Page 1

LIMITED WARRANTY

INSTALLATION INSTRUCTIONS

Compool Corporation warrants tot he purchaser oft his control system, for the period of

one year from the date of original purchase for use, that any defective product proved to

be caused by faulty workmanship or faulty material, will be repaired or replaced at

Compool's option for no charge, providing the product is returned to Compool

with all transportation charges prepaid.

First Ninety

shall be found to be defective due solely to faulty material and workmanship, Compool

Corporation will additionally cover the reasonable replacement cost charged by an

authorized service company.

After Ninety Days: Between the ninety-first day and the end of the first year after

installation, no allowances will be made for labor for the removal or reinstallation of any

soclaimed defective products

This warranty covers the Time Master Controller,

Valve Operators, and optional Remote Controls, including all components and parts.

It does not include Valves or Sensors. It extends to the first retail purchaser and any

subsequent owners of the system.

This limited warranty applies only to controls which have been installed and maintained

in strict accordance with installation and operating instructions provided by Compool

Corporation, using installation hardware supplied

Compool, and to controls which have been connected to the correct supply voltage.

This limited warranty does not apply to any controls which have been repaired or

altered by anyone other than Compool ora person authorized by it;

subject to misuse, neglect or accident; or which have been damaged by wind, freezing

or other cause, thing, person or act of God; or which have been subject to damage in

transit, during

have been damaged because of a defect in a component or part which is not part of the

Compool Control System; or upon which the serial number has been altered, effaced or

removed.

This warranty gives you specific legal rights and you may also have other rights which

vary from state to state. Compool

any other obligation or liability in connection with Compool controls. Compool

Corporation makes no warranty of merchantability or fitness for

warranty applicable to Compool controls is limited in duration to the duration of this

written warranty.

Compool Corporation shall not be liable for consequential or incidental damages

resulting from breach of this written warranty or any implied warranty. Some states do

not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation of incidental or consequential damages may not apply to you.

exerclse this warranty, send defective unit, with copy of dated receipt,

To

postage prepaid, to:

Computerized

Days: During the first ninety days after installation, if any Compool control

LX-10

Service Center, VOR-24

and/or recommended in writing by

orwhich have been

installation,or by someone other than Compool Corporation; or which

Corpora!ion does not authorize any person to create

any use. Any implied

599 Fairchild

COMPOOL CORPORATION

Drive, Mountain View, California 94043-221

Pool

Systems

MEMBER

[m

N.,,oN.L

fie..

INSTITUTt

599 Fairchild Drive

Mountain View

California 94043-221

(415) 964-2201

POOL

7

TIME MASTER

POOL-SPA CONTROL SYSTEM

IMPORTANT SAFETY PRECAUTIONS:

All wiring must

Basic safety precautions and local codes should be observed when installing

and using this electrical equipment.

FiEAD AND FOLLOW ALL INSTRUCTIONS

EQUIPMENT LOCATION:

All electrical equipment must

exception of the optional Spa-side Remote Control

1.

LX-10

2. Time Master inside house or other weather-protected area

3. VOR-24 Valve

4.

WS5L Water Sensor at filter pump

SS100 Spaside Remote Control (optionar) at spa site

5.

LOW VOLTAGE CABLES:

Determine lengths of 22AWG low voltage cable needed between equipment

6pair cable from Time Master to LX-10 Service Center.

1.

2. 2 conductor cable from gas heater to LX-10 Service Center.

3. Water Sensor is provided with 10 feet of 2 conductor cable.

4.

Valve Operators are provided with 15 feet of 3 conductor cable

5. Spa-side Remote Control is provided with 100 feet of 4 conductor cable

Remote Control is also available with 50. 150 or 200 feet of cable

Install cable. Place cable in plastic or metallic conduit where it runs

ihrough concrete, etc

NOTE: Never install low voltage cable and high voltage wires in the same

conduit A minimum distance of

of low voltage cable and AC current-carrying wires.

22AWG cable is available from Compool Corporation

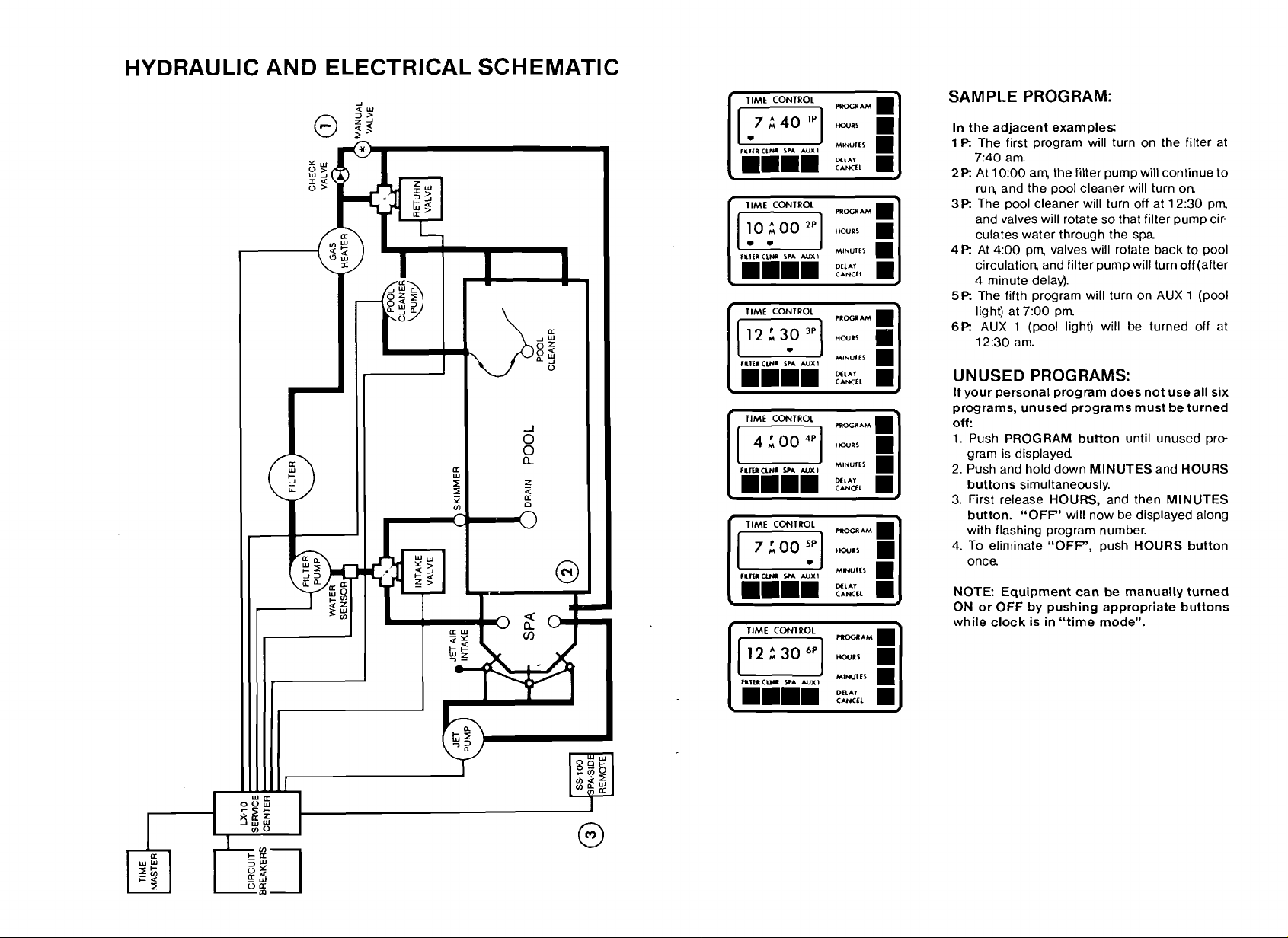

PLUMBING:

Fol!ow recommended schematic (see next page) for location of threeport valves

2" dia. plumbing is advised to ensure optimum filter pump efficiency.

1. A

Y2" spa makeup line, (incorporating a Y2" manual gate or ball valve and, for elevated

aY2" checkvalve) should be provided around the retum valve(see schematic).

spas,

This enables clean water to be circulated to the spa while the system is in POOL

mode

2. Spa should be at or above the level of the pool If spa is attached to pool provide a

dam between the two bodies of water to allow spa overflow into pool If spa is not

attached to pool an overflow, sufficient in size to carry full pumpflow, must be

7

installed at water level in the spa

be

performed by a qualified electrician.

be

located five feet or more from pool or spa with the

Service Center at t!le equipment pad area

Opemtors at threeport valves

12" must be maintained between parallel runs

underground

Page 2

HYDRAULIC AND ELECTRICAL SCHEMATIC

llME

CONTROL

rlru

CLNR

TLNCLNI

TIME

CONlllOL

FLlUUH

SPA

wx

SPA

WXI

SM

WXI

SAMPLE PROGRAM:

In the adjacent examples

1

P.

The first program will turn on the filter at

7:40 am.

2P:

At 10:OO arq the filter pump will continue to

run, and the pool cleaner will turn on

3P:

The pool cleaner will turn off at 12:30 pm

and valves will rotate so that filter pump circulates water through the spa

4

P:

At 4:00 pm valves will rotate back to pool

circulation, and filter pump will turn off (after

4 minute delay).

5P.

The fifth program will turn on AUX 1 (pool

light) at

6P:

7:00 pm

AUX 1 (pool light) will be turned off at

12:30 am.

I

UNUSED PROGRAMS:

If your personal program does not use all six

programs, unused programs must be turned

off:

1. Push PROGRAM button until unused pro

gram is displayed

2. Push and hold down MINUTES and HOURS

buttons simultaneously.

3. First release HOURS, and then MINUTES

button.

with flashing program number.

4. To eliminate

once

NOTE Equipment can be manually turned

ON or OFF by pushing appropriate buttons

while clock is in "time mode".

"OFP' will now be displayed along

"OFP', push HOURS button

Page 3

LOW VOLTAGE WlHlNti UlAGHAM

OPERATING INSTRUCTIONS

I I I

0 0 0

n k k k

ZZZZ

ommm

tttt

XOJZ

JWW(1:

m

(1:

+

0

Do not untwist pairs.

It is neccessary to retain

wires in pairs so that

appropriate connections

can be identified.

-

N

(1:

LA

:I

I

Ell

GENERAL CONTROL FEATURES

FILTER PUMP OFF DELAY. This causes the filter pump to run an additional

4

minutes every time it is turned off. The purpose of this is to protect the gas heater

and plumbing from possible scale build-up and thermal stress. These occur when

residual heat in the gas heater is not allowed to dissipate after heater is turned off.

POOLCLEANER ON DELAY. Every time the pool cleaner pump is turned on, this

circuit prevents it from running until

pump from damage caused by air in the water lines that may have entered into

the plumbing since it was last used.

4

minutes have passed. This protects the

TIME CONTROL

EQUIPMENT BUlTON FUNCTIONS:

FILTER:

CLN R:

SPA:

AUX1:

Turns filter pump ON and circulates POOL water.

Turns filter and cleaner pumps ON. (Cleaner delayed

Turns filter pump ON and circulates

operate. Overrides CLNR key and turns pool cleaner pump OFF,

if

CLNR "flag" is present.

even

Turns electrically controlled function ON. (lights, jets, etc.)

SPAwater. Allows heater to

4

minutes)

TEMPERATURE CONTROL

WATER TEMPERATURE Display:

Pool temperature is displayed when the pool is operating, spa temperature when

the spa is operating. If filter pump is off, display may be meaningless

THERMOSTAT:

Desired pool or spa temperature is set here.

HEATER CONTROL

SWITCH POSITIONS:

PO

0

L:

SPA:

OFF: Allows no heating.

Allows heating of pool to the preset temperature level.

Allows heating of spa to the preset temperature level.

I I I

000

nkkk

ZZZZ

ommm

tttt

X3XZ

dJJ(1:

mmmo m3mrr

-~m

aaa

r55p

<<<N

JJJ

tttt

xkxn

-I I -I

+

w

HIGH VOLTAGE

R6

R7

RELAYS

HEATER ON Light:

When lit, indicates that heater is on.

STATUS DISPLAY

The presence of a light next to an equipment label indicates that it is ON. The

absence of a light indicates OFF.

DELAY CANCEL

FILTER: To override the Filter Delay Circuit, press CANCEL OFF DELAY

CLNR: To override the Cleaner Delay Circuit, press CANCEL ON

BUlTON FUNCTIONS:

button. Provided that there is no "flag" present at either

FILTER, CLNR or SPA buttons, the filter pump will shut off

immediately.

DELAY button. Provided that there is a "flag" present at the

CLNR button, the pool cleaner pump will start immediately.

If SPA is on, CLNR is inoperative.

Page 4

SETTING

THE

1. Push PROGRAM button until no flashing

number appears on the right of the display.

The clock is now in

2. Push HOURS and MINUTES buttons until

correct time of day is displayed NOTE: Pay

attentinn

CLOCK

"time mode".

to the AM/PM indicator.

3.

If the spa is constructed in concrete and optional Spa-side Remote Control (model

SS-100) is to be used, select a convenient location in the deck or above water level in

the spa wall

Install

100. This pipe should be level and protrude beyond the finished surface of spa

can be cut back at a later date. Connect 1

'

either

Service Center.

Do not install Outdoor Remote Control until spa construction is completed.

SS-100 should not be submerged by the spa water.

a6" to 12" length of 1

%"

or

%"

conduit and provide conduit as necessary to location of LX-10

%"

pvc pipe at this location to provide a receptable for SS

l/2"

coupling and reducing bushing for

It

PROGRAMMING

There are six possible programs during a 24 hour period for turning the pool

equipment ON or OFF. More than one piece of equipment may be programmed

ON or OFF at the same time.

1. Push PROGRAM button once

The clock is now in "program mode".

2. Enter desired program time by pushing the HOURS and MINUTES buttons In

"program mode", minutes are advanced in ten minute increments

AWPM indicator.

the

3.

Push FILTER, CLNR, SPA, orAUX1 button to program equipment ON or OFF. The

presence of a "flag" above each button indicates that the equipment is

grammed ON. The absence of a "flag" indicates OFF.

4. Repeat the preceding sequence for the remaining five programs

NOTE: Each time change requires a new program.

5. After programming, push PROGRAM button to return clock

is forgotten, after four minutes the clock will automatically return to "time mode".

A1 P(l st Program) will flash on the right of the display.

Pay~ttention to

pre

(2P6P).

toL'time mode". If this

U-10

Select a convenient location (at the equipment pad area) to mount LX-10 Service

Center. Ensure that the location is greater than

further than 15 feet from the

appropriate

the enclosure. Do not drill and mount from inside the enclosure. Install to provide

drainage of compartment for electrical components

All low voltage connections are

hinged faceplate in left side

Strip jacket of Gpair cable

nections Strip insulation of each wire

with wiring diagram located on inside of enclosure cover.

NOTE For the convenience of the serviceman, the screw terminal can be unplugged

from printed circuit board without disconnecting wires

SERVICE CENTER:

5

feet from the water's edge and no

scr'ews through the three external mounting points located on the side of

threeport valves Mount the LX-10 on a flat surface, using

mads to printed circuit board, located behind

compartment.

6"

to identify the twisted pairs and assure correct cop

Y4",

and connect to screw terminal inaccordance

VALVE OPERATORS:

Mount Valve Operators (model VOR-24) to threeport valves in accordance with

instructions printed on box

Plug cables into side of each Valve Operator, and run cables

ment of

on printed circuit board:

RET

LX-10 Service Center. Plug other end of cables into appropriate valve socket

intake(suction) valve to INT valve socket, and return valve to

.~alve socket

t~ low voltage compart-

WATER SENSOR:

Select a convenient location to mount Water Sensor(mode1 WS5L) in the plumbing

system at the filter pump Ensure that thislocation is nogreaterthan 10 feet from LX-10

Service Center, otherwise cable will need to be extended Disconnect Water Sensor

WTS-

and

WTSe

from

Remove clamp kit from behind service panel in right side compartment of LX-10, and

i~stall Sensor in accordance with instructions

Cautior.: Overtighting of clamp can cause deformation of Oring seal.

Run cable from Sensor

if

necessary. Strip insulation

cable

acco:dance with wiring diagram located inside LX-10 cover. Pay special attention to

polarity of Sensor as indicated by color-coding.

terminals on printed circuit board of Time Master.

I~ation to low voltage compartment of LX-10. Cut off excess

l/4"

and connect to black-green pair of 6pair cable in

GAS HEATER:

Inside the heater, interrupt wire between thermostat and gas valve, and connect2 cop

ductor cable with wire nut% in accordance with wiring diagram which is located inside

LX-10 cover. Do not disconnect high limit and pressure switches

%",

Run cable to LX-10 low voltagecompartment Strip insulation

terminals on printed circuit board

and connect to HTR

Page 5

AUXILIARY EQUIPMENT CONTROL (OPTIONAL):

The standard Time Master system is provided with 3 power relays for controlling filter

pump, pool cleaner, and auxiliary 1 (pool light).

It is possible to control additional equipment (such as a jet pump, air blower, spa light,

etc) by installing extra relay kits (model RLY-LX). The LX-10 Service Center will

accommodate a total of 7 relays Note: Further relays may be controlled by an addt

tional Power Center (model

lnstall RLY-LX Relay Kit at the LX-10 in accordance with instructions provided.

LX-36).

SPAaSIDE REMOTE CONTROL (OPTIONAL):

When the spa construction is completed, install optional Spa-side Remote Control

SS100) in accordance with instructions provided:

(model

1. Cut back the

2.

Making sure that screw threads are facing out, glue adapter into receptacle using

pvc cement

3. Thread cable through gasket, and run through conduit to LX-10

compartment

4. Before installing SS-100, rotate 7 turns counterclockwise to avoid undue twisting

of cable

5. Screw

6.

At the LX-10, cut off excess cable

connections to REMOTE SWITCHES screw terminals in accordance with

wiring diagram located inside enclosure cover.

Connect black wire (switch common) to GND terminal, and connect red, yellow,

and green wires to desired terminal for

Note: for the convenience of the serviceman, the screw terminal can be unplugged

from printed circuit board without disconnecting wires

11/2" dia pvc receptacle flush with spa wall finish or surface of deck

low voltage

SS100 into adapter and finger-tighten. Caution: Do not use wrench

if

necessary. Strip insulation

SPq AUX 1, AUX

2,

'/a",

and make

AUX 3 and AUX

4.

INDOOR REMOTE CONTROL (OPTIONAL):

Select a convenient location inside the house or other weather-protected area to

mount the LVS-3(3 button indoor remote) or

temperature display).

Install in accordance with instructions provided At the

partment, strip jacket of cable

connections Strip insulation of each wire

terminals at REMOTE SWITCHES and REMOTE LAMPS terminal:

1. Select any three circuits from SPA, AUX 1, AUX

2. Number the circuits 1,

3. Make sure that the corresponding SW and LMP wires from the Indoor Remote are

connected to the appropriate circuit at the LX-10 REMOTE SWITCHES and

REMOTE LAMPS terminal.

NOTE:

If

accordance with previous instructions and run cable to LX-10 low voltage con

partment Wire nut to yellowblack pair of wires from LVS-3TR cable (red connects to

yellow, green connects to black), in accordance with wiring diagram located inside

LVS-3TR

A Label

Compool Corporation. This set of

ment identification at each remote control button.

the LVS3TR is being used install the second Water Sensor (included) in

Set for indoor remote controls (model LBL-100) is available from

2,

6"

and 3.

LVSSTR(3 button indoor remote w/ digital

to identify the twisted pairs and assure correct

'/4",

and connect to appropriate screw

100

different labels provides custom equip

LX-10 low voltage con

2,

AUX

3,

and AUX

4.

SYSTEM START-UP

Apply power to the system.

theTime Master, pullout batteryshield toactivate back-up battery, and push HOURS

At

button until digital readout is displayed

At the LX-10 Service center, turn SYSTEM CONTROL Switch

and FLOW CONTROL Switch to "POOL" position.

Check that Valve Operators have rotated to correct positions

valve, simply reverse the cable plug on the side of Valve Operator.

At the LX-10 Service Center, turn MANUAL CONTROL Switches to "ON positions

and check that all equipment is operating.

Turn OUTDOOR

Remote Control is functioning correctly.

Turn MANUAL CONTROL Switches

The system is now ready to be operated as desired

REMOTES Switch to"ONn position and check that optional Spa-side

to"OFF1 positions

to"SERV1CE position

Toadjust position of any

SYSTEM OPTIONS

TWO SPEED PUMP CONTROL:

If the system is equipped with a two speed filter pump, a Dual Speed Relay Kit (model

RLY-LXD) should be added at the LX-10 in accordance with installation instructions

provided

The system will automatically run the filter pump in high speed under any of the

following conditions

1. Whenever the heater is on

2. Whenever pool cleaner is running

3. Whenever spa is running

It is possible to eliminate one or more of these conditions by adjusting

Switch, which is located at the top of the printed circuit board See RLY-LXD

installation instructions for details

PROGRAMMABLE TWO SPEED PUMP CONTROL:

If the system is equipped with a two speed filter pump, it is additionally possible to

1

program the pump to run in high speed by using AUX

Time Master Controller. However, this feature will only operate when the filter pump is

running Install RLY-LXD as above.

U10

Adjust

Switches #1,

programmed OFF.

Program Switch (located at the bottom of the printed circuit board) so that

#3 and

#6

are programmed ON, and Switches #2, #4, #5, and #7 are

Program Button on the

ADDITIONAL VALVE CONTROL:

It is possible to add valve operators(mode1 VOR-24) to the system to actuate additional

threeport valvesfor pool cleaning or for a custom hydraulic feature(such as a fountain,

waterfall second spa, etc). A total of three valve operators may be added. Install Valve

Module (model

instructions provided, and connect valve operators accordingly.

MODVLV1) at LX-10 low voltage compartment in accordance with

U11 Program

Page 6

ADDITIONAL REMOTE CONTROL IN LIEU OF CLEANER:

If the system does not utilize aseparate pool cleanerpum~ it is possible to use the pool

cleaner relay to activate an additional remote circuit This circuit is controlled by the

Spa-side Remote Control

NOTE: CLNR Program Button on the Time Master Controller will be redundant.

Flag and Status Light may still be turned ON, but display is meaningless.

Adjust

U1O Program Switch (located at the bottom of the printed circuit board) so that

Switches #4,

programmed OFF.

Modify low voltage wiring as follows

Disconnect black wire of

circuit board, and subsitute with yellow wire from SS-100 Spa-side Remote

#5 and #6 are programmed ON, and Switches #1, #2, #3 and

blklyel pair from CLNR screw terminal on LX-10 printed

#7

are

SPA WATERFALL CONTROL:

For systems where spa water level is higher than that of the

Control (model RLY-WRFL) may be added

AUXl Button at theTime Master or an optional Remote Control switch can be used to

rotate the return valve operator to SPA position while system is in POOL mode, thus

creating an

the system is in SPA mode.

Install RLY-WRFL in accordance with instructions provided.

overflow(waterfall effect) from spa to pool This effect will ceasewhenever

pooh

a Spa Waterfall

ELECTRIC HEATER CONTROL:

For systems which utilize a heat pump or electric heater in lieu of a gas heater, a Relay

Kit (model RLY-LX) should be added at the LX-10. Install RLY-LX in accordance with

instructions provided, and plug into ELEC HTR relay socket on printed circuit board

The power relay is capable of controlling a heat pump, an electric heater rated up to

3KV4 or the magnetic contactor of a larger electric heater.

HIGH VOLTAGE WIRING:

All high voltage connections are made to terminal blocks, which are located be

hind service panel in right side compartment of LX-10 Service Center.

A high voltage wiring label is located adjacent to terminal blocks.

Knock out holes are provided on bottom of enclosure for conduit mounting.

Provide a separate circuit breaker (if possible) to power the system. Either 1

230VAC can be used System draws less than 1 amp. Run wires from circuit breaker to

high voltage compartment of LX-10, and connect to top terminal blockwhich is marked

"SYSTEM POWER".

to wiring label.

Provide independent circuit

Note: AUX 2,"AUX

(model RLY-LX).

Run wires from breakers to high voltage compartment of LX-10, and connect to

LlNE 2 of relevant terminal blocks

and

Connect pumps and other high voltage equipment to LOAD 1 and LOAD 2 terminals at

relevant terminal blocks Each individual terminal

230V AC. A relay allocation chart is provided inside enclosure cover for the service

man's convenience

To reduce the risk of electric shock provide a continuous green insulated copper wire,

no smaller than #12

electrical supply panel

A wire connector is provided for bonding to local ground points To further reduce the

risk of electric shock this connector should be bonded with a

any metal ladders, water pipes, or other metal within 5 feet of pool or spa

Install2 jumpersfor1 15V, or1 jumperfor230Vwiring, according

3,

AWG between grounding bus of LX-10 and grounding terminal of

breakers(if possible) for FLTR, CLNR, and AUX

and AUX 4 are optional and require additional relay kits

blockcan be wired for either 11 5 or

#8 AWG copper wire to

15VAC or

1.

LlNE 1

FREEZE SENSOR:

A Recirculating Freeze Sensor(mode1 FPS-C) may be added to the system It protects

the plumbing and equipment from possible freeze damage by running the filter pump

whenever the temperature falls to approx

instructions provided

An Auxiliary Pump Freeze

activate auxiliary equipment (such as jet pump) during potential freezing conditions

Install FPS-AUX in accordance with instructions provided

Sensor(mode1 FPS-AUX) may also beadded to the system to

41'F. Install FPS-C in accordance with

CUSTOM OPTIONS:

Additional custom options are also available. These options, however, require custom

adjustments at the factory.

Consult

SAVE THESE INSTRUCTIONS

Compool Corporation for details.

TIME MASTER:

Select a convenient location inside the house or other weather-protected area to

mount Time Master Controller.

Unscrew faceplate from enclosure, and use enclosure as a template to mark and cut

(

8%" wide by 4%" high) in sheetrock or wall

hole

provided, install enclosure into wall.

Strip jacket of

twisted pairs and assure correct connections

Strip insulation of each wire

screw terminal in accordance with wiring diagram located inside enclosure.

Caution: Do not untwist pairs

retain wires in pairs so that appropriate connections can be identified

Note: For the convenience of the

'

screw terminal can be unplugged from printed

circuit board without disconnecting wires

Mount faceplate to enclosure.

panel in^

Using the mounting clips

6pair cable 6" to identify the

l/4"

and connect to

It is necessary to

sewiceman

Loading...

Loading...