Page 1

OWNER’S MANUAL

PENTEK INTELLIDRIVE

NOTICE D’UTILISATION

MC

PENTEK INTELLIDRIVE

MANUAL DEL USUARIO

PENTEK INTELLIDRIVE

PID10, PID20, PID30, PID50

™

™

Installation/Operation/Parts

For further operating,

installation, or maintenance

assistance:

Call 866-9 PENTEK

(866-973-6835)

English ................... Pages 2-23

293 WRIGHT STREET, DELAVAN, WI 53115 WWW.PUMPS.COM

PH: 1-866-9 PENTEK

© 2016 Pentair plc. All Rights Reserved. PN957 (Rev. 10/20/16)

Installation/Fonctionnement/Pièces

Pour plus de renseignements

concernant l’utilisation,

l’installation ou l’entretien,

Composer le (866) 9 PENTEK

(866-973-6835)

Français .............. Pages 24-45

Instalación/Operación/Piezas

Para mayor información sobre

el funcionamiento, instalación o

mantenimiento de la bomba:

Llame al 866-9 PENTEK

(866-973-6835)

Español ..............Paginas 46-67

Page 2

Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual

contains important instructions that should be

followed during installation, operation, and

maintenance of the PENTEK

Frequency Drive (VFD).

This is the safety alert symbol. When you see

this symbol on your PENTEK

this manual, look for one of the following signal

words and be alert to the potential for personal

injury!

indicates a hazard which, if not

avoided, will result in death or serious injury.

indicates a hazard which, if not

avoided, could result in death or serious injury.

indicates a hazard which, if not

avoided, could result in minor or moderate injury.

NOTICE addresses practices not related to

personalinjury.

Carefully read and follow all safety instructions in

this manual and on the PENTEK

Keep safety labels in good condition. Replace

missing or damaged safety labels.

California Proposition 65 Warning

This product and related accessories

contain chemicals known to the State of California

to cause cancer, birth defects or other reproductive

harm.

Risk of high-voltage electrical shock

from EMI/RFI filter inside drive. Can shock, burn

or kill if the front cover of the PENTEK

INTELLIDRIVE is open or removed while power is

connected to the Drive or the Drive is running. The

front cover of the Drive must be closed during

operation.

• Make all wiring connections, then close and

fasten the cover before turning on power to drive.

• NEVER open the box when power is connected to

Drive.

• Before doing any service or maintenance inside

Drive or when connecting or disconnecting any

wires inside Drive:

1. DISCONNECT power.

2. WAIT 5 minutes for retained voltage

todischarge.

3. Open box.

• Before starting any wiring or inspection

procedures, check for residual voltage with a

voltage tester.

• NEVER connect power wiring to

mounting the box.

• NEVER handle or service

hands. Always make sure hands are dry before

working on

Drive

• NEVER reach into or change the cooling fan while

power is applied to Drive.

• NEVER touch the printed circuit board when

power is applied to Drive.

INTELLIDRIVE Variable

INTELLIDRIVE or in

INTELLIDRIVE.

Drive

with wet or damp

.

Drive

before

property damage or death if installed with incorrect

Risk of fire. Can cause severe injury,

or inadequate circuit breaker protection. To ensure

protection in the event of an internal fault in the

PENTEK

INTELLIDRIVE, install the Drive on an

independent branch circuit protected by a circuit

breaker (see Table 2 for circuit-breaker sizing), with

no other appliances on the circuit.

Risk of burns. The Drive can become

hot during normal operation. Allow it to cool for

5minutes after shut-down and before handling it to

avoid burns.

NOTICE To avoid damage to Drive or problems

with Drive:

• Connect output cables to 3-wire 1-phase and

3-phase submersible motors as follows:

Red to R, Yellow to Y, Black to B.

Any other order will reverse the motor rotation

(3-phase) and may damage the motor.

• Connect output cables to 2-wire 1-phase

submersible motors as follows:

Connect to Y and B only.

Connect Ground to green screw.

• Above ground 3-phase motors may have different

lead colors. Generally connect output leads

asfollows:

R to L1, Y to L2, B to L3.

Verify rotation after startup.

• Do not modify equipment.

• Do not use power factor correction capacitors

as they will damage both motor and

INTELLIDRIVE

.

PENTEK

• Do not remove any parts unless instructed to do

so in Owner’s Manual.

• Do not use a magnetic contactor on Drive for

frequent starting/stopping.

• Do not install or operate Drive if it is damaged or

parts are missing.

• Before starting Drive that has been in storage,

always inspect it and test operation.

• Do not carry out a megger (insulation resistance)

test on the control circuit of the

Drive

.

• Do not allow loose foreign objects which can

conduct electricity (such as screws and metal

fragments) inside Drive box at any time. Do not

allow flammable substances (such as oil) inside

Drive box at any time.

• Ground Drive according to the requirements of

the National Electrical Code Section 250, IEC536

Class 1, or the Canadian Electrical Code (as

applicable) , and any other codes and ordinances

that apply.

• All installation, service work, and inspections

must be done by qualified electrician.

Page 3

Table of Contents 3

Fan

EMI/RFI Filter

Safety .............................................................2

Owner’s Information .................................................3

Description ...................................................... 4-5

Installation ....................................................... 6-9

Initial Startup ................................................... 10-11

Programming ................................................... 12-15

I/O Connections ................................................ 16-17

Additional Information ..............................................18

Troubleshooting ................................................ 19-21

Software Updates ..................................................22

Warranty .........................................................23

Owner’s Information

PENTEK INTELLIDRIVE Model No. _________________________

PENTEK INTELLIDRIVE Serial No. _________________________

Pump Model No. _________________________

Pump Serial No. _________________________

Motor Model No. _________________________

Motor Service Factor Amps _________________________

Risk of electric shock. Can

shock, burn or kill.

• Drive’s internal

components retain

high voltage for up to

5minutes after input

power is disconnected.

• EMI/RFI Filter carries

high voltage when pump

is running.

• Disconnect power and

wait 5 minutes before

opening

PENTEK

INTELLIDRIVE

cover.

Pressure Tank Model No. _________________________

Pressure Tank Serial No. _________________________

Dealer/Installer: _____________________________________________

_____________________________________________

Installer Phone No. _________________________

Date of Installation _________________________

Wire Lengths in Feet (Meters):

Circuit Breaker to Drive _________________________

PENTEK INTELLIDRIVE to Motor _________________________

Supply Voltage _________________________

Note to Installer: Record the data listed above for future reference. Give manual to

end user or attach to

PENTEK INTELLIDRIVE

when installation is complete.

Page 4

Description 4

Specifications/Ratings

Input Voltage ........... 1-Phase 230VAC Nominal (190–265VAC)

Input Frequency .........................................................50/60Hz

Ambient Temperate Range ............ -4 to 122 °F (-20° to 50 °C)

Output Connections ..................3-Phase, 3-Wire/1-Phase or

Max Motor Cable Length .......................................... 1,000 feet

Enclosure .................................................................. NEMA 3R

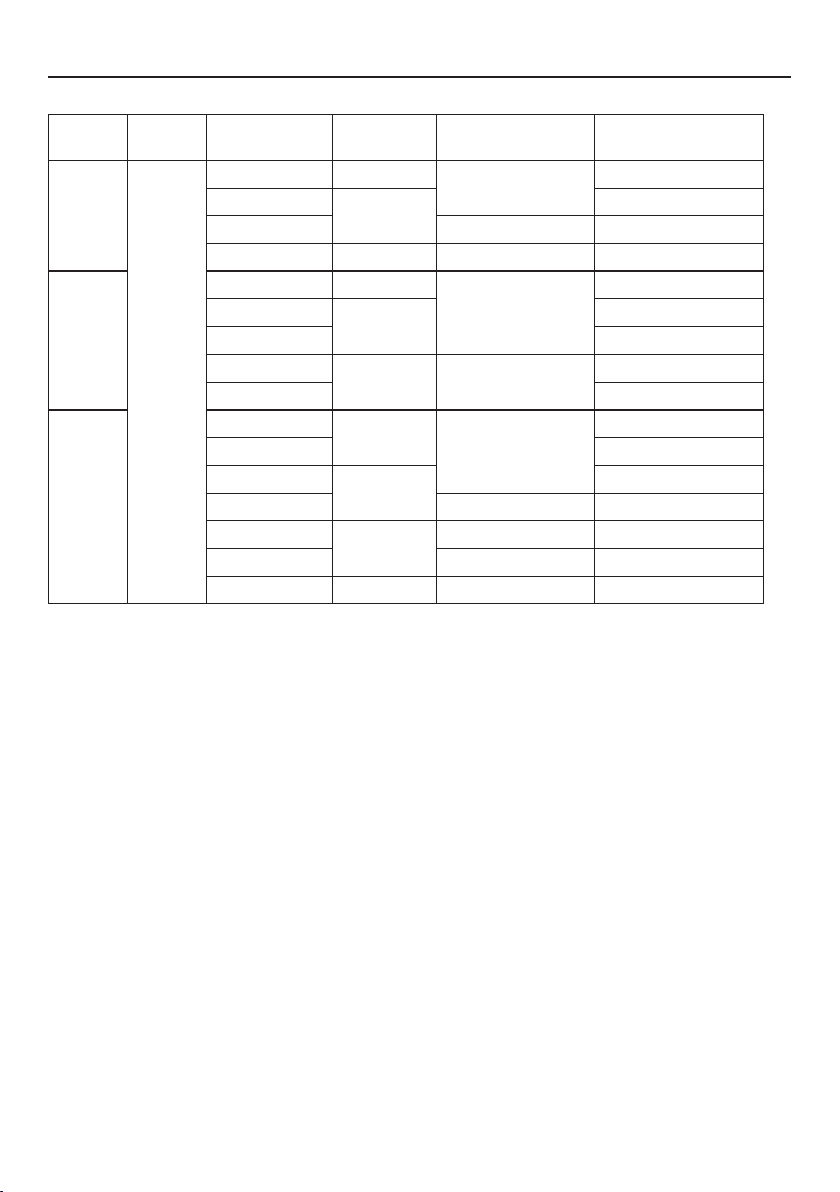

Table 1 - Specifications

Model Motor Type*

2-WIRE 1-PHASE

PID10

3-WIRE 1-PHASE 7.5A

3-PHASE 5A

2-WIRE 1-PHASE 0.5–1.5 HP 11A

PID20

3-WIRE 1-PHASE

3-PHASE

2-WIRE 1-PHASE 0.5–1.5 HP 11A

PID30

3-WIRE 1-PHASE 0.5–2 HP 13.5A

3-PHASE 0.5–3 HP 11.5A

2-WIRE 1-PHASE 0.5–1.5 HP 11A

PID50

3-WIRE 1-PHASE 0.5–2 HP 13.5A

3-PHASE 0.5–5 HP 18A

* Select drives by S.F. amps of pump motor.

HP

Range

0.5–1 HP

0.5–2 HP

Voltage

190V –

The PENTEK INTELLIDRIVE is specifically designed

to operate 4” submersible pumps and 3-phase

above ground pumps in water well and residential

booster applications. Each Drive is rated for

maximum output amp rating. Any use of Drive

outside of intended design parameters will void

warranty. If Drive is used with above ground motors

not rated for a Variable Frequency Drive, maximize

motor life by limiting lead length to 25 ft. Refer to

Input

265V

1-Phase/2-Wire

Maximum

Output

AMPS

9.5A

13.5A

8.5A

Enclosure

Type

NEMA 3R

outdoor

pump Owner’s Manual and the National Electrical

Code for proper wire size.

Each carton contains:

•

PENTEK INTELLIDRIVE Variable Frequency Drive

• Pressure Transducer

• 10’ Pressure Transducer Cable

• Quick Start Guide

• Owner’s Manual

PENTEK INTELLIDRIVE Model Number Structure

PIDXX

Product Family

PID - PENTEK INTELLIDRIVE

HP Range

10 = up to 1.0 HP

20 = up to 2.0 HP

30 = up to 3.0 HP

50 = up to 5.0 HP

The PID10 will operate a 1-Phase 2-Wire, 1-Phase

3-Wire, and 3-Phase motor up to 1HP.

The PID20 will operate a 1-Phase 2-Wire up to 1.5HP

and a 1-Phase 3-Wire or 3-Phase motor up to 2HP.

The PID30 will operate a 1-Phase 2-Wire up to 1.5HP,

1-Phase 3-Wire up to 2HP or 3-Phase motor up to 3HP.

The PID50 will operate a 1-Phase 2-Wire up to 1.5HP,

1-Phase 3-Wire up to 2HP, or 3-Phase motor up to 5HP.

Figure 1 - A typical residential installation layout

Page 5

Description 5

Transducer

The PENTEK INTELLIDRIVE uses a 4-20mA,

0-100PSI pressure transducer to control motor

speed (Drive settings may be changed to use a

max 300 PSI transducer).

The transducer (see Figure 1) senses pressure in

the pipe and converts it to an electrical signal.

The Drive senses and processes the signal in the

PID (Proportional, Integration, Derivative) control.

When operating in AUTOSTART mode, the Drive

increases and decreases the speed of the pump

motor as needed to maintain constant pressure in

the piping system.

Changes internal pressure setpoint from

15 PSI to transducer max -3PSI

Runs the Drive (with no pressure control)

to allow installer to pump out well.

Changes display to previous screen.

Selects menu items and confirms

Drive is in Warning Mode (TPM); refer to

Displays Drive’s current operating

condition and changes display

Figure 2 - PENTEK INTELLIDRIVE keypad functions

(default is 60 PSI).

numeric value changes.

Power is ON to Drive.

Troubleshooting section.

A fault has occurred.

parameters.

Stops the motor.

Keypad

The keypad programs the Drive, monitors the status

of the pump, and displays faults if they occur.

Each button has a unique function, as described in

Figure 2. The LCD display shows a text display of

the status of the Drive’s operation. Other LEDs light

up to indicate when certain buttons are pressed or

certain events occur.

Fan

The Drive uses a thermostatically controlled

internal fan which operates automatically when

necessary to cool the Drive components.

Views and changes parameters.

Shows last 15 faults.

With code, locks and unlocks password

protected keys.

Toggles between English, Spanish, and

French (default is English).

Left and right arrows move cursor.

Up and down arrows scroll through

menus and change numeric values.

Resets fault that stopped Drive/pump.

Checks for line fill, then starts pump in

constant pressure mode.

Page 6

Installation 6

Table 2 - Circuit breaker and wire sizes

Motor Volts Motor HP

1/2 14

2-wire

3-wire

230

3 phase

* With properly-sized circuit breakers, the Drive is protected from short circuit on the input and the output.

There is no risk of fire or electrical shock due to a short circuit. The Drive has NEC Class 10 overload

protection.

** Minimum 240V generator size.

3/4

1 20 4.4

1-1/2 10 25 5.3

1/2 14

3/4

1 3.5

1-1/2

2 5.8

1/2

3/4 2.8

1

1-1/2 20 4.4

2

3 30 7.3

5 6 50 12.6

(Typical installation with 400’ cable length from service entrance to drive)

Input Wire

Size

12

12

10 25

14

12

10

Circuit Breaker* Generator (kVA)**

15

15

15

25 5.5

2.2

3.1

2.3

3.0

5.3

2.1

3.4

Page 7

Installation 7

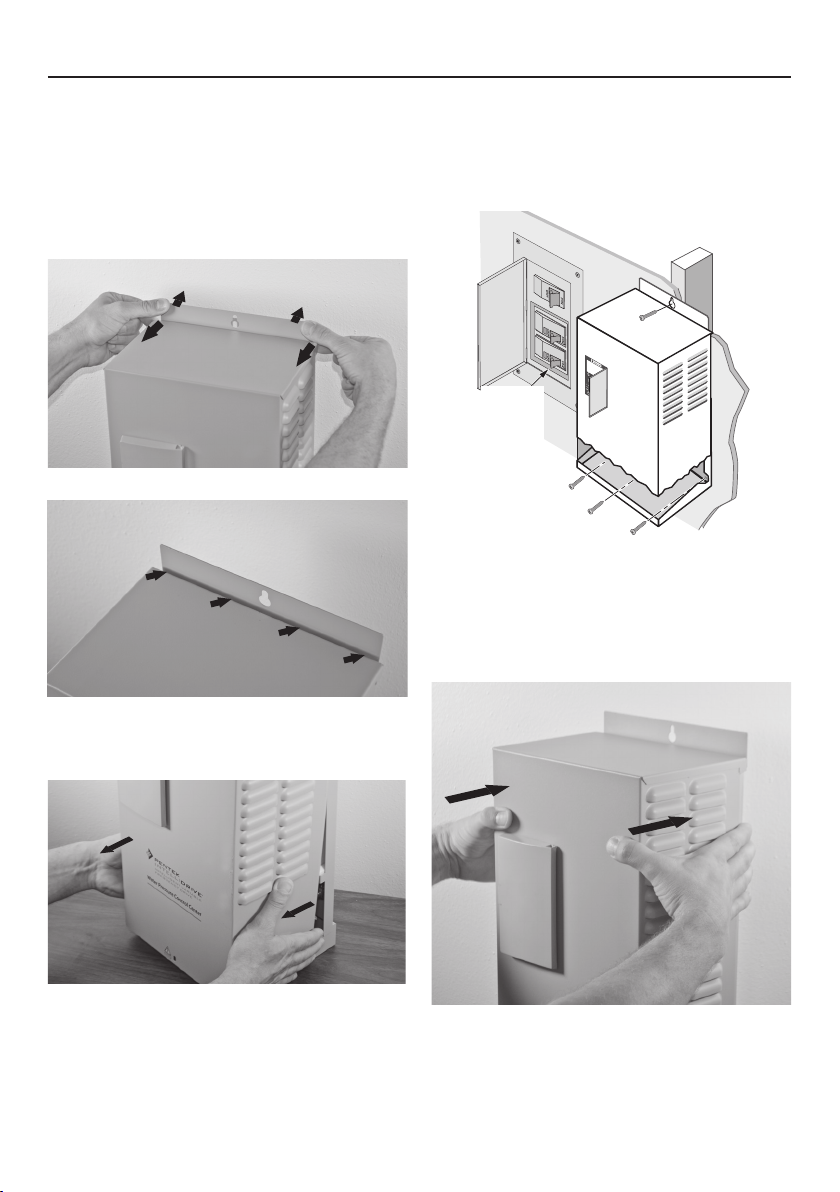

Mounting the Drive

To mount the Drive as shown in Figure 6, follow

this procedure:

1. First, remove the cover by backing out screw

at bottom of front cover.

2. Push on backplate with thumbs while pulling

the cover toward you with index fingers,

creating a gap. See Figures 3 and 4.

Figure 3 - Separate cover and backplate

5. Ensure the Drive’s ventilation holes are not

blocked and there is enough space around it

to allow free air flow (minimum 3” clearance

on top, bottom, and sides). See Figure 6. Once

the Drive is mounted, electrical wiring can be

connected.

Typical

230VAC

Circuit

Breaker

(Double

Width)

Figure 6 - Attaching Drive to wall

6. To reattach the Drive cover, hook the top of it

on backplate (be sure to leave a gap). Lower

bottom of cover into place. Push cover evenly

against backplate, eliminating the gap. See

Figure 7.

Figure 4 - Gap between cover and backplate

3. Pull bottom of cover towards you; lift up on

cover and remove. See Figure 5.

Figure 5 - Pull out bottom of cover

4. With the cover removed, permanently mount

the Drive using the top slotted hole, plus

either the three bottom holes (for flat surface

mounting) or the center bottom hole (for

attaching to a post or stud). See Figure 6.

Figure 7 - Reattaching Drive cover

7. Replace screw at bottom of front cover.

Page 8

Installation 8

Wiring

To allow for ease of wiring, the enclosure wiring

area is free of electronics other than the terminals.

Conduit holes and knockouts are located so

that the wire can be fed straight through to the

connectors, with minimal bending. The terminals

accept 6-14 AWG wire.

Installations that require larger wire gauge than

6AWG will require an external junction box. Run

6AWG wire from the Drive into the junction box,

then make external connections with wire nuts to

appropriately sized wire.

NOTICE For convenience in wiring, the input and

motor terminals unplug from the box. Pull them down

to remove them for ease of access, as shown in Figure

8.

Verify that the terminal connectors are completely

seated when you replace them. It is best practice

Figure 8 - Pull input and motor terminals down to

remove, making wiring easier.

to connect all output wires (larger wire gauge) first,

then all input wires.

Pump Connections

If the PENTEK INTELLIDRIVE is used with above

ground motors (3-phase only) not rated for Variable

Frequency Drive use, maximize motor life by

limiting lead length to 25 ft. Refer to the pump

owner’s manual, the National Electrical Code, and

local codes for proper wire size.

The output of the Drive is single phase (2-wire or

3-wire) or 3-phase, depending on motor selection

during startup.

The output power terminals (motor wire

connections) are located on the lower right side of

the Drive and are labeled R (Red), Y (Yellow), and

B (Black). To select the wire size, multiply the wire

length by 0.95 and then refer to the pump owner’s

manual, the Nation Electric Code, and local codes

for proper wire size.

NOTICE: Regardless of owner’s manual, wire

LENGTH may not exceed 1000 ft. (305 M).

NOTICE: 2-wire 1-phase connect to Y+B, not R+B.

Feed the motor cable through the 3/4” conduit hole

on the bottom right side and into the appropriate

terminals. If the wire is large enough to require a

larger conduit hole, remove the 1-1/4” knockout and

use the appropriate conduit connections. Attach the

motor ground wire to the grounding screw, located

on the grounding bar. Attach the motor power wires

to the terminals as shown in Figure 9.

NOTICE Drive does not sense motor temperature

and will not protect motor from over heating.

01+ 01+ I1+ I1- I2+ I2- V+ V- AI+ AI- P N SD CARD

Terminal

Input Power

Connections

Removable

(pull down)

Input

Ground Screw

Green Cable Shield/Screw

Input

Ground

Figure 9 - Basic Wiring Connections for Startup

Red to AI+

Black to AI–

Transducer Cable

Terminal

Removable

(pull down)

Red

Yellow

Black

Output

Connections

Submersible Motor: 3-Ph./ 3-W. 1-Ph., follow colors as above.

Submersible Motor: 1-Ph./ 2-W., connect to Y and B, any order.

Above-Ground Motors: L1 to R, L2 to Y, L3 to B; verify rotation.

Ground Screw

Motor Connections

Output Ground

Page 9

Installation 9

Pressure Tank Recommendations

Minimum tank size is two gallons. Use a precharged pressure tank with Drive, as shown in

Table3. The tank size must equal at least 20

percent of the pump’s rated flow in gallons per

minute (GPM), but cannot be less than two gallons

capacity. For example, a pump rated at 7GPM

would require a tank of two gallons capacity or

larger. A pump rated at 50 GPM would require a 10

gallon tank or larger. Tanks larger than 10gallons

can be used, but may require adjustment of Wake

Delayparameter.

Table 3 - Control Pressure Set Point and Tank

Pre-Charge Pressure Values (PSI).

Pressure

Point

Setting

(PSI)

25 18 65 46

30 21 70 49

35 25 75 53

40 28 80 56

45 32 85 60

50 35 90 63

55 39 95 67

60

(Default)

Precharge

Pressure

(PSI)

42 –

Pressure

Point

Setting

(PSI)

Precharge

Pressure

(PSI)

To connect the transducer wires:

1. Strip wire ½ inch

2. Push spring terminal up with finger or slotted

screwdriver

3. Insert wires from bottom

4. Release spring terminal

Input Power Connections

The input power terminals are located on the

lower left side and are marked L1 and L2 (see

Figure 9). There is a ground screw for the input

ground wire to the right of the connector (torque

to 10 inch lbs). Feed wire through the 3/4” conduit

hole on the bottom left side and into appropriate

terminals. If wire is large enough to require a larger

conduit hole, remove the 1-1/4” knockout and use

appropriate conduitconnections.

To determine the correct wire sizes for installation,

see Table 2.

NOTICE The PENTEK INTELLIDRIVE only accepts

230V single phase input power. If incoming power

does not match this, have a qualified electrician

alter supply voltage to 230V/1Ph before connecting

it to the Drive.

NOTICE Set pressure tank’s pre-charge to 70

percent of the system operating pressure. When

using an external set point as well as an internal

set point, pre-charge tank to 70 percent of the

lower setpoint of the two. Some applications may

require a different percentage when determining

the setpoint.

Transducer Connections

A 0-100 PSI 4-20 mA transducer is provided with

Drive. Install the transducer downstream of tank,

as shown in Figure 1. Install transducer in a tee

in a straight section of pipe with at least 1 foot of

straight pipe on each side of the tee (i.e., all fittings

must be at least 1 foot away from transducer).

Feed transducer cable through the open 1/2”

conduit hole on bottom of the Drive enclosure.

As shown in Figure 9, connect the red wire of the

transducer cable to AI+, connect black wire to AI–,

and connect the cable shield to the metal cable

shield screw.

Page 10

Initial Startup 10

Press Enter

Press Enter

Press Enter

Press Enter

Apply 230V to Drive

Set Time

Set Date

Setup Complete

1 Phase

Connection Type

(2 Wire or 3 Wire)

3 Phase

Motor Type

Subm or Above Gnd

Enter Service Factor Amps

Enter Motor Phase

(1 Phase or 3 Phase)

Press Enter

Use arrows to

scroll to Motor

Press Enter

Use arrows to

select 80 Hz

Press Enter to save

Press MAIN MENU button

Press Enter

Use arrows to select

Max Frequency

Initial Startup and

Programming Procedures

Ensure that the cover is installed before operating

the

PENTEK INTELLIDRIVE.

Most installations will only require the initial

startup settings. However, the installer may need

to set additional parameters. Information about

accessing all parameters, explanations of their

functions, and procedures for changing parameter

values, will be found later in this section.

Table 4 - Pentek Motor Service Factor Amps

Motor

Type

2-Wire

CS/CR

3-Wire

3-Phase

PENTEK Part

Number

Rating @

230V

HP

P42B0005A2-01 1/2 4.7

P42B0007A2-01 3/4 6.2

P42B0010A2-01 1 8.1

P42B0015A2-01 1-1/2 10.4

P42B0005A2-02 1/2 5.1

P42B0007A2-02 3/4 6.1

P42B0010A2-02 1 8.0

P42B0015A2-02 1 1/2 10.6

P42B0005A2 1/2 4.7

P42B0007A2 3/4 6.4

P42B0010A2 1 9.1

P42B0015A2 1-1/2 11.0

P43B0005A2-01 1/2 4.8

P43B0007A2-01 3/4 6.0

P43B0010A2-01 1 7.3

P43B0015A2-01 1-1/2 10.9

P43B0005A2-02 1/2 4.5

P43B0007A2-02 3/4 5.7

P43B0010A2-02 1 6.8

P43B0015A2-02 1 1/2 10.7

P43B0005A2 1/2 4.9

P43B0007A2 3/4 6.3

P43B0010A2 1 7.2

P43B0015A2 1-1/2 11.1

P43B0020A2 2 12.2

P43B0005A3 1/2 2.9

P43B0007A3 3/4 3.9

P43B0010A3 1 4.7

P43B0015A3 1-1/2 6.1

P43B0020A3 2 7.6

P43B0030A3 3 10.1

P43B0050A3 5 17.5

Service

Factor

Amps

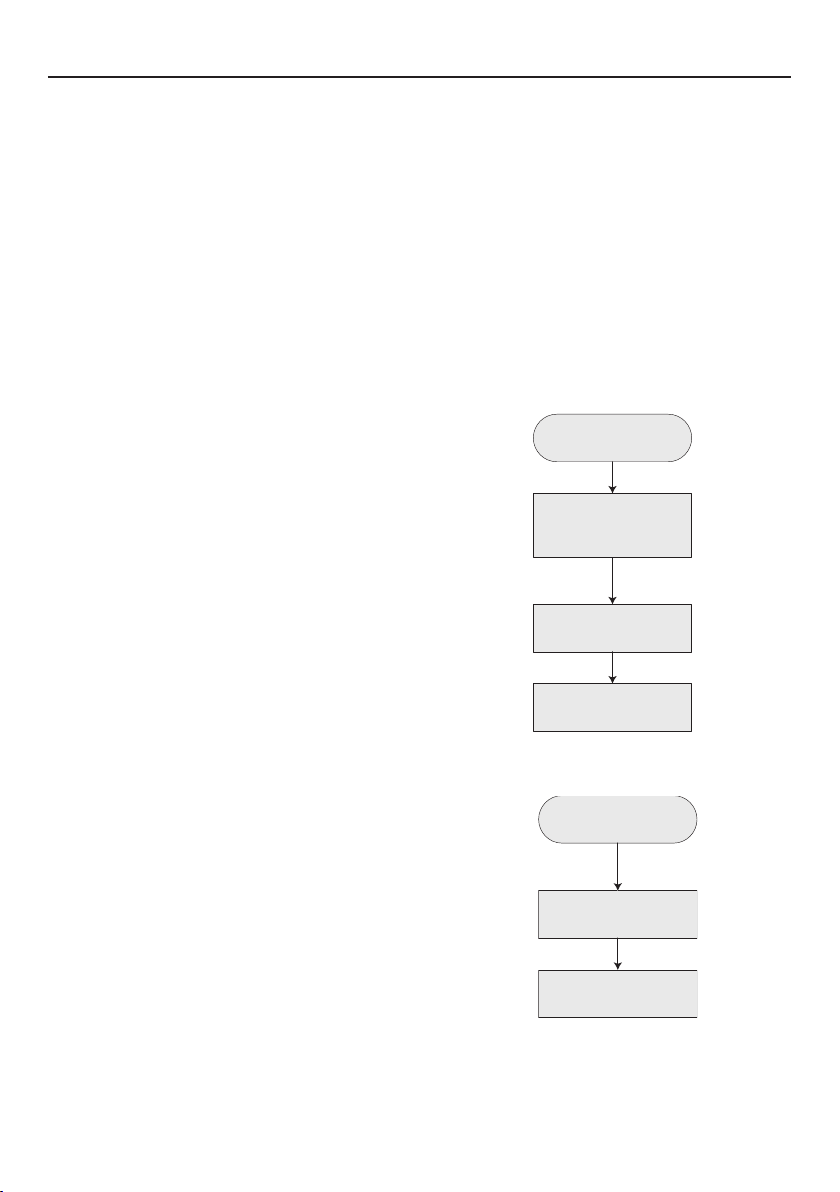

1. Program the Drive: Apply power to the

PENTEK INTELLIDRIVE. Setup Guide will appear

in the display. Follow keypress sequence shown in

Figure 10.

NOTICE If Setup Guide does not appear, refer to

Drive Reset Procedure, Figure 20.

Figure 10 - Drive Setup Guide.

2. Select 80 Hz Operation, if necessary (See 60 Hz

to 80Hz Operation for more information):

A. Press MAINMENU button.

B. Follow the keypress sequence shown in

Figure11.

Figure 11 - Select 80 Hz

(3-phase submersible operation only).

Page 11

Initial Startup 11

3. Pump out well (if necessary):

Direct pump’s discharge to appropriate location

not connected to system and press Pump Out.

The pump will run at 45 Hz.

Adjust frequency as appropriate:

A. Press ENTER

B. Change frequency value

NOTICE Above ground pumps should run at 60

Hz for this step (until pump is primed). Then

adjust frequency as necessary.

C. Press ENTER again.

Run the Drive in this mode until the well

discharge runs clear, then press STOP button to

stop Drive.

Risk of explosion. In Pump Out

mode, pump runs at a constant speed, which

can cause very high pressure if flow is restricted.

4. Verify installation: Make sure that the system

has properly-sized, pressure-relief valve and

pressure tank.

Make sure pressure tank’s precharge is correct.

See Table 6.

Make sure pump discharge is connected to

system.

Service Factor Amps

To maximize pump performance, be sure to

enter the correct Service Factor Amps (SF Amps)

in the

PENTEK INTELLIDRIVE

• Entering SF Amps higher than the motor rating

lets the Drive supply more amps to the motor

than the motor is designed for and may allow

the motor to overheat (see Table 4).

• Entering SF Amps lower than the motor rating

limits the output amps to less than the motor is

designed for and will reduce the performance

of the pump.

• For any 1-Phase 3-Wire motor, the correct

Service Factor Amp rating for the Drive is Cap

Start/Cap Run amps (see Table 4). This may

not match the motor nameplate, which (for a

Single Phase, 3-Wire motor) will generally be

Cap Start/ Induction Run Amps.

• For any 3-Phase or 1 Phase, 2-Wire motor, use

the motor nameplate Service Factor Amprating.

NOTICE

differ from motors of the same horsepower

from other manufacturers. For 1-Phase, 3-Wire

motors from all other submersible motor

manufacturers, enter the motor manufacturer’s

CS/CR service factor amps for your motor.

For 3-Phase or 2-Wire 1-Phase motors, use the

motor nameplate amp value. Also see Retro Fit

Applications. (Table 7)

PENTEK®

submersible motors may

.

5. System Start:

A. Open valves at the ends of lines so that air

will escape during pressurization.

B. Press Auto Start; close valves at the ends of

lines after all air has escaped.

C. The system goes into Constant Pressure

Operation as soon as the transducer registers

the Dry Run Sensitivity parameter (default

is 10 PSI). If system pressure does not reach

thatPSI value within 3 minutes, the Drive will

stop. Press Auto Start again to restart line fill.

If longer priming or line fill time is required,

adjust Fill Time parameter. See Table 5.

Changing a Parameter Value

This procedure works for ANY parameter.

A. Press MAINMENU button.

B. Follow the keypress sequence shown in

Figure12:

A shorthand way to remember this is:

• Press ENTER to highlight a value

• Use arrows to change valve

• Press ENTER again to save it

• If new value is not saved, any screen change will

result in the loss of the new value.

Table 5 lists all available commands and

parameters for the PENTEK INTELLIDRIVE.

Use arrows to

find parameter

Press Enter

Use arrows

to change value

Press Enter

to save

Figure 12 - Changing parameter value.

Page 12

Programming 12

60 Hz to 80 Hz Operation

When installing the PENTEK INTELLIDRIVE with

a motor and liquid end of the same HP rating,

operate it at 60 Hz (the default value). The Drive

can be operated at frequencies of up to 80 Hz

when the installation uses a 3-phase motor 2 times

the size of the pump. For example, a 1 HP pump

with a 2 HP 3-phase motor. This combination

will equal the performance of a conventional

2HPpump.

Press Main Menu and

shown in Figure11

follow the keypress sequence

. Be sure to press ENTER to save

the new Max Frequency selected. The Drive will

now use the new value selected.

NOTICE The Drive will not allow the output amps

to go above the Service Factor Amps selected on

the keypad. Because of this, some 80 Hz operations

may be limited. This protects the motor and may be

a commonoccurrence in a 80Hz operation.

Keypad Lock - Password

The password locks or unlocks the blue buttons

on keypad. All PENTEK

INTELLIDRIVE

units are

shipped from factory with the default password

7777. It can be changed to any other 1 to 4 digit

number. To reset password to a unique password

for unit, unlock keypad (see below) and follow the

keypress sequence shown in Figure 12 to make the

change.

If installer does not press the password button, then

the keypad will automatically lock 60 minutes after

the Drive is powered up. The time out period is

adjustable (see Table 5).

To unlock keypad press Password, use directional

arrows to select numeric code and press ENTER.

NOTICE For more detailed information on keypad

functions, see Figure 2.

Pump Out Operation

(Verify Keypad is unlocked) Press Pump Out Key.

Drive will ask “Is The Valve Open?” and the default

answer “No” will be displayed. Press ENTER to

highlight “NO”, use arrows to change display to

“Yes”, press ENTER. The Drive will start pump in

a constant speed mode (default 45Hz). The pump

will run until STOP or Auto Start are pressed. If

speed change is necessary, press enter to highlight

value, use arrows to change value, then press enter

to save. NOTICE: Above ground pumps should run

at 60Hz for this step (until pump is primed). Then

adjust frequency as necessary.

Setting the Pressure

NOTICE Default pressure setting is 60 PSI. If this

value is changed, adjust tank pressure accordingly

(see Table 3).

The Over Pressure parameter may need to be

adjusted if the default pressure setting is increased.

Do not set the Over Pressure paramter above the

operating pressure of the pressure relief valve in the

water system.

There are three ways to change the pressure

setpoint:

1. While running the pump

• Follow keypress sequence shown in Figure

13 to make desiredchange. This parameter

allows either Internal or External Setpoint

to be changed, depending on which one is

referenced at the time the change is made.

2. Via the PSI Preset (Shown in Figure 14).

3. Via the Main Menu (Main Menu/Settings/

Setpoint/Internal Setpoint)

Press Auto Start

Verify

“Running Fixed Press”

displayed on screen

Press Enter

Use arrows to

change the value

Press Enter to Save

Figure 13 - Change PSI Setpoint while running

pump.

Press PSI Preset

Press Enter

Use arrows to

change the value

Press Enter to Save

Figure 14 - Change PSI Setpoint using PSIPreset.

Page 13

Programming 13

Table 5 lists all available commands and parameters for the PENTEKINTELLIDRIVE.

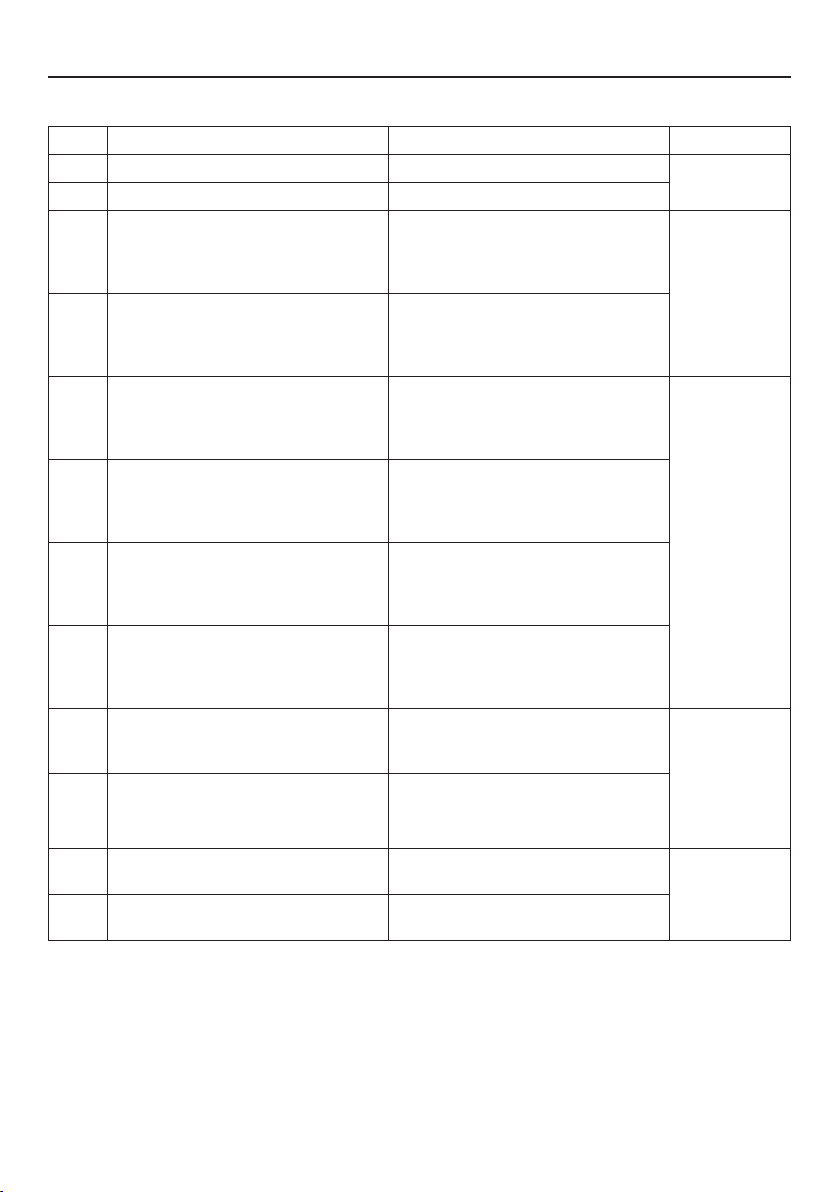

Table 5 - Main Menu and Parameters

Menu

Settings

Time/Date

PID Control

Sleep

Password

Parameter

Hour Format Hours 12Hr 12Hr 24Hr Selects 12 or 24 hour time scale.

Time HH:MM 1:00 AM 1 24

Date MM/DD/YYYY 1/1/12 – –

Proportional

Gain

Integration

Time

Derivation

Time

Derivative

Limit

Boost

Differential

Boost Delay MM:SS 1 Min 30 Sec 5 Min

Wake Up

Differential

Wake Delay MM:SS 15 Sec 3 Sec 2 Min

Password Time

Out

Password – 7777 0000 9999

Unit of

Measure

– 1500 0 10000

Milliseconds 1500 ms 20 ms

Milliseconds 60 ms 0 ms

– 120 0 2000

PSI 3 PSI 3 PSI 10 PSI

PSI 5 PSI 5 PSI 15 PSI

HH:MM 1 Hr 1 Min 6 Hr

Default Min. Max.

Value

Description

Sets current time. Used for time

stamp in fault log.

Sets current date. Used for date

stamp in fault log.

Sets the PID controller gain. Used

in conjunction with all PID Control

parameters to control how fast or

slow the Drive reacts to pressure

changes.

Sets the PID controller integration

time. Used in conjunction with all

65000

PID Control parameters to control

ms

how fast or slow Drive reacts to

pressure changes.

Sets PID controller derivation time.

Used in conjunction with all PID

10000

Control parameters to control how

ms

fast or slow Drive reacts to pressure

changes.

Sets derivative filter time constant

for PID controller.

First part of Boost Process. Pressure

boost that happens before it goes to

Wake Delay.

The time Drive takes to start Boost

Process after system has stabilized.

Pressure amount below setpoint that

wakes up Drive.

Second part of the Boost Process.

The time it takes to ramp down

pressure during the Boost Process.

Amount of time it takes to lock

keypad (after last button is pressed).

Password used to unlock keypad.

Page 14

Programming 14

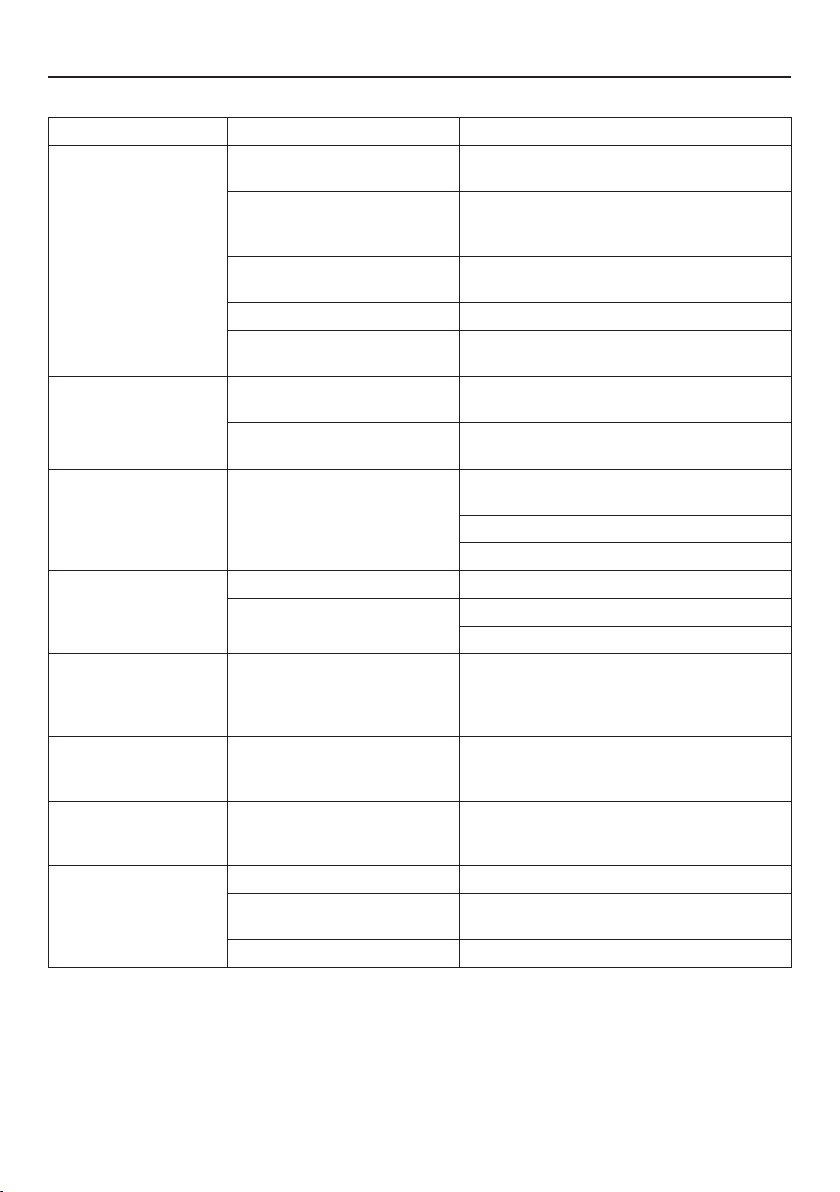

Table 5 - Continued

Menu

Settings

Setpoints

Sub Menu Parameter

Motor

Sensor

Parameter

Internal

Setpoint

External

Setpoint

Motor Phase _ 1 1 3

Connection

Type

Motor Type – Subm Subm

Service Factor

Amps

Min Frequency Hz 30 Hz 30 Hz

Max

Frequency

Max Sensor

Value

Unit of

Measure

PSI 60 PSI 15 PSI

PSI 40 PSI 15 PSI

Unit of

Measure

– 3 wire 3 wire 2 wire

A 00.0 A 00.0 A

Hz 60 Hz

PSI 100 PSI 100 PSI 300 PSI

Default Min Max

Default Min Max Description

Value

Sensor

minus 3

Sensor

minus 3

Above

1 below

1 above

Min Hz80 Hz

Description

Main pressure setpoint used. Sets

Max

main system operational pressure.

This parameter is accessed here,

Value

through PSI Preset button, or by

pressing Enter button while in

PSI.

Constant Pressure operation.

Second pressure setpoint. When

another pressure setting is desired

Max

other than Internal Setpoint.

Additional programming needed in

Value

I/O section. Requires an external

switch or timer to be wired to

PSI.

digital input terminals. It is only

active when there is voltage present

at the digital inputterminals.

Selects phase of motor to be

operated. An additional sub menu

will appear, based on phase

selection, to select proper motor

type.

Wire type for 1 phase motor

operation only. Can only access by

first setting Motor Phase parameter

to 1 Phase.

Motor type for 3 phase motor

operation only. Can only access by

Gnd

first setting Motor Phase parameter

to 3 Phase.

Per

Service factor amps (max. load) of

drive

motor the Drive is operating. Sets

and

maximum allowed amps at output

motor

of Drive. See Table 8 for values.

Minimum frequency (speed) motor

Max

will run.

Hz

Maximum frequency (speed)

motor will run. Up to 80Hz is only

available on submersible 3-phase

motors (when motor is 2x the HP

of pump).

Maximum pressure value of

transducer sensor used with Drive.

Only change if different transducer

is used with Drive, other than 100

PSI max scale.

Page 15

Programming 15

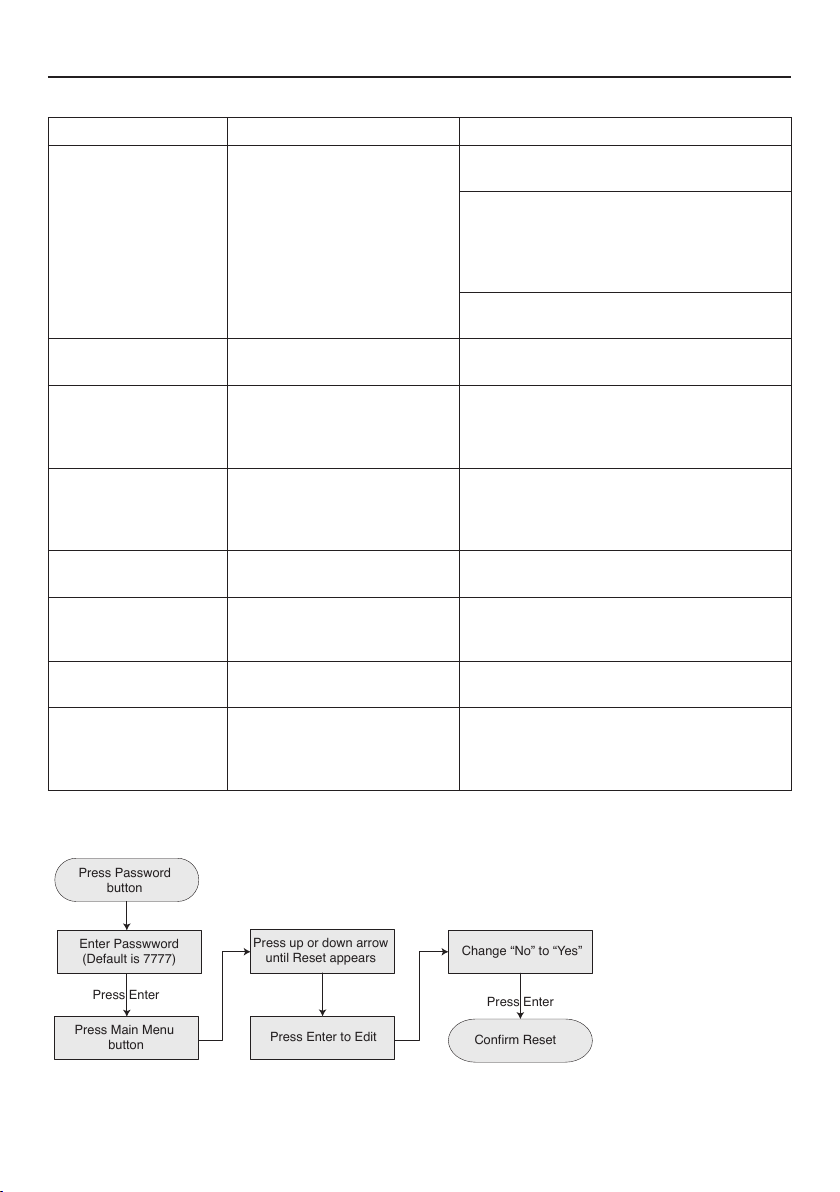

Table 5 - Continued

Menu or

Sub Menu

Ex Runtime

Dry Run

I/O

Over Press Over Pressure PSI 80 PSI 15 PSI 97 PSI

No Ground

Reset Factory Reset – No No Ye s

SW Update Software Update – Disabled Disabled Enabled Used to update software, if necessary.

Parameter Unit of Measure

Excessive

Runtime

Detection

Excessive

Runtime Hours

Auto Restart

Delay

Number of

Resets

Detection Time M:SS 15 Sec 5 Sec 10 Min

Sensitivity PSI 10 0 300

Fill Time M:SS 1 M 15 S 10 M

Digital Input 1

Digital Input 2

Relay Output – Unused – –

No Ground

Detection

_

Hours 24 1 100

Minutes 10 Min 3 Min 60 Min

– 3 0 5

– Unused – –

– Enabled

Value

Default Min Max

Disabled Disabled

Disabled

Enabled

Enabled

Description

Enables or disables Excessive Runtime

Detection.

Number of hours Drive can run before it

faults on Excessive Runtime.

Time Drive waits to restart pump when

Dry Run is detected.

Number of tries Drive attempts to restart

pump when Dry Run condition is

detected.

Time the Drive takes to recognize Dry

Run condition.

Pressure value that Dry Run condition

is detected at. Dry Run fault will occur

if this pressure cannot be met within

Detection Time window. Lower pressure

= less sensitivity.

Time allowed to fill (prime) pipes during

Auto Line Fill process. Relates to Dry Run

Sensitivity value. (Time starts after 55 Hz

is reached).

Selects operation of Drive when terminal

I1 or I2 is used. Select between Unused,

Run Enabled, Ext Fault, and Setpoint. The

Drive will respond to selected command

when voltage is present at I1 or I2

terminal.

Selects the operation of Drive when

terminal O1 is used. Select between

Unused, Run, and Fault. The Drive closes

the Relay when Run or Fault is selected.

Sets Over Pressure Warning value.

Change if higher than 80 PSI system

pressure is needed.

Selects whether Ground Detection

parameter is Enabled or Disabled. If

Disabled is selected, it will revert back to

Enabled after 72 hours. Warning LED will

flash entire time it is Disabled.

Resets all parameters to factory defaults.

Displays Setup Guide after it is complete.

Software version displayed here. Does

not clear fault log.

Page 16

I/O Connections 16

6956-0115

115 VAC

or

230 VAC

+

-

4. The I/O terminals are located in the center of

the wiring compartment, as shown previously

in Figure9.

The Digital Input connections (I1 and I2) are used to

control the Drive based on the state of an external

device, such as a flow switch, moisture sensor,

alternator, or other device. Programming is needed

to activate any of these functions (see Table 5).

The Output Relay (O1) is used to control an external

device based on two states of Drive; either Running

the pump or Faulted. Programming is needed to

activate any of these functions (see Table 5).

Cable Installation

Three 1/2” conduit knockouts are provided on the

bottom of the Drive enclosure for the I/O wires.

Break out the closest 1/2” knockout and route the

wires through. Use a cord grip to prevent the wire

from rubbing and causing a short.

NOTICE Never run low voltage I/O wire through

the same conduit hole as the 230V input wires or

motor wires.

To connect the external wires to the terminals:

1. Strip wire ½ inch

2. Push spring terminal up with finger or slotted

screwdriver

3. Insert wires from bottom

4. Release spring terminal

Connection Examples

Figures 15-18 show various connection schemes

for typical applications. Table 6 describes each I/O

terminal, including purpose and rating.

Figure 16 - Example external Input with

externalsupply

Figure 17 - Example Output relay with internal

24 volt supply

Figure 15 - Example Input with internal 24 volt

supply

+

115 VAC

or

230 VAC

-

Figure 18 - Example Output relay with

externalsupply

Page 17

I/O Connections 17

Table 6 - I/O Function, Connections, Ratings

Label Function Connection Rating

Positive connection for transducer Red transducer wire

AI+

Negative connection for transducer Black transducer wire

AI-

Positive side of 24 volt power supply.

V+

Used to power external devices.

Negative side of 24 volt power supply.

V-

Used to power external devices.

Positive connection of Digital Input 1.

Connect when using an external device to

I1+

control Drive.

Negative connection of Digital Input 1.

Connect when using an external device to

I1-

control Drive.

Positive connection of Digital Input 2.

Connect when using an external device to

I2+

control Drive.

Negative connection of Digital Input 2.

Connect when using an external device to

I2-

control Drive.

Output relay (dry contacts) connection.

O1+

Programmed to close when pump is

Running or Faulted.

Output relay (dry contacts) connection.

O1+

Programmed to close when pump is

Running or Faulted.

Positive connection of an RS-485

P

communication device (see Figure 19).

Negative connection of an RS-485

N

communication device (see Figure 19).

Positive side of 24V external device, i.e.,

flow switch, moisture sensor, alternator,

etc. Need to complete the circuit with V-.

See Figures 15 and 17.

Typically to I1-, I2-, or O1+. Used with

a flow switch, moisture sensor, alternator,

etc. Need to complete the circuit with V+.

See Figures 15 and 17.

From an external device i.e., flow switch,

moisture sensor, alternator, etc. Requires

complete circuit connection with I1-. See

Figures 15 and 16.

Can be from V- or from the negative side

of an external power supply. Requires

complete circuit connection with I1+. See

Figures 15 and 16.

From an external device, i.e., flow switch,

moisture sensor, alternator, etc. Requires

complete circuit connection with I2-. See

Figures 15 and 16.

Can be from V- or from the negative side

of an external power supply. Requires

complete circuit connection with I2+. See

Figures 15 and 16.

Positive wires of an external device. See

Figures 17 and 18.

Positive wires of an external device. See

Figures 17 and 18.

Positive wire from RS-485 device.

Negative wire from RS-485 device.

24 Volt

(supplied)

40mA maximum

output

Accepts 24VDC

and up to

230VAC

Accepts up

to 5Amps at

24VDC and

8Amps at up to

230VAC

*Only noninductive loads

Per RS-485

Standard

Page 18

Additional Information 18

RS-485 Communications

RS-485 is a US-based telecommunications

standard for binary serial communications between

devices. It is the protocol, or set of specifications,

that needs to be followed to allow devices that

implement the standard to speak to each other.

A fully compliant RS-485 port is included in the

PENTEK INTELLIDRIVE system to permit serial

connections among more than two devices on an

RS-485 compliant network. Figure 19 shows twowire connection to the Drive.

Figure 19 - Example RS-485 Connection

Lightning/Surge Protection

Lightning arrestors or other surge suppressing

devices can be used with this product. MOV(Metal

Oxide Varistor), SOV(Silicon Oxide Varistor).

Accessories

Part Description Qty Part Number

Alternating Control Panel 1 VFD-ALT

Moisture Sensor 1 VFD-WS

Surge Protection Kits 1 VFD-SGA

300 PSI Transducer 1 U17-2000

1” FPT Flow Switch 1.5 GPM

Normally Open

Filter Kit 1 VFD-SCRN

1 U17-1999

Retrofit Applications

When retrofitting an installation with the

PENTEK INTELLIDRIVE, most of the preceding

text can be applied. As a convenience, the

recommended Service Factor Amps for nonPENTEK motors is provided in Table 7. Always

verify Service Factor Amp values from current

manufacturer literature.

Table 7 - Service Factor Amps @ 230V

Service Factor Rating,

Motor Type HP

1/2 4.7

2-Wire

CS/CR

3-Wire

3-Phase

¹ CentriPro SFA data was taken from the March 2012 BMAID

manual on 4/2012.

² Franklin Electric SFA data was taken from the 7/2011 Franklin

Electric AIM manual on 4/2012.

NOTICE The PENTEK INTELLIDRIVE will not

operate Franklin Electric 2-wire motors.

3/4 6.4

1 9.1

1-1/2 11.0

1/2 4.9 4.3

3/4 6.3 5.7

1 7.2 7.1

1-1/2 11.1 11.5

2 12.2 13.2

1/2 2.9 2.9

3/4 3.9 3.8

1 4.7 4.7

1-1/2 6.1 5.9

2 7.6 8.1

3 10.1 10.9

5 17.5 17.8

in Amps

CentriPro¹ Franklin²

N/A

Repair Parts

Part Description Qty Part Number

Input Terminal Block

Connector

Output Terminal Block

Connector

Cooling Fan 1 PID-FAN-R

100 PSI Transducer 1 U17-1561-R

10’ Transducer Cable 1 VFD-10TCB

20’ Transducer Cable* 1 VFD-20TCB

50’ Transducer Cable* 1 VFD-50TCB

100’ Transducer Cable* 1 VFD-100TCB

200’ Transducer Cable* 1 VFD-200TCB

Keypad 1 PID-HMI-R

1/2” Cordgrip 10pk PID-GRP

* Purchase Separately

1 PID-CON2

1 PID-CON3

Page 19

Troubleshooting* 19

Fault Possible Causes Solution

Shorted output Check for any shorts in motor cables.

Damaged wire insulation Check motor wire insulation with a megger.

Over Current

Over Voltage

Under Voltage

Cannot Start Motor

Dry Run

Ground Fault

System Not Grounded

Missing Phase in 3-Phase motor Ohm cable and motor to confirm balanced Ohms.

Entered wrong Service Factor

Amps

Internal Drive short

Power cycling on and off Check for a generator or switching on input line.

High line voltage

Low line voltage

Temporary loss of power Check for local power outage.

Excessive load current Check motor is correctly sized for the application.

Loss of a motor phase

Power was removed from Drive Check correct voltage is present on all input lines.

Exceeding Service Factor Amps

No Service Factor Amps value

entered

There is an open (connection) in

motor wires

Locked rotor Pull pump check for debris in pump.

Operation at open discharge

Drive cannot read transducer

signal

Possible leak Check for pipe break or large leak.

Dry running pump Check water level in well.

Ground wire shorted to motor

phase

Long motor cable length

Ungrounded Drive

Unbalanced or three phase

incoming voltage.

Review motor perameters in main menu.

With power to Drive off, measure outputs with

ohmmeter to detect short.

Measure incoming line voltage to Drive; should

be between 190V and 265V.

Check correct voltage is present on all motor

leads.

Check Service Factor Amps entered are correct.

Check pump and motor are correct.

Check Service Factor Amps entered and are

correct.

Check resistance of all motor wires is correct.

May need to reduce Dry Run Sensitivity pressure

or apply back pressure on transducer.

Check linearity of transducer, as it may be

damaged. See Troubleshooting Guide for more

information.

Check the ground wire for short to motor phase

wire or check insulation integrity with a megger.

Motor cable length more than 1000 ft is not

recommended.

Ground Detect parameter can be disabled, but

will reactivate after 72 hours.

Line to line voltage must be twice line to ground

voltage.

Page 20

Troubleshooting 20

Troubleshooting, continued

Fault Possible Causes Solution

Intermittent connection

Open Connection

Open Transducer

Shorted Transducer

Over Temperature Excessive heating in drive

Excessive Runtime

Internal Fault Internal voltages are out of range

Hardware Fault Internal hardware failure

External Fault

Low Amps

Drive cannot read transducer

signal

Transducer wires crossed

Possible failed transducer

Short in transducer wires

Possible failed transducer

Leak detected Check for leaks in pipe system.

Application calls for long run

times

The external device detected fault

condition and closed the I1 or

I2 input

Motor not wired correctly to drive 2-Wire motor should be connected to Y & B

Thermal protector open in 1-phase

motor

Missing motor phase Check all motor connections at the Drive.

Check all transducer wires are securely connected

or for damaged cable insulation.

Check for proper wiring of all transducer wires

and verify cable connector securely attached to

transducer.

Check electrical system for ground loops or no

ground connection.

Check red is in AI+ and black is in AI-.

Check linearity of transducer; see Troubleshooting

Guide for more information.

Check for shorted transducer wire or damaged

insulation.

Check linearity of transducer; see Troubleshooting

Guide for more information.

Check ambient temperature is not above 50°C

(122°F).

Check for inoperable or unobstructed fan.

Check vents are not obstructed.

Extend Excessive Runtime Hours limitation.

Disable Excessive Runtime Fault.

Drive will auto reset and attempt to clear fault.

Fault Reset can be pressed to clear fault as well.

Then try to operate pump. If fault continues Drive

may need replacement.

Fault Reset can be pressed to clear fault. Then

try to operate pump. If fault continues Drive may

need replacement.

Check external device.

Wait 20 minutes then restart pump.

*For additional Troubleshooting information, please visit www.sta-rite.com/resources/images/16455.pdf for

a downloadable guide.

Page 21

Troubleshooting 21

Press Password

button

Press Main Menu

button

Press up or down arrow

until Reset appears

Enter Passwword

(Default is 7777)

Press Enter

Press Enter

Press Enter to Edit

Change “No” to “Yes”

Confirm Reset

Troubleshooting, continued

Warning Possible Causes Solution

Verify ground wire is connected on both incoming

voltage side and motor side of Drive.

Ungrounded Drive, with ground

Warning LED flashing

detection parameter disabled (will

operate for 72 hours and then

fault).

Jam Warning

Over Pressure Warning

Debris in pump stopping motor

from turning (locked rotor).

Pressure rising above Over

Pressure setting.

Temp Derate Plugged vents, fan not working,

high ambient temp, direct

sunlight, etc. Also high power

draw.

Hardware Fault Internal drive error. Power cycle the drive. If Fault continues drive may

Parameter Out of Range Internal drive error. Power cycle the drive. Reset drive to factory

Temp Meas Error Internal drive error. Power cycle the drive.

With the power disconnected, use an ohmmeter

to verify which pipe the Drive’s transducer

is connected to. Also verify that the input

ground wire is at the same potential, e.g., has

approximately the same ohm reading.

Verify the input ground is connected all the way

back to electrical panel.

Drive tries to free debris in pump by reversing or

pulsing motor.

Drive stops and waits 1 minute, then checks

that pressure is below the Overpressure Setting

pressure. Below it restarts, if not checks again in

another minute. Can increase over-pressure value.

Improve ventilation, verify fan is working, provide

shade, etc. Verify proper system sizing.

need replacement.

defaults. If Fault continues, drive may need

replacement

DC Undervoltage Low voltage on DC Bus caused

by heavy loading, low incoming

Check wiring for shorts, imbalance, and voltage.

Verify proper grounding.

voltage, or unbalanced output

current.

Drive Reset Procedure

Follow this keypress sequence to test the Drive.

After confirming Reset, do

not press any keys until the

Setup Guide appears.

Figure 20 - Drive Reset Procedure

NOTICE In a domestic environment, this product may cause radio interference which may require

supplementary mitigation measures.

Page 22

22Software Updates 22

NOTE: If using the information at www.sta-rite.com/PIDupdate, please note that some internet browsers need to

be refreshed to show the most current software files. Please press Ctrl+F5 to refresh the webpage to verify that it is

displaying the latest data.

To determine whether you need to update, compare the software version number in

your Pentek Intellidrive against the software you plan to install. To find the software

version number currently loaded on your drive, press the password key on the keypad,

enter your password, and press Enter. Next, press the Main Menu key followed by the

up arrow key until SW Update is displayed, press Enter. The bottom row of information

indicates your existing software version. If the version number you plan to install is

higher than what is currently on the drive, an update is in order. Please follow the

directions below to update your software.

IMPORTANT: Read all safety instructions in the Pentek Intellidrive Owner’s Manual before updating your drive.

Downloading Software to the SD Card

1. Before downloading new files from www.sta-rite.com/PIDupdate, verify that the SD card is empty.

2. Using the links above, download the AOC and MOC files to the SD card.

NOTE: SD cards are typically used in digital cameras and can be purchased in the electronics/camera section of most

retail outlets. Minimal storage space is needed for these files. Cards as small as 1GB have more than enough space.

Use only standard size SD cards; micro and mini SD cards will not work.

Updating Software on the Drive

1. Before moving forward with the software update, make note of the set up parameters used in the drive.

2. Remove power from the Intellidrive. Confirm by seeing text and light disappear from keypad. Power is normally

removed using a switch in the breaker box or switch in the fuse box.

3. Remove the plastic guard from the SD card slot (see picture below for location). This is simply a plastic insert that

protects the terminals in the card slot.

4. Insert SD card into the slot in the drive.

5. Reapply power to the drive.

6. Using the password, unlock the drive.

7. Press the Main Menu key, press the up arrow key until SW Update is

displayed and press Enter.

8. Set the parameter “Software Update” to “Enabled” by pressing enter

to “highlight” the word Disabled. Press the up arrow key to change

the parameter to Enabled. Press enter to “save” the change (the word

“Enabled” will no longer be highlighted when saved).

9. Remove power from the IntelliDrive. Confirm by seeing the text and

lights disappear from keypad.

10. Reapply power to the drive.

11. Wait while software updates. The screen will remain blank for about

90 seconds while this happens. When text reappears software upload is

complete.

12. When the startup guide appears, enter data as prompted. Refer to Owner’s Manual as necessary.

13. In the main menu go to the parameter group “SW Update” and press Enter.

14. Verify parameter “Software Update” now displays “Disabled”.

15. Verify software version shows the version you intended to install.

16. Change other setup parameters using the previously recorded notes.

17. Remove power from the IntelliDrive. Confirm by seeing the text and light disappear from keypad.

18. Remove SD card.

19. Replace plastic guard. This helps protect the terminals inside the slot from corrosion, etc.

20. The software update is complete.

Page 23

23Warranty 23

Limited Warranty

PENTAIR warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from

defects in material and workmanship for the Warranty Period shown below.

Product Warranty Period

Water Systems Products — jet pumps, small centrifugal pumps,

submersible pumps and related accessories

PENTEK INTELLIDRIVE™

®

Pro-Source

Pro-Source

Pro-Source

Composite Tanks 5 years from date of original installation

®

Steel Pressure Tanks 5 years from date of original installation

®

Epoxy-Line Tanks 3 years from date of original installation

Sump/Sewage/Effluent Products

whichever occurs first:

12 months from date of original installation,

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

12 months from date of original installation, or

18 months from date of manufacture

Our warranty will not apply to any product that, in our sole judgment, has been subject to negligence, misapplication, improper

installation, or improper maintenance. Without limiting the foregoing, operating a three phase motor with single phase power through a

phase converter will void the warranty. Note also that three phase motors must be protected by three-leg, ambient compensated, extraquick trip overload relays of the recommended size or the warranty is void.

Your only remedy, and PENTAIR’s only duty, is that PENTAIR repair or replace defective products (at PENTAIR’s choice). You must pay

all labor and shipping charges associated with this warranty and must request warranty service through the installing dealer as soon

as a problem is discovered. No request for service will be accepted if received after the Warranty Period has expired. This warranty is

nottransferable.

PENTAIR IS NOT LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL, OR CONTINGENT DAMAGES WHATSOEVER.

THE FOREGOING LIMITED WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER EXPRESS AND IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE

FOREGOING LIMITED WARRANTIES SHALL NOT EXTEND BEYOND THE DURATION PROVIDED HEREIN.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitations on how long an implied warranty

lasts, so the above limitations or exclusions may not apply to You. This warranty gives You specific legal rights and You may also have

other rights which vary from state to state.

This Limited Warranty is effective June 1, 2011 and replaces all undated warranties and warranties dated before June 1, 2011.

PENTAIR

293 Wright Street • Delavan, WI 53115

Phone (262) 728-5551 • Fax (262) 728-7323

Page 24

24Sécurité 24

Instructions de sécurité importantes

CONSERVER CES INSTRUCTIONS - CONSERVER CES

INSTRUCTIONS - Ce manuel contient des instructions

importantes à suivre lors de l’installation, l’utilisation et

l’entretien du mécanisme d’entraînement à fréquence

variable (VFD) PENTEK INTELLIDRIVE.

Ceci est un symbole d’alerte de sécurité. Lorsque

ce symbole apparaît sur le PENTEK INTELLIDRIVE ou

dans ce manuel, rechercher une des mises en garde qui

suivent, car elles indiquent un risque de blessures!

indique un risque qui, s’il n’est pas évité,

causera des blessures graves, voire mortelles.

indique un risque qui, s’il n’est pas évité,

pourrait causer des blessures graves voire mortelles.

indique un risque qui, s’il n’est pas évité,

pourrait causer des blessures légères ou modérées.

REMARQUE concerne des pratiques qui ne causent pas

de blessures.

Lire soigneusement et suivre toutes les instructions de

sécurité figurant dans ce manuel ou sur le PENTEK

INTELLIDRIVE. Maintenir les étiquettes de sécurité

en bon état. Remplacer les étiquettes manquantes ou

endommagées.

Avertissement lié à la proposition 65 de la Californie

Ce produit et les accessoires connexes

contiennent des produits chimiques reconnus dans

l’État de Californie comme pouvant provoquer des

cancers, des anomalies congénitales ou d’autres

dangers relatifs à la reproduction.

Risque d’électrocution par haute tension

du filtre EMI/RFI à l’intérieur. Peut causer une

électrocution, des brûlures ou la mort si le couvercle

avant du PENTEK INTELLIDRIVE est ouvert pendant

que l’appareil est connecté à la tension ou fonctionne.

Le couvercle avant du PID doit être fermé pendant le

fonctionnement.

• Exécuter tous les branchements, puis fermer et fixer

le couvercle avant de mettre le PID sous tension.

• NE JAMAIS ouvrir le coffret pendant que le PID est

connecté.

• Avant tout entretien ou réparation dans le PID ou

pour brancher ou débrancher des fils à l’intérieur:

1. DÉBRANCHER l’alimentation.

2. ATTENDRE 5 minutes pour que la tension se

décharge.

3. Ouvrir le coffret.

• Avant de commencer les procédures de câblage ou

d’inspection, vérifier la tension résiduelle avec un

voltmètre.

• NE JAMAIS relier l’alimentation au PID avant de

monter le coffret.

• NE JAMAIS manipuler ou réparer le PID avec les

mains humides ou mouillées. S’assurer que l’on a

les mains sèches avant de travailler.

• NE JAMAIS approcher ou changer le ventilateur de

refroidissement sous tension.

• NE JAMAIS toucher la carte de circuits imprimés

quand le PID est sous tension.

dommages et des blessures graves voire mortelles,

Risque d’incendie. Peut causer des

en cas d’installation avec une protection par

disjoncteur incorrecte. Pour protéger en cas de

défaut interne du PENTEK INTELLIDRIVE, installer

l’appareil sur une dérivation indépendante protégée

par disjoncteur (voir Tableau 2 pour la taille du

disjoncteur), sans autre appareil sur le circuit.

Risque de brûlures. Le PID peut

chauffer en fonctionnement normal. Attendre 5

minutes après l’arrêt avant d’y toucher pour éviter

des brûlures.

REMARQUE our éviter d’endommager le PID ou

d’avoir des problèmes:

• Brancher les câbles de sortie à des moteurs

submersibles monophasés 3 fils et triphasés

comme suit:

Rouge à R, Jaune à Y, Noir à B.

Tout autre ordre inversera la rotation du moteur

(triphasé) et peut endommager le moteur.

• Brancher les câbles de sortie à des moteurs

submersibles monophasés 2 fils comme suit:

Brancher uniquement les fils Y et B.

Brancher la terre à la vis verte.

• Les moteurs triphasés de surface peuvent avoir des

couleurs de fils différentes. Brancher généralement

les fils de sortie comme suit:

R à L1, Y à L2, B à L3.

Vérifier la rotation après le démarrage.

• Ne pas modifier l’équipement.

• Ne pas utiliser de condensateurs de correction de

facteur de puissance, car ils endommageront le

moteur et le PENTEK INTELLIDRIVE.

• Ne pas retirer de pièces sauf instruction contraire

dans le manuel d’utilisation.

• Ne pas utiliser de contacteur magnétique sur le

PID pour des démarrages/arrêts fréquents.

• Ne pas installer, ni utiliser le PID s’il est

endommagé ou s’il manque des pièces.

• Avant de démarrer le PID qui a été en stockage,

toujours l’inspecter et tester son fonctionnement.

• Ne pas effectuer de test Megger (résistance

d’isolement) sur le circuit de commande.

• Ne pas laisser d’objet étranger pouvant conduire

l’électricité (comme des vis et des fragments

métalliques) à l’intérieur du coffret du PID.

Ne jamais utiliser de substances inflammables

(comme de l’huile) à l’intérieur du coffret du PID.

• Mettre le PID à la terre conformément aux

exigences du National Electrical Code Section

250, IEC 536 Classe 1 ou du Code canadien de

l’électricité (selon le cas) et tout autre code ou

règlement applicable.

• Le travail d’installation et de réparation et

les inspections doivent être effectués par un

électricien qualifié.

Page 25

25Table des matières 25

Fan

Filtre EMI/RFI

Sécurité ..........................................................24

Informations sur le propriétaire .......................................25

Description .................................................... 26-27

Installation ..................................................... 28-31

Démarrage initial ................................................ 32-33

Programmation ................................................. 34-37

Connexions E/S ................................................. 38-39

Informations supplémentaires .........................................40

Dépannage .................................................... 41-43

Mises à jour logicielles ..............................................44

Garantie ..........................................................45

Informations sur le propriétaire

PENTEK INTELLIDRIVE Modèle n° _________________________

N° de série PENTEK INTELLIDRIVE _________________________

N° de modèle de pompe _________________________

N° de série de pompe _________________________

N° de modèle de moteur _________________________

Intensité de facteur de surcharge _________________________

Risques d’électrocution.

Risque d’électrocution, de

brûlures ou de mort.

• Des composants internes

du PID restent sous

haute tension jusqu’à

5 minutes une fois

l’alimentation coupée.

• Le filtre EMI/RFI est sous

haute tension quand la

pompe tourne.

• Couper le courant et

attendre 5 minutes avant

d’ouvrir le couvercle du

PENTEK INTELLIDRIVE.

N° de modèle de réservoir sous pression _________________________

N° de série du réservoir sous pression _________________________

Concessionnaire/Installateur: _________________________________

____________________________________________________________

N° de téléphone de l’installateur _________________________

Date d’installation _________________________

Longueurs des fils en pieds (Mètres):

Disjoncteur du PID _________________________

PENTEK INTELLIDRIVE à moteur _________________________

Tension d’alimentation _________________________

Note pour l’installateur: Noter les informations ci-dessus pour consultation future.

Donner le manuel à l’utilisateur final et le fixer au PENTEK INTELLIDRIVE une fois

l’installation terminée.

Page 26

26Description 26

Remarque : Les enceintes classée

Te

Spécifications/Classements

Tension d’entrée .... Nominale monophasée 230V C.A (190–265V C.A.)

Fréquence d’entrée. ...................................................................50/60Hz

Plage de températures ambiantes .................... -4 à 122°F (-20° à 50°C)

Connexions de sortie ........triphasé, 3 fils/monophasé ou monophasé/2 fils

Longueur max. du câble du moteur ........................................ 1000 pieds

Coffret: .................................................................................... NEMA 3R

Tableau 1 - Spécifications

Modèle Type de moteur*

2 FILS MONOPHASÉ

PID10

3 FILS MONOPHASÉ

TRIPHASÉ 5A

2 FILS MONOPHASÉ

3 FILS MONOPHASÉ

PID20

PID30

PID50

TRIPHASÉ

2 FILS MONOPHASÉ

3 FILS MONOPHASÉ

TRIPHASÉ 0.5–3 CH 11.5A

2 FILS MONOPHASÉ

3 FILS MONOPHASÉ

TRIPHASÉ 0.5–5 CH 18A

Gamme de

puissance:

0.5–1 CH

0.5–1.5 CH 11A

0.5–2 CH

0.5–1.5 CH 11A

0.5–2 CH 13.5A

0.5–1.5 CH 11A

0.5–2 CH 13.5A

Entrée

Tension

190V –

* Sélectionner l’appareil selon l’intensité de facteur de surcharge du moteur de pompe.

Le PENTEK INTELLIDRIVE est conçu pour fonctionner avec

les pompes submersibles de 4 po, les pompes de surface

triphasées et les surpresseurs résidentiels. Chaque PID est réglé

pour fonctionner sur une puissance de sortie maximale. Toute

utilisation du PID hors des paramètres de conception prévus

annulera la garantie. Si le PID est utilisé avec des moteurs

de surface non conçus pour un mécanisme d’entraînement à

fréquence variable, optimiser la durée de vie du moteur en

limitant la longueur du câble à 25 pieds. Consulter le manuel

265V

Sortie

maximale

Maximum A

9.5A

7.5A

13.5A

8.5A

Coffret

NEMA 3R

extérieur

pour le calibre du câble.

Chaque emballage contient:

Un mécanisme d’entraînement à fréquence variable PENTEK

•

INTELLIDRIVE

• Un transducteur de pression

• Un câble du transducteur de pression de 10pi

• Un guide de démarrage

• Un manuel d’utilisation

Type

Structure des numéros de modèle du PENTEK INTELLIDRIVE

PIDXX

Famille de produits

PID - PENTEK INTELLIDRIVE

Gamme de puissance

10 = jusqu’à 1,0 ch

20 = jusqu’à 2,0 ch

30 = jusqu’à 3,0 ch

50 = jusqu’à 5,0 ch

Le PID10 fait fonctionner un moteur monophasé 2 fils et 3 fils

et triphasé jusqu’à 1 ch.

Le PID20 fait fonctionner un moteur monophasé 2 fils jusqu’à

1,5ch et monophasé 3 fils ou triphasé jusqu’à 2 ch.

Le PID30 fait fonctionner un moteur monophasé 2 fils jusqu’à

1,5ch, monophasé 3 fils jusqu’à 2ch ou triphasé jusqu’à 3 ch.

Le PID50 fait fonctionner un moteur monophasé 2 fils jusqu’à

1,5ch, monophasé 3 fils jusqu’à 2ch ou triphasé jusqu’à 5 ch.

d’utilisation de la pompe et le Code canadien de l’électricité

rre

Fils du

moteur

Figure 1 - Installation résidentielle type

NEMA 3R exigent un conduit étanche

8po

ou plus

Alimentation

depuis

disjoncteur

Avec pompe de surface

(triphasé seulement)

Du transducteur

à la commande

Fils du moteur

Terre

Clapet de pied

ou clapet antiretour

8po ou plus

Manomètre

Avec pompe

submersible

Réservoir

sous pression

Transducteur; à installer sur un

tuyau droit en aval du réservoir,

éloigné d'au moins un pied des

raccords de chaque côté

Clapet de décharge

(Nécessaire)

Pas à

l'échelle

Vers service

Page 27

27Description 27

Transducteur

Le PENTEK INTELLIDRIVE utilise un transducteur

de pression 4 - 20mA, 0 -100lb/po² pour

contrôler la vitesse du moteur (on peut modifier les

réglages de l’appareil pour utiliser un transducteur

de 300lb/po² max.).

Le transducteur (voir Figure 1) détecte la pression

dans le tuyau et la convertit en signal électrique.

L’appareil détecte et traite le signal dans la

commande PID. En mode AUTOSTART, le PID

augmente ou diminue au besoin la vitesse de

rotation du moteur de pompe pour maintenir une

pression constante dans les tuyauteries.

Modifie le point de consigne de pression

interne de 15lb/po² à la pression max.

du transducteur -3lb/po² (réglée par

Fait fonctionner le PID (sans contrôle

de la pression) pour permettre à

l’installateur de vider le puits.

Change l’affichage à l’écran précédent.

Sélectionne les articles du menu et confirme

les changements de valeurs numériques.

Le PID est en mode d’avertissement

(TPM); voir la section dépannage.

Affiche la condition de fonctionnement

du PID et modifie les paramètres

Figure 2 - Fonctions du clavier PENTEK INTELLIDRIVE

défaut à 60lb/po²).

Le PID est alimenté.

Une anomalie s’est produite.

d’affichage.

Arrête le moteur.

Clavier

Le clavier programme le PID, surveille l’état de la

pompe et affiche les anomalies éventuelles.

Chaque bouton a une fonction unique, décrite à la

Figure 2. L’écran à cristaux liquides affiche l’état de

fonctionnement du PID. D’autres DEL s’allument

quand on enfonce certaines touches ou qu’il se

produit certains événements.

Ventilateur

Le PID utilise un ventilateur interne à commande

thermostatique qui fonctionne automatiquement

pour refroidir les composants si nécessaire.

Affiche et modifie les paramètres.

Affiche les 15 dernières anomalies.

Avec le code, verrouille et déverrouille

les touches protégées par mot de passe.

Permet de passer de l’anglais à l’espagnol et

au français (l’anglais est la langue par défaut).

Les flèches gauche et droite déplacent le

curseur.

Les flèches haut et bas font défiler les

menus et changent les valeurs numériques.

Réinitialise le PID en cas d’anomalie

ayant arrêté le PID/la pompe.

Vérifie le remplissage des tuyaux, puis démarre

la pompe en mode de pression constante.

Page 28

28Installation 28

Tableau 2 - Tailles des disjoncteurs et fils

Moteur Volts

2 fils

3 fils

230

Triphasé

* Avec des disjoncteurs adaptés, le PID est protégé des courts-circuits côtés entrée et sortie. Il n’y a pas de

risque d’incendie ou d’électrocution à cause d’un court-circuit. Le PID est protégé contre les surcharges

conformément à la norme NEC Classe 10.

** Génératrice de 240V minimum.

Puissance

moteur

1/2 14

3/4

1 20 4.4

1-1/2 10 25 5.3

1/2 14

3/4

1 3.5

1-1/2

2 5.8

1/2

3/4 2.8

1

1-1/2 20 4.4

2

3 30 7.3

5 6 50 12.6

(Installation type avec 400pi de câble entre le branchement et le PID)

Fil d’entrée

Calibre

12

12

10 25

14

12

10

Disjoncteur* Génératrice (kVA)**

15

15

15

25 5.5

2.2

3.1

2.3

3.0

5.3

2.1

3.4

Page 29

29Installation 29

Montage du PID

Pour le montage, illustré à la Figure 6, suivre cette

procédure:

1. Retirer d’abord le couvercle en dévissant la

vis en bas du couvercle avant.

2. Pousser la plaque arrière avec les pouces tout

en tirant le couvercle vers soi avec les index

pour créer un espace. Voir les figures 3 et 4.

Figure 3 - Séparer le couvercle de la plaque arrière

5. S’assurer que les trous de ventilation ne sont

pas bouchés et que l’espace est suffisant pour

que l’air circule autour (dégagement d’au

moins 3po en haut, en bas et sur les côtés).

Voir la figure 6. Une fois le PID monté, on

peut brancher le câblage électrique.

Type

Disjoncteur

230V C.A.

(Double

largeur)

Figure 6 - Fixation du PID au mur

6. Pour refixer le couvercle, accrocher le haut

sur la plaque arrière (laisser un espace).

Abaisser le bas du couvercle en place. Pousser

le couvercle uniformément contre la plaque

arrière, éliminant l’espace. Voir la figure 7.

Figure 4 - Espace entre le couvercle et la plaque arrière

3. Tirer le bas du couvercle vers soi; soulever le

couvercle et le retirer. Voir la figure 5.

Figure 5 - Tirer sur le bas du couvercle