Pentair P42B0005A1-01, P42B0007A2-01, P42B0015A2-01, P42B0010A2-01, P42B0005A1 Electronic Manual

...

®

pentek

ElEctroNics MaNual

inStallatiOn • OPeratiOn • MaintenanCe

WWW.pUMpS.COM

Table of Contents

SECTION 1: General Safety Guidelines

SECTION 2: Nomenclature

2.1 Motors

Driv

2.2

2.3

es

Submersibl

e Motor Controls

SECTION 3: Installation and Setup

3.1 General Installation Guidelines

Proper Gr

3.2

3.3

Corrosiv

Check Val

3.4

3.5

St

ounding

e Water and Ground

ves

art-Up

SECTION 4: Electrical Power

4.1 Mixing Wire Size with Existing Installation

Wire Splicing

4.2

4.3

3-Phase Start

Checking Motor R

4.4

4.5

3-Phase Current Balancing

Transformer Sizing

4.6

Using a Generat

4.7

4.8

Special Applications

ers

otation

or

SECTION 5: XE Series 4” SubmersibleMotors

5.1 Motor Inspection

5.2 Testing

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

age and Transportation

Stor

4” Motor Specific

4” Motor Dimensions

4” Motor Fuse Sizing

Cable Lengths

4” Motor Ov

Motor Cooling

Starting F

ations

erload Protection

requency

SECTION 6: Pentek® 6” Submersible Motors

6.1 Motor Inspection

6.2 Testing

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11 Troubleshooting

age and Drain/Fill Instructions

Stor

Motor Specific

Motor Dimensions

Motor Fuse Sizing and Cable Selection

Overl

Motor Cooling

Head Loss In Casing

oad Protection

Starting F

ations

requency

SECTION 7: Hitachi® 6” Submersible Motors

7.1 Motor Inspection

7.2 Testing

7.3

7.4

7.5

7.6

7.7

7.8

7.9

7.10

7.11 Troubleshooting

age and Drain/Fill Instructions

Stor

Motor Specific

Motor Dimensions

Motor Fuse Sizing and Cable Selection

Overl

Motor Cooling

Head Loss In Casing

oad Protection

Starting F

ations

requency

SECTION 8: Pentek Intellidrive™ Variable

Frequency Drives

8.1 General Safety

Description

8.2

8.3

8.4

8.5

8.6 I/O Connections

8.7

8.8 Troubleshooting

8.9 Warranty

tallation

Ins

Initial Startup Pr

Advanc

Wiring Sizing, Repair P

ed Programming

ogrammingProcedure

arts, Specifications

SECTION 9: PPC Series 50/60 Hz Variable

Frequency Drives

9.1 Pentek PPC-Series Drives

PPC3 Series Specifications

9.2

9.3

PPC5 Series Specifications

Wiring Connections

9.4

9.5

ansducer Connection

Tr

9.6 Pentek Assistant

Timer Function

9.7

9.8

Helpful Hints

PPC3 and PPC5 Tank Sizing

9.9

9.10

React

ors And Filters

SECTION 10: PPX NEMA Pump Panels

10.1 Description

SECTION 11: Submersible Motor Controls

11.1 How it Works

Specific

11.2

11.3

Mounting and Inst

11.4

ations

allation

Wiring Connections and Replac

ement Parts

SECTION 12: Motor Protective Devices - 50/60 Hz

12.1 How They Work

Specific

12.2

12.3

Mounting And Inst

Wiring Connections

12.4

ations

allation

SECTION 13: Troubleshooting

13.1 Pump And Motor Problem Analysis

Motor T

13.2

13.3

Tes

13.4

13.5 Submersible Controls Troubleshooting

roubleshooting Flow Charts

ting Submersible Motor Insulation and Winding

Resistance

Smart Pump Prot

ector Troubleshooting

SECTION 14: Appendix

14.1 Installation Checklist

Choosing A Pump Sy

14.2

14.3

Sizing Submersibl

How t

14.4

14.5

14.6 Record of Installation

Hitachi® is a registered trademark of Hitachi Industrial Equipment Systems Co., Ltd.

All other brand or product names are trademarks or registered trademarks of Pentair Ltd.

o Select the Correct Pumping Equipment

Sizing Tank

s

stem

e Pump, Motor, and Tanks

© 2013 PN793 (08/20/13)

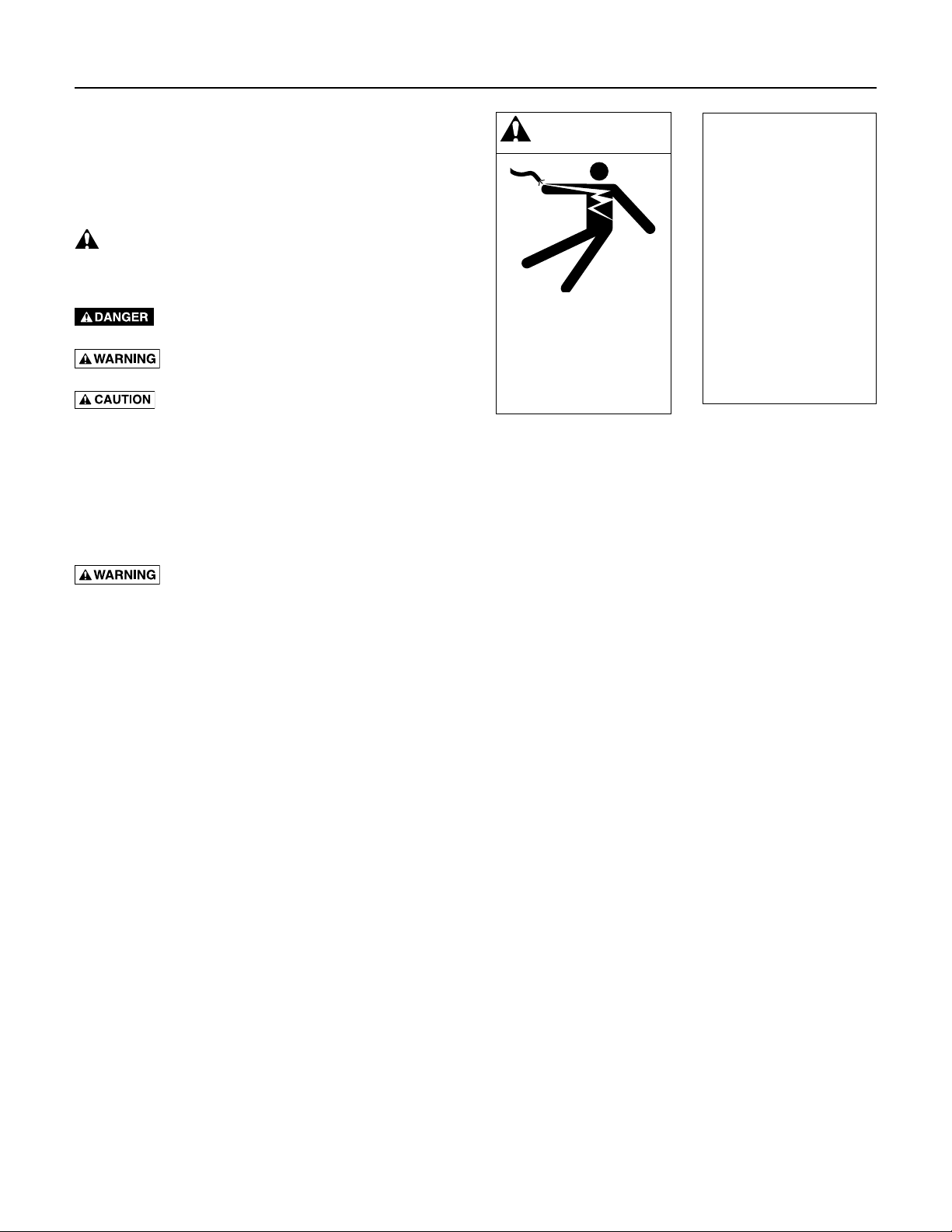

SECTION 1: General Safety Guidelines

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

Always refer to the equipment owner’s manual for safety

information relevant to that product.

This is the safety alert symbol. When you see this

symbol on your product or in this manual, look for one of

the following signal words and be alert to the potential for

personal injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

indicates a hazard which, if not avoided,

could result in death or serious injury.

indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE addresses practices not related to personal

injury.

Carefully read and follow all safety instructions in this

manual and on product.

Keep safety labels in good condition.

Replace missing or damaged safety labels.

Fatal Electrical Shock Hazard.

• Groundmotor,controls,allmetalpipeand

accessories connected to the motor, to the power

supply ground terminal. Ground wire must be at least

as large as motor supply cables.

• Disconnectpowerbeforeworkingonthesystem.

• Donotusethemotorinaswimmingarea.

WARNING

Hazardous voltage. Can

shock, burn, or cause death.

Ground pump before

connecting to power supply.

Disconnect power before

working on pump, motor

ortank.

All work

must be done

by a trained

and qualified

installer

or service

technician.

2

SECTION 2: Nomenclature

2.1 Motors

Table 2-1: Motor Nomenclature

Sample:

P43B0010A2-01 is a PENTEK 4” Stainless Steel Motor

1 HP, 60 Hz., 230 V, 1 Ph., Rev. 1

Nomenclature

Name Plate Example:

Brand

P = PENTEK

Motor Size

42 = 4 inch, 2-wire

43 = 4 inch, 3-wire

Motor Material

B = All stainless steel

S = CBM

Horsepower

0005 = 1/2 HP

0007 = 3/4 HP

0010 = 1 HP

0015 = 1-1/2 HP

0020 = 2 HP

0030 = 3 HP

0050 = 5 HP

0075 = 7-1/2 HP

0100 = 10 HP

P 43 B 0 0 1 0 A 2 -01

Frequency

A = 60 Hz.

B = 50 Hz.

C = 50/60 Hz.

Voltage

1 = 115 V, 1 Ph.

2 = 230 V, 1 Ph.

3 = 230 V, 3 Ph.

4 = 460 V, 3 Ph.

5 = 575 V, 3 Ph.

8 = 200 V, 3 Ph

Revision Code

3

SECTION 2: Nomenclature

Ser

SMC_(Std.

SMC5 (50 Hz)

SMC - CR 50 2 1

1 (Single)

PID – 10

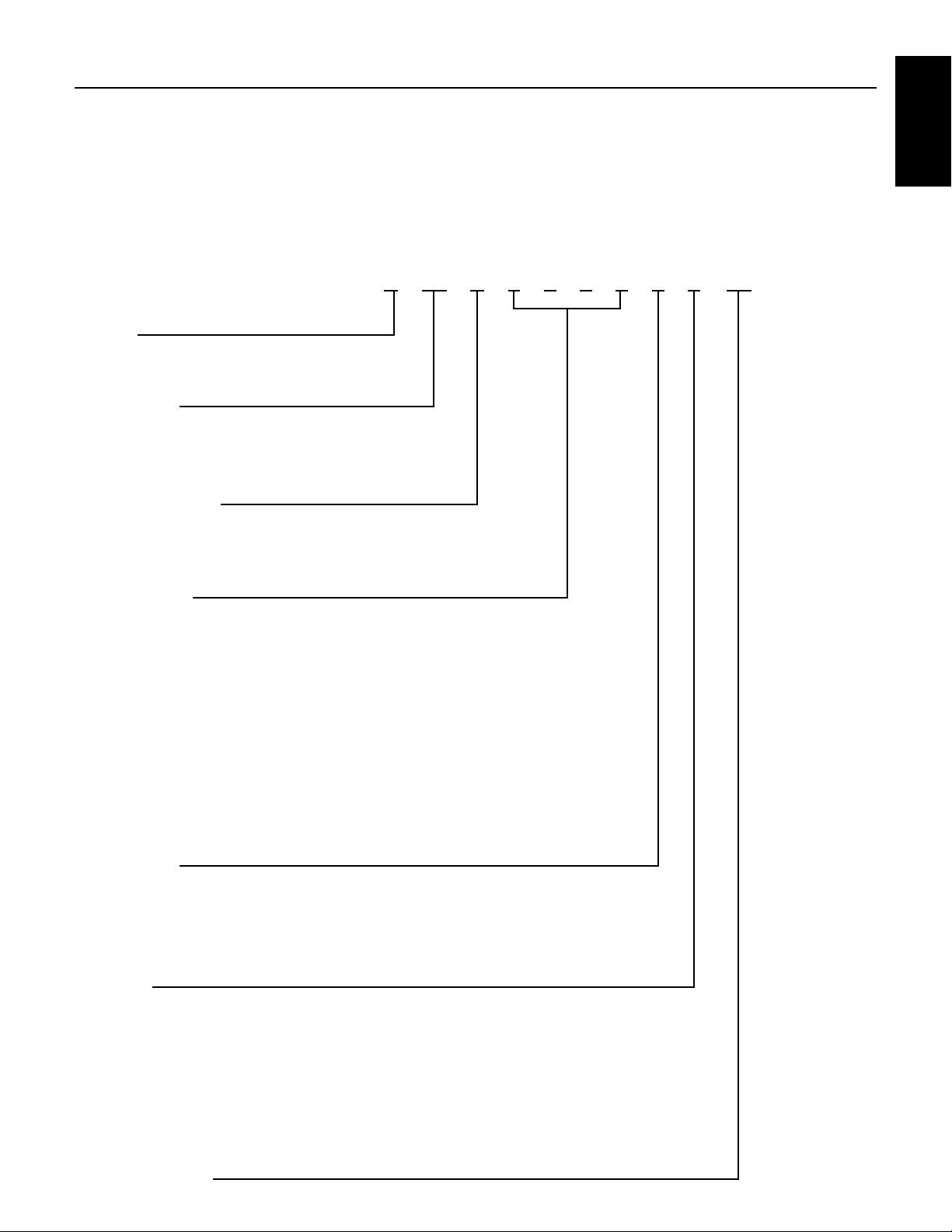

2.2 Drives

Variable / High Speed Drive Nomenclature

The chart below shows the naming for a PPC5, 460 volt,

4amp drive with a NEMA 1 enclosure.

Note that the output current (amps) of the control must

be greater than or equal to the maximum rated motor

current. Output of all drives is 3-phase power.

PID Variable Frequency Drive Nomenclature

Product Family

PID = Pentek IntelliDrive

HP Rating:

10 = up to 1 HP

20 = up to 2 HP

50 = up to 5 HP

2.3 Submersible Motor Controls

The chart below shows the naming for a Submersible

Motor control, Standard box, capacitor run, 5horsepower,

230 volt single phase drive.

ies

Style

)

CR (Cap Run)

IR (Induction Run)

CRP (Cap Run

with contactor)

HP x 10

05 (0.5 hp)

07 (.75 hp)

10 (1 hp)

15 (1.5 hp)

20 (2 hp)

30 (3 hp)

50 (5 hp)

Voltage

1 (115 v)

2 (230 v)

Phase

4

SECTION 3: Installation and Setup

3.1 General Installation Guidelines

• Inordertoavoidabrasiontothepowerandcontrol

cables, pad the top of the well casing (a rubber pad is

recommended) where the cable will pass over it; use

a cable reel for cable control.

• Theunitmustalwaysbeeasytorotateinthe

hoistinggear.

• Laypowerandcontrolcablesoutstraightonthe

ground (no loops) before installation. Guide cables

during lowering so that they are not stretched or

squeezed while pump is being installed. Make sure

that cable insulation is not nicked or damaged before

or during installation. Never use the electrical cables

to move the motor/pump.

• Thepumpandmotorareheavy.Makesurethatall

connections are secure and that the hoisting gear is

adequate to do the job before starting to lift pump.

Don’t stand under the unit. Don’t allow extra people

into the area while hoisting the unit.

• Ifmotororpump/motorunitareattachedtoa

supporting girder, do not remove girder until unit

isvertical.

• Installpumpatleast10’(3m)belowthelowestwater

level during pumping, but at least 6’ (2m) above the

bottom of the well.

• 6”motorscanbeoperatedinverticalorhorizontal

(when lead wire is at 12:00 position facing motor

flange) positions.

• 4”motorscanbeoperatedinverticalorhorizontal

positions. Note that the thrust bearing will have

shorter life in a non-vertical application. In such an

installation, keep frequency of starts to less than

10perday.

3.2 Proper Grounding

Hazardous voltage. Can shock, burn

or cause death. Installation or service to electrical

equipment should only be done by qualified electrician.

Control panels must be connected to supply ground

Proper grounding serves two main purposes:

1. It provides a path to ground in case of a ground-fault.

Otherwise the current would present a shock or

electrocution hazard.

2. It protects equipment from electrical surges.

Use wire the same size as, or larger than motor’s

current-carrying wires (consult Tables in the motor

section).

Installations must comply with the National Electric Code

as well as state and local codes.

All systems must have lightning (surge) protection with a

secure connection to ground.

An above ground lighting (surge) protection must be

grounded metal-to-metal and extend all the way to

the water bearing layer to be effective. Do not ground

the lightning (surge) protection to the supply ground

or to a ground rod as this will provide little or no surge

protection to the unit.

All motors are internally grounded and requires a 3 or

4-wire drop cable.

3.3 Corrosive Water and Ground

Some waters are corrosive, and can eventually corrode

the ground wire. If the installation uses a metal well

casing, any ground current will flow through it. In the

case of plastic piping and casing, the water column would

carry the current in a ground fault situation.

To prevent this, route the motor ground wire and the

motor power leads through a GFCI with a 10 mA set

point. In this way, the GFCI will trip when a ground fault

has occurred AND the motor ground wire is no longer

functional.

3.4 Check Valves

Check valve installation is necessary for proper pump

operation. The pump should have a check valve on its

discharge, or within 25 feet (7.62 m) of the pump. For very

deep wells, locate a check valve at least every 200 feet

(61m) vertical.

• Useonlyspringtypeorgravity-poppetcheck

valves. Swing type valves can cause water hammer

problems.

• Donotusedrain-backstylecheckvalves(drilled).

Check valves serve the following purposes:

• MaintainPressure:Withoutacheckvalve,thepump

has to start each cycle at zero head, and fill the drop

pipe. This creates upthrust in the motor, and would

eventually damage both the pump and motor.

• PreventWaterHammer:Iftwocheckvalvesareused,

and the lower one leaks, then a partial vacuum forms

in the pipe. When the pump next starts, the flow fills

the void area quickly, and creates a shock wave that

can break piping and damage the pump. If you get

water hammer on pump start, this may be the cause.

• PreventBack-Spin:Withoutafunctioningcheck

valve, upon shutoff, the water drains back through

the pump, and cause it to rotate backwards. This can

create excessive wear on the thrust bearing, and if the

pump restarts as water is flowing down the pipe, it

will put an excessive load on the system.

and Setup

Installation

5

SECTION 3: Installation and Setup

3.5 Start-Up

NOTICE: To avoid sand-locking pump, follow procedure

below when starting pump for the first time. NEVER start

a pump with discharge completely open unless you have

done this procedure first.

1. Connect a pipe elbow, a short length of pipe and a

gate valve to pump discharge at well head.

2. Make sure that controls will not be subjected to

extreme heat or excess moisture.

3. Make sure power is OFF. DO NOT START PUMP YET.

4. Set gate valve on discharge 1/3 open; start pump.

5 Keep gate valve at this setting while water pumps out

on ground. Let it run until water is clear of sand or

silt. (To check solids in water, fill a glass from pump

and let solids settle out).

6. When water is completely clear at 1/3 setting, open

gate valve to approximately two-thirds open and

repeatprocess.

7. When water is completely clear at 2/3 setting, open

gate valve completely and run pump until water is

completely clear.

8. Do not stop the pump until the water is clear.

Otherwise sand will accumulate in the pump stages

which may bind or freeze the pump.

9. Remove gate valve and make permanent installation.

NOTICE: The motor may draw higher than normal current

while the riser pipe is filling. After the riser pipe is full,

the amp draw should drop back to less than the allowed

current given on the motor nameplate.

When pump is in service, the amp draw must be

approximately equal to or lower than the service factor

amps given on the motor nameplate. If not, recheck

entire installation and electrical hook-up to find out why

amp draw is higher than normal.

Motor Torque

The motor exerts a strong torque force on the downpipe

and any other supporting structures when it starts. This

torque is usually in the direction that would unscrew

right-hand threads (the motor’s reaction movement is

clockwise as seen from above).

All pipe and pump joints must be tightened to safely

handle the starting torque. Tighten all threaded

joints to a minimum of 10 ft.-lb per horsepower.

i.e. 20 HP = 200ft.-lb; 50 HP = 500 ft.-lb.

Tack welding or strap welding may be required with

higher horsepower pumps.

6

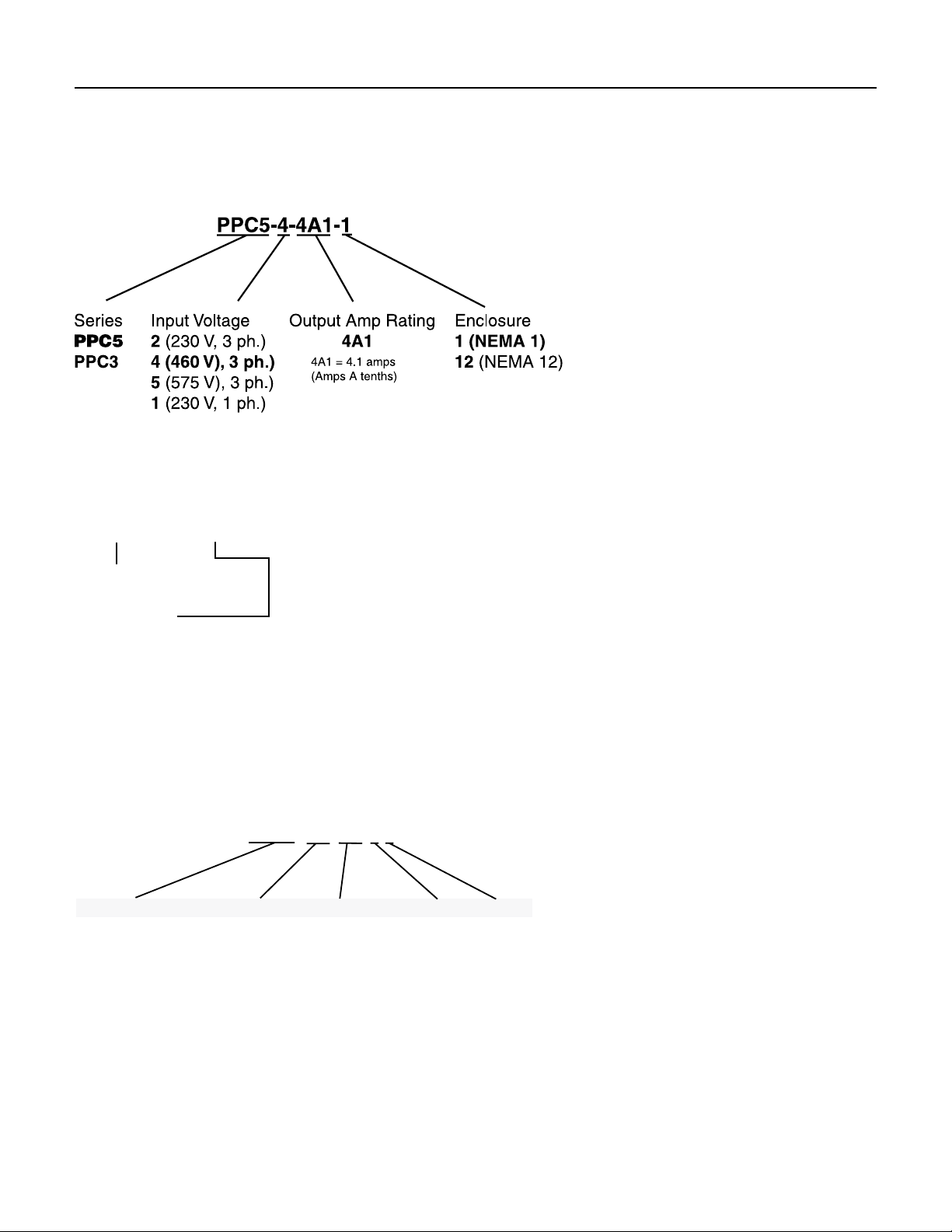

SECTION 4: Electrical Power

Ser

4.1 Mixing Wire Size with Existing

Installation

Using two different cable sizes.

Sometimes conditions make it desirable to use more

than one size cable, such as replacing a pump in an

existinginstallation.

For example: Installing a pump with a 4”, 5 HP, 230

volt, single phase motor, with the motor setting at 370’

(112.8m) down the well and with 160’ (48.8m) of #8cable

buried between the service entrance and the wellhead.

160 Ft. AWG 8

370 Ft.

Pump

Controls

vice Entrance

(Main Fuse Box

From Meter)

5 HP (4.9 kw)

230V 1Ph Motor

Figure 4-1: Mixing Wire Sizes: Example

In order to avoid replacing the buried cable, the question

is: What size cable is required in the well? Calculate

asfollows:

1. According to Table 5-9, a total of 326’ (112.8m) of #8

cable is the maximum length cable to power a 5HP

motor. The percent of this total that has been used

by the 160’ (48.8m) of cable in the buried run is:

160’ / 326’ = .49 or 49%.

2. With 49% of the allowable cable already used, 51%

of the total length is left for use in the well. To avoid

running a cable that is too small (gauge) and lowering

the voltage to the motor, we have to find a cable size

large enough so that 370’ (112.8m) is less than 51%

of the total length allowed for that size.

3. 370 ÷ 51% = 726 feet.

4. From Table 5-9 we find that the total allowable length

for #4 cable is 809’ (246.6 m).

This is longer than needed. Therefore, #4 cable can

be used for the 370’ (112.8m) of cable in the well.

Any combination of sizes can be used, provided that

the total percentage of the length of the two sizes of

cable is not less than 100% of the allowed lengths.

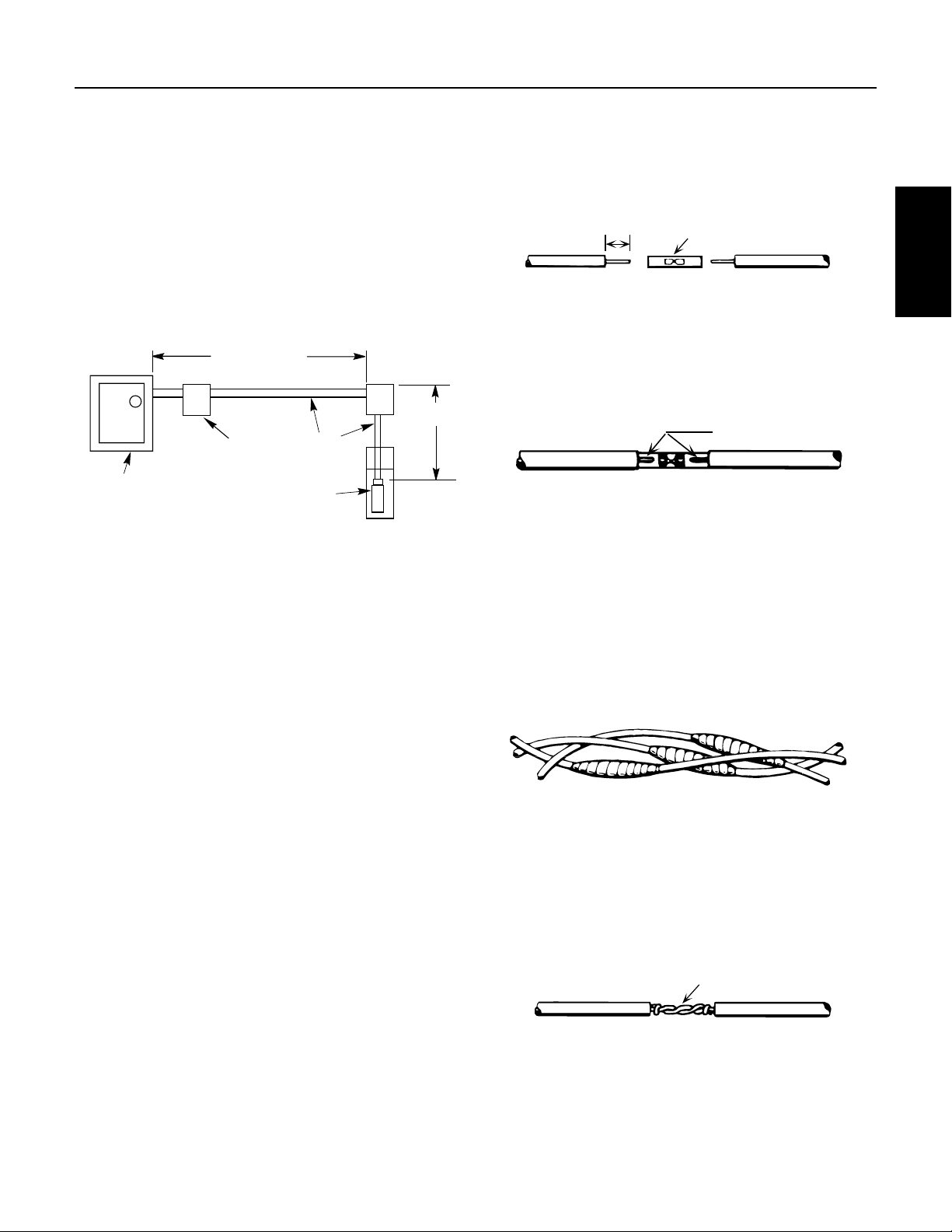

Cable

B. Cut off power supply wire ends. Match colors

and lengths of wires to colors and lengths of

motorleads.

C. Trim insulation back 1/2” (13mm) from supply

wire and motor lead ends (Figure 4-2).

1/2"

(12.7mm)

Butt Connector

Figure 4-2: Insert Wires

D. Insert motor lead ends and supply wire ends

into butt connectors. Match wire colors between

supply wires and motor leads.

E. Using crimping pliers, indent butt connector lugs

to attach wires (Figure 4-3).

Indent here

Figure 4-3: Indent Connectors

F. Cut Scotchfil

™

electrical insulation putty into

3 equal parts and form tightly around butt

connectors. Be sure Scotchfil overlaps insulated

part of wire.

G. Using #33 Scotch® tape, wrap each joint tightly;

cover wire for about 1-1/2” (38mm) on each side

of joint. Make four passes with the tape. When

finished you should have four layers of tape tightly

wrapped around the wire. Press edges of tape

firmly down against the wire (Figure 4-4).

Completed splice

Figure 4-4: Wrap Splices

NOTICE: Since tightly wound tape is the only means

of keeping water out of splice, efficiency of splice will

depend on care used in wrapping tape.

NOTICE: For wire sizes larger than No. 8 (7mm2), use

soldered joint rather than Scotchfil putty, Figure 4-5.

Alternate method

twist and solder

Electrical Power

4.2 Wire Splicing

Splice wire to motor leads. Use only copper wire for

connections to pump motor and control box.

1. Taped splice (for larger wire sizes)

A. Stagger lead and wire length so that 2nd lead is

2” (50mm) longer than 1st lead and 3rd lead is

2”(50mm) longer than second.

Figure 4-5: Twist Wires

Scotchfil™ is a trademark of 3M Company.

Scotch is a registered trademark of 3M Company.

7

SECTION 4: Electrical Power

2. Heat shrink splice (For wire sizes #14, 12 and 10 AWG

2

(2, 3 and 5mm

):

A. Remove 3/8” (9.5mm) insulation from ends of

motor leads and power supply wires.

B. Put plastic heat shrink tubing over motor leads

between power supply and motor.

C. Match wire colors and lengths between power

supply and motor.

D. Insert supply wire and lead ends into butt

connector and crimp. Match wire colors

between power supply and motor. Pull leads to

checkconnections.

E. Center tubing over butt connector and apply heat

evenly with a torch (match or lighter will not

supply enough heat, Figure 4-6).

Connector

Heat shrink tubing

Figure 4-6: Heat-Shrink Tubing Applied

NOTICE: Keep torch moving. Too much concentrated heat

may damage tubing.

Low Voltage Control

This starter arrangement uses a transformer to allow

the coil to be energized by a lower voltage. Note that the

secondary circuit must be fused, and the coil sized for the

secondary voltage.

Overload

Control

Coil

Control

Device

Thermal

Overload

L1

L2

Heaters

3-Phase

Motor

L3

Figure 4-8: Low Voltage Control

Separate Voltage Control

This arrangement uses power from a separate source to

energize the coil.

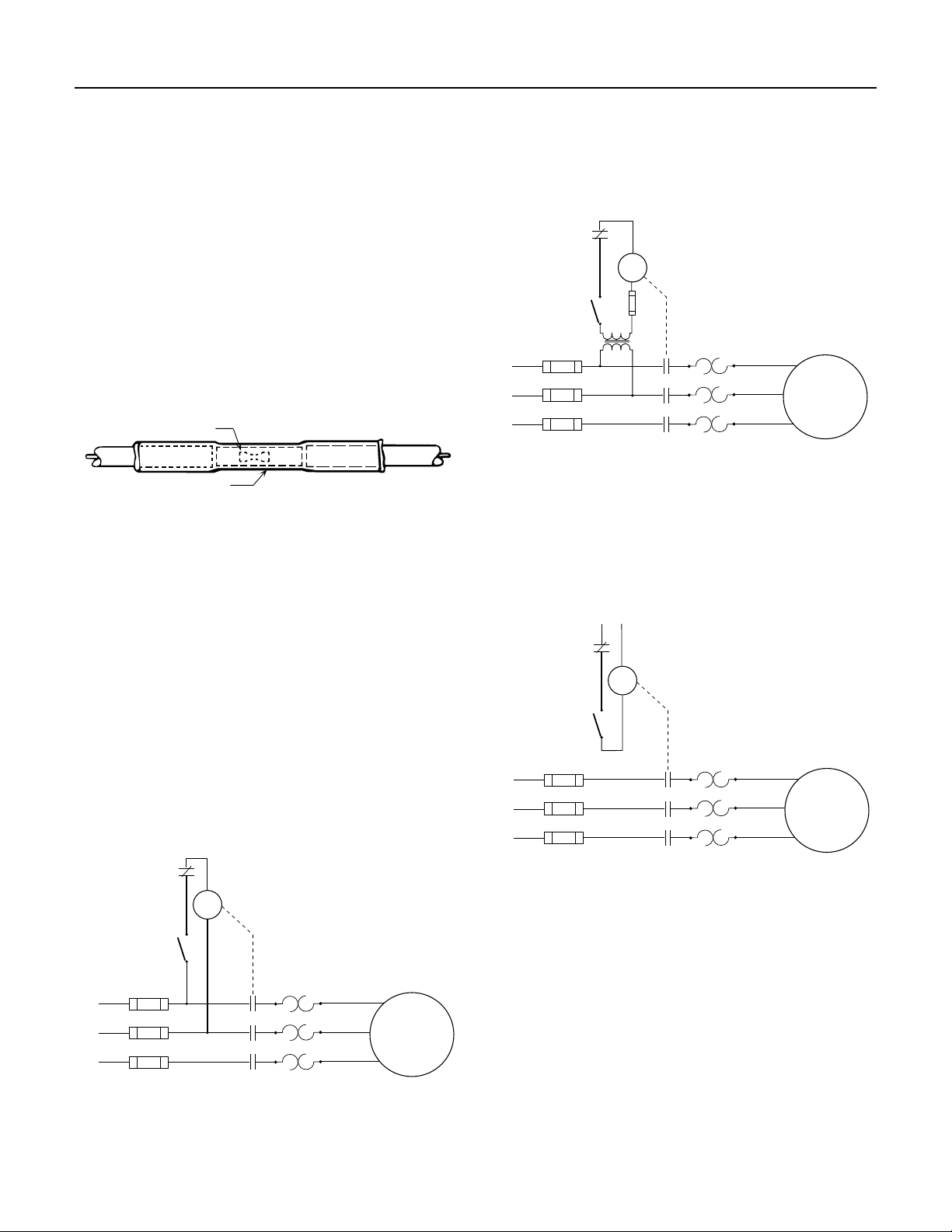

4.3 3-Phase Starters

Starters are used to start the motor by engaging contacts

that will energize each line simultaneously. The contacts

are closed when the coil is energized.

Figures 4-7 through 4-9 show three types of starters used

on the motors. The control device in the secondary circuit

is typically a pressure switch. Other control could be

provided by level control, timers or manual switches.

Line Voltage Control

This commonly-used control has a coil energized by line

voltage. The coil voltage matches the line voltage.

Overload

Control

Coil

Control

Device

Thermal

Overload

L1

L2

L3

Heaters

3-Phase

Motor

Separate

Voltage

Overload

Control

Coil

Control

Device

Thermal

Overload

L1

L2

L3

Heaters

Figure 4-9: Separate Voltage Control

3-Phase

Motor

Figure 4-7: Line Voltage Control

8

SECTION 4: Electrical Power

Starter

L1

L2

L3

T1

T2

T3

Arrangement 1

Starter

L1

L2

L3

T1

T2

T3

Arrangement 2 Arrangement 3

Starter

L1

L2

L3

T1

T2

T3

Arrangement 3

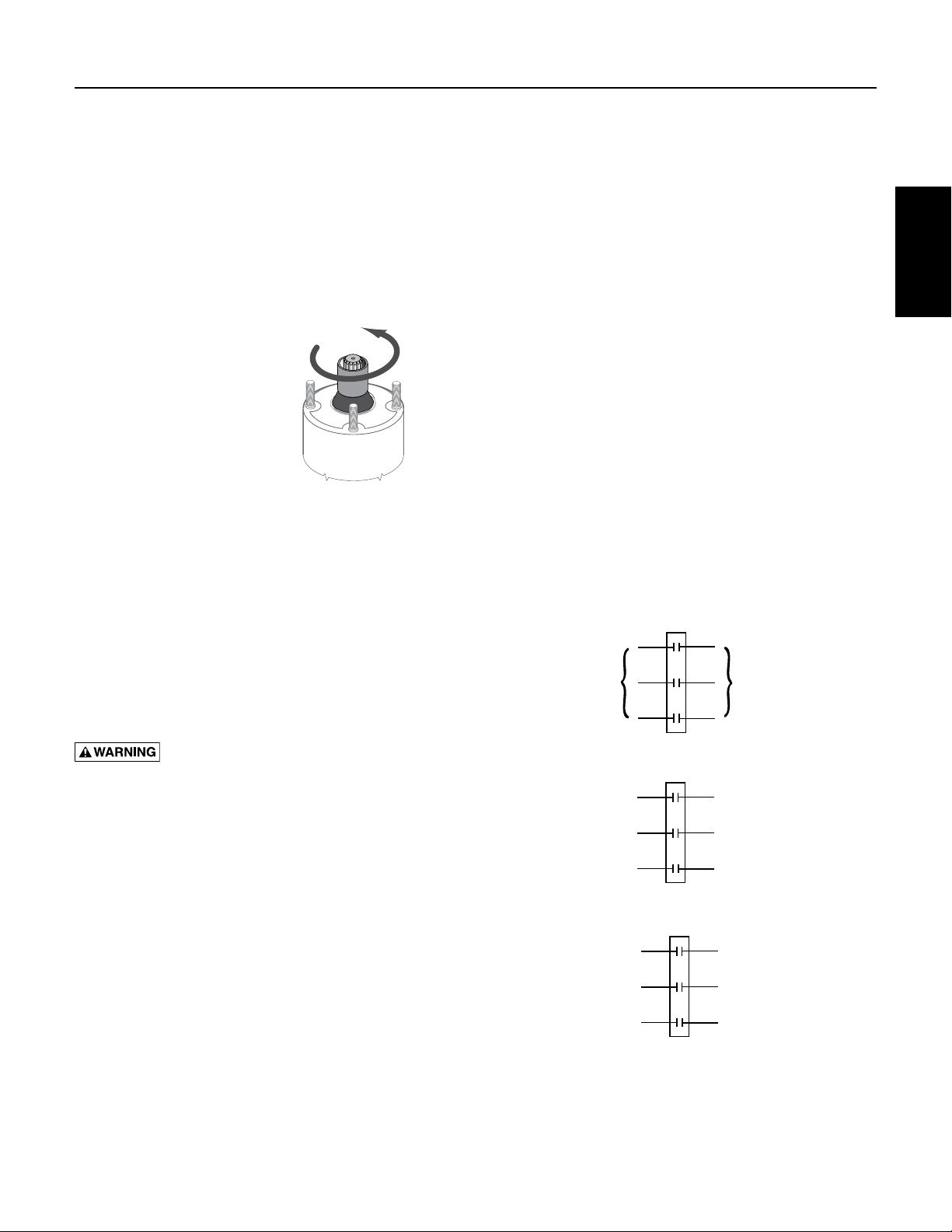

4.4 Checking Motor Rotation

To check rotation before the pump is installed, follow

thesesteps:

During testing or checking rotation (such as “bumping”

or “inching”) the number of “starts” should be limited to

3and total run time of less than 15 seconds.

Bumping must be done while motor is in horizontal

position and followed by a full 15 minute cooling-off

period before any additional “starts” are attempted.

Energize the motor

briefly, and observe the

direction of rotation.

It should be counterclockwise when viewed

from the pump (shaft)

end.

To check rotation after

the pump is installed:

NOTICE: NEVER

continuously operate a

pump with the discharge

valve completely closed

(dead head). This can overload the motor due to lack of

cooling, or destroy the pump and will void the warranty.

After energizing the motor, check the flow and pressure

of the pump to make sure that the motor is rotating in the

correct direction. To correct a wrong rotation, switch any

two of the three cable connections (three-phase motor

only). The setting that gives the most flow and pressure is

correct.

A cooling-off period of 15 minutes is required

betweenstarts.

Hazardous voltage. Disconnect power

before working on wiring.

Input voltage, current and insulation resistance values

should be recorded throughout the installation and

should be used for preventive maintenance.

Figure 4-10: Motor Rotation

Here is an example of current readings at maximum

pump loads on each leg of a three wire hookup. Make

calculations for all three possible hookups.

A. For each hookup, add the readings for the three legs.

B. Divide each total by three to get average amps.

C. For each hookup, find current value farthest from

average (Calculate the greatest current difference

from the average).

D. Divide this difference by the average and multiply by

100 to obtain the percentage of unbalance.

Use smallest percentage unbalance, in this case

Arrangement 2 (Table 4.1).

Us e the Current-Balance worksheet

located in the Installation Record

After trying all three lead hookups, if the reading furthest

from average continues to show on the same power lead,

most of the unbalance is coming from the power source.

Call the power company.

If the reading furthest from average changes leads as the

hookup changes (that is, stays with a particular motor

lead), most of the unbalance is on the motor side of the

starter. This could be caused by a damaged cable, leaking

splice, poor connection, or faulty motor winding.

Starter

L3

T3

Electrical

Power

Supply

L2

L1

Arrangement 2

Starter

L3

T2

T1

L2

To Motor

T2

T1

Electrical Power

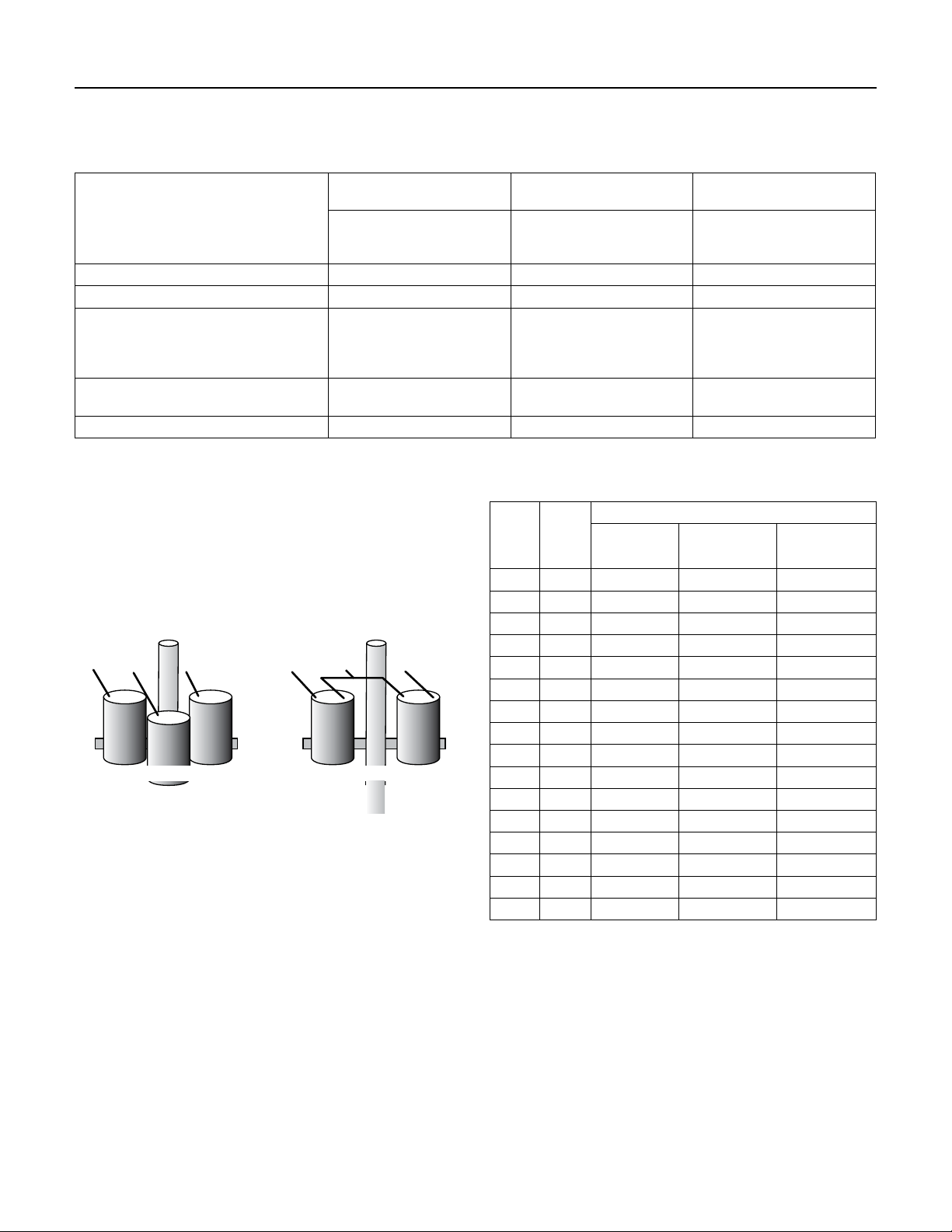

4.5 3-Phase Current Balancing

Current Unbalance Test

Before checking for current unbalance, the pump must

be started, and rotation direction determined.

Determine current unbalance by measuring current in

each power lead. Measure current for all three possible

hookups (Figure 4-11). Use example and worksheet on

the Installation Checklist and Record in Section 12 to

calculate current unbalance on a three phase supply

system and retain for future reference.

NOTICE: Current unbalance between leads should not

exceed 5%. If unbalance cannot be corrected by rolling

the leads, locate the source of the unbalance.

L1

T3

Arrangement 3

Starter

L3

T1

L2

T3

L1

T2

Figure 4-11: 3-Phase Current Unbalance: Example

9

SECTION 4: Electrical Power

Use this worksheet to calculate current unbalance for our

installation.

Table 4-1: Electrical Current Unbalance Example

Arrangement 1

Amps

EXAMPLE

Total Amps 50 50 50

Average Amps 50 ÷ 3 = 16.7 50 ÷ 3 = 16.7 50 ÷ 3 =16.7

From Average Amps

Deviation L1

Deviation L2

Deviation L3

% Current Unbalance

Largest Deviation

% Unbalance + 8.4% 2.4% 4.2%

L1–T1=17

L2–T2=15.3

L3–T3=17.7

0.3

1.4

1.0

1.4 ÷ 16.7 0.4 ÷ 16.7 0.7 ÷ 16.7

Arrangement 2

Amps

L1–T3=16.7

L2–T1=16.3

L3–T2=17

0.0

0.4

0.3

Arrangement 3

Amps

L1–T2=16.7

L2–T3=16

L3–T1=17.3

0.0

0.7

0.6

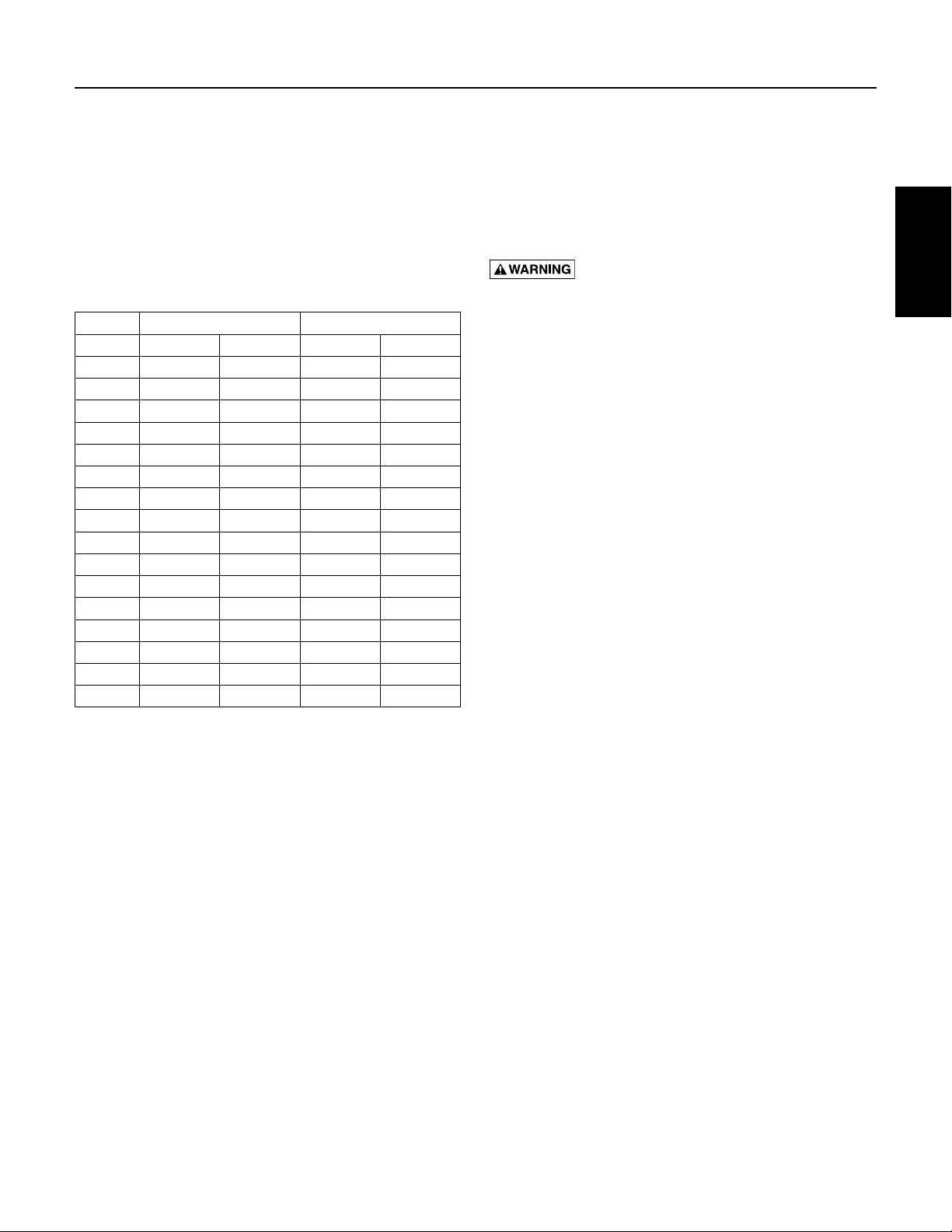

4.6 Transformer Sizing

A full three-phase power supply is recommended

for all three-phase motors and may consist of three

individual transformers or one three-phase transformer.

“Open” delta or wye connections which use only two

transformers can be used, but are more likely to cause

unbalanced current problems. Transformer ratings

should be no smaller than listed in Table 4-2 for supply

power to the motor alone.

T1

T2

Full 3-Phase (Delta)

T3

Figure 4-12: Three Phase Power

Transformers are rated by KVA capacity. This must be

high enough capacity for the motor being installed. If the

transformer capacity is too small, the motor will receive

reduced voltage and may be damaged.

Any other loads in the system would be in addition to the

motor alone.

Refer to Table 4-2. Note that the open delta configuration

can only use 87% of the rated power of the two

transformers.

T1 T2 T3

Wye or Open Delta 3-Phase

Table 4-2: Transformer Capacity

KVA Rating (smallest) For Each Transformer

HP kW

1/2 0.37 1.5 1.0 0.5

3/4 0.55 1.5 1.0 0.5

1 0.75 2.0 1.5 0.75

1-1/2 1.1 3.0 2.0 1.0

2 1.5 4.0 2.0 1.5

3 2.2 5.0 3.0 2.0

5 3.7 7.5 5.0 3.0

7.5 5.5 10.0 7.5 5.0

10 7.5 15.0 10.0 5.0

15 11.0 20.0 15.0 7.5

20 15.0 25.0 15.0 10.0

25 18.5 30.0 20.0 10.0

30 22.0 40.0 25.0 15.0

40 30.0 50.0 30.0 20.0

50 37.0 60.0 35.0 20.0

60 45.0 75.0 40.0 25.0

Required KVA

Open WYE or D

2Transformers

3Transformers

WYE or D

10

SECTION 4: Electrical Power

4.7 Using a Generator

Selecting a generator

Select a generator that can supply at least 65% of rated

voltage upon start-up of the motor.

The chart shows ratings of generators, both externally

and internally regulated. This chart is somewhat

conservative. Consult the generator manufacturer if you

are uncertain.

Table 4-3: Ratings of Generators

Motor Externally Regulated Internally Regulated

HP kW KVA kW KVA

1/2 2.0 2.5 1.5 1.9

3/4 3.0 3.8 2.0 2.5

1 4.0 5.0 2.5 3.1

1-1/2 5.0 6.3 3.0 3.8

2 7.5 9.4 4.0 5.0

3 10.0 12.5 5.0 6.25

5 15.0 18.8 7.5 9.4

7-1/2 20.0 25.0 10.0 12.5

10 30.0 37.5 15.0 18.8

15 40.0 50.0 20.0 25.0

20 60.0 75.0 25.0 31.0

25 75.0 94.0 30.0 37.5

30 100.0 125.0 40.0 50.0

40 100.0 125.0 50.0 62.5

50 150.0 188.0 60.0 75.0

60 175.0 220.0 75.0 94.0

Frequency

It is highly important that the generator maintain

constant frequency (Hz), since the motor’s speed depends

uponfrequency.

A drop of just 1 to 2 Hz can noticeably lower pump

performance. An increase of 1 to 2 Hz can cause

overloadconditions.

Generator Operation

Start the generator before starting the pump motor.

The pump motor must be stopped before turning off

thegenerator.

If the generator runs out of fuel, and the pump is still

connected, it will put excess strain on the thrust bearings

as the generator slows.

Risk of electrocution. Use transfer

switches when the generator is used as a backup to the

power grid. Contact your power company or generator

manufacturer for proper use of standby or backup

generators.

4.8 Special Applications

Using Phase Converters

Phase converters allow three-phase motors to operate

from one-phase supply. Various styles of phase

converters are available. Many converters do not supply

a properly balanced voltage, and using these will void the

motor’s warranty unless approval is obtained first.

Guidelines For Phase Converters:

• Currentunbalancemustbelessthan5%.

• Convertertobesizedtoservicefactorcapacity

• Maintainmotorcoolingwithacoolingflowofatleast

3’ per second.

• Fusesandcircuitbreakersmustbetime-delaytype.

Motor Starting with Reduced Voltage

Starting a motor with full voltage will bring it to full speed

in less than 1/2 second. This can:

• Spiketheloadcurrent,causingbriefvoltagedipsin

other equipment.

• Over-stresspumpandpipingcomponentsbecauseof

high torque.

• Causewaterhammer.

Electrical Power

Voltage Regulation

There is a significant difference in the performance of

internally and externally regulated generators.

An external regulator senses output voltage dips

and triggers an increase in the voltage output of the

generator.

An internal regulator, senses current and responds to

increased current by supplying more voltage.

Motor Starters (3-Phase Only)

Various types of motor starters are available.

Autotransformers are recommended because of reduced

current draw.

When motor starters are used, they should supply

a minimum of 55% of rated voltage for adequate

startingtorque.

11

SECTION 5: XE Series 4” Submersible Motors

5.1 Motor Inspection

Check the motor for damage in shipping.

Before installation, check the following.

• Checkoveralltools,especiallythehoistinggear,for

wear or damage before hoisting unit.

• Inspectthemotorcableforanynicksorcuts.

• Verifythatmotornameplatedatamatches

registration card information exactly.

• Verifythatmotornameplatevoltageiscorrectfor

available power supply voltage. Voltage must not vary

more than +/-10% from nameplate rated voltage.

• Verifythatthewelldiameterislargeenoughto

accommodate the motor/pump unit all the way to the

pump setting depth.

• Forinstallationswithtightwellcasings,makesure

that riser pipe flanges are recessed to protect

the power and control cables from abrasion and

squeezing during installation.

Heavy object. Lifting equipment must be

capable of lifting motor and attached equipment.

• Ifthetotallengthofthepumpmotorunit(without

any riser pipe) exceeds 10’ (3m), the unit must be

supported with a girder while hoisting. Do not remove

supporting girder until unit is standing vertically in the

hoist. Check for damage.

5.2 Testing

Insulation Resistance

To check for insulation resistance:

1. Disconnect power to the motor for this test.

2. Connect an Ohm meter (resistance in Ω) between the

power leads and the motor ground or well casing.

20KΩ Damaged motor, possible result of

lightning strike.

500KΩ Typical of older installed motor in well.

2 MΩ Newly installed motor

10 MΩ Used motor, measured outside of well

20 MΩ New motor without cable

5.3 Storage and Transportation

The motors are filled with a non-toxic, Propylene Glycol

and water solution to prevent damage from freezing

temperatures. The solution will prevent damage from

freezing temperatures to -40˚F (-40˚ C). Motors should

be stored in areas that do not go below this temperature.

The solution will become slushy between 0˚F (-17˚C) and

-40˚F (-40˚C) but no damage occurs. If this occurs, allow

the motor to sit in the well for several minutes before

operating.

Storage site should be clean, well vented, and cool.

Keep humidity at the storage site as low as possible.

Protect motor and cables from direct sunlight.

Protect power supply cables and control cables from

moisture by taping the cable ends with electrician’s tape.

Do not kink power supply or control cables.

Take care when moving unit (packed or unpacked) with

crane or hoisting gear not to knock it against walls, steel

structure, floors, etc. Do not drop motor.

Do not lift motor or motor/pump unit by power supply or

control cables.

12

SECTION 5: XE Series 4” Submersible Motors

5.4 4” Motor Specifications

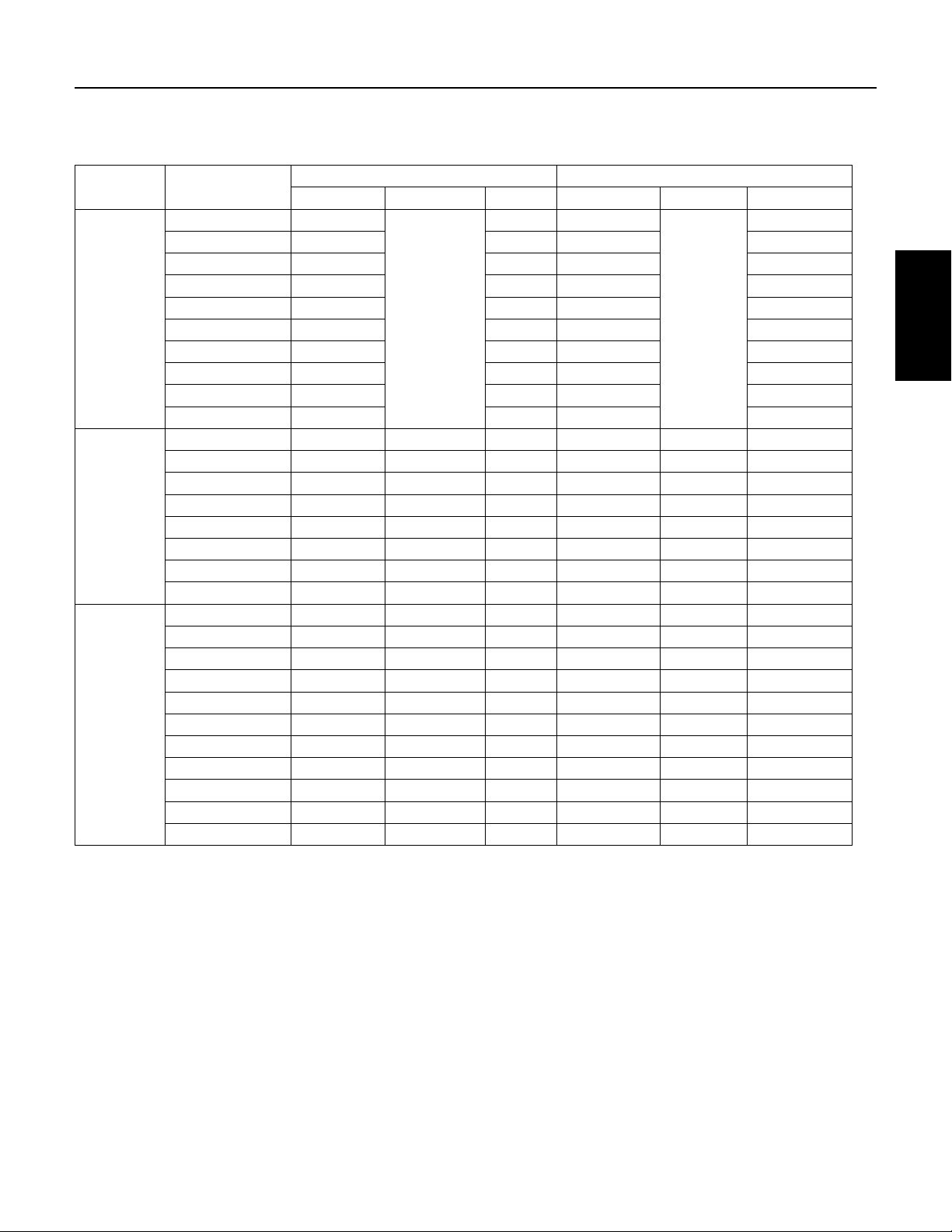

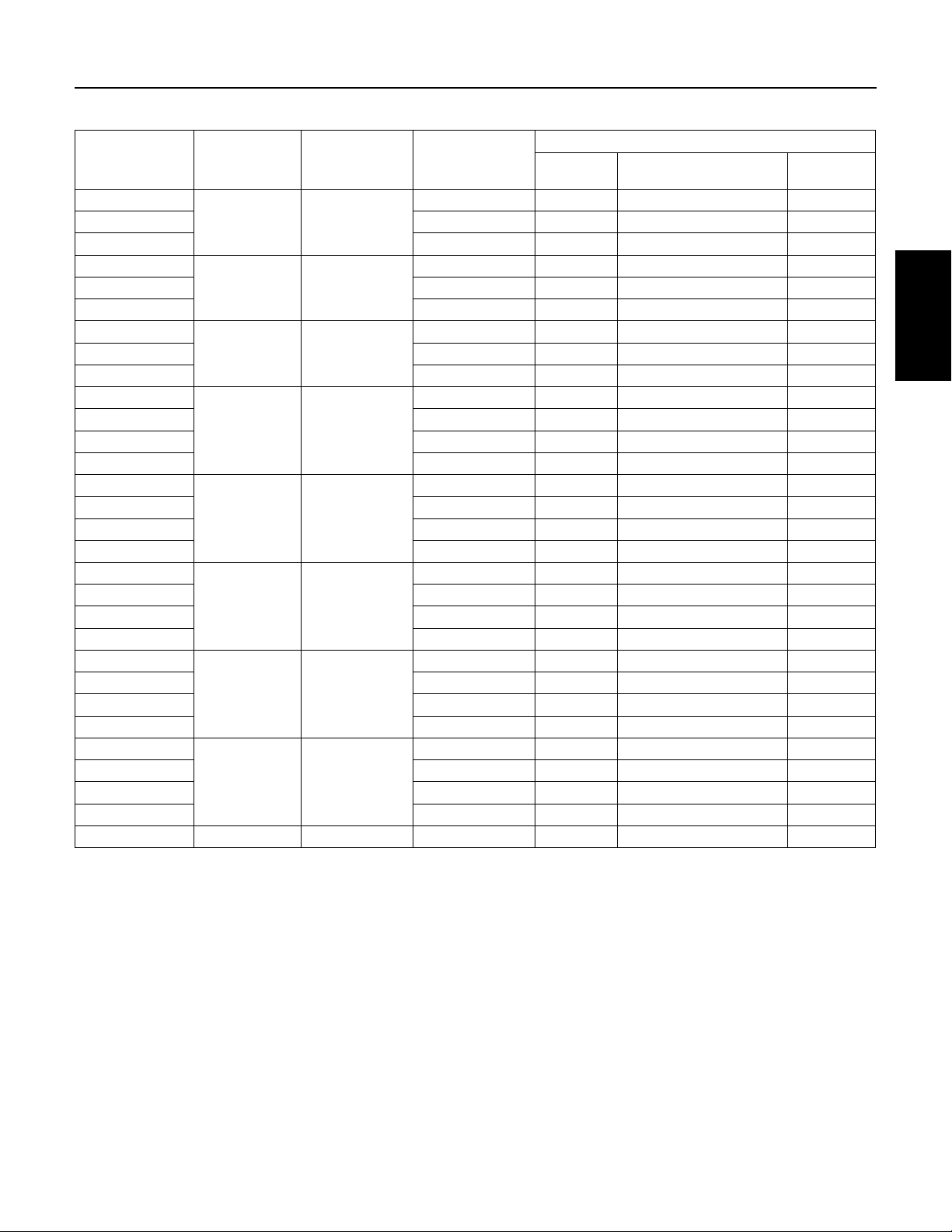

Table 5-1: Single Phase Motor Specifications (115 and 230 Volt, 60 Hz, 3450 RPM)

Motor Type

PSC

2-Wire

CSIR

3-Wire

CSCR

3-Wire

Pentek® Part

Number

P42B0010A2-01 7.9 1679 9.1 1990

P42B0015A2-01 9.2 2108 11.0 2520

P42B0005A1-01 7.9 910 9.8 1120

P42B0005A2-01 4.0 845 4.7 1050

P42B0007A2-01 5.0 1130 6.2 1400

P42B0010A2-01 6.7 1500 8.1 1800

P42B0015A2-01 9.0 2000 10.4 2350

P42B0005A1 7.4 845 9.5 1088

P42B0005A2 3.7 834 4.7 1073

P42B0007A2 5.0 1130 6.4 1459

P43B0005A1-01 8.8/8.8/0 8.8 675 10.9/10.9/0 10.9 980

P43B0005A2-01 5.3/5.3/0 5.3 740 6.1/6.1/0 6.1 1050

P43B0007A2-01 6.6/6.6/0 6.6 970 7.8/7.8/0 7.8 1350

P43B0010A2-01 8.1/8.1/0 8.1 1215 9.4/9.4/0 9.4 1620

P43B0005A1 11.0/11.0/0 11.0 733 12.6/12.6/0 12.6 1021

P43B0005A2 5.5/5.5/0 5.5 745 6.3/6.3/0 6.3 1033

P43B0007A2 7.2/7.2/0 7.2 1014 8.3/8.3/0 8.3 1381

P43B0010A2 8.4/8.4/0 8.4 1267 9.7/9.7/0 9.7 1672

P43B0005A2-01 4.2/4.1/1.8 4.2 7.15 4.8/4.3/1.8 4.8 960

P43B0007A2-01 4.8/4.4/2.5 4.8 940 6.0/4.9/2.3 6.0 1270

P43B0010A2-01 6.1/5.2/2.7 6.1 1165 7.3/5.8/2.6 7.3 1540

P43B0015A2-01 9.1/8.2/1.2 9.1 1660 10.9/9.4/1.1 10.9 2130

P43B0005A2 4.1/4.1/2.2 4.1 720 4.9/4.4/2.1 4.9 955

P43B0007A2 5.1/5.0/3.2 5.1 1000 6.3/5.6/3.1 6.3 1300

P43B0010A2 6.1/5.7/3.3 6.1 1205 7.2/6.3/3.3 7.2 1530

P43B0015A2 9.7/9.5/1.4 9.7 1693 11.1/11.0/1.3 11.1 2187

P43B0020A2 9.9/9.1/2.6 9.9 2170 12.2/11.7/2.6 12.2 2660

P43B0030A2 14.3/12.0/5.7 14.3 3170 16.5/13.9/5.6 16.5 3620

P43B0050A2 24/19.1/10.2 24.0 5300 27.0/22.0/10.0 27 6030

Amps (Y/B/R) Y Only Watts Amps (Y/B/R) Y Only Watts

Full Load Service Factor

XE Series Motors

13

SECTION 5: XE Series 4” Submersible Motors

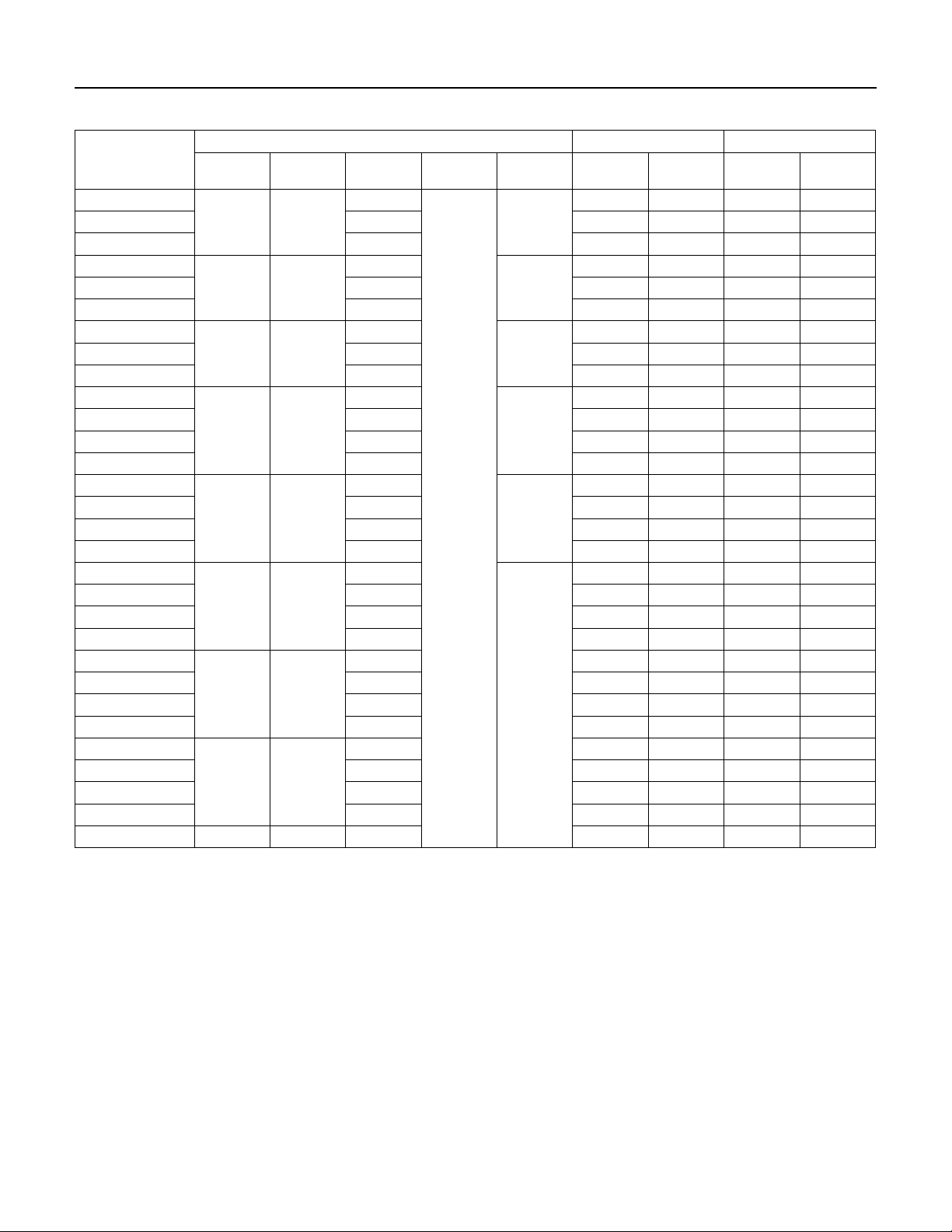

Table 5-2: Three Phase Motor Specifications (230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM)

Pentek® Part

Number

P43B0005A8

P43B0005A3 230 2.4 610 2.9 880

P43B0005A4 460 1.3 610 1.5 875

P43B0007A8

P43B0007A3 230 3.3 850 3.9 1185

P43B0007A4 460 1.7 820 2.0 1140

P43B0010A8

P43B0010A3 230 4.0 1090 4.7 1450

P43B0010A4 460 2.2 1145 2.5 1505

P43B0015A8

P43B0015A3 230 5.2 1490 6.1 1930

P43B0015A4 460 2.8 1560 3.2 1980

P43B0015A5 575 2 1520 2.4 1950

P43B0020A8

P43B0020A3 230 6.5 1990 7.6 2450

P43B0020A4 460 3.3 2018 3.8 2470

P43B0020A5 575 2.7 1610 3.3 2400

P43B0030A8

P43B0030A3 230 9.2 2880 10.1 3280

P43B0030A4 460 4.8 2920 5.3 3320

P43B0030A5 575 3.7 2850 4.1 3240

P43B0050A8

P43B0050A3 230 15.7 4925 17.5 5650

P43B0050A4 460 7.6 4810 8.5 5530

P43B0050A5 575 7.0 5080 7.6 5750

P43B0075A8

P43B0075A3 230 24.0 7480 26.4 8570

P43B0075A4 460 12.2 7400 13.5 8560

P43B0075A5 575 9.1 7260 10.0 8310

P43B0100A4 10 7.5 460 15.6 9600 17.2 11000

HP kW Volts Hz

1/2 0.37

3/4 0.55

1 0.75

1-1/2 1.1

2 1.5

3 2.2

5 3.7

7-1/2 5.6

Rating Full Load Maximum Load (SF Load)

Service

Factor

200

1.6

200

1.5

200

1.4

200

1.3

200

60

200

200 18.3 4850 20.2 5515

200 27.0 7600 30.0 8800

1.25

1.15

Amps Watts Amps Watts

2.9 600 3.4 870

3.8 812 4.5 1140

4.6 1150 5.5 1500

6.3 1560 7.2 1950

7.5 2015 8.8 2490

10.9 2890 12.0 3290

14

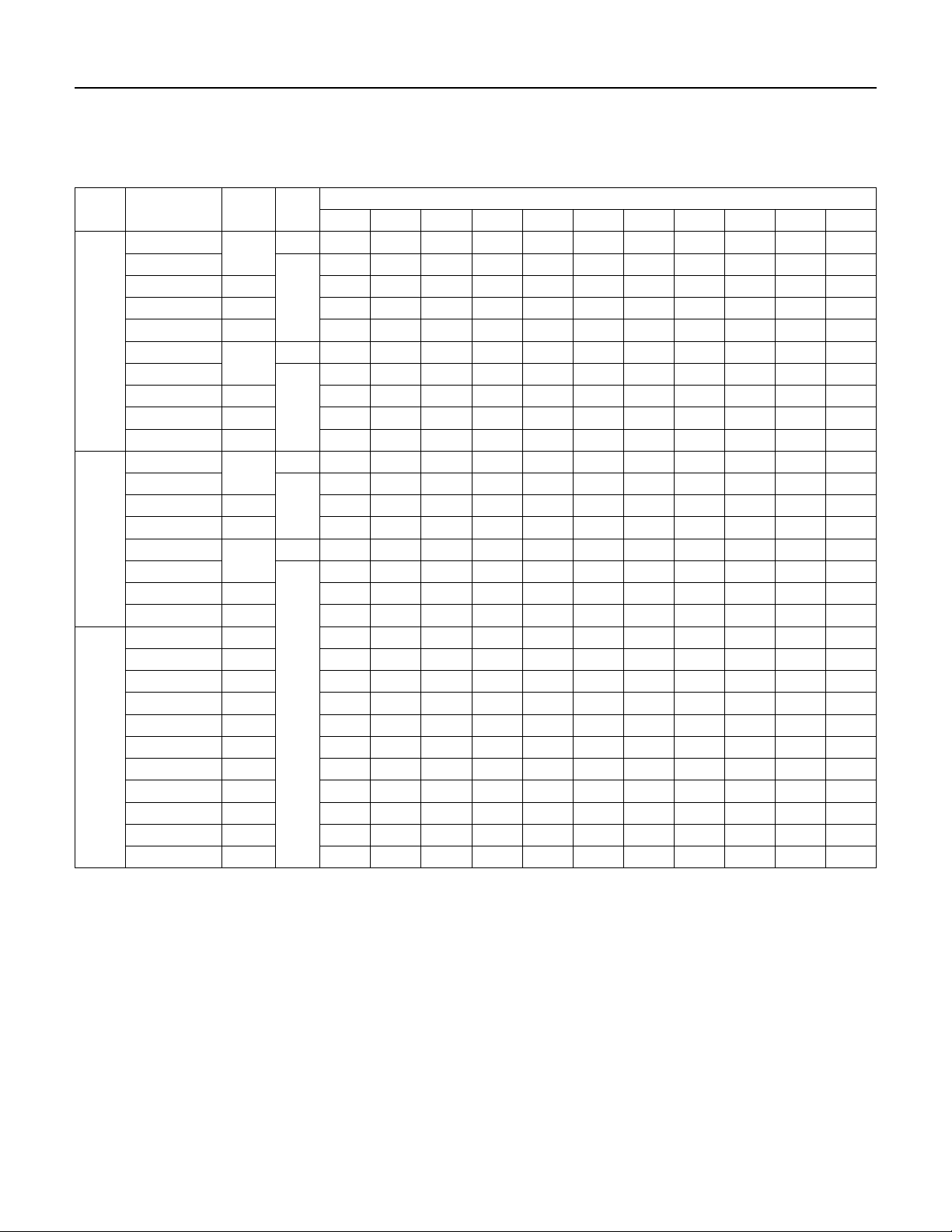

SECTION 5: XE Series 4” Submersible Motors

Table 5-3: Single Phase 4” Motor Electrical Parameters (115 and 230 Volt, 60 Hz, 3450 RPM, 2 and 3 wire)

Motor

Type

PSC

2-Wire

CSIR

3-Wire

CSCR

3-Wire

Pentek® Part

Number

P42B0005A1-01 1.4-2.0 42.1 54 99.6 99.9 28 H

P42B0005A2-01 6.1-7.2 45 58.5 92 97 16 J

P42B0007A2-01 5.9-6.9 50.5 61

P42B0010A2-01 4.2-5.2 50 59 24

P42B0015A2-01 1.8-2.4 56.5 62.5

P42B0005A1 1.3-1.8 49 61 99 36.4

P42B0005A2 4.5-5.2 50 62

P42B0007A2 3.0-4.8 55

P42B0010A2 4.2-5.2 58 94 96 21.7 F

P42B0015A2 1.9-2.3 59 64 99 99 42 H

P43B0005A1-01 1.0-1.4 2.5-3.1 57 62 65 78 44 M

P43B0005A2-01 5.1-6.1 12.4-13.7 52 58.5 61 75 21

P43B0010A2-01 2.0-2.6 9.3-10.4 63 66 66 41

P43B0005A1 0.9-1.6 5.7-7.0 51 59 54 69 49.6 N

P43B0005A2 4.2-4.9 17.4-18.7 50 58 58 71 22.3 M

P43B0007A2 2.6-3.6 11.8-13.0 55 61 61 72 32

P43B0010A2 2.2-3.2 11.3-12.3 59 62 66 75 41.2

P43B0005A2-01 5.1-6.1 12.4-13.7 54.5 61.5 77 87 21

P43B0007A2-01 2.6-3.3 10.4-11.7 62 69 86

P43B0010A2-01 2.0-2.6 9.3-10.4 66 71 86 41

P43B0015A2-01 2.1-2.5 10.0-10.8 68 69 81 87 49 J

P43B0005A2 4.2-4.9 17.4-18.7 52 62 76 85 22.3 M

P43B0007A2 2.6-3.6 11.8-13.0 56 65 85 90 32

P43B0010A2 2.2-3.2 11.3-12.3 62 68 86 92 41.2

P43B0015A2 1.6-2.3 7.9-8.7 66 67 80 85 47.8 J

P43B0020A2 1.6-2.2 10.8-12.0 68 69

P43B0030A2 1.1-1.4 2.0-2.5 72 72 97 76.4

P43B0050A2 0.62-0.76 1.36-1.66 71 71 97 98 101 E

Resistance *

Winding Efficiency % Power Factor %

Main

Start

Resistance

FL SF FL SF

98

97

65

96

Locked Rotor

Amps

98

99

76

91

95 49.4

18

44 H

19.5

24.8 J

32

32

KVA Code

F

K

XE Series Motors

LP43B0007A2-01 2.6-3.3 10.4-11.7 60 64.5 64

L

L

G

* Main winding is between the yellow and black leads. Start winding is between the yellow and red leads.

15

SECTION 5: XE Series 4” Submersible Motors

Table 5-4: T

Pentek® Part

P43B0005A8 4.1-5.2 62 68.5 22

P43B0005A3 5.72-7.2

P43B0005A4 23.6-26.1 9

P43B0007A8 2.6-3.0 69 74 32

P43B0007A3 3.3-4.3 66 71 27

P43B0007A4 14.4-16.2 69 73.5 14

P43B0010A8 3.4-3.9 66 70 29

P43B0010A4 17.8-18.8 65 69 13

P43B0015A8 1.9-2.5 72 74 40

P43B0015A4 12.3-13.1 72 73 16.3

P43B0015A5 19.8-20.6 73 74 11.5 J

P43B0020A8 1.4-2.0 74

P43B0020A4 8.00-8.67 74 23

P43B0020A5 9.4-9.7 78 78 21.4 M

P43B0030A8 0.9-1.3

P43B0030A3 1.3-1.7 58.9

P43B0030A4 5.9-6.5 76 30

P43B0030A5 9.4-9.7 78 78 21.4

P43B0050A8 0.4-0.8

P43B0050A3 .85-1.25 93

P43B0050A4 3.58-4.00 77 77 48

P43B0050A5 3.6-4.2 75 75 55 M

P43B0075A8 0.5-0.6 74 74 165

P43B0075A3 0.55-0.85 75 75 140

P43B0075A4 1.9-2.3 76 76 87 L

P43B0075A5 3.6-4.2 77 77 55 J

P43B0100A4 1.8-2.2 79 80 110 K

Number

hree Phase

Motor Electrical Parameters (230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM)

Line to Line Resistance Ohms

% Efficiency

FL SF

61 68

75

77

76 76

77

Locked Rotor Amps KVA Code

17.3

51

71 K

113

R

MP43B0010A3 4.1-5.1 69 72 26.1

LP43B0015A3 2.8-3-4 75 76 32.4

KP43B0020A3 1.8-2.4 75 44

J

J

16

SECTION 5: XE Series 4” Submersible Motors

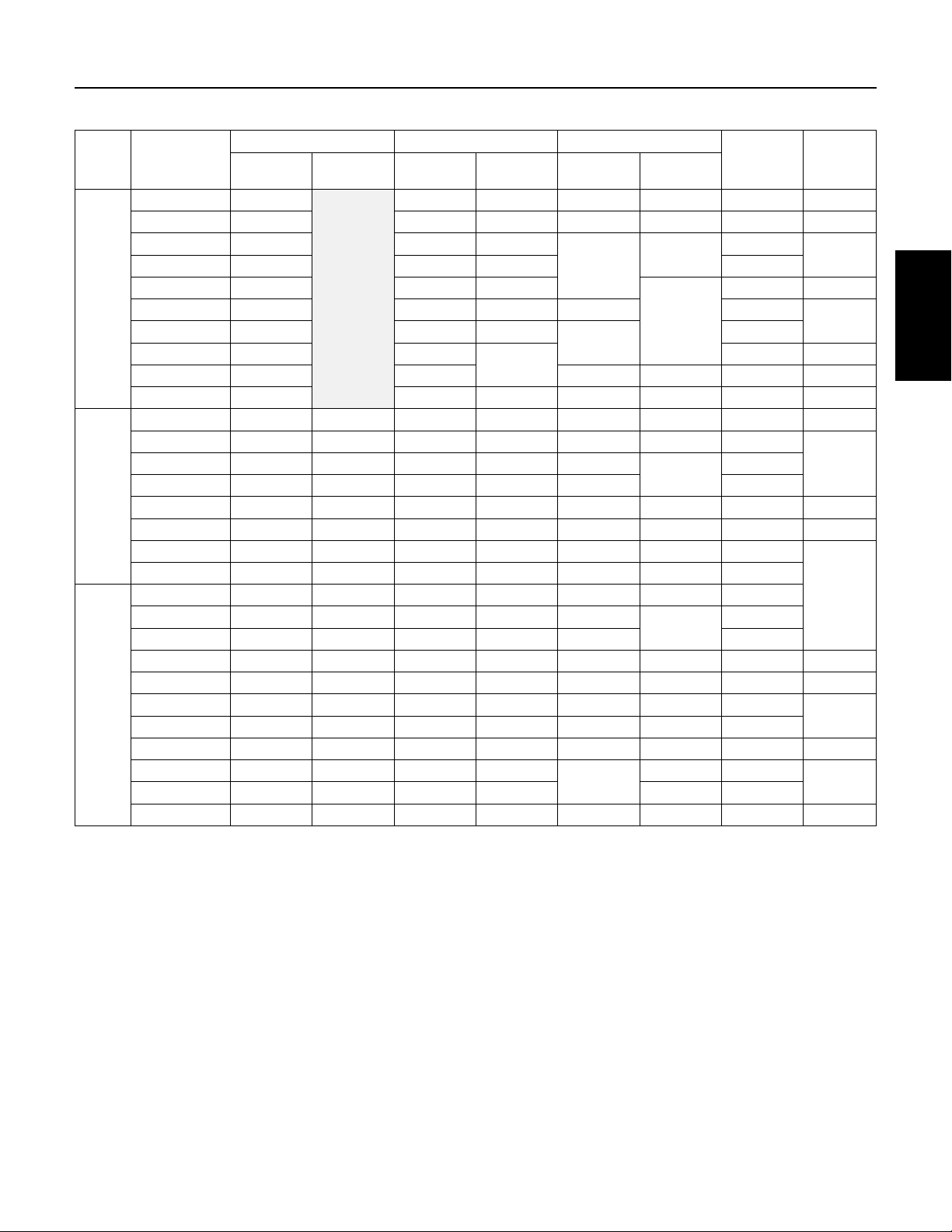

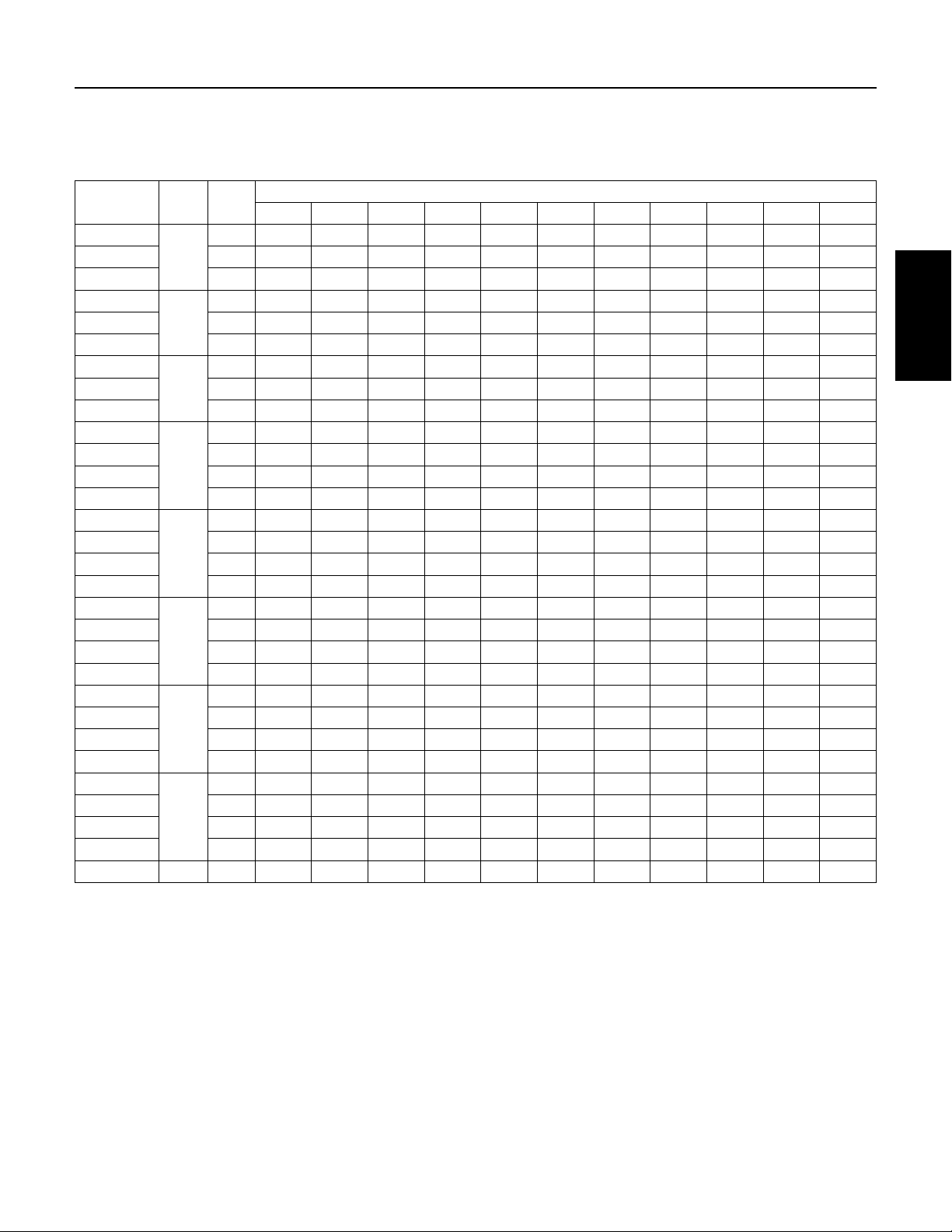

5.5 4” Motor Dimensions

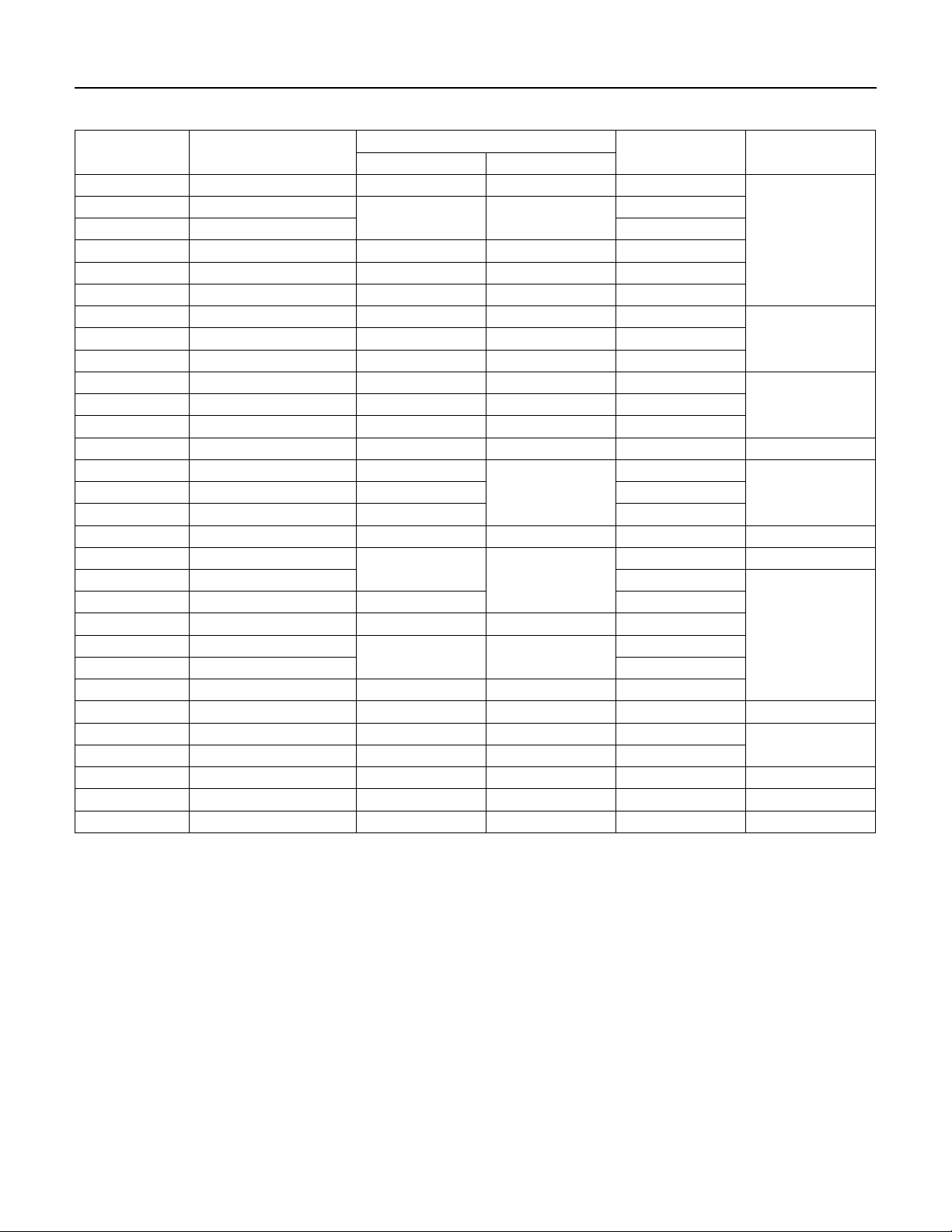

Table 5-5: Single Phase Motor Dimensions (115 and 230 Volt, 60 Hz, 3450 RPM)

Motor Type

4-Inch

2-Wire

4-inch

3-Wire

Pentek® Part

Number

P42B0005A1-01

P42B0005A2-01

P42B0007A2-01 3/4 0.55 11.9 302 21.4 9.7

P42B0010A2-01 1 0.75 12.5 318 23.2 10.5

P42B0015A2-01 1-1/2 1.1 14.2 361 27.3 12.4

P42B0005A1

P42B0005A2

P42B0007A2 3/4 0.55 12.4 314 22.7 10.3

P42B0010A2 1 0.75 13.3 337 24.5 11.1

P42B0015A2 1-1/2 1.1 14.9 378 28.9 13.1

P43B0005A1-01

P43B0005A2-01 9.2 234 16.7 7.6

P43B0007A2-01 3/4 0.55 10.3 262 19.8 9.0

P43B0010A2-01 1 0.75 11.2 284 22.0 10.0

P43B0005A1

P43B0005A2 9.7 246 18.1 8.2

P43B0007A2 3/4 0.55 10.8 275 21.4 9.7

P43B0010A2 1 0.75 11.7 297 23.1 10.5

P43B0005A2-01 1/2 0.37 9.2 234 16.7 7.6

P43B0007A2-01 3/4 0.55 10.3 262 19.8 9.0

P43B0010A2-01 1 0.75 11.2 284 22.0 10.0

P43B0015A2-01 1-1/2 1.1 12.8 325 26.0 11.8

P43B0005A2 1/2 0.37 9.7 246 18.1 8.2

P43B0007A2 3/4 0.55 10.8 275 21.4 9.7

P43B0010A2 1 0.75 11.7 297 23.1 10.5

P43B0015A2 1-1/2 1.1 13.6 345 27.4 12.4

P43B0020A2 2 1.5 15.1 383 31.0 14.1

P43B0030A2 3 2.2 18.3 466 40.0 18.1

P43B0050A2 5 3.7 27.7 703 70.0 31.8

HP kW

1/2 0.37 10.5 267 18.1 8.2

1/2 0.37 11.0 279 19.2 8.7

1/2 0.37

1/2 0.37

Inches mm Lb Kg

Length Weight

9.6 244 17.9 8.1

10.0 253 18.9 8.6

XE Series Motors

17

SECTION 5: XE Series 4” Submersible Motors

Table 5-6: Three Phase Motor Dimensions (230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM)

Pentek® Part Number HP kW

P43B0005A8

1/2 0.37 10 254 18.9 8.6P43B0005A3

P43B0005A4

P43B0007A8

3/4 0.55 10.8 275 21.4 9.7P43B0007A3

P43B0007A4

P43B0010A8

P43B0010A3

P43B0010A4

P43B0015A8

P43B0015A3

P43B0015A4

P43B0015A5

P43B0020A8

P43B0020A4

P43B0020A5

P43B0030A8

P43B0030A3

P43B0030A4

P43B0030A5

P43B0050A8

P43B0050A4

P43B0050A5

P43B0075A8

P43B0075A3

P43B0075A4

P43B0075A5

P43B0100A4 10 7.5 30.7 780 78 35.4

1 0.75

1-1/2 1.1

2 1.5

3 2.2

5 3.7

7-1/2 5.6

Inches mm Lb Kg

11.7 297 23.1 10.5

13.8 351 27.4 12.4P43B0020A3

15.3 389 32 14.5

21.7 550 55 24.9P43B0050A3

27.7 703 70 31.8

Length Weight

18

SECTION 5: XE Series 4” Submersible Motors

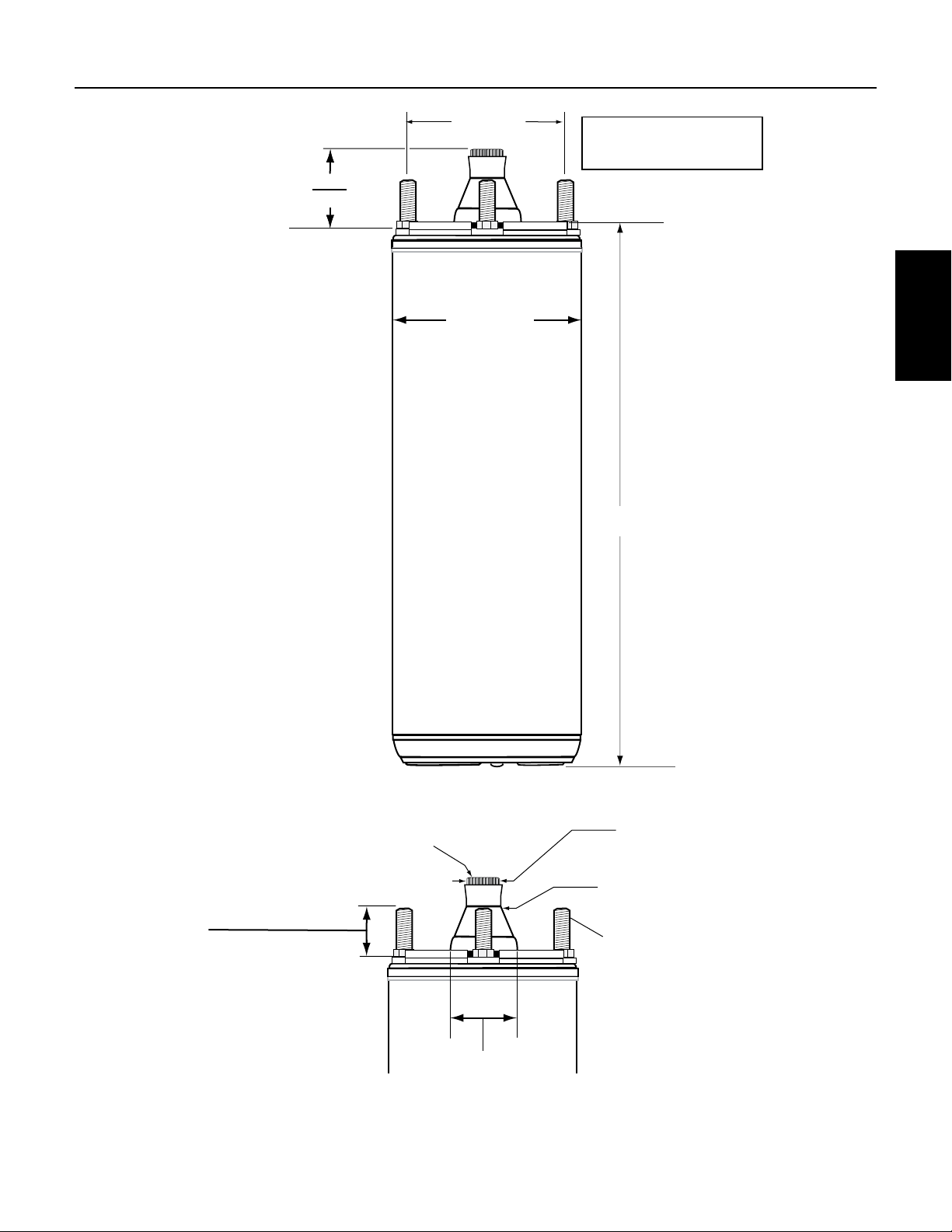

3.00 (7.62)

Shaft free end-play

.005 -.040 (.127 - 1.02)

1.508 (38.30)

1.498 (38.05)

All dimensions

in inches (mm)

3.750 (95.2)

XE Series Motors

4” Motor

Length

14 Teeth 24/48 Pitch

30 Degee Pressure Angle

Min 0.50 (23.1) Full Spline

ANSI B92.1 Compliant

0.97 (24.6) max

0.79 (20.1) min

1.5 (38.1)max.

Figure 5-1: XE Series 4” Motor Dimensions – Single and Three Phase

0.6255 (15.89)

0.6245 (15.86)

Sand Boot

(4) 5/16 - 24

UNF-2A Threaded

Studs on 3” (76.2)

Dia. Circle

19

SECTION 5: XE Series 4” Submersible Motors

5.6 4” Motor Fuse Sizing

Table 5-7: SINGLE PHASE Motor Fuse Sizing (115 and 230 Volt, 60 Hz, 3450 RPM)

Fuse Sizing Based on NEC

Motor Type Pentek® Part Number HP kW Volts

4-Inch

PSC

2-Wire

4-Inch

CSIR

3-Wire

4-Inch

CSCR

3-Wire

P42B0005A1-01

P42B0005A2-01

P42B0007A2-01 3/4 0.55 20

P42B0010A2-01 1 0.75 25

P42B0015A2-01 1-1/2 1.1 35 20 30

P42B0005A1

P42B0005A2

P42B0007A2 3/4 0.55 20 15

P42B0010A2 1 0.75 25

P42B0015A2 1-1/2 1.1 30 25

P43B0005A1-01

P43B0005A2-01

P43B0007A2-01 3/4 0.55 20 20

P43B0010A2-01 1 0.75 25 15 25

P43B0005A1

P43B0005A2

P43B0007A2 3/4 0.55 20 20

P43B0010A2 1 0.75 25 15 25

P43B0005A2-01 1/2 0.37 15

P43B0007A2-01 3/4 0.55

P43B0010A2-01 1 0.75

P43B0015A2-01 1-1/2 1.1 30 15 25

P43B0005A2 1/2 0.37 15

P43B0007A2 3/4 0.55

P43B0010A2 1 0.75

P43B0015A2 1-1/2 1.1 30 15 25

P43B0020A2 2 1.5 30 20 25

P43B0030A2 3 2.2 45 25 40

P43B0050A2 5 3.7 70 40 60

1/2 0.37

1/2 0.37

1/2 0.37

1/2 0.37

115 30 20 25

230

115 25 15 20

230

115 30 20 30

230

115 30 20 30

230

Standard Fuse Dual Element Time Delay Fuse

15 10 15

15

15

15

20 15

20 15

Circuit

Breaker

15 20

10

15

10

10

10

10

10

20

15

15

10

10

20

SECTION 5: XE Series 4” Submersible Motors

Table 5-8: THREE PHASE Motor Fuse Sizing (230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM)

Pentek®

Part Number

P43B0005A8

P43B0005A3 230 6 6 6

P43B0005A4 460 3 3 3

P43B0007A8

P43B0007A3 230 6 6 6

P43B0007A4 460 3 6 3

P43B0010A8

P43B0010A3 230 10 6 10

P43B0010A4 460 6 3 6

P43B0015A8

P43B0015A3 230 15 10 15

P43B0015A4 460 10 6 6

P43B0015A5 575 6 3 6

P43B0020A8

P43B0020A3 230 15 15 20

P43B0020A4 460 15 6 10

P43B0020A5 575 10 6 10

P43B0030A8

P43B0030A3 230 25 15 25

P43B0030A4 460 15 10 15

P43B0030A5 575 10 10 10

P43B0050A8

P43B0050A3 230 45 30 40

P43B0050A4 460 25 15 20

P43B0050A5 575 20 15 20

P43B0075A8

P43B0075A3 230 70 45 60

P43B0075A4 460 40 25 35

P43B0075A5 575 25 20 25

P43B0100A4 10 7.5 460 45 25 35

HP kW Volts

200 10 6 10

1/2 0.37

200 15 10 10

3/4 0.55

200 15 10 10

1 0.75

200 20 10 15

1-1/2 1.1

200 25 15 20

2 1.5

200 35 20 30

3 2.2

200 60 35 50

5 3.7

200 80 50 70

7-1/2 5.6

Standard

Fuse

Fuse Sizing Based on NEC

Dual Element Time Delay Fuse

Circuit

Breaker

XE Series Motors

21

SECTION 5: XE Series 4” Submersible Motors

5.7 Cable Lengths

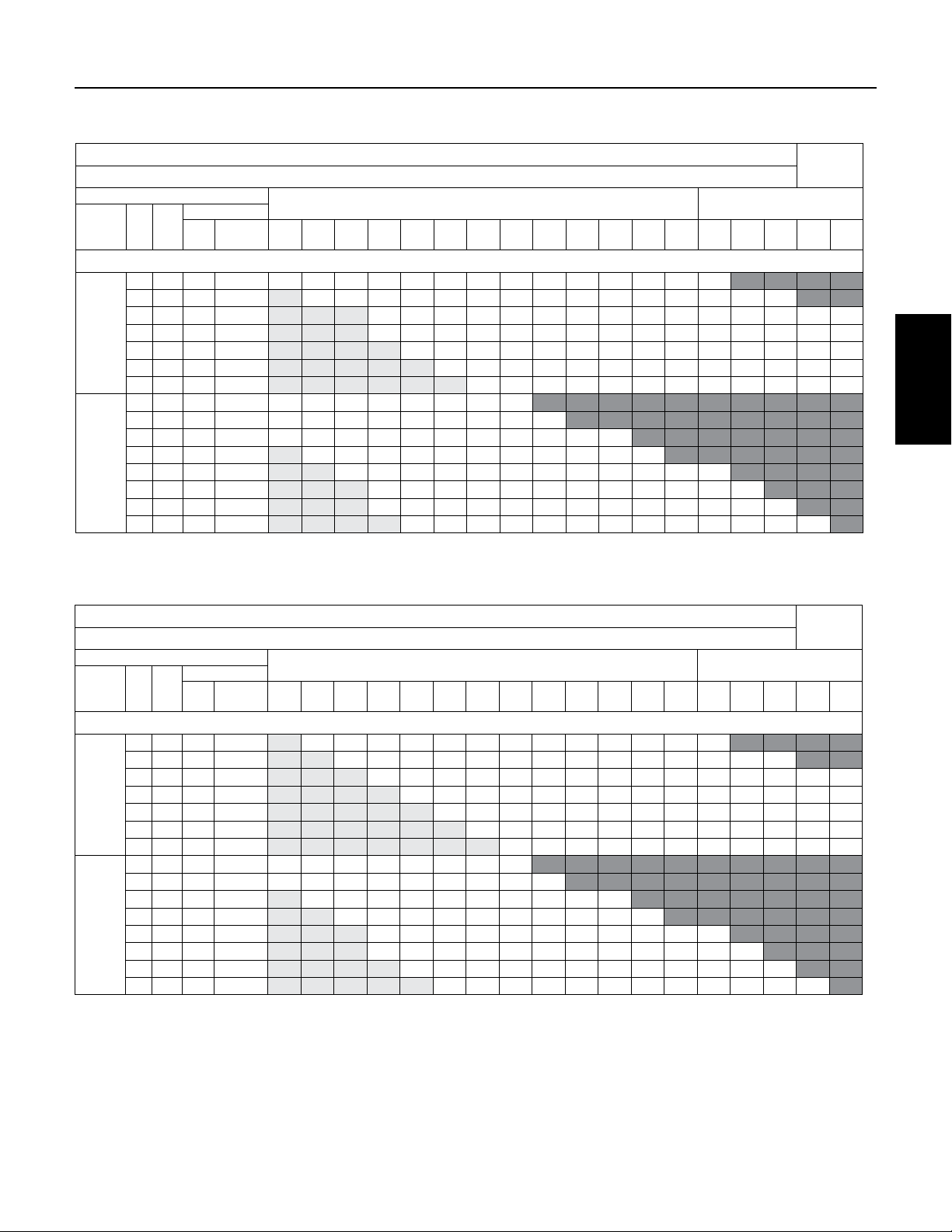

Ta ble 5-9: Cable Lengths, SINGLE PHASE 115 and 230 Volt, 60 Hz, 3450 RPM, 2- and 3-wire Motors, 60° and 75° C.

Service Entrance to Motor: Maximum Length in Feet

Motor

Type

PSC

2-Wire

CSIR

3-Wire

CSCR

3-Wire

Pentek® Part

Number

P42B0005A1-01

P42B0005A2-01

P42B0007A2-01 3/4 353 562 897 1420 2210 3523 4429 5594 7046 8895 11222

P42B0010A2-01 1 271 430 686 1087 1692 2697 3390 4281 5394 6808 8590

P42B0015A2-01 1-1/2 211 335 535 847 1318 2100 2640 3335 4201 5303 6690

P42B0005A1

P42B0005A2

P42B0007A2 3/4 342 545 869 1376 2141 3413 4291 5419 6826 8617 10871

P42B0010A2 1 241 383 611 968 1506 2400 3018 3811 4801 6060 7646

P42B0015A2 1-1/2 199 317 505 801 1246 1986 2496 3153 3972 5013 6325

P43B0005A1-01

P43B0005A2-01

P43B0007A2-01 3/4 281 447 713 1129 1757 2800 3521 4446 5601 7070 8920

P43B0010A2-01 1 233 371 592 937 1458 2324 2921 3689 4648 5867 7402

P43B0005A1

P43B0005A2

P43B0007A2 3/4 264 420 670 1061 1651 2632 3309 4178 5264 6644 8383

P43B0010A2 1 226 359 573 908 1413 2252 2831 3575 4504 5685 7173

P43B0005A2-01 1/2 457 726 1158 1835 2855 4551 5721 7225 9102 11489

P43B0007A2-01 3/4 365 581 927 1468 2284 3641 4577 5780 7281 9191 11596

P43B0010A2-01 1 300 478 762 1206 1877 2992 3762 4751 5985 7554 9531

P43B0015A2-01 1-1/2 201 320 510 808 1257 2004 2519 3182 4008 5059 6383

P43B0005A2 1/2 447 711 1135 1797 2796 4458 5604 7078 8916 11254

P43B0007A2 3/4 348 553 883 1398 2175 3467 4359 5505 6935 8753 11044

P43B0010A2 1 304 484 772 1223 1903 3034 3814 4817 6068 7659 9663

P43B0015A2 1-1/2 197 314 501 793 1234 1968 2474 3124 3936 4968 6268

P43B0020A2 2 180 286 456 722 1123 1790 2251 2843 3581 4520 5703

P43B0030A2 3 133 211 337 534 830 1324 1664 2102 2648 3342 4217

P43B0050A2 5 206 326 507 809 1017 1284 1618

HP Volt

1/2

1/2

1/2

1/2

115 112 178 284 449 699 1114 1401 1769 2229 2814 3550

230

115 115 183 293 463 721 1150 1445 1825 2299 2902 3662

230

115 101 160 255 404 629 1002 1260 1591 2004 2530 3192

230

115 87 138 221 349 544 867 1090 1376 1734 2188 2761

230

14 12 10 8 6 4 3 2 1 0 00

464 739 1178 1866 2903 4628 5818 7347 9256 11684

466 742 1183 1874 2915 4648 5843 7379 9295 11733

359 571 912 1444 2246 3581 4502 5685 7162 9040

348 553 883 1398 2175 3467 4359 5505 6935 8753

Wire Size, AWG

2042 2577

* Table data are generated per NEC standards.

22

SECTION 5: XE Series 4” Submersible Motors

Ta ble 5-10: Cable Lengths, THREE PHASE 230, 460, 200 and 575 Volt, 60 Hz, 3450 RPM Motors, 60° and 75° C.

Service Entrance to Motor: Maximum Length in Feet

Pentek® Part

Number

P43B0005A8

P43B0005A3 230 756 1202 1917 3037 4725 7532 9469

P43B0005A4 460 2922 4648 7414

P43B0007A8

P43B0007A3 230 562 894 1426 2258 3513 5601 7041 8892

P43B0007A4 460 2191 3486 5560 8806

P43B0010A8

P43B0010A3 230 466 742 1183 1874 2915 4648 5843 7379

P43B0010A4 460 1753 2789 4448 7045

P43B0015A8

P43B0015A3 230 359 571 912 1444 2246 3581 4502 5685 7162 9040

P43B0015A4 460 1370 2179 3475 5504

P43B0015A5 575 2283 3631 5792

P43B0020A8

P43B0020A3 230 288 459 732 1159 1803 2874 3613 4563 5748 7256 9155

P43B0020A4 460 1153 1835 2926 4635 7212

P43B0020A5 575 1336 2126 3390 5370

P43B0030A8

P43B0030A3 230 217 345 551 872 1357 2163 2719 3434 4326 5460 6889

P43B0030A4 460 827 1315 2098 3323 5171

P43B0030A5 575 1660 2641 4212 6671

P43B0050A8

P43B0050A3 230 125 199 318 503 783 1248 1569 1982 2496 3151 3976

P43B0050A4 460 516 820 1308 2072 3224 5140

P43B0050A5 575 721 1147 1829 2897 4507

P43B0075A8

P43B0075A3 230 211 334 519 827 1040 1314 1655 2089 2635

P43B0075A4 460 325 516 824 1305 2030 3236 4068 5138 6472

P43B0075A5 575 548 871 1390 2202 3426

P43B0100A4 10 460 255 405 647 1024 1593 2540 3193 4033 5080

* Table data are generated per NEC standards.

HP Volt

1/2

3/4

1

1-1/2

2

3

5

7-1/2

14 12 10 8 6 4 3 2 1 0 00

200 657 1045 1667 2641 4109

200 423 674 1074 1702 2648

200 346 551 879 1392 2166 3454 4342

200 265 421 672 1064 1655 2638 3317

200 217 344 549 870 1354 2158 2714 3427 4317 5449

200 159 253 403 638 993 1583 1990 2513 3166 3996

200 94 150 239 379 590 940 1182 1493 1881 2374 2995

200 64 101 161 255 397 633 796 1005 1266 1598 2017

Wire Size, AWG

XE Series Motors

23

SECTION 5: XE Series 4” Submersible Motors

5.8 4” Motor Overload Protection

Single Phase Motors

Single phase motors have overload protection either

in the motor or in the control box. Motors less than or

equal to 1HP have built-in protection. This automatic

protection will continue to cycle under a locked or stalled

rotorcondition.

Single phase motors larger than 1 HP use overload

protection located in the SMC (Submersible Motor

Controls) section. These are manual overloads and must

be manually reset if an overload condition occurs.

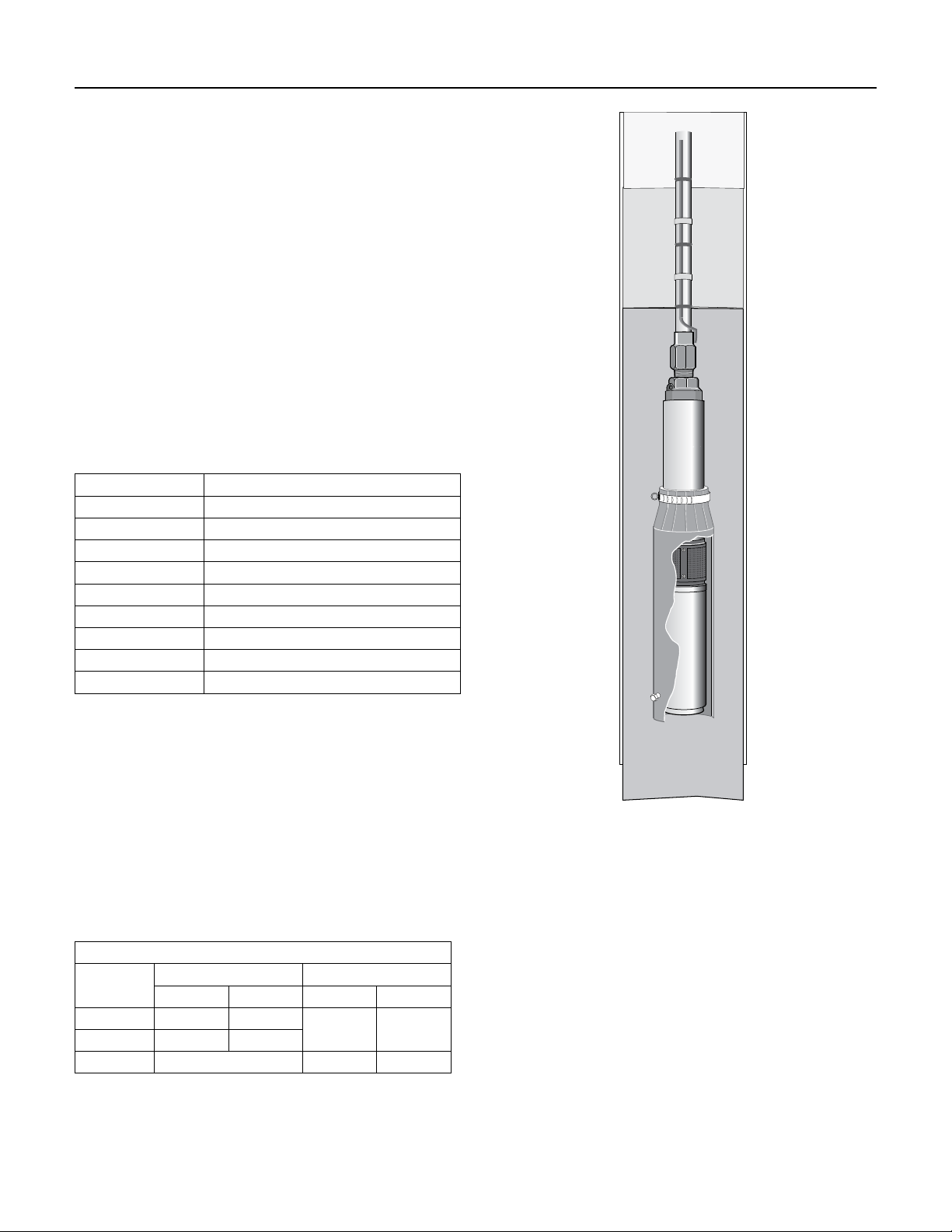

5.9 Motor Cooling

Pentek® 4” XE Series motors are designed to operate to a

maximum SF (Service Factor) horsepower in water up to

86° F (30° C).

4” motors: Minimum cooling water flow 3 HP and over

I.D of casing Flow GPM (LPM) required

4 1.2 (4.5

5 7 (26.5)

6 13 (49)

7 20 (76)

8 30 (114)

10 50 (189)

12 80 (303)

14 110 (416)

16 150 (568)

If the flow is less than specified, a flow-inducer sleeve

can be installed, as shown in Figure 5-2. The sleeve will

act like a smaller casing size to force flow around the

motor to aidcooling.

5.10 Starting Frequency

Recommended motor starting frequency is shown

below. Motor, pressure switch, tank, and pump life may

be extended by limiting starts per hour and starts per

day. Proper tank sizing is critical to control pump cycle

times. Excessive or rapid cycling creates heat which can

prematurely damage motors, switches, andcontrols.

Motor Starting Frequency

HP

1/2 thru 3/4 12.5 300

1 thru 5 4.2 100

7.5 thru 200 4.2 100

A one (1) minute minimum run time for pumps and motors up to 1.5HP and

two (2) minutes for 2HP and larger motors is recommended to dissipate heat

build-up from starting current.

24

Single Phase Three Phase

Starts/hr Starts/24hr Starts/hr Starts/24hr

12.5 300

Figure 5-2: Flow Inducer Sleeve

SECTION 6: Pentek® 6” Submersible Motors

6.1 Motor Inspection

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance.

This is the safety alert symbol. When you see this

symbol in this manual, look for one of the following

signal words and be alert to the potential for personal

injury!

indicates a hazard which, if not avoided, will

result in death or serious injury.

indicates a hazard which, if not avoided,

could result in death or serious injury.

indicates a hazard which, if not avoided,

could result in minor or moderate injury.

NOTICE

personalinjury.

Carefully read and follow all safety instructions in this

manual.

Keep safety labels in good condition. Replace missing

or damaged safety labels.

California Proposition 65 Warning

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

APPLICATION LIMITS

Maximum Immersion Depth: 985 ft. (300 m)

Maximum Water Temperature: 95°F (35°C)

pH content of the water: 6.5–8

Minimum Cooling Flow Rate: 0.5 feet per second (fps)

(0.15meters per second (mps)).

Required line voltage at the motor under operating

conditions (±10%).

NOTICE When calculating voltage at the motor, be sure

to allow for voltage drop in the cable.

The sum of the absolute values of the voltage and

frequency must not vary from the sum of the nominal

values by more than ±10%.

Operating with current unbalanced on the three legs of

the circuit can overheat and damage the motor and will

void the warranty. Current imbalance must not exceed

5% maximum.

Maximum Sand Content: 50ppm (max. size 0.1–0.25mm)

Maximum Chlorine Ion Content: 500ppm

addresses practices not related to

This product and related accessories

6.2 Testing

ELECTRICAL

(See Table 1, Page 4, for Motor Electrical

Specifications)

1. Risk of electrical shock if the cable is

damaged. Inspect the motor cable for any nicks or

cuts. Do not use the motor cable to pull, lift, or

handle the motor. Protect the motor cable during

storage, handling, moving, and installation of the

motor.

2. Inspect the motor to determine that it is the correct

horsepower, voltage, and size for the job and that

there is no shipping damage. Verify that the motor

nameplate voltage matches the available power

supply voltage. The nameplate rated voltage must

not vary more than ± 10% from the power supply

voltage.

3. On all new installations and after the motor has

sat idle for a long period of time, check the motor’s

internal electrical resistance with a megohmmeter

with lead wires connected. Prior to installation, the

motor should have an insulation value of at least

500 megohms. After installation, the motor and

power cable should have a minimum insulation

value of 1 megohm. If the minimum values are

below the listed values, contact the factory before

starting the motor.

4. Fuses or circuit breakers and overload protection

are required. Fuses or circuit breakers and

overloads must be sized in accordance with National

Electrical Code (NEC) or Canadian Electrical Code

(CEC) requirements, as applicable, and with all

applicable local codes and ordinances. See

Section 6 for these specifications.

5. Wire and ground the motor in accordance with

National Electrical Code (NEC) or Canadian

Electrical Code (CEC) requirements, as applicable,

and with all applicable local codes and ordinances.

6.3 Storage and Drain/Fill Instructions

LIFTING

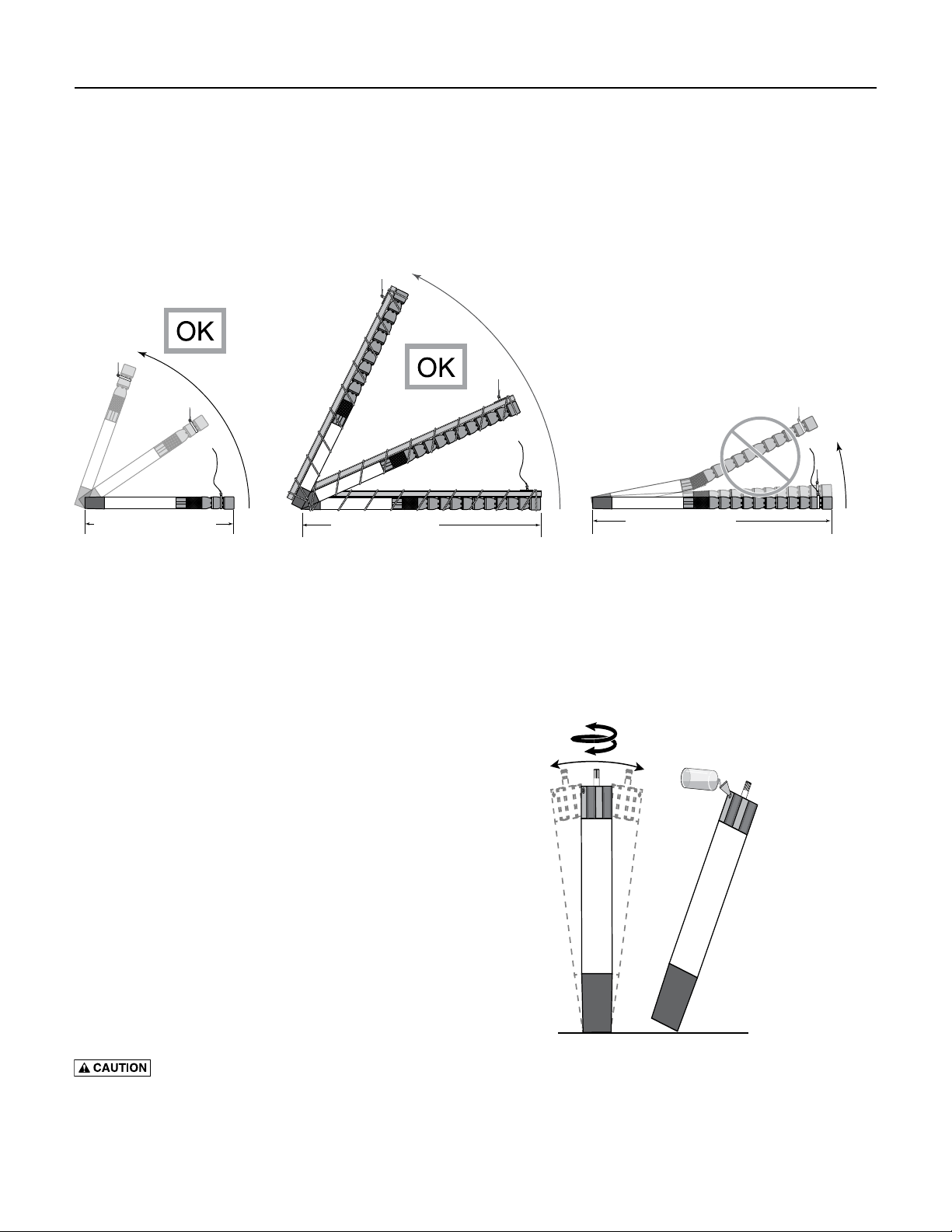

1. Heavy Object. Lifting equipment must be

capable of lifting motor and attached equipment. Check

over all tools, especially the hoisting gear, for wear or

damage before hoisting the unit.

2. If the total length of the pump and motor unit (without

any riser pipe attached) exceeds 10ft (3m), support the

unit with a girder while hoisting (see Figure 1). Do not

remove the supporting girder until the unit is standing

vertically in the hoist. Check for damage.

Pentek 6” Motors

25

SECTION 6: Pentek® 6” Submersible Motors

A. Rock motor

while turning

shaft.

B. Fill motor;

repeat rocking

and lling until

motor is full.

6.3 Storage and Drain/Fill Instructions

Figure 1: When the pump and motor together

(without any riser pipe) are 10ft (3m) long or more,

support the assembly before lifting to avoid bending

it in the middle. Never try to lift the motor or pump

by the motor cables.

MOTOR STORAGE AND INSTALLATION

1. The motor is filled at the factory with anti-freeze

2. Verify that the motor is full before installing. If not, fill

from falling over.

Less Than 10 Ft (3 M)

which will protect it in temperatures down to –22ºF

(-30ºC). Do not install, transport or store the motor

below these temperatures if the motor is filled. If

storage is necessary at temperatures below –22ºF

(-30ºC), drain the anti-freeze from the motor.

it with clean water (see below). Installing a motor that

is not filled with liquid will void the warranty. Before

installation, check all water fill and drain plugs,

mounting bolts, and cable connections for tightness.

Refill the motor with clean water as follows:

A. Stand the motor on end (vertically) and remove the

fill plug with a 5mm hexagonal nut driver.

B. Turn the motor shaft by hand while rocking the

motor back and forth (see Figure 2).

C. Pour in clean water until the motor is as full as

possible.

D. Repeat the turning/rocking procedure.

E. Check the liquid level. If necessary, add more clean

water.

F. When the motor is full, re-install the fill plug.

Tighten it with the 5mm hexagonal nut driver.

Support motor while rocking to prevent motor

10 Ft (3M) or More

Support the pump and motor!

10 Ft (3M) or More

Lack of support will destroy the motor!

Figure 2: Rock Motor gently from side to side while

turning shaft by hand (A), then fill with clean water (B).

Repeat until full.

26

10’ (3M)

or more

Well

Water

Flow Inducer

Sleeve

Motor

Pump

NOT TO SCALE

SECTION 6: Pentek® 6” Submersible Motors

6.3 Storage and Drain/Fill Instructions

NOTICE To avoid damaging the motor thrust bearing,

do not hammer on the shaft, coupling, or slinger. Check

the motor rotation by hand to make sure that it turns

freely.

1. To avoid damage to the motor diaphragm, make

sure that the bottom of the motor does not touch

the dirt or mud at the bottom of the well. Install the

motor at least 10’ above the well bottom.

2. To install the motor horizontally, lay it down with

the lead wires at 12 o’clock when you are facing

the motor shaft. To prevent any load on the shaft

and bearings and to avoid any damaging vibrations

to the motor, mount the motor solidly on the pump

end and make sure that the pump and motor are

accurately aligned.

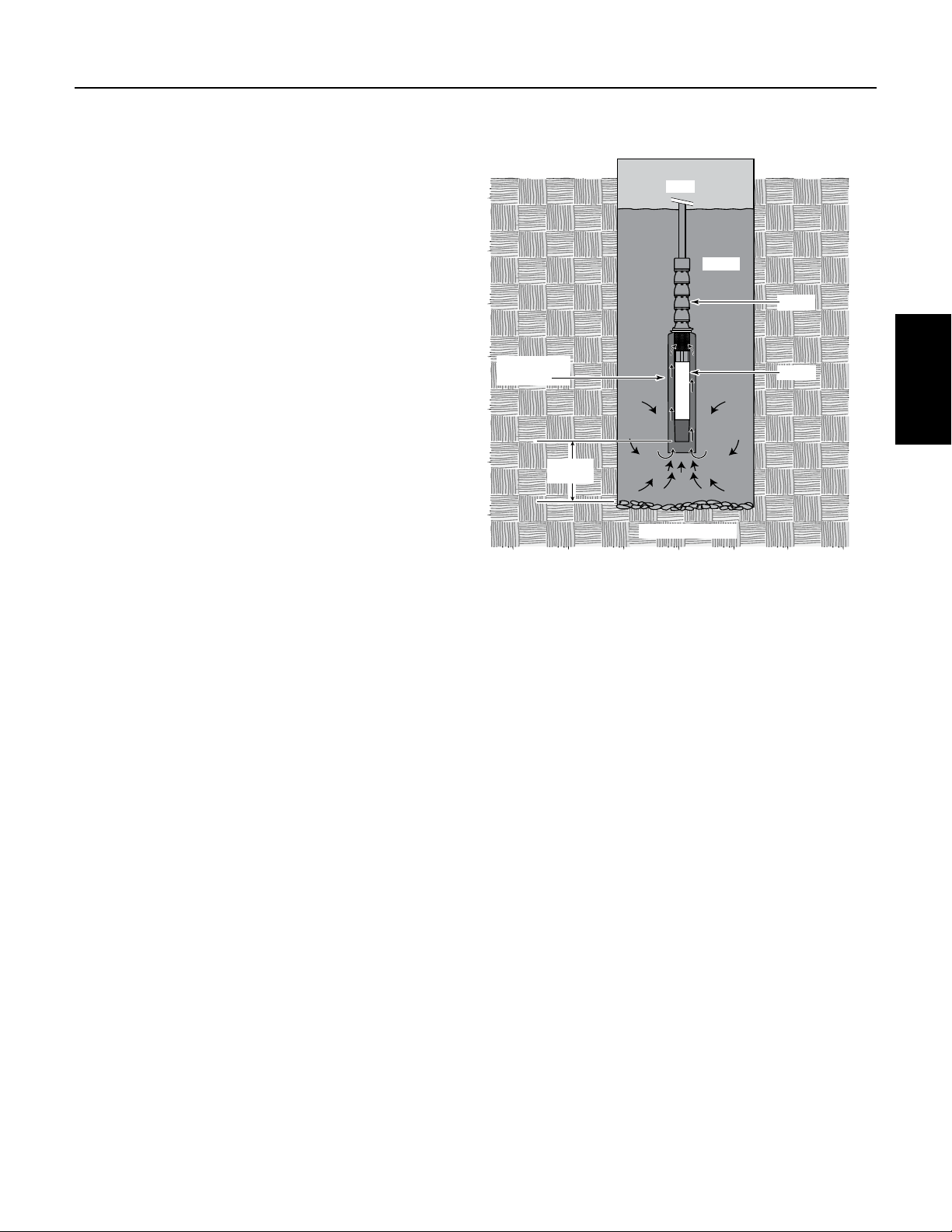

3. Install the motor so that during operation water

flows past all parts of it at a rate of at least 0.5 fps

(0.15 mps). If the well will not provide this flow,

install a sleeve on the motor to channel water past

it (see Figure 3). Do not try to operate the motor in

mud or sand. To do so will damage the motor and

void the warranty.

4. Electrical connections: Connect the three motor

leads to the three hot motor leads (black, brown,

and blue) in the incoming cable. Connect the

ground wire (green and yellow) in accordance with

NEC or CEC requirements (as applicable) and in

accordance with all applicable local codes and

ordinances. Apply power momentarily to check

rotation. If the motor runs backwards, interchange

any two power leads to reverse direction of rotation.

Figure 3: If flow past motor is less than .5 fps (0.15 mps),

install a flow inducer sleeve as shown. Flow must be at

least .5 fps (0.15 mps) for adequate motor cooling. The

flow inducer sleeve should not touch the

motor.

Pentek 6” Motors

side of the

27

SECTION 6: Pentek® 6” Submersible Motors

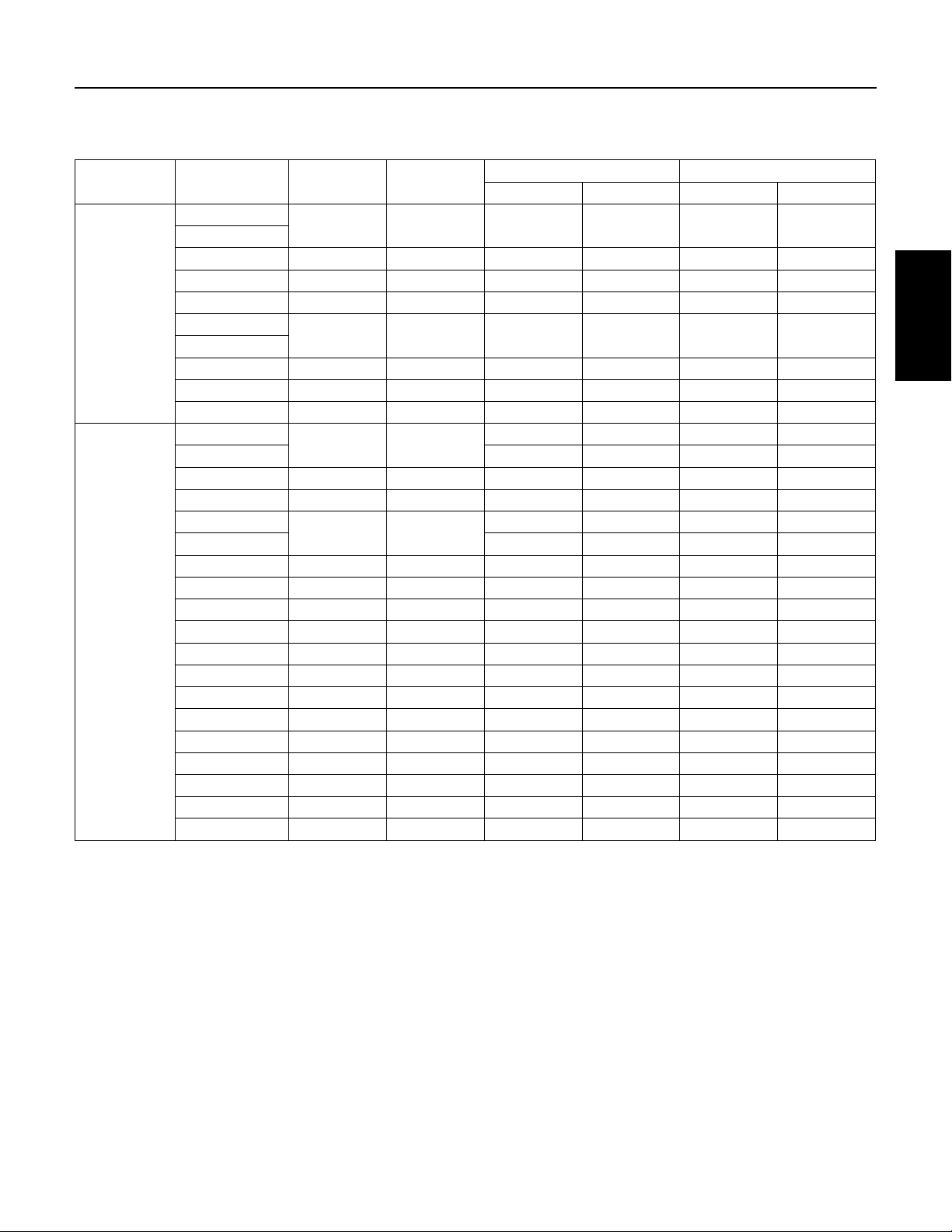

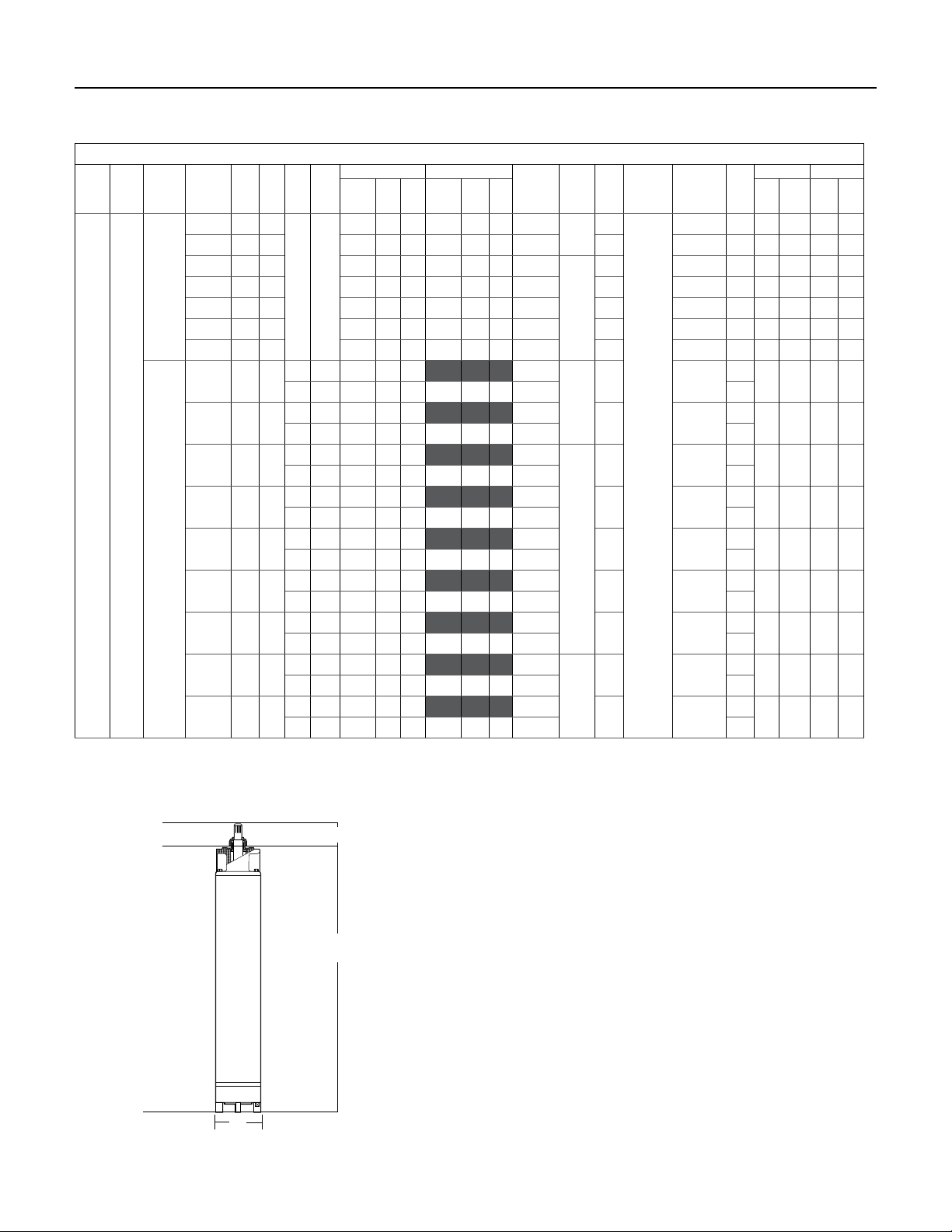

6.4 Motor Specifications

Ordering Information

MOTOR

TYPE PHASE NOTE

are 60 Hz

6” Three

Motors are

dual rated

50 Hz &

SERVICE FACTOR 1.00 SERVICE FACTOR 1.15

PENTEK

MODEL # HP KW HZ VOLTS

6PM2-5-2 5 4

6PM2-7-2 7-1/2 6 21.2 79 85 23.2 79 86 146.4 J 0.5389 3460 24.9 632 102 46

6PM2-10-2 10 8 30.8 77 81 33.0 78 83 187.6

Motors

6PM2-15-2 15 11 43.2 78 84 47.0 78 86 281.8 J 0.2782 3450 31.8 807.5 121 55

only

6MP2-20-2 20 15 57.4 79 85 63.0 79 87 394.5 J 0.2101 3450 35.1 892.5 147 67

6PM2-25-2 25 19 69 81 86 76.0 80 88 480.2 J 0.1605 3450 38.0 964.5 165 75

6PM2-30-2 30 22 76.6 84 88 85.0 84 89 614.2 K 0.1445 3500 41.8 1,060.5 190 86

6PM2-5-4 5 4

6PM2-7-4 7-1/2 6

6PM2-10-4 10 8

6PM2-15-4 15 11

6PM2-20-4 20 15

60 Hz

6MP2-25-4 25 19

6PM2-30-4 30 22

6PM2-40-4 40 30

6PM2-50-4 50 37

60 230

50 380 8.9 75 87 45.6

60 460 10.6 75 83 8.2 77 85 51.1 3460

50 380 12.5 79 87 66.8

60 460 15.4 79 85 11.6 79 86 73.2 3460

50 380 17.8 78 85 85.6

60 460 15.4 77 81 16.5 78 83 93.8 3440

50 380 25.6 77 87 127

60 460 21.6 78 84 23.5 78 86 140.9 3450

50 380 34 78 89 170.2

60 460 28.5 79 85 31.5 79 87 197.3 3450

50 380 41 79 89 219

60 460 34.5 81 86 38.0 80 88 240.1 3450

50 380 46 83 90 276.8

60 460 38 84 88 42.5 84 89 307.1 3500

50 380 62.5 83 90 393.1

60 460 52.7 84 88 58.0 84 89 439.7 3490

50 380 77.6 83 90 449.8

60 460 64.3 85 87 70.8 85 89 500.5 3480

EFF. %P.F.

AMPS

15 .2 75 83 16.4 77 85 102.1

% AMPS

EFF. %P.F.

LOCKED

ROTOR

THRUST

AMPS

% IN MM LBS KG

KVA

LOAD

CODE

K

1763

J 0.3964 3440 29.2 741.5 116 53

3485

K 2.9674

1763

J 1.9828

J 1.4648

J 0.9916

3485

J 0.7192

J 0.5640

K 0.5036

K 0.3958

6182

K .3295

INSULATION

CLASS

F

WINDING

LENGTH WEIGHT

RESISTANCE

(OHM) RPM

0.7873 3460 22.7 577 90 41

2820

22.7 577 90 41

2820

24.9 632 102 46

2800

29.2 741.5 116 53

2810

31.8 807.5 131 55

2810

35.1 892.5 147 67

2820

38.0 964.5 165 75

2880

41.8 1060.5 190 86

2860

47.1 1197 209 95

2840

49.9 1267 292 132

6.5 Motor Dimensions

D

28

L

1

Nominal diameter 6"/152.4 mm

Effective diameter 5.43"/138 mm

Shaft extension length 2.87" / 73 mm

L

For lengths, refer to Ordering Information tables.

Dimensions are for estimating purposes only.

SECTION 6: Pentek® 6” Submersible Motors

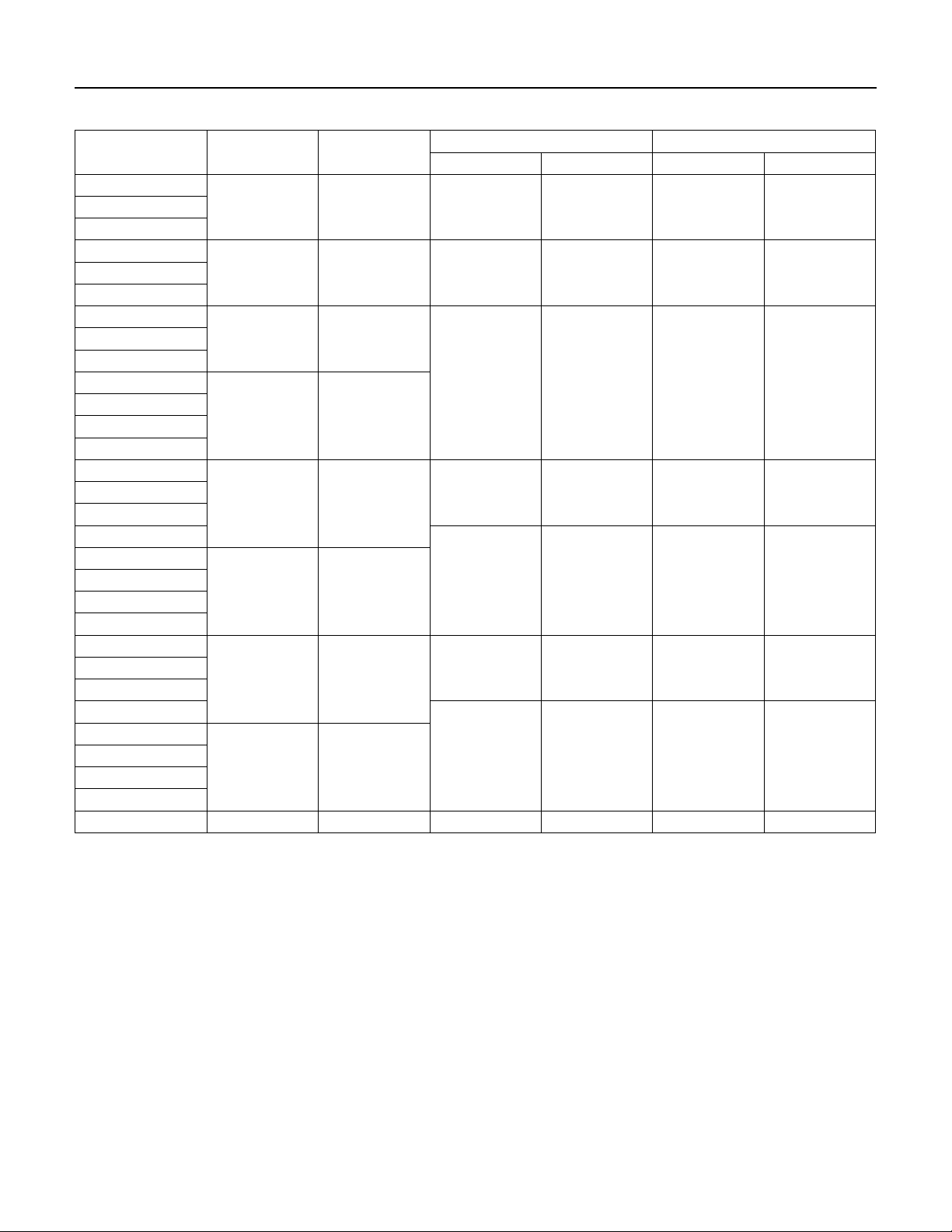

6.6 Motor Fuse Sizing and Cable Selection

CABLE SELECTION

COPPER CABLE SIZE - From Main Breaker Panel to Motor (in feet)

MOTOR

FUSE

VOLTS /

HZ HP KW

THREE PHASE

5 3.7 45 25 154 245 391 620 965 1538 1933 2442 3076 3883 4899 6184 7791 9198

7.5 5.5 60 40 - 174 277 438 682 1087 1367 1726 2174 2745 3463 4372 5508 6502 7806 9124

10 7.5 90 50 - - - 308 479 764 961 1213 1529 1930 2434 3073 3872 4571 5488 6415 7334 9125

230 V

15 11 125 80 - - - 216 337 537 675 852 1073 1355 1709 2158 2719 3210 3853 4504 5149 6407

60 Hz

20 15 175 110 - - - - 251 400 503 636 801 1011 1275 1610 2028 2394 2874 3360 3842 4780

25 18.5 225 125 - - - - - 332 417 527 664 838 1057 1334 1681 1985 2383 2785 3184 3962

30 22 250 125 - - - - - - 373 471 593 749 945 1193 1503 1775 2130 2490 2847 3543

5 3.7 20 10 617 982 1566 2480 3859 6152 7734 9767

7.5 5.5 30 20 436 694 1107 1753 2728 4349 5467 6904 8698

10 7.5 45 25 307 488 778 1233 1918 3057 3844 4854 6115 7719 9738

460 V

60 Hz

15 11 70 40 - 343 546 865 1347 2147 2699 3408 4293 5419 6837 8631

or

20 15 90 50 - - 408 646 1005 1601 2013 2543 3203 4043 5101 6439 8113 9578

380 V

50 Hz

25 18.5 110 60 - - - 535 833 1328 1669 2108 2655 3351 4228 5338 6725 7939 9531

30 22 125 70 - - - 479 745 1187 1492 1884 2374 2997 3781 4773 6013 7099 8522 9961

40 30 150 100 - - - - 546 870 1093 1381 1740 2196 2770 3497 4406 5202 6244 7299 8345

Lengths only meet the US National Electrical Code ampacity requirements for individual conductors rated 60° C in free air or water, NOT in magnetic enclosures, conduit or direct buried. Refer

to NEC Table 310.15(B)(17) for more information.

STD

Dual

Element

14 12 10 8 6 4 3 2 1 0 00 000 0000 250 300 350 400 500

AWG MCM

60˚

Pentek 6” Motors

CABLE SELECTION

COPPER CABLE SIZE - From Main Breaker Panel to Motor (in feet)

MOTOR

FUSE

VOLTS /

HZ HP KW

THREE PHASE

5 3.7 45 25 - 245 391 620 965 1538 1933 2442 3076 3883 4899 6184 7791 9198

7.5 5.5 60 40 - - 277 438 682 1087 1367 1726 2174 2745 3463 4372 5508 6502 7806 9124

10 7.5 90 50 - - - 308 479 764 961 1213 1529 1930 2434 3073 3872 4571 5488 6415 7334 9125

230 V

15 11 125 80 - - - - 337 537 675 852 1073 1355 1709 2158 2719 3210 3853 4504 5149 6407

60 Hz

20 15 175 110 - - - - - 400 503 636 801 1011 1275 1610 2028 2394 2874 3360 3842 4780

25 18.5 225 125 - - - - - - 417 527 664 838 1057 1334 1681 1985 2383 2785 3184 3962

30 22 250 125 - - - - - - - 471 593 749 945 1193 1503 1775 2130 2490 2847 3543

5 3.7 20 10 617 982 1566 2480 3859 6152 7734 9767

7.5 5.5 30 20 436 694 1107 1753 2728 4349 5467 6904 8698

10 7.5 45 25 - 488 778 1233 1918 3057 3844 4854 6115 7719 9738

460 V

60 Hz

15 11 70 40 - - 546 865 1347 2147 2699 3408 4293 5419 6837 8631

or

20 15 90 50 - - - 646 1005 1601 2013 2543 3203 4043 5101 6439 8113 9578

380 V

50 Hz

25 18.5 110 60 - - - 535 833 1328 1669 2108 2655 3351 4228 5338 6725 7939 9531

30 22 125 70 - - - - 745 1187 1492 1884 2374 2997 3781 4773 6013 7099 8522 9961

40 30 150 100 - - - - - 870 1093 1381 1740 2196 2770 3497 4406 5202 6244 7299 8345

Lengths only meet the US National Electrical Code ampacity requirements for individual conductors rated 75° C in free air or water, NOT in magnetic enclosures, conduit or direct buried. Refer

to NEC Table 310.15(B)(17) for more information.

STD

Dual

Element

14 12 10 8 6 4 3 2 1 0 00 000 0000 250 300 350 400 500

AWG MCM

75° C

29

Loading...

Loading...