Page 1

AM-1 Series™

NPT

Union

PROPORTIONAL THERMOSTATIC MIXING AND DIVERTING

VALVE STANDARD AND “C” TEMPERATURE RANGE MODELS NPT, UNION SWEAT, THREAD, CPVC AND PEX MODELS

INSTALLATION INSTRUCTIONS

Patent Information: U.S. Patent No. 6,079,625.

INSTALLATION

APPLICATION

The AM-1 Series™ family of quality valves in a variety of

temperature ranges and connections, for master mixing or

diverting applications.

SPECIFICATIONS

Temperature Range:

C Model: 70°F–120°F (21°C–49°C)

Standard Model: 70°F–145°F (21°C–63°C)

Connections:

Straight-through design (HOT and COLD at same level).

Construction:

Nickel plated brass construction. EPDM o-rings. Made in

USA.

Lead Free Plumbing Code Compliance: The wettable sur-

faces of lead free models contain less than .25% of lead by

weighted average

Operating Pressure: 150 psi (1034 kPa) maximum.

IMPORTANT

NOTE TO INSTALLER:

qualified individual, in accordance with local codes and

ordinances. It is the responsibility of the installer to properly

select, install and adjust these devices as specified in these

instructions. For installations which require compliance with

Building/Mechanical/Plumbing Codes, the appropriate AM-1

Series™ valve must be chosen and installed, and the

discharge temperature set and locked according to these

instructions. AM-1 “C” Series models with the temperature

range, 70°F–120°F (21°C–49°C) and "Standard" models with

temperature range 70°F–145°F (21°C–63°C) are ASSE

1017 (point of source application) certified, and CSA

IAPMO

tubs, showers, bathing facilities and other outlets. These

valves should be installed where they will be accessible for

cleaning, servicing or adjustment.

Mounting must comply with all local codes.

This product should be installed by a

®

®a

®

listed. These models shall be used to supply water to

and

ASSE 1017 Applications—Point of

Source

These AM-1 Series models can be installed in any position

consistent with the intended use. For domestic hot water

supply, the valve must be installed as shown in Fig. 1. There

shall be no shut-off valves installed between the cold water

line and the cold water connection on the AM-1 Series valve.

Check valves shall be installed as indicated for NPT models;

all AM-1 models with union fittings are supplied with integral

check valves on both the hot and cold ports. A cold water

service valve may be installed, as indicated, between the cold

water supply line to the distribution system and the cold water

line supplying both the water heater and the AM-1 Series

valve.

Operating Temperature: 212 °F (100 °C) maximum.

a

-UCPVC and -UPEX models are not CSA listed.

®

CUS

62-3075EFS-03

Page 2

AM-1 SERIES™

WARNING

M25029A

(1)

T

(1)

HEAT

TRAP

6

(152)

8

(203)

MAX

WATER

HEATER

EXPANSION

TANK

ALLOWABLE

SERVICE

VALVE

LOCATION

AM SERIES

WATER USE FIXTURES

RECIRCULATION

PUMP

M

COLD

WATER

SUPPLY

C

V

H

TO DISHWASHER

IF PERMITTED

BY CODES

T

AQUASTAT

(1)

CHECK VALVE

L

1

4

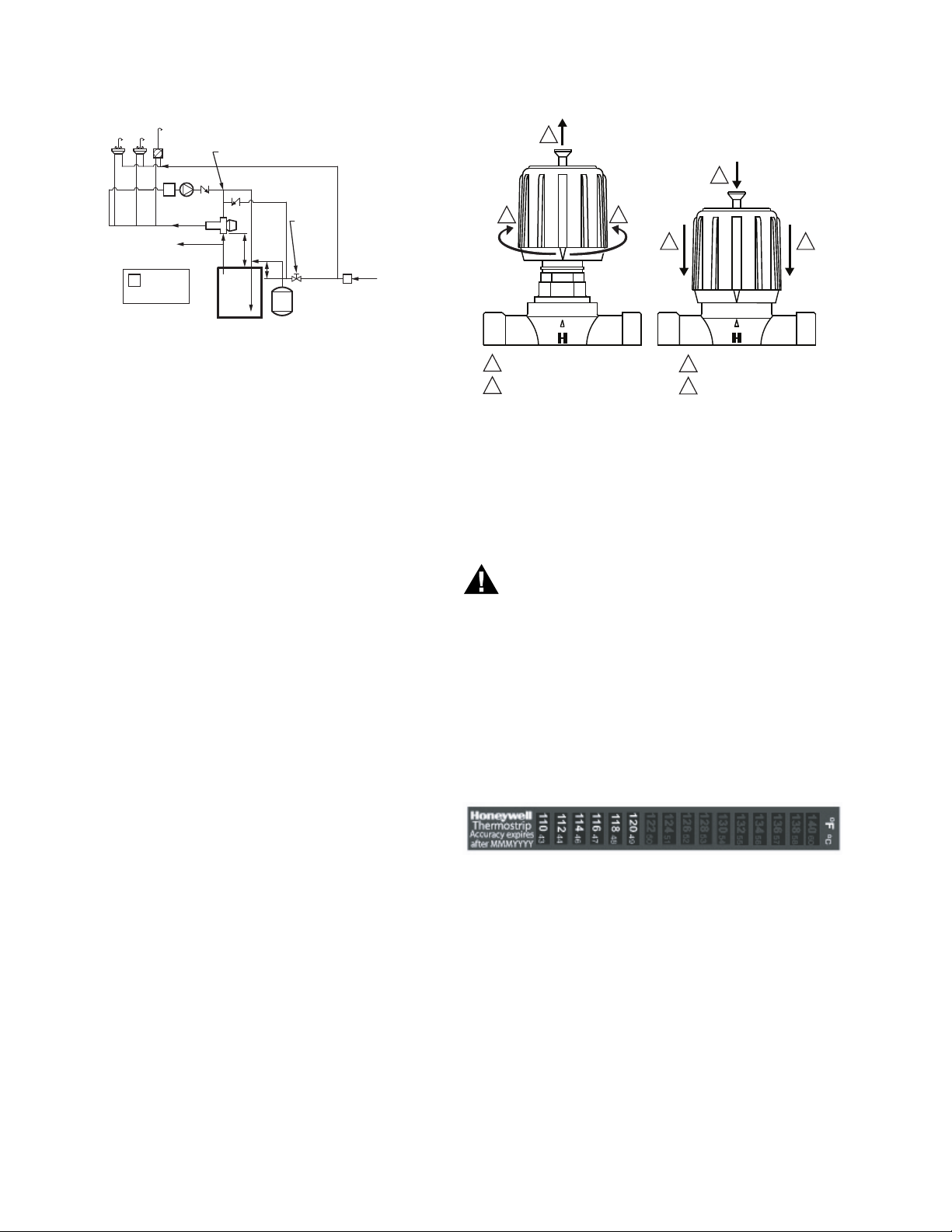

Fig. 1. AM-1 Series ASSE 1017 application

Installation of Union Sweat, CPVC and PEX Connections

— Union sweat connections, if used, should be soldered

prior to assembly to the valve, or without the sealing

gasket or optional check valve present. After the joint

has cooled, the sealing gasket and/or check valves

may be installed.

— CPVC fittings are limited to a system maximum tem-

perature of 180° F (82° C) and 100 psi (689 kPa).

— PEX fitting and crimp ring (provided by Installer) are

deigned to meet ASTM F1807 requirements.

— PEX tubing used with PEX fittings must meet ASTM

F876 requirements.

VALVE ADJUSTMENT

To adjust temperature setting of the mixing valve, attach

thermostrip (supplied with the valve) to the piping connected

to the Mix port of the valve. Loosen handwheel screw, lift

handwheel and turn to desired temperature as indicated on

the thermostrip. Reposition the hand wheel and retighten

screw.

2

c

1

LOOSEN SCREW, LIFT HAND WHEEL.

TURN HAND WHEEL CLOCKWISE

2

OR COUNTER CLOCKWISE TO

ADJUST TEMPERATURE.

2

33

H

c

REPOSITION HAND WHEE

3

TO LOCK POSITION.

4

RETIGHTEN SCREW.

H

M27487

Thermostrip Installation

Clean pipe and firmly apply Thermostrip on mix outlet of

valve. Flow water and adjust mixed outlet temperature for

desired setting range. Actual mixed water temperature is

indicated in green with 2° F (1° C) increments. Blue means

slightly lower and brown means slightly higher.

Water Temperature above 120°F (49° C) can cause

serious injury. Mixing valve temperature setting

should be done by licensed contractor per local

code requirement. To ensure correct temperature

control, use water thermometer at faucet outlet.

The thermostrip is ONE TIME USE ONLY for initial system

temperature setting. Check expiration date printed on

temperature strip to ensure temperature reading accuracy. If

necessary, contact your Honeywell distributor to obtain a

replacement thermostrip, part number TS205-064.

Temperature Setting Procedure

It is possible to limit the temperature range. To use this

feature:

62-3075EFS—03 2

Fig. 2. Thermostrip.

Post Installation Procedure

1. Write temperature setting on CAUTION label and sign in

space provided.

2. Attach CAUTION label to AM-1 valve.

3. Explain CAUTION label to owner.

4. Deposit this instruction sheet with owner.

OPERATION

The AM-1 series valve provides for automatic operation

through the use of a thermostatic element in the product. The

element will control the mixing of the hot and cold supply to

Page 3

provide mixed tempered water to connected fixtures. This

provides constant water temperature under different working

conditions.

MAINTENANCE PROCEDURES

AM-1 SERIES™

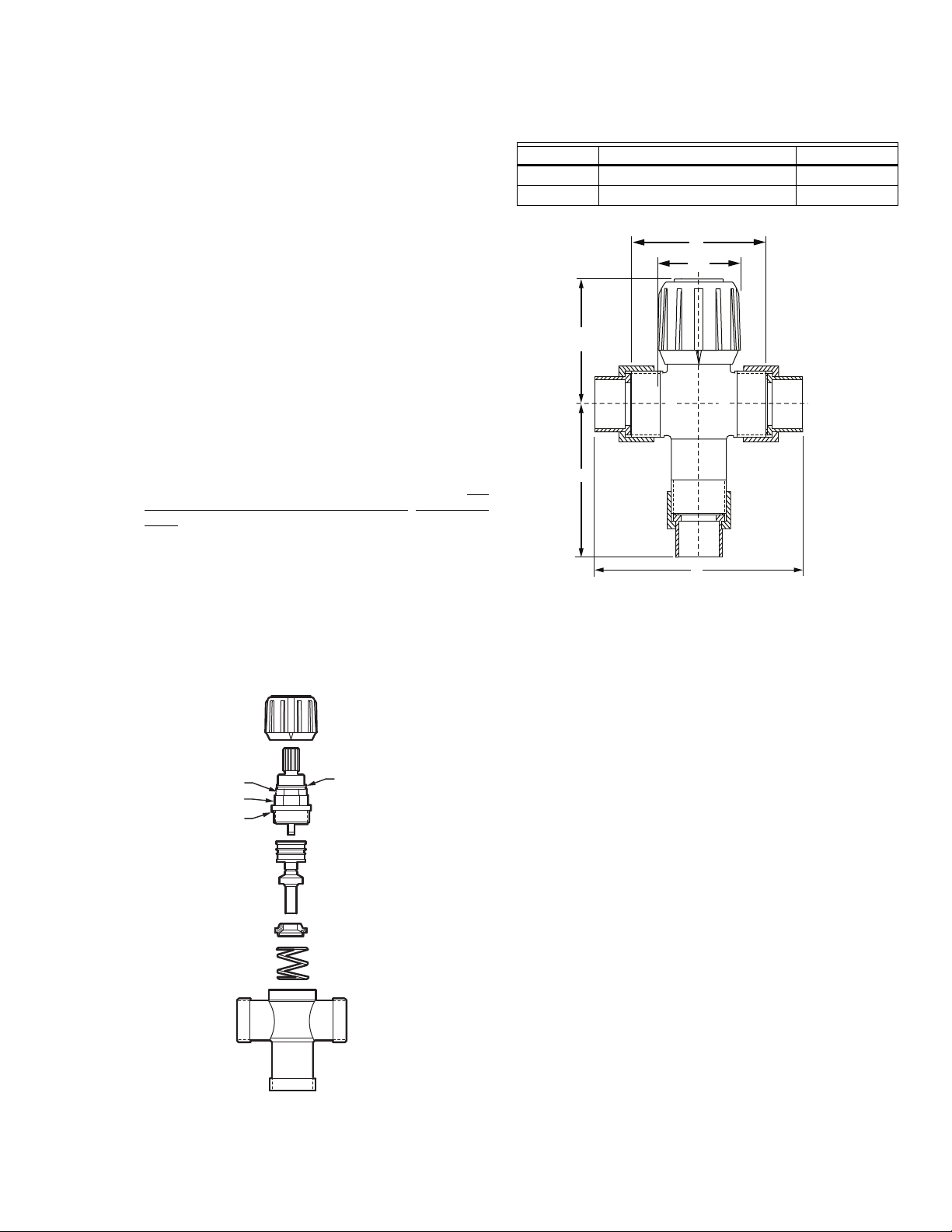

Table 1. AM-1 Series Replacement Kits

Model Temperature Range Part No.

C 70°–120° F (21°–49°C) AM-1-020 RP

STD 70°–145° F (21°–63° C) AM-1-025 RP

Hard water conditions may result in scale deposits, causing

binding of internal parts in extreme cases. Cleaning the

internal parts will usually restore the valve to proper operating

conditions. In some cases, it may be necessary to replace the

lower assembly.

To clean and/or replace the lower assembly, shut off water

and:

1. With a screwdriver, remove screw and handwheel.

2. Loosen upper nut (do not remove) to allow engaging an

adjustable wrench on lower nut. Unscrew lower nut

(counterclockwise). This removes top assembly.

3. Brass top assembly will pop up. Remove lower assem-

bly, diffuser and spring.

4. Carefully remove any scaling (calcium deposit) or for-

eign particles from valve seat and other internal parts.

Use vinegar to remove calcium. Soak parts until calcium

becomes soft and can be scrubbed and washed off. Do

not use solvents or scratch metallic / Teflon® coated surfaces.

5. Replace cleaned spring, diffuser and lower assembly

following instructions below or use new replacement kit

assembly. For correct kit number, see Table 1.

Install spring, diffuser and lower assembly:

A. Insert spring onto diffuser.

B. Insert diffuser with spring end first into body.

C. Fit valve top assembly into lower assembly and insert into valve.

D. Tighten lower nut.

E. Reposition handwheel and insert screw. Turn handwheel to

desired temperature setting.

A

Ø 1-51/64

(46)

2-1/4

(57)

H

B

MIX

C

Fig. 4. Dimensions in in. (mm).

C

M23938

HANDWHEEL

UPPER NUT

LOWER NUT

O RING

H

H

MIX

RETAINING RING

TOP ASSEMBLY

LOWER ASSEMBLY

DIFFUSER

SPRING

C

VALVE BODY

M23941

Fig. 3. AM-1 Series valves assembly.

3 62-3075EFS—03

Page 4

AM-1 SERIES™

AM-1 Series™ is a trademark of Honeywell International, Inc.

ASSE® is a registered trademark of the American Society of Sanitary Engineering.

®

CSA

is a registered trademark of the Canadian Standards Association.

®

IAPMO

is a registered trademark of the International Association of Plumbing and Mechanical Officials.

ASTM® is a registered trademark of the American Society for Testing and Materials.

®

Tefl on

is a registered trademark of E.I. du Pont de Nemours and Company.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2010 Honeywell International Inc.

62-3075EFS—03 M.S. Rev. 11-10

Printed in U.S.A.

Page 5

MC

NPT

Union

SÉRIE AM-1

VANNE THERMOSTATIQUE DE MÉLANGE ET DE RÉPARTITION À ACTION

PROPORTIONNELLE À GAMME DE TEMPÉRATURE STANDARD ET «C»,

MODÈLES NPT ET UNION À SOUDER, FILETÉ, ET MODÈLES À RACCORDS

PVC-C ET PEX

NOTICE D’INSTALLATION

APPLICATION

La famille de vannes de qualité de série AM-1MC convenant à

une variété de plages de températures et de systèmes de

branchement pour les applications de mélange et de

répartition.

CARACTÉRISTIQUES TECHNIQUES

Information sur le brevet : Brevet américain n

o

6,079,625.

INSTALLATION

IMPORTANT

REMARQUE À L'INTENTION DE L'INSTALLATEUR : Ce

produit doit être installé par une personne compétente,

conformément aux codes et aux règlements locaux. Il

incombe à l'installateur de choisir correctement, de bien

installer et d'ajuster ces appareils, conformément aux

présentes directives. Dans le cas d'installations qui doivent

être conformes aux codes du bâtiment, de mécanique, de

plomberie, la vanne AM-1 qui convient doit être choisie et

installée et la température à la sortie doit être réglée et

bloquée conformément aux présentes directives. Les modèles

de série AM-1 offrant les gammes de températures suivantes :

21 °C-49 °C (70 °F-120 °F) et 21 °C-63 °C (70 °F-145 °F) sont

certifiés ASSE

répertoriés CSA

alimenter en eau les baignoires, les douches, les installations

de bain et d'autres robinets. Ces vannes devraient être

installées dans un endroit accessible pour le nettoyage,

l'entretien ou l'ajustement.

L'installation doit être conforme à tous les codes

locaux en vigueur.

®

1017 (application au point de source), et sont

®a

et IAPMO®. Ces modèles servent à

Limites de la température :

Modèle C : 21 °C–49 °C (70 °F–120 °F)

Modèle standard : 21 °C-63 °C (70 °F-145 °F)

Connexions :

Conception à passage direct (l'eau chaude et l'eau froide sont

au même niveau).

Construction :

Corps de laiton nickelé. Joints toriques en EPDM. Fabriqué

aux États-Unis.

Conformité au code de plomberie relatif aux installations

sans plomb : Les surfaces soumises à l'eau sont des

modèles sans plomb contenant une teneur en plomb moyenne pondérée inférieure à 0,25 %

Pression de service : 11034 kPa (150 psi) maximum.

Température de service : 100 °C (212 °F) maximum.

Applications ASSE 1017-Au point de source

Ces vannes de série AM-1 peuvent être installées dans

n'importe quelle position qui convient à l'usage prévu. Dans le

cas d'installation pour eau chaude domestique, la vanne doit

être installée comme l'illustre la Fig. 1. Il ne doit y avoir aucun

robinet d'arrêt entre la canalisation d'eau froide et le raccord de

la canalisation d'eau froide de la vanne AM-1. Dans le cas des

modèles NPT, les clapets antiretour doivent être installés selon

les indications; tous les modèles AM-1 dotés de raccords

unions sont livrés avec des clapets antiretour intégraux aux

orifices d'eau chaude et d'eau froide. Il peut y avoir un robinet

de service sur la canalisation d'eau froide, selon les

indications, entre la canalisation de distribution d'eau froide et

le système de distribution et entre la canalisation d'eau froide

qui alimente à la fois le chauffe-eau et la vanne AM-1.

a

Les modèles -UCPVC et -UPEX ne sont pas répertoriés

CSA.

®

CUS

Page 6

SÉRIE AM-1

AVERTISSEMENT

A

MF27487

DESSERRER LA VIS, SOULEVER

LE VOLANT DE MANOEUVRE.

FAIRE TOURNER LE VOLANT DE

MANOEUVRE DANS LE SENS

HORAIRE OU ANTI-HORAIRE POUR

RÉGLER LA TEMPÉRATURE.

1

2

REMETTRE LE VOLANT DE

MANOEUVRE EN PLACE

POUR BLOQUER LA POSITION.

RESSERRER LA VIS.

3

4

33

4

1

2

2

c

H

c

H

MC

PPAREILS CONSOMMANT DE L’EAU

(1)

T

POMPE

SÉRIE AM

VERS LE

LAVE-VAISSELLE

SI LE CODE LE PERMET

AQUASTAT

T

(1)

CLAPET ANTIRETOUR

RECIRCULATION

(1)

C

M

H

8

(203)

MAX

CHAUFFEEAU

PIÈGE À

CHALEUR

(152)

6

EMPLACEMENT

PERMIS POUR

LE ROBINET

DE SERVICE

RÉSERVOIR

D’EXPANSION

ARRIVÉE

D’EAU

FROIDE

V

MF25029A

Fig. 1. Application ASSE 1017 de la vanne AM-1.

Installation des raccords unions à souder, PVC-C et PEX

— Les raccords union à souder, s’ils sont utilisés,

devraient être soudés avant d’être fixés à la vanne, ou

sans que la garniture d’étanchéité ou le clapet antiretour en option ne soit présent. Une fois que le joint est

refroidi, la garniture d’étanchéité et (ou) le clapet antiretour pourront être installés.

— Les raccords de PVC-C ne peuvent servir que dans

les systèmes ou la température maximale est de

82 °C (180 °F) et la pression de 689 kPa (100 psi).

— Le raccord PEX et la bague de sertissage (fournis par

l'installateur) sont conçus pour respecter les exigences de la norme ASTM F1807.

— Les tuyaux PEX employés avec les raccords PEX

doivent PEX doit respecter les exigences de la norme

ASTM F876.

Installation de la bande thermique

Nettoyer la canalisation et appliquer fermement la bande

thermique à la sortie d'eau mélangée. Faire couler l'eau et

ajuster la température à la sortie d'eau mélangée jusqu'à

obtenir la gamme de température souhaitée.

La température réelle de l'eau mélangée apparaît par

incrément de 1 °C (2 °F). Le bleu signifie que la température

est légèrement plus basse, et le brun signifie que la

température est légèrement plus élevée.

AJUSTEMENT DE LA VANNE

À plus de 49 °C (120 °F), l'eau chaude peut causer

des blessures graves. Le réglage de la

Pour régler la température de la vanne de mélange, appliquez

la bande thermique (fournie avec la vanne) au tuyau relié à

l'orifice de mélange de la vanne. Desserrez la vis du volant de

manœuvre, soulevez le volant, puis tournez-le jusqu'à la

température désirée indiquée sur la bande thermique.

température de la vanne de mélange doit être fait

par un entrepreneur autorisé, conformément aux

exigences du code local. Pour assurer une bonne

régulation de la température, placer le

thermomètre à la sortie du robinet.

Remettez le volant de manœuvre en place et resserrez la vis.

La bande thermique est à USAGE UNIQUE et sert au réglage

Réglage du point de consigne de température

Il est possible de limiter la gamme de température. Pour se

prévaloir de cette caractéristique :

initial de la température du système. Vérifiez la date

d'expiration imprimée sur la bande afin de vous assurer de la

précision de la température indiquée. En cas de besoin,

communiquez avec votre distributeur Honeywell pour obtenir

une bande thermique de remplacement (numéro de pièce

TS205-064).

Fig. 2. Bande thermique.

62-3075EFS—03 6

Page 7

SÉRIE AM-1

MC

Après l'installation

1. Inscrire le point de consigne sur l'étiquette de MISE EN

GARDE et apposer votre signature dans l'espace prévu

à cet effet.

2. Fixer l'étiquette de MISE EN GARDE à la vanne AM-1.

3. Expliquer la MISE EN GARDE au propriétaire.

4. Remettre les présentes directives d'installation au pro-

priétaire.

FONCTIONNEMENT

Les vannes de série AM-1 sont conçues pour un

fonctionnement automatique et font appel à un élément

thermostatique intégré à l'appareil. Cet élément

thermostatique commande le mélange de l'eau chaude et de

l'eau froide afin de fournir de l'eau mélangée tiède aux

robinets des appareils sanitaires. L'eau est ainsi acheminée à

température constante peu importe les conditions d'utilisation.

MAINTENANCE

L'eau calcaire peut entraîner des dépôts qui, dans les cas

extrêmes, peuvent faire gripper les pièces internes. Il suffit

généralement de nettoyer les pièces internes pour que la

vanne retrouve son fonctionnement d'origine. Dans certains

cas, il peut être nécessaire de remplacer les pièces

inférieures.

Pour nettoyer et (ou) remplacer les pièces inférieures, couper

l'arrivée d'eau et :

1. À l'aide d'un tournevis, retirer la vis et le volant de

manœuvre.

2. Desserrer l'écrou du haut (sans le retirer) pour pouvoir

insérer une clé à molette autour de l'écrou du bas.

Dévisser l'écrou du bas (dans le sens anti-horaire). On

parvient ainsi à enlever la partie supérieure

3. La partie supérieure en laiton sortira de son logement.

Retirer la partie inférieure, le diffuseur et le ressort.

4. Enlever soigneusement tout dépôt de calcaire ou parti-

cules étrangères du siège de la vanne et des autres

pièces internes. Utiliser du vinaigre pour nettoyer le calcaire. Faire tremper les pièces jusqu'à ce que le calcaire ramollisse et qu'il soit possible de l'enlever en le

frottant et en lavant les pièces. Ne pas utiliser de solvants ou de tampons métalliques ou recouverts de

Te fl o n®.

5. Remettre en place le ressort, le diffuseur et la partie

inférieure en suivant les directives ci-dessous, ou

encore utiliser une trousse de remplacement. Pour connaître le numéro de la trousse de remplacement, consulter le Tableau 1.

Installation du ressort, du diffuseur et de la partie inférieure :

A. Insérer le ressort sur le diffuseur.

B. Insérer le diffuseur dans le corps de vanne, côté ressort en

premier.

C. Faire correspondre la partie supérieure de la vanne à la partie

inférieure et insérer le tout dans la vanne.

D. Resserrer la vis inférieure.

E. Repositionner le volant de manœuvre et insérer la vis. Tourner le

volant de manœuvre au réglage de température voulu.

VOLANT

ÉCROU DU HAUT

ÉCROU DU BAS

JOINT TORIQUE

H

H

MIX

ANNEAU DE RETENUE

PARTIE SUPÉRIEURE

PARTIE INFÉRIEURE

DIFFUSEUR

RESSORT

C

CORPS DE VANNE

MF23941

Fig. 3. Assemblage des vannes de série AM-1.

Tableau 1. Trousses de remplacement pour vanne AM-1.

o

Modèle Gamme de température N

C

21 °C - 49 °C (70 °F - 120 °F) («C»)

de pièce

AM-1-020 RP

STD 38 °C - 63 °C (100 °F - 145 °F) AM-1-025 RP

7 62-3075EFS—03

Page 8

SÉRIE AM-1

2-1/4

(57)

MC

A

Ø 1-51/64

(46)

MIX

C

C

M23938

H

B

Fig. 4. Dimensions en po (mm).

AM-1 SeriesMC est une marque de commerce de Honeywell International Inc.

ASSE® est une marque déposée de l'American Society of Sanitary Engineering.

CSA® est une marque déposée de l'Association canadienne de normalisation.

IAPMO® est une marque déposée de l'International Association of Plumbing and Mechanical Officials.

ASTM® est une marque déposée de l'American Society for Testing and Materials.

Tef lo n® est une marque déposée de E.I. du Pont de Nemours and Company.

Solutions de régulation et d’automatisation

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35, Dynamic Drive

Toronto (Ontario) M1V 4Z9

customer.honeywell.com

® Marque de commerce déposée aux É.-U.

© 2010 Honeywell International Inc.

Tous droits réservés

62-3075EFS—03 M.S. Rev. 11-10

Imprimé aux États-Unis

Page 9

AM-1 Series™

NPT

Union

VÁLVULA TERMOSTÁTICA PROPORCIONAL MEZCLADORA Y DE DESVÍO

MODELOS ESTÁNDAR Y DE RANGO DE TEMPERATURA "C" - MODELOS DE

CONEXIONES PARA NPT, SOLDADURA, ROSCA, COMPRESIÓN, CLORURO DE

POLIVINILO CLORINADO (CPVC) Y POLIETILENO RETICULADO (PEX).

INSTRUCCIONES DE INSTALACIÓN

INSTALACIÓN

IMPORTANTE

El montaje debe cumplir con todos los códigos

locales.

NOTA PARA EL INSTALADOR: Este producto debe instalarse

por una persona calificada, de acuerdo con los códigos y

reglamentos locales. El instalador es responsable de

Seleccionar, instalar y regular estos accesorios de forma

adecuada, tal como se especifica en estas instrucciones. Para

instalaciones en las que se requiere el cumplimiento de

códigos de construcción, mecánicos o de plomería, se debe

escoger e instalar la válvula AM-1 Series™ adecuada, y se

debe fijar y bloquear la temperatura de descarga según estas

APLICACIÓN

La familia de válvulas de calidad AM-1 Series™ se utilizan en

una amplia gama de rangos de temperatura y conexiones,

para mezclas o derivaciones perfectas.

ESPECIFICACIONES

Rango de temperatura:

Modelo C: 70°F a 120°F (21°C a 49°C)

Modelo estándar: 70°F-145°F (21°C-63°C)

Conexiones:

Diseño de conexión directa (CALIENTE y FRÍO al mismo

nivel).

Estructura:

Estructura de bronce niquelado. O-rings de EPDM (juntas

tóricas de monómero de etilen-propilen-dieno). Fabricado

en EE.UU.

Cumplimiento de la normativa de plomería sin contenido

de plomo: Las superficies de los modelos sin contenido de

plomo que reciben humedad contienen menos de 0.25%

de plomo por promedio ponderado

Presión de funcionamiento: 150 psi (1034 kPa) máximo.

Temperatura de funcionamiento: 212 °F (100 °C) máximo.

Información de patente: Patente de EE.UU. No. 6,079,625

instrucciones. Los modelos "C" de la serie AM-1 con rango de

temperatura de 70°F-120°F (21°C-49°C) y los modelos

"estándar" con rango de temperatura de 70°F-145°F (21°C63°C) tienen la certificación ASSE

de origen) y forman parte de la lista CSA

modelos se deben usar para suministrar agua a bañeras,

duchas, instalaciones de baño y otras salidas. Estas válvulas

se deben instalar en lugares en donde serán accesibles para

la limpieza, mantenimiento y regulación.

®

1017 (aplicación en punto

®

a

y IAPMO®. Estos

Aplicaciones ASSE 1017: punto de origen

Estos modelos de la serie AM-1 se pueden instalar en

cualquier posición que se aplique para el uso deseado. Para

suministro de agua caliente en el hogar, la válvula se debe

instalar como se muestra en la fig. 1. No debe haber instalada

ninguna válvula de cierre entre la tubería de agua fría y la

conexión de agua fría en la válvula de la serie AM-1. Se debe

instalar la válvula de retención como se indica para los

modelos NPT, todos los modelos AM-1 con uniones se

suministran con válvulas de retención completas en los

terminales de agua caliente y de agua fría. Se puede instalar

una válvula de servicio de agua fría como se indica, entre la

tubería de suministro de agua fría al sistema de distribución y

la tubería de agua fría que suministra al calentador de agua y

a la válvula de la serie AM-1.

a

Los modelos UCPVC y UPEX no se encuentran en la lista

de CSA.

®

CUS

Page 10

AM-1 SERIES™

ADVERTENCIA

ARTEFACTOS DE USO DE AGUA

RECIRCULACIÓN

1

(1)

AL LAVAPLATO,

SI LO PERMITE

LA REGLAMENTACIÓN

AQUASTAT

T

(1)

VÁLVULA DE RETENCIÓN

T

BOMBA

AM SERIES

(1)

C

M

H

8

(203)

MAX

CALENTADOR

DE AGUA

TRAMPA

DE CALOR

(152)

6

UBICACIÓN

AUTORIZADA

DE LA VÁLVULA

DE SERVICIO

TANQUE DE

EXPANSIÓN

FUENTE

DE AGUA

FRÍA

V

MS25029A

Fig. 1. Aplicación ASSE 1017 de AM-1 Series

Instalación de Conexiones de Soldadura, de CPVC y PEX.

— Si se utilizan conexiones de soldadura, deberían sol-

darse antes de ensamblar a la válvula o sin la junta de

sellado o la válvula opcional de retención. La junta de

sellado y/o las válvulas de retención pueden instalarse

una vez que la unión se ha enfriado.

— Los acoplamientos de CPVC se limitan a una temper-

atura máxima del sistema de 180° F (82° C) y 100 psi

(689 kPa).

— La conexión PEX y el anillo de presión (proporciona-

dos por el instalador) están diseñados para cumplir los

requisitos de la norma ASTM F1807.

— La tubería PEX usada con conexiones PEX debe

cumplir los requisitos de la norma ASTM F876.

AJUSTE DE VÁLVULAS

Para regular el ajuste de temperatura de la válvula

mezcladora, fije el termómetro (suministrado con la válvula) a

la tubería conectada al terminal de mezcla de la válvula.

Afloje el tornillo de la manivela, levante la manivela y gire

hasta alcanzar la temperatura deseada como se indica en el

termómetro. Vuelva a colocar la manivela y ajuste el tornillo

otra vez.

Procedimiento de ajuste de la temperatura

Es posible limitar el rango de temperatura. Para emplear esta

función:

4

2

c

1

SUELTE EL TORNILLO Y

LEVANTE LA MANIVELA.

GIRE LA MANIVELA EN EL SENTIDO

2

DE LAS AGUJAS DEL RELOJ O EN EL

SENTIDO CONTRARIO PARA AJUSTAR

LA TEMPERATURA.

2

33

H

c

VUELVA A COLOCAR LA MANIVELA

3

EN LA POSICIÓN DE BLOQUEO.

4

VUELVA A APRETAR EL TORNILLO.

H

MS27487

Instalación de la Tira Térmica

Limpie el tubo y aplique con firmeza la tira térmica en la salida

mezcladora de la válvula. Haga correr el agua y ajuste la

temperatura de salida al rango deseado. La temperatura real

del agua mezclada se indica en verde con incrementos de 2°

F (1° C). El azul significa que la temperatura es ligeramente

menor y el marrón indica que es apenas mayor.

Temperaturas superiores a los 120° F (49° C)

pueden provocar lesiones serias. Un contratista

con licencia debería fijar la temperatura de la

válvula mezcladora conforme a los requisitos del

código local. Para garantizar un control de

temperatura correcto, utilice un termómetro de

agua en la boca de salida de la llave.

El termómetro es PARA USAR UNA SOLA VEZ para el

ajuste inicial de la temperatura del sistema. Verifique la fecha

de expiración impresa en la banda de temperatura para

asegurarse de la exactitud de la lectura de la temperatura. De

ser necesario, póngase en contacto con su distribuidor

Honeywell para obtener un termómetro de repuesto, número

de parte TS205-064.

62-3075EFS—03 10

Fig. 2. Tira térmica.

Procedimiento Posterior a la Instalación

1. Anote el ajuste de temperatura en la etiqueta de PRE-

CAUCIÓN y firme en el espacio que se proporciona.

2. Pegue la etiqueta de ADVERTENCIA a la válvula AM-1.

3. Explique la etiqueta de ADVERTENCIA al propietario.

4. Deje esta hoja de instrucciones en poder del propi-

etario.

Page 11

FUNCIONAMIENTO

La válvula AM-1 series funciona en forma automática a través

del empleo de un elemento termostático en el producto. El

elemento controlará la mezcla del suministro caliente y frío

para brindar agua templada a las piezas con las que se

conecta. De esta forma, se brinda una temperatura constante

del agua bajo las diferentes condiciones de funcionamiento.

PROCEDIMIENTOS DE MANTENIMIENTO

TUERCA SUPERIOR

TUERCA INFERIOR

JUNTA TÓRICA

AM-1 SERIES™

MANIVELA

ANILLO DE RETENCIÓN

ENSAMBLAJE SUPERIOR

ENSAMBLAJE INFERIOR

El uso de agua dura puede dar como resultado la formación

de depósitos de sarro, lo que provoca el agarrotamiento de

las piezas internas en casos extremos. La limpieza de las

piezas internas restablece generalmente la válvula a las

condiciones de operación normales. En algunos casos, puede

ser necesario reemplazar el ensamblaje inferior.

Para limpiar y/o reemplazar el ensamblaje inferior, corte el

agua y:

1. Con la ayuda de un destornillador, extraiga el tornillo y

la manivela.

2. Suelte la tuerca superior (sin extraerla) para permitir la

colocación de una llave ajustable en la tuerca inferior.

Desatornille la tuerca inferior (en el sentido contrario al

de las agujas del reloj). Ello permitirá la extracción del

ensamblaje superior.

3. El ensamblaje superior de latón saldrá. Extraiga el

ensamblaje inferior, el difusor y el resorte.

4. Elimine cuidadosamente todo sarro (depósito de calcio)

o partículas extrañas del asiento de la válvula y de otras

piezas internas. Use vinagre para remover el calcio.

Moje las piezas hasta que el calcio se ablande y se

pueda raspar y eliminar con el lavado. No use solventes

ni raye las superficies de metal o revestidas con

Te fl o n®.

5. Vuelva a colocar el resorte, el difusor y el ensamblaje

inferior limpios con ayuda de las instrucciones a continuación o use un conjunto de kit de recambio nuevo.

Para conocer el número de kit correcto, consulte la

Tabla 1.

Instale el resorte, el difusor y el ensamblaje inferior:

DIFUSOR

RESORTE

C

H

H

CUERPO DE LA VÁLVULA

MIX

MS23941

Fig. 3. Ensamblaje de las válvulas serie AM-1.

Tabla 1. Kits para reemplazar la válvula serie AM-1.

Modelo Rango de temperatura Pieza No.

C 70° - 120° F (21°-49°C) (“C”) AMP-1-020 RP

STD 100° - 145° F (38° - 63° C) AM-1-025 RP

A

Ø 1-51/64

(46)

2-1/4

(57)

A. Inserte el resorte en el difusor.

B. Inserte el difusor introduciendo en primer lugar el extremo del

resorte en el cuerpo.

C. Coloque el ensamblaje superior de la válvula en el ensamblaje

inferior e inserte en la válvula.

D. Apriete la tuerca inferior.

E. Cambie la ubicación del volante manual e inserte el tornillo. Gire

el volante manual a la graduación de temperatura deseada.

MIX

C

C

M23938

H

B

Fig. 4. Dimensiones en pulg. (mm).

11 62-3075EFS—03

Page 12

AM-1 SERIES™

AM-1 Series™ es una marca de Honeywell International, Inc.

®

es una marca registrada de American Society of Sanitary Engineering.

ASSE

CSA es una marca registrada de Canadian Standards Association.

®

IAPMO

es una marca registrada de International Association of Plumbing and Mechanical Officials.

®

es una marca registrada de American Society for Testing and Materials.

ASTM

®

es una marca registrada de E.I. du Pont de Nemours and Company.

Tefl on

Automatización y control desenlace

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35, Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® Marca Registrada en los EE. UU.

© 2010 Honeywell International Inc.

todos Los Derechos Reservados

62-3075EFS—03 M.S. Rev. 11-10

Impreso en EE. UU..

Loading...

Loading...