Pella 812W0100 User Manual

© 2009 Pella Corporation

INSTALLATION INSTRUCTION - INSTRUCCIONES DE INSTALACIÓN

FOR CLAD AWNING, CASEMENT &

NON-RECTANGULAR CASEMENT WINDOW

PARA LAS VENTANAS DE MADERA RECUBIERTAS DE ALUMINIO

TIPO BISAGRAS, BATIENTE Y BATIENTE NO-RECTANGULAR

Part Number: 812W0100

Corner

Flashing

Tape

Corner

Flashing

Tape

Top

Flashing

Tape

Side

Flashing

Tape

Fin

Corner

Side

Flashing

Tape

Window Bottom

Window Top

Nailing Fin

Sill Flashing Tape #1

Sill Flashing Tape #2

Water Resistive Barrier

Sheathing

Framing

Always read the Pella® Limited Warranty before purchasing or installing Pella products. By

installing this product, you are acknowledging that this Limited Warranty is part of the terms of the

sale. Failure to comply with all Pella installation and maintenance instructions may void your Pella

product warranty. See Limited Warranty for complete details at http://warranty.pella.com.

Installation Instructions for Typical Wood Frame Construction.

ese instructions were developed and tested for use with typical wood frame wall construction

in a wall system designed to manage water. ese instructions are not to be used with any

other construction method. Installation instructions for use with other construction methods,

multiple units or bow and bay windows, may be obtained from Pella Corporation, a local Pella

retailer, or by visiting http://www.pella.com. Building designs, construction methods, building

materials, and site conditions unique to your project may require an installation method

dierent from these instructions and additional care. Determining the appropriate installation

method is the responsibility of you, your architect, or construction professional.

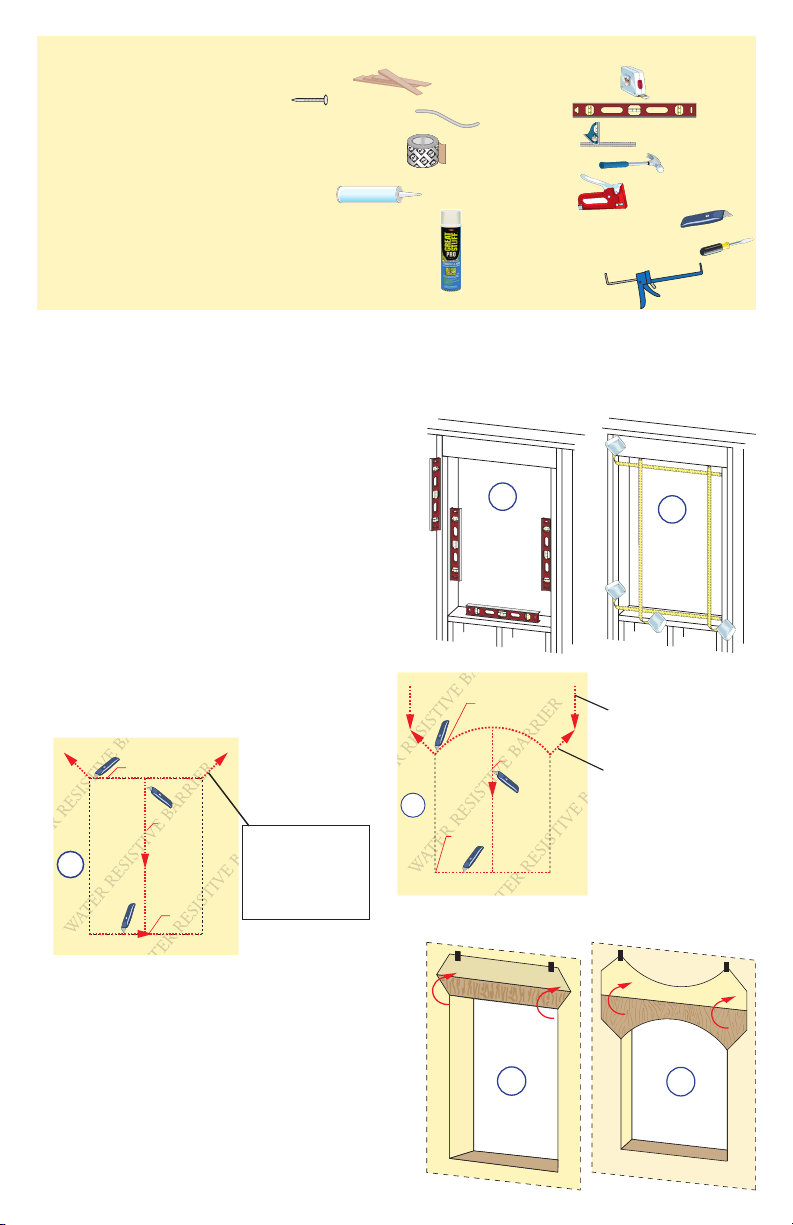

YOU WILL NEED TO SUPPLY: TOOLS REQUIRED:

Exterior

1D

• Cedar or Impervious shims/spacers (12 to 20)

• 2" galvanized roong nails (1/4 lb.)

• Closed cell foam backer rod/sealant backer (12 to 30 ft.)

• Pella® SmartFlash™ foil backed butyl window and door

ashing tape or equivalent

• High quality exterior grade polyurethane or silicone sealant

SEALANT

(1 tube per window)

SEALANT

• Great Stu ™ Window and Door Insulating Foam Sealant

by the Dow Chemical Company or equivalent low pressure

polyurethane window and door foam - DO NOT use high

pressure or latex foams

• Interior trim and/or jamb extensions (15 to 40 ft.)

• Tape measure

• Level

• Square

• Hammer

• Stapler

• Scissors or utility knife

• Small at-blade screwdriver

• Sealant gun

REMEMBER TO USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

ROUGH OPENING PREPARATION

1

A. Verify the opening is plumb and level.

Note: It is critical that the bottom is level.

B. Verify the window will t the opening.

Measure all four sides of the opening to make

Interior

1A

sure it is 3/4" larger than the window in

both width and height. On larger openings

measure the width and height in several

places to ensure the header or studs are not

bowed.

Note: 1-1/2" or more of solid wood blocking

is required around the perimeter of the

opening. Fix any problems with the rough

opening before proceeding.

C. Cut the water resistive barrier (1C).

Water Resistive Barrier

1st cut

1C

3rd cut

2nd

cut

4th cut:

Make a 6" cut up from

each top corner at a 45˚

angle to allow the water

resistive barrier to be

lapped over the fin at the

head of the window.

Water Resistive Barrier

st

cut

1

2nd cut

1C

3rd cut

5th cut:

Cut down to meet the 6"

45° cut on each corner.

4th cut:

Make a 6" cut up from

each top corner at a 45°

angle to allow the water

resistive barrier to be

lapped over the fin at the

head of the window.

*Additional shape cut patterns at end of instruction.

Interior

1B

D. Fold the water resistive barrier (1D). Fold

side aps into the opening and staple to

inside wall. Fold top ap up and temporarily

fasten with ashing tape.

Exterior

1D

ROUGH OPENING PREPARATION (continued)

1

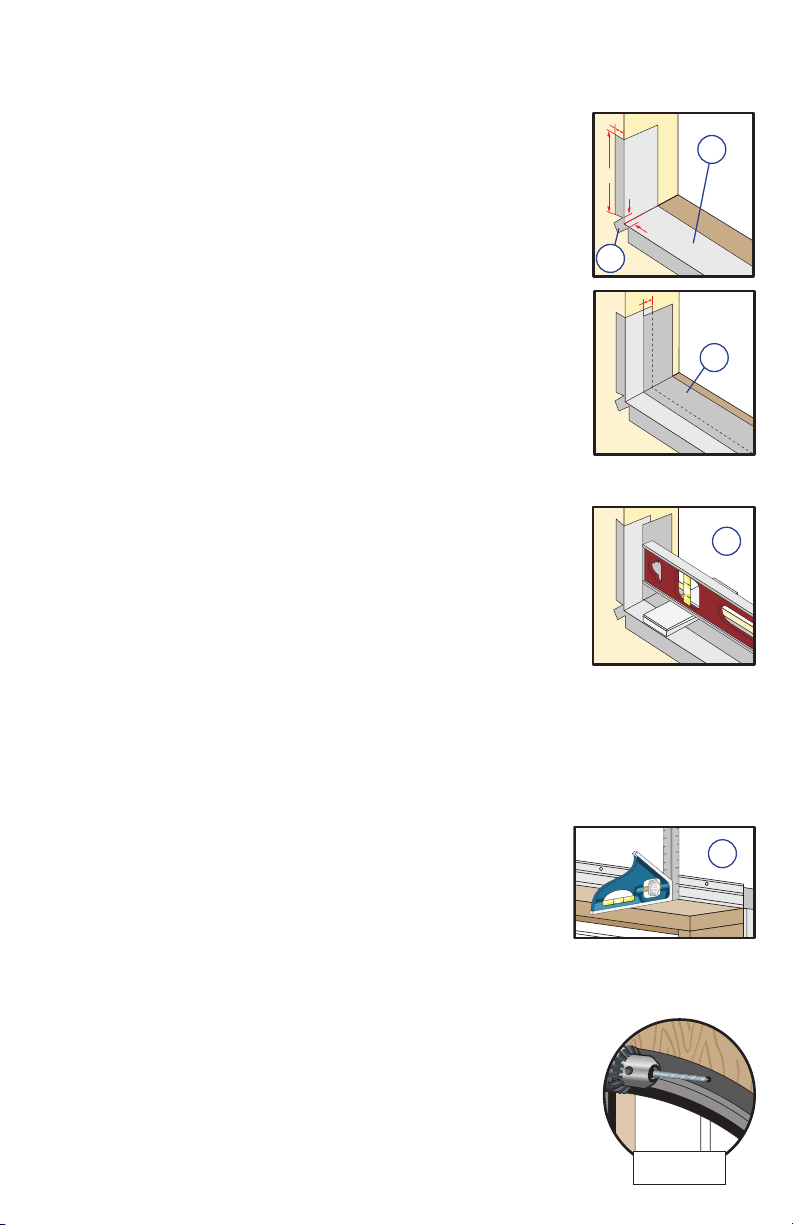

E. Apply sill ashing tape #1. Cut a piece of ashing tape 12"

longer than the opening width. Apply at the bottom of the

opening as shown (1E) so it overhangs 1" to the exterior.

Note: e tape is cut 12" longer than the width so that it

will extend 6" up each side of the opening.

F. Tab the sill ashing tape and fold. Cut 1" wide tabs at each

corner (1/2" from each side of corner) (1F). Fold tape to the

exterior and press rmly to adhere it to the water resistive

barrier.

G. Apply sill ashing tape #2. Cut a piece of ashing tape

12" longer than the opening width. Apply at the bottom,

overlapping tape #1 by at least 1". Do not allow the tape to

extend past the interior face of the framing (1G).

Note: e ashing tape may not fully cover the framing

members.

SETTING AND FASTENING THE WINDOW

2

A. Install and level sill spacers. Place 1" wide by 3/8" thick spacers

on the bottom of the window opening 1/2" from each side.

Spacers are also required at points where windows are joined in

multiple window applications. Add shims as necessary to ensure

the spacers are level. Once level, attach spacers and shims to

prevent movement.

Note: Improper placement of shims or spacers may result in

bowing the bottom of the window.

B. Remove plastic wrap and cardboard packaging from window. DO NOT remove plastic

shipping spacers located between the window sash and frame. e shipping spacers will help

keep the window square during installation. DO NOT unlock or open the window until it

is fully fastened.

Note: If screens, grilles or hardware are removed from the window at this time, label

them and store them in a protected area.

1"

6"

1F

1"

1/2"

1/2"

1E

1G

2A

C. Fold out installation n to 90°. Be careful not to remove or

tear the n corners.

Note: If the n is not at 90°, the window will not line up

correctly on the interior.

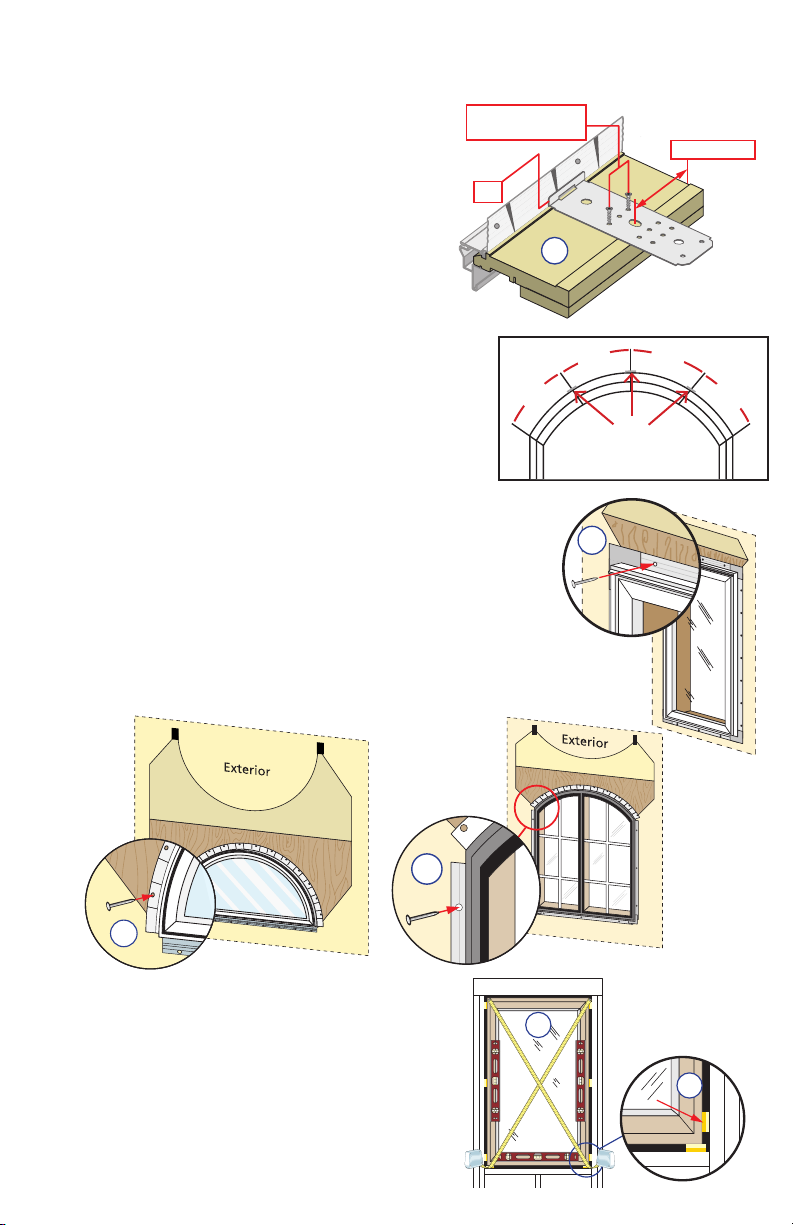

D. Curved Units with Fins:

Curved Units with frame radius > 12" will be provided with xed n.

On windows with xed extruded n, drill 1/8" diameter holes in the n every 12".

Fixed

Extruded Fin

2C

SETTING AND FASTENING THE WINDOW (continued)

6“ from end

Lip

#6 x 5/8” corrosion

resistant screws

2D

2

D. Curved Units with Fins (Continued):

Curved Units with frame radius ≤ 12", full circle

and elipse units will be provided with a exible

non-structural n on the curved portion of the

unit.

Note: is n is intended for ashing only, not as

structural support.

Installation Clips for Structural Support:

Determine installation clip placement. Clips

(provided) should be evenly spaced across the curved

frame member and no more than 16" on center.

Place the clips so the lip is facing up and against the

instillation n. Secure each clip by driving a #6 x 5/8"

corrosion resistant screws through the outer two holes

of the three holes shown.

16"

max

16"

max

Clip

16"

max

max

16"

TWO OR MORE PEOPLE WILL BE REQUIRED FOR THE

FOLLOWING STEPS.

E. Insert the window from the exterior of the building. Place

the bottom of the window on the spacers at the bottom of the

opening, then tilt the top into position. Center the window

between the sides of the opening to allow clearance for

shimming, and insert one roong nail in the rst hole from

the corner on each end of the top nailing n. ese are used

to hold the window in place while shimming it plumb and

square.

2E

F. Plumb and square window. Place shims 1" from

the bottom and top of the window between the

window and the sides of the opening. Adjust

the shims as required to plumb and square the

window in the opening. If the frame height

exceeds 53", place shims at the midpoint of the

window sides.

Note: Do not shim above the window or in the

space between the spacers at the bottom of the

window. DO NOT over shim.

2E

2E

Interior

2F

2F

Loading...

Loading...