Penske Racing Shocks 8760 User Manual

Adjustable Shocks Technical Manual

8100, 8660, 8760 Series

Main Office

150 Franklin St. • P.O. Box 1056

Reading, P A 19603

(610) 375-6180 • (610) 375-6190 Fax

Southeast Midwest

771-28 Fentress Blvd. • P.O. Box 11586 12666 US-12 • P.O. Box 666

Daytona Beach, FL 32120 Brooklyn, MI 49230

(386) 274-5336 • (386) 274-5442 Fax (517) 592-6681 • (517) 592-3696 Fax

T able of Contents Page

8100 Series Shock

Parts List ............................................................................................... 2

Damper Specifications and Part Lengths.............................................. 3

8760 Series Shock

Parts List ............................................................................................... 4

Damper Specifications and Part Lengths.............................................. 5

8100 Series Compression Adjuster

Parts List ............................................................................................... 6

Operational Guide ................................................................................. 7

8660 Series Compression Adjuster

Parts List ............................................................................................... 8

Operational Guide ................................................................................. 9

8760 Series Compression Adjuster

Parts List ............................................................................................... 10

Operational Guide ................................................................................. 11

Rebound Adjusters.................................................................................... 12

Disassembly / Assembly Instructions ..................................................... 13

Suggested Maintenance ........................................................................... 14

Trouble Shooting ....................................................................................... 14

Valving

General Valving Characteristics............................................................. 15

A Guide To Damper Tuning................................................................... 16

Basic Start-up Procedure...................................................................... 17

Valve S tacks.......................................................................................... 18

VDP and Digressive V alving Information Options.................................. 19

VDP 55mm Linear Base Shim .............................................................. 19

Preload Shim Spacers........................................................................... 19

Pistons

Flow Rate Through Multiple Bleed Holes .............................................. 20

Piston Selection .................................................................................... 21

Linear Piston ......................................................................................... 22

Digressive Piston................................................................................... 23

Velocity Dependent Piston (VDP) ......................................................... 24

Damping Adjustments........................................................................... 26

REV: 3/27/01

#5

Dyno Graph Overview ............................................................................... 28

Notes ........................................................................................................... 32

1

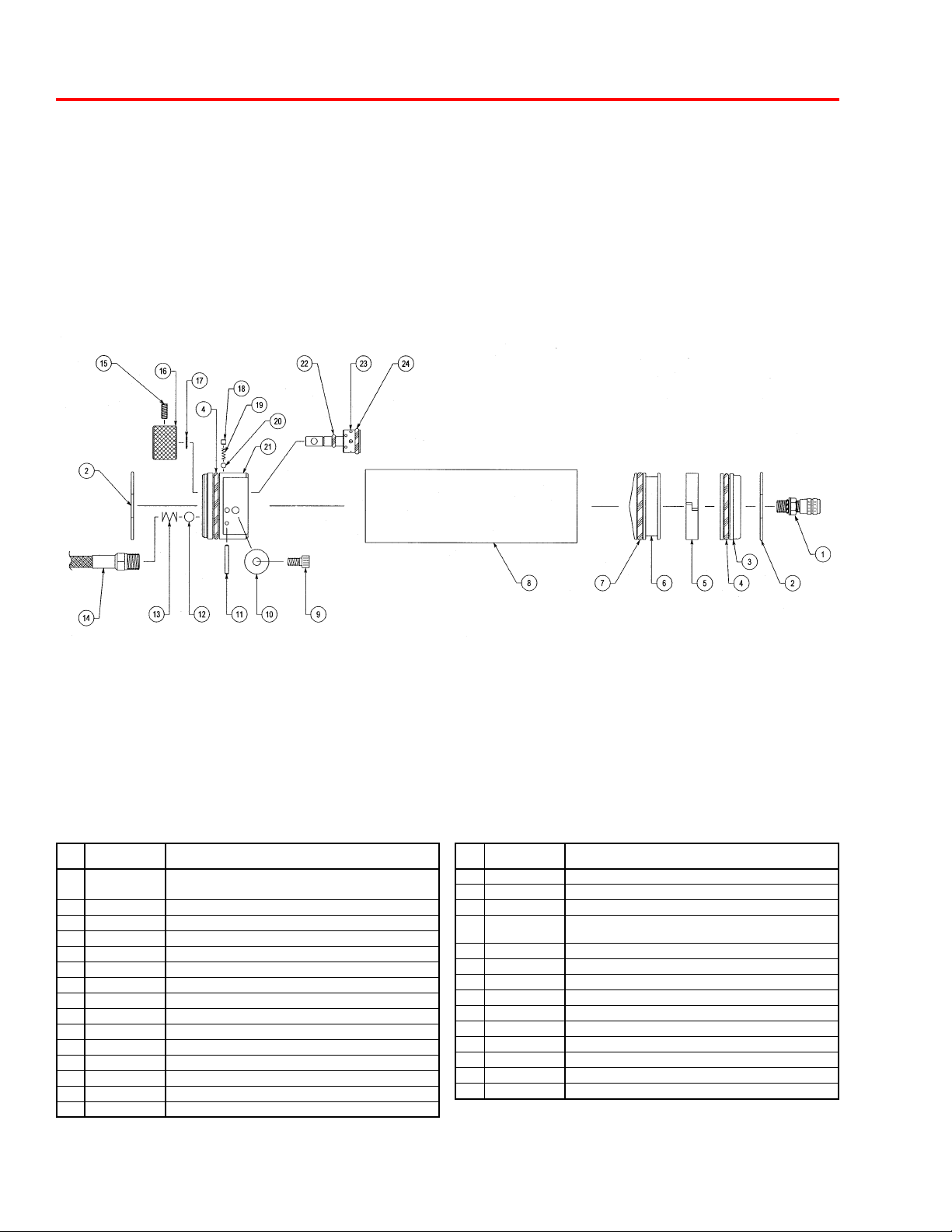

8100 Series Parts List

ITEM

NO.

PART

NO.

DESCRIPTION

Aluminum Coil-over

Double Adjustable

1 BD-81__* Body, Aluminum Coil-over (10.0" - 24.0")

2 RH-812__* Ride Height Adjuster, 8100, (2.25" or 2.50")

3 OR-2221-B O-Ring, 2-221, Buna 70

4 HO-87__* Hose (4" - 36" in 1" increments)

5 FT-__* Fitting, (45o or 90o), 1/8" NPT

6 BC-81__* Body Cap, 8100, (0o, 45o, 90o, 135o)

7 MO-8T Mono Ball, .500 ID, Teflon

MO-15T Monoball, 15mm ID, Teflon

8 RR-16 Retaining Ring, 1.025 Spiroloc

JT-76RD Jet, Rebound Complete

9 RR-05 Retaining Ring, .250 Internal

10 JT-76HAT Jet, Top Hat

11 SP-15 Spring, (FF71)

12 JT-76POP Jet, Poppet

13 JT-RDHSNG Jet, Rebound, Straight Thru

14 NE-76 Needle

15 OR-2007-B O-Ring, 2-007, Buna 70

16 MR-8100 Metering Rod

17 NT-02R Ring Nut, .500 x 20

(Includes Items 9-13)

2

ITEM

NO.

18 VS-__* Valve S tack

19 PB-55 Piston Band, 55mm

20 PI-____* Piston

21 OR-2028-B O-Ring, 2-028, Buna 70

22 VW-99 Top Out Plate, 1.375 x .500

23 BU-10DU10 Bushing, DU .625 x .625

24 OR-2221-B O-Ring, 2-221, Buna 70

25 SB-765 Shaft Bearing, 55mm

26 OR-21 14-V O-Ring, 2-114, Viton 75

27 SL-09 Shaft W iper, .625 Poly (Blue)

28 OR-2312-B O-Ring, 2-312, Buna 70

29 SH-_____* Shaft, Adjustable, (10.0" - 24.0")

30 RS-81 Rebound Screw, Adjustable Shaft

31 OR-2008-B O-Ring, 2-008, Buna 70

32 SR-812__* Spring Retainer, 8100, (2.25" or 2.50")

33 NT-04J Jam Nut, .625 x 18

34 EY - 81 160 Eyelet, 1.60 Sweep, 0

See Pages 6 and 7 for 8100 Series Adjuster.

* Incomplete Part Number

PART

NO.

AS-76SB Assembly, Shaft Bearing Complete

EY -81 1690 Eyelet, 1.60 Sweep, 90

EY -81200 Eyelet, 2.00 Sweep, 0

EY -81230 Eyelet, 2.30 Sweep, 0

(Includes Items 23-27)

DESCRIPTION

o

o

o

o

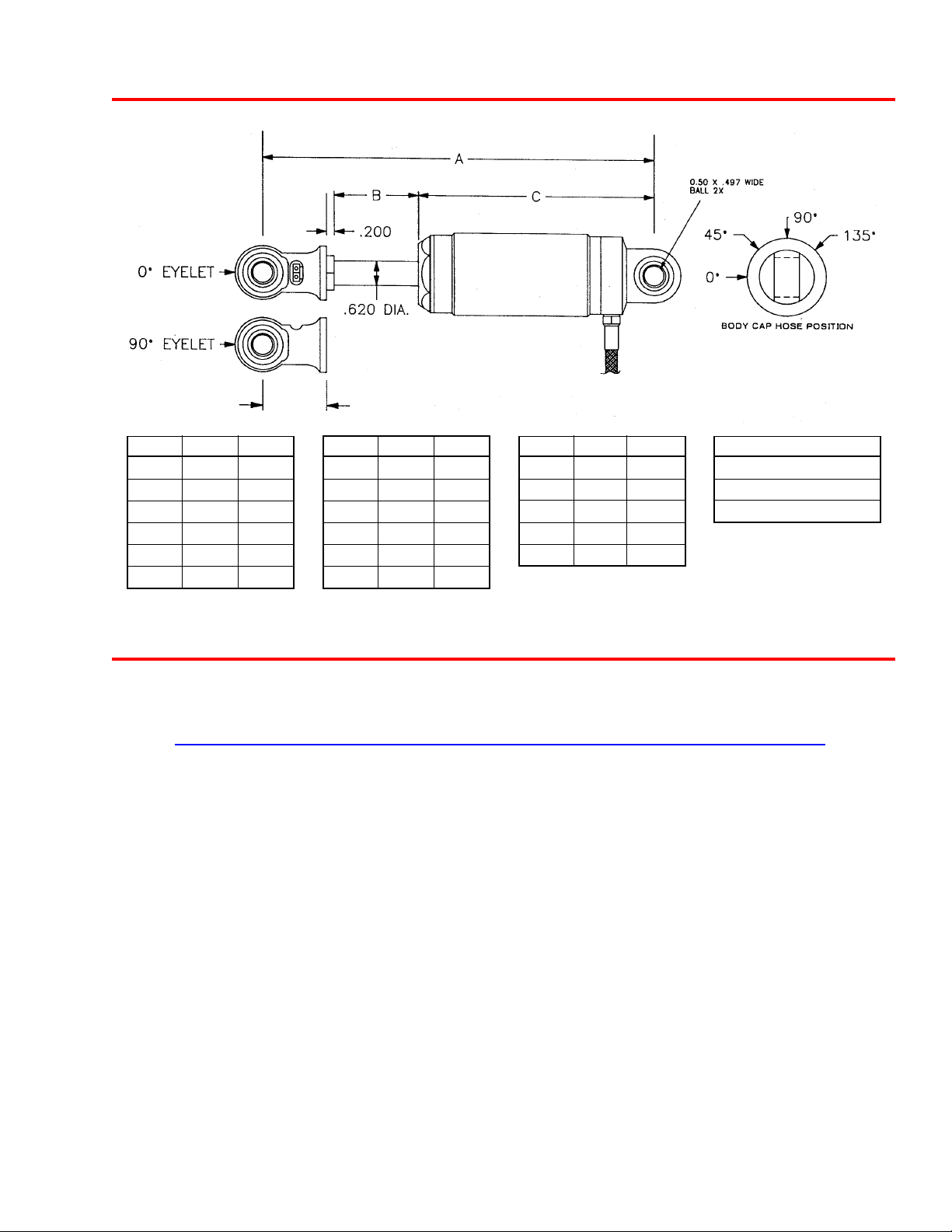

8100 Damper Specifications

D

ABC

10.0 2.125 6.075

10.5 2.375 6.325

11.0 2.625 6.575

11.5 2.875 6.825

12.0 3.125 7.075

12.5 3.375 7.325

ABC

13.0 3.625 7.575

13.5 3.875 7.825

14.0 4.125 8.075

14.5 4.375 8.325

15.0 4.625 8.575

15.5 4.875 8.825

8100 Series Part Lengths

SH-___A BD-81___

Part Shock Shaft Metering Body

Suffix Size Length Rod Length Length

100 10.0” 5.625 1.750 4.275

105 10.5” 5.875 2.000 4.525

110 11.0” 6.125 2.250 4.775

115 11.5” 6.375 2.500 5.025

120 12.0” 6.625 2.750 5.275

125 12.5” 6.875 3.000 5.525

130 13.0” 7.125 3.250 5.775

135 13.5” 7.375 3.500 6.025

140 14.0” 7.625 3.750 6.275

145 14.5” 7.875 4.000 6.525

150 15.0” 8.125 4.250 6.775

155 15.5” 8.375 4.500 7.025

160 16.0” 8.625 4.750 7.275

175 17.5” 9.375 5.500 8.025

180 18.0” 9.625 5.750 8.275

200 20.0” 10.500 6.625 9.400

220 22.0” 11.500 7.625 10.400

240 24.0” 12.500 8.625 11.400

ABC

16.0 5.125 9.075

17.5 5.875 9.875

18.0 6.125 10.075

20.0 7.125 11.075

24.0 9.125 13.075

D

1.6 (0o or 90o) (std.)

2.0 (0o)

2.3 (0o)

3

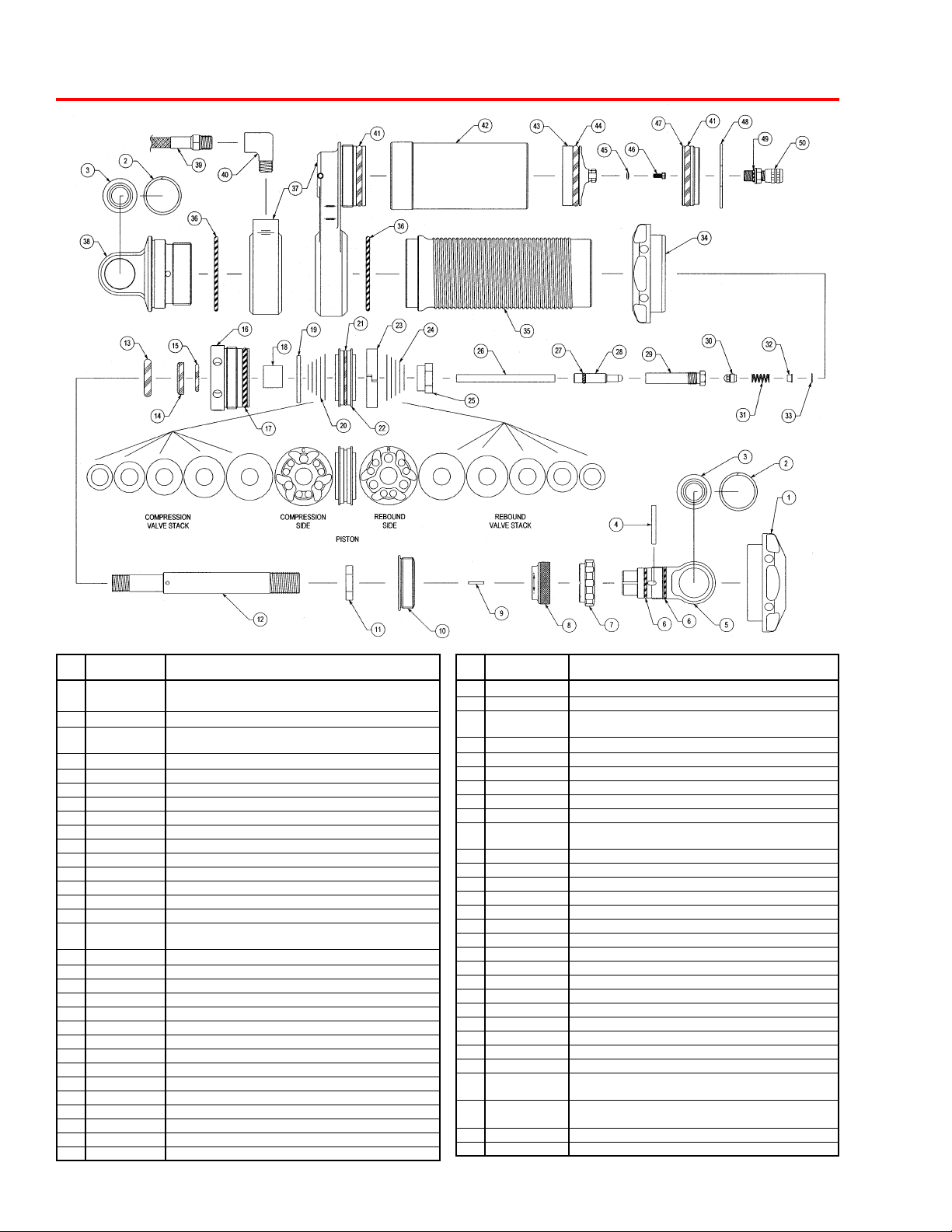

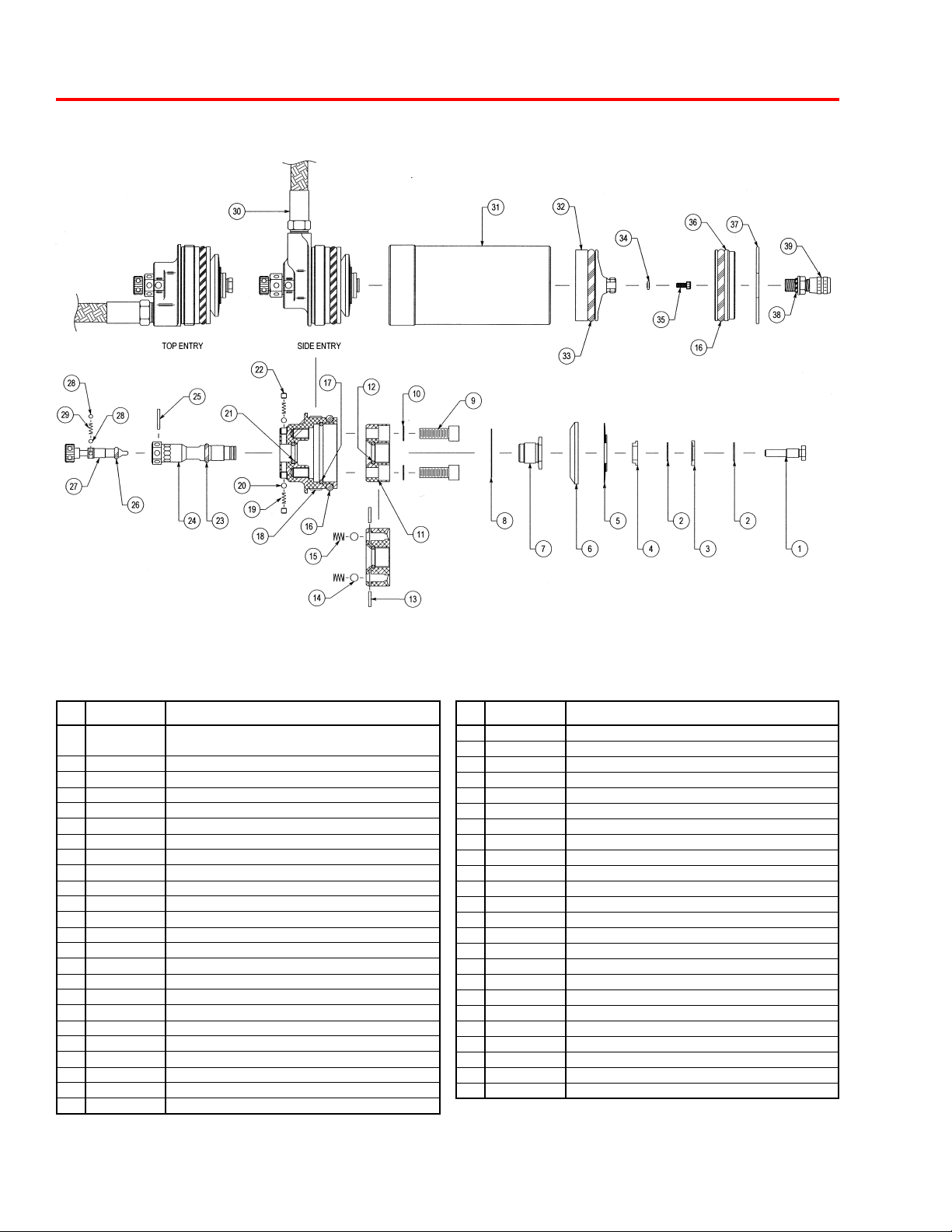

8760 Series Parts List

ITEM

NO.

PART

NO.

DESCRIPTION

8760 Aluminum Coil-over (Piggyback)

8760 Aluminum Coil-over (Remote Reservoir)

1 SR-762__* Spring Retainer, 8760, (2.00", 2.25" or 2.50")

AS-76EY__* Assembly, 8760 Eyelet Complete (2.1”, 2.3”,2.6”)

2 RR-10 Retaining Ring, .875 Spiroloc

3 MO-8T20 Monoball, .500 ID x .875 OD

4 DO-09 Dowel Pin, 1/8" x 1 1/8"

5 EY-76__* Eyelet, 8760, (2.10", 2.30", or 2.60")

6 OR-2017-B O-Ring, 2-017, Buna 70

7 KN-76RD Knob, Rebound Adjuster

8 CP-76RD Cap, Rebound Adjuster

9 DO-06 Dowel Pin, 1/16" x 3/8"

10 SR-76SRM Spring Retainer, 8760, Mount

11 NT-12J Jam Nut, .562 x 18

12 SH-76___* Shaft, 8760, (10.0" - 24.0")

13 OR-2312-B O-Ring, 2-312, Buna 70

AS-76SB__* Assembly, 8760 Shaft Bearing (45mm, 55mm)

14 SL-09 Shaft W iper, .625 Poly (Blue)

15 OR-21 14-V O-Ring, 2-114, Viton 75

16 SB-76_ Shaft Bearing, 8760, (45mm or 55mm)

17 OR-2221-B O-Ring, 2-221, Buna 70 (55mm)

OR-2219-B O-Ring, 2-219, Buna 70 (45mm)

18 BU-10DU10 Bushing, DU .625 x .625

19 VW-99 Top Out Plate, 1.375 x .500

20 VS-___* Valve Stack

21 OR-2025-B O-Ring, 2-025, Buna 70 (45mm)

OR-2028-B O-Ring, 2-028, Buna 70 (55mm)

22 PI-____* Piston

23 PB-___* Piston Band, (45mm or 55mm)

24 VS-___* Valve Stack

25 NT-02R Ring Nut, .500 x 20

26 MR-8760 Metering Rod

(Includes Items 2-8)

(Includes Items 14-18)

4

ITEM

NO.

27 OR-2007-B O-Ring, 2-007, Buna 70

28 NE-76 Needle

29 JT-RDHSNG Jet, Rebound, Straight Thru

30 JT-76POP Jet, Poppet

31 SP-15 Spring, (FF71)

32 JT-76HAT Jet, Top Hat

33 RR-05 Retaining Ring, .250 Internal

34 RH-762__* Ride Height Adjuster, 8760, (2.00", 2.25" or 2.50")

35 BD-76___* Body, 8760, (55mm, 10.0" - 24.0")

36 OR-2136-B O-Ring, 2-136, Buna 70 (55mm)

37 HG-76PB___* Housing, Piggyback, (45mm or 55mm)

38 BC-76___* Body Cap,8760, (45mm or 55mm)

39 HO-87__* Hose (4" - 36" in 1" increments)

40 FT-__* Fitting, (45o or 90o), 1/8" NPT

41 OR-2222-B O-Ring, 2-222, Buna 70

42 RB-76_* Reservoir Body, 8760, (4.00", 5.00" or 6.00")

43 PI-76 Piston, Floating, 1.75 Diameter

44 OR-4222-B Quad Ring, 4-222, B-70

45 SL-87 Seal, Dowty

46 SC-18 Screw, SHCS, 4-40 x 1/4"

47 CP-76 Cap, Reservoir Port O-Ring

48 RR-06 Wire Ring, .0625 Wire Diameter x 1.900

49 OR-2010-B O-Ring, 2-010, Buna 70

50 IU-20-A Air Valve, Port O-Ring, Aluminum

See Pages 8-11 for 8660 and 8760 Series Adjuster.

* Incomplete Part Number

PART

NO.

JT-76RD Jet, Rebound Complete

OR-2133-B O-Rint, 2-133, Buna 70 (45mm)

CO-76____* Collar, Body, (45mm or 55mm)

BC-76E___* Body Cap, 8760, Extended (.250”,.500”,1.00”) 55mm

AS-76RESCAP Assembly, 8760 Reservoir Cap

IU-04 Valve Core, 2000 psi

IU-06 Valve Cap, High Temperature

(Includes Items 29-33)

(Includes Items 47, 41, 49, 50)

DESCRIPTION

(45mm, 10.0" - 13.5")

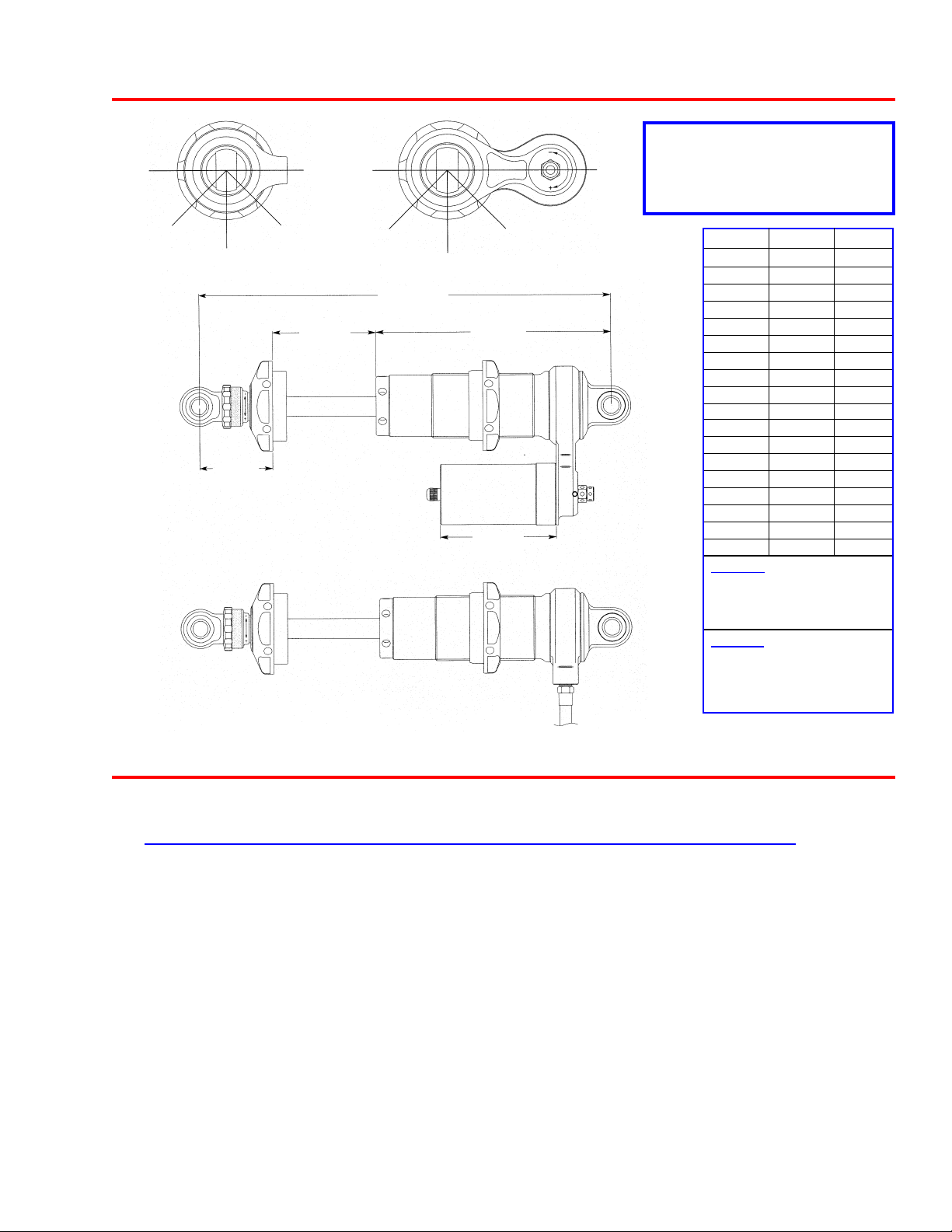

8760 Series Damper Specifications

o

0

180

o

o

0

180

o

45mm (1.87 OD) = 2.00” ID

Spring Hardware

55mm (2.06 OD) = 2.25” or 2.50” ID

Spring Hardware

o

45

o

90

135

o

o

45

o

90

135

o

DIM “A” DIM “B” DIM “C”

10.0 1.875 5.850

10.5 2.125 6.100

1 1.0 2.375 6.350

1 1.5 2.625 6.600

12.0 2.875 6.850

12.5 3.125 7.100

DIM “B”

Stroke

DIM “A”

Eye to Eye

DIM “C”

Body Length

13.0 3.375 7.350

13.5* 3.625 7.600

14.0 3.875 7.850

14.5 4.125 8.100

15.0 4.375 8.350

15.5 4.625 8.600

Dim “E”

16.0 4.875 8.850

17.5 5.625 9.600

18.0 5.875 9.850

20.0 6.875 10.850

DIM “D”

Reservoir Length

22.0 7.875 11.850

24.0 8.875 12.850

DIM “D”

4.00

5.00

6.00

DIM “E”

2.277 for 2.100 Eyelet (std.)

2.477 for 2.300 Eyelet

2.777 for 2.600 Eyelet

* 13.5 (DIM “A”) max for 45mm

8760 Series Part Lengths

SH-76___ BD-76___

Part Overall Shaft Metering Body

Suffix Length Length Rod Length Length

100 10.0” 5.250 2.525 3.915

105 10.5” 5.550 2.775 4.165

110 11.0” 5.750 3.025 4.415

115 11.5” 6.000 3.275 4.665

120 12.0” 6.250 3.525 4.915

125 12.5” 6.500 3.775 5.165

130 13.0” 6.750 4.025 5.415

135 13.5” 7.000 4.275 5.665

140 14.0” 7.250 4.525 5.915

145 14.5” 7.500 4.775 6.165

150 15.0” 7.750 5.025 6.415

155 15.5” 8.000 5.275 6.665

160 16.0” 8.250 5.525 6.915

175 17.5” 9.000 6.275 7.665

180 18.0” 9.250 6.525 7.915

200 20.0” 10.250 7.525 8.915

220 22.0” 11.250 8.525 9.915

240 24.0” 12.250 9.525 10.915

5

8100 Series Compression Adjuster Parts List

ITEM

NO.

PART

NO.

DESCRIPTION

8100 Series CD Adjuster Option

Available in 5.5" and 7" Body Lengths

1 IU-22-S Air Valve, Port O-Ring, Steel

IU-04 Valve Core, 2000 psi

IU-06 Valve Cap, High Temperature

OR-2010 O-Ring, 2-010, Buna 70

2 RR-06 Wire Ring, .0625 Wire Diameter x 1.900

3 CP-81R Cap, 8100 Reservoir

4 OR-2221-B O-Ring, 2-221, Buna 70

5 PB-55 Piston Band, 55mm

6 PI-81R Piston, Reservoir 1.72 Diameter

7 OR-2323-M O-Ring, 2-323, Moly 70

8 RB-81__* Reservoir Body, 8100, (5.50" or 7.00")

9 SC-24 Screw, SHCS, 10-24 x 3/8"

10 VW-03 Washer, V alve, .635 x .015 x .191

11 DO-04 Dowel Pin, 3/32" x 3/4"

6

ITEM

NO.

12 BA-250-ST Ball, Steel - 1/4"

13 SP-10 Spring, (TA2086)

14 HO-87__* Hose (4" - 36" in 1" increments)

15 SC-02 Screw, Socket Set, 8/32" x 3/8"

16 KN-81 Knob, CD 8100

17 RR-02 Retaining Ring, .250 External

18 SC-08 Screw, Socket Set, 8-32 x 1/8"

19 SP-14 Spring, (A109)

20 BA-125-ST Ball, Steel - 1/8"

21 HG-81D Housing, CD 8100 Dished

22 OR-2006-B O-Ring, 2-006, Buna 70

23 DR-81 Drum, CD 8100

24 OR-2013-B O-Ring, 2-013, Buna 70

* Incomplete Part Number

PART

NO.

AS-81UD Assembly, Update 8100 CD Adj with Knob

(Includes Items 4, 9-13, 15-24)

DESCRIPTION

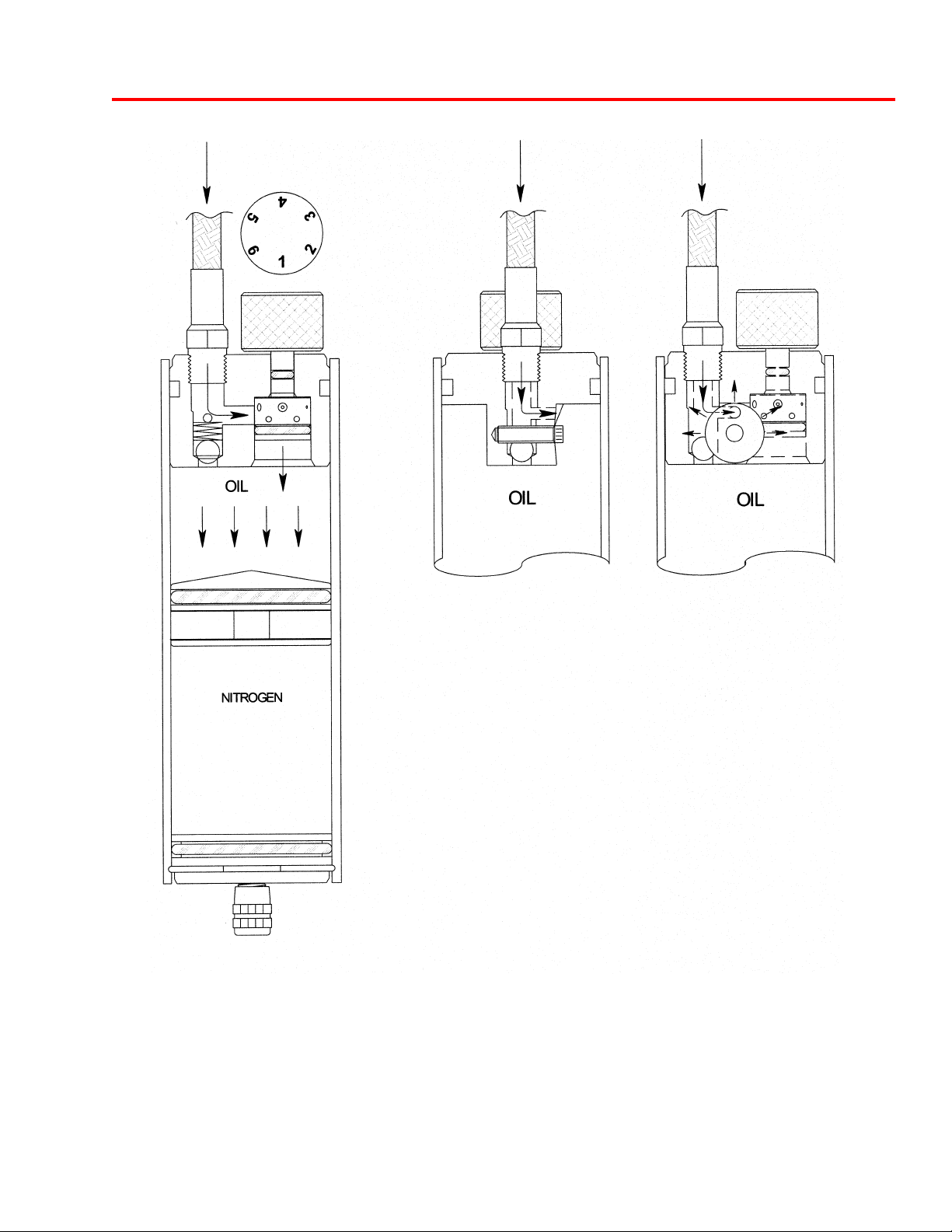

8100 Series Compression Adjuster

Figure 1

Figure 2

The 8100 compression adjuster is located in the remote reservoir

assembly. The remote reservoir serves as an extension of the shock

absorbers vital elements: oil and nitrogen. The remote reservoir

theory allows for the use of increased volumes of oil and nitrogen

while allowing for smaller shock packaging. Increased nitrogen

volume is essential for consistent damping forces throughout a long

race and extreme conditions.

In the compression mode of the shock absorber, fluid is forced into

the remote reservoir in direct proportion to the area of the shaft

entering the shock body. As fluid enters the reservoir, it must pass

through the compression adjuster. Inside the compression adjuster is

the CD drum. The CD drum has (6) settings, numbered (1-6), with

number one setting (the largest hole) being full soft and number six

(the smallest hole) being full firm. As fluid is forced through the CD

drum (Figure 1), it is metered through one of the preassigned orifices

in the drum; it then enters the reservoir body,moving the floating

piston. The floating piston is designed to separate the fluid and

nitrogen, eliminating any chance of aeration.

In the event of high speed shaft velocities, fluid passing through the

hole in the CD drum could pack-up, causing an increase in damping

forces, due to the fact that fluid can no longer pass through the hole.

In this event, the fluid forces open the blow-off valve (Figure 2). The

blow-off valve makes a more linear damping curve.

Note: The remote compression adjuster is a fine tuning device for the

main valving located inside the shock absorber.

7

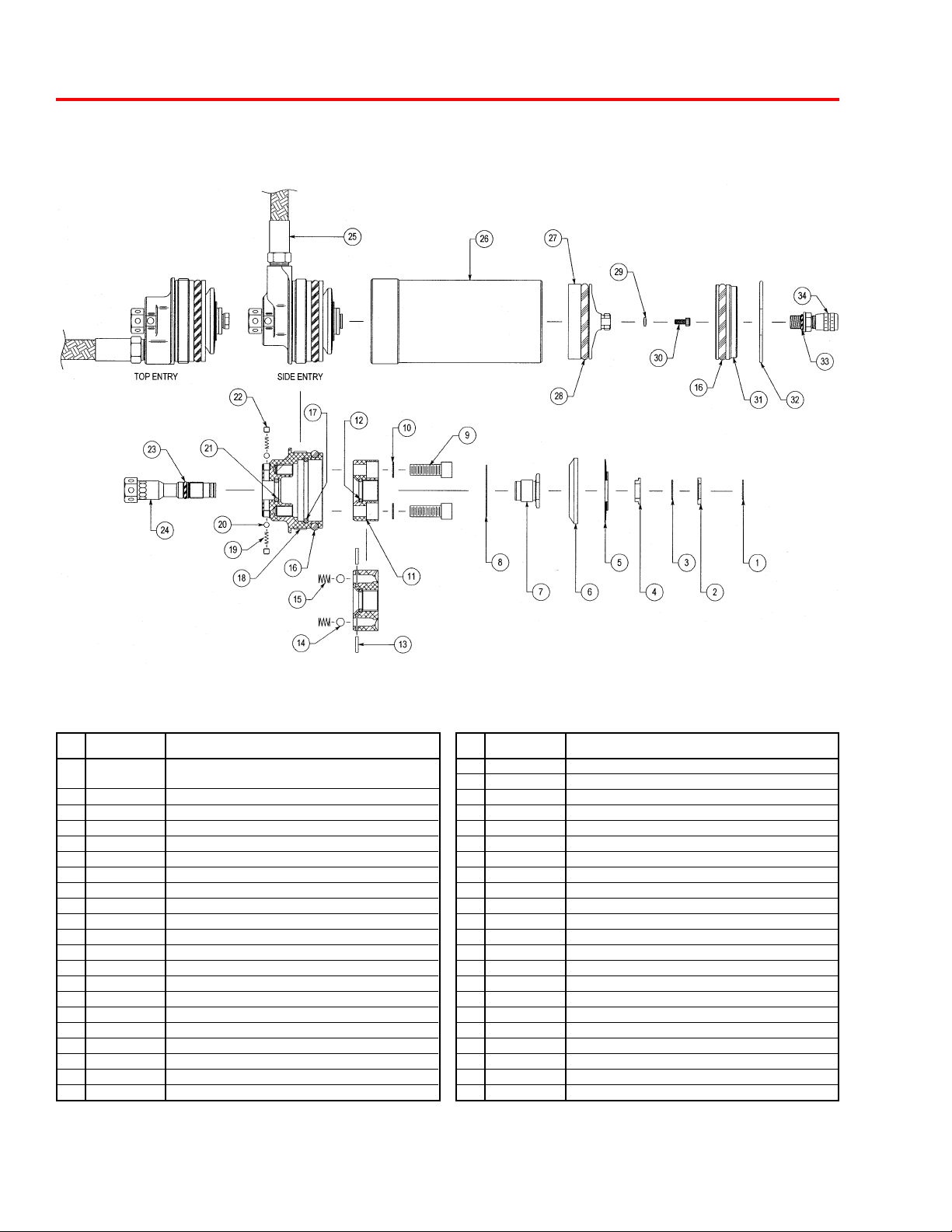

8660 Series Compression Adjuster Parts List

ITEM

NO.

10 VW-01-C Crush Washer, .25 ID, Copper

11 PI-76CD Piston, Compression Adjuster

12 OR-2013-B O-Ring, 2-013, Buna 70

13 DO-06 Dowel Pin, 1/16" x 3/8"

14 BA-187-ST Ball, Steel - 3/16"

PART

NO.

Available in 4", 5", and 6" Body Lengths

1 RR-12 Retaining Ring, .343 External

2 CA-92 Cage, CD Clasp .343 Diameter

3 RR-12 Retaining Ring, .343 External

4 CA-90 Cage, CD Top Hat .343 Diameter

5 VW-91 Washer , Valve, 1.475 x .010

VW-88 Washer, V alve, 1.350 x .008

VW-66 Washer, V alve, 1.200 x .006

VW-44 Washer, V alve, 1.050 x .004

VW-28 Washer, V alve, .900 x .008

VW-30 Washer, V alve, .900 x .010

VW-38 Washer, V alve, .900 x .020

6 CA-76CD Cage, Compression Adjuster

7 SC-76INS Screw, Piston Insert

8 VW-70 Washer , Valve, 1.200 x .010

9 SC-06 Screw, SHCS, 1/4" -20 x 3/4"

DESCRIPTION

8660 Series Adjuster Option

ITEM

NO.

15 SP-16 Spring, (1460)

16 OR-2222-B O-Ring, 2-222, Buna 70

17 OR-2028-B O-Ring, 2-028, Buna 70

18 HG-76____* Housing, 8760, (Side Entry or Top Entry)

19 SP-14 Spring, (A109)

20 BA-125-ST Ball, Steel - 1/8"

21 OR-2013-B O-Ring, 2-013, Buna 70

22 SC-08 Screw, Socket Set, 8/32" x 1/8"

23 OR-2010-B O-Ring, 2-010, Buna 70

24 SH-86CD Shaft, CD High Speed

25 HO-87___* Hose (4" - 36" in 1" increments)

26 RB-76___* Reservoir Body, 8760, (4.00", 5.00" or 6.00")

27 PI-76 Piston, Floating 1.75 Diameter

28 OR-4222-B Quad Ring, 4-222, Buna 70

29 SL-87 Seal, Dowty

30 SC-18 Screw, SHCS, 4 - 40 x 1/4"

31 CP-76 Cap, Reservoir Port O-Ring

32 RR-06 Wire Ring, .0625 Wire Diameter x 1.900

33 OR-2010-B O-Ring, 2-010, Buna 70

34 IU-20-A Air Valve, Port O-Ring, Aluminum

* Incomplete Part Number

PART

NO.

IU-04 Valve Core, 2000 psi

IU-06 Valve Cap, High Temperature

DESCRIPTION

8

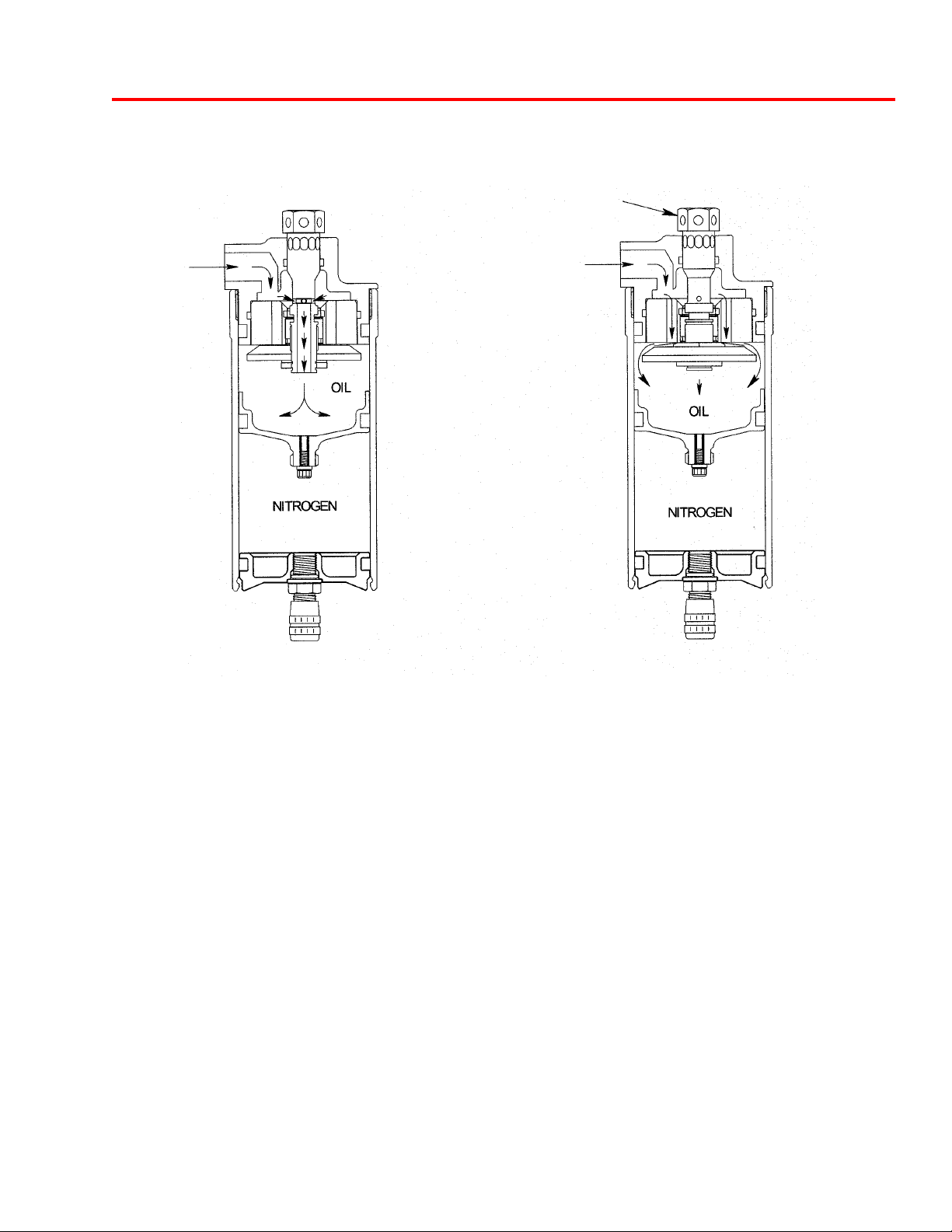

8660 Series Compression Adjuster

Fixed Low Speed Bleed Circuit

High Speed Flow Circuit

Compression Adjuster

COMPRESSION ADJUSTMENT

In the state of low shaft velocities (i.e. corner entry, exit, and power down), oil is displaced within the damper in

direct proportion to the volume of the shaft entering the body. The displaced fluid passes through the compression adjuster where it is metered through a fixed, low speed bleed orifice. Due to the small diameter of this

orifice and the viscosity of the damper fluid, a pressure loss occurs across the orifice. This loss of pressure is a

loss of energy in the fluid due to friction and the subsequent opposing damping force is generated.

As the shaft velocities increase, the same amount of fluid must pass through the low speed bleed orifice, but at

a much higher rate. The viscosity of the fluid causes a greater resistance to flow at the orifice entrance which in

turn produces a large internal force on the CD housing. The other major internal components, namely the piston

and shim cage, are designed to handle this extra force by allowing the shims to “blow off” proportionally to the

extra force generated, much like a coil spring compresses proportionally to the axial load applied. With this

arrangement, the low speed bleed orifice still meters fluid during high speed shaft movements, but the extra

forces generated are handled with the shims which have less resistance to flow at higher velocities. They are

designed to virtually bypass the low speed orifice and form a new fluid circuit. The force at which this occurs

can be varied by turning the compression adjuster in or out, which preloads the shims. Therefore, as the preload

on the shims increases, the static force required for them to activate is increased as well. The name designation

for the parts also clue one in to their purpose, with the low speed bleed orifice handling low velocity bleed flows

and the piston/shim arrangement handling high velocity flows. This principle originated in the main shaft piston/

shim arrangement and follows similar behavior.

NOTE: When making adjustments, use the full soft setting (adjuster wound all the way in against the reservoir

body) as a starting point when counting the number of “clicks” to the desired setting. The full soft setting should

correspond to a clicker number designation of 0. This starting datum has been proven to be most reliable and

repeatable when making compression adjustments. There are 22 +/- clicks of adjustment.

9

8760 Series Compression Adjuster Parts List

ITEM

NO.

10 VW-01-C Crush Washer, .25 ID, Copper

11 PI-76CD Piston, Compression Adjuster

12 OR-2013-B O-Ring, 2-013, Buna 70

13 DO-06 Dowel Pin, 1/16" x 3/8"

14 BA-187-ST Ball, Steel - 3/16"

15 SP-16 Spring, (1460)

16 OR-2222-B O-Ring, 2-222, Buna 70

17 OR-2028-B O-Ring, 2-028, Buna 70

PART

NO.

Available in 4", 5", and 6" Body Lengths

1 J T -76CDSH Jet, High Speed Shaft

2 RR-12 Retaining Ring, .343 External

3 CA-92 Cage, CD Clasp .343 Diameter

4 CA-90 Cage, CD Top Hat .343 Diameter

5 VW-91 Washer , Valve, 1.475 x .010

VW-88 Washer, V alve, 1.350 x .008

VW-66 Washer, V alve, 1.200 x .006

VW-44 Washer, V alve, 1.050 x .004

VW-28 Washer, V alve, .900 x .008

VW-30 Washer, V alve, .900 x .010

VW-38 Washer, V alve, .900 x .020

6 CA-76CD Cage, Compression Adjuster

7 SC-76INS Screw, Piston Insert

8 VW-70 Washer , Valve, 1.200 x .010

9 SC-06 Screw, SHCS, 1/4" -20 x 3/4"

DESCRIPTION

8760 Series Adjuster Option

ITEM

NO.

18 HG-76____* Housing, 8760, (Side Entry or Top Entry)

19 SP-14 Spring, (A109)

20 BA-125-ST Ball, Steel - 1/8"

21 OR-2013-B O-Ring, 2-013, Buna 70

22 SC-08 Screw, Socket Set, 8/32" x 1/8"

23 OR-2010-B O-Ring, 2-010, Buna 70

24 SH-76CD12 Shaft, CD High Speed 12pt

25 DO-18 Roll Pin, 1/16" x 1/2"

26 OR-2004-B O-Ring, 2-004, Buna 70

27 SC-76CDLS Screw, CD Low Speed

28 BA-093-ST Ball, Steel - 3/32"

29 SP-12 Spring, (3648)

30 HO-87__* Hose (4" - 36", in 1" increments)

31 RB-76__* Reservoir Body, 8760, (4.00", 5.00", or 6.00")

32 PI-76 Piston, Floating 1.75 Diameter

33 OR-4222-B Quad Ring, 4-222, Buna 70

34 SL-87 Seal, Dowty

35 SC-18 Screw, SHCS, 4 - 40 x 1/4"

36 CP-76 Cap, Reservoir Port O-Ring

37 RR-06 Wire Ring, .0625 Wire Diameter x 1.900

38 OR-2010-B O-Ring, 2-010, Buna 70

39 IU-20-A Air Valve, Port O-Ring, Aluminum

* Incomplete Part Number

PART

NO.

IU-04 Valve Core, 2000 psi

IU-06 Valve Cap, High Temperature

DESCRIPTION

10

Loading...

Loading...