Penske Racing Shocks 8900 User Manual

Table of Contents Motorcycle Shocks

Motorcycle Shock Technical Manual

8900 Series

Main Office

150 Franklin St.

Reading, PA 19602

(610) 375-6180 • (610) 375-6190 Fax

Midwest

12666 US-12 • P.O. Box 666

Brooklyn, MI 49230

(517) 592-6681 • (517) 592-3696 Fax

REV: 11/21/01

#8

Table of Contents Page

Installation .................................................................................................. 2

Notes ........................................................................................................... 3

Ride Height Adjustment ............................................................................ 4

Adjustment Recommendations................................................................ 5

8900 Series Shock

Parts List ............................................................................................... 6

Specifications....................................................................................... 7

8981 Series Compression Adjuster

Parts List ............................................................................................... 8

Operational Guide ............................................................................... 9

8986 Series Compression Adjuster

Parts List ............................................................................................... 10

Operational Guide ............................................................................... 11

8987 Series Compression Adjuster

Parts List ............................................................................................... 12

Operational Guide ................................................................................. 13

8900 Series Rebound Adjuster................................................................. 14

Disassembly / Assembly Instructions ..................................................... 15

Suggested Maintenance ........................................................................... 16

Trouble Shooting ....................................................................................... 16

Valving

General Valving Characteristics............................................................. 17

A Guide To Damper Tuning................................................................... 18

Basic Start-up Procedure...................................................................... 19

Valve S tacks.......................................................................................... 20

VDP and Digressive V alving Information Options.................................. 21

VDP 55mm Linear Base Shim .............................................................. 21

Preload Shim Spacers........................................................................... 21

Pistons

Flow Rate Through Multiple Bleed Holes .............................................. 22

Piston Selection .................................................................................... 23

Linear Piston ......................................................................................... 24

Digressive Piston................................................................................... 25

Velocity Dependent Piston (VDP) ......................................................... 26

Damping Adjustments........................................................................... 28

Dyno Graph Overview ............................................................................... 30

Notes ........................................................................................................... 34

1

Installation

Your new Penske Racing Shock comes pre-adjusted at baseline settings. However, you must check

your rear sag before you race! This is very important for optimum performance.

*

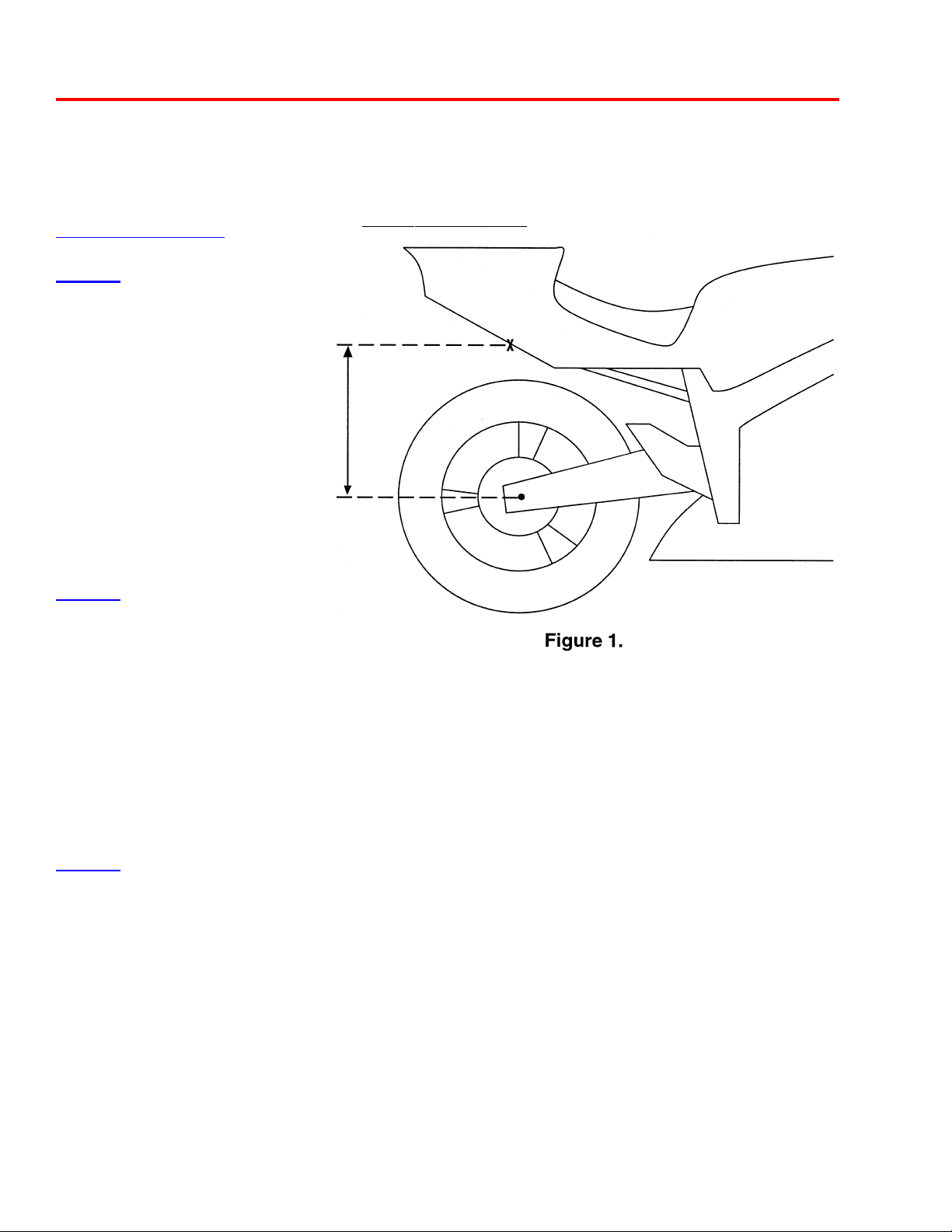

Setting the Sag*

STEP 1

1) Without a rider on the bike,

have an assistant lift the

rear of the motorcycle until

the rear wheel is off the

ground slightly.

2) Using a tape measure,

measure the distance

between the axle center line

and a convenient location

on the rear subframe

(Figure 1).

BUELL APPLICATIONS: Use Buell spring sag recommendations.

3) Record this measurement as "A".

STEP 2

1) This step requires the rider

and two additional people.

2) One person should hold the

front of the motorcycle, straddling

the front tire.

3) Have the rider, wearing all of their gear, sit on the bike in a tuck position.

4) The third person should then measure the distance between the axle center line and a convenient

location on the rear subframe (same locations used in Step 1).

5) Record this measurement as "B".

STEP 3

1) Subtract "B" from "A". This number is your sag.

The amount of sag required varies from rider to rider and from track to track.

The sag should be between 7/8" and 1 1/6".

If the sag is greater than 1 1/6", preload the spring by turning the adjustable spring collar.

If the sag is less than 7/8", remove preload by turning the adjustable spring collar.

2

Notes

3

Ride Height Adjustment

Adjusting Rear Ride Height

1. Loosen the jam nut with 1" wrench.

2. Adjust the eyelet length (shorter or longer). See #2 below.

3. Tighten the jam nut. See #3 below .

FOR BUELL AND FLA T TRACK

APPLICA TIONS ONLY!

Ride Height Affects

Going

length "eye to eye" will:

1. Raise the rear ride height.

LONGER with rear shock

WW

W

WW

WW

W

WW

#2

#3

.470" (12mm)

CAUTION!!!

DO NOT EXCEED

THIS LENGTH

Going SHORTER with rear shock

length "eye to eye" will:

1. Lower the rear ride height.

XX

X

XX

XX

X

XX

2. Transfer weight from the rear wheel

to the front wheel.

3. Make the front turn in quicker.

4. Reduce chain torque to the rear wheel.

4

2. Transfer more weight to the rear wheel.

3. Make the front turn in slower.

4. Increase chain torque to the rear wheel.

Adjustment Recommendations

Road Race Track Tuning: Symptoms and Suggestions

A. Change only one adjustment at a time, and send the rider out for evaluation and feedback.

B. Take notes: Keep track of rider comments, lap times, tire conditions, and current

weather conditions.

C. Be patient, go back to your original settings if you get lost.

Symptom: Tuning List:

Harsh over bumps: 1. Go softer with low speed compression, 2 to 4 clicks at a time

(counter clockwise)

2. Go softer with high speed compression, 1 to 2 clicks at a time.

3. Increase rear spring sag, -1/2 to 1 turn at a time on spring perch.

4. Change to a softer spring rate.

5. Note: Too soft on compression can bring about a harsh feeling by

allowing too much shock travel.

Excessive wheel spin

exiting corners: 1. Repeat above steps.

2. Rebound can be too fast, allowing the rear to unload and spin

the tire. Use caution when changing rebound.

Wallowing exiting corner: 1. Stiffen low speed compression (clockwise).

2. Stiffen high speed compression, 1 to 2 clicks at a time.

3. Decrease rear spring sag.

4. Slow down rebound, 1 to 2 clicks at a time (clockwise).

5. Change to a stiffer spring rate.

Slow turn-in: 1. Raise fork legs in triple clamps

2. Increase rear eyelet length, 1/2 to 1 turn at a time.

Cannot exceed 12mm of thread exposed.

3. Soften fork compression

4. Increase front fork sag

5. Speed-up rear rebound.

Mid corner push - front: 1. Stiffen rear low speed compression

2. Slow down fork rebound

5

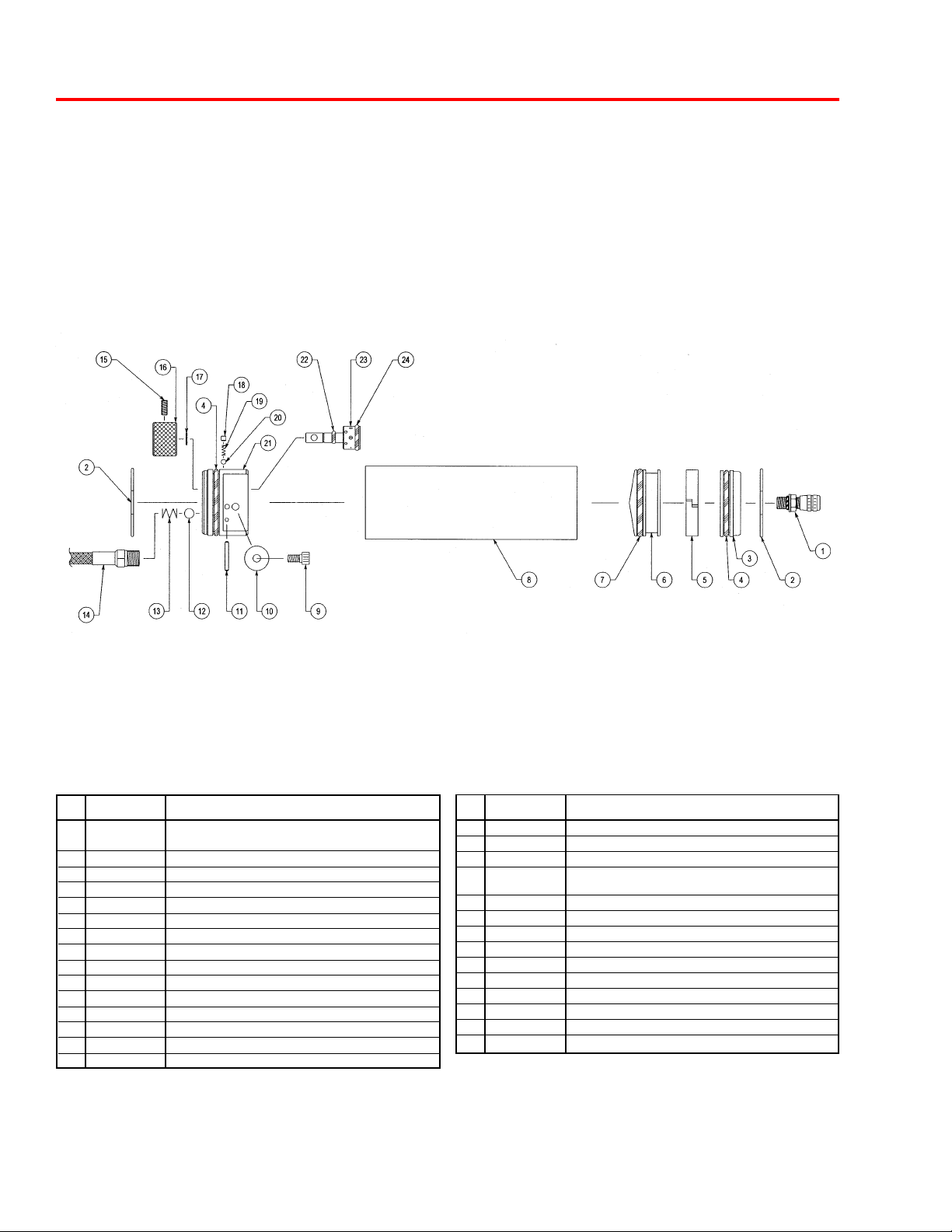

8900 Series Shock Parts List

ITEM

NO.

10 JT-76HAT Jet, Top Hat

1 1 SP-15 Spring, (FF71)

12 JT-76POP Jet, Poppet

13 JT-RDHSNG Jet, Rebound, Straight Thru

14 NE-76 Needle

15 OR-2007-B O-Ring, 2-007, Buna 70

16 MR-8100 Metering Rod

17 NT-02R Ring Nut, 1/2" - 20

18 VS-__* Valve Stack

19 PB-55 Piston Band, 55mm

20 PI-____* Piston

21 OR-2028-B O-Ring, 2-028, Buna 70

PART

1 BD-81__* Body, Aluminum Coil-over (10.0" - 24.0")

2 RH-89225 Ride Height Adjuster, 8900, 2.25"

3 OR-2221-B O-Ring, 2-221, Buna 70

4 HO-87__* Hose (4" - 36" in 1" increments)

5 FT-__* Fitting, (45o or 90o), 1/8" NPT

6 BC-81__* Body Cap, 8100, (0o, 45o, 90o, 135o)

7 MO-8T Mono Ball, .500 ID, Teflon

8 RR-16 Retaining Ring, 1.025 Spiroloc

*

9 RR-05 Retaining Ring, .250 Internal

NO.

BC-89CL Body Cap, 8900 Clearance

MO-8T20 Mono Ball, .500 x .875 OD

MO-15T Monoball, 15mm ID x 1.00 OD

RR-10 Retaining Ring, .875 Spiroloc

JT-76RD

Jet, Rebound Complete (Includes items 9-13)

DESCRIPTION

The following parts

are in the rebound

adjuster for

Buell And C&J

Applications Only!

ITEM

NO.

22 VW-99 Top Out Pl ate, 1.375 x .504

23 BU-10DU06 Bushing, DU .625 x .375

24 BR-37 Bump Rubber, Top Out (Clear)

25 OR-2221-B O-Ring, 2-221, Buna 70

26 SB-89 Shaft Bearing, 8900

27 OR-2114-V O-Ring, 2-114, Viton 75

28 SL-09 Shaft Wiper, .625 Poly (Blue)

29 OR-2312-B O-Ring, 2-312, Buna 70

30 SH-_____* Shaft, Adjustable, (10.0" - 24.0")

31 NT-04J Jam Nut, 5/8" - 18

32 SR-89SRM Spring Retainer, 8900 Mount

33 CP-76RD Cap, Rebound Adjuster

34 KN-76RD Knob, Rebound Adjuster

35 OR-2017-B O-Ring, 2-017, Buna 70 Duro

36 OR-2017-B O-Ring, 2-017, Buna 70 Duro

37 DO-09 Dowel Pin, 1/8” x 1 1/8”

38 SM-89KB Shaft Mount, 8900, Knob Platform

39 NT-06J Jam Nut, 11/16" - 20

40 EY-89___* Eyelet, 8900, Motorcycle Model _____

41 SR-89225 Spring Retainer, 8900, 2.25"

42 RR-06 Wire Ring, .0625 Wire Diameter x 1.900

NOTE: Each shock also includes (1) BR-38 Bump Rubber, 38 gr.

ITEM

32 MR-89 Metering Rod, 8900

33 BU-04-BZ Bushing, .200 Bronze

34 SC-08 Screw, Socket Set, 8-32 x 3/8"

35 SP - 14 Spring, (A109)

36 BA-125-ST Ball, Steel 1/8"

37 SM-89 Shaft Mount, 8900, Adj. Platform

38 RS-89 Rebound Screw, 8900/Slotted

39 OR-2009-B O-Ring, 2-009, Buna 70 Duro

PART

NO.

*

AS-89SB

AS-89KBPLAT

*

CL-89___* Clevis, 8900, Motorcycle Model _____ (not shown)

PART NO.

Assembly, 8900 Shaft Bearing

(Includes items 23-28)

Assembly, 8900 Knob Platform

(Includes items 32-38)

DESCRIPTION

DESCRIPTION

6

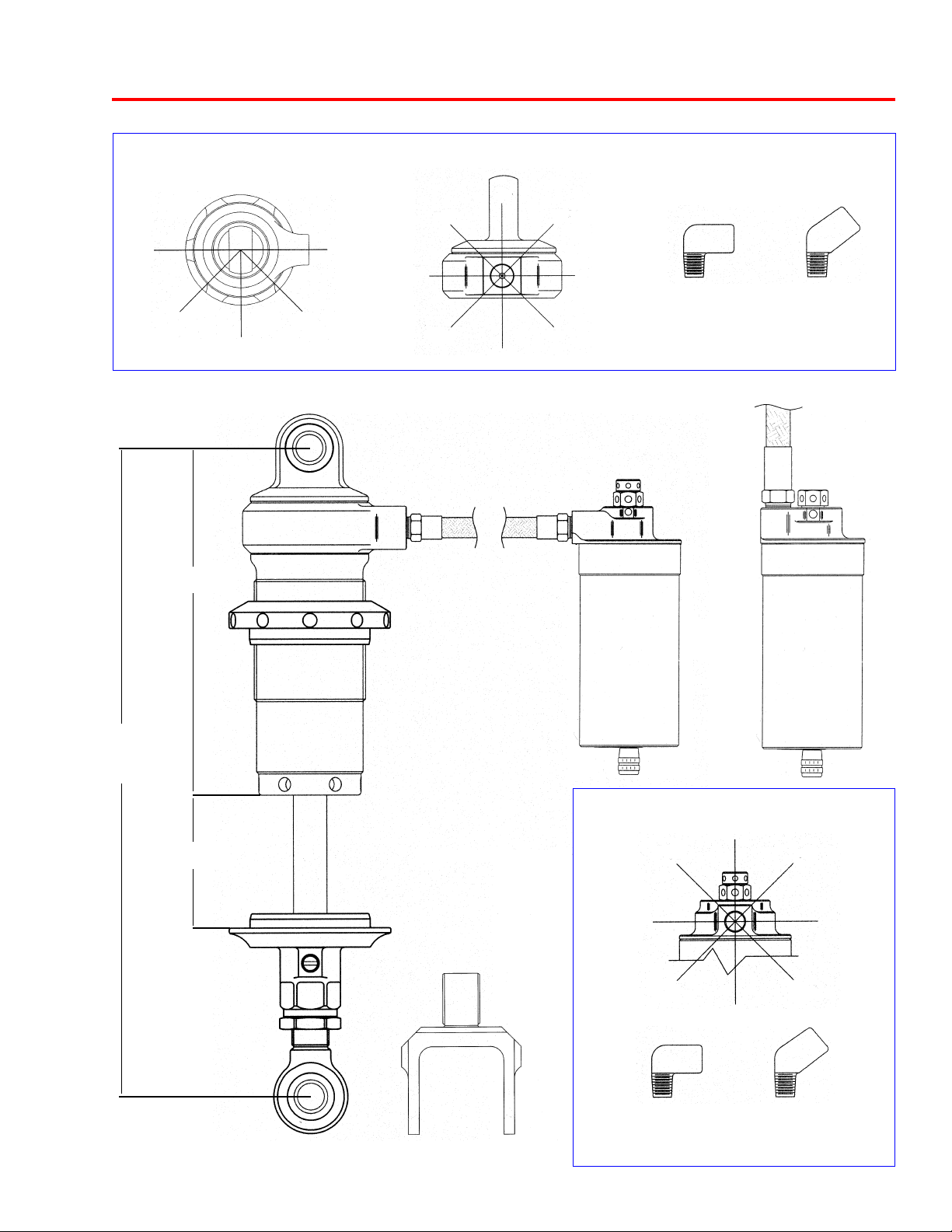

8900 Series Shock Specifications

Body Cap Clocking

o

90

o

135

135

o

180

o

180

o

o

225

270

o

o

0

o

45

o

90

Body Cap Bushing

Total Width: ________ Bolt Diameter: ________

ÈÈ

Type of Adjuster ________________

45

315

o

o

0

o

__ 90o Fitting __ 45o Fitting

__ None

Extended

Length

(shortest)

Body Length

È

È

Stroke

È

Reservoir Clocking

o

90

o

135

o

180

o

225

o

270

315

o

45

o

0

o

È

Eyelet Bushing

Total Width: ________ Bolt Diameter: ________

__ 90o Fitting __ 45o Fitting

__ None

7

8981 Series Compression Adjuster Parts List

ITEM

NO.

PART

NO.

DESCRIPTION

8981 Series CD Adjuster Option

Available in 5.5" and 7" Body Lengths

1 IU-22-S Air Valve, Port O-Ring, Steel

IU-04 Valve Core, 2000 psi

IU-06 Valve Cap, High Temperature

OR-2010 O-Ring, 2-010, Buna 70

2 RR-06 Wire Ring, .0625 Wire Diameter x 1.900

3 CP-81R Cap, 8100 Reservoir

4 OR-2221-B O-Ring, 2-221, Buna 70

5 PB-55 Piston Band, 55mm

6 PI-81R Piston, Reservoir 1.72 Diameter

7 OR-2323-M O-Ring, 2-323, Moly 70

8 RB-81__* Reservoir Body, 8100, (5.50" or 7.00")

9 SC-24 Screw, SHCS, 10-24 x 3/8"

10 VW-03 Washer, Valve, .635 x .015 x .191

11 DO-04 Dowel Pin, 3/32" x 3/4"

8

ITEM

NO.

12 BA-250-ST Ball, Steel - 1/4"

13 SP-10 Spring, (TA2086)

14 HO-87__* Hose (4" - 36" in 1" increments)

15 SC-02 Screw, Socket Set, 8/32" x 3/8"

16 KN-81 Knob, CD 8100

17 RR-02 Retaining Ring, .250 External

18 SC-08 Screw, Socket Set, 8-32 x 1/8"

19 SP-14 Spring, (A109)

20 BA-125-ST Ball, Steel - 1/8"

21 HG-81D Housing, CD 8100 Dished

22 OR-2006-B O-Ring, 2-006, Buna 70

23 DR-81 Drum, CD 8100

24 OR-2013-B O-Ring, 2-013, Buna 70

* Incomplete Part Number

PART

NO.

AS-81UD Assembly, Update 8100 CD Adj with Knob

(Includes Items 4, 9-13, 15-24)

DESCRIPTION

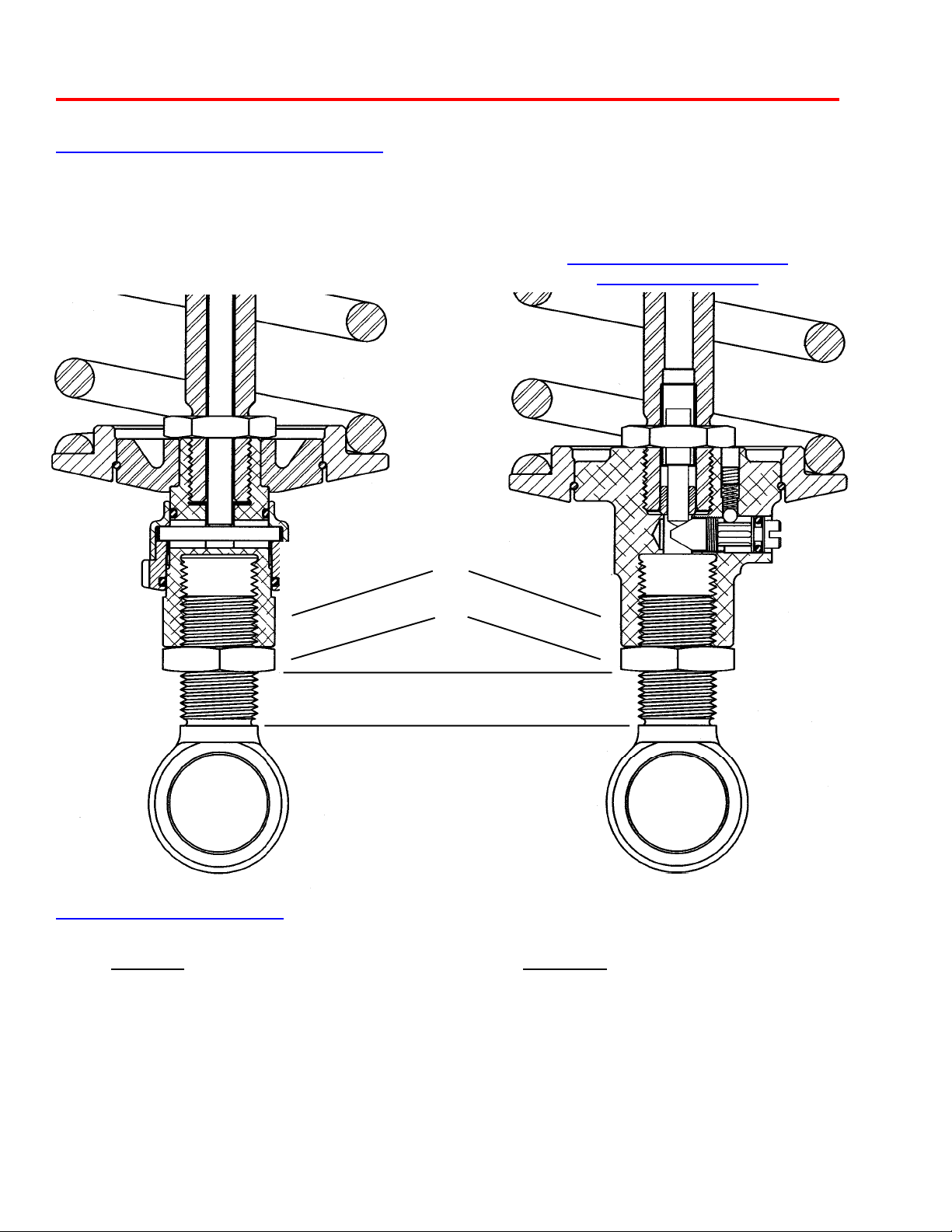

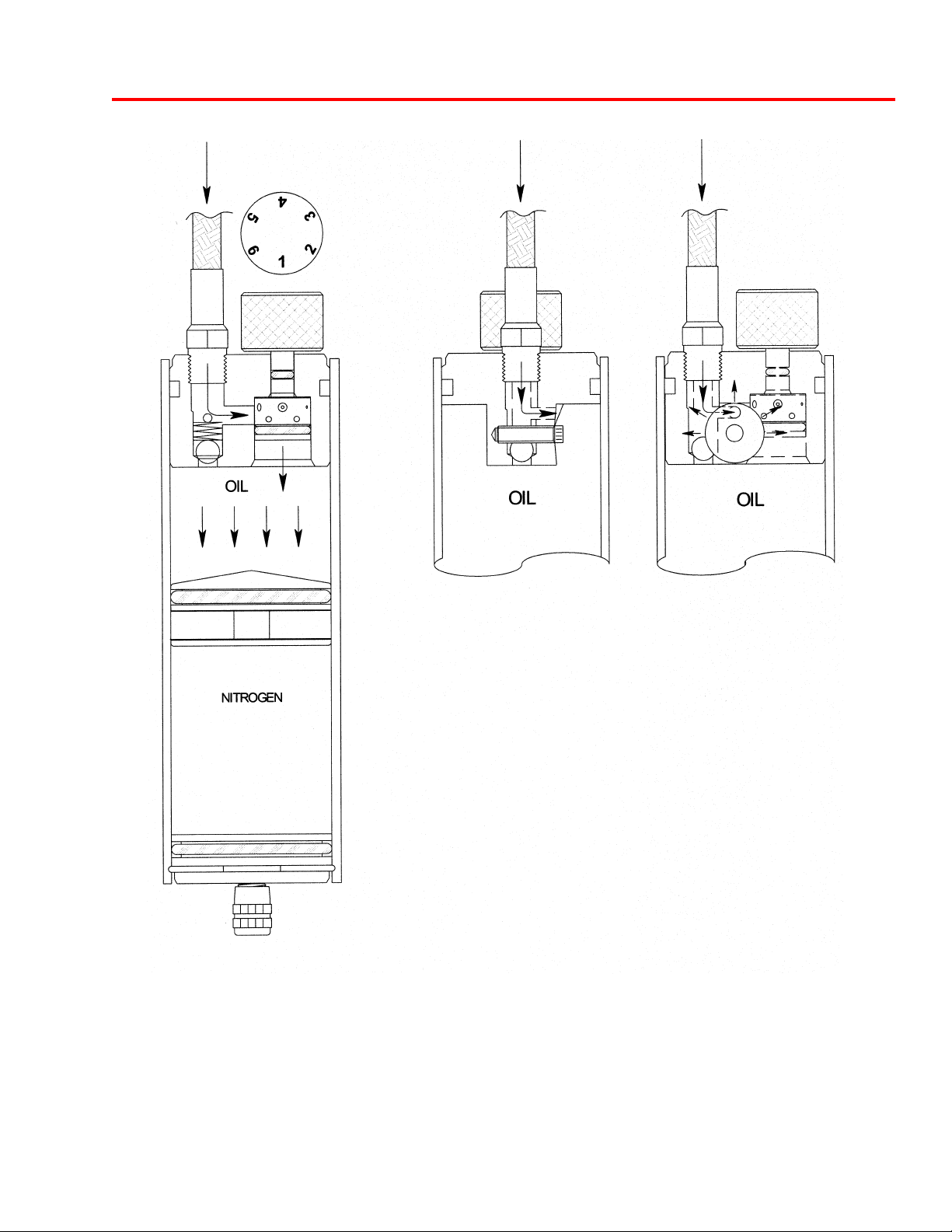

8981 Series Compression Adjuster

Low Speed High Speed

Figure 1

Figure 2

The 8981 compression adjuster is located in the remote reservoir

assembly . The remote reservoir serves as an extension of the shock

absorbers vital elements: oil and nitrogen. The remote reservoir theory

allows for the use of increased volumes of oil and nitrogen while

allowing for smaller shock packaging. Increased nitrogen volume is

essential for consistent damping forces throughout a long race and

extreme conditions.

In the compression mode of the shock absorber, fluid is forced into the

remote reservoir in direct proportion to the area of the shaft entering the

shock body. As fluid enters the reservoir, it must pass through the

compression adjuster. Inside the compression adjuster is the CD drum.

The CD drum has (6) settings, numbered (1-6), with number one setting

(the largest hole) being full soft and number six (the smallest hole)

being full firm. As fluid is forced through the CD drum (Figure 1), it is

metered through one of the preassigned orifices in the drum; it then

enters the reservoir body , moving the floating piston. The floating piston

is designed to separate the fluid and nitrogen, eliminating any chance

of aeration.

In the event of high speed shaft velocities, fluid passing through the

hole in the CD drum could pack-up, causing an increase in damping

forces, due to the fact that fluid can no longer pass through the hole.

In this event, the fluid forces open the blow-off valve (Figure 2). The

blow-off valve makes a more linear damping curve.

Note: The remote compression adjuster is a fine tuning device for the

main valving located inside the shock absorber.

9

8986 Series Compression Adjuster Parts List

ITEM

NO.

10 VW-01-C Crush Washer, .25 ID, Copper

11 PI-76CD Piston, Compression Adjuster

12 OR-2013-B O-Ring, 2-013, Buna 70

13 DO-06 Dowel Pin, 1/16" x 3/8"

14 BA-187-ST Ball, Steel - 3/16"

PART

NO.

8986 Series Adjuster Option

Available in 4", 5", and 6" Body Lengths

1 RR-12 Retaining Ring, .343 External

2 CA-92 Cage, CD Clasp .343 Diameter

3 RR-12 Retaining Ring, .343 External

4 CA-90 Cage, CD Top Hat .343 Diameter

5 VW-91 Washer , Valve, 1.475 x .010

VW-88 Washer, Valve, 1.350 x .008

VW-66 Washer, Valve, 1.200 x .006

VW-44 Washer, Valve, 1.050 x .004

VW-28 Washer, Valve, .900 x .008

VW-30 Washer, Valve, .900 x .010

VW-38 Washer, Valve, .900 x .020

6 CA-76CD Cage, Compression Adjuster

7 SC-76INS Screw, Piston Insert

8 VW-70 Washer , Valve, 1.200 x .010

9 SC-06 Screw, SHCS, 1/4" -20 x 3/4"

DESCRIPTION

10

ITEM

NO.

15 SP-16 Spring, (1460)

16 OR-2222-B O-Ring, 2-222, Buna 70

17 OR-2028-B O-Ring, 2-028, Buna 70

18 HG-76____* Housing, 8760, (Side Entry or Top Entry)

19 SP-14 Spring, (A109)

20 BA-125-ST Ball, Steel - 1/8"

21 OR-2013-B O-Ring, 2-013, Buna 70

22 SC-08 Screw, Socket Set, 8/32" x 1/8"

23 OR-2010-B O-Ring, 2-010, Buna 70

24 SH-86CD Shaft, CD High Speed

25 HO-87___* Hose (4" - 36" in 1" increments)

26 RB-76___* Reservoir Body, 8760, (4.00", 5.00" or 6.00")

27 PI-76 Piston, Floating 1.75 Diameter

28 OR-4222-B Quad Ring, 4-222, Buna 70

29 SL-87 Seal, Dowty

30 SC-18 Screw, SHCS, 4 - 40 x 1/4"

31 CP-76 Cap, Reservoir Port O-Ring

32 RR-06 Wire Ring, .0625 Wire Diameter x 1.900

33 OR-2010-B O-Ring, 2-010, Buna 70

34 IU-20-A Air Valve, Port O-Ring, Aluminum

* Incomplete Part Number

PART

NO.

IU-04 Valve Core, 2000 psi

IU-06 Valve Cap, High Temperature

DESCRIPTION

8986 Series Compression Adjuster

Fixed Low Speed Bleed Circuit

High Speed Flow Circuit

Compression Adjuster

COMPRESSION ADJUSTMENT

In the state of low shaft velocities (i.e. corner entry, exit, and power down), oil is displaced within the damper in

direct proportion to the volume of the shaft entering the body. The displaced fluid passes through the compression adjuster where it is metered through a fixed, low speed bleed orifice. Due to the small diameter of this

orifice and the viscosity of the damper fluid, a pressure loss occurs across the orifice. This loss of pressure is a

loss of energy in the fluid due to friction and the subsequent opposing damping force is generated.

As the shaft velocities increase, the same amount of fluid must pass through the low speed bleed orifice, but at

a much higher rate. The viscosity of the fluid causes a greater resistance to flow at the orifice entrance which in

turn produces a large internal force on the CD housing. The other major internal components, namely the piston

and shim cage, are designed to handle this extra force by allowing the shims to “blow off” proportionally to the

extra force generated, much like a coil spring compresses proportionally to the axial load applied. With this

arrangement, the low speed bleed orifice still meters fluid during high speed shaft movements, but the extra

forces generated are handled with the shims which have less resistance to flow at higher velocities. They are

designed to virtually bypass the low speed orifice and form a new fluid circuit. The force at which this occurs

can be varied by turning the compression adjuster in or out, which preloads the shims. Therefore, as the preload

on the shims increases, the static force required for them to activate is increased as well. The name designation

for the parts also clue one in to their purpose, with the low speed bleed orifice handling low velocity bleed flows

and the piston/shim arrangement handling high velocity flows. This principle originated in the main shaft piston/

shim arrangement and follows similar behavior.

NOTE: When making adjustments, use the full soft setting (adjuster wound all the way in against the reservoir

body) as a starting point when counting the number of “clicks” to the desired setting. The full soft setting should

correspond to a clicker number designation of 0. This starting datum has been proven to be most reliable and

repeatable when making compression adjustments. There are 22 +/- clicks of adjustment.

11

Loading...

Loading...