Pella 818T0101 User Manual

Part Number: 818T0101© 2011 Pella Corporation

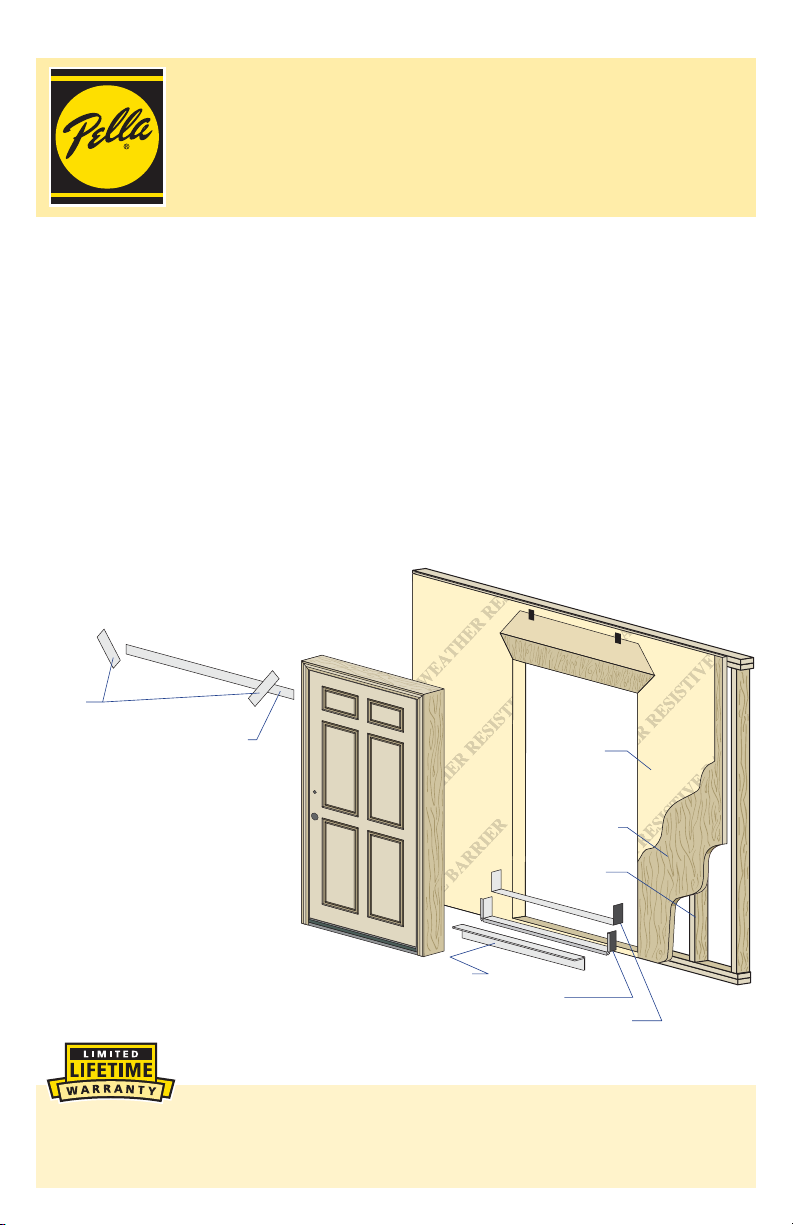

INSTALLATION INSTRUCTION –

SINGLE PANEL, SINGLE PANEL WITH SIDELIGHT

COMBINATION AND 20 MINUTE FIRE RATED

WOOD FRAME ENTRY DOOR

Installation Instructions for Typical Wood Frame Construction.

These instructions were developed and tested for use with typical wood frame wall

construction in a wall system designed to manage water. These instructions are not

to be used with any other construction method. Installation instructions for use

with other construction methods may be obtained from Pella Corporation, a local

Pella retailer or by visiting http://www.pella.com. Building designs, construction

methods, building materials, and site conditions unique to your project may require an

installation method different from these instructions and additional care. Determining

the appropriate installation method is the responsibility of you, your architect, or

construction professional.

REMEMBER TO USE APPROPRIATE

PERSONAL PROTECTIVE EQUIPMENT.

Side

Flashing

Tape

installing Pella products. By installing this product, you are acknowledging that this

Limited Warranty is part of the terms of the sale. Failure to comply with all Pella

installation and maintenance instructions may void your Pella product warranty. See

Limited Warranty for complete details at http://warranty.pella.com.

To p

Flashing

Tape

Sill Support

Sill Flashing Tape #1

Sill Flashing Tape #2

Always read the Pella® Limited Warranty before purchasing or

Weather

Resistive

Barrier

Sheathing

Framing

YOU WILL NEED TO SUPPLY: TOOLS REQUIRED:

Ř Composite/impervious shims/spacers (12 to 20)

Ř #8 x 3" corrosion resistant woodscrews

Ř 16d galvanized finish nails or exterior grade

finish screws

Ř Pella foil backed butyl window and door flashing

tape or equivalent

Ř Closed cell foam backer rod/sealant backer

(17 to 21 ft.)

Ř Great Stuff™ Window and Door Insulating Foam

Sealant by the Dow Chemical Company or

equivalent low pressure polyurethane window

and door foam - DO NOT use high pressure or

latex foams.

Ř High quality exterior grade polyurethane sealant

(2 to 3 tubes per door)

Ř Pella aluminum sill support or 2 x 4 wood blocking

Ř Interior trim and/or jamb extensions (15 to 40 ft.)

Ř Aluminum head flashing

Ř Installation Clips (Optional)

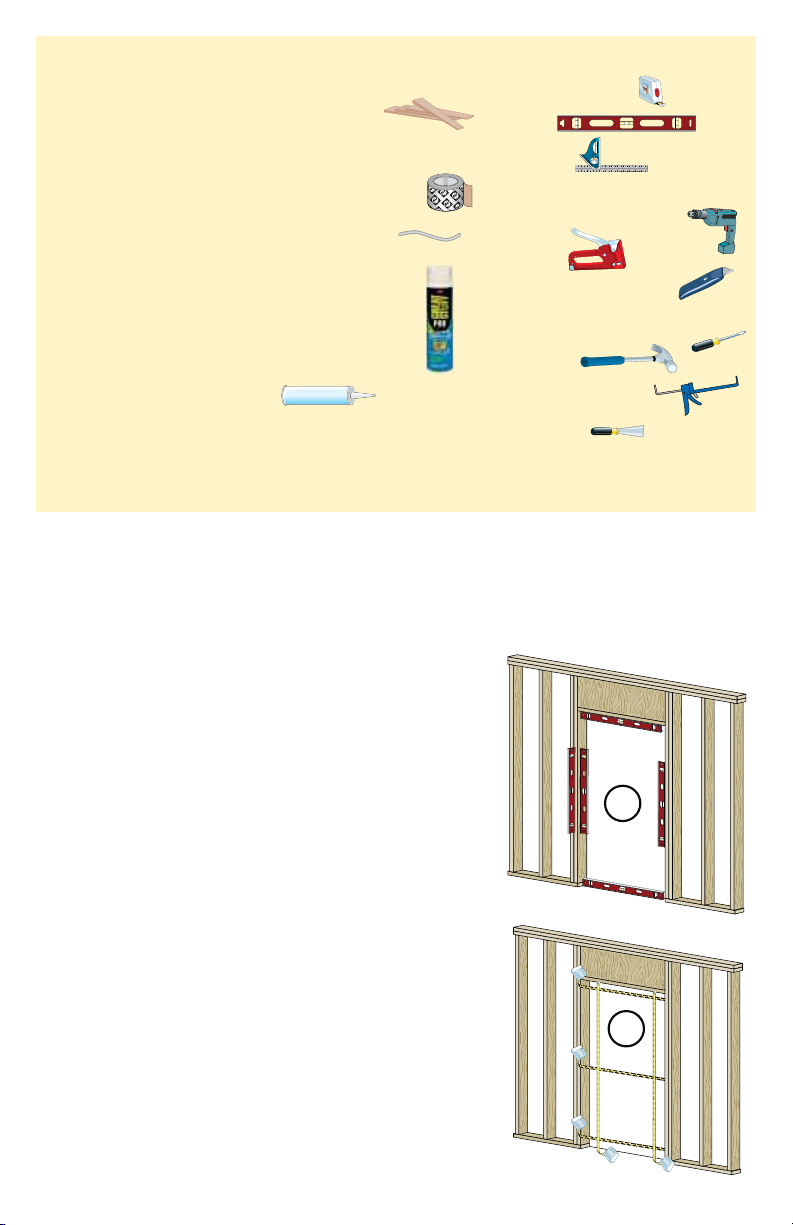

ROUGH OPENING PREPARATION

1

SEALANT

SEALANT

Ř Tape measure

Ř Level

Ř Square

Ř Drill with 1/8" and 3/16" drill bits

Ř Stapler

Ř Scissors or utility knife

Ř #2 & #3 Phillips screwdrivers

Ř Hammer

Ř Caulking gun

Ř Putty knife

A. Confirm the opening is plumb and level.

Note: It is critical the bottom is level.

B. Determine the finished floor height. If the

finished floor height will be more than 1"

higher than the surface the door will be set

on, add a filler board under the sill. The top

of the filler board should be within 1" of the

finished floor height.

C. Confirm the door will fit in the opening.

Measure all four sides of the opening to

make sure it is 3/4" larger than the door in

width and 1/2" larger in height. Measure the

opening width in several places to ensure

the studs are not bowed.

Note: 1-1/2" or more of solid wood

blocking (studs) is required around the

perimeter of the opening. Check the

wall for plumb and the opening for

square by checking opening diagonal

measurements. Fix any problems with the

rough opening before proceeding.

Interior

1A

1A

Interior

1C

1C

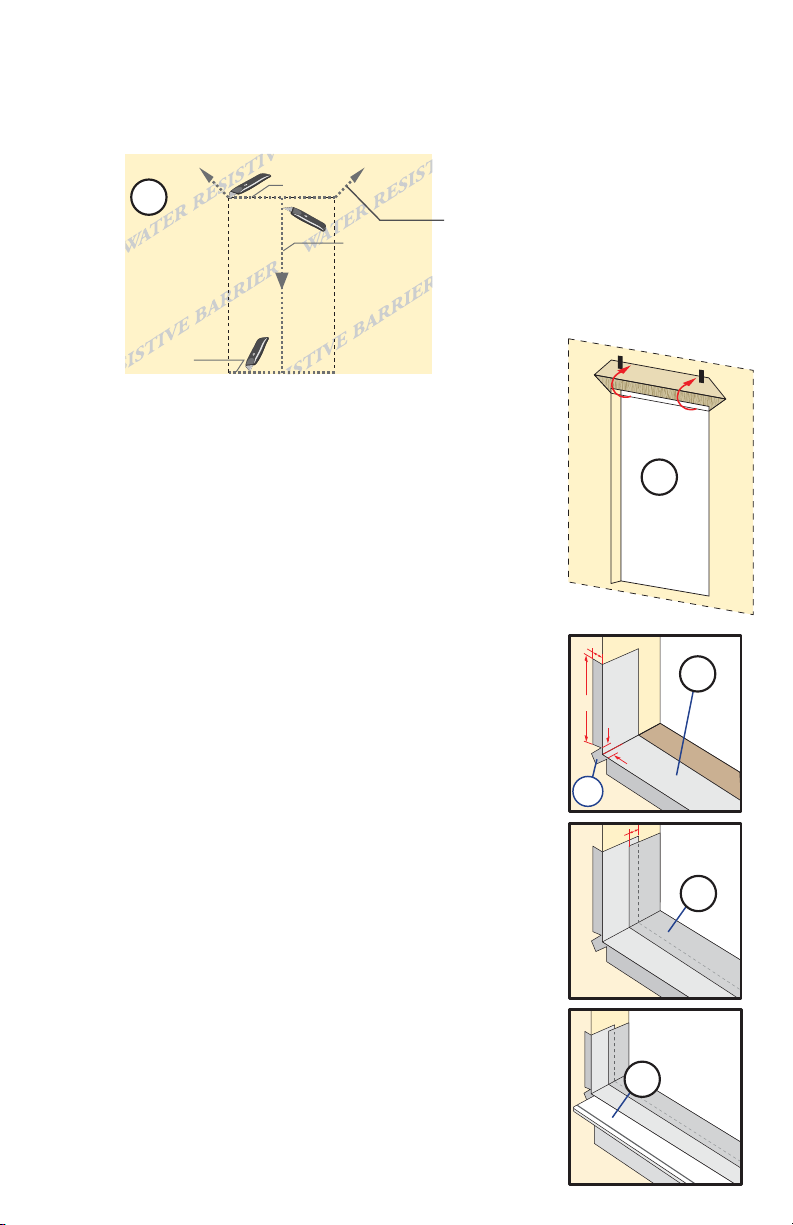

ROUGH OPENING PREPARATION

(CONTINUED)

1

D. Cut the weather resistive barrier, if applicable (1D).

Water Resistive Barrier

1D

1D

2nd cut

E. Fold the weather resistive barrier (1E). Fold side

flaps into the opening and staple to inside wall. Fold

top flap up and temporarily fasten with flashing tape.

F. Apply sill flashing tape #1. Cut a piece of

flashing tape 12" longer than the opening width.

Apply at the bottom of the opening as shown (1F)

so it overhangs 1" to the exterior.

Note: The tape is cut 12" longer than the width

so it will extend 6" up each side

of the opening.

G. Tab the sill flashing tape and fold. Cut 1" wide

tabs at each corner (1/2" from each side of corner)

(1G). Fold tape to the exterior and press firmly to

adhere it to the weather resistive barrier.

H. Apply sill flashing tape #2. Cut a piece of

flashing tape 12" longer than the opening width.

Apply at the bottom further towards the interior,

overlapping tape #1 by at least 1". Do not allow the

tape to extend past the interior face of the framing

(1H). If the wall depth is greater than 5", add a

third piece of flashing tape. The flashing tape

should come to within 1" of the interior face of the

framing.

Note: The flashing tape does not need to extend

all the way to the interior of the framing.

1st cut

3rd cut

4th cut:

Make a 6" cut up from

each top corner at a 45°

angle to allow the weather

barrier to be lapped over

the fin at the head of

the door.

1"

6"

1G

1G

1/2"

1"

1/2"

1E

1E

1F

1F

1H

1H

I. When required for adequate sill support,

attach the optional aluminum sill support or wood

blocking to the exterior of the box plate to support

the exterior edge of the door sill (1I). Place the sill

support flush with the sill rough opening.

1I

1I

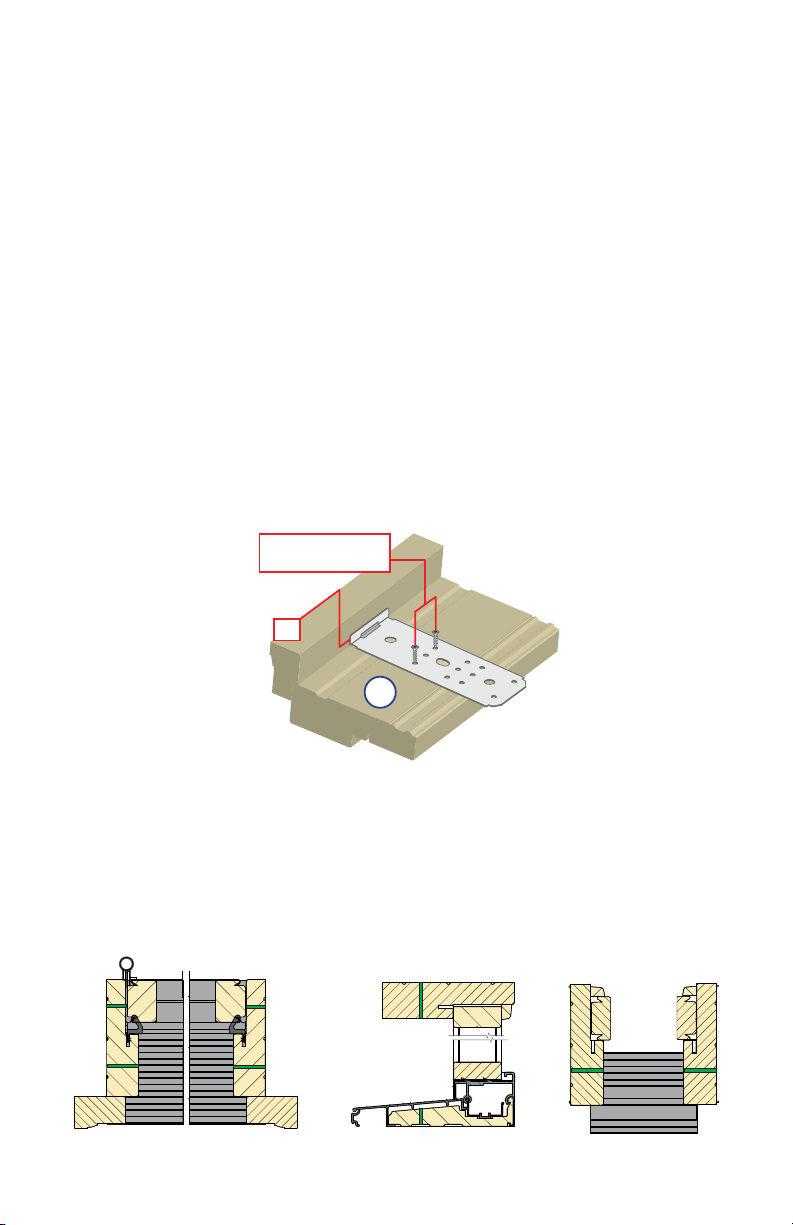

2

PREPARE THE DOOR FOR INSTALLATION

TWO OR MORE PEOPLE WILL BE REQUIRED TO HANDLE

THE PANEL AND FRAME SAFELY.

A. Remove plastic wrap and cardboard packaging from door. DO NOT remove

plastic shipping spacers. The shipping spacers will help keep the door square

during installation. DO NOT open the door until it is fully fastened.

If Attaching with fasteners through the Brickmould go to Step 3

Anchoring Method – (Installation Clip or Frame Screw Through Frame)

B. Doors using Installation Clips: Install installation clips. Place each clip so

the lip is facing up and against the brickmould at the locations shown in the

placement diagram. Secure each clip by driving a #6 x 5/8" corrosion resistant

screw through each of the outer two holes of the three holes shown.

Note: If clips are to be bent; pre-bend before attaching to frame.

#6 x 5/8" corrosion

resistant screws

Lip

2B

C. Doors using Frame Screws: Open door panels; drill and counter-sink 3/16"

diameter clearance holes through the door frame jambs, (head and sill of

sidelight units) but not into the rough opening at the locations shown. Where

applicable, clearance holes are drilled though open hinge screw holes and

each strike hole.

Pilot Hole

Pilot Hole

Alternative Pilot Hole

for Screw Install

DOOR UNIT, JAMB TO JAMB

Pilot Hole

Alternative Pilot Hole

for Screw Install

Pilot Hole Pilot Hole

Pilot Hole

SIDELIGHT UNIT, HEAD TO SILL SIDELIGHT UNIT, JAMB TO JAMB

2

PREPARE THE DOOR FOR INSTALLATION

Anchor Spacing for Single Units:

Ř 2 – #10 x 2-1/2" screws at each hinge

Ř 2 – #10 x 2-1/2" screws at each strike

Ř #10 x 3" screw or clip directly across from each hinge

Ř #10 x 3" screw or clip 6" from each corner on 81-1/2" entry door frames only

(not sidelights) interacting with the rough opening

Ř #10 x 3" screw or clips as indicated on 97-1/2" entry door frames

Anchor Spacing for Combination Units:

Ř 2 – #10 x 3" screws at each sidelight head and sill

Ř #10 x 3" screw or clip at other indicated locations

Ř 2 - #10 x 2-1/2" screws at each hinge

Ř 2 - #10 x 2-1/2" screws at each strike

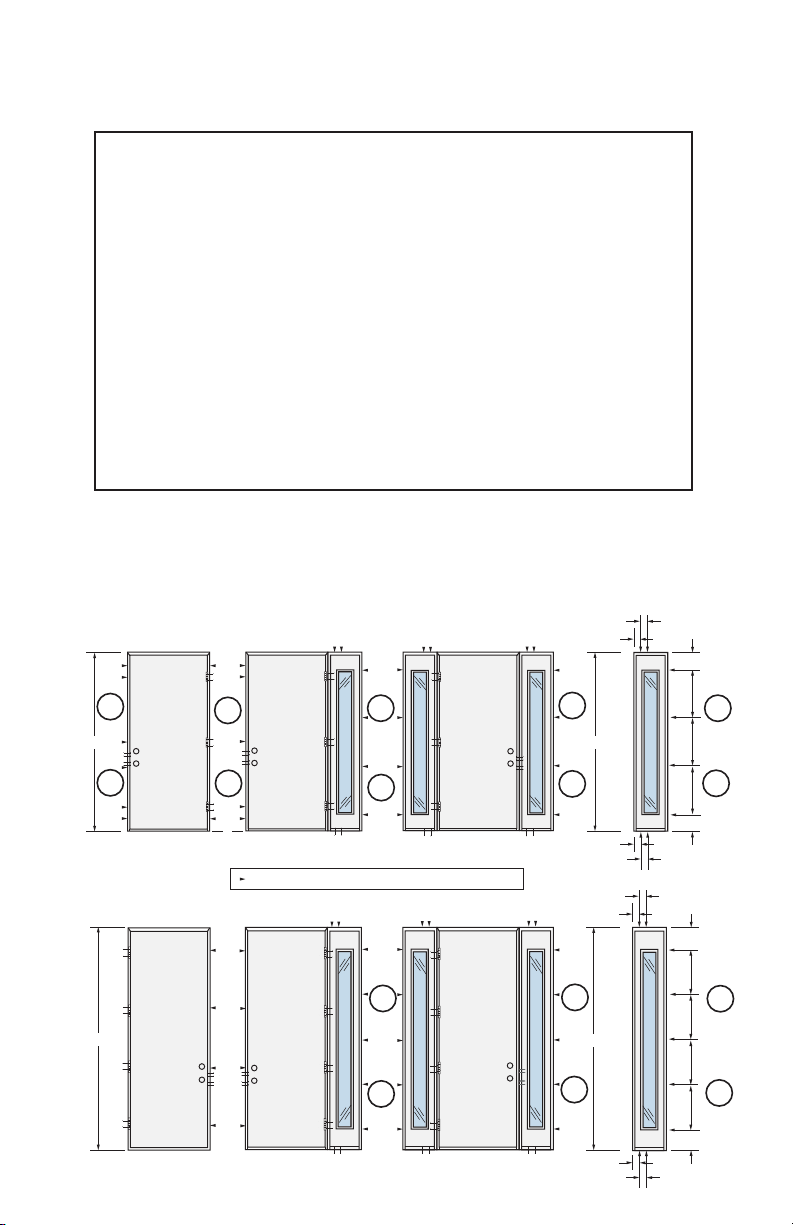

Diagrams for placement of installation clips or frame screw clearance

holes for 6'8" and 8' height doors and single doors with sidelights.

6"

2B

81-1/2"

6"

6"

2B

2B

2B

81-1/2"

3"

3"

9-1/4"

21"

2B

21"

97-1/2"

2C

2C

6"

6"

6"

= Screw or clip location other than at hinge or strike.

2C

2B

2C

2C

2B

2C

97-1/2"

3"

3"

3"

3"

3"

3"

21"

9-1/4"

6-3/4"

21"

21"

21"

21"

6-3/4"

2C

2B

2C

Loading...

Loading...