Page 1

®

SHIFT

SEQUENCE

F1 F2 F3 F4 F5

MON ACK PREV NEXT HOLD PATTERN PRESET MACRO PGM

1

23

4

5

6

7

8

9

0

CLEARCAM

KBD300

MADE IN USA.

KBD300

Universal

Keyboard

Installation/

Operation Manual

C527M (11/97)

Pelco • 300 W. Pontiac Way, Clovis • CA 93612-5699 USA • Pelco Online @ http://www.pelco.com

In North America and Canada: Tel (800) 289-9100 or FAX (800) 289-9150 • DataFAX (800) 289-9108

International Customers: Tel (1-209) 292-1981 or FAX (1-209) 348-1120 • DataFAX (1-209) 292-0435

Page 2

CONTENTS

Section Page

1.0 GENERAL ..................................................................................................1

1.1 IMPORTANT SAFEGUARDS AND WARNINGS ...............................1

2.0 DESCRIPTION ..........................................................................................2

3.0 INSTALLATION ..........................................................................................4

3.1 WALL JACK WIRING .........................................................................5

3.2 KEYBOARD ADDRESSING ..............................................................7

4.0 SPECIFICATIONS .....................................................................................8

5.0 WARRANTY AND RETURN INFORMATION ...........................................10

LIST OF ILLUSTRATIONS

Figure Page

1 KBD300 Keyboard Definitions ...........................................................3

2 Wall Jack Wiring Schematic............................................................... 5

3 Keyboard Cabling Diagram ................................................................6

4 Keyboard Rear Panel .........................................................................6

LIST OF TABLES

Table Page

A Keyboard Addresses..........................................................................7

REVISION HISTORY

Manual # Date Comments

C527M 11/97 Original version.

ii

12 Pelco Manual C527M (11/97)

Page 3

1.0 GENERAL

1.1 IMPORTANT SAFEGUARDS AND WARNINGS

Prior to installation and use of this product, the following WARNINGS should be

observed.

1. Installation and servicing should only be done by Qualified Service Personnel

and conform to all Local codes.

2. Unless the unit is specifically marked as a NEMA Type 3, 3R, 3S, 4, 4X ,6 or

6P enclosure, it is designed for Indoor use only and it must not be installed

where exposed to rain and moisture.

3. Only use replacement parts recommended by Pelco.

4. After replacement/repair of this unit’s electrical components, conduct a resistance measurement between line and exposed parts to verify the exposed

parts have not been connected to line circuitry.

The product and/or manual may bear the following marks:

This symbol indicates that dangerous voltage constituting a

risk of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION:

RISK OF

ELECTRIC SHOCK.

DO NOT OPEN.

TO REDUCE THE RISK OF ELECTRICAL SHOCK,

DO NOT REMOVE COVER. NO USER-

SERVICEABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

CAUTION:

Please thoroughly familiarize yourself with the information

in this manual prior to installation and operation.

Pelco Manual C527M (11/97) 1

Page 4

2.0 DESCRIPTION

The KBD300 keyboard provides complete programming and operational control of

the CM6700 Matrix Switcher. This keyboard features a three axis joystick that includes a twisting, return-to-center head for full control of variable speed pan, tilt and

zoom fuctions.

Included in this package:

Qty Description Pelco Part Number

1 KBD300 Keyboard, 120 V AC, or KBD300

KBD300 Keyboard, 230 VAC KBD300-X

1 12 V AC wall mount transformer, 120 VAC, or TRF112.0S.20

12 V AC wall mount transformer , 230 V AC TRF212.0S.25

1 RJ-45 modular wall jack CON12J008Z03G0Z

1 Keyboard data cable WIRA220122

See the CM6700 Installation/Operation Manual (C523M-A) for detailed operating

instructions.

2 Pelco Manual C527M (11/97)

Page 5

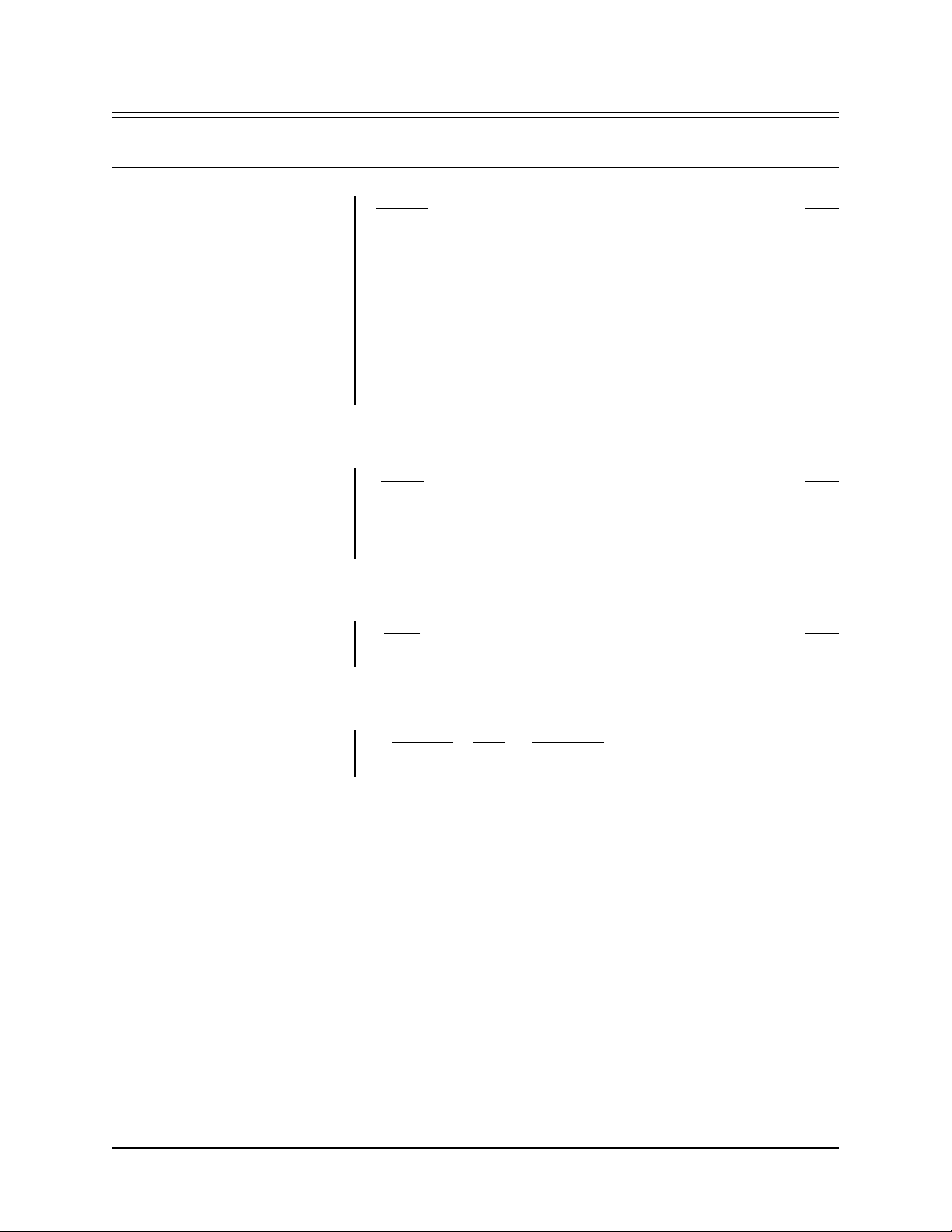

2

3

4

5

6

1

SHIFT

F1 F2 F3 F4 F5

23

6

5

9

8

0

SEQUENCE

NEAR FAR

OPEN

17

MON ACK PREV NEXT HOLD PATTERN PRESET MACRO PGM

1

16

15

14

4

7

CLEAR CAM

13

1. DIGIT DISPLAY LED Displays monitor number in Run

mode and P in program mode.

2. SHIFT KEY Press to activate Multiplexer Mode.

3. SHIFT KEY LED Illuminates when Multiplexer Mode is

active.

4. SEQUENCE KEYS

When Sequence Status Indicator displays O on monitor

(sequence not running and not on hold)

PREVIOUS (PREV) Press to step backward through

all available system cameras. Hold for two seconds to start

a sequence in reverse.

NEXT Press to step forward through all available system

cameras. Hold for two seconds to start a sequence.

HOLD No function.

When Sequence Status Indicator displays F or B (sequence running forward or backward)

PREVIOUS (PREV) Press to step backward through a

sequence and/or reverse a forward sequence.

NEXT Press to step forward through a sequence and/or

reverse a backward sequence.

HOLD Press to place a sequence on hold.

When Sequence Status Indicator displays H (sequence

on hold)

PREVIOUS (PREV) Press to step backward through

the camera sequence, including presets. Hold for two seconds to start a sequence in reverse.

NEXT Press to step forward through the camera sequence. Hold for two seconds to start a sequence.

HOLD No function.

5. FUNCTION KEYS, Normal Operation

F1 Press to activate the NO/NC relay.

F2 Press to activate the F2 open collector output.

F3 Press to activate the F3 open collector output.

F4 Press to activate a receiver/driver auxiliary for selected

camera. Press and hold for momentary aux.

F5 Press to deactivate a receiver/driver auxiliary for selected camera.

* The turbo pan

7

feature may be

disabled. Place

switch 4 on the

rear panel DIP

switch block in

the off position.

CLOSE

KBD300

MADE IN USA.

11

6. FUNCTION KEYS, Multiplexer Mode (Shift Key LED

Illuminated)

F1 Press to activate digital zoom.

F2 Press to activate Picture in Picture.

F3 Press to activate Quad display.

F4 Press to activate Nine-screen display.

F5 Press to activate 16-screen display.

7. PROGRAM KEY (PGM) Press to enter the program

mode.

8. MACRO KEY Start a salvo sequence (macro 1 or 2) by

first entering the macro number then pressing this key.

9. PRESET KEY Send a camera to a preset by first enter-

ing the preset number then pressing this key. Program a

preset by first entering the preset number then holding

the key for two seconds

10. PATTERN KEY Press to begin a pattern. Hold for two

seconds to program a pattern.

11. LENS CONTROL KEYS Control camera lens functions;

focus and iris.

12. PTZ FUNCTION JOYSTICK Variable speed, vector-

solving, bi-directional joystick with twisting head zoom

control. Turbo pan* is achieved by full joystick deflection

in either pan direction.

13. CLEAR KEY Clear a numeric entry.

14. CAMERA KEY (CAM) Select a camera by first enter-

ing the camera number then pressing this key.

15. NUMBER PAD Enter numbers.

16. ALARM ACKNOWLEDGE (ACK) Press to acknowl-

edge an alarm.

17. MONITOR KEY (MON) Select a monitor by first enter-

ing the monitor number then pressing this key .

See Figure 4.

8

9

10

12

*

Figure 1. KBD300 Keyboard Definitions

Pelco Manual C527M (11/97) 3

Page 6

3.0 INSTALLATION

NOTE:

Refer to the CM6700

Installation/Operation Manual

(C523M-A) for detailed operating

instructions.

Communication to the CM6700 keyboards is RS-485. Wall jack, modular data cable,

and 12 VAC transformer (all supplied) combine to provide a local, single cable plugin connection to the keyboard. A double-sided sticky pad, to secure the wall jack to

a suitable surface, is also supplied.

All cabling between wall jacks is user supplied.

Maximum cable distance for RS-485 communication over 24-gauge wire is 4000

feet. For user supplied cable, Pelco recommends using shielded twisted pairs such

as Belden 9843, or similar cable that meets or exceeds the basic requirements for

EIA RS-485 applications.

4 Pelco Manual C527M (11/97)

Page 7

3.1 WALL JACK WIRING

IMPORTANT:

Wall jacks must be

wired in a daisy-chain configuration.

1. Determine the location of all keyboards.

2. Run wall jack interconnect cable (user supplied) from the SCU to the closest

keyboard location. Then to the next nearest location, and the next, etc.

Wall jacks must be within 6 feet (1.8 m) of the nearest suitable electrical outlet.

Do not mount the wall jack at this time.

3. Make cable connections between wall jacks according to Figure 2. All connections between keyboard wall jacks are one-to-one. Notice that Pin 5 is connected to Pin 4 between SCU wall jack and the first keyboard wall jack.

4. At each keyboard wall jack, wire a transformer to pins 5 and 6. Polarity is

unimportant.

5. Secure the wall jack to a suitable surface.

6. Plug keyboard transformers into a suitable 115 VAC outlet.

7. Plug in all Data Cables according to Figure 3.

WALL JACK

PIN ASSIGNMENTS

45

3

2

1

6

7

8

SCU WALL

JACK

PIN

1

2

3

4

5

6

7

8

USER

SUPPLIED

CABLE

FIRST KBD

WALL JACK

12 VA C

WALL

TRANSFORMER

PIN

1

2

3

4

5

6

7

8

SECOND KBD

WALL JACK*

PIN

12 VA C

WALL

TRANSFORMER

1

2

3

4

5

6

7

8

TRANSFORMER

THIRD KBD

WALL JACK*

PIN

1

2

3

4

5

6

7

8

12 VA C

WALL

* AS NEEDED

Figure 2. Wall Jack Wiring Schematic

Pelco Manual C527M (11/97) 5

Page 8

VIDEO INPUTS

1 3 5 7 9 11 13 15

2 4 6 8 10 12 14 16

VIDEO OUTPUTS

1

2

3

4

CM6700 SCU

SCU

WALL JACK

USER SUPPLIED

CABLE (SEE FIGURE 2)

ADDITIONAL

KEYBOARDS

AS NEEDED

SWITCHER/CONTROLLER

DATA CABLE

6' CABLE

WALL

TRANSFORMER

10' CABLE

KEYBOARD

DATA CABLE

Figure 3. Keyboard Cabling Diagram

KEYBOARD

DATA

KBD

KBD

KBD300 RJ-45

CONNECTOR

PIN 1

DIP SWITCH

COVER PLATE

PIN FUNCTION

1 TxD+

2 TxD3 12 VAC/DC

4 NON POLAR

}

5 GND

6

7 RxD8 RxD+

1234

KEYBOARD

DIP SWITCH

Figure 4. Keyboard Rear Panel

6 Pelco Manual C527M (11/97)

Page 9

3.2 KEYBOARD ADDRESSING

NOTE:

Assign keyboard addresses

logically, in ascending order , to avoid

confusion when keyboard access to

monitors is programmed. The address assigned determines the keyboard number in the access menu.

Each keyboard in the system must have a different address. To make programming easier, address keyboards in ascending order.

Set the keyboard DIP switch address, refer to Figure 4.

1. Remove the two screws and the DIP switch cover plate from the rear of the

keyboard.

2. Position the switches according to Table A.

3. Replace the cover plate.

Table A. Keyboard Addresses

Keyboard Address Switch Setting

123

1 0 OFF OFF OFF

2 1 ON OFF OFF

3 2 OFF ON OFF

4 3 ON ON OFF

5 4 OFF OFF ON

6 5 ON OFF ON

7 6 OFF ON ON

8 7 ON ON ON

Connect the keyboard to the wall jack using the 10-foot (1.8 m) modular cable (supplied).

Turbo Feature

The KBD300’s turbo pan feature may be disabled by setting switch 4 on the rear

panel DIP switch block in the off position. See Figure 4.

Pelco Manual C527M (11/97) 7

Page 10

4.0 SPECIFICATIONS

Keyboard Keypad: Mechanical

Joystick: 3 axis, vector solving, with twisting return-to-center head

7-Segment

Digital Display: Red LED, 2 cells

Shift Mode

Indicator: Green LED

Electrical

Input voltage: 12 VAC or ±12 VDC

Power

Consumption: 1 watt

Ambient

Operating

Temperature: 20° to 120° F (-7° to 49° C)

Humidity: 10% - 90% non-condensing

Connector Type: RJ-45 8-pin modular (female)

Keyboard Communication

Protocol: RS-485

Baud Rate: 9600

General

Dimensions: 9.50" x 7.125" x 2.25" (24.13 cm x 18.1 cm x 5.72 cm)

Weight: 2.5 lbs (1.12 kg)

(Design and product specifications subject to change without notice.)

8 Pelco Manual C527M (11/97)

Page 11

NOTES

Pelco Manual C527M (11/97) 9

Page 12

5.0 WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in

material or workmanship for a period of one (1) year after the date of shipment.

Exceptions to this warranty are as noted below:

• Two (2) years on all standard motorized and fixed focal length lenses.

• Two (2) years on Legacy®, Intercept®, CM6700/CM8500/CM9500/CM9750/

CM9760 Matrix, Spectra™, DF5 Series and DF8 Fixed Dome products.

• Two (2) years on WW5700 series window wiper (excluding wiper blades).

• Two (2) years on cameras.

• Six (6) months on all pan and tilts, scanners or preset lenses used in continuous motion applications (e.g., preset scan, tour and auto scan modes).

Pelco will warranty all replacement parts and repairs for 90 days from the date of

Pelco shipment. All goods requiring warranty repair shall be sent freight prepaid to

Pelco, Clovis, California. Repairs made necessary by reason of misuse, alteration,

normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss resulting from the specific use or application made of the Products. Pelco’s liability for

any claim, whether based on breach of contract, negligence, infringement of any

rights of any party or product liability, relating to the Products shall not exceed the

price paid by the Dealer to Pelco for such Products. In no event will Pelco be liable

for any special, incidental or consequential damages (including loss of use, loss of

profit and claims of third parties) however caused, whether by the negligence of

Pelco or otherwise.

®Pelco and the Pelco logo are

registered trademarks of Pelco.

©Copyright 1997, Pelco. All rights

reserved.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(209) 292-1981 to obtain a Repair Authorization number (RA), and provide the

following information:

1. Model and serial number

2. Date of shipment, P .O. number , Sales Order number , or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product which does not fall under

the warranty conditions stated above, please include a written explanation with the

product when returned.

Ship freight prepaid to: Pelco

300 West Pontiac Way

Clovis, CA 93612-5699

Method of return shipment shall be the same or equal to the method by which the

item was received by Pelco.

RETURNS

In order to expedite parts returned to the factory for repair or credit, please call the

factory at (800) 289-9100 or (209) 292-1981 to obtain an authorization number (CA

number if returned for credit, and RA number if returned for repair). Goods returned

for repair or credit should be clearly identified with the assigned CA/RA number and

freight should be prepaid. All merchandise returned for credit may be subject to a

20% restocking and refurbishing charge.

Ship freight prepaid to: Pelco

300 West Pontiac Way

Clovis, CA 93612-5699

10 Pelco Manual C527M (11/97)

Loading...

Loading...