Pella 816G0101 User Manual

© 2010 Pella Corporation

Part Number: 816G0101

INSTALLATION INSTRUCTION - INSTRUCCIONES DE INSTALACIÓN

FOR PELLA

®

PRECISION FIT®, CASEMENT, RENOVATION POCKET

REPLACEMENT AND FIXED WINDOW REPLACEMENT

Lea las instrucciones en español en el reverso.

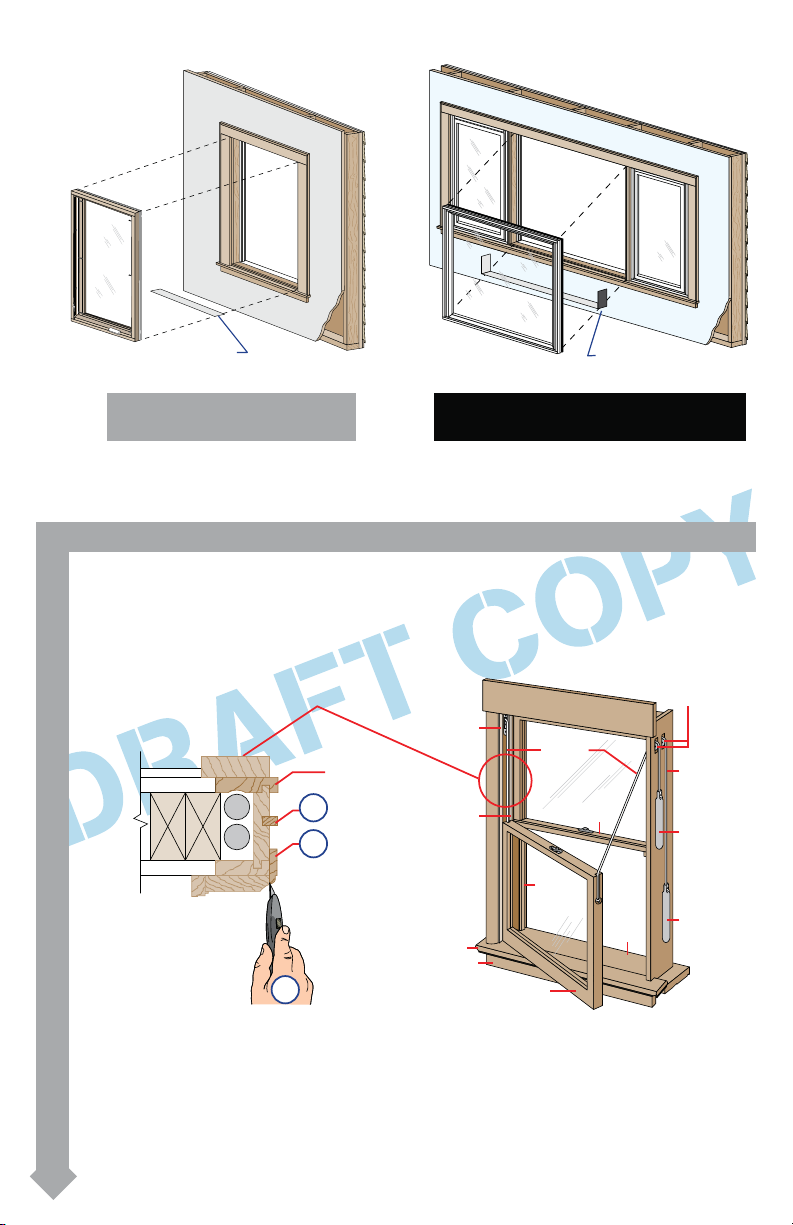

Important! e Pella Precision Fit Casement Replacement Window is designed to replace older style

double-hung windows. e original window frame will remain in place and only the existing sash

will be removed. e Pella Precision Fit Casement Fixed Window is a companion to the Precision Fit

Casement and is designed to replace the xed center window that shares a common stool and sloped

sill with the adjacent windows and has removable interior stops. is application is typically found

in older homes. e original window frame will remain in place and only the existing sash, glass and

existing stops must be removed. ese instructions are not to be used with any other construction

methods. Read these instructions thoroughly before beginning. Failure to install as recommended will

void any warranty, express or implied. For types of installation other than shown, contact your local

Pella representative or visit http://www.pella.com. Building designs, construction methods, building

materials and site conditions unique to your project may require an installation method dierent

from these instructions and additional care. Determining the appropriate installation method is the

responsibility of you, your architect or construction professional.

YOU WILL NEED TO SUPPLY: TOOLS REQUIRED:

• Cedar or Impervious shims/spacers (12 to 20)

• Wood blocking and bracing

• Closed cell foam backer rod/sealant backer (12 to 30 ft.)

• Pella® SmartFlash™ foil backed butyl window

and door ashing tape or equivalent

• High quality exterior grade polyurethane or silicone sealant

(1 tube per window)

SEA

SEA

LAN

LANT

T

• Tape measure

• Level

• Square

• Hammer

• Utility knife

• Sealant gun

• Screwdrivers

(#2 Phillips and Flat blade)

• Great Stu ™ Window and Door Insulating Foam Sealant

by the Dow Chemical Company or equivalent low pressure

• Rotary cutting tool w/ cut-o wheel (if

existing window has press t pulleys)

polyurethane window and door foam -

DO NOT use high pressure or latex foams

• Drill

• Pliers

• Putty Knife

Installation will require two or more

persons for safety reasons.

• Pry bar

• T-25 TORX® Driver

• Chisel

REMEMBER TO USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

Always read the Pella Limited Warranty before purchasing or installing Pella products.

By installing this product, you are acknowledging that this Limited Warranty is part of the terms of

the sale. Failure to comply with all Pella installation and maintenance instructions may void your Pella

product warranty. See Limited Warranty for complete details at http://warranty.pella.com.

CAUTION: Many windows in older homes are painted with lead-based paint. Removal of old

windows may disturb this paint. Proper precautions must be taken to minimize exposure to dust

and debris. Consult state or local authorities for more information.

INTERIOR

INTERIOR

Flashing tape

Pocket Replacement –

Go to Step 1 SASH REMOVAL

POCKET REPLACEMENT:

1

SASH REMOVAL

Note: Verify the opening and window dimensions prior to removing the existing

window sash.

POCKET REPLACEMENT

&YUFSJPS

CMJOETUPQ

$

1BSUJOHTUPQ

*OUFSJPS

"

TBTITUPQ

"

Flashing tape

Fixed Window Replacement – Go to

Step 6 FIXED SASH REMOVAL on page 7

#BMBODF

DPSEQVMMFZT

*OUFSJPS

TBTITUPQ

1BSUJOH

TUPQ

4UPPM

"QSPO

#PUUPN

TBTI

#PUUPN

CBMBODF

DPSET

5PQTBTI

&YUFSJPS

CMJOE

TUPQ

4JMM

5PQ

CBMBODF

DPSE

#PUUPN

TBTI

XFJHIU

5PQTBTI

XFJHIU

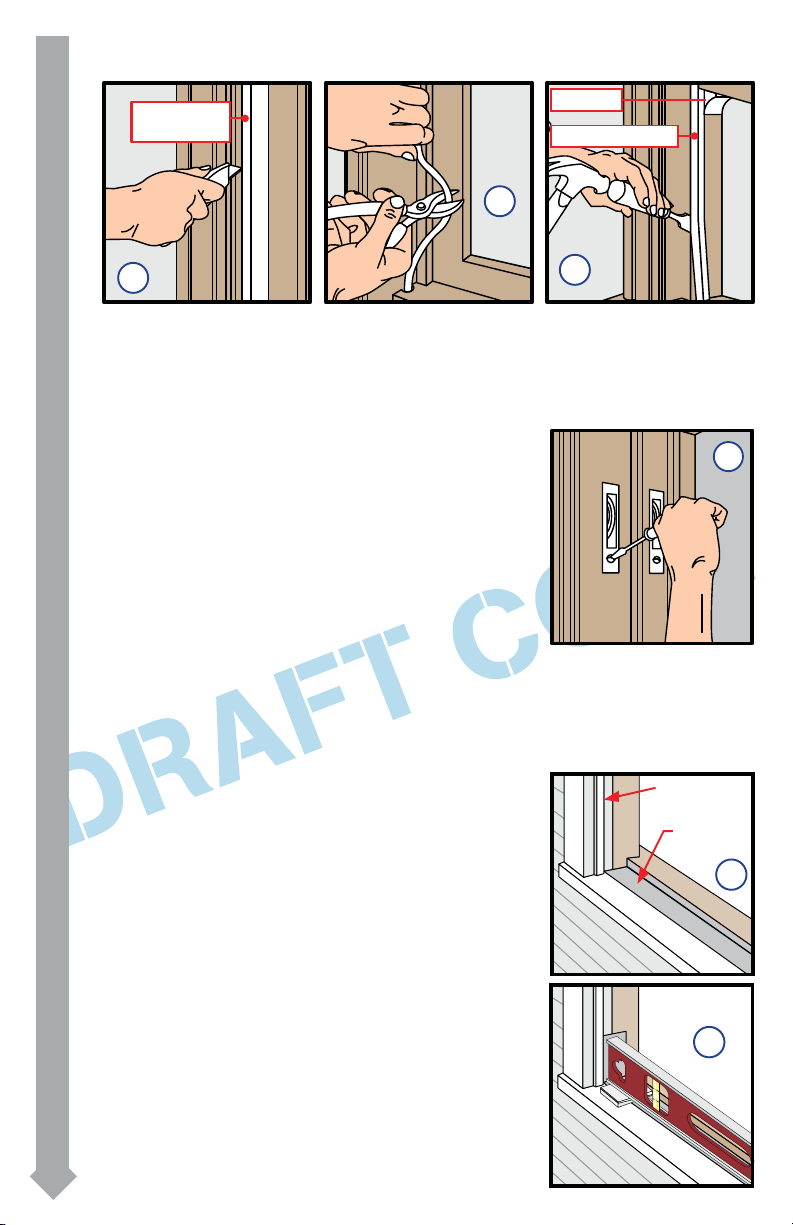

A. Score paint or varnish along interior sash stops with a sharp utility knife.

Remove the interior sash stops at jambs (sides) and head (top) using a putty knife

and pry bar.

1

SASH REMOVAL (CONTINUED)

*/5&3*03

4"4)4501

8&%(&

1"35*/(4501

#

"

B. Cut the balance cords on the bottom sash and lift out the sash. Allow weights to fall

to the bottom of the weight pocket.

C. Remove the parting stops by prying them out or by pulling them out with a channel

lock. ere may be a small wedge of wood at the bottom of the upper sash that is next

to the parting stops. To make it easier to remove the parting stop, use a chisel to knock

o the wedge.

POCKET REPLACEMENT

D. Lower the top sash and cut the balance cords

allowing the balance weights to fall into the weight

pocket. Remove the top sash.

E. Remove the balance cord pulleys. Unscrew and

remove the balance cord pulleys. If the pulleys are

press-in t type, follow these steps:

1. Cut o accessible portions of the collars using a rotary

cutting tool with cut-o wheel.

2. Bend up the remaining areas of the collars.

3. Knock the pulleys into the balance cavity. (e pin will fall with the pulleys.)

4. If desired, remove pulleys via bottom balance access panel.

NOTE: If the pulleys and pins are not removed, they may interfere with the

replacement window’s attachment screws.

F. If desired, insulate the weight chamber by lling it

with low pressure window and door insulating foam.

2

PREPARE THE OPENING

A. Apply one piece of sill ashing tape to the sill of the

existing window. Cut the tape the same length as the

width of the existing window sill. Place one side of the

tape against the vertical leg of the stool, and work the

tape into the corner before applying to the sill. Press

down rmly. DO NOT allow the ashing tape to

extend past the blind stops.

$

&

#MJOETUPQ

'MBTIJOH

5BQF

"

B. Check to ensure the existing sill is level and not

bowed (humped) upward. If necessary, place shims

on the bottom of the window opening 1/2" from each

side. Shim sill only at the jambs. Once level, attach

shims to prevent movement.

Note: Improper placement of shims may result in

bowed (humped) sill.

2B

2

PREPARE THE OPENING (CONTINUED)

C. Remove plastic wrap and card board packaging from window. DO NOT remove

plastic shipping spacers located between the window sash and frame. e shipping

spacers will help keep the window square during installation. DO NOT unlock or

open window until it is fully fastened in the opening.

Note: If screens, grilles or hardware are removed from the window at this time,

label them and store them in a protected area.

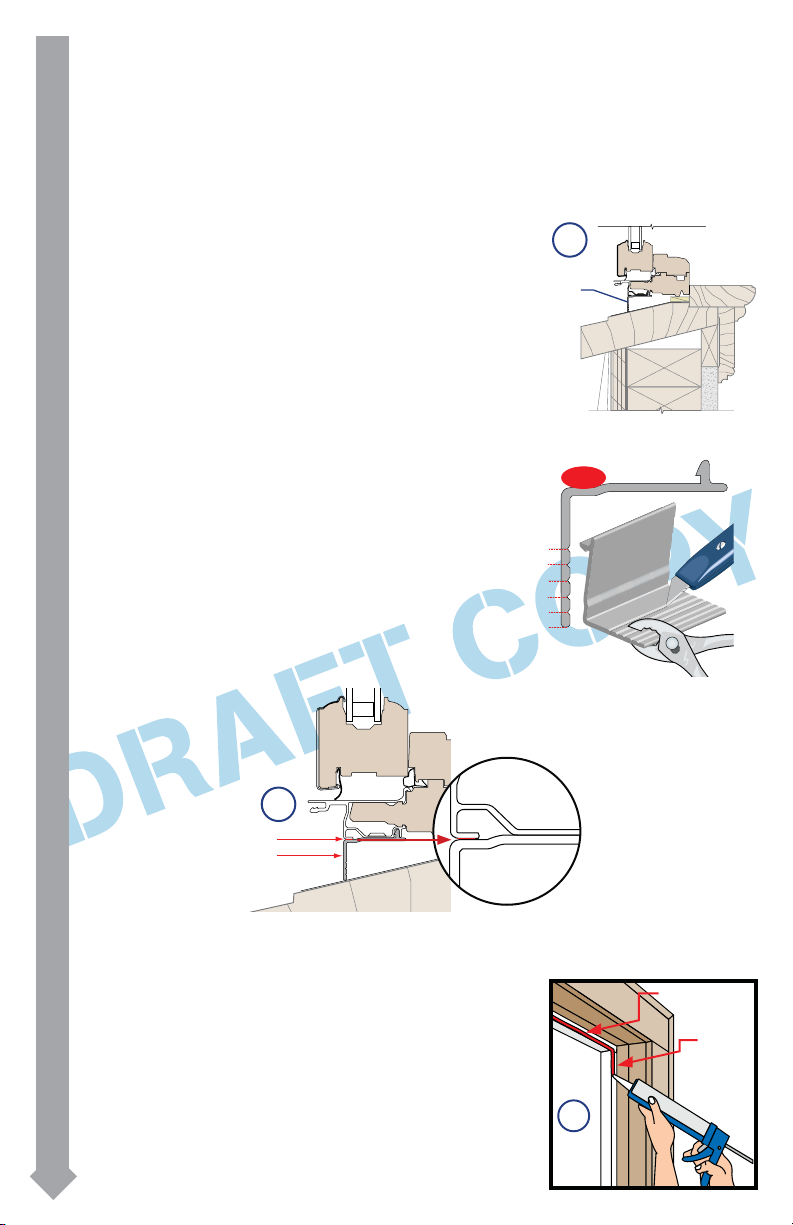

D. Test t the window. e window should be

approximately 1/2” smaller than the opening

in both width and height. Measure the distance

between the frame and the sloped sill, this will

be the height to which to cut the sill adapter.

Check to ensure the window rests against the

exterior blind stops and will make contact with

the sealant to be applied in steps 3 A, B, and C.

Conrm the installation screws will fasten into

solid wood. If not, repair the existing frame to

ensure there is solid wood at the installation

screw locations.

POCKET REPLACEMENT

E. Trim the sill adapter to the proper

height by breaking o the grooved leg at

the desired dimension (see chart). Once

trimmed, apply a bead of sealant to the sill

adapter. Attach the sill adapter into the sill

by using a board and hammer.

Note: Scoring the leg groove multiple times

at the desired dimension with a utility

knife will help the leg break easier. e sill

adapter may also be trimmed to correct

dimension using a table saw.

2E

2D

Sill Adapter

Sealant goes here

5/16” - 3/8”

7/16” - 1/2”

9/16” - 5/8”

11/16” - 3/4”

13/16” - 7/8”

15/16” - 1”

Score leg at desired dimension.

Use pliers to break off leg.

2E

2E

Sealant

Sill Adapter

3

SEALING AND FASTENING THE WINDOW

A. Apply a 3/8" continuous bead of sealant to the

interior face of the existing blind stops at the head

and both jambs.

Note: Sealant bead placement is critical to ensure

contact with replacement window

Head blind

stop

Jamb

blind

stop

3A

Loading...

Loading...