Page 1

System 2

TM

Modular DE Filter

O W N E R’ S M A N U A L

INSTALLATION, OPERATION & PARTS

MODELS

PLDE36 PLDE48

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

International: 262-728-5551, FAX: 262-728-7550

www.starite.com

Union City, TN • Delavan, WI • Mississauga, Ont. • Murrieta, CA

© 2005, Sta-Rite Industries S749 (Rev. 6/24/05)

This manual should be furnished to

the end user of this filter; its use will

reduce service calls and chance of

injury and will lengthen filter life.

E

S

O

L

C

O

P

E

N

Page 2

Table of Contents

Safety Instructions.........................................................2

General Information......................................................3

Specifications ...............................................................4

Installation....................................................................5

Initial Startup.............................................................5-6

Filter Disassembly / Assembly ....................................6-7

Module Cleaning Procedure..........................................8

Special Cleaning Instructions ........................................8

System Inspection/Winterizing ......................................9

Repair Parts List ..........................................................10

Troubleshooting Guide................................................11

Warranty ....................................................................12

READ AND FOLLOW

SAFETY

INSTRUCTIONS!

This is the safety alert symbol. When you see this

symbol on your filter or in this manual, look for one

of the following signal words and be alert to the potential

for personal injury.

warns about hazards that will cause death, se-

rious personal injury, or major property damage if ignored.

warns about hazards that can cause death, se-

rious personal injury, or major property damage if ignored.

warns about hazards that will or can cause

minor personal injury or property damage if ignored.

NOTICE indicates special instructions not related to hazards.

Carefully read and follow all safety instructions in this

manual and on equipment. Keep safety labels in good

condition; replace if missing or damaged.

Incorrectly installed or tested equipment

may fail, causing severe injury or property

damage. Read and follow instructions in

owner's manual when installing and operating equipment. Have a trained pool professional perform all pressure tests.

1. Do not connect system to a city water system or other

external source of pressurized water.

2. Use equipment only in a pool or spa installation.

3. Trapped air in system can cause explosion. BE SURE all

air is out of system before operating or testing equipment.

Before pressure testing, make the following safety checks:

• Check all clamps, bolts, lids, lock rings and system ac-

cessories before testing.

• Release all air in system before testing.

• Tighten Sta-Rite pump trap lids to 30 ft. lbs. (4.1 kg-cm)

torque for testing.

• Water pressure for test must be less than 25 PSI (172 kPa).

• Water Temperature for test must be less than 100oF.

(38oC).

• Limit test to 24 hours. After test, visually check system

to be sure it is ready for operation. Remove pump trap

lid and retighten hand tight only.

NOTICE: These parameters apply to Sta-Rite equipment

only. For non-Sta-Rite equipment, consult equipment

manufacturer.

2

Hazardous

Pressure!

Can cause tank

explosion.

Do not connect filter to

compressed air under any

circumstances.

Page 3

3

GENERAL

INFORMATION

• Clean a new pool as well as possible before filling pool

and operating filter. Excess dirt and large particles of

foreign matter in the system can cause serious damage

to the filter and pump.

• With a modular Diatomaceous Earth (DE) filter in place

and operating correctly, clean water is returned to the

pool faster than pool water is being contaminated. A

typical pool installation will require approximately one

week to obtain and maintain the sparkle that your filter

is capable of giving you.

• Do not use more than the recommended amount of DE

in your filter. Excess DE can cause a buildup of DE and

“bridging” between the pleats which will plug the filter.

• Maximum pressure is 50 PSI (345 kPa). DO NOT connect the filter to a city water system or to an individual

water well system.

Hazardous pressure. Open air release

valve to vent all air from system before operating

system. NEVER operate filter with air trapped inside.

• The Sta-Rite modular DE filter is designed to filter

water for swimming pools and spas. On a new pool

installation, we recommend:

1.Disassemble the filter after the initial cleanup.

Hazardous pressure. To prevent severe in-

jury or major property damage, exactly follow "Filter

Disassembly/Assembly Procedure" on Pages 6 and 7.

2.Remove and hose down the element assembly to remove spent DE and contaminants.

• Maintain pool water pH between 7.2 and 7.6.

• Make sure that internal air bleed tube and filter are

clean and installed properly at top of module before

operating filter.

• Make sure that Posi-Lok™ Ring is securely locked in

place before operating filter.

• Maintain pressure gauge in good working order.

Replace a damaged gauge immediately.

• Cleaning interval is based on pressure rise, not on

length of time filter is operated. Different water conditions will have different normal cleaning intervals.

• Check local codes for restrictions on waste water and

DE disposal requirements.

NOTICE: Some pool disinfectants may clog filter module. To maximize module life and filter cycle time,

closely follow disinfectant manufacturer’s instructions

when cleaning pool or filter (see Page 7).

Owner’s Information

Serial Number_____________________________________

Dealer ___________________________________________

Dealer’s Telephone # _______________________________

Purchase Date_____________________________________

Installation Date ___________________________________

Pressure Gauge Reading at Startup____________________

When to Clean the Filter

The filter module should normally be cleaned when the

pressure gauge reading increases 10 PSI over the start-up

pressure (record the start-up pressure under “Owner’s

Information”, below, right).

In some pools, accessories such as fountains or pool cleaners may be noticeably affected by the normal decrease in

flow as the filter becomes dirty. If so, clean the filter more

frequently (that is, at a pressure increase of less than 10

PSI) in order to maintain the required flow.

Page 4

4

SPECIFICATIONS

FIGURE 1A – Dimensions in inches (mm)

Table 1 - Recommended DE Manufacturers

Johns Manville Celite 545™

GREFCO, Inc. Decalite 4200™

Eagle-Picher Minerals, Inc. Celatom™

Table 2 - Filter Specifications

PLDE36

Filter Area sq. ft. (m2) 36 (3.3)

Lbs. (kg) of DE Used 5.4 lbs. (2.4 kg.)

Maximum Flow Rate gpm (L/m) 72 (273)

Max. Operating Pressure psi (kPa) 50 (345)

Max. Continuous Water Temperature F(C) 104° (40°)

PLDE48

Filter Area sq. ft. (m2) 48 (4.5)

Lbs. (kg) of DE Used 7.2 lbs. (3.3 kg.)

Maximum Flow Rate gpm (L/m) 96 (363)

Max. Operating Pressure psi (kPa) 50 (345)

Max. Continuous Water Temperature F(C) 104° (40°)

One half pound of DE will fill a one pound coffee can.

FIGURE 2 – Pressure Drop Curve

FIGURE 1B – Piping Connections

Normal Operation

Backwash Mode

45.25

(1150)

20

15

PLDE36

36

(914)

18.5

(470)

7-13/16

(198)

9-3/16

(233)

18.5

(470)

Water Inlet pumped

from pool

Water Outlet

To Pool

Inlet

Outlet

10

5

Pressure drop (PSI)

0

20 40 60 80

100

PLDE48

Flow (GPM)

Flow out to drain if

separation tank

is not used.

Water Outlet

To Separation Tank

Water Inlet pumped

from pool

Page 5

5

INSTALLATION

Installation of filter should only be done by qualified, licensed personnel.

Filter Assembly

Filter mount must:

• Be solid, level, rigid, vibration free, and provide for adequate drainage.

• Be as close to pool as possible to reduce pressure loss

from pipe friction.

• Provide weather and freezing protection.

• Provide adequate ventilation to prevent motor from

overheating.

• Provide space and lighting for easy access for servicing

pump and piping (See Figure 1, Page 4, for space

requirements).

Piping (See Figure 1B for correct connections):

NOTICE: Make sure that the filter and all piping can be

drained for winterizing. See “Winterizing”, Page 9.

• Piping must conform to local/state plumbing and sanitary codes.

• Use teflon tape, Plasto-Joint Stik®1, or Silastic RTV

#732®on all male connections of plastic pipe and fittings. DO NOT use pipe compounds on plastic pipe; it

will cause the pipe to crack. Do not use sealant on

unions – assemble them dry and hand tight.

• Support pipe independently to prevent strains on filter.

• Fittings restrict flow; for best efficiency use fewest possible fittings.

• For ease of maintenance, Sta-Rite union couplings are

provided to connect the piping to the filter inlet and

outlet ports.

• Keep piping tight and free of leaks: pump suction line

leaks may cause trapped air in filter tank or loss of

prime at pump; pump discharge line leaks may show

up as dampness or jets of water.

• NOTICE: Overtightening can crack filter ports.

Valves:

• A check valve installed ahead of filter inlet will prevent

contaminants from draining back into pool.

• A check valve installed between filter and heater will

prevent hot water from backing up into filter and deforming internal components.

• For installation allowing backwashing, install Sta-Rite

Two Position Slide Valve or Multiport Selector Valve

with filter. See Table 3. If you intend to clean your filter

according to “Module Cleaning Procedure”, Page 7, no

slide or multi-port valve is required. See Figure 1B,

Page 4, for correct water flow when connecting pipe.

• Filter ports and valve ports are furnished with union

connections. DO NOT use pipe sealants on union collar (nut).

1

Lake Chemical Co., Chicago, IL

• Use care before assembly not to damage union sealing

surfaces or O-Ring.

• To allow recirculation during precoat (if precoat pot is

used), install a recirculation line with shut-off between

pad return line and pump suction.

Electrical:

• BE SURE filter grounding and bonding meets local and

National Electrical Code standards. All wiring, grounding and bonding of associated equipment must meet

local and National Electrical Code Standards.

INITIAL START-UP

Be sure pump is OFF

before starting procedure.

Do not operate these filters at more than 50 PSI

(345 kPa) under any circumstances!

To prevent serious damage to the element

fabric, NEVER run your DE filter without a

diatomaceous earth precoat!

1. Securely lock Posi-Lok™ ring in place by rotating ring

CLOCKWISE until it “clicks” past the safety latch (see

Figure 3). Stop turning as soon as the ring clicks past the

latch. The ring may feel slightly loose, but it will tighten

up when pump is on and filter is under pressure.

2. Fill trap on pump with water.

3. Open air release valve on top of filter.

4. Open isolation valves.

5. Start pump to purge air from system.

6. When steady stream of water comes from air release

Figure 3 – Rotate Posi-Lok™ Ring until tab locks

behind the safety latch.

Port Multi-port Valve Plastic Slide Valve

Size Part Number Part Number

2" 18201-0300 14935-0300

TABLE 3 - Sta-Rite valves for use with Model PLDE36

and PLDE48 filters

NOTICE: Use of valves other than those listed above

could cause reversed water flow through filters and

damage to internal filter components.

Tab

Latch

2149 1195

Page 6

6

valve, close the valve.

NOTICE: Leaking around the Posi-Lok™ ring may indi-

cate that the ring is not fully locked. In this case, proceed as follows:

a. Stop the pump, close the isolation valves, and

open the air release valve to release any pressure

within the filter.

b. Remove the drain plug and drain all water from the

filter.

c. Push down on the top of the filter to fully seat the

upper tank shell.

d. Rotate the Posi-Lok™ clockwise until it locks be-

hind the safety latch (see Figure 3).

e. If the ring was already locked, remove it and the

upper tank shell. Inspect and clean the O-ring and

all sealing surfaces. Relubricate the O-ring.

NOTICE: Lubricate O-ring only with the silicone grease

provided or equivalent, as other lubricants may cause the

ring to swell. DO NOT lubricate

Posi-Lok™ ring or threads on lower tank shell as this may

collect grit and make removal difficult.

7. To prepare precoat slurry, mix diatomaceous earth (DE)

and water. DO NOT use more DE than recommended.

NOTICE: Using more than the recommended amount

of DE will clog the filter. Using less than the recommended amount will give an uneven precoat and

shorten the life of the element.

8. Empty slurry slowly into skimmer to precoat filter element with an even filtering precoat.

After filter is operating, record filter pressure gauge reading in owner's manual for future use.

NOTICE: When installed on a new pool, after approximately 48 hours of operation disassemble filter and clean

out plaster dust , construction debris, etc. (see “Module

Cleaning Procedure", Page 8).

CLEANING THE FILTER

When to Clean:

NOTICE: If installation does not allow backwashing, use

module cleaning procedure regularly (see Page 8).

1. With a new filter:

a. Record filter operating pressure at startup. When

pressure reaches 10 PSI (69kPa) above startup operation pressure, stop pump for 30-60 seconds to

allow filtering cake to release.

b. Restart pump to form new cake. Pressure should

now be less than 10 PSI (69kPa) above startup operating pressure.

c. If pressure is still more than 10 PSI (69kPa) above

startup operating pressure, backwash filter (see below).

2. Thoroughly clean air bleed assembly on top of filter

module EVERY time filter is opened. Be sure to remove

all debris from screen. Replace screen if damaged.

3. At least twice a year, manually clean filter module according to instructions, Page 8. At least once a year,

follow instructions under “Special Cleaning

Instructions”, Page 8, as well.

Filter Backwash Procedure:

To prevent equipment damage and possible

injury turn pump OFF before changing valve position.

NOTICE: Before backwashing with a separation tank, review

separation tank owner's manual for instructions.

1. Stop pump.

2. Change valve position.

a. If using Multi-port Valve, set it to backwash position.

b. If backwashing with a Two Position Slide Valve, push

handle to full down position.

3. Start pump and run it for 3 minutes.

4. Stop pump and open tank bottom side drain.

NOTICE: A 1-1/2” drain valve is recommended.

5. Start pump and run 1 minute, backwashing through filter valve and tank drain.

6. STOP PUMP, return filter valve to filter position and

close tank drain.

NOTICE: Do not vacuum pool while backwashing filter.

7. Compare pressure reading on gauge with reading

recorded after initial startup. The two readings should

be very close; if not, do "Module Cleaning

Procedure", Page 8.

FILTER DISASSEMBLY/

ASSEMBLY PROCEDURE

Hazardous pressure. Before disassembling

filter:

1. STOP PUMP.

2. CLOSE isolation valves.

3. OPEN air release valve and drain fitting.

4. WAIT until all pressure is released and water drained from

filter tank and system before loosening Posi-Lok™ Ring.

Disassembly:

1. Stop the pump.

2. Close isolation valves to prevent flooding.

3. Open air release valve on top of filter tank to release all

pressure from inside of tank.

NOTICE: Make sure that waste water disposal complies

with local codes and ordinances.

4. Remove drain plug and drain all water from tank.

Hazardous pressure.

Can cause severe

injury or major

property damage

from tank blow up.

Release all pressure and

read instructions before

working on filter.

Page 7

7

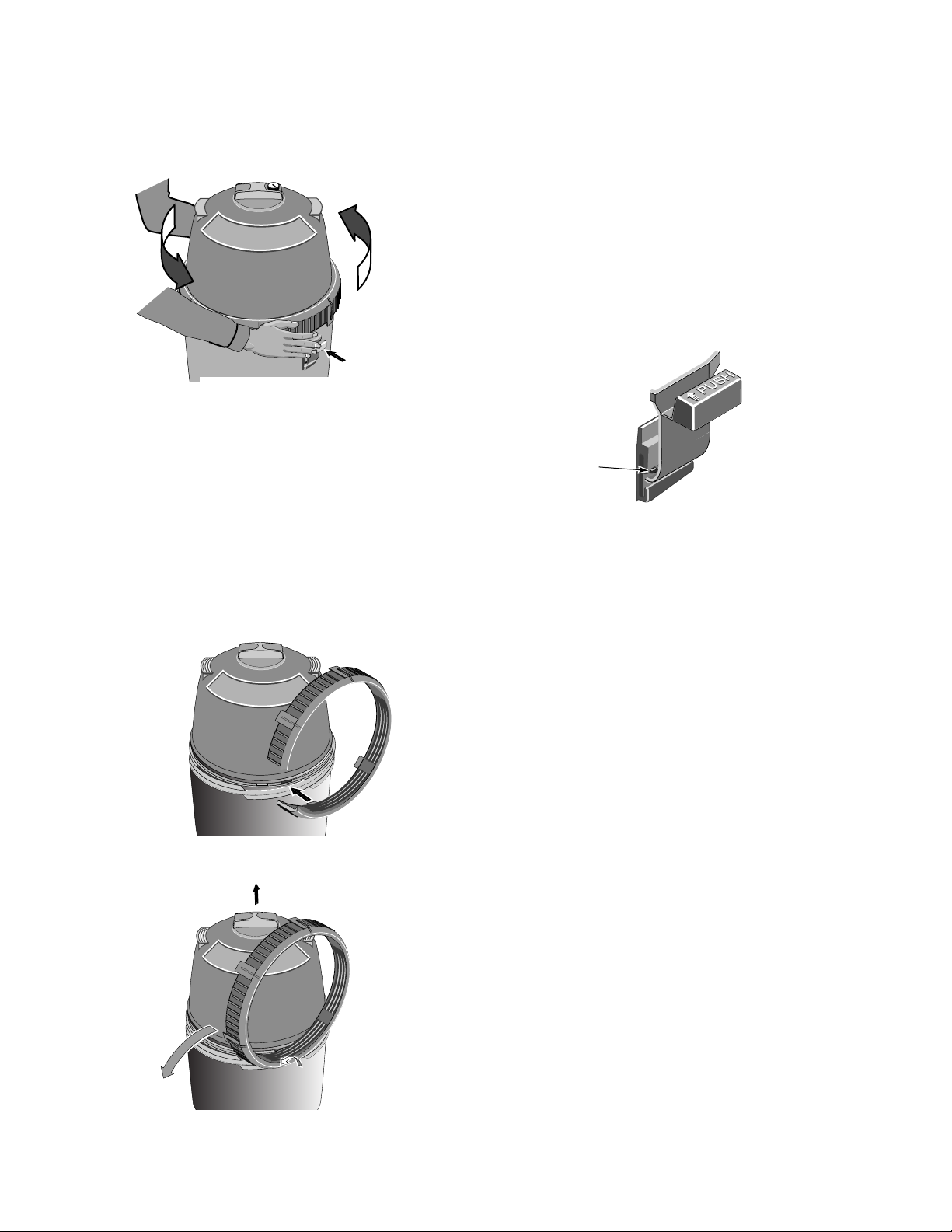

5. Remove Posi-Lok™ ring as follows:

a. Press safety latch (below the ring) toward the tank to

release it (see Figure 4).

b. Hold latch in the release position and rotate ring

COUNTERCLOCKWISE to remove. If ring is difficult

to turn, tap gently with a rubber mallet to overcome

initial resistance.

NOTICE: DO NOT use screwdriver or bladed instrument

that may damage shell surfaces to pry tank shells apart.

6. Separate upper and lower tank shell halves using tabs

on bottom of Posi-Lok™ ring. Insert tab into slot located at tank joint and twist ring to pry shell halves

apart. See Figures 5 and 6.

7. Remove O-ring from upper tank shell. Inspect for

cuts, cracking, deformation or signs of wear; replace

if necessary.

NOTICE: To avoid strain or damage, allow filter module to drain before lifting it out of the tank.

SAFETY LATCH (See Figure 7)

The purpose of the safety latch is to hold the Posi-Lok™

ring in the locked position. If the latch is damaged, replace it as follows:

1. Press down on the small catch behind the safety latch

and press or tap the latch out of the “Tee” slot in the

tank (see Figure 7).

2. Snap the new latch into position.

NOTICE: DO NOT operate the filter if the safety latch

is damaged or will not hold the Posi-Lok™ ring in the

locked position.

Assembly:

1. Inspect and clean the tank, ring threads and O-ring

groove. Replace damaged parts as necessary.

2. Install the filter by placing the port in the bottom of the

filter cartridge over the tank outlet port. Push down

firmly to seal.

3. Ensure that the air bleed assembly on top of the module is clean and properly mounted.

NOTICE: Lubricate O-ring only with the silicone

grease provided or equivalent, as other lubricants may

cause the ring to swell. DO NOT lubricate Posi-Lok™

ring or threads on lower tank shell as this may collect

grit and make removal difficult.

4. Install the O-ring in the upper tank shell O-ring

groove. Be sure that the

O-ring is clean and not twisted.

5. Push the upper tank shell into the lower tank shell to

compress the O-ring.

6. Place the Posi-Lok™ ring squarely over the tank shell

threads and rotate COUNTERCLOCKWISE until the

ring falls into the slots; then rotate CLOCKWISE until

securely latched.

7. Follow instructions in the “Initial Startup” section of

this manual.

Figure 5 – Insert ring tab in slot in filter body.

Figure 4 – Depress safety latch to unscrew

Posi-Lok™ Ring.

Figure 6 – Roll ring to one side to loosen upper tank

half.

Figure 7 – Safety Latch

RELEASE

RELEASE

Depress Safety Latch

to unscrew Posi-Lok™

Small

Catch

Page 8

MODULE CLEANING PROCEDURE

Risk of chemical burns. Do not attempt to

acid clean the filter or module. If the filter requires acid cleaning, have a trained pool professional do the

job.

Follow all steps in the “Disassembly” section of this manual.

The filter module should be removed and cleaned when

pressure rises more than 10 psi (69 kPa) above startup

pressure. See also “When to Clean the Filter,” below.

NOTICE: Do not expose the filter module to sunlight for

any extended period of time.

NOTICE: When sanitizing your pool using PHMB (poly-

hexamethylene biquanide based) cleaners, use

only

PHMB cleaners to clean the module. When using PHMB

sanitizers, the filter module MUST be cleaned more thoroughly and frequently than for a pool using chlorine.

Follow manufacturer’s instructions carefully. Use of any

other type of cleansers with PHMB pool sanitizers will

void the filter’s warranty.

NOTICE: Avoid washing filter debris into the outlet port.

Remove drain plug and flush foreign material from inside

of tank before removing filter module.

1. With a hose equipped with a soft flow nozzle, wash as

much dirt as possible off of the filter module while it is

still inside the tank. Allow tank to drain completely.

2. Make sure that the inside of the tank is clean. Lift out

the module and hose it down thoroughly. Spray the entire module surface. Allow module to drain.

3. Inspect the module. If necessary, repeat the washing

operation. If the module is damaged, replace it.

NOTICE: If this cleaning method does not remove all

deposits, see “Special Cleaning Instructions” section in

this manual.

4. Inspect and clean air bleed filter at top of module.

5. Follow all steps in the “Assembly” and “Initial Startup”

sections of this manual.

Special Cleaning Instructions:

Use this procedure to clean scale or oils which are not removed by hosing down module. Be sure to dispose of

spent chemicals according to all applicable codes and

waste disposal ordinances. Use a soft stream nozzle to

minimize flying water and spray.

Risk of fire or explosion. Isolate filter from

system before chemical cleaning; rinse filter

and elements completely before returning to service. If

filter cannot be isolated, remove media and clean at another location. Follow chemical manufacturer’s instructions for use. Do not mix chemicals except as directed by

manufacturer. Do not allow cleaning chemicals to mix

with or to come in contact with chlorine, bromines, other

chemicals, or chemical feed devices.

1. Sponge or spray the module according to chemical

manufacturer’s directions.

2. If soaking is required, remove the module from the filter tank and submerge it in a separate tank. Follow

cleaner manufacturer’s instructions carefully.

3. After completing chemical manufacturer’s instructions,

drain and rinse the module completely. Dispose of

cleaners in accordance with local codes and disposal

ordinances.

4. Rinse the inside of the filter tank. Drain it completely.

5. Follow instructions in the “Assembly” and “Initial

Startup” sections of this manual.

8

Recommended Specialty Filter Cleaners

Filter Cleanse™, Great Lakes Biochemical

BIOGUARD Strip Kwik™, BIOGUARD KleenIt™,

Softswim®Filter Cleaner,** BIOLABS, Inc.

Filter Kleen™, Haviland Products Co.

BAQUA CLEAN™, ** Zeneca, Inc.

** MUST be used when using any PHMB

based sanitizer.

When to Clean the Filter

The filter module should normally be cleaned when the pressure

gauge reading increases 10 PSI over the start-up pressure (record

the start-up pressure under “Owner’s Information”, Page 3).

In some pools, accessories such as fountains or pool cleaners may

be noticeably affected by the normal decrease in flow as the filter

becomes dirty. If so, clean the filter more frequently (that is, at a

pressure increase of less than 10 PSI) in order to maintain the required flow.

Page 9

9

SYSTEM INSPECTION

General:

Wash the outside of the filter with a mild detergent and

water. Rinse off with a hose.

NOTICE: DO NOT use solvents to clean the filter; solvents may damage plastic components in the system.

NOTICE: Open the air bleed valve and bleed all air from

the filter each time the pump is stopped and restarted.

Weekly Inspection:

1. Remove debris from the pool skimmer basket.

2.

Stop the pump; open the air release valve to release all

pressure.

3. Remove the trap cover and basket; remove debris.

4. Check the pump for leaks. If found, see the pump

owner's manual.

5. Replace the trap basket and the cover. Tighten the

cover securely hand tight. DO NOT use a lid wrench

to tighten it.

6. Start the pump. When the filter air release valve runs a

solid stream of water, close the valve.

7. When the system has returned to normal operation,

check the filter pressure. If the filter pressure is 10 PSI

(69kPa) or more higher than the initial startup pressure, the filter needs cleaning. See “Module Cleaning

Procedure”, Page 8.

WINTERIZING

Explosion hazard. Purging the system with

compressed air can cause components to

explode, with risk of severe injury or death to anyone

nearby. Use only a low pressure (below 5 PSI), high vol-

ume blower when air purging the pump, filter, or piping.

NOTICE: The filter outlet piping will not empty through

the filter drain. Make sure that the outlet piping has a separate drain for winterizing.

NOTICE: Protect the filter from freezing. Allowing the filter to freeze will damage it and will void the warranty.

1. Clean the filter according to instructions (Page 8) be-

fore winterizing.

2. Stop the pump.

3. Open the air release valve; open all the system valves.

4. Remove the drain plugs from the trap, pump, and filter.

5. Drain the system piping.

a. Gravity drain system as far as possible.

b. Protect areas which retain water with non-toxic

propylene glycol

antifreeze (“RV antifreeze”).

6. Loosen the union nuts (if used) to drain all water from

the filter interior. Leave these nuts loose until the system is restarted.

7. Disassemble the filter (follow instructions under “Filter

Disassembly”, Pages 6 and 7). Remove the filter module and store it in a warm, dry area.

Page 10

10

A

Key Part

No. Description Qty. PLDE36 PLDE48

1 Posi-Lok™ Ring 1 27001-0054S 27001-0054S

2 Air Release Valve with O-ring 1 25010-0200 24206-0103S

3 Presure Gauge 1 15060-000T 15060-000T

4 Tank Upper Half with Air Relief Valve 1 27001-0020S 27001-0030S

5 Tank O-Ring 1 27001-0061S 27001-0061S

6 Filter Module 1 27002-0036S 27002-0048S

6A Air Bleed Assembly 1 24800-0122 24800-0122

7 Diverter 1 27001-0015S 27001-0015S

8 Tank Lower Half* 1 27001-0016S 27001-0016S

9 Drain Plug 1 27001-0022S 27001-0022S

10 Safety Latch 1 27001-0051 27001-0051

11 Tank Support Base 1 27001-0018S 27001-0018S

12 2" Union Adapter Package (includes 2) 1 PKG 188 PKG 188

REPAIR PARTS LIST

EXPLODED VIEW

* Includes Key Nos. 7, 8, 9, 10.

2

E

S

O

L

C

O

P

E

N

PLDE 48

2

PLDE 36

4

3

1

3

6

6

4

5

10

9

8

7

11

12

Page 11

11

1. Short Cycle Time:

NOTICE: Cycle Time will vary with each installation and be-

tween different areas of the country. The following causes and

remedies are for cycle times shorter than normal for your area.

A. Chlorine residual too low; maintain proper residual (con-

sult pool professional for recommendation).

B. Flow rate too high; restrict flow to rated capacity of filter

(see instruction plate on filter or specifications on Page 4).

C. Filter is too small; install an additional filter.

D. Improper/insufficient precoat; see precoat instructions

(Page 5).

E. Filter module is dirty or plugged; thoroughly clean the fil-

ter (see No. 4, “Plugged Module Cloth”, and “Module

Cleaning Procedure", Page 8).

F. Too much DE; check for clogged filter module.

G. Water is chemically out of balance; consult pool

professional.

H. Algae in the pool. Apply heavy dose of chlorine or

algicide as recommended by the pool manufacturer.

2. Low Flow/High Pressure:

A. Elements plugged; clean filter thoroughly (see Page 8).

B. Pipe blocked downstream from filter; remove obstruction.

C. Piping too small; use larger pipe (consult dealer for sizing).

D. Filter area too small; install an auxiliary filter (consult

dealer for recommendation).

E. Outlet port check valve obstructed (if applicable);

remove obstruction to allow valve to open.

3. Low Flow/Low Pressure:

A. Pump too small; consult dealer for recommendations.

B. Plugged pump or plugged hair and lint trap; clean

thoroughly.

4. Plugged Module Cloth:

NOTICE: The pleated filter material may look matted after use.

However, as long as the DE adheres to the pleated cloth, the filter

is operating properly.

A. Insufficient precoat; see precoat instructions (Page 6).

B. Insufficient cleaning; follow cleaning instructions closely

and clean thoroughly (see Page 8).

C. Water is chemically out of balance; consult pool

professional.

D. Excessive air in filter; non-precoated areas may plug. Vent

air from tank and check for pump suction pipe leaks.

Clean air bleed filter in grid assembly with a hose and soft

flow nozzle.

E. Filter is too small. Install an additional filter.

F. Pool water contains iron. See “Special Cleaning

Instructions”, Page 8.

G. Algae in pool. Apply heavy dose of chlorine or algaecide

as recommended by the pool manufacturer.

H. Use of incorrect chemicals with PHMB sanitizers. Replace

filter module.

I. Not enough D.E. precoat. See precoat instructions

(Page 4).

5. Pool Water Not Clean:

A. Chlorine residual too low; maintain adequate

chlorine residual (consult pool service technician for

recommendation).

B. Broken filter module passing DE into pool; replace defec-

tive module.

C. Insufficient or improper precoat; follow precoating instruc-

tions and use recommended amount of DE (see Page 4).

D. Inadequate turnover rate; consult dealer to verify that

equipment is properly sized for your pool.

E. Pump is too large and is overpumping. Reduce the flow

rate.

F. The filter is installed backwards. Reinstall it correctly.

G. Pool water contains iron. See “Special Cleaning

Instructions”, Page 8.

H. Heavy or improper application of powdered chlorine

tablets using a binder. See “Special Cleaning Instructions”,

Page 8.

I. Algae in the pool. Apply heavy dose of chlorine or algi-

cide as recommended by the pool manufacturer.

6. Pool Accessories Stop Working:

A. Clean filter and observe performance of accessories.

B. If accessories perform better after filter has been cleaned,

use a shorter cleaning cycle for the filter (that is, clean the

filter after a pressure rise of less than 10 PSI).

TROUBLESHOOTING GUIDE

Page 12

CREATE A RECORD OF YOUR WARRANTY AT STA-RITE:

• Complete a warranty registration at www.staritepool.com by clicking on “Register Products” and selecting Sta-Rite Pool

OR

• Complete bottom portion completely and mail within 10 days of installation to Sta-Rite, Attn.: Pool Warranty Dept., 293 Wright St., Delavan , WI 53115

Warranty Registration Card

Name

Address

City State Zip

Installation (or Purchase) Date

Product Purchased

Model Number

■■ New installation ■■ Replacement

Years pool has been in service ■■ less than 1 ■■ 1-3 ■■ 3-5 ■■ 5-10

This product was purchased from:

Company name

Address

City State Zip

STA-RITE LIMITED WARRANTY

For technical information about this product, contact the installer or call Sta-Rite at 262-728-9181.

Visit www.staritepool.com

• for more information about Sta-Rite products listed above

• to locate a Sta-Rite dealer near you

Product Specific Warranties (from date of installation)

Product Limited

Family Warranty Exceptions

Filters 1 Year System 3 Tank Bodies - 10 Yrs

Filter Valves 1 Year

Pumps 1 Year

Heaters 2 Years *Commercial Application - 1 Yr

Controls 1 Year

Above Ground Systems 1 Year

Lights and Niches 1 Year Lamps and Bulbs - 90 Days

White Goods 1 Year

Maintenance Equipment 90 Days

Drainer/Utility Pumps 90 Days

Replacement Parts 90 Days

Cleaners: Lil Shark 1 Year

Cleaners: Calypso 1 Year

Cleaners: Pool Shark 2 Years Footpad and Seal Flaps - 1 Yr

Cleaners: Great White 2 Years

* Commercial and multi-family application.

Retain this warranty certificate in a

safe and convenient location for your records.

Pumps, filters, skimmers, underwater lights (excluding bulbs), accessories and fittings manufactured by Sta-Rite are warranted to

be free of defects in material and/or workmanship for one (1) year

from the original date of installation.

The foregoing warranties relate to the original consumer purchaser

(“Purchaser”) only. Sta-Rite Industries shall have the option to repair or replace the defective product, at its sole discretion.

Purchasers must pay all labor and shipping charges necessary to

replace the product covered by this warranty. Requests for warranty service must be made through the installing dealer. This warranty shall not apply to any product that has been subject to

negligence, misapplication, improper installation or maintenance,

or other circumstances which are not in Sta-Rite’s direct control.

Failure to have product installed by a professional in compliance

with local codes will void any and all manufacturers warranty.

This warranty sets forth Sta-Rite’s obligation and Purchaser’s exclusive remedy for defective products.

STA-RITE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL,

INCIDENTAL OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN

LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, SHALL NOT EXTEND BEYOND THE

DURATION OF THE APPLICABLE EXPRESS WARRANTIES

PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or

consequential damages or limitations on how long an implied warranty lasts, so the above limitations or exclusion may not apply to

you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Supersedes all previous publications.

S4877PS (Rev. 7/21/04)

Page 13

Filtro modular de tierra

de diatomeas “System 2

TM”

MANUAL DEL PROPIETARIO

INSTALACIÓN, OPERACIÓN Y REPUESTOS

MODELOS

PLDE36 PLDE48

Sta-Rite Pool/Spa Group

293 Wright Street, Delavan, WI 53115

Internacional: 262-728-5551, FAX: 262-728-7550

www.starite.com

Union City, TN • Delavan, WI • Mississauga, Ont. • Murrieta, CA

© 2005, Sta-Rite Industries S749 (Rev. 6/24/05)

Este manual se debe entregar al usuario

final de este filtro; su uso reducirá las

llamadas de servicio y la posibilidad de

lesiones, y alargará la vida útil del filtro.

E

S

O

L

C

O

P

E

N

Page 14

Índice

Instrucciones de seguridad ............................................2

Información general ......................................................3

Especificaciones............................................................4

Instalación ....................................................................5

Arranque inicial .........................................................5-6

Desensamblaje / ensamblaje del filtro.........................6-7

Procedimiento de limpieza del módulo..........................8

Instrucciones especiales para la limpieza .......................8

Inspección del sistema / acondicionamiento

para el invierno.............................................................9

Lista de piezas de repuesto ..........................................10

Guía para la localización de fallas ...............................11

Garantía .....................................................................12

¡LEA Y SIGA LAS

INSTRUCCIONES

DE SEGURIDAD!

Este es el símbolo de alerta de seguridad. Cuando

vea este símbolo en su filtro o en este manual, busque

alguna de las siguientes palabras de advertencia y esté alerta

a la posibilidad de lesiones personales:

advierte acerca de los peligros que provocarán

lesiones personales graves, muerte o daños materiales considerables

si se ignoran.

advierte acerca de los peligros que

pueden

provocar

lesiones personales graves, muerte o daños

materiales considerables si se ignoran.

advierte acerca de los peligros que provocarán

o podrán

provocar

lesiones personales o daños materiales menores

si se ignoran.

La etiqueta AVISO indica instrucciones especiales que no están

relacionadas con peligros.

Lea y siga cuidadosamente todas las instrucciones de seguridad

en este manual y en el equipo. Mantenga las etiquetas de seguri-

dad en buen estado; reemplace las etiquetas de seguridad faltantes

o dañadas.

Los equipos mal instalados o probados pueden

fallar, provocando lesiones graves o daños materiales. Es importante leer y seguir las instrucciones

que aparecen en el manual del propietario

cuando se instalen y se operen equipos. Haga que un profesional

competente de piscinas realice todas las pruebas de presión.

1. No conecte el sistema a un sistema de aguas públicas ni a

otra fuente externa de agua presurizada.

2. Use el equipo sólo en instalaciones de piscinas o jacuzzis.

3. El aire atrapado en el sistema puede provocar explosiones.

VERIFIQUE que haya salido todo el aire del sistema antes de

hacer funcionar o de realizar las pruebas del equipo.

Antes de realizar la prueba de presión, haga las siguientes verificaciones de seguridad:

• Antes de realizar la prueba, inspeccione todas las

abrazaderas, los pernos, las tapas, los aros de fijación y los

accesorios del sistema.

• Antes de realizar la prueba descargue todo el aire en el sistema.

• Apriete las tapas de la trampa de la bomba Sta-Rite a una tor-

sión de 30 ft. lbs. (4.1 kg-cm) para realizar la prueba.

• La presión del agua para la prueba debe ser inferior a 25 PSI

(172 kPa).

• La temperatura del agua para la prueba debe ser inferior a

100° F (38˚ C).

• Limite la prueba a 24 horas. Después de realizada, inspec-

cione el sistema visualmente para verificar que esté listo para

funcionar. Saque la tapa de la trampa de la bomba y vuelva a

apretarla a mano solamente.

AVISO: Estos parámetros corresponden sólo a los equipos

Sta-Rite. Para equipos que no son Sta-Rite, consulte con el

fabricante de los mismos.

2

¡Presión peligrosa!

Puede provocar

una explosión del

tanque.

No conecte el filtro al

aire comprimido bajo

ninguna circunstancia.

ADVERTENCIA

PELIGRO

ADVERTENCIA

PRECAUCIÓN

Page 15

3

INFORMACIÓN

GENERAL

• Limpie una piscina nueva a fondo antes de llenarla y hacer

funcionar el filtro. El exceso de suciedad y de partículas de

materias extrañas grandes en el sistema puede provocar

daños graves en el filtro y en la bomba.

• Con un filtro modular de diatomeas (DE) instalado y funcionando debidamente, el agua limpia vuelva a la piscina con

mayor rapidez de lo que el agua de la piscina se puede contaminar. Una instalación de piscina típica requerirá aproximadamente una semana para obtener el brillo que puede

obtener con el filtro.

• No use más tierra de diatomeas en el filtro que la cantidad

recomendada. El exceso de diatomeas puede provocar su

acumulación entre los pliegues y la obstrucción del filtro.

• La presión máxima es de 50 PSI (345 kPa). NO conecte el filtro a un sistema de aguas públicas ni a un sistema de pozo de

agua individual.

Presión peligrosa. Abra la válvula de

desahogo de aire para purgar todo el aire del sistema antes

de hacerlo funcionar. NUNCA opere el filtro si hay aire atrapado en su interior.

• El filtro modular de diatomeas Sta-Rite ha sido diseñado para

filtrar agua en piscinas de natación y los balnearios. En una

nueva instalación de piscina, recomendamos:

1. Desarmar el filtro después de la limpieza inicial.

Presión peligrosa. Para evitar le-

siones graves o daños materiales considerables, siga exactamente el “Procedimiento de desensamblaje / ensamblaje del

filtro” en las Páginas 6 y 7.

2. Saque el elemento y lávelo a manguera para eliminar la tierra

de diatomeas usada y los contaminantes.

• Mantenga el pH del agua de la piscina entre 7.2 y 7.6.

• Verifique que el tubo interno de purga de aire y el filtro estén

limpios y debidamente instalados en la parte superior del módulo antes de operar el filtro.

• Verifique que el Aro Posi-Lok

TM

esté debidamente fijado en

posición antes de operar el filtro.

• Mantenga el manómetro en buen estado de funcionamiento.

Reemplace un manómetro averiado inmediatamente.

• Los intervalos de limpieza se basan en el aumento de presión

y no en el tiempo de operación del filtro. Aguas de diferentes

condiciones requerirán intervalos de limpieza normales

diferentes.

• Verifique todos los códigos locales para obtener información

sobre las restricciones asociadas a aguas servidas y a los requerimientos para la eliminación de tierra de diatomeas.

AVISO: Ciertos desinfectantes de piscinas pueden tapar el

módulo filtrante. Para maximizar la vida útil del módulo y el

tiempo de ciclo del filtro, observe estrictamente las instrucciones del fabricante del desinfectante cuando limpie la

piscina o el filtro (consulte la Página 7).

Información del propietario

Número de serie___________________________________

Concesionario_____________________________________

Número de teléfono del concesionario ________________

Fecha de compra __________________________________

Fecha de instalación _______________________________

Lectura inicial del manómetro _______________________

Cuando limpiar el filtro

El módulo filtrante generalmente se debe limpiar cuando la lectura

del manómetro aumente 10 psi por encima de la presión inicial

(registre la presión inicial en la “Información del Propietario”, que

aparece a continuación).

En ciertas piscinas, los accesorios, como las fuentes o los

limpiadores de piscina pueden verse afectados considerablemente

por el descenso normal de flujo cuando el filtro se ensucia. En ese

caso, limpie el filtro con mayor frecuencia (es decir, a un aumento

de presión menor de 10 psi) para mantener el flujo requerido.

ADVERTENCIA

ADVERTENCIA

Page 16

4

ESPECIFICACIONES

FIGURA 1A – Dimensiones en pulgadas (mm)

Cuadro 1 - Fabricantes de tierra

de diatomeas recomendados

Johns Manville Celite 545™

GREFCO, Inc. Decalite 4200™

Eagle-Picher Minerals, Inc. Celatom™

Cuadro 2 - Especificaciones del filtro

PLDE36

Área del filtro sq. ft. (m2) 36 (3.3)

Lbs. (kg) de diatomeas usadas 5.4 lbs. (2.4 kg.)

Máximo caudal gpm (L/m) 72 (273)

Máx. presión de operación psi (kPa) 50 (345)

Máx. temperatura continua del agug F(C) 104° (40°)

PLDE48

Área del filtro sq. ft. (m2) 48 (4.5)

Lbs. (kg) de diatomeas usadas 7.2 lbs. (3.3 kg.)

Máximo caudal gpm (L/m) 96 (363)

Máx. presión de operación psi (kPa) 50 (345)

Máx. temperatura continua del agug F(C) 104° (40°)

Media libra de tierra de diatomeas llenará una lata de café

de una libra.

FIGURA 2 – Curva de la caída de presión

FIGURA 1B – Conexiones de tubería

Operación normal

Modo de retrolavado

Caída de presión (psi)

Flujo (gpm)

Salida

Admisión

Admisión de agua

bombeada desde la

piscina

Salida de agua

hacia la piscina

Salida de agua hacia el

tanque de separación

Admisión de agua

bombeada desde la

piscina

Flujo hacia el desagüe

si no se usa un tanque

de separación

45.25

(1150)

20

15

PLDE36

36

(914)

18.5

(470)

7-13/16

(198)

9-3/16

(233)

18.5

(470)

Water Inlet pumped

from pool

Water Outlet

To Pool

Inlet

Outlet

10

5

Pressure drop (PSI)

0

20 40 60 80

Flow (GPM)

100

PLDE48

Water Outlet

To Separation Tank

Water Inlet pumped

from pool

Flow out to drain if

separation tank

is not used.

Page 17

5

INSTALACIÓN

La instalación del filtro debe ser realizada sólo por personas

calificadas y competentes.

Ensamblaje del filtro

La instalación del filtro debe:

• Ser firme, nivelada, rígida, sin vibraciones y con un drenaje

adecuado.

• Estar lo más cerca posible de la piscina para reducir la pérdida de presión debido a la fricción de las tuberías.

• Proporcionar protección contra la intemperie y las heladas.

• Proporcionar una ventilación adecuada para evitar que el

motor se recaliente

• Proporcionar un espacio y una iluminación suficientes para acceder fácilmente a la bomba y a las tuberías en caso de reparaciones y mantenimiento (Consulte la Figura 1, Página 4, para

obtener información sobre los requerimientos de espacio).

Tubería (Consulte la Figura 1B para las conexiones correctas):

AVISO: Verifique que el filtro y la tubería se puedan drenar para

acondicionarlos para el invierno. Consulte la

“Acondicionamiento para el invierno”, Página 9.

• Las tuberías deben cumplir con los códigos sanitarios y de

plomería locales y estatales.

• Use cinta de teflón, Plasto-Joint Stik

®1

, o Silastic RTV #732®en

todas las conexiones macho de tuberías y accesorios de plástico. NO use compuestos para tuberías en tuberías de plástico

ya que pueden rajar la tubería. No use compuestos selladores

en las uniones - ármelas en seco y apriételas a mano.

• Apoye la tubería independientemente para evitar ejercer presión sobre el filtro.

• Los accesorios limitan el flujo; para mayor eficacia, use la

cantidad menor posible de accesorios.

• Para facilitar el mantenimiento, se suministran empalmes de

unión Sta-Rite para conectar la tubería a los orificios de admisión y de salida del filtro.

• Mantenga la tubería hermética y sin fugas: fugas en la línea

de aspiración de la bomba pueden hacer que el aire quede

atrapado en el tanque del filtro o que la bomba pierda cebadura; fugas en la línea de descarga de la bomba se pueden

hacer evidentes a través de humedad o chorros de agua.

• AVISO: Los orificios del filtro se pueden rajar si se aprieta

demasiado.

Válvulas:

• Si se instala una válvula de retención delante de la admisión

del filtro, ésta impedirá que los contaminantes se drenen de

regreso hacia la piscina.

• Una válvula de retención instalada entre el filtro y el calentador, impedirá que el agua caliente entre al filtro y deforme

los componentes internos.

• Para una instalación con retrolavado, instale una Válvula

Corrediza de dos Posiciones o una Válvula de Selección

Múltiple de Sta-Rite con el filtro. Consulte el Cuadro 3. Si

tiene la intención de limpiar el filtro según el “Procedimiento

de limpieza del módulo”, Página 7, no necesitará instalar una

válvula corrediza o múltiple. Consulte la Figura 1B, Página 4,

para obtener información sobre el flujo de agua correcto

cuando conecte la tubería.

• Las conexiones de unión vienen equipadas con los orificios

para el filtro y la válvula. NO use compuestos selladores de

tuberías en el collarín de unión (tuerca).

1

Lake Chemical Co., Chicago, IL

• Antes del ensamblaje, tenga cuidado de no dañar las superficies de sellado de las uniones ni el aro tórico.

• Para permitir la recirculación durante la colocación de la capa

filtrante, instale una tubería de recirculación con cierre entre la

línea de regreso de atenuación y la aspiración de la bomba.

Información eléctrica:

• VERIFIQUE que la puesta a tierra y la conexión del filtro

cumplan con las normas locales y del Código Nacional de

Electricidad. Todo el cableado, la puesta a tierra y las conexiones de los equipos asociados deben cumplir con las normas locales y del Código Nacional de Electricidad.

ARRANQUE INICIAL

Verifique que la bomba esté apagada antes de iniciar el

procedimiento de arranque.

¡No opere estos filtros a más de 50 PSI (345 kPa) bajo

ninguna circunstancia!

Para evitar daños graves al material del elemento, NUNCA haga marchar su Filtro de Diatomeas sin

antes haber colocado una capa filtrante de diatomeas.

1. Fije el aro Posi-Lok

TM

haciéndolo girar HACIA LA DERECHA

hasta que haga clic, después del pasador de seguridad (consulte la Figura 3). Deje de girar cuando el aro haga clic después del pasador. Es posible que el aro quede ligeramente

flojo, pero se ajustará más cuando se encienda la bomba y el

filtro esté bajo presión.

2. Llene la trampa en la bomba con agua.

3. Abra la válvula de desahogo de aire en la parte superior del

filtro.

4. Abra las válvulas de aislamiento.

5. Encienda la bomba para extraer el aire del sistema.

Figura 3 – Gire el Aro Posi-LokTMhasta que la lengüeta

quede trabada detrás del pasador de seguridad.

Tamaño Número de repuesto Número de repuesto de la

del orificio de la válvula multivía válvula corrediza de plástico

2" 18201-0300 14935-0300

AVISO: El uso de válvulas que no sean las arriba indicadas,

puede provocar un flujo de agua inverso por el filtro y dañar

los componentes internos del mismo.

CUADRO 3 - Válvulas Sta-Rite para usar con los filtros

Modelos PLDE36 y PLDE 48

Lengüeta

Pasador

PRECAUCIÓN

Tab

Latch

2149 1195

Page 18

6

6. Cuando salga un chorro firme de agua de la válvula de desahogo de aire, cierre la válvula.

AVISO: Fugas alrededor del aro Posi-Lok

TM

pueden indicar

que el aro no está totalmente trabado. En este caso, proceda

de la siguiente manera:

a. Detenga la bomba, cierre las válvulas de aislamiento y

abra la válvula de desahogo de aire para soltar la presión

que pueda haber dentro del filtro.

b. Saque el tapón de desagüe y drene toda el agua del filtro.

c. Empuje la parte superior del filtro hacia abajo para aco-

modar bien la estructura superior del tanque.

d. Gire el aro Posi-Lok

TM

hacia la derecha hasta que quede

trabado detrás del pasador de seguridad (consulte la

Figura 3).

e. Si el aro ya estaba trabado, sáquelo y saque la estructura

superior del tanque. Inspeccione y limpie el aro tórico y

todas las superficies de sellado. Vuelva a lubricar el aro

tórico.

AVISO: Lubrique el aro tórico sólo con la grasa de silicona suministrada o con un producto equivalente, ya que otros lubricantes pueden hacer que el aro se hinche. NO lubrique el aro

Posi-Lok

TM

ni las roscas en la estructura inferior del tanque, ya

que pueden acumular polvo y dificultar su remoción.

7. Para preparar el compuesto de la capa filtrante, mezcle la

tierra de diatomeas con agua. NO use más que la cantidad

de tierra de diatomeas recomendada.

AVISO: Si se usa más que la cantidad recomendada de tierra

de diatomeas, se tapará el filtro. Si se usa menos que la cantidad recomendada se obtendrá una capa filtrante irregular que

acortará la vida útil del elemento.

8. Vacíe el compuesto lentamente en el espumador para cubrir

el elemento del filtro con una capa filtrante uniforme.

Una vez que el filtro esté funcionando, registre la lectura del

manómetro del filtro en el manual del propietario para referencia futura.

AVISO: Cuando la instalación sea en una piscina nueva, después de unas 48 horas de operación, desarme el filtro y limpie

el polvo de yeso y la suciedad de la construcción que se pueda

haber acumulado. (consulte el “Procedimiento para la limpieza

del módulo”, Página 8).

LIMPIEZA DEL FILTRO

Cuando limpiarlo:

AVISO: Si la instalación no permite retrolavado, realice el proced-

imiento de limpieza del módulo con regularidad (consulte la Página 8).

1. Con un filtro nuevo:

a. Registre la presión de operación inicial. Cuando la pre-

sión llegue a 10 PSI (69kPa) por encima de la presión inicial de operación, detenga la bomba por 30-60 segundos

para permitir la salida de la pastilla de filtración.

b. Vuelva a encender la bomba para formar una nueva

pastilla. Ahora la presión deberá ser inferior a 10 PSI

(69kPa) por encima de la presión inicial de operación.

c. Si la presión es aún más de 10 PSI (69kPa) por encima de

la presión inicial de operación, retrolave el filtro (ver a

continuación).

2. Limpie a fondo la unidad de purga de aire en la parte superior del módulo filtrante CADA vez que abra el filtro.

Asegúrese de eliminar toda la suciedad de la malla.

Reemplace la malla si está averiada.

3. Al menos dos veces al año, limpie el módulo filtrante a

mano, según las instrucciones que aparecen en la Página 8.

Al menos una vez al año, también siga las instrucciones de la

sección “Instrucciones especiales para la limpieza”, Página 8.

Procedimiento de retrolavado del filtro:

Para evitar dañar el equipo y provocar

posibles lesiones, apague la bomba antes de cambiar la posición

de la válvula.

AVISO: Antes de retrolavar con un tanque de separación, consulte

las instrucciones del fabricante en el manual del propietario.

1. Detenga la bomba.

2. Cambie la posición de la válvula.

a. Si usa una válvula multivía, colóquela en la posición de

retrolavado.

b. Si el retrolavado se realiza con una válvula corrediza de

dos posiciones, empuje el mango a la posición completamente hacia abajo.

3. Encienda la bomba y hágala marchar por 3 minutos.

4. Detenga la bomba y abra el desagüe lateral en el fondo del

tanque.

AVISO: Se recomienda usar una válvula de desagüe de 1-1/2”.

5. Encienda la bomba y hágala marchar por 1 minuto, retrola-

vando a través de la válvula del filtro y del desagüe del

tanque.

6. DETENGA LA BOMBA, vuelva a colocar la válvula del filtro

en la posición de filtración y cierre el desagüe del tanque.

AVISO: No aspire la piscina mientras esté retrolavando el filtro.

7. Compare la lectura de presión en el manómetro con la lec-

tura registrada después del arranque inicial. Las dos lecturas

deben ser bastante similares, de lo contrario, siga el

“Procedimiento de limpieza del módulo”, Página 8.

PROCEDIMIENTO

DE DESENSAMBLAJE /

ENSAMBLAJE DEL

FILTRO

Presión peligrosa. Antes de desarmar el

filtro:

1. DETENGA LA BOMBA.

2. CIERRE las válvulas de aislamiento.

3. ABRA la válvula de desahogo de aire y el accesorio de desagüe.

4. ESPERE hasta que se haya descargado toda la presión y se

haya drenado toda el agua del tanque del filtro y del sistema

antes de aflojar el aro Posi-Lok

TM

.

Desensamblaje:

1. Detenga la bomba.

2. Cierre las válvulas de aislamiento para evitar una inundación.

3. Abra la válvula de desahogo de aire en la parte superior del

tanque del filtro para descargar toda la presión del interior

del tanque.

AVISO: Verifique que la eliminación de las aguas servidas se

realice conforme con los códigos y las reglas locales.

4. Saque el tapón de desagüe y drene toda el agua del tanque.

Presión peligrosa. Puede

provocar lesiones graves

o daños materiales

considerables debido

a la explosión del tanque.

Libere toda la presión y lea

las instrucciones antes de

trabajar en el filtro.

ADVERTENCIA

PRECAUCIÓN

ADVERTENCIA

Page 19

7

5. Saque el aro Posi-LokTMde la siguiente manera:

a. Oprima el pasador de seguridad (debajo del aro) hacia el

tanque para aflojarlo (consulte la Figura 4).

b. Mantenga el pasador en la posición soltada y gire el aro

HACIA LA IZQUIERDA para sacarlo. Si es difícil hacer

girar el aro, se deberá golpetear suavemente con un martillo de caucho para aflojar la resistencia inicial.

AVISO: NO use un destornillador ni un instrumento con una

hoja que pueda dañar las superficies de la estructura para separar las mitades del tanque.

6. Separe las mitades superior e inferior de la estructura del

tanque usando las lengüetas en la parte inferior del aro

Posi-Lok

TM

. Introduzca la lengüeta en la ranura ubicada en la

junta del tanque y gire el aro para separar las mitades de la

estructura. Consulte las Figuras 5 y 6.

7. Saque el aro tórico de la mitad superior de la estructura del

tanque. Verifique que no tenga cortes, rajaduras, deformaciones o señales de desgaste, y reemplace de ser necesario.

AVISO: Para evitar ejercer presión o causar daños, deje que

el módulo filtrante se drene antes de sacarlo del tanque.

PASADOR DE SEGURIDAD

(Consulte la Figura 7)

La finalidad del pasador de seguridad es mantener el aro

Posi-Lok™ en la posición trabada. Si el pasador está averiado,

reemplácelo de la siguiente manera:

1. Oprima la pequeña traba detrás del pasador de seguridad y

presione o golpetee para sacar el pasador de la ranura en

forma de T en el tanque (consulte la Figura 7).

2. Coloque el nuevo pasador.

AVISO: NO opere el filtro si el pasador de seguridad está

averiado o si no puede mantener el aro Posi-Lok

TM

en la posi-

ción trabada.

Ensamblaje:

1. Inspeccione y limpie el tanque, las roscas del aro y la ranura

del aro tórico. Reemplace las piezas averiadas según se

requiera.

2. Instale el filtro colocando el orificio en la parte inferior del

cartucho del filtro sobre el orificio de salida del tanque.

Presione con firmeza hacia abajo para que quede hermético.

3. Verifique que la unidad de purga de aire en la parte superior

del módulo esté limpia y debidamente instalada.

AVISO: Lubrique el aro tórico sólo con la grasa de silicona

suministrada o con un producto equivalente, ya que otros

lubricantes pueden hacer que el aro se hinche. NO lubrique

el aro Posi-Lok

TM

ni las roscas en la estructura inferior del

tanque, ya que pueden acumular polvo y dificultar su

remoción.

4. Instale el aro tórico en la ranura del aro tórico en la mitad superior de la estructura del tanque. Verifique que el aro tórico

esté limpio y no esté doblado.

5. Empuje la mitad superior del tanque en la mitad inferior del

mismo para comprimir el aro tórico.

6. Coloque el aro Posi-Lok

TM

debidamente sobre las roscas de la

estructura del tanque y hágalo girar HACIA LA IZQUIERDA

hasta que el aro caiga en las ranuras y luego gire HACIA LA

DERECHA hasta que haya quedado firmemente enganchado.

7. Siga las instrucciones de la sección de “Arranque inicial” en

este manual.

Figura 5 – Introduzca la lengüeta del aro en la

ranura de la unidad del filtro.

Figura 4 – Oprima el pasador de seguridad para

destornillar el aro Posi-Lok

TM

.

Figura 6 – Ruede el aro hacia un lado para aflojar la

mitad superior del tanque.

Figura 7 – Pasador de seguridad

Traba pequeña

RELEASE

RELEASE

Depress Safety Latch

Small

Catch

Page 20

PROCEDIMIENTO DE

LIMPIEZA DEL MÓDULO

Riesgo de quemaduras de índole

química. NO trate de limpiar el filtro o el módulo con ácido. Si

el filtro requiere limpieza con ácido, contrate a un profesional

capacitado para piscinas para realizar ese trabajo.

Siga todos los pasos indicados en la sección de

“Desensamblaje” de este manual.

Es necesario sacar y limpiar el módulo filtrante cuando la presión

se eleva más de 10 psi (69 kPa) por encima de la presión inicial.

También consulte “Cuando limpiar el filtro,” a continuación.

AVISO: NO exponga el módulo filtrante a la luz del sol por un

período de tiempo prolongado.

AVISO: Cuando desinfecte su piscina con productos de limpieza

de PHMB (a base de polihexametileno biguanida), use sólo productos de limpieza de PHMB para limpiar el módulo. Cuando

use desinfectantes de PHMB, SE DEBERÁ limpiar el módulo filtrante más a fondo y con mayor frecuencia que para una piscina

que usa cloro.

Siga atentamente las instrucciones del fabricante. El uso de

cualquier otro tipo de productos de limpieza con los desinfectantes para piscina de PHMB anulará la garantía del filtro.

AVISO: Evite lavar la suciedad del filtro por el orificio de salida.

Saque el tapón de desagüe y descargue todo el material del interior del tanque antes de sacar el módulo filtrante.

1. Con una manguera equipada con una boquilla de flujo

suave, lave toda la suciedad posible del módulo filtrante

mientras aún se encuentre dentro del tanque. Drene el

tanque completamente.

2. Verifique que el interior del tanque esté limpio. Saque el módulo y lávelo bien con una manguera. Rocíe toda la superficie del módulo y deje que se drene.

3. Inspeccione el módulo. De ser necesario, repita la operación

de lavado. Si el módulo está averiado, reemplácelo.

AVISO: Si este método de limpieza no elimina todos los depósitos, consulte la sección de “Instrucciones especiales para

la limpieza” en este manual.

4. Inspeccione y limpie el filtro de purga de aire en la parte superior del módulo.

5. Siga todos los pasos en las secciones de “Ensamblaje” y de

“Arranque inicial” de este manual.

Instrucciones especiales para la limpieza:

Use este procedimiento para limpiar la oxidación o los aceites

que no se pueden eliminar simplemente lavando el módulo con

una manguera. Asegúrese de eliminar los producto químicos usados según los códigos y las normas de eliminación de desechos

que correspondan. Use una boquilla de chorro suave para reducir los salpicones de agua y el rocío.

Riesgo de incendio o de explosión. Aísle el filtro del sistema antes de la limpieza con productos químicos; enjuague completamente el filtro y los elementos antes de volver a

ponerlos en servicio. Si no se puede aislar el filtro, saque el medio

y límpielo en otro lugar. Siga las instrucciones para el uso, del fabricante del producto químico. NO mezcle sustancias químicas excepto según lo que indique el fabricante. NO permita que los

productos químicos de limpieza se mezclen o entren en contacto

con cloro, bromo, con otras sustancias químicas o con dispositivos

de alimentación de productos químicos.

1. Pase la esponja o rocíe el módulo según las instrucciones del

fabricante del producto químico

2. Si es necesario ponerlo en remojo, saque el módulo del

tanque filtrante y sumérjalo en un tanque separado. Siga

atentamente las instrucciones del fabricante del producto de

limpieza.

3. Después de terminar con las instrucciones del fabricante del

producto químico, drene y enjuague el módulo completamente. Elimine los productos de limpieza según los códigos y

las normas locales

4. Enjuague el interior del tanque filtrante. Drénelo

completamente.

5. Siga las instrucciones de las secciones de “Ensamblaje” y

“Arranque inicial” de este manual.

8

Productos de limpieza especializados para la

limpieza del filtro que se recomiendan

Filter Cleanse™, Great Lakes Biochemical

BIOGUARD Strip Kwik™, BIOGUARD KleenIt™,

Softswim®Filter Cleaner,** BIOLABS, Inc.

Filter Kleen™, Haviland Products Co.

BAQUA CLEAN™, ** Zeneca, Inc.

** SE DEBE usar cuando se usen desinfectantes a base

de PHMB.

Cuando limpiar el filtro

El módulo filtrante generalmente se debe limpiar cuando la lectura

del manómetro aumente 10 psi por encima de la presión inicial

(registre la presión inicial en la “Información del Propietario”, que

aparece a continuación).

En ciertas piscinas, los accesorios, como las fuentes o los

limpiadores de piscina pueden verse afectados considerablemente

por el descenso normal de flujo cuando el filtro se ensucia. En ese

caso, limpie el filtro con mayor frecuencia (es decir, a un aumento

de presión menor de 10 psi) para mantener el flujo requerido.

ADVERTENCIA

PELIGRO

Page 21

9

INSPECCIÓN DEL SISTEMA

General:

Lave el exterior del filtro con un detergente suave y agua.

Enjuague a manguera.

AVISO: NO use solventes para limpiar el filtro, ya que estos

pueden dañar los componentes de plástico en el sistema.

AVISO: Abra la válvula de purga de aire y descargue todo el aire

del filtro cada vez que detenga y vuelva a encender la bomba.

Inspección semanal:

1. Saque la suciedad de la cesta del espumador de la piscina.

2. Detenga la bomba; abra la válvula de desahogo de aire para

descargar toda la presión.

3. Saque la cubierta y la cesta de la trampa y retire la suciedad.

4. Verifique que no haya fugas en la bomba. Si encuentra fugas,

consulte el manual del propietario de la bomba.

5. Vuelva a colocar la cesta y la cubierta de la trampa. Apriete

la cubierta a mano con firmeza. NO use una llave de tuercas

para apretar la tapa.

6. Encienda la bomba. Cuando salga un chorro firme de agua

de la válvula de desahogo de aire del filtro, ciérrela.

7. Cuando el sistema haya regresado a su operación normal,

verifique la presión del filtro. Si la presión del filtro está a 10

PSI (69kPa) o más por encima de la presión inicial de arranque, será necesario limpiar el filtro. Consulte el

“Procedimiento de limpieza del módulo”, Página 8.

ACONDICIONAMIENTO

PARA EL INVIERNO

Peligro de explosión. Si se purga el sistema con aire comprimido, existe el peligro de que los componentes exploten y provoquen lesiones graves o muerte a las

personas que estén en su cercanía. Use sólo un soplador de

gran volumen y baja presión (debajo de 5 PSI), cuando purgue

el aire de la bomba, del filtro o de la tubería.

AVISO: La tubería de salida del filtro no se vaciará por el

desagüe del filtro. Verifique que la tubería de salida tenga un

desagüe separado para el acondicionamiento para el invierno.

AVISO: Proteja el filtro con heladas. Si el filtro se congela, se

dañará y la garantía quedará anulada.

1. Limpie el filtro según las instrucciones (Página 8) antes de

acondicionarlo para el invierno.

2. Detenga la bomba.

3. Abra la válvula de desahogo de aire; abra todas las válvulas

del sistema.

4. Saque los tapones de desagüe de la trampa, de la bomba y

del filtro.

5. Drene la tubería del sistema.

a. Drene al máximo el sistema por gravedad.

b. Proteja las áreas que retienen agua con un anticongelante

no tóxico de propilenglicol (“Anticongelante VR”).

6. Afloje las tuercas de unión (si se usaron) para drenar todo el

agua del interior del filtro. Deje estas tuercas flojas hasta que

vuelva a encender el sistema.

7. Desarme el filtro (siga las instrucciones en la sección de

“Desensamblaje del filtro”, Páginas 6 y 7). Saque el módulo

filtrante y guárdelo en un lugar templado y seco.

ADVERTENCIA

Page 22

10

A

Clave

No. Descripción Cant. PLDE36 PLDE48

1 Aro Posi-Lok

TM

1 27001-0054S 27001-0054S

2 Válvula de desahogo de aire con aro tórico 1 25010-0200 24206-0103S

3 Manómetro 1 15060-000T 15060-000T

4 Mitad superior del tanque con válvula de desahogo de aire 1 27001-0020S 27001-0030S

5 Aro tórico del tanque 1 27001-0061S 27001-0061S

6 Módulo filtrante 1 27002-0036S 27002-0048S

6A Unidad de purga de aire 1 24800-0122 24800-0122

7 Desviador 1 27001-0015S 27001-0015S

8 Mitad inferior del tanque* 1 27001-0016S 27001-0016S

9 Tapón de desagüe 1 27001-0022S 27001-0022S

10 Pasador de seguridad 1 27001-0051 27001-0051

11 Base de apoyo del tanque 1 27001-0018S 27001-0018S

12 Paquete de adaptadores de unión de 2" (incluye 2) 1 PKG 188 PKG 188

LISTA DE PIEZAS DE REPUESTO

VISTA DETALLADA

* Incluye claves números 7, 8, 9, 10.

2

E

S

O

L

C

O

P

E

N

PLDE 48

2

PLDE 36

4

3

1

3

6

6

4

5

10

9

8

7

12

11

Page 23

11

1. Tiempo de ciclo corto:

AVISO: El tiempo de ciclo varía con cada instalación y entre difer-

entes áreas del país. Las siguientes causas y soluciones son para

tiempos de ciclo inferiores a los normales para su área.

A. Cloro residual demasiado bajo; mantenga el residuo adecuado

(obtenga las recomendaciones de un profesional de piscinas).

B Caudal demasiado alto; limite el flujo a la capacidad nominal

del filtro (consulte la placa de instrucciones en el filtro o las

especificaciones en la Página 4).

C. El filtro es demasiado pequeño; instale un filtro adicional.

D. Capa filtrante inadecuada / insuficiente; consulte las instruc-

ciones para la capa filtrante (Página 5).

E. El módulo filtrante está sucio o tapado; limpie el filtro a fondo

(consulte el No. 4, “Paño del módulo tapado”, y el

“Procedimiento de limpieza del módulo”, Página 8).

F. Demasiada tierra de diatomeas; verifique que el módulo filtrante

no esté tapado.

G. Incorrecto equilibrio químico del agua; consulte con un profe-

sional de piscinas.

H. Algas en la piscina. Aplique una dosis fuerte de cloro o de algi-

cida según las recomendaciones del fabricante de la piscina.

2. Bajo flujo / Alta presión:

A. Elementos tapados; limpie el filtro a fondo (consulte la Página 8).

B. Tubería bloqueada corriente abajo del filtro; elimine la obstrucción.

C. Tubería demasiado pequeña; use una tubería más larga (consulte

con el concesionario para determinar el tamaño adecuado).

D. Área del filtro demasiado pequeña; instale un filtro auxiliar

(obtenga recomendaciones del concesionario).

E. Válvula de retención en el orificio de salida obstruida (si corre-

sponde); retire la obstrucción para permitir que la válvula se abra.

3. Bajo flujo / Baja presión:

A. Bomba demasiado pequeña; obtenga las recomendaciones del

concesionario.

B. Bomba tapada o trampa de cabello y pelusa tapada; limpie a

fondo.

4. Paño del módulo tapado:

AVISO: El material plegado del filtro puede parecer opaco después del

uso. Sin embargo, siempre que la tierra de diatomeas se adhiera al paño

plegado, el filtro estará funcionando debidamente.

A. Capa filtrante insuficiente; consulte las instrucciones para la

capa filtrante (Página 6).

B. Limpieza insuficiente; siga atentamente las instrucciones de

limpieza y limpie a fondo (consulte la Página 8).

C. Incorrecto equilibrio químico del agua; consulte con un profe-

sional de piscinas.

D. Demasiado aire en el filtro; las áreas sin capa filtrante se pueden

tapar. Ventile el aire del tanque y verifique que la tubería de aspiración de la bomba no tenga fugas. Limpie el filtro de purga de

aire en la unidad de rejilla con una manguera y una boquilla de

flujo suave.

E. El filtro es demasiado pequeño. Instale un filtro adicional.

F. El agua de la piscina contiene hierro. Consulte las “Instrucciones

especiales para la limpieza”, Página 8.

G. Algas en la piscina. Aplique una dosis fuerte de cloro o de un

algicida según las recomendaciones del fabricante de la piscina.

H. Uso de productos químicos incorrectos con desinfectantes de

PHMB. Reemplace el módulo filtrante.

I. No suficiente capa filtrante de diatomeas. Consulte las instruc-

ciones para la capa filtrante (Página 4).

5. El agua de la piscina no está limpia:

A. Cloro residual demasiado bajo; mantener el residuo adecuado

(obtenga las recomendaciones de un profesional de piscinas).

B. El módulo filtrante está roto y pasa tierra de diatomeas a la

piscina; reemplace el módulo defectuoso.

C. Capa filtrante insuficiente o inadecuada; siga las instrucciones

para la capa filtrante y use la cantidad recomendada de tierra de

diatomeas (consulte la Página 4).

D. Índice de renovación inadecuado; consulte con su concesion-

ario para verificar que el equipo sea del tamaño adecuado para

su piscina.

E. La bomba es demasiado grande y bombea demasiado. Reduzca

el caudal.

F. El filtro está instalado en posición inversa. Vuelva a instalarlo

correctamente.

G. El agua de la piscina contiene hierro. Consulte las “Instrucciones

especiales para la limpieza”, Página 8.

H. Aplicación fuerte o inadecuada de tabletas de cloro en polvo

usando un aglomerante. Consulte las “Instrucciones especiales

para la limpieza”, Página 8.

I. Algas en la piscina. Aplique una dosis fuerte de cloro o de

algicida según las recomendaciones del fabricante.

6. Los accesorios de la piscina dejan de funcionar:

A. Limpie el filtro y observe el desempeño de los accesorios.

B. Si los accesorios se desempeñan mejor después de haber

limpiado el filtro, use un ciclo de limpieza más corto para el

filtro (es decir, limpie el filtro después de que el aumento de

presión sea menor que 10 PSI).

GUÍA PARA LA LOCALIZACIÓN DE FALLAS

Page 24

PARA CREAR UN REGISTRO DE SU GARANTÍA CON STA-RITE:

• Llene un registro de garantía en www.staritepool.com pulsando en “Registro de Productos” y seleccionando Albercas Sta-Rite

O

• Llene la porción inferior y envíela por correo dentro de los 10 días de la instalación, a Sta-Rite, a la atención del Departamento de Garantías de Piscinas, 293 Wright St., Delavan, WI 53115.

Tarjeta de registro de garantía

Nombre

Dirección

Ciudad Estado Código postal/Zip

Fecha de instalación (o de compra)

Producto adquirido

Número de modelo

■■ Nueva Instalación ■■ Reemplazo

Años de servicio de la alberca ■■ menos de 1 ■■ 1-3 ■■ 3-5 ■■ 5-10

Este producto se compró en:

Nombre de la empresa

Dirección

Ciudad Estado Código postal/Zip

GARANTÍA LIMITADA DE STA-RITE

Para obtener información técnica sobre este producto, comuníquese con el instalador o llame a Sta-Rite, al 262-728-9181.

Visite www.staritepool.com

• para obtener más información sobre los productos Sta-Rite indicados arriba

• para ubicar un concesionario de Sta-Rite cercano a usted

Garantías Específicas de los Productos

(a partir de la fecha de su instalación)

Familia Garantía

de productos Limitada Excepciones

Filtros 1 Año Unidades de tanque del

Sistema 3 - 10 años

Válvulas de filtro 1 Año

Bombas 1 Año

Calentadores 2 Años *Uso comercial - 1 año

Controles 1 Año

Sistemas sobre el suelo 1 Año

Luces y nichos 1 Año Lámparas y focos - 90 Días