QUICK START GUIDE

PENTEK INTELLIDRIVE™ XL

Before beginning any installation, review Danfoss

Operating Instructions for VLT

®

AQUA Drive FC 202

0.25–90 kW (130R0336) for complete instructions

and warnings. This guide neither supplements nor

replaces the Owner’s Manual.

Welcome to your new Pentek Intellidrive XL. Please review

the following information to setup your drive for constant

pressure applications.

For further information please reference the Danfos Design

Guide for VLT AQUA Drive FC 202 (130R0337) and the

Danfoss Programming Guide for VLT AQUA Drive FC 202

(130R0338).

Safety

death. Ground pump before connecting to power supply.

Disconnect power before working on system

components.

California Proposition 65 Warning

chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm.

Hazardous voltage. Can shock, burn, or cause

Wire pump motor for correct voltage. See motor

nameplate.

Ground motor to drive before connecting to power

supply.

Meet National Electri cal Code, Canadian Elec tri cal

Code, and local codes for all wiring.

This product and related accessories contain

Basic Wiring for Constant Pressure using a

4-20mA Pressure Transducer

Refer to the Danfoss Operating Instructions for complete

information on wiring the drive. The steps listed below are

required for constant pressure operation with a 4-20mA

pressure transducer.

Set the DIP Switch

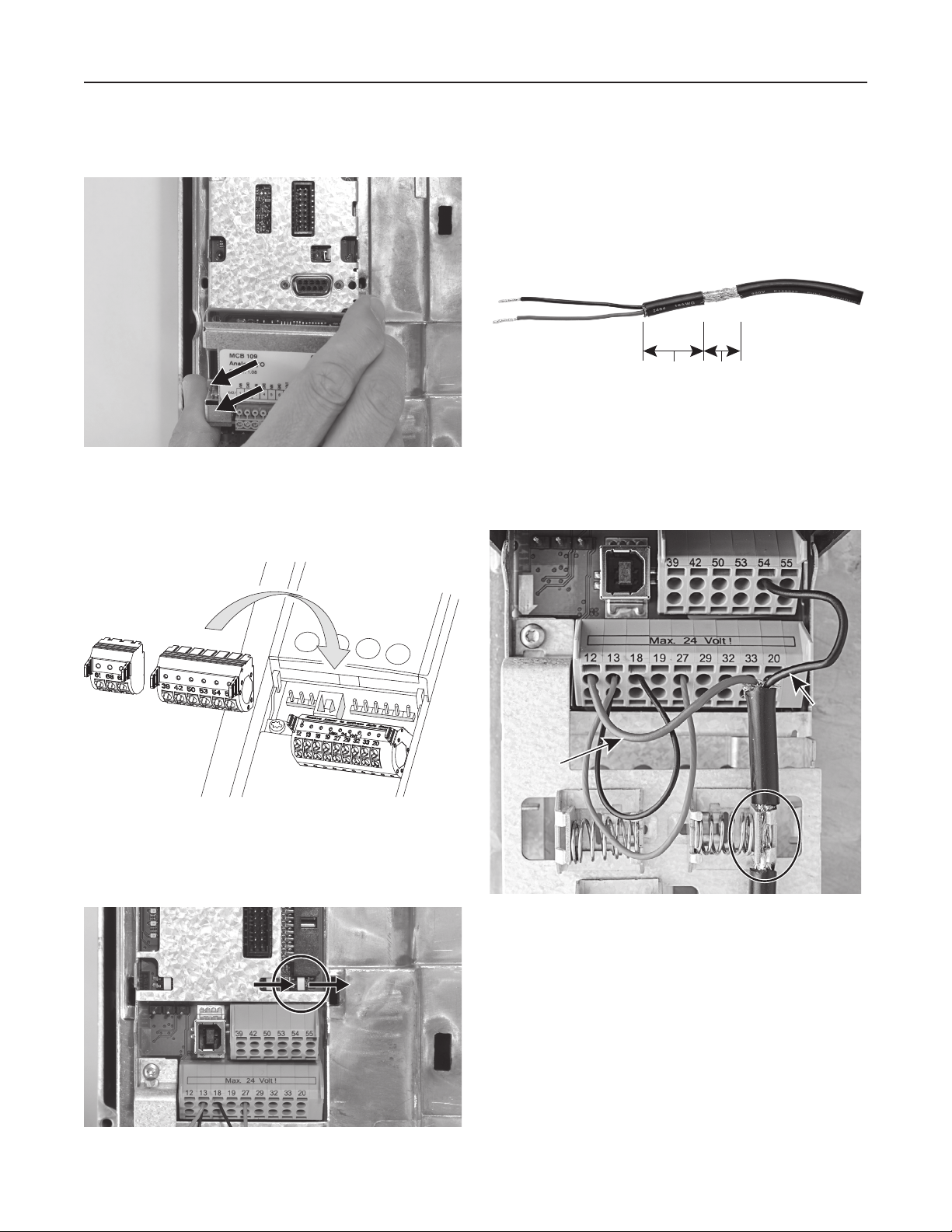

Step 1: Remove Keypad and Keypad Holder

The keypad holder is secured to the drive with four tabs.

Gently squeeze the keypad holder at the top and bottom

near where the holder is attached to the drive. See Figure 2.

Figure 2.

Once the holder has been loosened, pull the keypad and

keypad holder off of the drive. See Figure 3.

Figure 3.

Navigation

buttons

Drive

operation

Status

Off Remote Stop

Quick

Status

Menu

Back

On

Warn.

Alarm

Hand

On

O

Main

Menu

OK

Auto

1 (1)

System

display

Alarm

Log

Access SmartStart

Info

and common

parameters

On-board

help

Fault

reset

Cancel

Reset

On

Figure 1. Local Control Panel — Your interface to the

drive.

293 WRIGHT STREET, DELAVAN, WI 53115 www.BerkeleyPumps.com

PH: 888-237-5353 ORDERS FAX: 800-321-8793

© 2016 Pentair plc. All Rights Reserved. PN1011 (Rev. 10/05/16)

Basic Wiring 2

Step 2: Remove the MCB 109 Option Card

Grasp the card and pull straight out from the drive. See

Figure 4.

Figure 4.

Step 3: Install terminal block.

Retrieve the terminal blocks from the Accessory Bag and

install as shown. See Figure 5.

Step 5: Reassemble the components

Put the components back on the drive. To avoid damaging

the option card and keypad, please use care during the

reassembly process.

Prepare Transducer Cable

Remove insulation to expose cable shielding. See Figure 7.

Cut off green wire (if applicable).

1-1/2”

40 mm

Figure 7.

5/8”

16 mm

Wire the Pressure Transducer

The Black wire goes to Terminal 54. The Red wire goes to

Terminal 12. Clamp the bare spot on the cable to ground the

shielding. See Figure 8.

Figure 5.

Step 4: Set A54 dip switch

Using a small screwdriver, move the switch to the right. See

Figure 6.

Figure 6.

Black

wire

Red

wire

Figure 8.

Install Jumper Wires

Install an 18 - 22 AWG Jumper wire between Terminal 13

and Terminal 27. Install a second Jumper wire between

Terminal 13 and Terminal 18. See Figure 8.

Software Setup 3

ATTENTION: Before programming, the system must be able to be primed and then run with a

closed valve to teach the drive about no flow operation.

1

2

English?

Yes

To Next Step

No

OK

Select

language

OK

OK

3

Ag/Irrigation?

Yes

To Next Step

No

OK

Select

OK

Allow 3 to 5 seconds for the drive to configure. Please wait until the screen shows Step 5

before proceeding.

4

OKOK

Move between

characters and

set values

To Next Step

Software Setup 4

5

6

Above

Yes

To Next Step

Select Motor Power

Select Motor Voltage

No

OK

Select

OK

OKOK

OKOK

To Next Step

7

8

Select Motor Current

OKOK

Enter Motor Nominal Current

Select Motor Speed

OKOK

To Next Step

OK

To Next Step

Software Setup 5

9

OK

To Next Step

The next step runs the drive manually. That step

(and the following steps) should be performed with

no flow in the system (i.e. with a closed valve). The

drive is learning about Sleep and Dry Run and to do

this properly, there should not be any flow in the

system – including flow into a pressure tank.

10

Hand

On

O

Ramp up the frequency (motor speed) until

the display indicates 30 Hz. Verify motor

rotation and fill pipes.

With a closed valve, slowly increase the

frequency (motor speed) to 50 Hz. Monitor

pressure on the display during ramp up to

avoid over pressurizing the system. Once

the drive has reached 50 Hz and a safe and

stable pressure, press the OFF button. If the

system over pressurizes before getting to

50 Hz, press OFF button and go to Appendix

A – Manual Sleep Setup to complete the drive

setup.

Software Setup 6

11

12

13

Quick

Menu

OK

To SmartStart

OKOK

Enabled

OK

14

15

Make sure the system is primed and a valve is closed.

Hand

On

Loading...

Loading...