Page 1

®

PG2000

Installation Manual

U.S. Patent Numbers

5,802,227; 5,825,954; 5,680,496;

Model No.s

840240

840241

840242

Pentair Water Pool and Spa, Inc.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

Visit us on the Internet at: www.pentairpool.com or www.staritepool.com

Rev. C 7-29-05 1 P/N 840259

6,002,216

Page 2

IMPORTANT SAFETY INSTRUCTIONS

When installing and using this electrical equipment, basic safety precautions should be followed, including

the following:

READ AND FOLLOW ALL INSTRUCTIONS

1. WARNING: To reduce the risk of injury, do not permit children to use this product unless they are closely

supervised at all times.

2. Check your local building codes before installation to ensure the PG2000 is located at least 5 feet from the

pool, or the minimum distance from the pool that local codes require.

3. The electrical supply for this product must include a suitable rated switch or circuit breaker to open all

ungrounded supply conductors to comply with Section 422-20 of the National Electrical Code, ANSI/

NFPA 70-2002. The disconnection means must be readily accessible to pool and spa users, but installed

at least 5 feet (1.5m) from the pool or spa water.

WARNING

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION

This PG2000 must be installed by a licensed or certified electrician in accordance with the National Electrical

Code and all applicable local codes and ordinances. Improper installation will create an electrical hazard which

could result in death or serious injury to pool users, installers, or others, due to electrical shock, and may also

cause property damage.

Disconnect all power before starting the installation process to all associated pool equipment. Failure to do so may

lead to severe electrical shock, which can result in death or severe personal injury.

WARNING

Before installing this FIBERworks® product, read and follow all warning notices and instructions accompanying this light

product. Failure to follow safety warnings and instructions can result in severe injury, death, or property damage. You are

going to be using a sophisticated device which requires knowledgeable handling in order to insure its optimum

performance. Please do not touch anything until you have read and understood these instructions. If you have any

questions, please call our service hotline, Monday through Friday, 7:30 a.m. to 4:30 p.m.: (800) 831-7133.

WARNING

It is recommended that FIBERworks® be installed by trained and certified FIBERworks® dealers only. This installation

manual assumes that your PG2000 will be properly installed in full accordance with the instructions provided, the National

Electrical Code, and any local codes applicable for an electrical installation of this type.

SAVE THESE INSTRUCTIONS.

P/N 840259 2 Rev. C 7-29-05

Page 3

Table of Contents

SECTION I. Before You Begin Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

®

The Installer’s Ten Laws of FIBERworks

The Pool Designer/Salesperson’s Ten Laws of FIBERworks

A. FIBERCAD Design Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

B. Wide Angle Lens positioning with the PG2000 centered at end of the pool . . . . . . . . . . . . . . . . . 6

C. Wide Angle OptiFusion Lens positioning on the side of the pool with the PG2000

centered on side of pool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION II. Running Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SECTION III. Installing Lens Housings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

SECTION IV. Preparing to Mount the PG2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

SECTION V. Feeding or Pulling the AmerGlow Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SECTION VI. AmerGlow Lens Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

SECTION VII. Installing the Ferrule Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

SECTION VIII. Installing the PG2000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SECTION IX. Synchronization of SAm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

®

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

®

/SAL® and Fiberworks® (Wiring Diagrams) . . . . . . . . . . . . . . . . .25

SECTION X. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

PG2000 Specifications

Electrical

Input Voltage .............................. 120 V @ 2 A

Power Consumption ................... Approximately 200 Watts

Mechanical

Dimensions ................................. 15 in. x 10½ in. x 12 in.

Weight ....................................... 20 lbs.

Materials .................................... High strength plastic

This unit will accommodate up to 600 FIBERworks® fibers.

Contents of the Shipping Carton

This package should contain all of the following items:

√ PG2000

√ Sub-terrain Mounting Base

√ Ferrule Kit

√ PG2000 Installation Manual - (this manual)

√ Owner's Manual

√ Warranty Registration Card

®

To perform this installation, you will need the following items:

Electrical wire and conduit to connect main power, FIBERworks® cable and fittings as required,

Professional Termination Kit, (p/n 21005500), and the tools/equipment listed in relevant sections of this

manual.

Rev. C 7-29-05 3 P/N 840259

Page 4

SECTION I. Before You Begin Installation

The Installer’s Ten Laws of FIBERworks

1. DO NOT ATTEMPT INSTALLATION WITHOUT RECEIVING CERTIFIED TRAINING OR

WATCHING INSTALLATION VIDEO.

2. Take your time and be patient when terminating - Rushing a 90 second FiberKnife 400 fiber termination can

cause 30% loss of light.

3. Use only prescribed Termination tools - FIBERworks® FiberKnife and shield.

(DO NOT USE MECHANICAL CUTTERS OR KNIFE BLADE HEATED WITH TORCH.)

4. Make conduit runs as direct as possible - plastic fiber loses 2% of light per foot; see Table 1, Light

Transmission Versus Distance.

5. When handling the cable do not bend final 12 in. of cable before lens.

6. Push lens and final 1 in. of cable into lens body - DO NOT PULL IN!

7. Sub-terrain Mounting Base should be installed below grade so that bottom of PG2000 is at or slightly above

finished landscape or concrete grade and protected from grass.

Locate the PG2000 above water level whenever possible. If raised water features are being lit, be sure

the end of the conduit inside the Generator is filled with RTV, other suitable sealant or conduit seal kit

#22002000 and locate the Generator so water will drain away from it and not accumulate inside of or

around the PG2000. This will prevent water from flooding the electrical portion of the unit.

®

8. Be sure conduits are located by cable size as in the template in the back cover of this manual and cut off level

with top of Sub-terrain Base (finished grade).

9. PROPER TERMINATION AT PG2000; see PG2000 Installation Steps.

a. First, mechanically cut all cables to equal length about 14 in. above the top of the Sub-terrain Base.

b. Strip all cable jackets 0-2 in. above Sub-terrain Base.

c. SANITY SAVER- one wrap of electrical tape over fiber bundle end.

d. Install ferrule and tighten with 3-4 in. of fiber extending out of fiber disk; see Picture 9, pg. 20.

e. Hot knife cut. Hold blade angled at 15 degrees, as if you were cutting cream cheese. Don’t stop and

restart, but rather keep continuous light pressure. Don’t saw or wiggle knife. Ease up pressure as you

come to end of cut.

f. Be sure ferrule is fully rotated and secured by ferrule thumb screws.

g. Wrap electrical tape or tie wrap around bundle at 2-3 in. above conduit.

10. WHEN IN DOUBT CALL your FIBERworks® Specialist or Technical Service at 800-831-7133.

P/N 840259 4 Rev. C 7-29-05

Page 5

The Pool Designer/Salesperson’s Ten Laws of FIBERworks

®

1. The color of fiber optics is fantastic... but don’t just sell fiber optics, sell FIBERworks®! More Light... More

Color... More Friendly than other similar fiber optic systems... from the World’s Leading Manufacturer of

Underwater Lights!

2. Delight your customers and get referrals. Don’t undersize - never use fewer fibers or fewer lights than

recommended.

3. The Longer the fiber optic cable, the more it will cost and the less light it will transmit to the pool, spa, water

feature or landscape light. Distance costs 2% of light per foot; see Table 1, Light Transmission Versus

Distance.

4. Choose your PG2000 location(s) wisely. Give your biggest cables the shortest runs. If you design “never

ending” decks, design a planter between 5 and 10 feet (depending on code) from the primary lens location.

5. Colored surfaces absorb light. The darker the surface, the more light it will absorb. Do not waste your

customer’s money on underwater fiber optics for dark surfaces. They will not fully appreciate the dramatics of

fiber optic colors. Use Amerlites

®

, AquaLights® or HiLites®.

6. The darker your pool surface, the more dramatic will be perimeter FIBERworks®. Dark pools make great

reflecting pools and fantastic perimeter FIBERworks pools. For perimeter installations over 200' consult your

FIBERworks® Specialist.

7. FIBERworks® powerfully illuminates the wall and floor surface toward which the lens is pointed... modest

illumination is on the wall which holds the lens. AmerGlow 12, 30, 50, 70 or 100 cables make great step lights

and shadow fillers when directed toward or across the wall holding the AmerGlow 325, 225 or 170 cables.

8. There are two underwater lenses available. The Wide Angle Lens spreads light about 180 degrees and should

be used for most underwater applications. The Standard Lens spreads light about 70 degrees and should be

used for opposite wall shadow filling, up lighting into a fountainhead, and up lighting into a waterfall or cascade.

9. Always use Certified FIBERworks ®Installers. A rushed or poor installation can kill performance by 30%.

Schedule training as soon as possible or order FIBERworks® Installation Video [P/N P3-202].

10. WHEN IN DOUBT CALL Technical Service at 800-831-7133 OR- complete a FIBERCAD FORM

(located in the Pentair Water Pool and Spa, Inc. Catalog), AND fax a scale drawing to 727-461-5080.

NOTE

FIBERworks Application Manual is available on-line @ www.pentairtraining.com and www.pentairpool.com.

Rev. C 7-29-05 5 P/N 840259

Page 6

A. FIBERCAD Design Assistance.

NOTE

FIBERworks Application Manual is available on-line @ www.pentairtraining.com and www.pentairpool.com.

For assistance in designing your fiber optic lighting, fax a FIBERCAD form (located in the Pentair Water

Pool and Spa, Inc. Catalog) and scale drawing to 727-461-5080.

If designing your own lighting layout, it is critical to keep the PG2000 as close to the pool as possible (less

than 15’ is desirable) and cable runs as short as possible to maximize light output; see Table 1, Light

Transmission vs Distance.

B. Wide Angle Lens positioning with the PG2000 centered at end of the pool.

1. AmerGlow 170, 225 and 325 only, with the lens(es) positioned at the end of the pool. Whenever possible, the

lens(es) should not face directly toward the home or entertainment area.

a. For white or nearly white concrete, fiberglass or vinyl pools, Wide Angle Lenses intended to illuminate the

entire length of the pool can be placed in either the shallow end or deep end 6 to 8 inches below water

level.

b. For light or medium colored pools, place the Wide Angle lens(es) in the deep end 6 to 8 inches below

water level.

c. Use single AmerGlow 170, 225, 325 in center of end wall or Dual AmerGlow 170’s or 225’s each 2 to

3.5 feet from center line (4 to 7 feet apart). Pools over 18 feet wide should have dual lenses in the end wall.

C. Wide Angle OptiFusion Lens positioning on the side of the pool with the PG2000 centered on side of pool.

1. AmerGlow 100, 70, 50 and 30 only, unless pool is over 20 ft. wide, with the lens(es) positioned at the side of

the pool. Whenever possible, the lens(es) should not face directly toward the home or entertainment area.

a. Lenses should be located and directed to offer uniform illumination of the entire pool allocating more light

for areas with greater floor and wall surface area such as the deep end. Also see Light Transmission vs

Distance table for more help.

b. The best lighting is achieved on the surfaces the lens is facing.

c. Lens(es) in concrete or fiberglass pools should be located approximately 1/3 of the distance between the

water surface and the beginning of the transition from wall to floor.

• Place 9 in. below water level in 3 foot shallow ends to reduce the intensity of hot spots on the floor.

d. In vinyl pools, locate lens(es) as follows:

HTPED

WOLEBSEHCNI

LENAPFOPOT

.tf3.ni21

.tf4.ni21

.tf5.ni51

.tf6.ni51

.tf7.ni81

.tf8.ni81

.tf9.ni12

.tf01.ni12

P/N 840259 6 Rev. C 7-29-05

Page 7

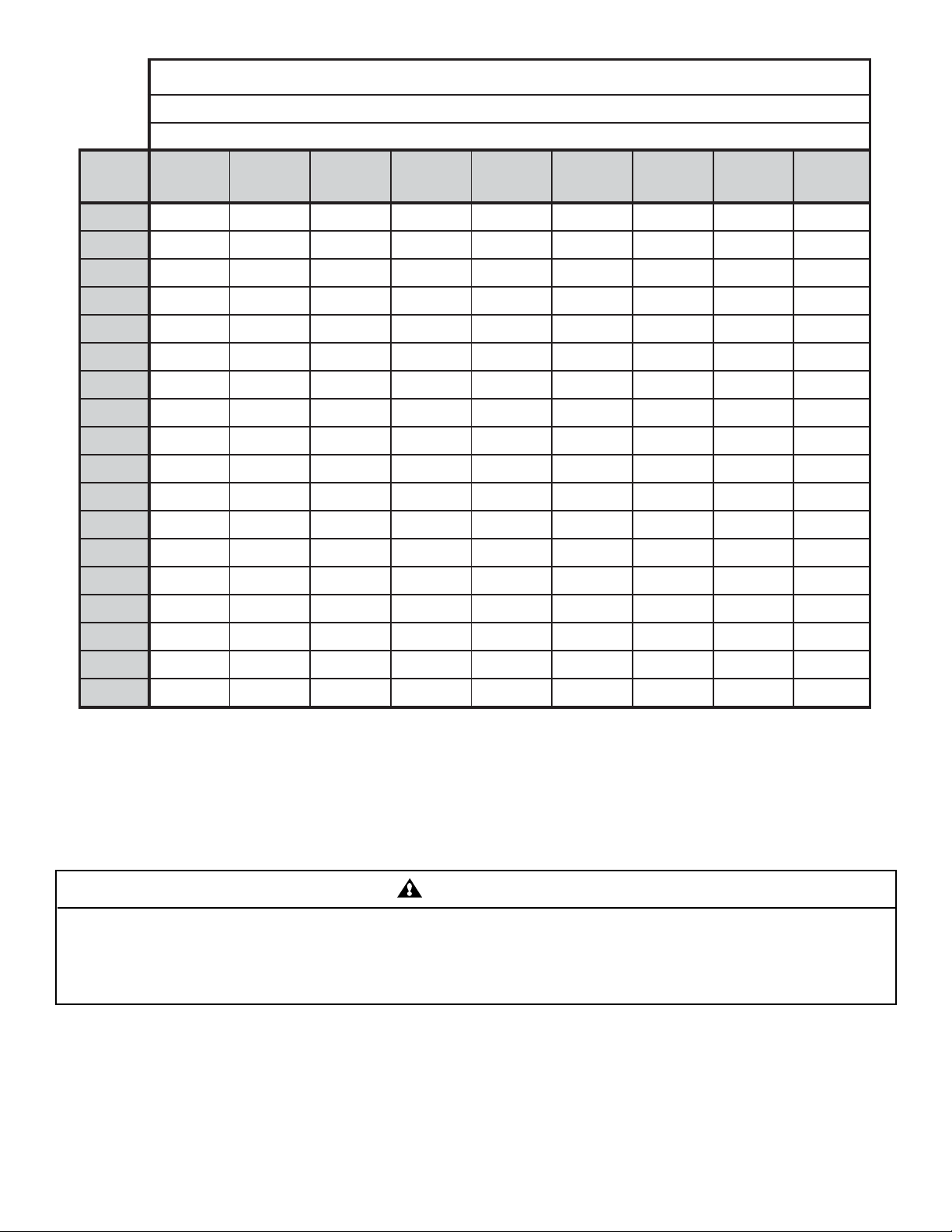

.1ELBAT

.tf01taNOISSIMSNARTTHGILTNELAVIUQEREBIF

SEZISELBACWOLGREMA

elbaC

htgneL

0152352207100107050321

212136123616976849221%0.4

410038027512956648211%8.7

618829911519826447211%4.11

816721915415806346201%9.41

026624819312875145201%3.81

52042661621472573229 %1.62

03712051311767433028 %2.33

53691631301062403817 %6.93

0477132139558372617 %4.54

5406111148945352516 %7.05

0554100167541322315 %4.55

551311986048202215 %7.95

068112826635281114 %6.36

0779761503125194 %2.07

523

.viuqerebif

522

.viuqerebif

071

.viuqerebif

001

.viuqerebif

07

.viuqerebif

05

.viuqerebif

03

.viuqerebif

21

.viuqerebif

thgiLfo%

tsoL

0897551442712173 %7.57

0956544302410162 %1.08

0013573826111852 %8.38

This table shows the effect of longer cable runs on light transmission. Longer cable runs have the same effect as cutting

down on the number of fibers.

** The first 10’ is considered unavoidable and is used here as a standard for comparison.

(For example: 69' of 325, 50' of 225 and 37' of 170 all have the same output as 10' of 100.)

WARNING

Provide adequate lighting to your pool for nighttime use. The amount of light needed will vary with the size and shape of the

pool. This may require additional lighting sources. Failure to provide adequate lighting can result in swimming and diving

hazards that can cause severe injury or death. Consult your local building department or a lighting professional to determine

lighting requirements.

Rev. C 7-29-05 7 P/N 840259

Page 8

SECTION II. Running Conduit

A. General conduit tips.

• Use electrical sweep elbows and 45’s or heat bend PVC pipe. DO NOT use plumbing 90° or 45° elbows. Using

the right conduit and fittings will allow the cable to be fed much easier, and will prevent damage to the fiber optics.

• Use rigid PVC pipe or SMOOTH ID flexible electrical PVC for all cable runs. Flexible water PVC pipe

is not recommended for this type of installation because of its high friction walls.

• Make your job easier - use electrician’s lube when feeding cable.

B. Choosing the best size conduit for the job.

a. For AmerGlow 325, 225 or 170 use 1 in. or larger rigid PVC conduit; use 1½ in. for AmerGlow 325 over 20 ft.

b. Use ¾ in. or larger conduit for AmerGlow 100 or 70.

c. Use ½ in. or larger conduit for AmerGlow 50, 30 or 12.

NOTE

Do not reduce fiberglass lens housing or standard gunite lens housing to less than 1 in. in rear socket or lens assembly will not seat properly.

C. Electrical conduit requirements, see Wiring the PG2000 for Wiring Diagram.

a. For manual operation at PG2000, RF2000 Wireless Control or single remote toggle switch operation, use

½ in. electrical conduit to run 3 - 18 AWG (black, white and green) or larger wires to each PG2000 location.

b. For dual remote toggle switch or automated remote control operation (Compool, etc.), use ½ in. electrical

conduit to run 4 - 18 AWG (red, black, white and green) or larger wires to each PG2000 location.

c. It is very important that the unit be properly grounded - there is serious risk of electrical shock or

electrocution otherwise.

WARNING

The PG2000 must be properly grounded. Consult the National Electrical Code and all other applicable local codes and

ordinances for proper grounding techniques. Improper installation will create an electrical hazard which could result in death or

serious injury to pool users, installers, or others, due to electrical shock, and may also cause property damage.

d. Make sure the conduit comes up in the correct area in the front of the PG2000; see Section IV for this information.

e. Extend conduit up above the bottom of the PG2000 at least six inches.

D. Running the conduit for AmerGlow fiber optic cable.

a. Using the sizes determined above, run the conduit from the pool wall to the PG2000 location.

b. Conduit near the PG2000 should be at least 4 in. deep if using the sub-terrain mounting base to mount the PG2000.

c. Use only electrical sweep elbows and 45’s - DO NOT use plumbing 90’s or 45’s, as they can damage the

fiber optics or prevent pulling the cable.

d. The lens body should be located according to recommendations in the “Before You Begin Installation...”

Section. Conduit should slope to that depth.

e. If using smaller than 1 in. conduit, do not bush down

within 2 in. from rear of lens body.

f. Use a 12 in. minimum straight section of conduit

behind the lens housing.

4 in.

Gunite

1¼ in. min.

g. For gunite pools, the recessed cut back for lens

housing should be as shown in Figure 1. Dimension

“A” should be 1 in. for a FIBERworks Standard

A

Conduit

Gunite fitting, and 1½ in. for a FIBERworks Invisible

Gunite fitting.

P/N 840259 8 Rev. C 7-29-05

Plaster

Surface

Figure 1.

Page 9

h. At the PG2000 location, leave at least 6 in. of conduit

above the anticipated sub-terrain mounting base or deck

surface and place tape over both ends of conduit. The

tape and extra length will help prevent debris from getting

into the conduit until the cable is run. The conduit should

be cut off level with top of Sub-terrain Base (finished

grade) location just before the fiber optic cable is run

(does not apply to electrical conduit).

(FINISHED LANDSCAPE

OR DECK LEVEL)

i. Use the template on the back page of this manual to

determine conduit location inside the PG2000 if you are

Figure 2.

installing on a poured concrete deck, on a wood deck or

in the ground.

j. For either type of installation, use duct tape or tie wrap to bundle the conduit together in the PG2000 area.

Keeping the conduit together will help when preparing the cable later.

SECTION III. Installing Lens Housings

• FIBERworks® lens housings are installed the same way regular water return fittings are installed.

CAUTION

Use only FIBERworks lens housings. Other fittings will not seal conduit. Each FIBERworks lens housing has a label identifying it

as such. Do not use excessive glue, as the overflow may run onto the O-ring sealing surface.

SECTION IV. Preparing to Mount the PG2000

A. Choose one of the following two methods for installation of the PG2000.

1. Mount the PG2000 on BURIED Sub-terrain Mounting Base (included). This allows the unit to be located

away from the deck, for example, in a garden near the pool, among some shrubbery, etc. Be sure the unit is

situated such that the air vents are not going to be blocked by overgrowth. The sub-terrain mounting base can

also be poured into the concrete deck or pad.

2. Mount the PG2000 directly onto a flat concrete surface or a wood deck without the Sub-terrain Base using the

lag screws, washers and anchors (included).

B. Installing the Sub-Terrain mounting base; see Figure 2 and Pictures on pg. 10.

1. If conduit has already been run, set mounting base over top of conduit to determine if the bottom flange or side

arches need to be cut. The top shoulder of the base should be at or slightly above finished landscape or deck

level.

2. Leveled base can be secured in place with 3/8 in. rebar angled through holes provided in corners of bottom

flange, see Picture 3 on pg. 10

3. Cut fiber conduit below or at top of base and cut electrical conduit 6 in. above finished landscape or deck level,

see Figure 2. See PG2000 Conduit Template on pg. 28 of these instructions.

Note

Flat side of base is back of the PG2000. Locate this side away from line of site to the PG2000.

C. Mounting to a wood deck or a poured concrete surface.

1. What you’ll need:

√ Drill with ½ in. Masonry Bit

√ Hammer

√ ½ in. Nut Driver

(continued on page 11)

Rev. C 7-29-05 9 P/N 840259

Page 10

Sub-terrain Base & Deck Installation

Tools and Material Required:

√ Hammer

√ Side Cutters

√ Phillips Screwdriver

√ Hacksaw or PVC Cutters

√ Four 12 in. lengths of 3/8 in. Rebar or Rod

√ Drill with ½ in. Concrete Bit

√ Ratchet Driver w/4 in. Extension

√ ½ in. Socket

1. Conduits set per PG2000 template.

2. Cut sub-base flanges as needed.

ELECTRIC CONDUIT IN FRONT

AND EXTENDING 6 IN.

ABOVE SUB-BASE

4. Backfill 1 to 4 in. below shoulder for mulch or concrete. Cut fiber

conduit below or at top of base.

P/N 840259 10 Rev. C 7-29-05

3. Drive 3/8 in. rebar at an angle in the corners.

ELECTRIC

CONDUIT

IN FRONT

5. For concrete deck mount, drill for two ½ in. lead shield anchors

provided and secure with lag screws and washers provided.

Page 11

2. Installing the PG2000 directly to deck.

a. Cut fiber optic conduits ½ in. above the deck. Cut electrical conduit 6 in. above deck, see PG2000

Conduit Template on pg. 24 of these instructions.

b. Remove outer body from PG2000 by removing one black #6 screw on each side at bottom. Carefully lift

outer body up and set aside with screws placed inside for safe keeping.

c. Set PG2000 subassembly on deck over conduit with electric conduit all the way to the front.

d. On concrete, mark two holes in deck and drill for provided anchors using ½ in. masonry drill bit. Tap

anchors into holes.

e. Set PG2000 subassembly aside until cables are run.

SECTION V. Feeding or Pulling the AmerGlow Cable

A. What you’ll need:

√ Electrical Tape

√ Fish tape (optional)

√ Electrician’s lube (optional)

B. Tips, tricks and traps.

• Use electrician’s lube on the cable, to help it through the conduit. Though not necessary, it can make the task

easier and quicker.

• Cover the end of the cable with electrical tape, or similar, to make a pilot tip. This will make guiding the cable

through the conduit easier. This applies whether pushing the cable through from the pool side, or pulling it

with fish tape.

• At the PG2000 location, after the cable is pulled and lenses are set, seal the conduit around the cables with

RTV silicone caulking or conduit seal kit #22002000. This will help keep debris out of the conduit during the

rest of the installation, and provide an added precaution to prevent water from entering the PG2000 should

the conduit develop a leak during its lifetime.

• Leave about 1 foot of cable extending past the end of the lens housing at the pool (only necessary if installing

lens on job location).

• Once the cable is finished and the lens is installed at the pool end, you should have a minimum of 15 in.

extending up above the PG2000 mounting location. This will allow easier installation into the PG2000. Also,

a few extra inches in the fiber bundle will accommodate fiber re-termination if the fiber ends were to become

damaged over years of service. Additionally, it allows for later addition of fibers for landscape or pool

lighting.

• If the lens assembly and/or PG2000 are not to be installed immediately, tape the ends of the cable to protect

the fiber.

CAUTION

On factory pre-cut cable, avoid manually bending the first 12 in. of cable on the lens side. This can disturb the factory termination

and prevent maximum performance of the system.

• Know your cable length - do not underestimate the cable length required. Allow 15 in. extra for pre-cut

cable and 19 in. for bulk cable from pool wall to bottom of PG2000. (Top of Sub-terrain Base.)

Rev. C 7-29-05 11 P/N 840259

Page 12

C. Pulling or feeding pre-cut cable.

1. For Standard Gunite lens housing and Fiberglass lens housing remove the spacer and spacer O-ring using

diagonal-cutters.

2. Remove the reminder tag from the cable.

3. If needed, push the fish tape through the conduit from the PG2000 side.

NOTE

In many cases, AmerGlow cable may be fed through conduit without the use of a fish tape.

4. Attach the cable to fish tape at the poolside with duct or electrical tape, cover the fibers completely with tape.

5. Reel up fish tape while second person pushes the cable from the pool side. If necessary, apply electrician’s lube

on the cable as it is fed through.

a. Keep the last foot of cable on the lens side as straight as possible.

b. Be careful not to damage the lens assembly.

6. Stop feeding the cable when one foot is left on the pool side.

a. Make sure the lens O-ring and spacer O-ring (if applicable) are in position and clean.

b. Clean the O-ring sealing surface on the inner flange of the lens housing.

7. Continue to pull the cable until the lens assembly is 1 in. away from the seated position.

CAUTION

DO NOT snug the lens into place by pulling on the cable! This may cause the cable to pull away from the lens, and will impair

performance of the Termination.

8. Place the lens retaining nut onto the lens and PUSH the lens into place.

9. Hand tighten the lens using the lens tightening tool, until the O-ring is seated.

a. For standard gunite and fiberglass lens housings (which do not use the spacer and spacer O-ring), hand

tighten ¼ turn past the seated O-ring position.

b. For Invisible Gunite and Vinyl Liner housings (which use the spacer and spacer O-ring), hand tighten the

lens retaining nut ½ turn past the O-ring’s seated position.

D. Pulling or feeding bulk cable.

1. Push the fish tape through the conduit from the pool end. In many cases, AmerGlow cable may be fed through

conduit without the use of fish tape.

2. Attach the cable to the end of the fish tape using duct or electrical tape. Cover the fibers completely with tape.

Pull cable through conduit using electrician’s lube if needed.

3. Leave about one (1) ft. of cable extending past the lens housing, and about one (1) ft. above the PG2000

mounting surface. If desired, leave cable on spool and cut to exact length after lens is assembled.

SECTION VI. AmerGlow Lens Assembly

A. What you’ll need:

√ Fiber Termination Kit, P/N 21005500. Contains: cable stripper, hot knife, spare blades, cutting shield, lens

tightening tool, and OptiFusion gel.

√ Cable Cutters

√ Wire snips

√ Channel locks

√ Crescent wrench

√ Electrical Tape

P/N 840259 12 Rev. C 7-29-05

Page 13

B. Preparing the cable.

Black Knob

NOTE

There should be about 1 foot of cable sticking out of the lens housing at this point.

WARNING

FiberKnife reaches extreme temperatures. Grasp only by the handle. Failure to follow these directions can lead to severe burns.

1. Plug in the FiberKnife and set it on the stand provided.

a. Let the knife warm up for 15 minutes. This is especially important for larger cable sizes.

b. Keep the knife out of the wind while warming, as the breeze can cool it off.

c. Allow at least 5 minutes between large cable cuts for the knife to reheat.

2. Use the cable stripping tool to strip back 1 in. of the cable jacket, see Picture 1 on pg. 14.

CAUTION

DO NOT damage any of the fibers. If the fibers are nicked they can break, reducing light output.

• Practice on some spare cable a few times. With a little practice, you will be able to make good cuts with this stripper.

• There is an extra blade inside the stripper handle.

a. Adjust the stripper and practice a few times on an extra piece of cable if you haven’t used it before. The

blade should be exposed about the thickness of the cable jacket.

b. Adjust the cutting depth by turning the black knob on the end of the cable stripper.

c. Push the spring tension guide open with thumb, and place stripper on cable as shown in Figure 3.

d. Rotate the stripper around the cable with the black knob turning toward opening; as shown in Figure 4.

e. The cable stripper blade is directional - if it does not cut

properly, be sure that the blade is in correct orientation.

f. Once jacket is almost separated remove stripper and bend

jacket to finish separation and remove jacket.

g. Fan the fiber ends to remove the excess powder from them.

3. If you are installing an invisible gunite or vinyl liner lens housing,

place the spacer with spacer O-ring onto the cable - the direction is

indicated on the spacer.

Figure 3.

4. Assemble the seal nut; see Figure 5.

a. Wrap electrical tape around the end of the fibers.

Figure 4.

b. Slide the compression nut onto the cable with the threads

toward the end.

c. Choose the correct grommet size and slide it onto the cable until

1/16 in. past the edge of the jacket. The cable size is molded

onto the back of the grommet.

d. Straighten the cable coming out of the lens housing, and try to

keep it straight from this point on.

e. Place the seal nut over the grommet and tighten compression nut.

(continued on page 15)

Rev. C 7-29-05 13 P/N 840259

Page 14

AmerGlow Lens Assembly

Tools and Material Required:

√√

√ Cable Stripper

√√

√√

√ Crescent Wrench

√√

√√

√ Hot Knife

√√

√√

√ Cutting Shield

√√

√√

√ Lens Tightening Tool

√√

√√

√ Electrical Tape

√√

√√

√ OptiFusion Gel (Standard Lens)

√√

1. Remove 1 in. of the jacket with the stripper.

GROMMET FLUSH

WITH FRONT FACE

1/16 IN. OF JACKET SHOWING

2. Add tape, spacer ( if needed), compression nut and grommet.

4. Screw on cutting shield.

3. Add seal nut and tighten.

5. Angle hotknife 15 degrees.

CHECK FOR AIR BUBBLES IN GEL

(STANDARD LENS)

6. Fill Standard Lens reservoir with gel. (No gel required in

Wide Angle Lens.)

P/N 840259 14 Rev. C 7-29-05

7. Slowly screw on lens cap.

Page 15

AmerGlow Lens Assembly Installation Steps, continued.

INVISIBLE GUNITE

LENS HOUSING

VINYL LINER

LENS HOUSING

BEFORE OR AFTER

FACE PLATE

8. Cable in fitting, use a spacer if needed.

9. Hand-tighten the retainer nut.

(4. e.) • Hold the seal nut stationary with your hand and rotate the compression nut using a crescent wrench.

• If you use channel locks to hold the seal nut, be careful not to damage the O-ring.

• Tighten the compression nut until the grommet is flush with the front surface of the seal nut (for smaller

cables) or there is only one thread left showing on the compression nut (for larger cables).

• Pull on the completed assembly to be sure cable does not move.

Compression Nut

FIBERworks Lens Housing

(Invisible Gunite shown)

Seal Nut

O-ring

Grommet - select

proper size for cable

1/16"

1"

Spacer with O-ring - use

with Invisible Gunite and

Vinyl Liner Lens Housing

Lens

O-ring

Seal Nut

Lens

O-ring

Wide

Angle

Lens

Standard

Lens

Lens Retaining

Nut

Figure 5.

Rev. C 7-29-05 15 P/N 840259

Page 16

5. Cut the fiber.

Note

This is the most critical step for a successful installation.

a. Screw the Cutting Shield onto the seal nut until it bottoms out. At this point, only fiber should be sticking

out past the edge of the cutting shield. If jacket or grommet is sticking out, disassemble seal nut assembly

and adjust the grommet position.

b. Hold the cable at the seal nut, keeping the cable straight.

CAUTION

DO NOT use too much force - you will only damage the FiberKnife and/or your cut. Let the heat of the knife do the cutting.

DO NOT saw, wiggle or rotate the blade back and forth.

On the larger cables, it may help to rotate the handle side of the blade downward slightly.

• Place the blade against the cutting shield at a 10-15 degree angle; see Figure 6.

• Press with a light to moderate constant pressure using the cutting shield ring as a guide.

• Ease up towards the end of the cut to keep the last few fibers from folding over.

6. Remove the Cutting Shield.

WARNING

Shield may be hot. Exercise caution when removing it. Failure to do so could cause burns.

7. Inspect the cut.

a. The cut should be smooth and flat, with no visible lines or surface bubbles. When training and performing

your first cuts, using a small magnifying glass can help see imperfections that may be difficult to see with the

naked eye.

b. A good professional cut is critical to the performance of the fiber optic system.

c. There are several things which can cause a bad cut:

• The cable jacket was not completely stripped back.

• Sawing or wiggling the blade during cutting, or incorrect blade angle.

• Burrs on the edge of the cutting shield.

• The FiberKnife is not warmed up enough. Allow enough time between cuts for the knife to reheat, and

keep it out of the wind while it is heating.

• The blade needs replacing about every 15 - 20 cuts; replacement pack of 3 blades, P/N 21005600.

C. Installing lenses

1. Wipe the fiber face with an Optic Prep Pad or a clean cloth to remove any

residual powder.

2. If using the Standard Lens, fill the entire gel cup located on the inside of the

lens with OptiFusion gel until it crests above the gel cup edge. If using the

Wide Angle Lens, NO GEL IS REQUIRED, see Picture 6 on pg. 14.

Fiber Knife

Blade

3. Assemble the lens to the seal nut.

a. Make sure the lens and seal nut O-rings are clean and in place.

b. Hold the compression nut with a wrench and hand tighten the lens onto

the seal nut until lens bottoms out. Keep the end of the cable straight

during this step.

P/N 840259 16 Rev. C 7-29-05

Cutting Shield

Figure 6.

Page 17

4. Install the lens into the lens housing.

a. If applicable, make sure the spacer and spacer O-ring are in position and clean. The spacer is marked

“This Side Toward Pool”.

b. Clean the O-ring sealing surface on inner flange of lens housing.

c. Feed or pull the cable until the lens assembly is about 1 in. away from the seated position.

CAUTION

DO NOT seat lens housing by pulling on cable. This may cause the cable to pull away from the lens, and impair light performance.

d. Place the lens retaining nut onto the lens and PUSH the lens into place.

e. Hand tighten the lens using the lens tightening tool, until the O-ring is seated.

• For Standard Gunite and Fiberglass lens housings (which do not use the spacer and spacer O-ring),

hand tighten ¼ turn past the seated O-ring position.

• For Invisible Gunite and Vinyl Liner housings (which use the spacer and spacer O-ring), hand tighten

the lens retaining nut ½ turn past the O-ring’s seated position.

FIBERworks makes your job easier:

For vinyl liner pools, the lens is sealed in the lens body before the liner is installed. You do not need to install the seal plate and cut your liner

until the pool is completely filled.

SECTION VII. Installing the Ferrule Assembly, see Pictures on pg. 19

A. Preparing and installing the cable

WARNING

FiberKnife reaches extreme temperatures. Grasp only by the handle. Failure to follow these directions can lead to severe burns.

1. Plug in FiberKnife, and allow to heat for 15 minutes, out of the wind.

2. Mechanically cut all cables to equal length about 14 in. above the top of the Sub-terrain Base.

3. Use the cable stripping tool to strip back cable jacket 0 to 2 in. above the PG2000 base.

a. Adjust the stripper and practice a few times on an extra piece of cable if you haven’t used it before.

The blade should be exposed about the thickness of the cable jacket.

b. Adjust the cutting depth by turning the black knob on the end of the cable stripper.

c. Push the spring tension guide open with thumb, and place stripper on cable as shown in Figure 3.

d. Rotate the stripper around the cable with the black knob turning toward opening; as shown in Figure 4.

e. The cable stripper blade is directional - if it does not cut properly, be sure that the blade is in correct

orientation.

f. Once jacket is almost separated remove stripper and bend jacket to finish separation and remove jacket.

g. Fan the fiber ends to remove the excess powder from them.

B. Loading the fiber into the ferrule

1. Gather all of the stripped cable ends together evenly and apply ONE wrap of electrical tape around the fibers

at the end.

a. Fan the fiber ends to remove any excess powder from between the fibers.

Rev. C 7-29-05 17 P/N 840259

Page 18

b. Arrange the bundle so that the fibers from the primary pool/spa underwater lenses or perimeter cable are

mixed together and lie in the center of the fiber bundle. Locate less important fibers on the outside of the

fiber bundle. Shine a flashlight from the lens back to the PG2000 to help identify the fibers.

c. If the total number of fibers is less than 200 then add additional fibers to the fiber bundle until the total

number of fibers is either 100 or 200. These additional fibers should be at least 6 inches long and arranged

on the outside of the fiber bundle.

WARNING

Fibers outside the 400 fiber bundle diameter do not provide adequate light output for primary pool/spa underwater lenses or

perimeter cable. Outer 200 fibers are intended only for accessory lighting. For primary pool/spa lighting and perimeter cable

use only the center 400 fibers. If 600 fibers are installed into the ferrule and all cables are of nearly equal importance and length,

mix all of the fibers together in the ferrule assembly. Failure to provide adequate lighting can result in swimming and diving

hazards that can cause severe injury or death.

2. Select the proper compression nut and grommet for the number of fibers; see Table 2.

3. See Table 2 to determine if the ferrule insert is needed in the assembly.

4. Slide the compression nut, grommet, ferrule insert (if applicable, smaller diameter pointing out), and then ferrule

body onto the fiber bundle, see Figure 7 for proper orientation. Leave about 3 to 4 inches of fiber sticking out

past the two posts on the top of the ferrule.

Table 2

Number Compression Nut Grommet (size indicated Ferrule Insert

of fibers (check inner dia.) on back except 400 (located on disk tree)

and 600 grommet)

100 Small I.D. 70 yes

200 Small I.D. 225 yes

200-300 Small I.D. 225 yes

300-425 Small I.D. 325 yes

425-500 Small I.D. 400 (small I.D. cylinder) no

500-600 Large I.D. 600 (large I.D. cylinder) no

5. Tighten the compression nut until the fibers are securely held by the ferrule assembly.

a. DO NOT use ferrule mounting flanges for leverage when tightening

assembly as they may break off. Make sure fibers are not twisted or

tangled.

b. Pull on the fiber bundle to verify fibers are held securely by ferrule

assembly. It may be necessary to apply a few wraps of electrical tape

underneath the grommet to ensure a good grip.

6. Install the fiber disk onto the ferrule assembly.

a. Choose the correct metal fiber disk according to the number of fibers. The

maximum fiber capacity is on each disk. See Table 3 for the proper metal

fiber disk size.

F

IBERRANGE

.3ELBAT

N

UMBER ONNEW

M

ETALFIBERDISK

ylno001001

ylno002002

522-502522

552-032552

092-062092

CAUTION

This unit is designed for use with new metal fiber disks in the ferrule assembly. Install unit

using only new metal fiber disks like those included with this parts kit. Use of original plastic

disks with this unit may lead to failure of fiber cable.

033-592033

004-533004

594-504594

006-005006

(Continued on page 21)

P/N 840259 18 Rev. C 7-29-05

Page 19

Ferrule Assembly Installation Steps,

as detailed in Sec. VIII A - D.

Tools and Material Required:

14 IN.

√√

√ Cable Cutters

√√

√√

√ Crescent Wrench

√√

√√

√ Phillips Screwdriver

√√

√√

√ Electrical Tape

√√

2. Strip jackets from 0 to 2 in. above the base.

KEEP FINGERS

OFF "EARS"

√√

√ Cable Stripper

√√

√√

√ Hot Knife

√√

√√

√ Cutting Shield

√√

1. Cut all cables 14 in. above Sub-terrain Base.

TAPE OVER THE END

OF THE BUNDLE

4 IN. OF FIBER

PAST "POSTS".

USE FERRULE "INSERT" IF

LESS THAN 425 FIBERS.

3. Assemble comp. nut, grommet, and ferrule body.

4. Securely tighten the ferrule assembly.

6. Select the correct "numbered" fiber disk.

Rev. C 7-29-05 19 P/N 840259

5. Pull on ferrule to check tightness.

7. Snap disk into "ears".

Page 20

Ferrule Assembly Installation Steps, continued.

"POSTS" AT

TOP & BOTTOM

8. Screw on the cutting shield.

10. Inspect the cut, no lines or "puddles".

TOTALLY COVER THE EAR

9. Hot knife cut, at a 15 deg. blade angle.

11. Set PG2000, but do not screw to base.

12. Tip PG2000 back and secure "ears" under thumb screws.

14. Carefully install outer body.

P/N 840259 20 Rev. C 7-29-05

13. Secure PG2000 to base with 4 screws provided.

15. Secure outer body with two screws.

Page 21

b. Slide the fiber disk, tapered end down, over the fiber bundle. Snap the fiber disk into the fiber disk support

posts on the ferrule.

CAUTION

Make sure there is enough slack in the cable(s) to be put in place. There should be about 3-4 in. of slack in the fiber bundle. If

not, readjust the ferrule accordingly. This will provide ample fiber for future trimming of bundle required about every 5 years.

C. Cut the fiber, see Pictures on page 20.

1. Place the Cutting Shield onto the ferrule assembly and thread on until it bottoms out.

2. Hold the cable and ferrule assembly so the support posts are at the top and bottom (not on the sides), keeping

the cable and fiber bundle as straight as possible.

3. Place the FiberKnife blade against the Cutting Shield guide

ring at a 10-15 degree angle starting at the top Support

Post.

Fiber Disk

IMPORTANT

Press with a light to moderate constant pressure using the cutting shield

ring as a guide. IMPORTANT: Do not rush - allow 3 – 4 minutes to cut

600 fibers.

DO NOT use too much force - Let the heat of the knife do the

cutting.

DO NOT saw, wiggle or rotate the blade back and forth.

On the larger fiber bundles, it may help to rotate the handle side

of the blade downward slightly.

a. Ease up towards the end of the cut to keep the last few

fibers from folding over.

4. Remove Cutting Shield and wipe the fiber face with an optic

prep pad or clean cloth. This removes any residual powder.

WARNING

Shield may be hot. Exercise caution when removing it. Failure to do so

could cause burns.

5. Inspect the cut.

Fiber Disk

Support Posts

Ferrule

Mounting

Flanges

Ferrule Insert

(less than 425 fibers)

Ferrule Body

Grommet

Compression Nut

Figure 7.

a. The cut should be smooth and flat, with no visible lines or surface bubbles. When training and performing

your first cuts, use of a small magnifying glass can help see imperfections that may be difficult to see with the

naked eye.

b. A good professional cut is critical to the performance of the fiber optic system. There are several things

which can cause a bad cut:

• Sawing or wiggling the blade during cutting.

• Holding the blade at an incorrect angle.

• Burrs on the edge of the cutting shield.

• The FiberKnife is not warmed up enough. Allow enough time between cuts for the knife to reheat, and

keep it out of the wind while it is heating.

• The blade needs replacing (about every 15 - 20 cuts. Pack of 3 blades, P/N 21005600).

Rev. C 7-29-05 21 P/N 840259

Page 22

SECTION VIII. Installing the PG2000

A. Preparation.

1. Seal the conduit around the cable with RTV silicone or conduit seal kit #22002000 to prevent water from

entering or leaking from the conduit.

2. Remove outer body from PG2000 by removing one black #6 screw on each side at bottom. Carefully lift outer

body up and set aside with screws placed inside or in a pocket for safe keeping.

3. Remove bag of screws from back of Sub-terrain mounting base (if used) and put inside outer body or pocket

for safe keeping.

4. Holding the PG2000 by the bottom or the two Black posts in front, carefully set it down over the ferrule fiber

bundle and electrical conduit. (Do not secure to base or deck at this time.)

B. Connecting the ferrule bundle.

1. Tip PG2000 back and twist lock the ferrule assembly into the optic port (hole) and the retaining screws under

the PG2000 light bulb.

3. Be sure that the ferrule "ears" are securely against both screws and tighten the thumbscrews.

• The ferrule body should be centered in the optic port. The alignment of the ferrule assembly is CRITICAL

to the performance of the fiber optic system.

C. Mounting the PG2000 to the Sub-terrain Base.

1. Secure PG2000 to Sub-terrain Base (if used) using the screws provided in the package taped to the Sub-terrain

Base and set aside in step A-3.

D. Mounting the PG2000 to a wood or concrete deck.

1. First see Section IV, C., in this manual.

2. Secure PG2000 to the wood deck or into the anchors previously installed in the concrete using the lag screws

and washers provided in the PG2000 parts bag.

E. Wiring the PG2000.

WARNING

RISK OF ELECTRICAL SHOCK OR ELECTROCUTION

This PG2000 must be installed by a licensed or certified electrician in accordance with the National Electrical Code and

all applicable local codes and ordinances. Improper installation will create an electrical hazard which could result in

death or serious injury to pool users, installers, or others, due to electrical shock, and may also cause property damage.

P/N 840259 22 Rev. C 7-29-05

Page 23

1. For manual operation, operation by a single remotely located toggle switch or automatic control button,

(such as Compool® or IntelliTouch®), or for use with optional RF2000 Wireless Control, (P/N 840069).

See Figure 8 for proper setting of the toggle switches on bottom of the PG2000.

PG2000 Manual, Single Remote Switch or

RF2000 Wireless Control Wiring Schematic

Optional Remote Switch

1 Toggle Switch

Service

Panel

or

1 Compool/IntelliTouch Relay

PG PG

Neutral

Ground

Line

Green

Black

White

This application requires that only three, minimum #18 gauge, wires be run to the unit (black/white/green).

Connect Black supply wire to Black wire in unit, Connect White to White and Green to Green.

NOTE: YELLOW WIRE IS NOT USED IN THIS CASE.

TOGGLE SWITCH POSITIONS

MANUAL CONTROL

POWER

OFF

COLOR

OFF

POWER

ON

COLOR

ON

REMOTE SWITCH CONTROL

POWER

COLOR

RF2000 WIRELESS CONTROL

POWER

COLOR

Figure 8.

Rev. C 7-29-05 23 P/N 840259

Page 24

2. For operation by two remotely located toggle switch or automatic control buttons, (such as Compool® or

IntelliTouch®). See Figure 8 for proper setting of the toggle switches on bottom of the PG2000.

PG2000 Dual Remote Switch

Wiring Schematic

2 Toggle Switches

or

2 Compool/IntelliTouch Relays

Service

Panel

PG PG

Yel

Line

Neutral

Green

Ground

This application requires that four, minimum #18 gauge, wires be run to the unit (black/red/white/green).

Connect Black supply wire to Black wire in unit, Connect Red to Yellow, White to White and Green to Green.

Connect the Black wire to the Light Bulb power switch or relay and the Yellow/Red wire to the Color Wheel

power switch or relay. Provide a jumper wire from the load side of the Light Bulb switch or relay to the supply

(line) side of the Color Wheel switch or relay. This will prevent the color wheel from turning when the light bulb

is not turned on. For automatic control system such as Compool®, refer to the controller's manual to determine

which buttons operate the two relays.

A note about FreedomSynchTM PG2000's (840242) wiring and operation.

The wiring for these units is exactly the same as for all other PG2000s. Units can be connected in parallel or in series. All synchronization is self

contained within the unit’s electronics, and is locked to the 60 Hz AC power line. If there is more than 100 ft. difference between wire lengths of the

first and last PG2000 in a series, increase the wire gauge to reduce line losses that might prevent the synchronization circuitry from operating

properly once the colorwheels are turned on simultaneously, it will take about 1½ minutes for the colors to synchronize. Please refer to the Owner’s

Manual for proper operation of these models.

Black

Red

White

Yel

F. Carefully place outer body back onto the PG2000 and secure with two black #6 screws (previously set

aside) at the bottom.

G. Test functionality of unit.

NOTE

When cycling system off, then back on, it may take up to 3-4 minutes before the lamp "restrikes"

or comes back on. The lamp must cool down before restriking. All metal halide lamps have this

characteristic and this is a normal function of the PG2000.

P/N 840259 24 Rev. C 7-29-05

Page 25

SECTION IX. Sychronization of SAm®/SAL® and FIBERworks® (Wiring Diagrams)

PG2000 & S

Service

Panel

Line

Neutral

Ground

Am

or S

AL

Synchronization Switch

Wiring Schematic

3 Toggle Switches

or

3 Compool/IntelliTouch Relays

Black

Black

White

Green

Red

PG2000

#840242

Yel

SAm/

SAL

NOTE

There may be slight color variations between the SAm®/SAL® and PG2000 depending on the application. These variations are caused

by differences in initial light intensity and attenuation of the water and/or reflective surfaces (i.e. pool wall coloring).

In order for instructions to work you must have P/N 840242 – 7 Color, Electronic Synchronized PG2000

(all other part numbers must use visual synchronization method).

A. Compool® Programming

1. If you use a Compool system, you can automate the process by programming two identical start and run

times for the SAm® or SAL® auxiliary channel(s). (i.e., Program 1 - ON: 8:00 PM, Run Time: 4 Hours;

Program 2 - ON: 8:00 PM, Run Time: 4 Hours.) The two channels for the PG2000 should be

programmed to come on only one time. (i.e., Program 1 - ON: 8:00 PM, Run Time: 4 Hours).

Of course, you could also program SAm®, SAL® or FIBERworks® to run alone or even out of

synchronization if desired.

B. IntelliTouch® Programming

If you use an IntelliTouch system, you can automate the process by identifying the applicable circuit as a SAm®,

SAL® or Color Wheel (go to MENU/SETUP/ADVANCED/CIRCUIT FUNCTIONS). Once this is done, you will

have the option in the Programming to set these circuits to "SMART START". All circuits set to "SMART

START" and programmed to come on at the same time will automatically synchronize.

(continued on next page)

Rev. C 7-29-05 25 P/N 840259

Page 26

C. PG2000 Synchronization Procedures with SAm/SAL light

Listed below are the procedures to follow if you have a SAm/SAL underwater color light installed in your pool or

spa and wish to synchronize your fiber optics with SAm/SAL.

D. Synchronization Start Conditions

1. SAm/SAL is ON and colorwheel is stopped on ANY color (including white).

2. PG2000 power is ON and the colorwheel is OFF.

E. Synchronization Procedure

1. Simultaneously toggle SAm/SAL OFF/ON and turn the PG2000 colorwheel ON.

2. Allow about 1½ minutes for colors to synchronize. Enjoy!

3. To stop both lights on the same color, simultaneously toggle SAm/SAL OFF/ON and turn the PG2000

colorwheel OFF.

F. Visual Synchronization Method (for use with P/N 840241 only)

1. Turn SAm/SAL ON, colorwheel is stopped on ANY color (including white).

2. Turn PG2000 ON and colorwheel ON.

3. When PG2000 transitions between purple and magenta toggle SAm/SAL OFF/ON.

4. To stop both lights on the same color, simultaneously toggle SAm/SAL off and on while turning the PG2000

colorwheel off.

P/N 840259 26 Rev. C 7-29-05

Page 27

SECTION X. Technical Data

A. Replacement Parts

Item No. Part No. Description

1 840321 Body assy., w/mounting screws

2 23506100 Screw, #6 x 3/8 in., Pph mach., black

3 840323 Socket

4 840322 Fan

5 840188 Reflector

6 23505600 Fuse, 3 amp

7 840219 Switch, toggle

8 840220 Boot, toggle

9 840233 Ferrule nut, #10-24, knurled

10 840324 Colorwheel assy.

11 840236 Fuse, 1/2 amp

12 840304 Capacitor

13 840211 Bulb, 150w, MH

NOT SHOWN

840325 Ferrule assy.

SAVE THESE INSTRUCTIONS.

Rev. C 7-29-05 27 P/N 840259

Page 28

PG2000® Conduit Template

A

Electrical ............................................ C

AmerGlow 100, 170, 225, 325 ........ B,C

AmerGlow 12, 30, 50, 70 ........... A, B, C

B

C

Pentair Water Pool and Spa, Inc.

1620 Hawkins Ave., Sanford, NC 27330 • (919) 566-8000

10951 West Los Angeles Ave., Moorpark, CA 93021 • (805) 523-2400

© 2005 Pentair Water Pool and Spa, Inc. All rights reserved.

This document is subject to change without notice.

Trademarks and Disclaimers. The Pentair Water Pool and Spa logo is a trademark of Pentair Water Pool and Spa, Inc. PG2000, FIBERworks, SAm, SAL, Amerlite, AquaLight,

HiLite, Compool, and IntelliTouch are registered trademarks of Pentair Water Pool and Spa, Inc. Other trademarks and trade names may be used in this document to refer to either

the entities claiming the marks and names of their products. Pentair Water Pool and Spa, Inc. disclaims any proprietary interest in trademarks and trade names other than its own.

P/N 840259 28 Rev. C 7-29-05

Loading...

Loading...