Pella 81CM0100 User Manual

Part Number: 81CM0100© 2011 Pella Corporation

INSTALLATION INSTRUCTIONS - INSTRUCCIONES DE INSTALACION

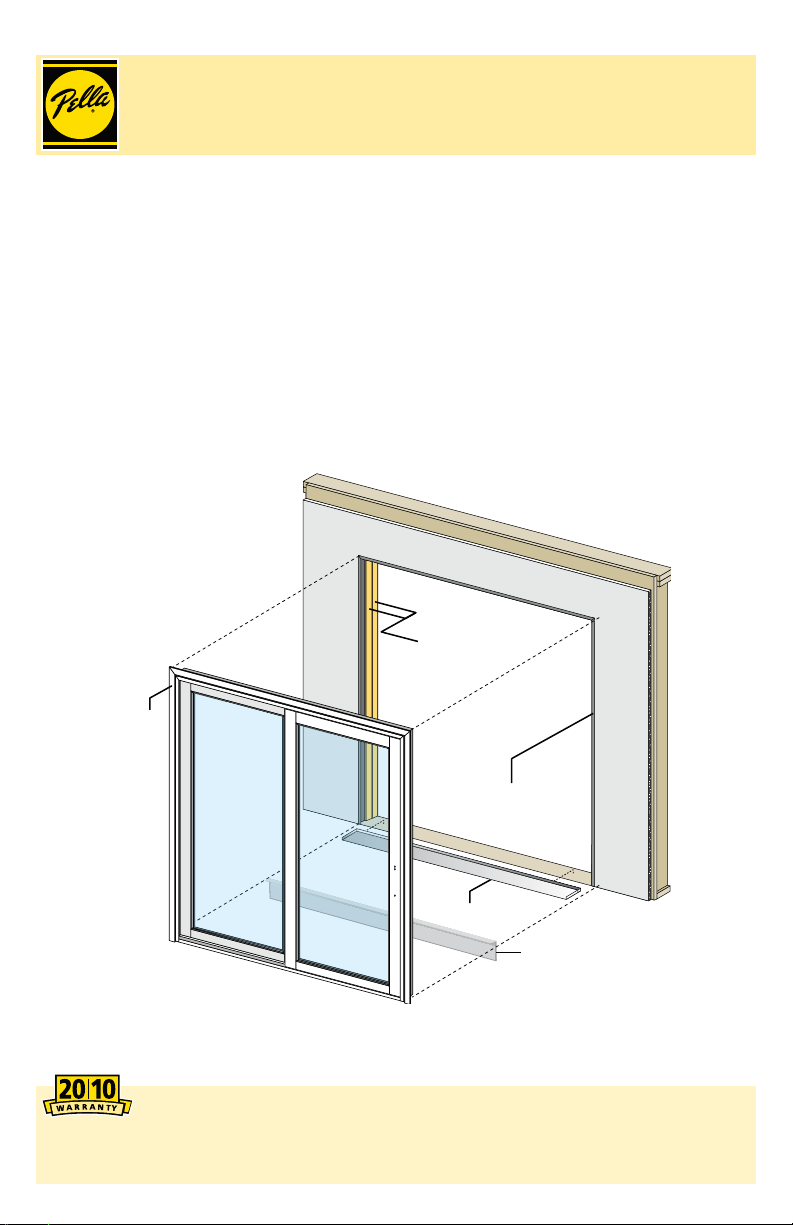

ALUMINUM-CLAD SLIDING PATIO DOORS WITH

FLUSH FLANGE

Lea las instrucciones en español en el reverso

Installation Instructions for Replacement of Aluminum Sliding Doors in Hard Coat Stucco

Applications in arid climates.

These instructions are designed for typical hard coat stucco exterior applications in arid climates.

The installation must leave the existing aluminum door frame and weep system in place. These

instructions are not to be used with any other construction method and rely on the integrity

of the existing aluminum sliding door and flashing system. Building designs, construction

methods, building materials, and site conditions unique to your project may require an installation

method different from these instructions and additional care. Determining the appropriate

installation method is the responsibility of you, your architect, or construction professional. If you

have questions, please contact your local Pella retailer.

REMEMBER TO USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

Wood

Blocking

Flush

Flange

Existing Aluminum

Door Frame

Sill Pan

Optional Sill Nose

Always read the Pella® Limited Warranty before purchasing or installing Pella

Warranty is part of the terms of the sale. Failure to comply with all Pella installation and

maintenance instructions may void your Pella product warranty.

See Limited Warranty for complete details at http://warranty.pella.com.

products. By installing this product, you are acknowledging that this Limited

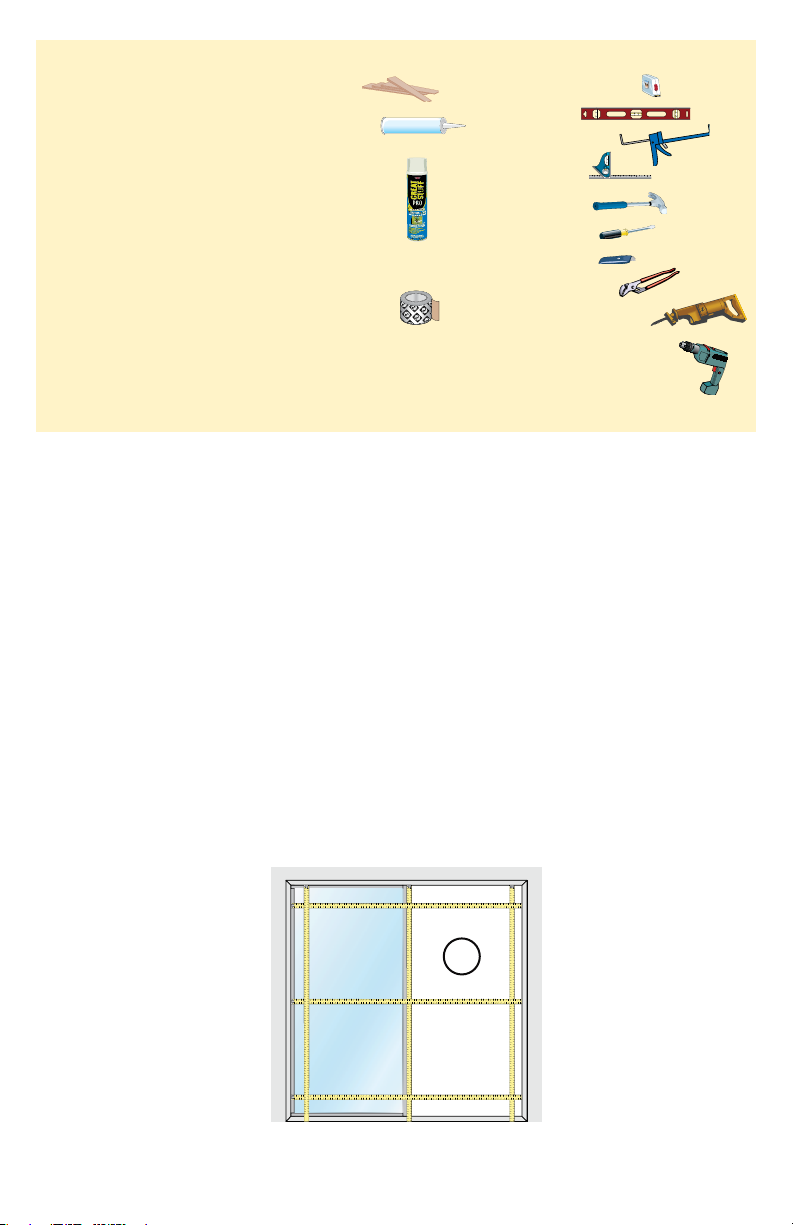

YOU WILL NEED TO SUPPLY: TOOLS REQUIRED:

ŘComposite or Impervious shims/spacers

(12 to 20)

ŘHigh quality exterior grade polyurethane or

silicone sealant (3 to 4 tubes per door)

ŘGreat Stuff™ Window and Door Insulating

Foam Sealant by the Dow Chemical Company

or equivalent low pressure polyurethane

window and door foam - DO NOT use high

pressure or latex foams.

ŘWood blocking, 3/4" x 4" x 96" (2 or 3 pieces)

ŘScrews (#10 x 3-1/2")

ŘPella® SmartFlash™ foil backed butyl flashing

tape or equivalent.

ŘSill pan

Installation will require two or

more persons for safety reasons.

4&"-"/5

4&"-"/5

ŘTape measure

ŘLevel

ŘSealant gun

ŘSquare

ŘHammer

ŘScrewdriver

ŘUtility knife

ŘWide jaw pliers

ŘReciprocating saw

Ř1/8" and 1/4" drill bit

ŘDrill

BEFORE YOU START

1

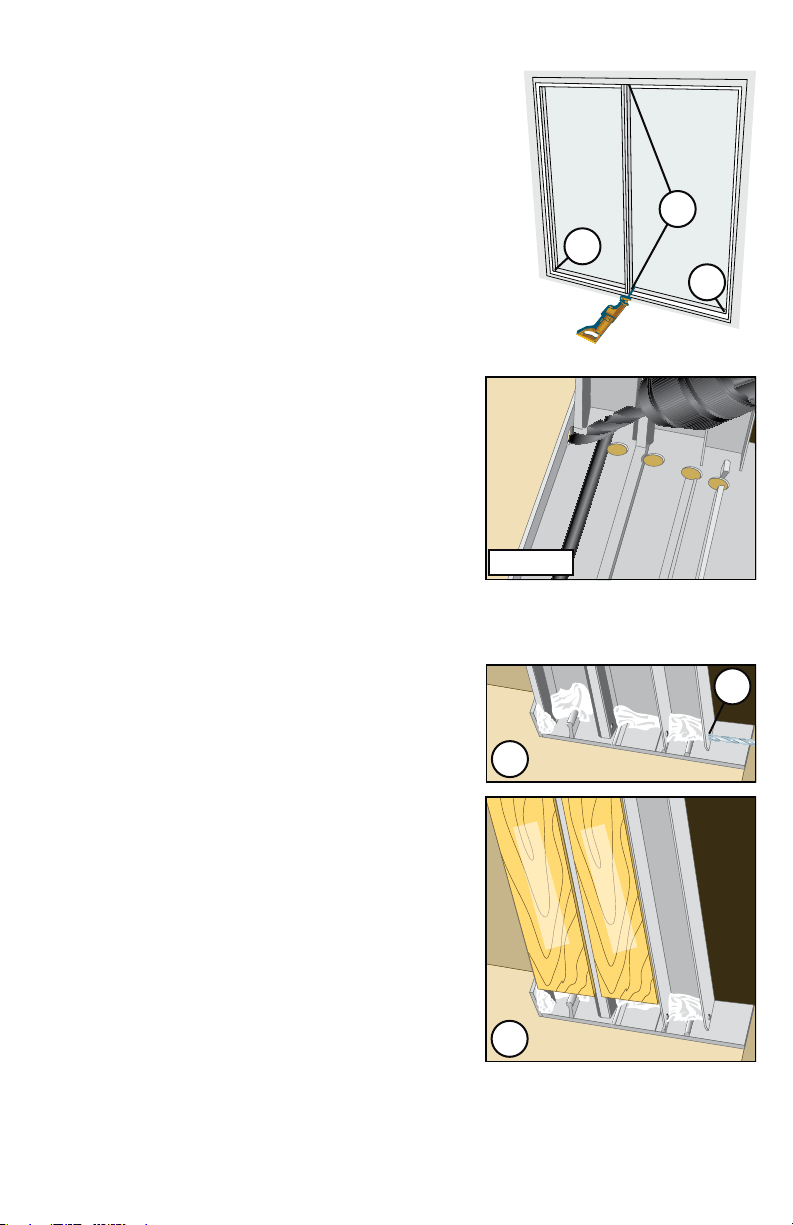

A. Remove the vent panel from the existing door frame. Check the dimensions of the

existing door and the new door to make sure the new door will fit correctly. The opening

must be 1/2" larger than the new door frame in both width and height. Measurements

should be taken as follows:

Width - measure the inside dimension of existing jambs.

Height - measure from the subfloor or cement slab to the lowest point of the existing head.

Confirm the flange will overlap the stucco by 1/2".

1A

OPENING PREPARATION

2

A. Prepare the door opening by removing the venting

panel and the glass from the existing fixed side of the

aluminum door frame.

Note: It may be necessary to cut the divider

between the venting panel and fixed glass areas

with a reciprocating saw. The existing aluminum

frame is left in place so as not to disturb the existing

exterior stucco flashing or drainage system.

B. Cut the existing door sill out of the opening. Using a

reciprocating saw or side grinder, cut the existing sill as

close to the longest leg of the jamb extrusion as possible.

Note: Be careful to avoid damage to the interior

flooring materials. Drilling holes in the sill prior

to cutting may make the removal of the existing

sill easier. If existing sill has a stainless steel cap

on the sill, removing the cap prior to cutting will

make cutting easier.

C. Clean old sealant and other debris from the

door opening.

D. Remove the door lock strike from the lock

jamb of the existing door frame.

2A

2B

2B

2B NOTE

E. Place a bead of sealant at each joint where the

existing door frame jambs meet the existing

door sill pieces. Fill any holes in the jamb and

head with sealant.

F. If the weep holes of the existing sill have been

cut away, drill new weep holes in the existing

door jambs. Be sure to drill weep holes in all

vertical jamb legs, except the most interior leg.

Note: Ensure all new or existing weep holes are

open before proceeding with the installation.

G. Cut wood blocking to fill the vent and fixed panel

cavities in the head and jamb of the existing door

frame. The depth of the blocking should be the

same height as the tallest leg of the existing jamb

extrusion. Cut the head blocking to fill the entire

length of the head in both channels. Cut the

jamb blocking to fill both jamb channels to within

approximately 1" of the bottom of the jamb.

H. Set the wood blocking in sealant in the existing door frame. Make sure the blocking is

flush with the furthest protruding part of the existing jamb. Place a 3/16" bead of sealant

in the door panel cavities, then insert the wood blocking into the head cavities followed

by the jamb cavities. Next insert the wood blocking into the jamb panel cavities of the

existing door frame. Secure the blocking by pre-drilling and inserting #8 x 2-1/2" screws.

INTERIOR

2E

Wood Blocking

2G

Wood Blocking

2F

OPENING PREPARATION (CONTINUED)

2

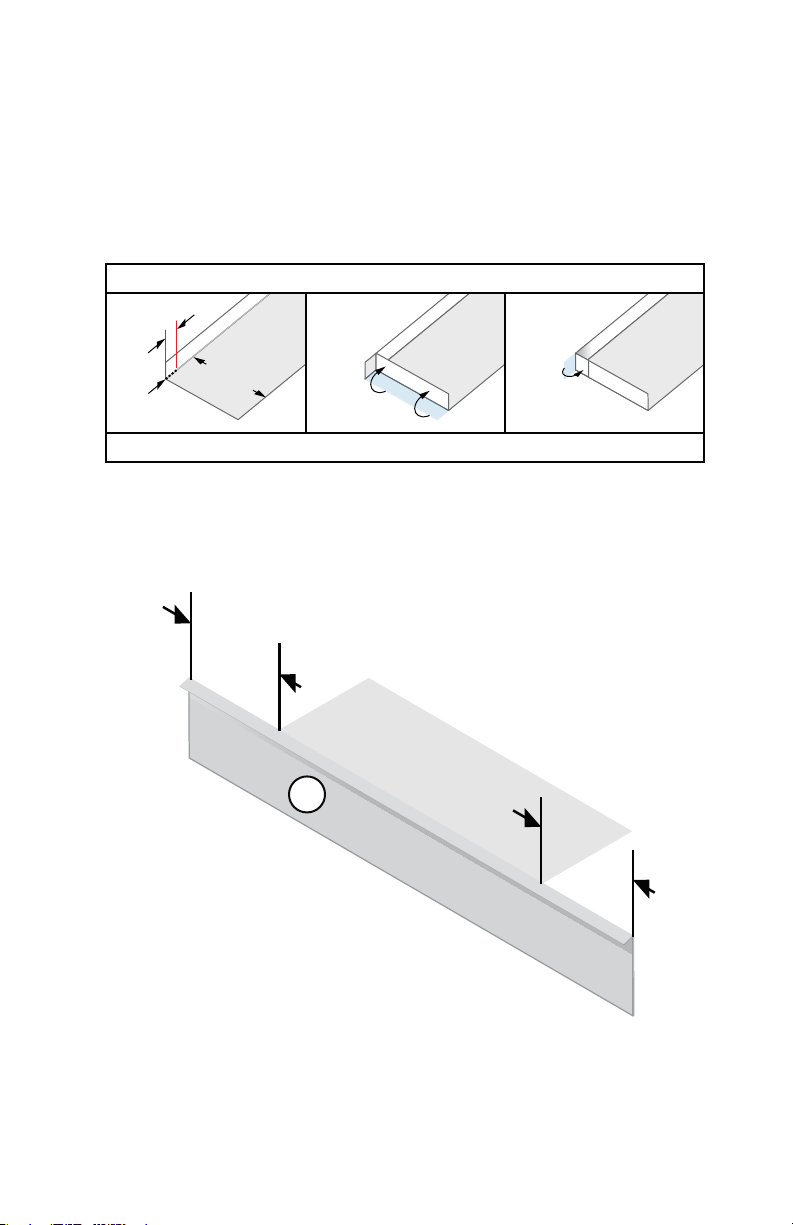

I. Construct a sill pan for the door. Measure the rough opening width and add 2". Measure

1" up from each end and cut through the vertical leg of the pan material. If there is a step

down at the exterior of the door opening, make the sill pan depth equal to the door frame

depth - 2-1/8". If there is NO step down, make the sill pan depth equal to the frame depth.

Bend the bottom (side) flaps of the pan material up, then bend the back leg around the

end of the pan.

Dry fit the sill pan and the door into the opening.

$0/4536$5"%0034*--1"/

i

4JMMQBO

EFQUI

$VU

IFSF

3&1&"545&14'0301104*5&&/%

J. If there is a step down at the exterior of the door opening, cut the sill nosing to the

rough opening width plus two times the flange width. Notch the sill nosing. If there is

NO step down, skip to step K.

'-"/(&

8*%5)

'PME

VQ

FOE

'PME

JOUBC

306()01&/*/(8*%5)

2J

4JMM/PTJOH

'-"/(&

8*%5)

Note: If the new door frame is deeper than the existing door frame, it will be necessary

to cut the interior flooring material back to allow the door flush flanges to contact the

existing aluminum door frame.

Loading...

Loading...