Pella 808F0105 User Manual

Part Number: 808F0105© 2011 Pella Corporation

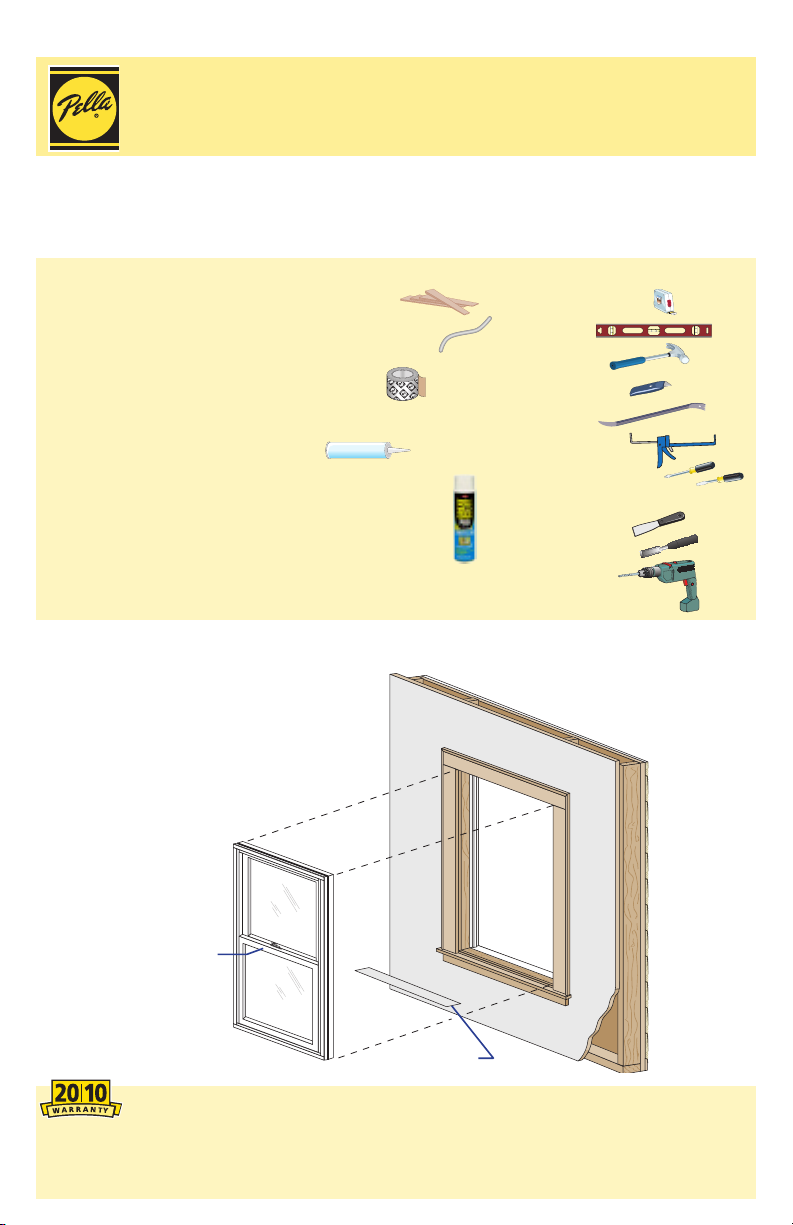

INSTALLATION INSTRUCTION INSTRUCCIONES DE INSTALACION

PELLA® PRECISION FIT AND RENOVATION POCKET

REPLACEMENT DOUBLE-HUNG VENT WINDOW

Important! The Pella Replacement Window is designed to replace older style double-hung

windows. The original window frame will remain in place and only the existing sash will be

removed. Read these instructions thoroughly before beginning. Failure to install as recommended

will void any warranty, express or implied. For types of installation other than shown, contact your

local Pella representative or visit http://www.pella.com.

YOU WILL NEED TO SUPPLY: TOOLS REQUIRED:

• Cedar or Impervious shims/spacers (12 to 20)

• Closed cell foam backer rod/sealant backer (12 to 30

ft.)

• Pella® SmartFlash™ foil backed butyl window

and door flashing tape or equivalent

• High quality exterior grade polyurethane or silicone

sealant (1 tube per window)

• Great Stuff ™ Window and Door Insulating Foam

Sealant by the Dow Chemical Company or equivalent

low pressure polyurethane window and door foam -

DO NOT use high pressure or latex foams.

Installation will require two or more persons for safety reasons.

SEALANTSEALANT

• Tape measure

• Level

• Hammer

• Utility knife

• Pry bar

• Sealant gun

• Screwdrivers

(#2 Phillips and Flat blade)

• Putty knife

• Wood chisel

• Drill

REMEMBER TO USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

INTERIOR

Checkrail

Flashing tape

Always read the Pella® Limited Warranty before purchasing or installing Pella

is part of the terms of the sale. Failure to comply with all Pella installation and maintenance

instructions may void your Pella product warranty. See Limited Warranty for complete details at

http://warranty.pella.com.

products. By installing this product, you are acknowledging that this Limited Warranty

1

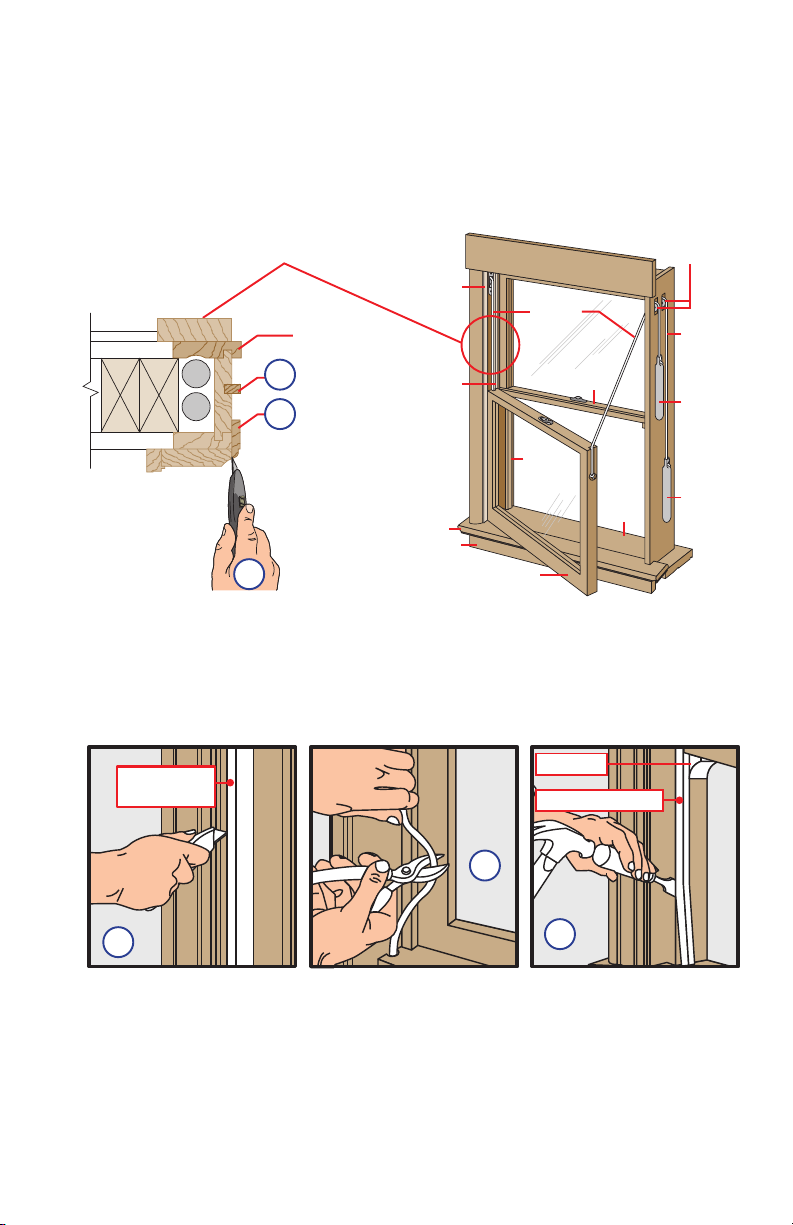

DOUBLE-HUNG SASH REMOVAL

CAUTION: Many windows in older homes are painted with lead-based paint. Removal

of old windows may disturb this paint. Proper precautions must be taken to minimize

exposure to dust and debris. Consult state or local authorities for more information.

Note: Verify the opening and window dimensions prior to removing the existing

window sash.

Interior

1A

Exterior

blind stop

1C

Parting stop

Interior

1A

sash stop

sash stop

Parting

stop

Stool

Apron

Bottom

balance

cords

Top sash

Exterior

blind

stop

Sill

Bottom

sash

Balance

cord pulleys

Top

balance

cord

Bottom

sash

weight

Top sash

weight

A. Score paint or varnish along interior sash stops with a sharp utility knife. Remove the

interior sash stops at jambs (sides) and head (top) using a putty knife and pry bar.

INTERIOR

SASH STOP

WEDGE

PARTING STOP

1B

1A

B. Cut the balance cords on the bottom sash and lift out the sash. Allow weights to fall to the

bottom of the weight pocket.

C. Remove the parting stops by prying them out or by pulling them out with a channel lock.

There may be a small wedge of wood at the bottom of the upper sash that is next to the

parting stops. To make it easier to remove the parting stop, use a chisel to knock off the

wedge.

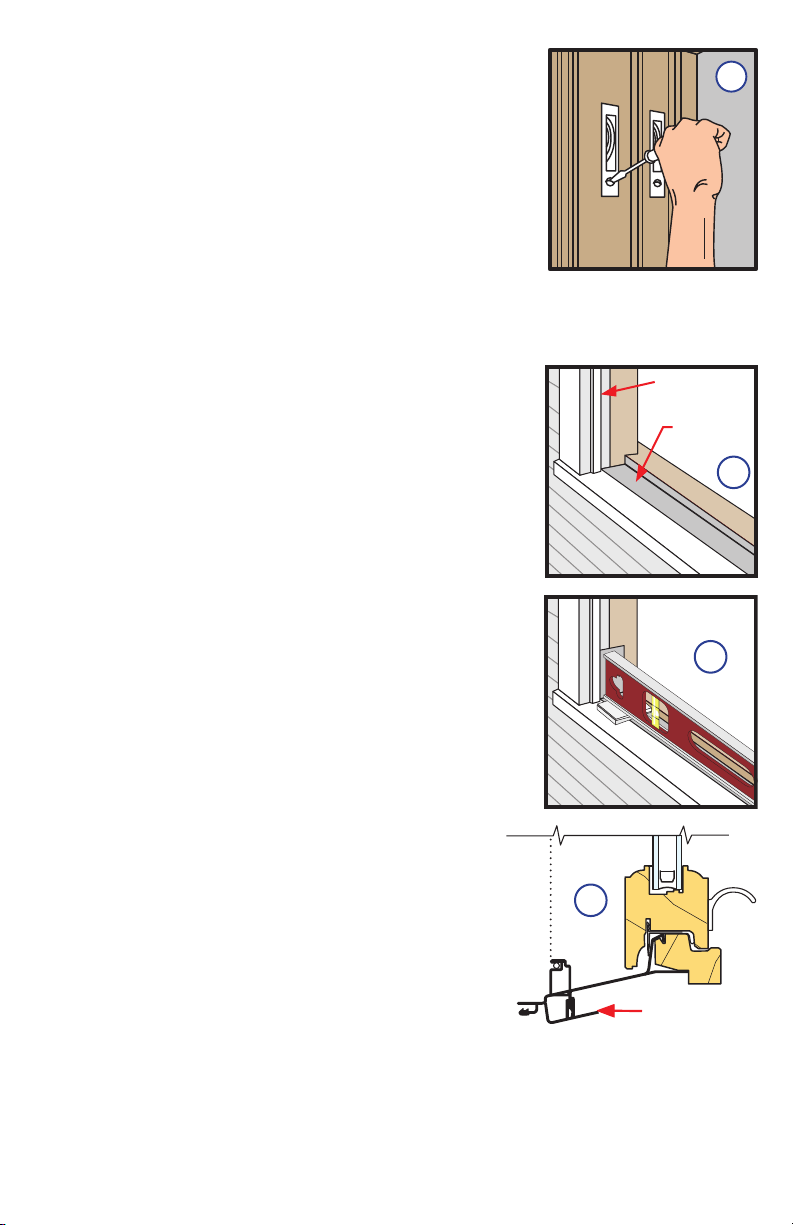

1C

D. Lower the top sash and cut the balance cords allowing the

balance weights to fall into the weight pocket. Remove the

top sash.

E. Remove the balance cord pulleys. Unscrew and remove the

balance cord pulleys. If they cannot be removed easily, drive

them into the jamb using a hammer.

F. If desired, insulate the weight chamber by filling it with low

pressure window and door insulating foam.

2

PREPARE THE OPENING

A. Apply one piece of sill flashing tape to the sill of the

existing window. Cut the tape the same length as the

width of the existing window sill. Place one side of the tape

against the vertical leg of the stool, and work the tape into

the corner before applying to the sill. Press down firmly.

DO NOT allow the ashing tape to extend past the blind

stops.

B. Check to ensure the existing sill is level and not bowed

(humped) upward. If necessary, place shims on the bottom

of the window opening 1/2" from each side. Shim sill

only at the jambs. Once level, attach shims to prevent

movement.

1E

Blind stop

Flashing

Tape

2A

2B

Note: Improper placement of shims may result in bowed

(humped) sill.

C. Remove plastic wrap, cardboard packaging and sill

packaging board from window. DO NOT cut the checkrail

bands or remove plastic shipping spacers located between

the window sash and frame. The shipping spacers will help

keep the window square during installation.

Note: If screens, grilles or hardware are removed from

the window at this time, label them and store them in

a protected area.

D. Remove the sill adapter for existing sills that slope

less than 13 degrees. For existing sills that slope

13 degrees or more, fully extend the adjustable sill

adapter.

Note: Usage of the sill adapter with existing sill angles

less than 13 degrees may cause bowed (humped) sills,

resulting in screen fit issues.

E. Test fit the window. The window should be approximately 1/2" smaller than the

opening in both width and height. Check to ensure the window rests against the

exterior blind stops and will make contact with the sealant applied in steps 3 A, B and

C. If the sill adpater is present, verify it is extended to meet the existing sill. Verify that

the installation screws will fasten into solid wood. If not, repair the existing frame to

insure there is solid wood at installation screw locations.

2D

Sill Adapter

Loading...

Loading...