Page 1

EVERPURE® PRO

REVERSE OSMOSIS WATER FILTRATION SYSTEM

INSTALLATION AND OPERATING INSTRUCTIONS

©2014 Pentair Residential Filtration, LLC

Page 2

TABLE OF CONTENTS

WARNING:

Operating Specifications ...................................................... 2

System Dimensions .............................................................2

Production Capabilities........................................................2

Tools Required .....................................................................3

Precautions ..........................................................................3

How Reverse Osmosis Works .............................................. 4

Installation ..........................................................................5

System Startup ..................................................................11

Testing Your Reverse Osmosis System ..............................12

Maintenance .......................................................................12

Troubleshooting ................................................................. 14

Performance Data ..............................................................16

California Proposition 65 Warning .....................................17

Replacement Parts ............................................................18

NOTE: If your water pressure and temperature are at the

low end of the listed range (40 psi [2.8 bar] and 40°F

[4.4°C]), and the TDS level is near the maximum

(1500 ppm), the system will not function properly.

Under these extreme conditions, pre-warming the

supply water using a 25 feet (7.62 m) coil of tubing

between the supply adapter and the system, and/

or installing a booster pump to increase the water

pressure will allow the system to perform effectively.

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

Systems certified for cyst reduction may be

used on disinfected waters that may contain

filterable cysts.

NOTE: Substances reduced are not necessarily in your

water. System must be maintained according to

manufacturer’s instructions, including replacement

of filter cartridges.

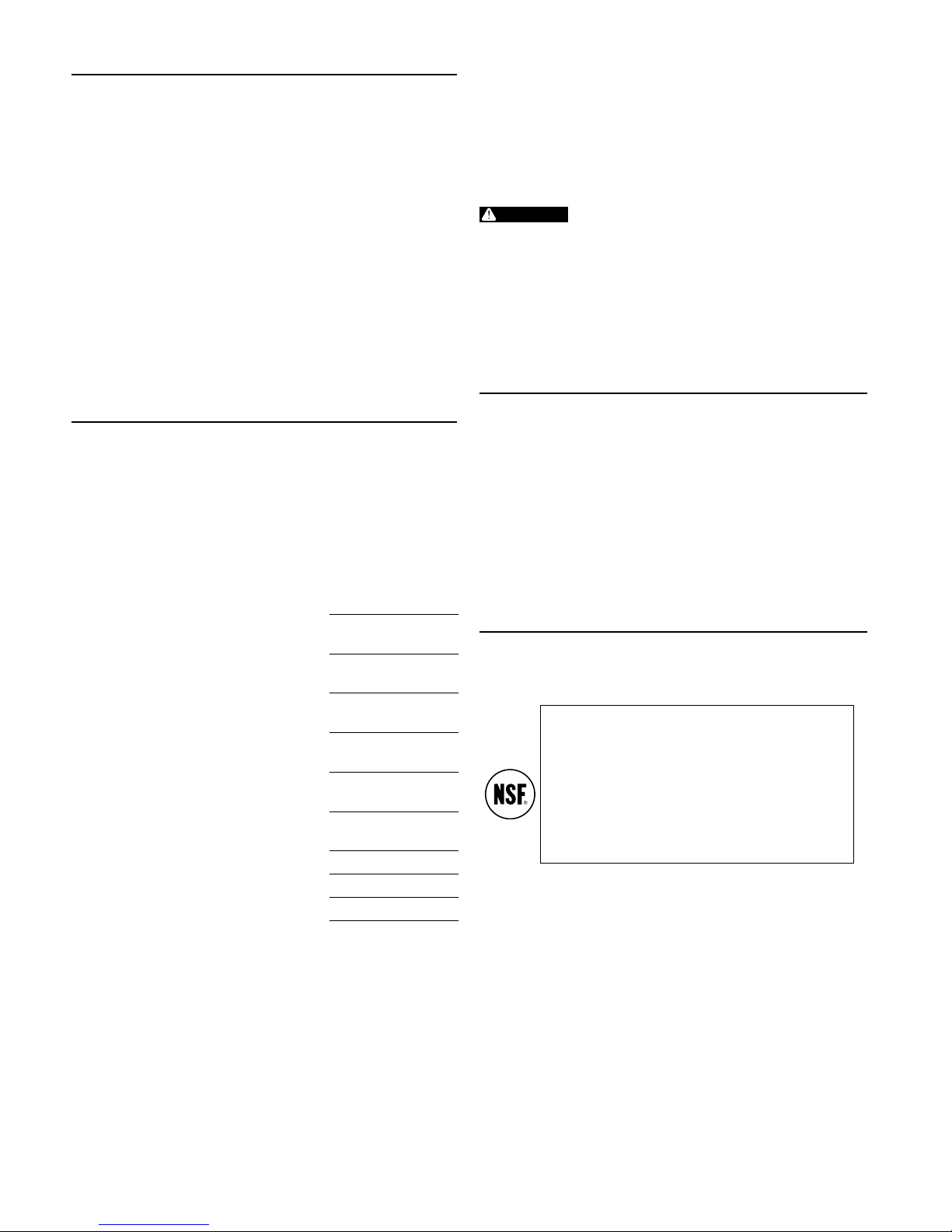

SYSTEM DIMENSIONS

OPERATING SPECIFICATIONS

IMPORTANT! Before installing this reverse osmosis system,

make certain your water supply complies with the following

operating specifications. Failure to comply may reduce the

effectiveness of the system and will void the warranty. Consult

your local water treatment utility or a certified water testing

lab to determine the quality for your water and use the table

below to record your results for future reference.

Specifications Your Water

Pressure Range: 40–100 psi

(2.7–6.9 bar)

Temperature

Range:

Total Dissolved

Solids: <1500 ppm

Maximum

Hardness †: 10gpg (171 mg/L)

Sulfide, Iron and

Manganese‡: <0.01 ppm

Chlorine in Water

Supply: <2 ppm

Water Supply pH

Limits: 4–11

Turbidity: 1 NTU Max

Model #

Date of Purchase:

†IMPORTANT: If the hardness of your water is above 10 gpg

(171 mg/L), lime scale will build up rapidly on the membrane

inside of the RO membrane cartridge. Scale buildup will plug

the RO membrane cartridge and make the system ineffective.

We do not recommend these reverse osmosis systems be used

with water in excess of 10 gpg (171 mg/L) hardness, unless the

water is softened prior to the reverse osmosis system.

‡See your local dealer or water treatment specialist to reduce

these substances in your water.

40–100°F

(4.4–37.8°C)

System Dimensions: 13.75 inches W x 4.75 inches D x

12.75 inches H

(349 mm x 121 mm x 318 mm)

System Weight: 6.1 lbs. (2.7 kg)

Tank Dimensions: 11.3 inches Dia x 16.75 inches H

(287 mm x 425 mm) (with valve)

Tank Capacity: 1.9–3.2 gallons (7.2–12.1 L)

(depending on water pressure)

Tank Weight (full): 40 lbs. (18.2 kg.)

(depending on water pressure)

PRODUCTION CAPABILITIES

Tested by NSF International according to NSF/ANSI Standard 58

has given 5.7 gallons per day. Source water test parameters are

50 psig, 77ºF, pH of 7.5 ± 0.5 and 750 ppm total dissolved solids.

The PRO is Tested and Certified by NSF

International against NSF/ANSI Standard 58 for

the reduction of Total Dissolved Solids, Fluoride,

Turbidity, Nitrate/Nitrite, Lead, Selenium,

Pentavalent Arsenic, Copper, Cadmium,

Hexavalant Chromium, Trivalent Chromium,

Barium, Cysts, Radium 226/228 and NSF/ANSI

Standard 42 for the reduction of chlorine taste

and Odor.

NSF ANSI Standard 58 certified to reduce cysts such

as Cryptosporidium and Giardia by mechanical means.

EPA Est. No 090375-MEX-001

2 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Page 3

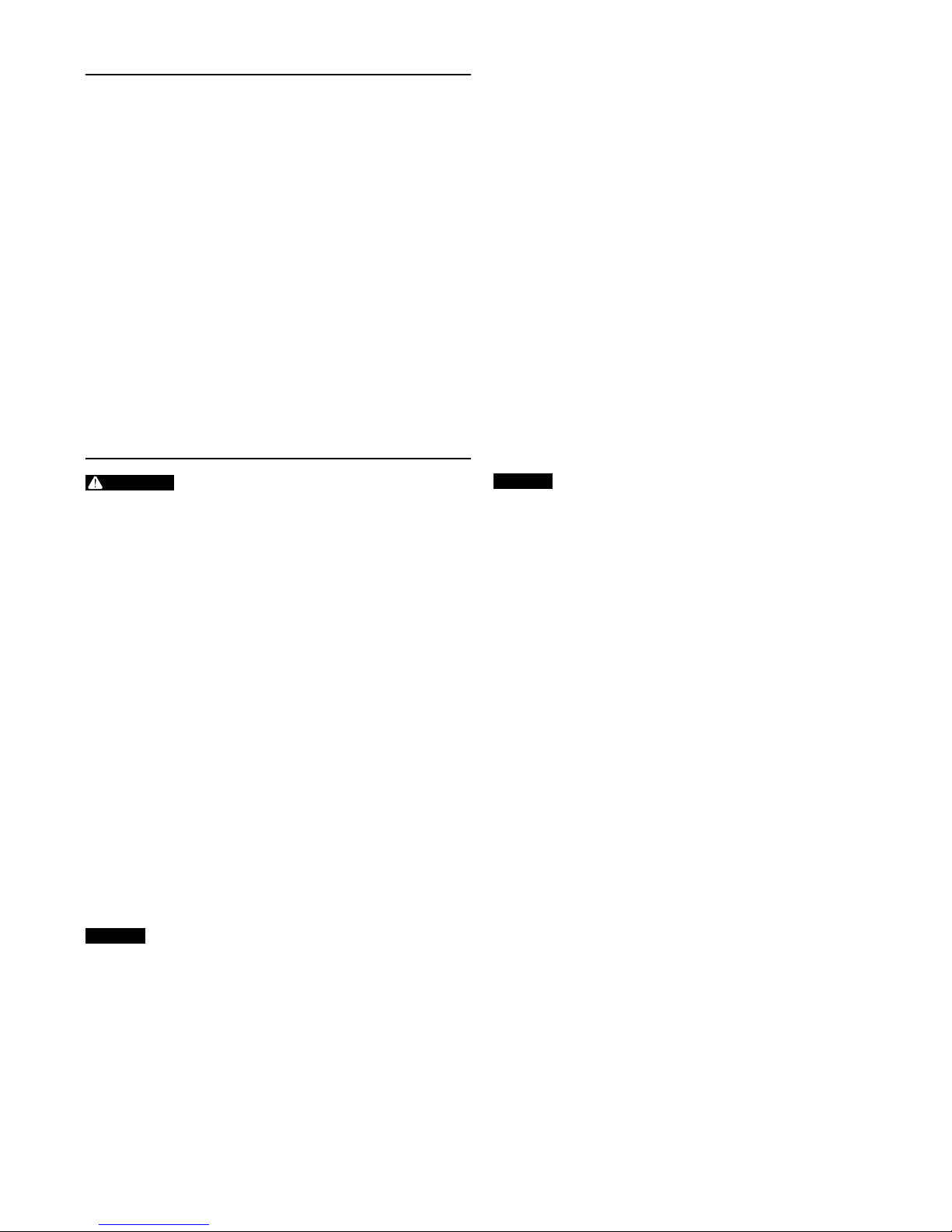

TOOLS REQUIRED

WARNING:

CAUTION

CAUTION

Tools Required

• Hand or electric drill

• Screwdriver - Phillips

• (2) Adjustable wrenches

• Drill bits: 1/8-inch, 1/4-inch and 3/8-inch

• Metal file

• Safety glasses

• Utility knife or tube cutter

• Needle-nose pliers

• Measuring tape

If sink does not have hole for separate faucet:

• Center punch

• 1-1/4 inch bi-metal or carbide-tipped hole saw

• Respirator

NOTE: All tools listed will not be necessary for installation.

Read installation procedures before starting to

determine required tools.

PRECAUTIONS

The PRO system contains a replaceable

membrane critical to the efficiency of the

system. Replacement of the reverse osmosis

membrane should be with one of identical

specifications, as defined by the manufacturer,

to assure the same efficiency and contaminant

reduction performance.

The PRO system contains a replaceable

The PRO is acceptable for treatment of

The PRO shall only be used for arsenic

The Reverse Osmosis (RO) system will not

Because of the product’s limited service life and to

Do not use Plumber’s Putty in the installation of

NOTE:

membrane, critical for the effective reduction

of total dissolved solids. Product water should

be tested periodically to verify that the system

is working properly.

influent concentrations of no more than 27

mg/L nitrate and 3 mg/L nitrite in combination

measured as N and is certified for nitrate/

nitrite reduction only for water supplies with

a pressure of 40 psig (280 kPa) or greater.

reduction on chlorinated water supplies

containing detectable residual free chlorine at

the system inlet. Water systems using an inline chlorinator should provide a one-minute

chlorine contact time before the RO system.

protect against disease-causing bacteria or

remove naturally-occurring harmless bacteria.

The PRO system must be protected against

freezing which can cause the filter housing to

crack and leak water.

prevent costly repairs or possible water damage,

we strongly recommend that the filter housings be

replaced every ten years. If your housing has been in

use for longer than this period, it should be replaced

immediately. Date the bottom of any new filter

housing to recommend the next replacement date.

this product as it may cause cracking of the filter

housing threads.

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 3

• Your water must be within required limits for

satisfactory operation. If not, your membrane life may

be shortened and your warranty will be voided (see

Operating Specifications, page 1).

• Install on cold water line only.

• Make certain that installation complies with all state

and local laws and regulations.

• The reverse osmosis membrane and replacement

cartridges included with this system have limited

service lives. Changes in taste, odor, and color of the

filtered water indicate that the cartridge(s) and/or

membrane should be replaced (see Maintenance, page

10). On the monitored model (PRO) the green light

indicates optimum performance while the amber light

indicates that the membrane is in need of changing.

• During extended periods of non-use (such as during a

vacation), remove the membrane from the membrane

housing and place it in a sealed plastic bag. Store

membrane in refrigerator for future use. DO

NOT FREEZE.

• If system stands for more than 2–3 days without being

used, the storage tank should be emptied.

Membrane Precautions

Chlorine will destroy the Reverse Osmosis

membrane. If you use these RO systems with a

chlorinated or periodically-chlorinated water

supply, it is ABSOLUTELY NECESSARY to use a

carbon prefilter (included with the system). This

carbon prefilter should be changed at least every

3 months to avoid chlorine breakthrough. See

warranty for disclaimers and limitations that apply

to the RO membrane.

NOTE: To make sure no chlorine is present in the water that

reaches the membrane, use a test kit that tests

free-chlorine to check the reject water that flows

from the membrane to the drain. No chlorine should

be detected.

Page 4

HOW REVERSE OSMOSIS WORKS

The Everpure PRO uses a semi-permeable membrane to

reduce dissolved salts, improving the taste and odor of your

water. The RO membrane is made of multiple layers of

micron-thin film wound around a hollow center core. Water

molecules can pass through the membrane, while dissolved

salts are rejected.

The Everpure PRO system features triple-filter action. Your

household water supply is prefiltered to reduce dirt and

chlorine that may foul the membrane. The RO membrane

separates this prefiltered water into PRODUCT WATER and

REJECT WATER. Your household water pressure forces the

product water through the membrane and into the storage

tank. Dissolved salts cannot pass through the membrane and

are sent to the drain as reject water. When you open the RO

faucet, product water is drawn from the storage tank through

a post-polishing filter. The post-polishing filter takes out any

remaining taste or odor in the water and provides you and your

family with cleaner, great-tasting water.

The PRO system also features an auto shut-off valve, which

shuts off the system once the pressure in the storage tank

reaches 2/3 of the incoming water pressure (your household

water pressure). When you open the faucet to draw water from

the storage tank, the pressure inside the tank drops and the

auto shut-off valve opens. The system then begins to operate,

replenishing the water you took from the storage tank. For

each gallon of water produced, 9 gallons are discharged as

reject water. The storage tank can hold up to

3.2 gallons of water at a time, more than enough for the

average family’s drinking and cooking needs.

When used under operating conditions specified on page 2 of

the manual, your Reverse Osmosis membranes should last

12–24 months.

NOTE: The PRO unit will indicate a need for a membrane

The precise life span of your system’s membrane will depend

on the quality of the water entering the system and the

frequency with which you use it. Frequent use prevents the

dissolved salts from building up on the membrane as scale.

The more water the system is required to produce, the longer

the membrane will last. You may wish to find a variety of uses

for your system in order to prolong the life of the membrane.

The life of the membrane will also depend upon the regularity

with which you replace the prefilter cartridge in the system.

change with an amber light; see LIGHT INDICATOR

READINGs, page 10 for details.

4 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Page 5

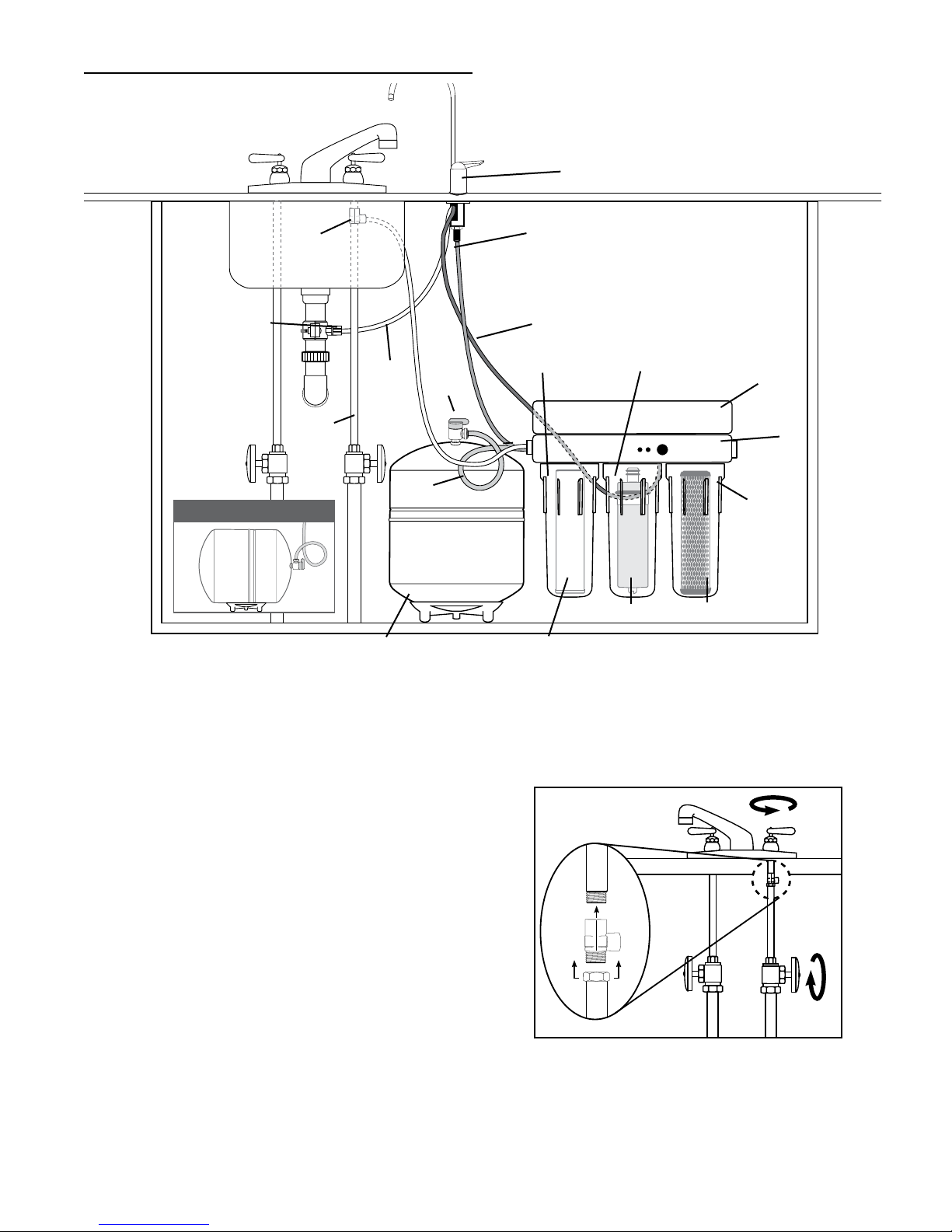

INSTALLATION

Drinking Water Faucet

Supply

Adapter

Drain

Clamp

Cold

Water

Optional Tank Installation

White

Green

Storage

Tank

Tank

Valve

Blue

Red

Post-polishing

Filter Housing

Post-polishing

Filter

Membrane

Housing

Membrane

Manifold

Cover

Manifold

Prefilter

Housing

Prefilter

Figure 1

Installing the Water Supply Adapter

NOTE: Read all installation and operating instructions

before installing and using your RO system.

The supply adapter fits 1/2-NPS supply threads. If local codes

permit, it may be used to connect the PRO to the cold water

supply line. If local codes do not permit the use of the supply

adapter, alternate connectors can be obtained from your local

plumbing wholesaler.

See Figure 2.

1. Turn off cold water supply line. If cold water line does not

have a shut-off valve under the sink, you should install one.

2. Turn on the cold water faucet and allow all water to drain

from line.

3. Disconnect cold water line from the threaded stub on

bottom of main faucet.

4. Apply plumber tape onto threads of faucet stub and supply

adapter. Screw the water supply adapter to the threaded

faucet stub as shown.

5. Using the nut that previously connected the cold water line

to the faucet, screw the cold water line to the male supply

adapter threads.

Figure 2

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 5

Page 6

Selecting the Faucet Location

CAUTION

The drinking water faucet should be positioned with function,

convenience and appearance in mind. An adequate flat area is

required to allow faucet base to rest securely. The faucet fits

through a 1-1/4 inch hole. Most sinks have pre-drilled

1-1/2 inch or 1-3/8 inch diameter holes designed for spray

hoses. The drinking water faucet may be installed using one of

these holes, despite their larger size. If these pre-drilled holes

cannot be used or are in an inconvenient location, it will be

necessary to drill a 1-1/4 inch hole for the faucet in the sink or

through the countertop next to the sink.

Mounting the Faucet

1. Loosen brass stem-nut on faucet, remove metal “C”

disc (Figure 4).

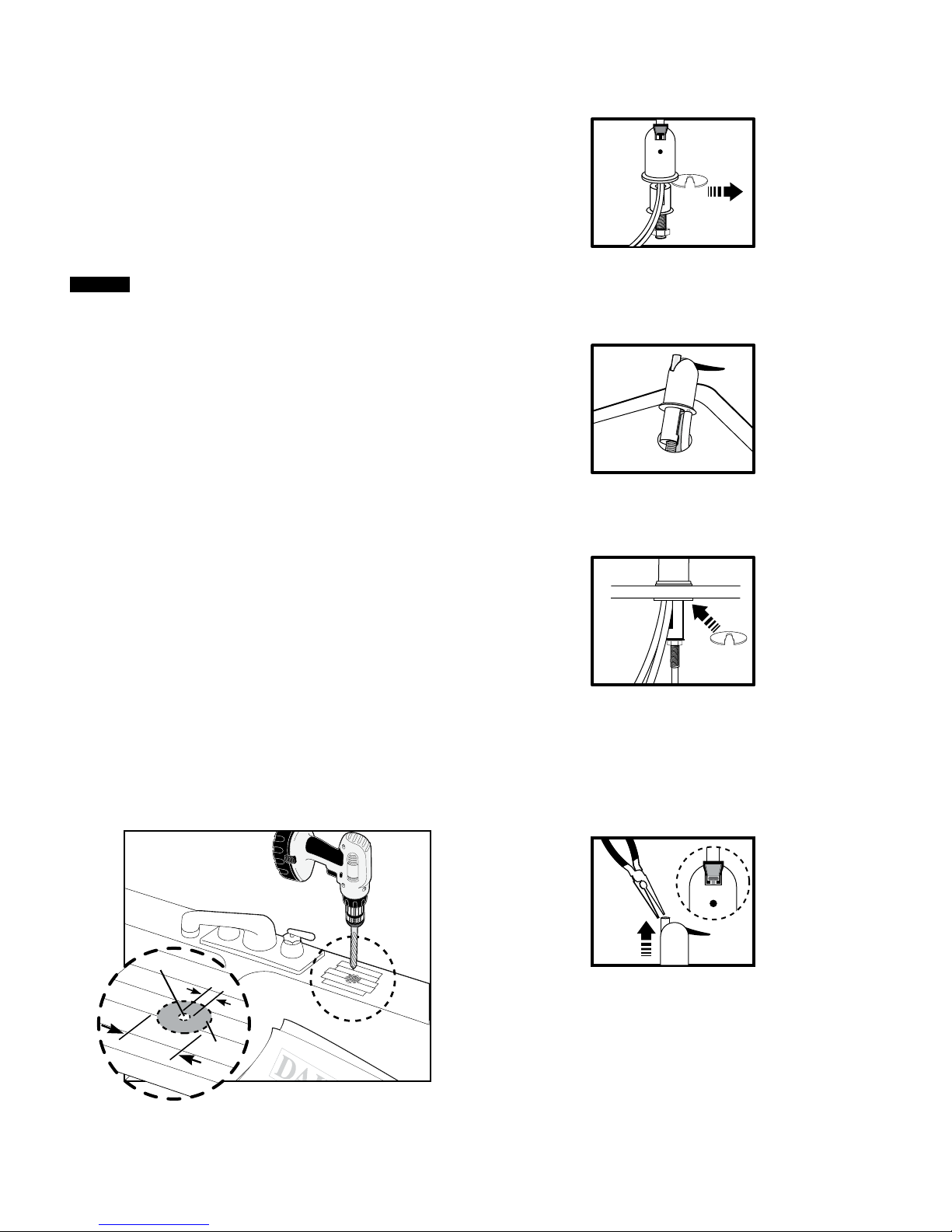

Drilling the Faucet Hole

This procedure may generate dusts which can

cause severe irritation if inhaled or if they come

into contact with the eyes. The use of safety

glasses and respirator for this procedure

is recommended.

DO NOT ATTEMPT TO DRILL THROUGH AN ALL-

PORCELAIN OR PORCELAIN-COATED SINK. For

applications on these types of sinks we recommend

using the sprayer hole or mounting the faucet

through the countertop.

When drilling through a countertop make sure the

area below the drilled area is free of wiring and

piping. Make certain that you have ample room to

make the proper connections to the bottom of

the faucet.

Do not drill through a countertop that is more than

1-inch thick.

Do not attempt to drill through a tiled, marble,

granite or similar countertop. Consult a plumber

or the countertop manufacturer for advice

or assistance.

The following instructions apply to stainless steel sinks only.

See Figure 3.

1. Line bottom of sink with newspaper to prevent shavings,

parts or tools from falling down the drain.

2. Place masking tape over the area to be drilled to help

prevent scratches if drill bit slips.

3. Mark point with center punch. Use a 1/4-inch drill bit to

drill a pilot hole through sink.

4. Use a 1-1/4 inch hole saw to enlarge hole. Smooth rough

edges with a file.

Figure 4

2. Holding the faucet, feed the three tubes through the hole in

the sink. Position the faucet handle at the desired

location (Figure 5).

Figure 5

3. Center the faucet and slip “C” disc between the white

spacer and the bottom of the counter or sink. Tighten the

stem nut with a wrench until it is tight (Figure 6).

Figure 6

4. Making sure the faucet handle is in the down position, use

a needle-nose pliers to pull the short plastic tube out of

the top of the faucet base (Figure 7).

NOTE: If handle should come off faucet base, make sure the

T-Bar is parallel to the front of the faucet base before

inserting handle. If T-Bar is not in the correct position

the faucet will not work properly.

Pilot Hole

1/4"

1-1/4"

Mounting

Hole

Figure 3

6 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Figure 7

Page 7

5. Lubricate the o-rings on the bottom of the faucet spout

with supplied silicone lubricant. Use lubricant

sparingly (Figure 8).

Figure 8

6. Insert goose-neck spout into faucet base firmly (Figure 9).

Figure 9

Installing the Drain Clamp

NOTE: If you have a single-basin sink with a disposal unit,

call Technical Support at 1-800-279-9404 for options.

NOTE: Before installing the drain clamp, check the drain

pipes under the sink for corrosion. Corroded pipes

should be replaced before continuing with

the installation.

1. Attach the drain clamp to a vertical section of the

drainpipe, about 6 inches above the trap. Make sure the

opening on the drain clamp is facing towards the drinking

water faucet (Figure 10).

3. Remove the drain clamp from the drainpipe and enlarge

the hole with a 3/8-inch drill bit (Figure 12). Use a file to

remove rough edges from the drilled hole.

Figure 12

4. Make sure the black rubber gasket is adhered to the inside

of the drain clamp and place the drain clamp assembly

over the drilled hole. Look through the hole and position

the clamp so that the center of the clamp hole is slightly

higher (about 1/16 inch) than the center of the drilled hole.

(Figure 13). Tighten the clamp securely.

Figure 13

5. Screw the plastic compression nut onto the drain clamp

until hand-tight (Figure 14).

Figure 10

2. Using the fitting hole of the drain clamp as a guide, drill a

1/4-inch hole through one side of the drain pipe (Figure 11).

Figure 11

EVERPURE

6 inches

Figure 14

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 7

Page 8

Connecting the Faucet to the Drain

CAUTION

NOTE: This is a gravity drain line. Any loops, kinks or sharp

bends must be eliminated before proceeding. Failure

to create a straight line to the drain may result in

reject water leaking through the air gap in the faucet

onto the counter top and below the faucet.

1. Align the white 3/8-inch tubing from the faucet with the

compression nut on the drain clamp. Create as straight a path

as possible with the tubing. Cut the tubing squarely below the

nut and remove the internal and external burrs (Figure 15).

Figure 15

2. Loosen the compression nut two complete turns. Insert the

tubing into the nut until it stops. Tighten with fingers, then

tighten 1 to 2 turns with a wrench (Figure 16).

Installation of Mounting Screws

When tank is full, it weighs approximately 40

pounds. Provide ample support under the tank.

If system is being installed under the kitchen sink, locate it

on back or right side wall. Make sure to allow ample space

for installation. To change the filter cartridges, a minimum

of 1-1/2 inches of clearance is required underneath the filter

housings. A minimum of 2 inches of clearance from the left

side of the unit is also required or 6 inches from the left

bracket mounting screw hole.

Install mounting screws at least 13-3/4 inches from cabinet

floor and 5-3/8 inches apart. Leave a 5/16 inch space between

the head of the screw and the wall to slip bracket onto screws.

Figure 16

Figure 17

8 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Page 9

Connecting the Faucet to the System

CAUTION

CAUTION

1. Locate the red tubing (reject water line) from the drinking

water faucet. Place a mark on the red tubing 5/8 inch from

the end. Moisten the end of the tubing with water and insert

tubing into the red quick-connect fitting found behind the

membrane (middle) housing. Insert tubing until the mark is

flush with the quick-connect opening (Figure 18).

Red quick-connect fitting

Figure 18

2. If desired, use the 1/4-inch elbow included with the

installation kit. This elbow can be pressed in for installations

in situations where room is not available to bend the tubing.

This elbow fitting can also be swiveled. Locate the 1/4-inch

fitting with the blue quick-connect collar on the left hand

side of the RO system. Align the blue tubing from the faucet

with the quick-connect fitting on the RO system. Place a

mark on the blue tubing 5/8-inch from the end. Moisten the

end of the tubing with water and insert until the mark is

flush with the quick-connect opening (Figure 19).

If tubing is not firmly connected, leaking will occur. It is

important for the tubing to be inserted all the way until the

mark is flush with the outer edge of the quick-connect insert.

NOTE: Tubing may be quickly and easily removed from the

fitting if necessary by pressing the collar around the

fitting while pulling the tubing with your other hand.

Connecting the Storage Tank to the System

When tank is full, it weighs approximately 40 lbs.

Provide ample support under the tank.

1. Remove the black protective cap to expose the 1/4-inch

threaded opening at the top of the tank (Figure 20).

2. Thread the tank valve onto the top of the tank opening by

turning it clockwise until snug.

3. Locate the green tubing. Place a mark on the green tubing

3/4 inch from each end. Moisten one end of the green

tubing with water and insert with a twisting motion into the

free port of the tank valve until the 3/4-inch mark is flush

with the quick-connect fitting (Figure 20).

Figure 20

4. Install free end of green tubing to green quick-connect

fitting or elbow as directed in Figure 21.

NOTE: Do not cut green tube. This line should be left at the

pre-cut length for future service.

Without

elbow

5/8"

Figure 19

With

elbow

5/8"

Figure 21

5. Place entire system over mounting screws on wall and

slide down.

Make certain system is firmly attached to wall to

prevent it from falling and possibly

becoming damaged.

NOTE: Use caution not to bend or pinch the tubing behind

the system while attaching to mounting screws.

NOTE: The pressurized storage tank has a capacity of

1.9–3.2 gallons. The tank’s air pressure is factory set

at 5–7 psi when tank is empty.

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 9

Page 10

Connecting the Supply Adapter and Inlet of Filter

CAUTION

See Figure 22.

1. Locate the pre-installed white plastic tubing on the lefthand side of the RO system. Place a mark 5/8 inch from the

end of the tubing.

2. Wet tubing with water and insert into supply adapter 5/8

inch until mark is flush with fitting.

NOTE: Disconnecting the tubing from the

Quick-Connect Fittings.

Routine maintenance and cartridge replacement will not

require that you disconnect the tubing from the filter system;

however, tubing may be quickly and easily removed from the

fitting if necessary. First, turn off the water supply to the filter.

Open faucet, then press in the gray collar around the fitting

while pulling the tubing with your other hand.

5/8-inch

(16mm)

Locking

Device

Membrane

O-rings

Brine

Housing

Seal

O-ring

Brine-

ring

o-rings

Figure 23

Faucet Operation

For controlled water flow, push the handle down. For constant

water flow, lift the faucet handle to lock it in the open position

(Figure 24).

Figure 22

Installing the Membrane

See Figure 23.

1. Using the housing wrench, unscrew the middle

(membrane) housing.

NOTE: Do not unwrap the tape around the membrane;

it is part of the membrane. Do not squeeze the

membrane.

2. Turn locking device clockwise to remove. Grasp the

membrane by the central tube (the end with the two

o-rings). Before insertion, lightly lubricate the brine seal

with the silicone lubricant (included with membrane).

3. Gently slide the membrane into the housing. Pressing on

the central tube of the membrane from the top only, push

the membrane fully into the housing until the central

tube is flush with the top of the housing. Be sure to push

the membrane straight down into the housing. If the

membrane is not centered in the housing, the locking

device will not fit properly. After the membrane is seated,

lightly lubricate the membrane o-rings with a small

amount of the silicone lubricant.

4. Insert, and turn the locking device counterclockwise. Screw

the housing back onto the RO system until it is hand-tight.

DO NOT OVER TIGHTEN.

The housing o-ring provides the watertight seal

between the cap and the housing. It is important

that the o-ring be properly seated in the groove

below the threads of the housing or a water leak

could occur.

Controlled

water flow

Constant

water flow

Figure 24

Battery Installation

1. Remove manifold cover.

2. Plug battery into leads.

3. Place battery in holder at the front of unit and replace cover.

10 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Page 11

SYSTEM STARTUP

CAUTION

CAUTION

CAUTION

NOTE: The reverse osmosis membrane is treated with a food

grade sanitizing agent that may cause an undesirable

taste. Although it is not harmful, it should be flushed

from the system.

The post-polishing filter may contain fine black

carbon particles. These fines are harmless, but may

make the water appear gray in color. The carbon

fines are flushed from the system with the first tank

full of water.

The RO system does not produce a high volume of

water on demand as an ordinary filter does. Water is

produced at a slow, drop-by-drop rate. The system

requires about 6–12 hours to fill the storage tank. As

water is taken from the tank, the system automatically

starts the cycle of replacing the water and then stops

water production when the tank is full.

Visually check the entire system for leaks. Remove

the manifold cover and check the top of the

manifold for leaks. If a leak is present,

see TROUBLESHOOTING.

1. Turn off valve at top of storage tank (Figure 25).

2. Turn on the cold water supply (Figure 25).

Closed Tank Valve

Open Tank Valve

Figure 25

3. Lift the faucet handle to lock it in the open position and let

it drip for 30 minutes.

NOTE: If the test button is pushed during the first 30

minutes of flushing, you may get an amber rather

than a green light indication. This is due to the

disinfectant agent being flushed from the membrane

and is not a problem.

4. Turn off cold water supply and wait for the faucet to stop

dripping. Place a tray under the system and remove the left

(post-polishing) filter housing. Dump the water from the

housing into the sink and insert the white post-polishing

filter with the black gasket end facing up. Check the

housing o-ring to make sure it is properly seated and screw

the housing back onto the manifold. HAND TIGHTEN ONLY.

5. Completely open the cold water supply until it comes to a

stop. Allow water to drip from the faucet for 3 more hours.

Then close the faucet and open the valve on the storage

tank. The tank valve is open when the handle lines up with

the tubing connection.

6. Allow 6–12 hours for the tank to fill. Periodically check

the installation for leaks. After the storage tank is filled,

open the faucet to flush the post-polishing filter. Allow 4–5

minutes for all of the water to drain from the tank.

7. Close faucet and allow tank to fill.

NOTE: Initially, the water may appear cloudy. This is a result

of air trapped in the post-polishing filter. It is not

harmful and will disappear in a matter of minutes. It

may take up to a week after installing a new postpolishing filter for the trapped air to dissipate.

The system is ready for operation. You can now enjoy quality

water from your Reverse Osmosis system.

Connecting your Reverse Osmosis System to

Refrigerator Icemaker / Water Dispenser

If you are connecting this unit to your refrigerator/

icemaker with initial RO installation, wait to turn

on the icemaker until the post-polishing filter has

been flushed according to step 6 in

SYSTEM STARTUP.

Use plastic tubing and fittings. Do not use copper

tubing or brass fittings.

NOTE: For optimum performance, it is recommended

that the distance between the RO system and the

refrigerator icemaker/water dispenser be no greater

than 10 feet (3 m). At distances greater than 10 feet,

the water pressure from the system may not be

adequate to deliver water to the refrigerator.

Materials Required

(available from your local hardware store)

• Shut-off valve

• 1/4-inch (0.635 cm) polyethylene tubing

(maximum length of 10 feet (3m) recommended)

• 1/4-inch x 1/4-inch x 1/4-inch (0.635 cm x 0.635 cm x

0.635 cm) compression or quick-connect tee

1. Turn off refrigerator water supply and icemaker. Consult

manufacturer’s guidelines.

2. Close tank valve (on top of storage tank).

3. Turn off water to RO system at the cold water supply.

4. Open drinking water faucet to relieve pressure.

5. Locate blue tubing leading to your drinking water

faucet. Cut and insert the 1/4-inch x 1/4-inch x 1/4-inch

compression or quick-connect tee into the blue tubing.

Consult manufacturer’s guidelines before installing the

supply adapter.

NOTE: When cutting this blue tubing, you may experience

some water leakage.

6. Using a length of 1/4-inch polyethylene tubing, connect

the icemaker/dispenser line with the free port on the

compression tee.

7. The shut-off valve should be installed as close to this port

of the tee as possible. Shut-off valve should be installed in

the OFF position. Consult manufacturer’s guidelines before

installing the shut-off valve.

8. Completely open cold water supply (until it comes to a stop).

9. Open tank valve.

10. Turn off the drinking water faucet.

11. Open shut-off valve at the supply adapter.

12. Turn on icemaker. Consult manufacturer’s instructions.

13. Check for leaks and tighten connections if necessary.

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 11

Page 12

TESTING YOUR REVERSE OSMOSIS SYSTEM

WARNING:

CAUTION

Dissolved Solids (TDS) Test

NOTE: Under NSF/ANSI Standard 58, it is highly

recommended that you (the consumer) have your

water tested at least every 6 months to verify that

your system is performing satisfactorily.

PRO Monitored Reverse Osmosis System

Light Indicator Readings on the PRO

The PRO is equipped with a monitor (Figure 26) that checks the

Total Dissolved Solids (TDS) that the system is reducing. This

allows the user to see the quality of the water that the system

is producing. Test the unit monthly. When the blue test button

is pushed, the light system will read one of the following colors:

Green light: Good Water

Amber light: If this is a new installation, call Technical

Support. Otherwise, draw 1 gallon of water

from the unit. After 10 minutes, push the

button to test. If the light is still amber,

change the prefilter and empty the tank. If

the light is still amber after 1 hour, you may

need to replace the membrane. Determine

when you last changed the membrane and

call Technical Support at 1-800-863-9392.

No light: The battery needs to be changed.

Figure 26

Nitrate Test Kit

A Nitrate Test Kit is included with this unit and is designed

to indicate nitrate levels in the drinking water. Test the water

monthly. The current EPA Maximum Contaminant Level

(MCL) for Nitrate as Nitrogen (N) is 10 mg/L or 10 ppm. The

current EPA maximum contaminant level (MCL)for Nitrite as

Nitrogen (N) is 1 mg/L or 1 ppm. Results showing any nitrate

breakthrough should be followed up with a laboratory analysis

of the water.

Consult with your doctor to see if you should

drink water with the nitrate/nitrite levels

found in your water.

Nitrate Test Kit

MAINTENANCE

Use only the replacement elements and parts referred to in

this manual. Failing to do so will void your warranty.

NOTE: Use a different sink or set aside water to wash and

rinse housings. Read appropriate instructions to

determine amount of water required.

Replacing the Prefilter and Post-polishing Filter

Cartridges

Replacement Filter Cartridges

The Gray/Black Prefilter Cartridge (D-15) should be replaced

every 3 months, or earlier if your water is highly turbid, and

when changing the membrane.

The White Post-polishing Filter Cartridge (D-20) should be

replaced at least every 12 months and when changing the

membrane.

Materials Required

• PRO Replacement

Cartridge Kit

• FDA-Grade silicone grease

• Clean washcloth

• Non-abrasive brush or sponge

• Clean rubber gloves (optional)

• Dishwashing soap

Replacing the Filter Cartridges

1. Close cold water supply and place a tray under the system

to catch any water that spills during removal of the filter

housings. If an icemaker is attached to the unit, turn it off and

also the shut-off valve found at the 1/4-inch supply adapter.

2. Lift the faucet handle to lock it in the open position.

3. After water flow from the faucet stops, unscrew the filter

housing from the left and/or right side of the manifold. Do

not remove the membrane (center) housing. Discard

used cartridges.

NOTE: Use clean rubber gloves or wash hands

thoroughly for this procedure to avoid

contaminating the cleaning solution or any of the

components of the system. It is recommended

that clean rubber gloves be worn when cleaning

and/or sanitizing the system and its components

or handling new filter cartridges.

4. Locate and remove o-ring from grooves in the sump. Wipe

grooves and o-ring clean of old lubricant and set aside.

Rinse out bottom of sump and fill 1/3 full with water. Add

1 tablespoon of bleach and scrub cap and bottom of sump

with non-abrasive sponge or cloth. Rinse thoroughly.

5. Inspect the o-ring for damage (i.e. nicks, scratches) and

replace damaged o-rings. See REPLACEMENT PARTS for

reorder information and part numbers

NOTE: Do not get any of the electronic circuits or wiring

wet when cleaning the unit.

6. Lightly lubricate the o-ring with a coating of clean silicone

grease. With two fingers, press o-ring securely into groove

below the threads of the housing.

Figure 27

Testing Instructions:

Testing instructions are included with the Nitrate Test Kit

(Figure 27). If the Nitrate Test Kit is missing, please call

1-800-279-9404 for replacement.

12 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

The housing o-ring provides the water-tight seal

between the cap and the bottom of the housing. It

is important that the o-ring be properly seated in

the groove below the threads of the housing or a

water leak could occur.

Page 13

7. Insert the new cartridge into the housing. Make sure the

CAUTION

CAUTION

CAUTION

CAUTION

cartridge slips over the standpipe in the bottom of the

housing.

NOTE: Be sure to install cartridges in proper

housings (Figure 1).

8. Screw the housing back onto the manifold.

HAND-TIGHTEN ONLY.

9. Slowly open the cold water supply until it comes to a stop.

Check for leaks.

10. Let water drip from drinking water faucet for 3 hours.

Continue to periodically check for leaks.

11. Close faucet and wait 6–12 hours to allow the tank to fill.

Open the drinking water faucet and drain one full tank to

flush the carbon fines out of the system.

12. If the unit is attached to an icemaker, wait one hour before

turning on the icemaker.

Replacing the Reverse Osmosis Membrane

Replacement Filter Cartridges

The Gray/Black Prefilter Cartridge and the White

Post-polishing Filter Cartridge should be replaced when

changing the membrane. See Materials Required below.

Materials Required

• PRO Replacement Cartridge Kit

• New membrane:

PRO_RM Membrane

• Clean rubber gloves

• Clean washcloth

• Dishwashing soap

• Chlorine bleach

• FDA-Grade silicone grease

• Needle-nose pliers

• Safety glasses

• Large bucket

• 9-volt battery

• Non-abrasive brush or sponge

The Membrane (PRO) should be replaced every 12–24 months.

NOTE: When handling the membrane, do not squeeze it, as

this will damage the membrane’s effectiveness.

NOTE: It is recommended that you sanitize the system each

time you change the membrane. It is not necessary to

sanitize the system when changing only the prefilter

or post-polishing filter cartridges.

NOTE: When installing a new membrane, it is recommended

that you also replace the prefilter and post-polishing

filter cartridges.

Removing the Filter Cartridges and Membrane

1. Turn off cold water supply. Place a tray under the system to

catch any water that spills during the removal of the filter

housings. If an icemaker is attached to the unit, turn it off

along with the shut-off valve found at the 1/4-inch

supply adapter.

2. Open the drinking water faucet to drain the tank. When the

tank is drained, close the faucet.

3. Unscrew the middle (membrane) housing.

4. Remove the locking device by turning it clockwise. Grasp

the membrane tube with a needle-nose pliers and pull.

Discard the old membrane.

5. Unscrew the pre- and postfilter housings from the

manifold and discard used cartridges.

6. Remove the housing o-ring from the grooves below the

housing threads. Wipe the o-rings clean and also the

grooves in the filter housing. Set o-rings aside.

NOTE: Use clean rubber gloves or wash hands thoroughly

for this procedure to avoid contaminating the

cleaning solution or any of the components of the

system. It is recommended that clean rubber gloves

be worn when cleaning and/or sanitizing the system

and its components or handling new filter cartridges.

7. Wash the housings in the sink with dish soap and a clean,

non-abrasive washcloth or brush. Clean the filter housings

and the inside of the manifold and rinse them well with

clean, potable water.

NOTE: Do not get any of the electronic circuits or wiring wet

when cleaning the unit.

WEAR SAFETY GLASSES WHILE PERFORMING THIS

PROCEDURE TO AVOID EYE CONTACT AND INJURY.

Read WARNING information on the bleach

container before using its contents.

Handle sanitizing solution carefully to avoid

contacting and injuring unprotected areas of

the body.

8. Make up a sanitizing solution of 1/3 teaspoon (1.5 ml) of

household bleach and 1 gallon (3.8 L) of clean, potable

water in a bucket. Mix solution well.

NOTE: Excessive concentrations of bleach may damage

plastic and rubber components. Rinse all parts that

contact bleach thoroughly with clean, potable water.

9. Lightly lubricate each housing o-ring with a coating of

clean silicone grease. With two fingers, press each o-ring

securely into groove below the threads of the housing.

The housing o-ring provides the water-tight seal

between the cap and the bottom of the housing. It

is important that the o-ring be properly seated in

the groove below the threads of the housing or a

water leak could occur.

10. Add one cup or 8 oz. (236 ml) of sanitizing solution to each

filter housing and install them onto the manifold. DO NOT

INSTALL FILTERS OR MEMBRANE AT THIS TIME.

NOTE: TIGHTEN FILTER HOUSINGS BY HAND ONLY. DO NOT

USE WRENCH.

11. Slowly open source water at the cold water supply until

completely open.

12. Open the drinking water faucet. Close the faucet as soon as

water begins to flow from the spout.

13. Wait 5 minutes, then close the source water at the cold

water supply.

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 13

Page 14

14. Wait 25 minutes, then open the drinking water faucet and

CAUTION

let the water flow to drain.

NOTE: Do not attempt to remove the filter housings until the

water flow stops.

15. Remove the filter housings and dispose of the water. Rinse

the housings thoroughly with clean, potable water.

16. Place the empty post-polishing filter housing on the left

side of the unit. HAND TIGHTEN ONLY.

NOTE: DO NOT put the post-polishing filter into the housing

at this time. It will be put into the housing after the

membrane has been flushed.

17. Insert the prefilter cartridge into the right housing and

attach to the right side of the unit. HAND TIGHTEN ONLY.

NOTE: Use the silicone lubricant supplied with the membrane

for steps 18,19 and 20.

18. Lightly lubricate the inside of the membrane (middle)

threaded cap (Figure 29).

Inside of threaded cap

Figure 28

19. Lightly lubricate both sides of the brine seal (Figure 29).

Locking Device

21. After the membrane is seated, lightly lubricate the two

small o-rings at the end of the membrane. Also, lightly

lubricate both brine ring o-rings (Figure 29).

The rubber o-rings provide the water-tight seal

between the cap and the housing. It is important

that the o-ring be properly seated in the groove

below the threads of the housing or a water leak

could occur.

22. Insert, then turn the locking device counter-clockwise.

Screw the housing back onto the RO system until it is

hand-tight. DONOTOVER TIGHTEN.

23. To complete the flushing of the membrane and postpolishing filter and assembly of the unit, completely open

the cold water supply until it comes to a stop. Allow water

to drip from the faucet for 3 more hours. Then close the

faucet and open the valve on the storage tank. The tank

valve is open when the handle lines up with the tubing

connection.

TROUBLESHOOTING

If you are experiencing a problem not listed in this manual,

shut off the cold water supply and close the tank valve. Call

Technical Support at 1-800-279-9404.

Leaks between the filter housing and manifold

1. Turn off cold water supply to system. Close tank valve.

Open drinking water faucet to relieve water pressure.

2. Using the housing wrench, remove the housing with the leak.

3. Remove and clean housing o-ring and lubricate with

clean silicone grease. Clean o-ring groove below threads

of housing to remove any dirt or particles that may be

preventing the o-ring from sealing completely. With two

fingers, insert o-ring in groove and press into place.

4. Tighten housing back onto manifold. HAND TIGHTEN ONLY.

5. Turn on cold water supply. Open tank valve. Close drinking

water faucet after water begins to flow. If leaks persist, call

Technical Support.

Membrane

O-rings

Brine

Housing

O-ring

Seal

Brine-ring

O-rings

Figure 29

20. Gently slide the membrane into the housing. Pressing on

the central tube of the membrane from the top only, push

the membrane fully into the housing until the central

tube is flush with the top of the housing. Be sure to push

the membrane straight down into the housing. If the

membrane is not centered in the housing, the locking

device will not fit properly.

Leak between tank valve and storage tank

1. Turn off water supply to system. Open faucet to drain

storage tank. Let faucet run for 3–5 minutes until it drips.

2. Remove green tubing from tank valve by pressing the collar

around the fitting while pulling the tubing with your

other hand.

3. Unscrew the tank valve from the storage tank.

4. Place two wraps of plumber tape on the threads of the

storage tank.

5. Thread the tank valve onto the top of the tank opening by

turning it clockwise until snug.

6. Cut off 1 inch of tubing. Tubing should be cut squarely.

Internal and external burrs should be removed. Place a

mark on tubing 3/4 inch from end of tubing.

7. Insert tubing until the mark is flush with the

quick-connect fitting.

8. Turn on water supply and close drinking water faucet.

9. Allow system to pressurize for several hours and check

for leaks.

10. Check for leaks after tank is fully pressurized (6–12 hours).

If leak persists, call Technical Support.

14 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Page 15

Leaks at quick-connect fittings

1. Close tank valve, close water supply and open drinking

water faucet.

2. Press collar around the quick-connect fitting while pulling

the tubing with your other hand.

3. Cut off 1 inch of tubing. Tubing should be cut squarely.

Internal and external burrs should be removed. Place a

mark on tubing 5/8 inch from end on 1/4-inch tubing or 3/4

inch from end on 3/8-inch tubing.

4. Insert tubing until the mark is flush with the

quick-connect fitting.

5. Open the saddle valve until it comes to a stop. Open the

tank valve and close drinking water faucet. If leaks persist,

call Technical Support.

Leaks from faucet

1. Check to make sure white tubing leading from the drinking

water faucet to the drain is as straight as possible (it is

usually necessary to cut this line during installation). Any

kinks or sags in this drain line will impede the flow of

water to the drain.

2. Check to make sure there is no foreign matter clogging the

drain line or at the drain clamp hole. If leaks persist, call

Technical Support.

3. Check to make sure the drain clamp and the drain hole are

properly aligned. Refer to Figure 13.

No flow or slow flow from the brine (reject) line

(Less than 6 fl. oz. or 180 milliliters per minute)

NOTE: Before checking brine (or reject) flow, make sure

the unit is producing water by turning the valve on

the storage tank off and opening the drinking water

faucet. Water should drip from faucet.

1. Replace prefilter according to REPLACING THE PREFILTER

AND POSTPOLISHING FILTER CARTRIDGES and recheck

the brine (or reject) flow rate.

2. If the prefilter is not at fault, the brine (or reject) flow

controller could be clogged. Call Technical Support.

Limited Flow at Drinking Water Faucet

1. Turn off water supply to system.

2. Lift drinking water faucet handle to lock it in the

open position.

3. Unscrew the blue cap at the base of the storage tank to

expose air valve. Use a small air compressor or bicycle

pump to add air to the storage tank. This will force the

water out of the storage tank through the faucet. Continue

to add air until no more water comes out of the faucet.

4. Turn off the drinking water faucet.

5. Using an air pressure gauge, adjust the pressure in the

storage tank to approximately 7 psi.

6. Replace the blue cap.

7. Open the cold water supply until it comes to a stop. Let the

system run 6–12 hours to fill the tank. A full tank weighs

approximately 40 pounds. If performance has not improved,

call Technical Support.

Gradual Return of Taste and Odor

After a long period of time a gradual return of noticeable taste

and odors may indicate that the system needs cleaning and

servicing. Replace all cartridges. See Replacing the Reverse

Osmosis Membrane, page 13.

Sudden Return of Taste and Odor

If shortly after complete servicing, noticeable taste and odors

return, contact Technical Support.

High TDS in Product Water

(amber light on PRO)

If high TDS (Total Dissolved Solids) are detected in the product

water, the amber light indicator on the PRO will light when the

blue button is pressed. The prefilter may need to be changed,

the RO membrane may need to be installed or replaced, or

the reject flow control tubing may be clogged. If this is a new

installation, call Technical Support. Otherwise, draw 1 gallon

of water from the unit. After 10 minutes, push the button to

test. If the light is still amber, change the prefilter and empty

the tank. If after 1 hour the light is still amber you may need to

replace the membrane. Determine when you last changed the

membrane and call Technical Support at 1-800-279-9404.

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 15

Page 16

PERFORMANCE DATA

WARNING:

Important Notice: Read this performance data and compare the

capabilities of this system with your actual water treatment

needs. It is recommended that before installing a water

treatment system, you have your water supply tested to

determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 58 for the

reduction of the substances listed below. The concentration

for the indicated substances in water entering the system

was reduced to a concentration less than or equal to the

permissible limit for water leaving the system, as specified in

NSF/ANSI 58.

Model PRO

Influent

Substance

Standard 58

Total Dissolved

Solids

Pentavalent

Arsenic†

Fluoride 8.0 ± 10% 1.5 mg/L 84.1% 91.2%

Cysts

Turbidity 11 mg/L ± 1 NTU 0.5 NTU 99.6% 99.9%

Lead 0.15 mg/L ± 10% 0.010 NTU 93.3% 97.7%

Nitrate plus

Nitrite

(both as N)

Nitrate 27.0 mg/L ± 10% 10.0 mg/L 90.2% 93.2%

Nitrite 3.0 mg/L ± 10% 1.0 mg/L 91.0% 93.5%

Selenium 0.10 mg/L ± 10% 0.05 mg/L 59.0% 84.7%

Copper 3.0 mg/L ± 10% 1.3 mg/L 97.8% 99.3%

Cadmium 0.03 mg/L ± 10% 0.005 mg/L 95.1% 97.6%

Hexavalent

Chromium

Trivalent

Chromium

Radium

226/228

Barium 10.0 mg/L ± 10% 2.0 mg/L 94.2% 97.4%

Standard 42

Std. 42

Chlorine

Reduction*

Production Rate:5.7 gpd (28.8 Lpd)

*Post filter only (D-20), Flow Rate=1.0 gpm (3.8 L/min); Capacity=1000 gallons (3785 L).

†The PRO shall only be used for arsenic reduction on chlorinated water supplies

containing detectable residual free chlorine at the system inlet. Water systems using an

in-line chlorinator should provide a one-minute chlorine contact before the RO system.

Challenge

Concentration

750 ± 40 mg/L 187 mg/L 97.3% 98.5%

0.30 mg/L ±10% 0.025 mg/L 98.2% 99.0%

Minimum 50,000/

mL

30.0 mg/L±10% 10.0 mg/L 90.1% 93.2%

0.3 ± 10% 0.1 mg/L 97.8% 98.7%

0.3 mg/L ± 10.0 0.1 mg/L 93.2% 96.8%

25 pCi/L ± 10% 5pCi/L

2.0 mg/L ± 10% ≥ 50% 87.5%

Do not use with water that is microbiologically

unsafe or of unknown quality without adequate

disinfection before or after the system.

Systems certified for cyst reduction may be

used on disinfected waters that may contain

filterable cysts.

NSF/ANSI Standard 58 certified to reduce cysts such as

Cryptosporidium and Giardia by mechanical means.

Maximum

Permissible

Product Water

Concentration

Reduction

Requirements

99.95% 99.99% 99.99%

Minimum

Reduction

Average

Reduction

EPA Est. No. 090375-MEX-001

The tested efficiency rating for these systems is 10.46%.

Efficiency rating means the percentage of the influent water

to the system that is available to the user as reverse osmosis

treated water under operating conditions that approximate

typical daily usage. The tested recovery rating is 20.36%.

Recovery rating means the percentage of the influent water to

the membrane portion of the system that is available to the user

as reverse osmosis treated water when the system is operated

without a storage tank or when the storage tank is bypassed.

NOTE: Substances reduced are not necessarily in your

water. Filter must be maintained according to

manufacturer’s instructions, including replacement

of filter cartridges.

Test Conditions

Flow Rate = as noted for filter system

Inlet Pressure = 60 psi (4.1 bar)

pH = 7.5±1

Temperature = 68°F ± 5°F (20°C ± 2.5°C)

Operating Requirements

Pressure = 40–100 psi (2.8–6.9 bar)

Temperature = 40–100°F (4.4–37.8°C)

Turbidity = 1 NTU Max.

The PRO has been tested for the treatment of water containing

pentavalent arsenic [also known as As(V), As(+5), or arsenate]

at concentrations of 0.30 mg/L or less. This system reduces

pentavalent arsenic, but may not remove other forms of

arsenic. This system is to be used on water supplies containing

a detectable free chlorine residual or on water supplies

that have been demonstrated to contain only pentavalent

arsenic. Treatment with chloramine (combined chlorine) is not

sufficient to ensure complete conversion of trivalent arsenic

to pentavalent arsenic. Please see the Arsenic Facts section of

the Performance Data Sheet for further information.

Testing was performed under standard laboratory conditions;

actual performance may vary.

The following performance claims for the PRO are not tested

or certified by NSF.

Model PRO

Average

Substance

Standard 58

Sulfate 759.5 ppm 7.0 ppm 99.1%

Magnesium 29.0 ppm 0.1 ppm 99.7%

Zinc 10.2 ppm 0.05 ppm 99.5%

Ammonia 3.27 ppm 0.57 ppm 82.5%

Tannin 3.70 ppm ND (2.0) ppm >49.5%

Testing performed at 73°F ± 5°F (22.7°C ± 2.5°C), pH of 7.5 and 50 psi (3.45 bar) pressure.

Influent

Concentration

Average (max.)

Effluent

Concentration

Average

Concentration

16 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Page 17

Arsenic Fact Sheet

WARNING:

Arsenic (abbreviated As) is found naturally in some well

water. Arsenic in water has no color, taste or odor. It must be

measured by a lab test. Public water utilities must have their

water tested for arsenic. You can get the results from your

water utility. If you have your own well, you can have the water

tested. The local health department or state environmental

health agency can provide a list of certified labs. The cost is

typically $15–$30. Information about arsenic in water can

be found on the Internet at the US Environmental Protection

Agency website: www.epa.gov/safewater/arsenic.html.

There are two forms of arsenic: pentavalent arsenic [also

called As(V), As(+5), and arsenate] and trivalent arsenic [also

called As(III), As(+3) and arsenite]. In well water, arsenic may

be pentavalent, trivalent, or a combination of both. Special

sampling procedures are needed for a lab to determine what

type and how much of each type of arsenic is in the water.

Check with the labs in your area to see if they can provide this

type of service.

Reverse osmosis (RO) water treatment systems do not remove

trivalent arsenic from water very well. RO systems are very

effective at removing pentavalent arsenic. A free chlorine residual

will rapidly convert trivalent arsenic to pentavalent arsenic.

Other water treatment chemicals such as ozone and potassium

permanganate will also change trivalent arsenic to pentavalent

arsenic. A combined chlorine residual (also called chloramine)

may not convert all the trivalent arsenic. If you get your water

from a public water utility, contact the utility to find out if free

chlorine or combined chlorine is used in the water system.

The PRO system is designed to remove pentavalent arsenic.

It will not convert trivalent arsenic to pentavalent arsenic.

The system was tested in a lab. Under those conditions, the

system reduced 0.30 mg/L (ppm) pentavalent arsenic to

0.010 mg/L (ppm)(the USEPA standard for drinking water) or

less. The performance of the system may be different at your

installation. Have the treated water tested for arsenic to check

if the system is working properly.

The RO component of the PRO system must be replaced every

12–24 months to ensure the system will continue to remove

pentavalent arsenic.

CALIFORNIA PROPOSITION 65 WARNING

This product contains chemicals known to the

State of California to cause cancer or birth

defects or other reproductive harm.

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 17

Page 18

REPLACEMENT PARTS

1 EV929510 PRO Replacement Cartridge Kit

2 EV929500 PRO Membrane Replacement Kit

3 SH144925 Nitrate/Nitrite Test Kit (PRO)

4 SH244820 Drinking Water Faucet

5 SH144747 Manifold Cover

6 154208 Manifold (PRO)

7 1143330 Housing O-ring (OR-233)

8 153126 Left and Right Housing

9 144988 Middle (Membrane) Housing

10 150424 Housing Wrench (SW-5)

1

11 144653 Auto Shut-Off Assembly

12 SH144764 3/8-inch Elbow

13 SH143370 1/4-inch Elbow

14 SH144616 Drain Clamp Assembly

15 SH143431

16 SH144847 Membrane Locking Device

17 SH144829 Tank Valve

18 SH144165 Storage Tank with Stand

1/2-inch x 1/2-inch x 1/4-inch Supply Adapter

2

3

4

11

14

15

5

8 9 8

12

6

13

16

10

7

17

18

18 • EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions

Page 19

IOWA RESIDENTS ONLY:

Store or seller’s name

Address

City State _____________________

Zip__________

Seller’s signature

Customer’s signature

Date

EVERPURE

®

PRO-Reverse Osmosis Water Filtration System Installation and Operating Instructions • 19

Page 20

For Everpure® Product Warranties visit:

Everpure® para las gasantías de los productos visite:

Pour Everpure® garanties produit visitez le site:

www.everpure.com

FILTRATION & PROCESS

5730 NORTH GLEN PARK ROAD, MILWAUKEE, WI 53209

P: 262.238.4400 | WWW.PENTAIRAQUA.COM | CUSTOMER CARE: 800.279.9404 | tech-supportpentair.com

All Pentair trademarks and logos are owned by Pentair, Inc. or its affiliates. All other registered and unregistered trademarks and logos are the property of their

respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Pentair is an equal opportunity employer.

161136 REV A JE14 © 2014 Pentair Residential Filtration, LLC. All Rights Reserved.

Loading...

Loading...