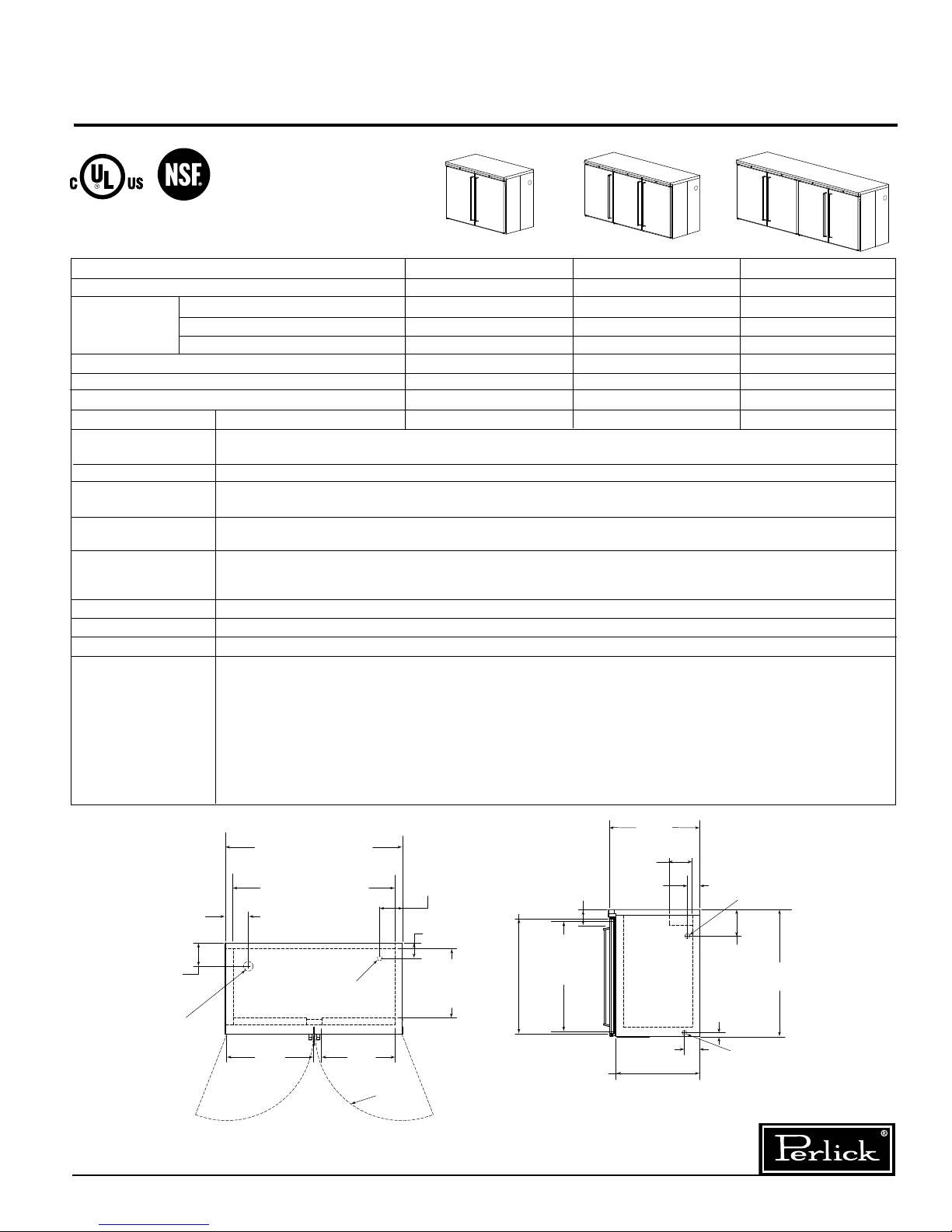

Page 3

Installation and Operating Instructions

23-1/2”

[597]

DOOR

R23-1/2”

6-3/16”

[157]

6-5/16”

[161]

4-1/2”

[107]

OPTIONAL

FLOOR

ACCESS

KIT 2”

5-1/8”

[130]

19 7/8”

[505]

DOOR

OPENING

18-3/4” [476]

BACK LINER

TO INSIDE OF

DOOR SILL

NOTE “A” 3/4” NPT DRAIN EXIT

NOTE “B” 1” NPS DRAIN ACCESS

6-3/8”

[163]

7-3/4”

[197]

24-3/4”

[629]

7-3/16”

[182]

34 1/2”

[876]

4-3/16”

[106]

22-3/4”

[578]

NOTE “A”

NOTE “B”

1-1/8”

[29]

3-7/16”

[87]

31-1/4”

[794]

DOOR

HEIGHT

27-7/16”

[697]

DOOR

OPENING

96” [2439] 4 DOOR

72” [1829] 3 DOOR

48” [1219] 2 DOOR

92” [2337] 4 DOOR

68” [1727] 3 DOOR

44” [1118] 2 DOOR

REFRIGERATION &

ELECTRICAL ACCESS

RIGHT OR LEFT

Sizes and Specifications, Custom Back Bar Cabinets – Remote

MODEL NOS. BR48 BR72 BR96

NUMBER OF DOORS 2 Door 3 Door 4 Door

CABINET Length 48” (1219) 72” (1829) 96” (2439)

DIMENSIONS Depth 24

(mm) Height 34

CASE CAPACITY

(based on 12oz. Long Neck bottle) 15 24 32

AMPS 1.6 2.0 2.5

EVAPORATOR CAPACITY @ 20° F (BTU/HR) 1900 2300 2300

SHIP WT. Lbs. (kg.) 310 (140) 400 (181) 540 (245)

INTERIOR

Door sill: High strength polyethylene. Door pan and ceiling: High strength polystyrene.

Floor pan: Stainless steel. Includes pilasters, (2) vinyl coated shelves and floor rack per door, and interior lights.

EXTERIOR Front, back, top and sides, stainless steel. Bottom galvanized steel. See optional accessories for door finishes.

DOOR HINGING Stainless steel hinges with standard locations as illustrated. For special hinging specify

hinge locations starting from left to right. Field reversible.

DOOR HARDWARE

Door handles: Choice of full length stainless steel, classic 6” black vinyl wrapped pull or top mounted

stainless steel pull tab. Lock finish:

REFRIGERATION Aluminum fin and copper tube evaporator, epoxy coated coil. Factory installed expansion valve. Choice of R22

or R404A. Copper tube connection stubbed out left side of evaporator assembly. Suction line accepts

copper tubing. Liquid line accepts

ELECTRICAL 115V, 60Hz., 1 phase AC. Contact Perlick for other voltage/ frequency requirements.

PLUMBING Independent floor drain or condensate evap. pan is req’d. Optional 2

INSULATION Foamed-in-place polyurethane, 2” walls, 1

OPTIONAL • Leg set • Brass hardware Door finishes

ACCESSORIES & • Tapping kit (classic and full length only) Black vinyl coated

MODIFICATIONS • Laminated top • Caster sets Stainless steel

• Laminated ends • Base plates Customers choice of laminate

• Floor access kit Painted in color of choice

Prepared for field lamination

Glass door with black vinyl coated frame

Glass door with stainless steel frame

Glass door with laminated frame

3

/4” (629) 243/4” (629) 243/4” (629)

1

/2” (876) 341/2” (876) 341/2” (876)

chrome

1

/4” O.D. copper tubing.

1

/8” I.D. floor access kit-left rear corner.

1

/2” top.

3

/8” O.D.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Form No. Z2278

Rev. 05.06.10

Page 4

Preparing the Cabinet for Use

BEAD SILICON

SEALER (RTV)

FLOOR

CABINET

Parts List

■

(2) Shelves plus (1) Floor Rack-per door.

■

Shelf Clips.

Suggested Tools

■

#2 Phillips Screwdriver.

■

10” Crescent Wrench.

9

■

/16” Allen Wrench.

5

■

/16” and 3/8” Hex Socket.

■

Power Drill or Driver.

Plumbing

Condensate from the cooling coil is automatically

evaporated through a condensate pan located in the

condensing unit housing. Each unit is also equipped

with a floor drain located in the right rear corner of

the cabinet. The drain can be plumbed to an external

floor drain by connecting to the 3⁄4” NPT thread out

the side or the 1” NPS thread out the bottom. Both

drains ports come plugged from the factory and can

be removed if needed.

Placing the Cabinet

Push the cabinet into place using rollers when

necessary. Important: Proper air flow around the

condensing unit is necessary for efficient operation.

Never obstruct the air flow in and out of the

condensing unit.

For sanitation purposes, it may be necessary to

seal the base of the cabinet to the floor. This can be

accomplished by laying a bead of silicone sealant

between the base of the cabinet and the floor as

shown by the figure at below.

NOTE:

Remote units require evaporator condensate to be

plumbed to an external drain.

Electrical

The cabinet must be connected to a separately

fused power source (see electrical specification

plate) and grounded in accordance with National

and Local Electrical Codes. Caution: Do not

attempt to operate the equipment on any other

power source than that listed on the Electrical

Specification plate.

Uncrating and Inspection

Remove all crating material before operating.

Carefully inspect cabinet for hidden damage. If

damage is discovered, file your claim immediately

with the transportation company. Perlick is

not responsible for damage in transit.

Installing Casters and Legs (Optional)

Leveling the Cabinet

When the cabinet is in place, check installation with

carpenter’s level. When level front to back and left

to right, accumulated water will drain out of cabinet

evaporator drain.

Installing Base Plate (Optional)

Attach brackets to cabinet bottom in holes provided. Attach base plate to brackets. (See separate

instructions, provided with kit). When returning

cabinet to upright position, be careful not to bend

brackets.

WARNING!

To avoid compressor damage, after returning

cabinet to an upright position, let unit stand for

24 hours before plugging it in and running the unit.

Attach four casters to the cabinet bottom; rigid casters at the rear and swivel casters on the front. Use

the supplied

1

/4”- 20 x 3/4” hex head self-tapping

machine screws.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2278

Rev. 05.06.10

4

Page 5

General Information

Refrigeration and Temperature Control

Self-contained units are equipped with a heavy-duty

refrigeration system that is factory set yo maintain a

product storage temperature of approximately 38° F.

Adjusting the Temperature

The temperature control is inside the cabinet on

the left-hand side of the evaporator fan panel

assembly. You will need a screwdriver to turn the

adjusting screw. Make small adjustments until the

desired temperature is achieved.

■

Colder Temperatures:

Turn the adjusting screw clockwise (to the right).

■

Warmer Temperatures:

Turn the adjusting screw counterclockwise

(to the left).

■

Temperature Control “OFF”:

Turn the adjusting screw completely counter clockwise to the “O” position until a click is

noted.

The condenser fan motor turns off and on with

the compressor. The evaporator fan motor is on

all the time.

NOTE:

Cabinet Temperatures lower than 34° will not

allow for proper defrosting of the evaporator coil. If

defrosting is necessary, turn the control knob to the

OFF position until coil is defrosted.

Cleaning the Cabinet

Use a mild detergent and water to clean the inside

and outside of the cabinet. Dry thoroughly. Never

use a scouring pad or abrasive cleanser.

NOTE: An industrial strength, commercial cleaner

can be used to clean the outside of painted

cabinets.

Cleaning the Condenser

Use a long handled, stiff brush to clean the dirt

from the front surface of the condenser. Keeping

the condenser free from dust and dirt will ensure

efficient operation.

CAUTION: Do not bend the fins while brushing the

front of the condenser.

Condenser

The condenser (located behind the front grille

cover) should be inspected every 30 days and

cleaned, if necessary.

Failure to keep the condenser clean will cause a

loss in condensing unit efficiency.

Recommended Cleaning Agents

JOB CLEANING AGENT* COMMENTS

Routine Cleaning Soap, ammonia, detergent Apply with sponge or cloth.

Can be used on all finishes.

Fingerprints and smears Areal 20, Lac-O-Nu, Lumin Wash, Provides barrier film to minimize

O’Cedar Cream Polish fingerprints. Can be used on all finishes.

Stubborn stains and Allchem Concentrated Cleaner, Rub lightly, using dry or damp

Discolorations Samae, Twinkle, Zud Restoro, cloth in the direction of polish

Grade F or FFF Italian Pumice, lines on the stainless steel.

Whiting or Talc, Liquid Nu Steel,

Copper’s or Revere Stainless Steel

Cleaner, Lumin Cleaner, Sta-Clean,

Cameo Copper Cleaner, Allen Polish

Highlite, Penny-Brite, Copper Brite

* Use of propriety names is intended only to indicate a type of cleaner and does not constitute an endorsement. Omission of

any proprietary cleaner does not imply its inadequacy. All products should be used in strict accordance with instructions on

the package. NOTE: Do Not Use Steel Wool or Scouring Pads to clean stainless steel.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2278

5

Rev. 05.06.10

Page 6

Replacement Parts — Custom Back Bar Cabinets

MODEL NOS. BS60 BS84 BS108

BR48 BR72 BR96

Condensing Units (BS Only)

Condensing unit 115 volt, 60 Hz. C22647 C22646 C22646

Condensing unit 515301063 515301062 515301062

Compressor 513200314 513200003 513200003

Fan motor assembly 515315009 515315009

Condenser coil 15352019 15352019 15352019

Terminal board 519100088 519100088 519100088

Overload protector US-PB10HBX1 US-PB12HBX1 US-PB12HBX1

Relay US-PB10HBX1 US-PB12HBX1 US-PB12HBX1

Capacitor

US-PB10HBX1 US-PB12HBX1 US-PB12HBX1

Evaporator Assembly

Self Contained (BS)

complete 65555-1 65555-2 65555-2

Remote (BR) complete 65555-1R 65555-2R 65555-2R

Evaporator coil (BS)

& (BR) C17511-1EP C17511-2EP C17511-2EP

Liquid & Suction line (BS) 65084 65085 65085

Fan blade 57699 57699 57699

Fan motor C15239A C15239A C15239A

Evaporator fan guard 65557 65557 65557

Temperature control 61283 61283 61283

Bulb clamp C6634 C6634 C6634

Wire harness, compressor bottom 65560 65560 65560

Wire harness, evaporator 65561 65561 65561

Wire harness, light jumper 65538 65539 65540

Wire harness, mullion heater 65571 65572 65573

Light bulb 63821 63821 63821

Light bulb guard 65525 65525 65525

Light socket 63484 63484 63484

Light switch 65535 65535 65535

Lock 63762 63762 36762

Space, lock 63761-1 63761-1 63761-1

Lock rail 65432-24SS or 65432-24 65432-24SS or 65432-24 65432-24SS or 65432-24

Grille rail 65432-12SS or 65432-12 65432-12SS or 65432-12 65432-12SS or 65432-12

Condensate pan 65565-1 65565-1 65565-1

Condensing unit housing end panel 66215-1SS 66215-1SS 66215-1SS

Grille RG-NL2 RG-NL2 RG-NL2

Condenser housing back 65435-12SS 65435-12SS 65435-12SS

Evaporator, liquid & suction line cover 65576-1L 65576-2L 65576-3L

Evaporator pan 65526-1DB 65526-2DB 65526-2DB

Door sill 65500-1 65500-1 65500-1

Door handle Several Options - Contact Factory

Door gasket 66237-4 66237-4 66237-4

Cabinet hinge group left 66264L 66264L 66264L

Cabinet hinge group right 66264R 66264R 66264R

Hinge pin 63679-1 63679-1 63679-1

End shelf kit (std. flat) 57928 57928 57928

Center shelf kit (std. flat) — 57929 57929

Left or right shelf (std. flat) 62307-2 62307-2 62307-2

Center shelf (std. flat) — 62308-2 62308-2

Pilaster strip C19271-1 C19271-1 C19271-1

Shelf clips (bag of 12) 63019-3 63019-3 63019-3

*Replacement door RD-NL2 RD-NL2 RD-NL2

515315009

Contact Perlick Milwaukee for complete door replacement. Cabinet serial no. required.

*

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2278

Rev. 05.06.10

6

Page 7

Reversing Door Hinge

Step #12 Step #11 Step #13

Step #14

Step #6

Step #7

Remove

these screws

Top Hinge Bracket

Bottom Hinge Bracket

Top Hinge Bracket

Bottom Hinge Bracket

Hinge Bushin

g

Tools Required

■

#3 Phillips Screwdriver.

1

■

/16” Allen Wrench.

■

Flathead Screwdriver

Right Hinged Door

(as shipped from factory)

Handle Styles

C31409-1

Not

65609-2

Reversible

65189

Operations to Perform on Cabinet

STEP 1:

Remove bottom hinge pin from

assembly.

65305-1

STEP 8:

Re-assemble hinge brackets to unit. Bottom right bracket

is assembled as the top left bracket. Top right bracket is

assembled as the bottom left bracket.

STEP 9:

Re-insert top hinge pin.

STEP 10:

Re-assemble lock rail from

STEP #3

Operations to Perform on Door

STEP 11:

Remove bottom

door hinge bracket

from door assembly and remove

door hinge bushing

from bracket.

Re-assemble door

hinge bracket to

previous position,

without bushing.

STEP 2:

Carefully lift and tilt out door

assembly from the unit and

set aside.

STEP 3:

Remove lock rail from

cabinet, requires removal of

four screws.

STEP 4:

Remove top hinge pin.

Remove top and bottom

hinge brackets from the unit.

STEP 5:

Remove hinge bushing from

bottom hinge bracket and

assemble to top hinge bracket.

STEP 6:

Taking care not to scratch the

surface, remove hole plugs from

the left hinge holes.

STEP 7:

Insert hole plugs into vacant right

hinge holes.

STEP 12:

Remove top door

hinge bracket from

door assembly and

assemble door

hinge bushing from

STEP 11 to bracket. Re-assemble door hinge bracket to

previous position with bushing attached.

STEP 13:

Door with full length SS handle:

There is no need to remove door handle. It will be

positioned correctly when door is reversed.

Door with SS pull tab or handle with wraparound bracket:

Remove the two screws mounting the handle and

reposition to appropriate location on the opposite

side of the door.

STEP 14:

Remove lock retainer and install on opposite end of door.

STEP 15:

What was the door top is now the door bottom. Carefully

lift the door onto the hinge brackets of the cabinet. The

two hinge bushings should meet. Reinsert the bottom

hinge pin to complete the door switching operation.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2278

7

Rev. 05.06.10

Page 8

[2] DOOR

MULLION HEATER MULLION HEATER MULLION HEATER

RED

BLACK

BLACK

BLACK

RED

BLACK

WHITE

WHITE

BLACK

BLACK

WHITE

WHITE

GREEN

BLACK

WHITE

GREEN

EVAPORATOR FAN EVAPORATOR FAN

NOTE:

FIELD WIRING FROM CABINET

JUNCTION BOX TO CONDENSING

UNIT MUST COMPLY WITH ALL

LOCAL AND NATIONAL ELECTRICAL

CODES.

CABINET

JUNCTION BOX

CONDENSING UNIT

EVAPORATOR

HOUSING

GROUND WIRE

JUNCTION BOX

PRESSURE SWITCH

FIELD INSTALLED

POWER CONNECTION

THESE WIRES CAPPED IN

SINGLE CABINET

INSTALLATIONS

LIGHT LIGHT LIGHT

LIGHT

WHITE

WHITE

LIGHT SWITCH

[3] DOOR [4] DOOR

[2] DOOR

MULLION HEATER MULLION HEATER MULLION HEATER

RED

BLACK

BLACK

BLACK

POWER CONNECTION

JUNCTION BOX

CONDENSING UNIT

WHITE

RED

GREEN

BLACK

WHITE

GREEN

BLACK

THERMOSTAT

BLACK

WHITE

WHITE

EVAPORATOR FAN EVAPORATOR FAN

LIGHT LIGHT LIGHT

LIGHT

WHITE

WHITE

LIGHT SWITCH

[3] DOOR [4] DOOR

Wiring Diagram – Custom Back Bar Cabinets

BR Series Remote

2, 3 and 4 Door

BS Series Self-Contained

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2, 3 and 4 Door

Form No. Z2278

8

Rev. 05.06.10

Loading...

Loading...