Pella 818K0100 User Manual

Part Number: 818K0100©2011 Pella Corporation

INSTALLATION INSTRUCTION - INSTRUCCIONES DE INSTALACION

WOOD HINGED PATIO DOOR – (INCLUDES – STANDARD,

PERFORMANCE UPGRADE AND HURRICANESHEILD® IMPACT

RESISTANT IN-SWING, OUT-SWING)

Instrucciones enspañol en el reverso.

Important Safety Information:

Pella® HurricaneShield® Products have been tested in accordance with the large missile impact

testing requirements have been certifi ed to meet those requirements. Check with the individual

(building owner, architect, contractor, installer and/or consumer) responsible for the project in

addition to local building code offi cials to determine if these products comply with local codes.

Pella HurricaneShield Products are neither hurricane proof nor are they shatter proof. Severe wind

and rain may produce temporary conditions which exceed product performance standards. When

these units are subjected to intense storms or extreme conditions, which exceed the intended

design pressures, air, water and fl ying debris infi ltration may occur.

These instructions were developed and tested for use with typical wood frame wall construction

in a wall system designed to manage water. These instructions are not to be used with any

other construction method. Installation instructions for use with other construction methods,

multiple units or bow and bay windows, may be obtained from Pella Corporation or a local Pella

retailer, or by visiting http://www.pella.com. Building designs, construction methods, building

materials, and site conditions unique to your project may require an installation method different

from these instructions and additional care. Determining the appropriate installation method is the

responsibility of you, your architect, or construction professional.

IMPORTANT NOTICE: To achieve maximum door performance, the performance upgrade

installation may be required. Additional performance information may be obtained from your

Pella retailer of www.pella.com. All HurricaneShield doors are required to use the Performance

Upgrade Installation steps contained within this instruction.

REMEMBER TO USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

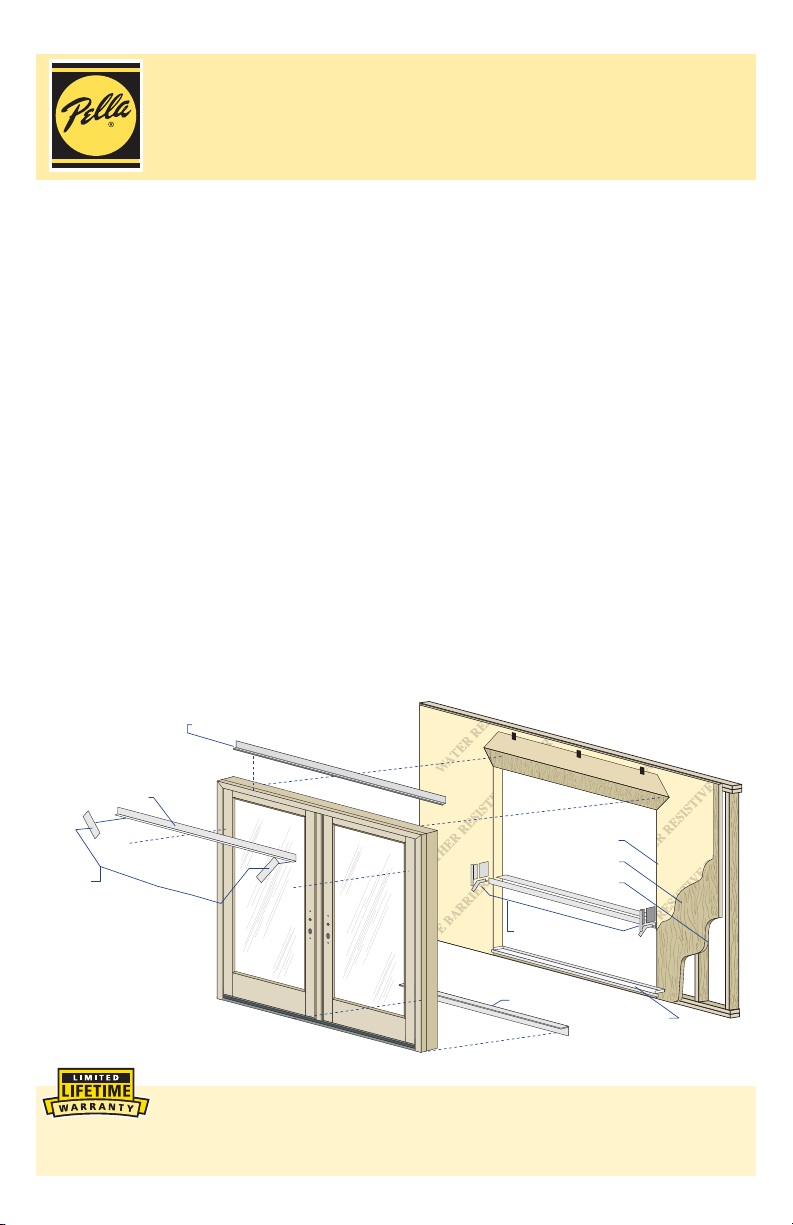

Aluminum Head Flashing

Top Flashing Tape

Water Resistive Barrier

Sheathing

Corner

Flashing

Tapes

Sill Support

Framing

Flashing Tape

Optional Sill Pan

Always read the Pella® Limited Warranty before purchasing or installing Pella

products. By installing this product, you are acknowledging that this Limited

Warranty is part of the terms of the sale. Failure to comply with all Pella installation and

maintenance instructions may void your Pella product warranty. See Limited Warranty for

complete details at http://warranty.pella.com.

The performance of any building is dependent upon the design, installation, and workmanship

of the entire building system. Pella Corporation strongly recommends consulting an

experienced architect, contractor, or structural engineer prior to installation of Pella products.

The individual (building owner, architect, contractor, installer and/or consumer) responsible

for the project must take into account local conditions, building codes, inherent component

limitations, the effects of aging and weathering on building components, and other design

issues relevant to each project.

The determination of the suitability of all building components for each project, as well as the

design and installation of fl ashing and sealing systems, are the responsibility of the building

owner, architect, contractor, installer and/or consumer.

YOU WILL NEED TO SUPPLY: TOOLS REQUIRED:

• Cedar or Impervious shims/spacers (12 to 20)

• 16d galvanized fi nish nails (1/4 lb.)

• #10 x 3-1/4" corrosion resistant wood screws

(Performance Upgrade and HurricaneShield)

• Masonry screws for concrete applications

(Minimum of 3/16" diameter x 3")

• Closed cell foam backer rod/sealant backer

(21 to 30 ft.)

®

• Pella

SmartFlash™ foil backed butyl window and door

fl ashing tape or equivalent

• High quality exterior grade polyurethane or silicone

SEALANT

sealant (2 to 3 tubes per door)

• Great Stuff

™

Window and Door Insulating Foam

SEALANT

Sealant by the Dow Chemical Company or equivalent

low pressure polyurethane window and door foam DO NOT use high pressure or latex foams

• Sill Pan (Optional)

6-5/8" x (Rough Opening Width + 2")

• Pella aluminum sill support or wood blocking

• Interior trim and/or jamb extensions (15 to 40 ft.)

• Aluminum Head Flashing

INSTALLATION CLIP OPTION:

• Tape measure

• Level

• Square

• Hammer

• Stapler

• Sealant gun

• Scissors or utility knife

• Tin snips

• Screwdrivers (#2 Phillips with

8" shaft and small fl at blade)

• T20 Torx Wrench

• Drill

• Drill bits 13/64" and 1/8"

and masonry bit for

concrete applications

• 6" or 8" installation clips

• #6 x 5/8" corrosion resistant fl at head wood screws

• #8 x 1-1/2" corrosion resistant screws or 3/16" x 1-1/2" masonry screw

1

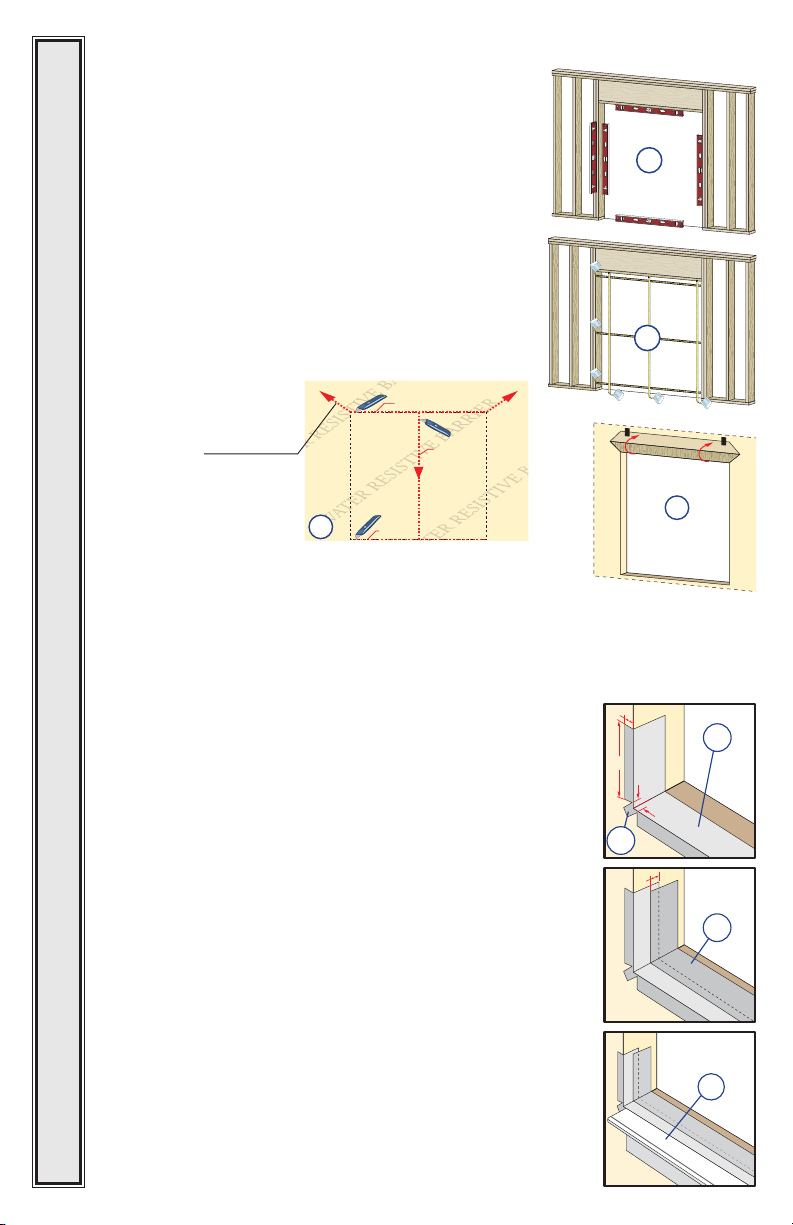

ROUGH OPENING PREPARATION

A. Confi rm the opening is plumb and level.

Note: It is critical that the bottom is level.

B. Confi rm the door will fi t the opening. Measure

all four sides of the opening to make sure it is 3/4"

larger than the door in width and 1/2" larger in height.

Measure the width at the top, bottom, and center.

Measure the height at the far left side, the far right

side, and in the center.

Note: 1-1/2" or more of solid wood blocking is

required around the perimeter of the opening.

Fix any problems with the rough opening before

proceeding.

C. Cut the water resistive barrier.

8BUFS3FTJTUJWF#BSSJFS

TUDVU

Interior

1A

Interior

1B

UIDVU

.BLFBDVUVQGSPN

FBDIUPQDPSOFSBUB

BOHMFUPBMMPXUIFXBUFS

SFTJTUJWFCBSSJFSUPCFMBQQFE

PWFSUIFmOBUUIFIFBEPG

UIFEPPS

P

$

SEDVU

OEDVU

D. Fold the water resistive barrier. Fold side fl aps into the

opening and staple to inside wall. Fold top fl ap up and

temporarily fasten with fl ashing tape.

For Doors Using Optional Sill Pan Go To Step 1I.

E. Apply sill fl ashing tape #1. Cut a piece of fl ashing tape 12"

longer than the opening width. Apply at the bottom of the

opening as shown (1E) so it overhangs 1" to the exterior.

Note: The tape is cut 12" longer than the width so that it

will extend 6" up each side of the opening.

F. Tab the sill fl ashing tape and fold. Cut 1" wide tabs at

each corner (1/2" from each side of corner) (1F). Fold tape

to the exterior and press fi rmly to adhere it to the water

resistive barrier.

G. Apply sill fl ashing tape #2. Cut a piece of fl ashing tape

12" longer than the opening width. Apply at the bottom,

overlapping tape #1 by at least 1". DO NOT allow the tape to

extend past the interior face of the framing (1G).

In-swing doors: If the wall depth is greater than 5", add a

third piece of fl ashing tape. The fl ashing tape should come to

within 1" of the interior face of the framing.

Note: The fl ashing tape may not fully cover the

framing members.

H. Attach the aluminum sill support or wood blocking to the

exterior of the box plate to support the edge of the door sill.

DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS

Place the sill support fl ush with the subfl oor.

GO TO STEP 2

1"

6"

1F

1/2"

Exterior

1D

1E

1/2"

£

1H

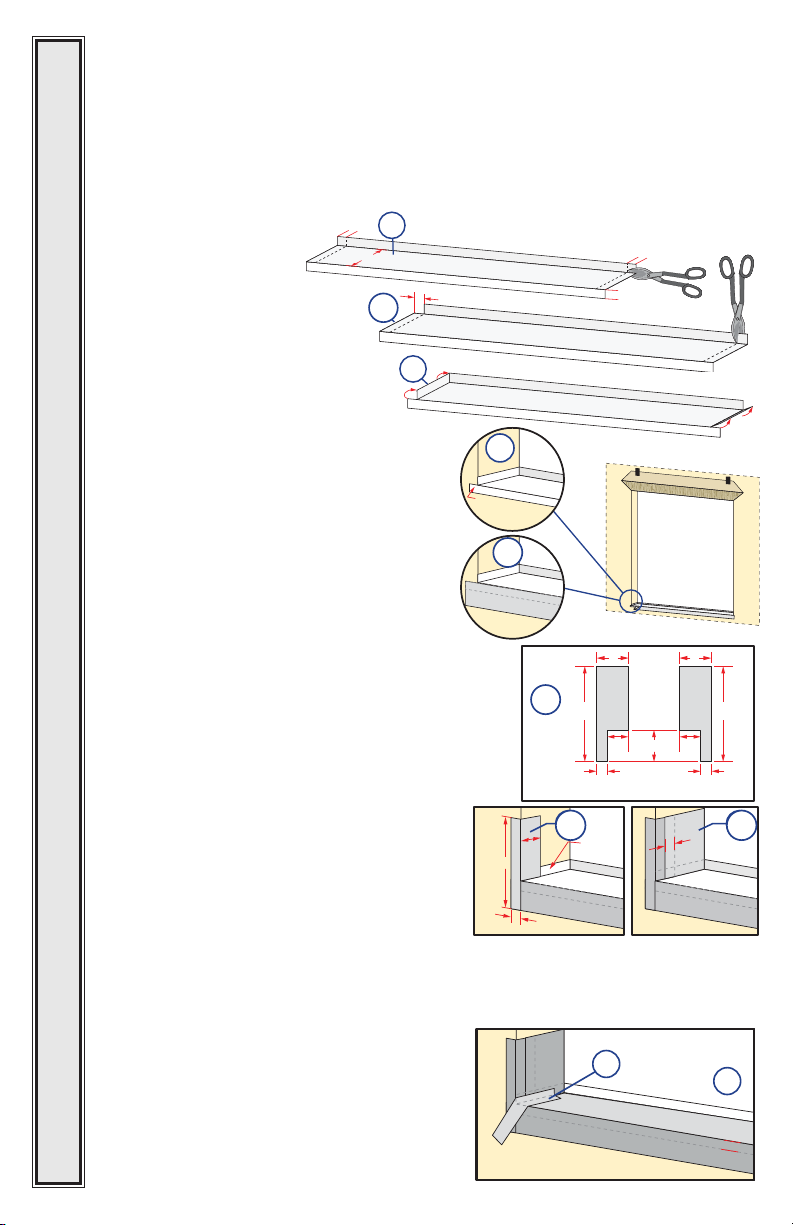

Optional Sill Pan Instructions.

I. Cut the sill pan to the width of the rough opening plus 2".

Note: The 2" added onto the rough opening width is for a 1" bend on each end.

J. Make a 1" cut in each fold at both ends of the sill pan.

Note: These cuts will allow the edges of the sill pan to be bent.

Note: 4-5/8" wide for Out-swing and In-swing for 4-9/16" wall condition. For

other wall conditions; measure wall depth and add 1/16".

1J

1"

1J

INTERIOR SILL PAN LIP

EXTERIOR SILL PAN LIP

1L

)

K. Cut 1" off each end of the

interior sill pan lip.

L. Bend each end of the center

Variable

(

1K

panel up.

M. Install the sill pan by sliding

into place until the exterior sill

pan lip is fl ush with the exterior

of the rough opening.

N. Apply sill fl ashing tape. Cut a piece

EXTERIOR SILL PAN LIP

of fl ashing tape 2" longer than the

opening width. Apply at the bottom of the

opening, covering the exterior sill pan lip

as shown.

Note: If applicable, apply spray

adhesive to building felt prior to

applying the fl ashing tape.

Weather Barrier

O. Cut two 9" pieces of fl ashing tape with a 1" x 3"

tab at the bottom, on opposite corners as shown.

P. Apply the tabbed 9" pieces of fl ashing tape.

The tape is applied so 2" will cover the inside of

the rough opening and lap over the side fl ange

of the sill pan. The 1" x 3" tab laps over the

bottom fl ashing tape as shown.

*/5&3*034*--1"/-*1

&95&3*034*--1"/-*1

&95&3*034*--1"/-*1

1M

1M

Install flush

against exterior

rough opening.

1N

1N

EXTERIOR SILL PAN LIP

Flashing Tape

1O

1O

*/5&3*034*--1"/-*1

9"

1" Tabs

1"

1"

Exterior

3"

2"

3"

3"

9"

2"

1" Tabs

Q. Cut two 6" pieces of fl ashing tape and

apply to each side of the rough opening,

overlapping the fi rst piece by 1" and

lapping the bottom over the side fl ange of

the sill pan as shown.

&95&3*034*--1"/-*1

'MBTIJOH5BQF

-

1P 1Q

4JEF

'MBOHF

R. Cut a piece of fl ashing tape to the width of the opening. Install to the fl anges of

the sill pan and overlap the tape from step 1N by 1”. If needed add a second or third

piece of fl ashing tape until the sill pan is covered to the interior sill pan lip.

Note: The purpose of this tape is to seal the sill screws when installing the door.

S. Cut two pieces of fl ashing tape 1-1/2" x

6" and apply to the bottom corners of the

opening by beginning in the corner of the sill

DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS • ALL DOORS

pan, with 3/4" of the tape applied to the sill

pan and 3/4" of the tape applied to the side

fl ange. The remainder of the tape is to be at a

1S

INTERIOR SILL PAN LIP

EXTERIOR SILL PAN LIP

45 degree angle onto the exterior.

.

&95&3*034*--1"/-*1

'MBTIJOH5BQF

1R

1"

T. Attach the aluminum sill support or wood

blocking to the exterior of the box plate to

support the edge of the door sill. Place the

sill support fl ush with the subfl oor.

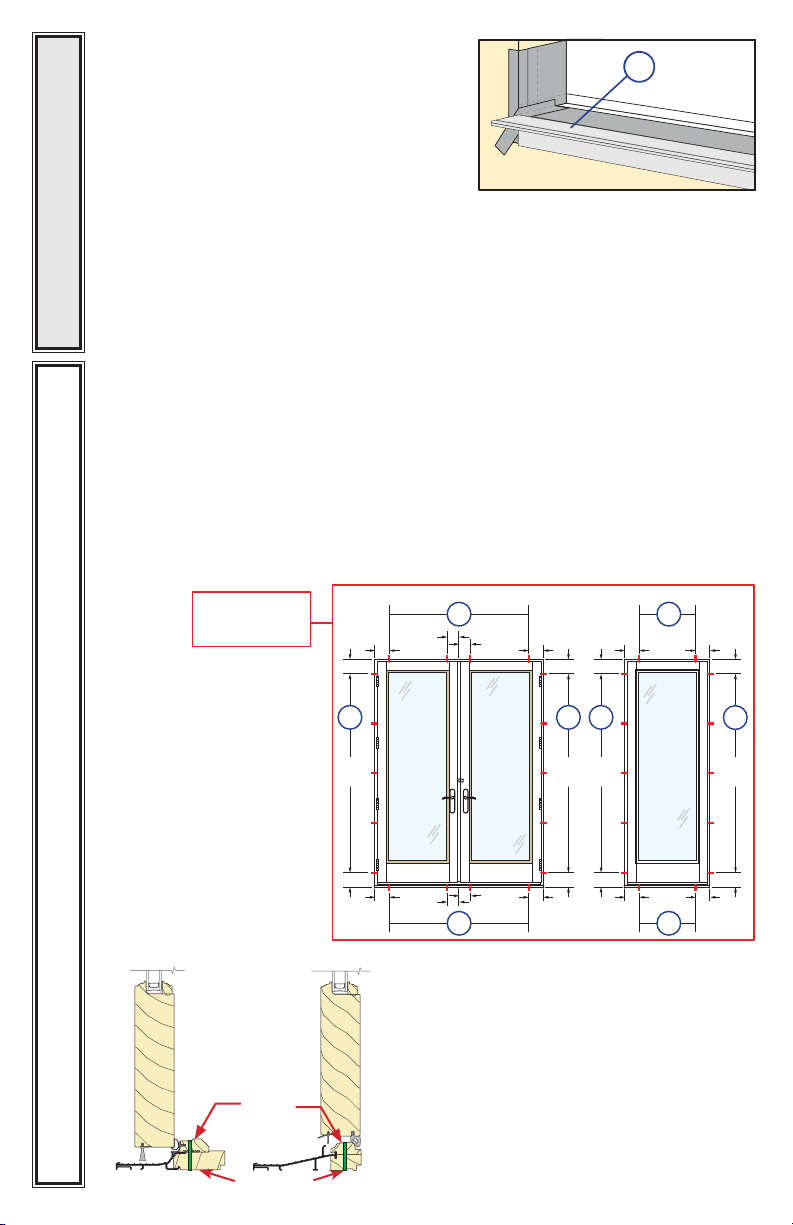

PREPARE THE DOOR FOR INSTALLATION

2

ALL DOORS

INTERIOR SILL PAN LIP

EXTERIOR SILL PAN LIP

TWO OR MORE PEOPLE WILL BE REQUIRED TO HANDLE THE PANEL AND

FRAME SAFELY.

A. Remove plastic wrap and cardboard packaging from door. Do not remove

plastic shipping spacers. The shipping spacers will help keep the door square

during installation. Do not unlock or open the door until it is fully fastened.

Note: If grilles or hardware are removed from the door at this time, label them

and store them in a protected area.

Standard Brickmould Installation go to Step 3

Applications for Performance Upgrade and HurricaneShield product requires

additional clip installation or screw installation. Clip installation prep is included in

Step 2B. Screw installation steps are included in Step 5.

For HurricaneShield and Performance

Upgrade Applications:

6"

DOUBLE OPERABLE

16" MAX

O.C.

2B

6"

6"

16" MAX

6"

O.C.

6"

6"

DIAGRAM FOR

PLACEMENT OF

FRAME SCREWS OR

INSTALLATION CLIPS

6"

1P

1T

SINGLE FIXED OR OPERABLE

2B

16" MAX

6"

6"

O.C.

6"

Out-Swing Sill

Out-Swing Sill In-Swing Sill

PERFORMANCE UPGRADE & HURRICANESHIELD DOORS

Screw

Location

Clearance Holes

2B

16"

MAX.

O.C.

6"

In-Swing Sill

16" MAX

6" 6"

O.C.

16" MAX

6"

6"

O.C.

5E

2B

16"

MAX.

O.C.

2B

16"

MAX.

O.C.

6"

6"

16" MAX

6" 6"

O.C.

2B

16"

MAX.

O.C.

6"

5E

Loading...

Loading...