Pentair Everpure MRS-100 Installation Manual

Installation and Operation Guide

MRS-100, MRS-225, MRS-100CC, MRS225CC

Reverse Osmosis Mineral Reduction System For Foodservice Applications

INTRODUCTION

The Everpure MRS (Mineral Reduction System) is a pre-engineered,

pre-assembled Reverse Osmosis (RO) system designed to provide

high purity water for many applications, such as premium espresso,

coffee and blended beverages, to name a few. It combines a

number of water treatment technologies into one easy to install

package. The system provides superior protection against taste and

odor causing contaminants while removing dirt, particulates and

dissolved solids that can foul or scale equipment.

Initial System Production

Water production depends on supply water pressure and temperature.

See PERFORMANCE section (page 5) for normalized production.

Influent Water Characteristics

The following table lists the allowable operating range of various

water properties within which the MRS will function properly.

Total Dissolved Solids (TDS) 0-150 0 PPM (0-150 0 mg/L)

pH 5-10

Chlorine

Chloramines 0-3 PPM (0-3 mg/L)

Turbidity 0-1 NTU

Iron 0-1 PPM (0-1 mg/L)

1

Reverse osmosis membrane lter used in this system will be damaged by chlorine. An

activated carbon lter has been provided with this system to protect the reverse osmosis

membrane from chlorine attack. Inuent chlorine should not exceed 3 mg/L.

The complete MRS consists of 5 major components:

The optional 5-micron pre-filter removes suspended particles, which

can lead to pre-mature plugging of the TO and/or RO membrane

cartridge. The TO cartridge removes most oxidizers, but mainly

reduces chlorine, preventing damage to the RO cartridge. The RO

cartridge contains a semi-permeable reverse osmosis membrane.

Here, most dissolved impurities are separated from the water and

flushed down the drain. The water that is able to pass through the

membrane, which is very low in dissolved impurities, is referred to

as permeate, RO water, or product water. Depending on the model,

the permeate will do one of the following:

• Systems without calcium carbonate (CC) cartridge - The permeate

will pass through the cartridge head with by-pass plug, exiting to

service and/or enters the optional storage tank.

• Systems with calcium carbonate (CC) cartridge - The permeate will

pass through calcium carbonate cartridge, where re-mineralization

occurs. This cartridge reintroduces a metered amount of TDS level

of the RO permeate. After remineralization, the treated water exits

to service and/or enters the optional storage tank.

The optional storage tank stores water that has been produced by

the RO System. This provides a water supply "buf fer ", enabling the

system to provide reasonable volumes of product water during high

demand periods.

Printed in U.S.A. EV3123-42 Rev A AU07

1

0-3 PPM (0-3 mg/L)

A unique car tridge monitor/alarm module is available. This device

can be set to provide simultaneous water throughput and operating

time indications over easily selectable ranges. This monitor helps in

determining cartridge change-out schedules.

OPERATING SPECIFICATIONS

Dynamic Operating Pressure: 25 –80 psi (1.7–5.5 bar)•

Static Operating Pressure: 100 psi (6.9 bar)•

Operating Temperature 40–100°F (4.4 –37.8°C)•

Inlet booster pump.1.

5-Micron Pre-filter (optional).2.

Granular Activated Carbon Taste & Odor (TO) cartridge.3.

Reverse Osmosis (RO) membrane cartridge.4.

Calcium carbonate (CC) re-mineralization cartridge (optional).5.

Connections•

Inlet /Outlet: 3/8-inch tube

Concentrate: 1/4-inch tube

Electrical•

Voltage: 115 volt AC

Hertz: 6 0

Phase: 1

Ampere: 1.5

Branch Circuit Protection: 15 or 20 AMP Ground Fault Protected

Pre-Installation Checklist

1. Can the unit be mounted within a reasonable distance of

the water supply and drain facilities?

2. Is there an un-switched 115 VAC GFIC (ground fault

interrupter circuit) protected receptacle available for powering

the system?

3. Is there adequate clearance and support to install

the unit and permit access for maintenance? The total system

weight will vary based on model and storage tank selected. See

specification table for approximate operating weights.

4. Does the inlet water supply meet the requirements listed

below?

A minimum of 25 PSI pressure on a consistent basisa.

Less than 1,5 00 ppm of Total Dissolved Solids (TDS)b.

Less than 10 GPG of water hardnessc.

pH level between 7.0-9.0d.

Turbidit y less than 1 NTUe.

NOTES:

Please read this manual prior to installing and operating the •

system.

Incoming water supplies that do not meet these requirements •

may need additional pre-treatment prior to the system. System

performance may be affected if requirements are not met,

including system output production and cartridge change-out

frequency.

If the supply pressure exceeds 80 PSI, install a pressure reducing •

valve. Adjust the pressure reducing valve to the required

operating pressure, not to exceed 80 PSI.

Consult with your local building inspector for approval and •

required permits to install this system. Additional equipment, such

as back-flow prevention devices, seismic restraint equipment, air

gaps, etc., may be required. Completed installation must meet all

local and national codes.

Do not connect the MRS system after any water filtration system,

unless specifically provided for use with the MRS.

UNPACKING AND INSPECTION

The MRS includes all the necessary fittings for installation. Lengths

of 1/4” tubing have been provided for connecting to the wastewater/

drain connection. Supply lines and distribution piping/tubing are not

included.

The MRS system is packaged as a complete unit in two cartons. At a

minimum, you should have the following:

Carton 1

Plate mounted processor assembly (Including the following)1.

pump A.

cartridge heads B.

transformerC.

Carton 2

TO cartridge1.

RO cartridge 2.

Calcium carbonate (CC) cartridge (optional)3.

Inspect the cartons for damage. Report any damage to freight

carrier immediately. Carefully unpack each item. Save the packaging

material temporarily, as it may be used to protect painted sur faces

during assembly.

SYSTEM ASSEMBLY

The MRS is configured as a two piece unit; with the processor

mounted on a vertical surface and the storage tank located nearby.

Locate the system in an area that is convenient to the inlet water

supply and drain facilities, with access for routing the product water

tubing/piping to the equipment. Install in a dry location, away from

all forms of corrosive and/or flammable materials. Consider ease of

access for servicing when selecting a location.

Processor Assembly Mounting

If the optional Pre-filter has been supplied, go to step to 2. If not 1.

supplied, go to step 5.

Position the MRS processor assembly so the rear of the 2.

mounting plate is accessible. Secure the wing bracket to the rear

of the mounting plate as shown Figure 1. Use the 5/16” hex bolts

and washers provided. Align the wing bracket so it is inward

and upward as far as possible – use a combination square to

maintain alignment. Tighten both bolts securely.

Attach Pre-filter head to Pre-filter bracket with 5/16” hex bolts, 3.

nuts and washers provided.

Insert elbow fitting into solenoid valve inlet. Connect 1/4” OD 4.

tubing between pre-filter outlet and elbow fit ting on solenoid

valve.

5. The processor framework has 6 mounting holes (3 keyhole

slots, 3 standard) on 4.5” centers for securing to a stationary

vertical surface. Evaluate the mounting surface for its abilit y

to properly support the weight of the processor when in

operation (Approximately 40 pounds).

continued on the next page . . .

2

Figure 1. Back view of Prefilter bracket.

Figure 2. MRS Assembly.

Inlet

(without optional Pre-filter)

Inlet

(with Pre- filter)

MRS

Processor

Pre-filter

(optional)

6TO-BW

Carbon

Cartridge

MRRO Car tridge

7CC-BW

Cartridge

(optional)

By-pass Plug

(Keep inserted if optional

7CC-BW car tridge is not used)

Prefilter bolts

Wing

bracket

Outlet

Storage

Tan k

(not shown,

not

included)

RO Reject

(1/4" John

Guest) route

to drain

6. Attach processor to the vertical surface with screws and

WARNING

WARNING

TUBE

FLOW

CONTROL

Model MRS-100

TUBE

FLOW

CONTROL

Model MRS-225

anchors designed for the mounting surface material.

Do not use screws smaller than #12 for mounting the

processor.

suppor t processor safely. Hollow walls, dry wall and other nonstructural surfaces are not suitable unless reinforced.

Mounting surface may require reinforcement to

Piping/Tubing Connections

Refer to Figure 2 for views of the piping, with a description of major 1.

components and connection points. These major components and

connections will be referred to in the following steps.

Prepare the plumbing to accept the RO system. It is recommended2.

that a three valve by-pass is installed to provide an uninterrupted

supply of water when the RO system requires service.

Note: The product water tubing/piping and associated fittings

connecting the RO product outlet to the equipment being serviced

should be food grade material that meets NSF Standard 51 or 61

with a minimum pressure rating of 75-PSI. The product water

will react with most metal piping, creating a corrosive condition,

in addition to imparting an objectionable taste. Plastic pipe or

reinforced tubing are generally very good choices for RO water

distribution materials. The size of the product water tubing/piping

should be 3/8" ID minimum. Distances of 25 feet or greater

the RO to the equipment being serviced should be 1/2" ID minimum.

Connect the inlet supply.3.

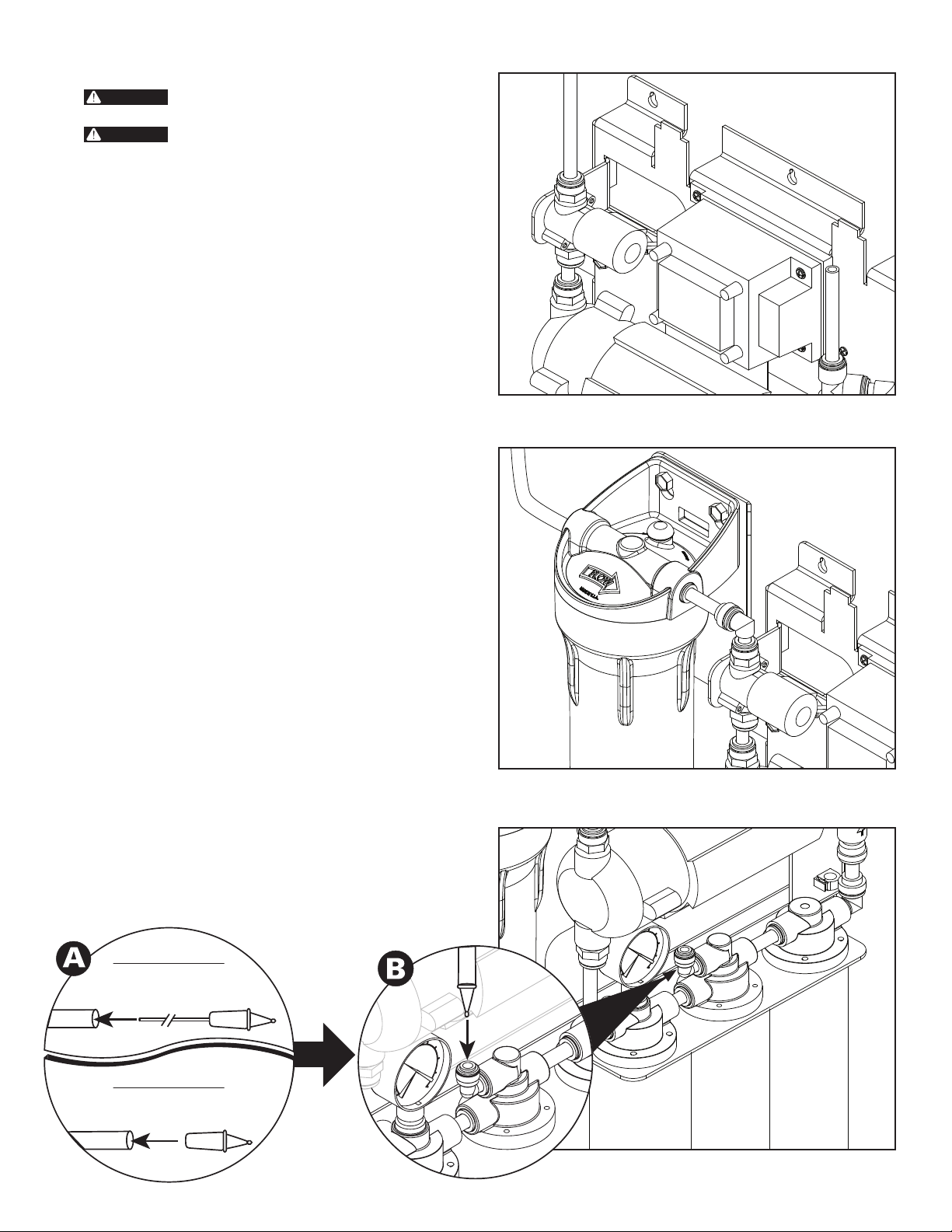

MODELS WITHOUT PRE-FILTER – See Figure 3. Connect to A.

the Inlet open por t (3/8 " JG) on the solenoid valve.

MODELS WITH PRE-FILTER – See Figure 4. Connect to the B.

Inlet open port (3/ 8" JG) on the pre-filter head.

Connect the appropriate size and t ype of tubing/piping and 4.

associated fit tings to the Outlet tee connection. Route the line(s)

to the equipment being serviced (i.e.; espresso, coffee, etc.).

Locate the storage tank directly below or adjacent to the 5.

processor assembly. Be sure the mounting surface is capable

of supporting the weight of the tank when full (see specification

table for operating weights). Connect a suitable length of 3/8"

inch OD tubing to the tank connection. Route this section of

tubing to the main processor assembly. Connect the tubing to the

elbow fitting at tached to the side of the outlet tee connection.

Note: The storage tank pre-charge pressure should be

checked and adjusted when the storage tank is empty. For

most applications, a low (5-10 psi) pre-charge pressure is

recommended, to attain maximum storage tank volume.

Close the inlet, outlet and by-pass ball valves.6.

Locate the correct reject flow control assembly based on the 7.

illustration below (A). Insert the reject flow control assembly

into the 1/4" OD tube (See A Below). Insert the 1/4" OD tube

with reject flow control assembly into the elbow fitting on RO

head (See B below). Route the other end of the tubing to a drain

nearby, securing it temporarily. Allow an air gap at the drain,

following any applicable local codes. See Figure 5.

continued on the next page . . .

from

Figure 3. No Prefilter

Figure 4. Pre-filter

Figure 5. RO Reject Flow Control Assembly

3

Loading...

Loading...