Page 1

R7184A,B,P,U

Interrupted Electronic Oil Primary

INSTALLATION INSTRUCTIONS

APPLICATION

The R7184A,B,P,U Interrupted Electronic Oil Primary is a

line voltage, safety rated, interrupted ignition oil primary

control for residential oil fired burners used in boiler s,

forced air furnaces and water heaters. The

R7184A,B,P, U used with a cad cell flame sensor,

operates an oil burner and optional oil valve. The primary

controls fuel oil, senses flame, controls ignition spark and

notifies a remote alarm circuit when in lockout.

The R7184 can be used with both hydronic and forced air

systems. When used with hydronic systems, line voltage

switching Aquastat® Controllers normally provide for the

starting and stopping of the combustion sequences. With

forced air systems, both mechanical and electron ic low

voltage thermostats control the starting and stopping of

the combustion process.

Some hydronic and forced air systems now require a

delayed valve-on and burner motor-off delay. The R7184

operates an oil valve that prevents the flow of oil when

the burner motor is running prior to combustion (delayed

valve-on) and when the burner motor is running after

combustion (burner motor-off delay).

The R7184 models are intended for use only on oil

burning appliances which do not require prep ur ge and

post-purge as a safety related function as defined in U L

296. The valve-on delay and burner motor-off delay in

this control are intended only to help establish draf t an d

reduce oil after-drip related problems.

FEATURES

Limited Recycle

This feature limits the number of recycle trials (for each

call for heat) to a maximum of three trials. If the flame is

lost three times and does not successfully satisfy a call

for heat, the R7184 locks out.

Pump Priming Cycle

T o facilitate purging air from the oil lines and filters, the

R7184 can be placed in a purge routine by pressing and

releasing the reset button during the safety check,

delayed valve-on , ignition or carry-over periods. The

lockout timing will be extended to 4 minutes and the

ignition set in the intermittent mode for this cycle only.

The R7184 automatically reverts to its labeled interrupted

and safety switch timing states. The pump primin g cycle

can only be entered if there have been no lockout

occurrences since the last successful heat call. To reset

the device so that the pump priming cycle can be

entered, press and hold the reset button for 30 seconds

until the LED flashes twice.

Disable Function

Pressing and holding the reset button will disabl e all

functions until the button is released. The R7184 will

restart at the beginning of the normal heat cycle on

safety check.

Limited Reset (Restricted Mode)

In order to limit the accumulation of unburned oi l in the

combustion area, the control can only be reset three

times. The reset count returns to zero each time a call for

heat is successfully completed.

To reset from restricted mode: Press and hold the reset

button for 30 seconds. When the LED flashes twice, the

device has reset.

SPECIFICATIONS

Models:

Table 1 lists the major features and the applicable w iring

diagram numbers for the R7184.

Timing:

Safe Start Check: 5 seconds (approximately).

Valve-on Delay: 15 seconds.

Burner motor-off Delay: 0, 2, 4, or 6 minutes, field-

selectable using DIP switch positions 1 and 2.

NOTE: For universal R7184U model, valve-on delay

and burner motor-off delay timings can be

enabled (values as listed) or disabled (values

are zero) in the field using DIP switch position 3.

Lockout: 15, 30 or 45 seconds (factory-programmed ).

Recycle: 60 seconds (fixed).

Ignition Carryover: 10 seconds (fixed).

® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc. • All Rights Reserved

69- 1233- 2

Page 2

R7184A,B,P,U INTERRUPTED ELECTRONIC OIL PRIMARY

Electrical Ratings:

Inputs:

Voltage: 102 to 132 Vac, 120 Vac nominal.

Current: 100 mA plus burner motor, valve and ignitor

loads.

Frequency: 60 Hz.

Outputs:

Relay Contacts:

Burner: 120 Vac, 10 full load amperes (FLA),

60 locked rotor amperes (LRA).

Valve: 120 Vac, 1A.

Ignitor: 120 Vac, 360 VA.

Alarm: 30 Vac, 2A.

Thermostat Current Available: 100 mA.

Table 1. R7184 Models.

Model

R7184A None None None 3,4,5 Yes

R7184B 15 None None 3,6,7

R7184P

R7184U Selectable 0 or 15 Selectable 0 or

a

Some select models may have a delay enable/disable swit ch.

b

Standard timings. Other timing may be availa ble on select mo dels.

c

Select models are provided with a T-T jumper which can be disa bled by cutting with a pair of side-cutting pliers.

Valve-on delay

a

15

(sec)

Burner motor-off

delay (min)

b

0/2/4/6

b

0,2,4,6

NOTE: Reduce burner FLA rating by Ignitor load. For

example, if the ignitor draws 3A (120 Vac, 360

VA), reduce the burner motor FLA to 7A.

Environmental Ratings:

Operating Ambient Temperature: -40°F (-40°C) to

+147°F (+64°C).

Shipping Temperature: -20°F (-29°C) to +150°F (+66°C).

Humidity: 90% relative humidity at 95°F (9 3°C)

noncondensing.

Approvals:

Underwriters Laboratories Inc.: Recogni zed.

Canadian Underwriters Laboratories Inc.

Alarm

Contacts

Optional 3,6,7 Yes

Yes 3,6,7 Yes

Typical Wiring Diagram

Fig. Reference No.

Thermostat

Terminal s T- T

c

Yes

INSTALLATION

When Installing this Product...

Read these instructions carefully. Failure to follow

1.

instructions can damage product or cause a

hazardous condition.

Check ratings given in these instructions and on

2.

product to make sure product is suitable for your

application.

Make sure installer is a trained, experienced

3.

service technician.

Use these instructions to check out product

4.

operation after installation.

R7184S7184

BURNER

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

Location

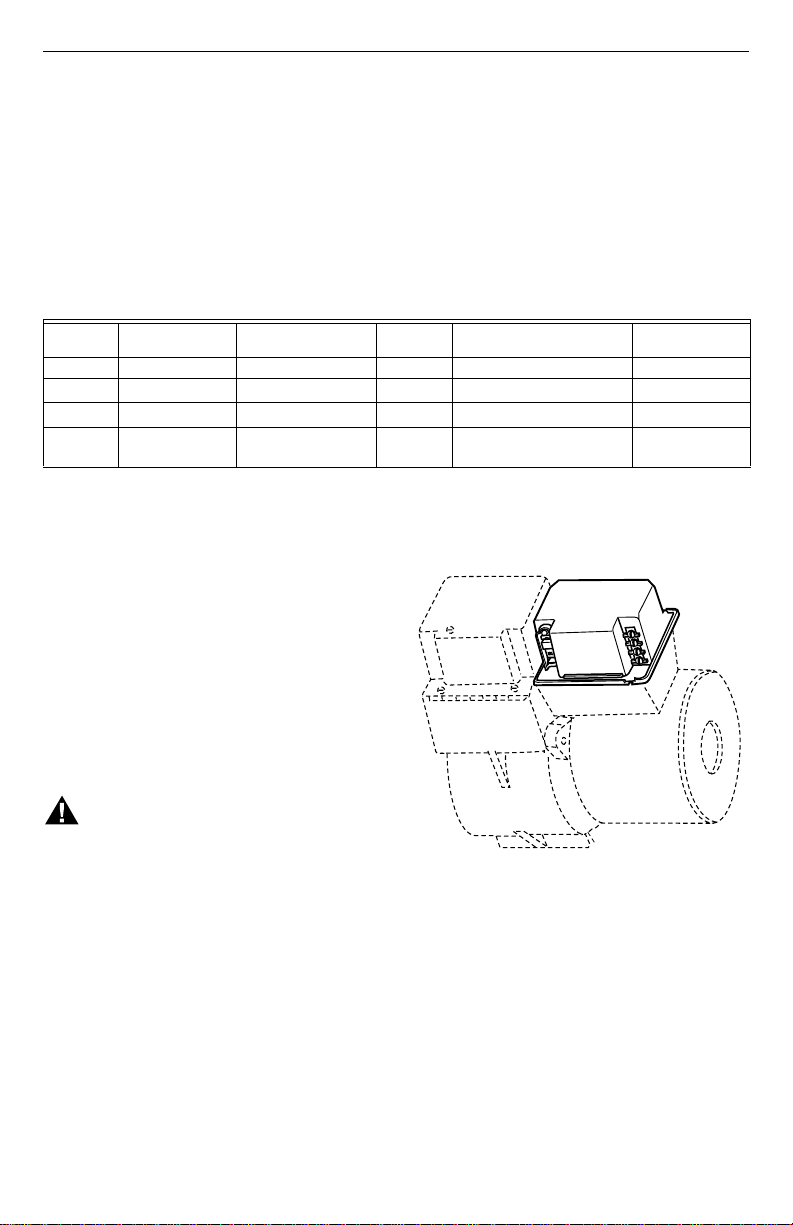

Mount on a 4 in. by 4 in. junction box, directly on

1.

the main burner or inside the appliance cabinet. In

replacement applications, mount in the same

location as the old control. See Fig. 1. Make sure

the operating temperatures are within the ambient

temperature range (see Specifications section).

Before mounting the control, make line voltage

2.

connections as shown in Fig. 2 through 7. Splice

lines with solderless connectors. Do not exceed

load ratings shown on the device label.

If necessary, use the control as a template to mark

3.

and drill new mounting holes.

Mount using No. 6 screws (obtained locally).

4.

69-1233—2 2

M17180A

Fig. 1. Mounting R7184 on junc tion box.

WIRING

Make sure wiring complies with all local codes and

1.

ordinances.

After mounting, make low voltage connections to

2.

the screw terminals (see Fig. 2 through 7).

Strip leads 3/8 in. (10 mm) and insert under

3.

terminal screw. See Fig. 1.

Connect thermostat leads to T-T.

4.

Switch Settings

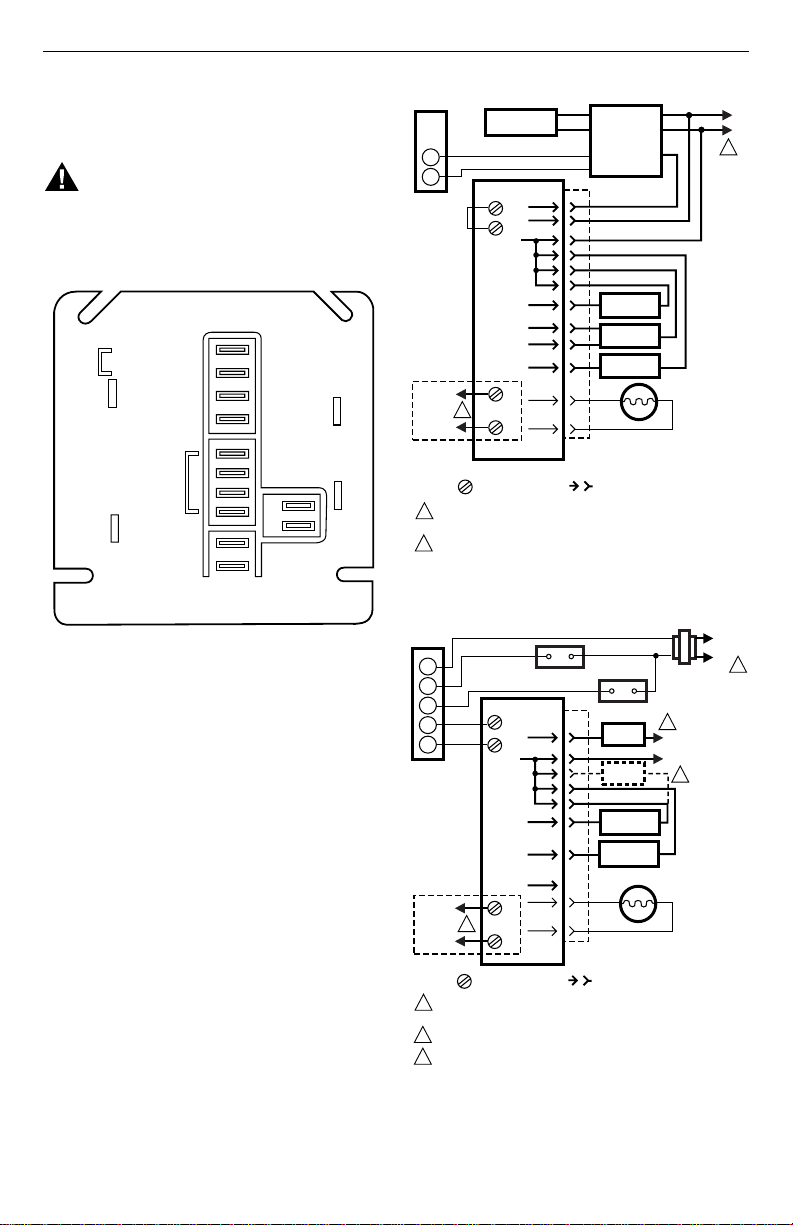

Figure 8 and Table 2 provide the switch settings for the

R7184U.

Page 3

R7184A,B,P,U IN TE RRUPTED ELECTRONIC OIL PRIMARY

CHECKOUT

Start System

WARNING

Fire Hazard.

Can cause serious injury or death.

Make sure combustion chamber is free of oil

and/or oil vapor before starting system.

INTERRUPTED

IGNITOR

INTERMITTENT

BURNER MOTOR

L1

L2

LIMIT

VALVE

Fig. 2. Wiring terminals.

Open hand valve in oil supply line.

1.

Make sure system is powered. Check circuit

2.

breaker or fuse and close system switch, if

provided.

Set thermostat to call for heat.

3.

Make sure burner lights and operates until call for

4.

heat ends.

Check Safety Features

Safe Start

Place a jumper across cad cell terminals.

1.

Follow procedure to turn on burner. Burner must

2.

not start, indicator light turns on and control

remains in Idle Mode.

Simulate flame failure:

Follow procedure to turn on burner.

1.

Close hand valve in oil supply line.

2.

Device enters recycle mode.

3.

Device tries to restart system after approximately

4.

60 seconds.

Safety switch locks out approximately in safety

5.

switch timing indicated on label. Indicator light

flashes at 1 Hz rate. Ignition and motor stop and oil

valve closes.

CAD CELL

M16453A

THERMOSTAT

R

W

TO

REMOTE

ALARM

CIRCUIT

LEGEND:

1

2

CIRCULATION

PUMP

R7184

LIMIT

T

T

JUMPER

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

OPTIONAL FEATURE ON SELECT MODELS.

L2

BURNER MOTOR

INTERRUPTED

IGNITOR

INTERMITTENT

VALVE

CAD

ALARM

CELL

SCREW TERMINAL

L8148A,C

C1

AQUASTAT®

CONTROLLER

C2

L1

JUNCTION

BOX

B2

B1

T

T

BURNER

MOTOR

IGNITOR

VALVE

CAD

CELL

1/4 IN. QUICK CONNECT TERMINAL

M17182B

Fig. 3. Wiring for typical oil-fired bo il er.

HOT

L1

(HOT)

L2

1

L1

L2

3

M17183B

T8600

RC

G

Y

R

W

TO

REMOTE

ALARM

2

CIRCUIT

LEGEND:

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

OPTIONAL FEATURE ON SELECT MODELS.

VALVE MAY BE ADDED AS SHOWN.

3

Fig. 4. Typical wiring diagram for 24 Vac thermostat

and R7184 for an oil-fired forced air system.

FAN RELAY

R7184

T

L1

T

L2

BURNER

MOTOR

INTERRUPTED

IGNITOR

INTERMITTENT

CAD

CELL

ALARM

SCREW TERMINAL

COOLING

CONTROL

LIMIT

VALVE

BURNER

MOTOR

IGNITOR

CAD

CELL

JUNCTION

BOX

1/4 IN. QUICK CONNECT TERMINAL

L1

L2

1

1

3 69-1233—2

Page 4

R7184A,B,P,U INTERRUPTED ELECTRONIC OIL PRIMARY

JUMPER

TO

REMOTE

ALARM

CIRCUIT

LEGEND:

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

OPTIONAL FEATURE ON SELECT MODELS.

2

3

VALVE MAY BE ADDED AS SHOWN.

Fig. 5. Typical wiring diagram for line voltage

Aquastat® thermostat and R 7184 for an oil burner

T8600

RC

G

Y

R

W

R7184

T

T

BURNER

MOTOR

INTERRUPTED

IGNITOR

INTERMITTENT

ALARM

2

SCREW TERMINAL

R7184

T

T

L1

L2

CAD

CELL

FAN RELAY

L1

LIMIT

L2

LINE VOLTAGE

THERMOSTAT

OR AQUASTAT®

CONTROL

VALVE

BURNER

MOTOR

IGNITOR

CAD

CELL

JUNCTION

BOX

1/4 IN. QUICK CONNECT TERMINAL

system.

COOLING

CONTROL

LIMIT

LIMIT

3

M17184B

1

L1

HOT

L2

1

L1

HOT

L1

(HOT)

L2

L2

1

JUMPER

TO

REMOTE

ALARM

CIRCUIT

LEGEND:

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

OPTIONAL FEATURE ON SELECT MODELS.

Fig. 7. Typical wiring diagram for line voltage

Aquastat® thermostat and R718 4B,P,U for valve-on

delay/burner motor-off delay oil burner system.

Simulate ignition failure:

Follow starting procedure to turn on burner, but do

1.

not open oil supply hand valve.

Observe that safety switch locks out approximately

2.

within safety switch timing as indicated on the

label. Indicator light flashes at 1 Hz rate. Ignition

and motor stop and oil valve closes.

OPERATION

R7184

T

T

VALVE

BURNER

MOTOR

INTERRUPTED

IGNITOR

INTERMITTENT

ALARM

2

SCREW TERMINAL

LIMIT

L2

L1

CAD

CELL

LINE VOLTAGE

THERMOSTAT

OR AQUASTAT®

CONTROL

OIL

VALVE

BURNER

MOTOR

IGNITOR

CAD

CELL

JUNCTION BOX

1/4 IN. QUICK CONNECT TERMINAL

LIMIT

M17186A

HOT

1

L1

L2

VALVE

BURNER

MOTOR

INTERRUPTED

IGNITOR

INTERMITTENT

TO

REMOTE

ALARM

2

CIRCUIT

LEGEND:

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

OPTIONAL FEATURE ON SELECT MODELS.

Fig. 6. Typical wiring diagram for 24 Vac thermostat

and R7184 for valve-on delay/bu r ner mo t or off oi l

CAD

ALARM

CELL

SCREW TERMINAL

burner system.

OIL

VALVE

BURNER

MOTOR

IGNITOR

CAD

CELL

JUNCTION

BOX

1/4 IN. QUICK CONNECT TERMINAL

M17185A

The R7184 is a microprocessor-based contr ol. The

indicator light provides diagnostic information for lockout,

recycling and patented cad cell status. There is a manual

reset button to exit the lockout mode and enter the idle

mode. Operation is shown in Table 4.

TROUBLESHOOTING AND MAINTENANCE

IMPORTANT:

Due to the potential hazard of line voltage, only

a trained, experienced service technician

should perform the troubleshooting procedure.

This control contains no field-serviceable parts.

Do not attempt to take it apart. Replace entire

control if operation is not as described.

To completely troubleshoot an oil burner ins tal la ti on,

check the burner and oil primary control for proper

operation and condition.

The indicator light on the oil primary control provid es

lockout, recycle and cad cell indications as follows:

69-1233—24

Page 5

R7184A,B,P,U IN TE RRUPTED ELECTRONIC OIL PRIMARY

Flashing at 1 Hz (1/2 second on, 1/2 second off):

1.

system is locked out or in restricted mode.

Flashing at 1/4 Hz (2 seconds on, 2 seconds off):

2.

control is in recycle mode.

VALVE ON DELAY TIME: 15 SEC. (FIXED)

BURNER MOTOR OFF DELAY TIME:

ON

ON

ON

1

1

2

2

0 MIN. 2 MIN.

(SHADED AREA IS SWITCH HANDLE POSITION)

1

4 MIN.

ON

2

6 MIN.

1

2

DELAY TIMES:

ENABLED DISABLED

33

M17535

On: cad cell is sensing flame.

3.

Off: cad cell is not sensing flame.

4.

Fig. 8. Switch settings for burner-o ff delay times.

Table 2. Switch Settings and Delays.

Delay Timings DIP Switch Settings

Burner Motor-Off Delay

Valve-On

Delay

(seconds)

(minutes)

R7184U R7184P R7184U R7184P

S-1 S-2

S-3 Enable/Disable

00— XX Off +

15 0 0.5 Off Off On +

15 2 2 Off On On +

15 4 4 On Off On +

15 6 8 On On On +

X = Don’t Care.

+ = S-3 not provided on R7184P models.

Check the piping to the oil tank.

Cad Cell Resistance Check

For proper operation it is important that the cad cell

resistance is below 1600 ohms. During a normal call for

heat, once the control has entered the Run mode, press

and release the reset button. Indicator light will flash 1 to

4 flashes. See Table 3 for equivalent cad cell resistance.

Table 3. Cad cell resistance when sensing flame.

Flashes Cad Cell Resistance in ohms

1 Less than 400

2 More than400 and less than 800

6.

Check the oil nozzle, oil supply and oil filter.

7.

Check Oil Primary Control

If the trouble is not in the burner or ignition hardwar e,

check the oil primary control by using the following

equipment:

Screwdriver.

1.

Voltmeter (0 to 150 Vac).

2.

Insulated jumper wire with both ends stripped.

3.

3 More than 800 and less than 1600

4 More than 1600 and less than 5000

Preliminary Steps

Check wiring connections and power supply.

1.

Make sure power is on to the controls.

2.

Make sure limit control is closed.

3.

Check contacts between ignitor and the

4.

electrodes.

Check the oil pump pressure.

5.

WARNING

Electrical Shock Hazard.

Can cause s er ious injury or death.

Troubleshoot with the system powered. Be

careful to observe all precautions to prevent

electrical shock or equipment damage.

Refer to Table 4 for further troubleshooting

information.

5 69-1233—2

Page 6

R7184A,B,P,U INTERRUPTED ELECTRONIC OIL PRIMARY

Table 4. R7184 Operation.

External Ac tion R7184 Action

Power applied to control. Internal safety check conducted. If no light or flame is detected and all internal

Thermostat or Aquastat

Control calls for heat.

Call for heat is satisfied.

Reset button pushed two

times without device

completing a call for heat.

conditions are correct, control enters Idle mode.

®

Shorts across T-T terminals (on as call for heat) in warm air system and/ or

1.

provides power to limit terminals in hydronic system.

Safety Period (4 seconds) internal and external check for flame or light. If flame or

2.

light is detected, control remains in Idle mode.

When flame or light is not present:

3.

a. R7184A,U (if valve-on delay is disabled) will apply power to the burner motor

and ignitor.

b. R7184B,P,U (if valve-on delay is enabled) will apply power to the burner motor

and ignitor, enter/complete valve-on delay period and then apply power to the

valve.

Control enters Trial for Ignition period.

4.

a. Monitors burner for flame.

b. When flame is not detected:

(1) Enters lockout mode (after lockout ti m e of 15, 30 or 45 seconds) .

(2) Shuts off valve, ignitor and burner motor.

(3) Flashes indicator light at 1 Hz (1/2 second on, 1/2 second off).

(4) Depress reset button to return to power up sequence.

c. When flame is detected, Carry-Over period begins:

Control enters Ignition Carry-Over period (cont inues to spark for 10 to 30

5.

seconds).

a. Turns on indicator light.

b. If flame is lost and lockout time has not expired, R7184 returns to Trial for

Ignition period.

c. If flame is lost and lockout time has expired, R7184 enters Recycle Mode.

Carry-Over time expires; ignitor turns off.

6.

Enters Run Mode:

7.

a. Flame is monitored until call for heat ends or flame is lost. If flame is lost:

(1) Control enters Recycle Mode.

(2) Recycle time starts (60 seconds).

(3) Burner and valve are turned off.

(4) Indicator light flashes at 1/4 Hz (2 seconds on, 2 seconds off).

(5) Returns to Idle mode at end of Recycle mode.

R7184A,U (if burner motor-off delay is disabled):

1.

a. Burner motor and oil valve shut off.

b. Indicator light turns off.

R7184B,P,U (if burner motor-off delay is enabled):

2.

a. Oil valve shuts off.

b. Burner motor runs for selected burner moto r-off delay.

c. Bu rner motor turns off.

d. Device returns to Idle mode.

R7184 enters Restricted mode.

1.

Indicator light flashes at 1Hz (1/2 second on, 1/2 second off).

2.

Reset device by pressing and holding reset button for a minimum of 30 seconds.

3.

Table 5. Troubleshooting Information .

Procedure Status Correct ive Actions

Condition: Burner does not start w ith a cal l for heat .

1. Check that limit switches are closed

and contacts are clean.

2. Check for line voltage power at the oil

primary control. Voltage should be 120

Vac.

3. Check indicator light with burner off,

no call for heat (no flame).

——

——

Indicator light is on. Cad cell or controller is defective, sees external light

or connections are shorted. Go to step 4.

Indicator light is off. Go to step 5.

69-1233—26

Page 7

R7184A,B,P,U IN TE RRUPTED ELECTRONIC OIL PRIMARY

Table 5. Troubleshooting Information (Continued).

Procedure Status Correct ive Actions

4. Shield cad cell from external light. Indicator light turns

5. On warm air systems, jumper

thermostat (T to T) terminals on R7184.

(On hydronic systems jumper Limit

terminal and L1 of R7184.)

IMPORTANT:

First remove one thermostat

lead.

Condition: Burner starts, then locks out on safety with indicator light flashing at 1 Hz rate (1/2 second on, 1/2

second off)

1. Check that limit switches are closed

and contacts are clean.

2. Check for line voltage power at the

oil primary control. Voltage should be

120 Vac.

3. Check indicator light with burner off,

no call for heat (no flame).

4. Shield cad cell from external light. Indicator light turns

.

off.

Indicator light stays

on.

Burner starts. Trouble in thermostat or limit circuit. Check

Burner does not start. • Disconnect line voltage pow er and open line

––

––

Indicator light is on. Cad cell or controller is defective, sees external light

Indicator light is off. Go to step 5.

off.

Indicator light stays

on.

Eliminate external light source or permanently shield

cad cell.

• Replace cad cell with new cad cell and recheck.

• If indicator light does not turn off, remove cad cell

leadwires from R7184 and recheck.

• If indicator light turns off, replace cad cell bracket

assembly. Refer to TRADELINE® Catalog for

bracket part numbers.

• If indicator light does not turn off, replace

controller.

thermostat or limit wiring connections.

switch.

• Check all wiring connections.

• Tighten any loose connections and recheck.

• If burner does not start, replace R7184.

or connections are shorted. Go to step 4.

Eliminate external light source or permanently shield

cad cell.

•

Replace cad cell with new cad cell and

recheck.

•

If indicator light does not turn off, remove cad

cell leadwires from R7184 and recheck.

•

If indicator light turns off, replace cad cell

bracket assembly. Refer to TRADELINE

®

catalog for bracket part numbers.

•

If indicator light does not turn off, replace

controller.

5. On warm air systems, jumper

thermostat (T to T) terminals on R7184.

(On hydronic systems, jumper Limit

terminal and L1 of R7184.)

IMPORTANT:

First remove one thermostat lead.

Burner starts. Trouble is in thermostat or limit circuit. Check

Burner does not start.

thermostat or limit wiring connections.

•

Disconnect line voltage power and open line

switch.

•

Check all wiring connections.

•

Tighten any loose connections and recheck.

•

If burner does not start, replace R7184.

Condition: Burner starts then locks out on safety with indicator light fl ashing at 1 Hz rate (1/2 second on, 1/2

second off)

6. Reset oil primary control by pushing

in and releasing red reset button.

Indicator light stops

flashing.

Indicator light

continues to flash at

a

1 Hz rate

.

Go to step 7.

Verify that control is not in restricted mode (see

footnote a). If not in restricted mode, replace R7184.

7 69-1233—2

Page 8

R7184A,B,P,U INTERRUPTED ELECTRONIC OIL PRIMARY

Table 5. Troubleshooting Information (Continued).

Procedure Status Correct ive Actions

7. Listen for spark after burner turns on

(after a 2 second delay.

Ignition is off. Spark ignitor could be defective. Check for line

Ignition is on. Go to step 8.

Ignition is on, but no

oil is being sprayed

into the combustion

chamber.

8. Check indicator light after flame is

established, but before oil primary

control locks out.

9. Check cad cell sighting for view of

flame.

• Disconnect line voltage power and

open line switch.

• Unplug cad cell and clean cad cell

face with soft cloth. Check sighting

for clear view of flame. Place cad cell

back in socket.

• Reconnect line voltage power and

close line switch.

• Start burner.

10. Check cad cell.

• Disconnect line voltage power and

open line switch.

• Remove exi sting cad ce ll an d repl ace

with new cad cell.

• Disconnect all wires from thermostat

terminals to be sure there is no call

for heat.

• Reconnect line voltage power and

close line switch.

• Expose new cad cell to bright light,

such as a flashlight.

11. Check cad cell bracket assembly.

• Disconnect line voltage power and

open line switch.

• Remove cad cell wires from quickconnect connectors on the R7184

and leave control leadwires open.

• Apply power to device.

• Place jumper across cad cell

terminals after burner motor turns on.

Indicator light is on

until the control locks

out and starts flashing

during lockout.

Indicator light stays

off.

Burner locks out. Go to step 10.

Burner keeps running. System is okay.

Indicator light is on. Place control back on burner. Go to step 6.

Indicator light is off. Go to step 11.

Indicator light is on. Replace cad cell bracket assembly. Refer to

Indicator light is off. Replace R7184.

voltage at ignitor terminals. If line voltage is present,

replace R7184.

Wait for Valve On Delay to complete (R7184B,P, and

U). Check oil valve, oil valve wiring, pump and oil

supply.

Replace R7184.

Go to step 9.

TRADELINE® Catalog for bracket part numbers.

Home and Building Control Home and Building Control

Honeywell Inc. Honeywell Limited-Honeywell Limitée

Honeywell Plaza 155 Gordon Baker Road

P.O. Box 524 North York, Ontario

Minneapolis, MN 55408-0524 M2H 3N7

69-1233—2 G.R. Rev. 5-00 www.honeywell.com

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

Loading...

Loading...