Page 1

Instruction

Manual

Instruction Manual

Total Construction Solutions

PENTAX Industrial Instruments Co.,Ltd.

2-5-2 Higashi-Oizumi / Nerima-ku, Tokyo 178-0063,Japan

Tel.+81 3 5905 1222 / Fax +81 3 5905 1225

E-mail:international@piic.pentax.co.jp

Website:www.pentax.co.jp/piic/survey

www.pentaxsurveying .com

PLP-601

PLP-602

PLP-601R

Automatic Self-leveling Laser

Automatic Self-leveling Laser

Automatic Self-leveling Laser

PLP-602R

Automatic Self-leveling Laser

Page 2

Page 3

3

Safety Precautions (must be followed)

The following items are intended to prevent possible injury to the user or

other people and/or damage to the instrument.

These safety precautions are important to the safe operation of this

product and should be observed at all times.

•

Distinctive Displays

The following displays are used to distinguish precautions by the

degree of injury or damage that may result if the precaution is ignored.

WARNING

Items indicated by this indication are precautions which,if ignored,

could result in death or serious injury.

CAUTION

Items indicated by this indication are precautions which,if ignored,

may result in injury or material damage.

• The term ‘injury’here refers to injuries such as cuts,bums or elec tric

shock,the treatment of which will not likely require hospitalization or

longterm attention.

• ‘Material damage’refers to damage to facilities,buildings,acquired

data,etc.

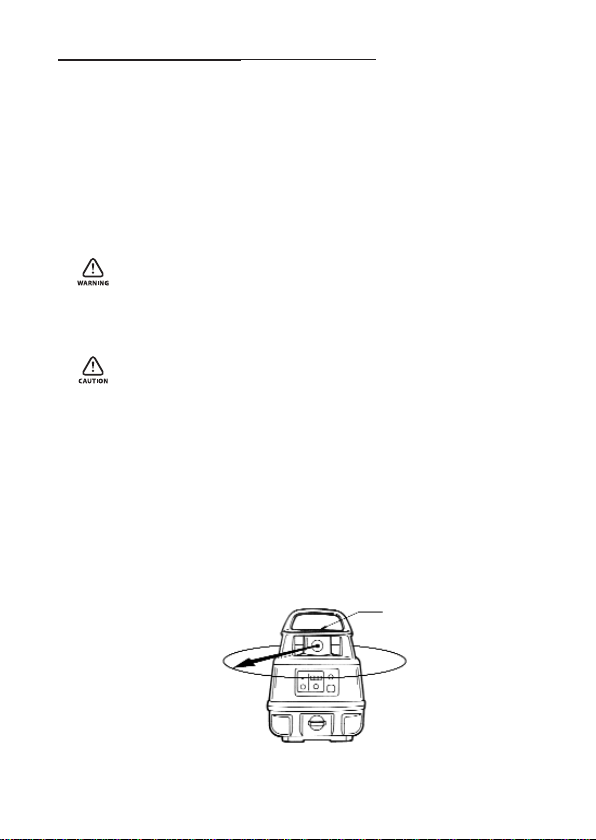

1.For safety in handling this laser

product,operate it according to the

instructions shown on the warning

label,the location of which is shown

in the following illustration.

3.Laser is emitted

from here and this

part is rotated.

2.Laser warning label

The label is put on the ceiling.

Page 4

4

WARNING

• While the instrument is operating,be careful not to expose your

eyes to the emitting laser beam (red light source).Exposure to a

laser beam for a long time may be hazardous to your eyes.

(Laser beam:Equivalent to class 2 Laser level)

• Do not try to dismantle the instrument.Have it repaired by your

dealer or authorized repair shop.Dismantling it by yourself may

worsen the trouble.

CAUTION

• Do not stand on the carrying case.The case could turn over

causing the person standing on it to fall.

• When attaching the instrument to a tripod,make sure the

instrument is securely fixed to the tripod and then securely

tighten the tripod leg clamps.If not securely fastened and/or

tightened,the main unit could fall off or the tripod could fall over.

• When carrying the tripod,be careful so that the tripod shoes do

not strike anyone.

• When setting the tripod,make sure not to stab someone’s hand

or foot with the tripod shoes.

• Operate this laser product with the height of laser avoiding that

of eyes of car drivers and pedestrians.

Avoid putting the laser on a highly reflective material such as mirror.

When disposing of this instrument,take a measure such as

breaking the battery cap so that the laser will not be emitted.

Page 5

5

Precautions

The instrument should not be stored or used in extreme temperatures or

job on a place subject to rapid change of temperature.

(Refer to the ambient temperature range) The instrument may not

function properly if used out of the ambient temperature range.

Page 6

6

Put into the carrying for storage and place in a dry area not subject to

vibration,dust or high moisture.

When storage and usage temperatures are widely different,leave the

instrument in the case until it can adjust to the surrounding temperature.

Page 7

7

The detector (option) may react to the Laser beam and further react to

the Fluorescent lamp,Site lamp,modulated light or an electric wave

(in or near the airport etc.) and so correct measurement is sometimes not

performed near these places.In these cases,please measure again after

stopping or cutting these modulated light or wave etc.

The instrument should be transported or carried carefully to avoid

impact or vibration.

Page 8

8

The instrument should be stored in the carrying case and packed with

cushioning material and handled with care as ‘Fragile’.

Check the ‘check and adjustment of the datumpoint’ of page 35 in this

manual and be sure to check to see if error exists before the instrument

is used.After the instrument has been stored a long time or it has

suffered an impact or vibration,be sure to check to see if trouble exists

before use.If any trouble exists,adjust or have it repaired.

Page 9

9

Be sure to observe the items in the instruction manual for proper use

of the instrument.

Please replace attached batteries with new ones before you work

because their voltage may be low.

Page 10

10

CONTENT

Safety Precautions

Precautions

• 1. For proper use of the instrument 11

1.1 Standard configuration

1.2 Description

1.3 Unpacking

1.4 Battery inser tion

• 2. Display and Keypad 17

2.1 Keypad

2.2 Role of keys

2.3 Warning display

• 3. Preparation for measurement 22

3.1 Setting up the tripod

3.2 Setting up the instrument

3.3 Arranging the detector

• 4. Measurement 26

4.1 Operating the instrument

4.2 Operating the detector:LS3

• 5. Maintenance and adjustment 33

5.1 Maintenance after use

5.2 Check and adjustment of the datum point

5.3 Troubleshooting

• 6. Specifications 39

• 7. Notice to the user of this product 40

Page 11

11

1. For proper use of the instrument

1.1 Standard configuration

The instrument (PLP-601 / PLP-602 /PLP-601R / PLP-602R)

Detector (LS6)

Rod Adapter (LA6)

D type battery (PLP-601 / PLP-602)

Charger (PLP-601R / PLP-602R)

Rechargeable Ni-MH battery built in the body (PLP-601R / PLP-602R)

Carrying Case

Instruction Manual

1

2

3

4

5

6

7

8

Page 12

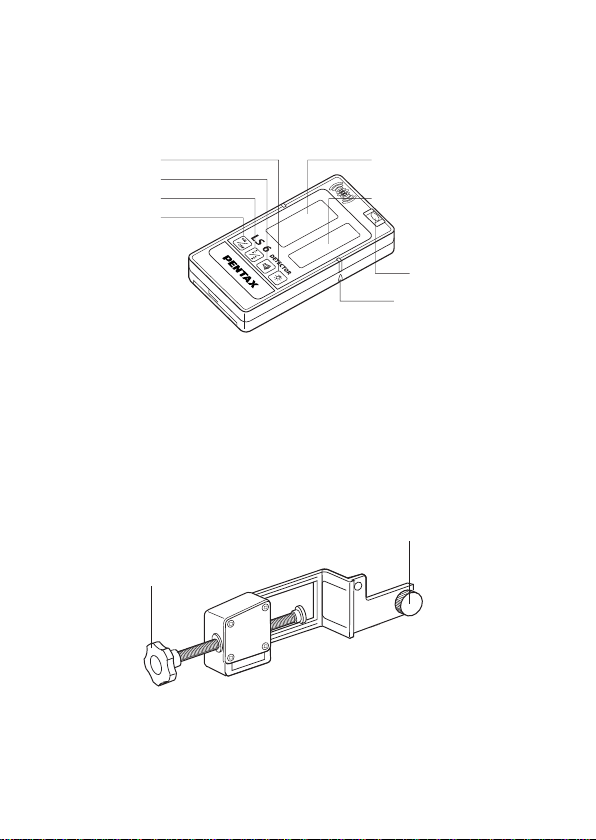

1.2 Description

12

Center mark

Top handle

Emitting beam aperture

Keypad

Detachable knob for

Rotor

Battery cap

Bottom plate

Page 13

13

Plate Vial

Beam Reception Window

LCD Display

Illumination Switch

Buzzer Switch

Accuracy Switch

Power Switch

Index

Fixing Knob

Detector Attaching Screw

Rod Adapter LA6

Page 14

14

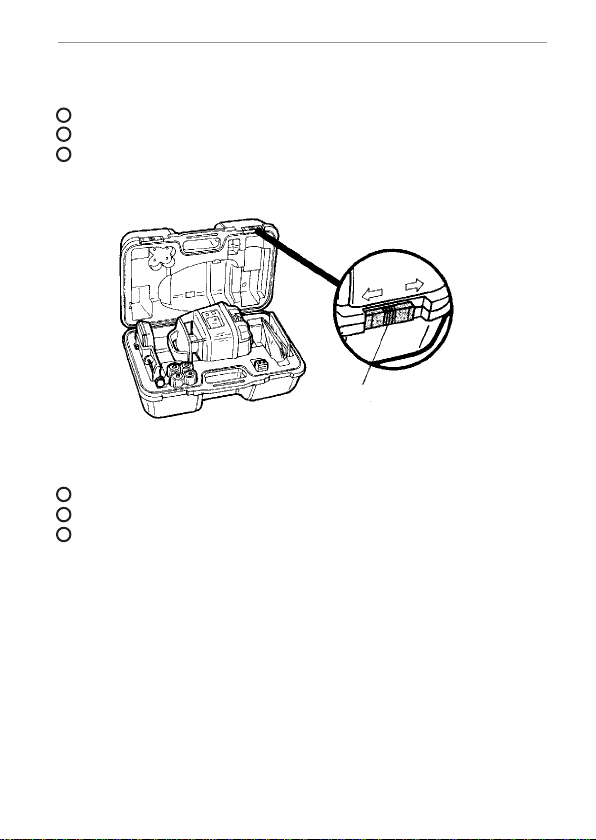

1.3 Unpacking

Taking the instrument out of the carrying case

Gently set down the carrying case so that its cover is upward.

Unlatch and open the case while pushing the latch lock.

Remember how the instrument is placed in the case before

removing it.

Putting the instrument into the carrying case

Set down the carrying case and open the cover

Gently put the instrument into the case

Close the case and secure the latch

NOTE:

• When taking out the instrument,be sure to secure it with your hands.

• When putting the instrument into the case, be sure to turn the power

switch off.

• If the case cover is difficult to close,check again whether or not the

instrument is properly inside the case.

1

2

3

1

2

3

Latch

Page 15

15

1.4 Battery insertion

Battery insertion for the instrument

Turn the detaching knob for battery cap counterclockwise and remove

the cap from the instrument.

Insert 4 pcs D type batteries into the battery box according to its

(+) and (-) marks.(PLP-601 / PLP-602)

While holding the instrument with one hand,push the battery cap into

the battery box and attach it by turning the knob clockwise.

1

2

3

Page 16

16

Battery insertion for the detector

LS6 Detector

Slide the battery cover while pushing its mark and remove it.

Insert the accumulated dry battery into the battery holder according

to its (+) and (-) marks.

Slide the battery cover to reinsert it.

CAUTION:

• Pay attention to the battery holder’s (+) and (-) marks for proper

battery insertion.

• Batteries must be of the same type. D o not use a combination of

batteries whose remaining capacity differs.

1

2

3

Rear View of LS6

Accumulated Dry Battery (6F22)

Battery Cover

Page 17

17

2.Display and Keypad

2.1 Keypad

2.2 Role of keys

(1) Power supply key

ONON

OFFOFF

BATTERY

CHECK POWER

OFF

LEVEL

MANUAL

MODE

Battery check key

Remaining battery display lamp

Auto/Manual

change key

Manual mode

display lamp

Off level

display lamp

Power

supply key

ON

OFF

BATTERY

CHECK POWER

OFF

LEVEL

MANUAL

MODE

ONON

OFFOFF

BATTERTERY Y

CHECKCHECK POPOWERWER

OFFOFF

LELEVELVEL

MANUMANUALAL

MODEMODE

Off level display lamp

Power

supply key

Pushing power supply key begins

the automatic self-leveling.

The off level display lamp blinks in

red during activating the leveling.

The blink interval becomes longer

gradually as the leveling comes

near to completion.

The color of the off level display

lamp turns to green when the

leveling is completed,a rotor

begins to rotate and then a laser

beam is emitted horizontally.

The lamp (green) is turned of

about 5 seconds later after the

leveling completion.

1

2

3

Page 18

18

(2) Battery check key

Remaining battery display lamp

NOTE:

• When 4 pcs rechargeable batteries type D are used,only 2 green

lamps are turned on even if they are fully charged.

The consumption status of a

battery can be confirmed by the

remaining battery display lamp

when the battery check key is

pressed after turning on the power

supply.

The remaining battery display

lamp is turned off about

15 seconds later after the battery

check key is pressed.

1

2

Turning on 3 green lamps

Turning on 2 green lamps

Turning on 1 green lamp

Blink of 1 red lamp

Turning on 1 red lamp

Workable enough.

Remaining capacity is little.

Prepare the spare battery.

Battery is to be replaced.

Replace the battery.

ON

OFF

BATTERY

CHECK POWER

OFF

LEVEL

MANUAL

MODE

ONON

OFFOFF

BATTERTERY Y

CHECKCHECK POPOWERWER

OFFOFF

LELEVELVEL

MANUMANUALAL

MODEMODE

Off level display lamp

Battery check key

Page 19

19

(3) Auto/manual change key

NOTE:

• Simple grade setting can be done by manual mode, but usually

performed without stopping the automatic self-leveling function

(without pressing the Auto/manual change key).

During the manual mode,the horizontal accuracy of emitted laser

beam is not guaranteed.

• During the manual mode, the manual mode display lamp is turned on

in red.

When the Auto/manual change

key is being pressed for more than

2 seconds,the manual mode

display lamp is turned on in red.

The automatic self-leveling begins

and the automatic self-leveling

function stops after completion of

automatic leveling.

During the manual mode,the laser

beam is emitted even if the

instrument is tilted largely

(out of correction area).

When the Auto/manual change

key is pressed again,the manual

mode display lamp is turned off,

the manual mode is reset and

returns to normal function.

1

2

3

4

ONON

OFFOFF

BATTERTERY Y

CHECKCHECK POPOWERWER

OFFOFF

LELEVELVEL

MANUMANUALAL

MODEMODE

Manual mode display lamp

Auto/manual change key

Page 20

20

(4) Switching the rotation speed

• Please switch the rotation speed after turning off the instrument

power supply.

[From 300 to 600 rpm]

NOTE:

• When the instrument is set to 600 rpm,the Manual mode display lamp

and off level display lamp blink in red for a few seconds after power

supply is turned on.

• Rotation speed is set to 300 rpm on factory shipping.

Push the power supply key while

pushing the Auto/Manual change

key.

Manual mode display lamp and off

level display lamp blink in red a

few seconds and tell that the

rotation is switched to 600 rpm.

The switched rotation speeds is

memorized even if power supply is

turned off.

Turn off the power supply and

then push the power supply key

while pressing the battery check

key to return to 300 rpm.

1

2

3

4

ONON

OFFOFF

BATTERTERY Y

CHECKCHECK POPOWERWER

OFFOFF

LELEVELVEL

MANUMANUALAL

MODEMODE

Manual mode display lamp

Auto/manual change key

Off level display lamp

ONON

OFFOFF

BATTERTERY Y

CHECKCHECK POPOWERWER

OFFOFF

LELEVELVEL

MANUMANUALAL

MODEMODE

Battery check

Power

supply key

Page 21

2.3 Warning display

Off level display lamp turns on in red as warning display and rotation of

rotor and emission of laser beam stop under following situation.

(1) When the instrument is tilted more than ± 5.7°(± 10%) then

power supply is turned on

Turn off the power supply and install the instrument horizontally

(within ± 5.7°) and turn on the power supply again.

(2) When some shock is added to the instrument while at work

Turn off the power supply and turn on the power supply again.

• If the work is to be continued,per form this procedure after resetting

the laser beam at the “reference mark”.

(3) When,status that the automatic self-leveling function does not

become stable continues for about 3’after power supply is turned on

Turn off the power supply and turn on the power supply again.

But warning is displayed farther,change the setting place of

instrument or stop the construction machines which may be the cause

of vibraton.

NOTE:

• After warning is displayed (Off level display lamp turns on in red),if no

key is pressed for about 10’,power supply is turned off automatically.

• At above (2), warning display does not work while automatic

self-leveling function stops (Off level display lamp turns on in red).

21

ONON

OFFOFF

BATTERTERY Y

CHECKCHECK POPOWERWER

OFFOFF

LELEVELVEL

MANUMANUALAL

MODEMODE

Off level display lamp

Page 22

22

3. Preparation for measurement

1.1 Setting up the tripod

[Arranging the tripod]

Prepare the normal tripod for Level instrument.

The dome head type and elevation type tripod for Level instrument

can be used.

[Selection of the place to set up the tripod]

Be sure to select a place where the job will not be interrupted and

the instrument can be set to have almost same distance to each

point to be measured.

1

2

Extraction

Nearly horizontal

Page 23

23

[Setting up the tripod]

For an extension tripod,adjust the legs to a suitable length and secure

the leg clamps.

Spread the legs to a proper extent for the tripod head to be nearly

level and push them into the ground.

Should the tripod head be off level,adjust it by expanding the legs

accordingly.

NOTE:

• For a tripod setting place,be sure to select a place where the ground

or floor has less vibration and there is no fear of upset.

• To set the tripod on a slippery floor,the legs must be secured.

Use a chain (or similar) to keep the legs from spreading.

1

2

3

Page 24

24

3.2 Setting up the instrument

[Mounting on the tripod]

Mount the instrument on the tripod head and while supporting the

instrument with one hand,secure it using the tripod center screw.

NOTE:

• Also when removing the instrument from the tripod,loosen the

center screw while supporting the instrument with one hand.

• Do not leave the instrument mounted on tripod without the center

screw being tightened.It may cause the instrument to fall and be

damaged.

Instrument

Tripod head

Center screw

Page 25

25

3.3 Arranging the detector

[Installing the rod adapter LA6]

LS6 detector

Mount the instrument on the rod adapter so that the guide pin of the

rod adapter is inserted into the guide hole in the back of the detector.

Tighten the attaching screw of the rod adapter into the detector.

NOTE:

• The rod adapter is to be used when the detector is used together with

a staff or plain rod.

1

2

Rod Adapter

Fixing screw

Detector

Page 26

26

4. Measurement

4.1 Operating the instrument

[Starting the operation]

Press the power supply key.

Automatic self-leveling function works and leveling begins

automatically.When leveling is completed,the rotor begins to rotate

and emits invisible laser beam.

NOTE:

• Before operating the instrument, per form the ‘Check and adjustment

of the datum point’on page 35.

• Before operating the instrument,confirm that the manual mode display

lamp is not turned on in red. While automatic self-leveling function,

(the manual mode display lamp turns on in red) pay attention that

the horizontal accuracy of emitted laser beam is not guaranteed.

• When the status that the automatic self-leveling function is not stable

continues for about 3’,the off level display lamp turns on in red and

rotation of rotor and the emission of laser beam stop.

•

While not in operation,be sure to turn the instrument’s power switch off.

WARNING

• While the instrument is operating, be careful not to expose your

eyes to the emitting laser beam (red light source).Exposure to a

laser beam for a long time may be hazardous to your eyes.

(Laser beam:Equivalent to class 2 Laser level)

ON

OFF

TERY Y

CHECKPOPO

WER

OFF

VEL

MANUALAL

MODE

1

2

OFF

Manual mode

display lamp

Auto/Manual

change key

MANU

MODE

BATTER

CHECK

LELEVEL

ON

WER

OFF

Off level

display lamp

Power

supply key

Page 27

27

4.2 Operating the detector:LS6

[Power switch]

Push the power switch to turn on the power to the detector.

Pushing the power switch again turns off the power.

NOTE:

• The liquid crystal displays all light up as shown in the above figure with

the power switch pressed.This permits checking for any defects in the

liquid crystal display.

• The battery’s remaining capacity is always indicated with the power

turned on.Check when to replace the battery,referring to the figure

on the above.

• The power turns off automatically if no laser beam is received and any

key not operated for about ten minutes.To turn on the power again,

push the power key once again.

1

2

6

Page 28

28

[Selecting the reference level detecting accuracy]

Push the detection accuracy selection switch to select the needed

detection accuracy.

High accuracy detection:

To be selected for detecting the reference level with accuracy.

Low accuracy detection:

To be selected if high accuracy is not needed or when stable reference

level cannot be obtained due to slight vibration at job site.

NOTE:

• For the detection accuracy to be selected,check with the mark in the

liquid crystal display (see the figure on the above).

• The detection accuracy alternates each time the detection accuracy

selection switch is pressed.

• High detection accuracy is initiated when the power turns on.

• If the point to be measured is distant, the reference level may not be

displayed stably by the influence of heat waves shimming or the

instrument slightly vibrating.Under such conditions,

select ‘Low detection accuracy’.

High accuracy

Low accuracy

Page 29

29

[ON or OFF of the beam reception buzzer]

Push the beam reception buzzer switch to select either the buzzer

sounding or silenced.

[Illuminating the display]

Push the illumination switch to illuminate the display.

Pushing the switch again turns off the illumination.

NOTE:

• For either the buzzer sounding or silencing to be selected,check with

the mark in the liquid crystal display (see the figure on the above).

• The buzzer sounding/silencing alternates each time the buzzer switch

is pushed.

• The buzzer sounding is initiated when the power turns on.

• The illumination turns off automatically if no laser beam is received

and any switch is not operated for about one minute.

To illuminate the display again,push the illumination switch once more.

1

2

6

6

Page 30

30

[Detecting the reference level]

At the measuring point,set the position of the detector nearly to the

height of the beam emitting aperture of the instrument.

Position the detector where the buzzer sound (or the beam reception

display appears) by directing the detecting display nearly toward the

instrument and moving the detector up and down.

Move the detector up and down again according to the beam

reception display (or the buzzer) and obtain the reference level.

NOTE:

• When detecting the reference level, the detector should face the

instrument in the range of about 40°,to the right and left from

the front.

Move the detector down as it is positioned high.

The buzzer sound beeps at short intervals.

This is the reference position.

The buzzer sound beeps continuously.

Move the detector up as it is positioned low.

The buzzer sounds lasting beeps intermittently.

Page 31

31

[Direct marking]

After the reference level has been detected, mark a line along the

detector’s index,or its top or bottom end.

[Plain rod marking]

After the reference level has been detected, mark a line along the plain

rod’s top or bottom end.

NOTE:

• If a line was marked along the detector’s top or bottom end,be sure to

make measurement compensation as described on the back of the

detector.

• The detector should previously be positioned correctly on the plain rod

according to the reference mark.

[Plain rod marking]

After the reference level has been detected, mark a line along the plain

rod’s top or bottom end.

6

Page 32

32

[Reading the staff]

After the reference level has been detected, read the staff,using the

index on the rod adapter.

NOTE:

• When detecting the reference level,slightly loosen the fixing screw for

the rod adapter and move the detector up and down along the staff.

Staff

Index

Rod Adapter

Page 33

33

5. Maintenance

5.1 Maintenance after use

[Stains on the main body]

Brush dust off and wipe off moisture with tissue paper.

Clean off any stains with a soft,dry cloth.

Excessive stains should be removed with a soft cloth soaked in a water

diluted neutral detergent and squeezed dry.

Do not use benzine,thinner,gasoline or chemicals.

[Stains on the glass surface]

Brush dust off.

Gently wipe off stains with a silicone cloth or a cleaning cloth for eye

glass lenses.

Excessive stains should be wiped off with soft cotton cloth

impregnated with a cleaning liquid for eye glass lenses.

1

2

3

Page 34

34

[Handling the battery]

If the instrument is not to be used for a long time,be sure to remove

the batteries from the instrument and the detector and store them.

NOTE:

• Be sure not to use chemicals such as benzine, thinner or gasoline.

• Be careful not to scratch the glass surface.

• Leaving the batteries in the instrument for extended period may cause

power consumption even if it is not in use.

• If used battery is left in the battery holder,the instrument of the

detector may be damaged by the battery fluid leakage.

leakage

Page 35

35

5.2 Check and adjustment of the datum point

[Check]

Set up the instrument on the tripod halfway between two walls or

pillars about 40m away so that the ‘X side’of the instrument faces the

‘Wall A’ and level it.

Operate the instrument and turn on the power to the detector.(use the

detection accuracy initially set.)

Mark the reference point detected for both walls.(A,B)

Arrange a pair of target plates (with the same scale) and fix them to the

walls (A and B) so that the center values of the target plates coincide

with the reference point marks.

Loosen the center screw of the tripod to turn the instrument 180 for

the ‘X side’to face the ‘Wall B’and tighten the center lock screw again

for the instrument to be leveled again.

1

2

3

4

5

Over view

(Keypad)

X side

Page 36

36

Read the target plates on the walls (A,B) to detect the reference points.

If the readings of the target plates differ less than ±5 mm, the

instrument needs not to be adjusted.

If more than ± 5 mm,proceed to the following (Adjustment)

procedure.

6

7

8

Wall A Wall B

X side in 1 X side in 5

Target

Detector

Appr. 20m Appr. 20m

Page 37

37

5.3 Troubleshooting

PLP-601 / PLP-602 / PLP-601R / PLP-602R

Rotor Display Content Checking point

Display lamps are Battery capacity Replace with fresh

not turned on. is low. batteries or charge

battery

Incorrect battery Check the polarity

insertion. of the batteries.

Lamp turns on. Instrument’s tilt Turn off the power

exceeds auto leveling supply and reset the

area.(± 5.7°) instrument level

Instrument is tilt (±5.7°) and turn on

largely by any cause. again.

After power supply Turn off the power

turns on,unstable supply and turn on

state of auto again.

self-leveling function Turn off the power

continues supply and turn on

approx.3 min. again.

NOTE*

Lamp & lamp Defect of instrument Turn off the power

blink mutually itself. supply and turn on

again.If the lamps blink

farther, instrument need

to be repaired.

*

NOTE:

• When the operation is continued,set the laser beam on the reference

mark and perform it.

Does not rotate

ONON

OFFOFF

BATTERTERY Y

CHECKCHECK POPOWERWER

OFFOFF

LELEVELVEL

MANUMANUALAL

MODEMODE

Manual mode display lamp:

Off level display lamp:

3

1

1

2

2

1

1

2

2

1

3

2

1

2

1

Page 38

38

Detector LS6

Rotor Display Content Checking point

Can rotate Cannot detect Battery capacity Replace with fresh

is low. battery.

Incorrect battery Check the polarity

insertion. of the batteries.

Can rotate Battery indicator Battery capacity Replace with fresh

blinks is low. battery.

NOTE:

• If the instrument is not returned to normal,even through these

measures,connect your dealer or authorized shop.

1

1

2

2

Page 39

39

6. Specifications

INSTRUMENT PLP-601R / PLP-602R

Accuracy of reference beam: ±10”(PLP-601/PLP-601R)

± 12” (PLP-602/PLP-602R)

Measuring range: Radius 1~200m (PLP-601/PLP-601R)

Radius 1~120m (PLP-602/PLP-602R)

Automatic self-leveling range: ± 10% (± 5.7°)

Light source: Visible Laser Diode (635nm Max 1.0mW)

Rotation speed: 300rpm / 600rpm (can be switched)

Operation power supply: 4 x D type batteries (PLP-601/ PLP-602)

Rechargeable Ni-MH battery (PLP-601R/ PLP-602R)

Operation time: 24 hours on manganese battery (PLP-601/PLP-602)

48 hours on alkaline battery (PLP-601/PLP-602)

18 hours on Rechargeable Ni-MH battery (PLP-601R/PLP602R)

Charging time: 2 hours (PLP-601R/ PLP-602R)

Waterproof: IPX6 Watertight type

Working temperature range: -20°C ~+50°C (-4°F ~ +122°F)

Tripod attaching screw: JIS/B type (5/8”x 11 thread)

Dimensions: 170w x 170D x 225H mm

Weight: 2.5kg (w/battery)

DETECTOR LS6

Detection Accuracy: HIGH ± 1mm LOW ± 2.5mm

Beam reception indicator: Liquid crystal display / buzzer

Sensitivity of vial: 30’/ 2mm

Power supply voltage: DC9V battery(6F22 or 6LF22)

Operation time: Approx 40 hours on alkaline battery (6LF22)

Auto power off: Power supply:Approx.10 min.

Illumination: Approx.1 min

Dimensions: 140w x 68H x 25L mm / 200g

Page 40

40

7. Notice to the user of this product

To assure compliance with the Safety Standard 21 CFR,Chapter I.

Subchapter J.The U.S.bureau of Radiological Health requires the

following information to be provided to the user:

1) Specifications of Laser Radiation.

A. This laser system is designed and built to have a GaAIAs laser

diode radiating at 635nm ± 15 nm.

B. Radiant power

This laser product is designed and built to radiate a maximum

average radiant power of 10µW as scanning beam during

functional operation.The user may be subject to this radiation as a

scanned beam while the rotor is rotating until such time that the

instrument is turned off.

•

For a period of less than 10 seconds during the operation the

user may be subjected to this radiation.

2) The following labels are affixed to and must remain attached to

this laser product.

A. Certification Label

‘This laser product conforms to the provisions of 21 CFR 1040.10

and 1040.11.For a class 2 laser product.’

Located on the surface of the base of top-handle.

B. Caurion Label

‘Laser beam,do not look into the laser beam source directly.’

Located near to exit aperture,facing upward.

3) Caution to maintain the safety in compliance with the standard.

•

To maintain the safety standard,refrain from any operation,maintenance or adjustment other than described in this instruction manual.

•

Operation,maintenance or adjustment other than those specified in

this instruction manual may result in hazardous radiation exposure.

•

Maintenance and repair not covered in this manual must be done by

an authorized Pentax dealer.

Page 41

41

Page 42

Page 43

Page 44

Member symbol of the Japan

Surveying Instruments Manufacturers’

Association representing the high quality

surveying products.

Printed in Belgium

Total Surveying Solutions

PENTAX Industrial Instruments Co.,Ltd.

2-5-2 Higashi-Oizumi

Nerima-ku,Tokyo 178-0063,Japan

Tel.+81 3 5905 1222

Fax +81 3 5905 1225

E-mail:international@piic.pentax.co.jp

Website:www.pentax.co.jp/piic/survey

Japan Surveying Instruments Manufacturers’ Association

Loading...

Loading...