Page 1

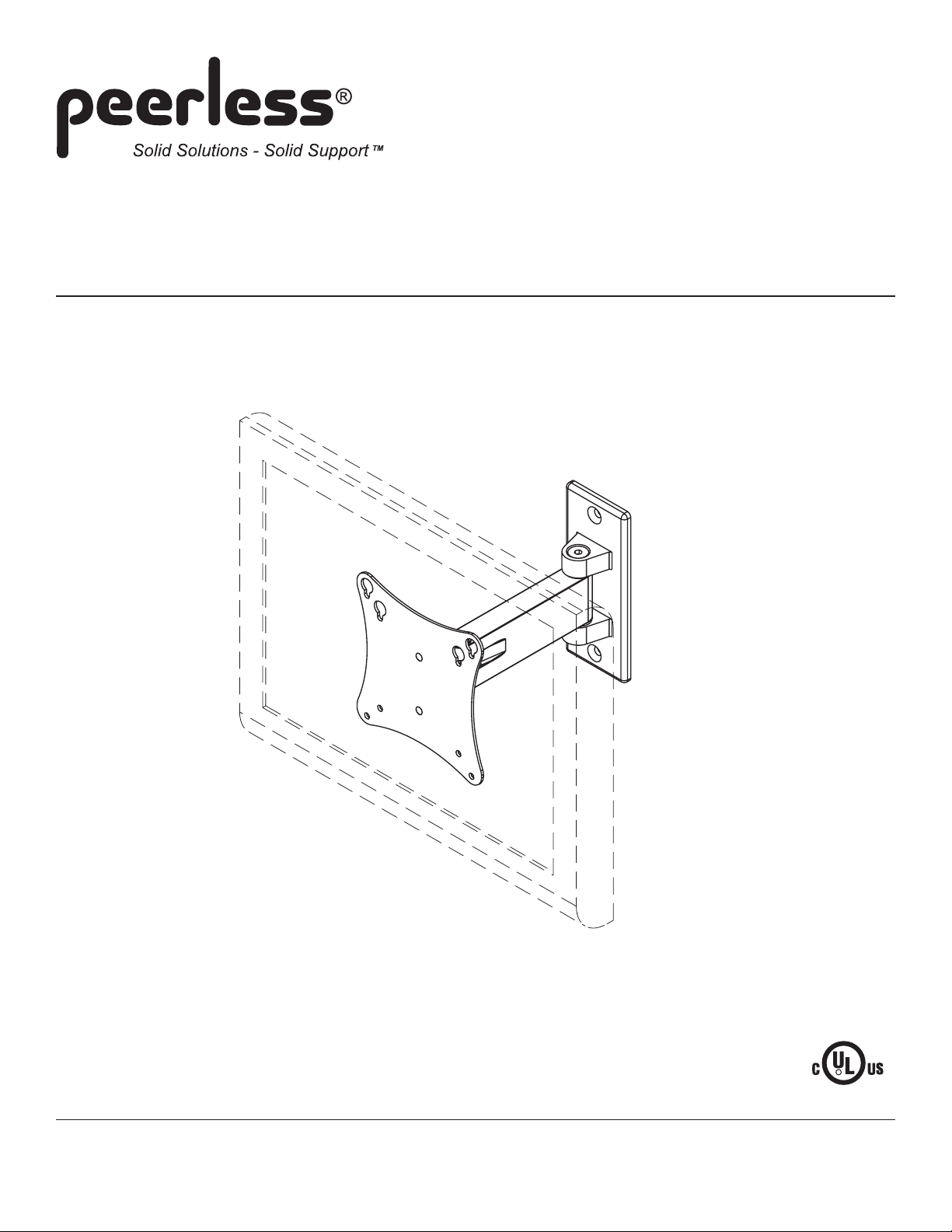

Installation and Assembly:

LCD Screen Long Pivot Wall Mount

Models: SP730P, SP730P-S, D-LPL-100, RTLPL-100S

Features:

• Fits 10" - 22" LCD screens

• Arm extends up to 6" from wall or folds flat to save space

• Supports screens with VESA® 75 or 100 mounting holes

• Features ball joint at the screen for additional side-to-side swivel

and upward and downward tilt

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 729-0307 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

Max UL Load Capacity: 25 lb (11.3 kg)

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

R

Page 2

Notes:

• Read entire instruction sheet before you start installation and assembly .

• Screen must be attached to the mount to enable tilting.

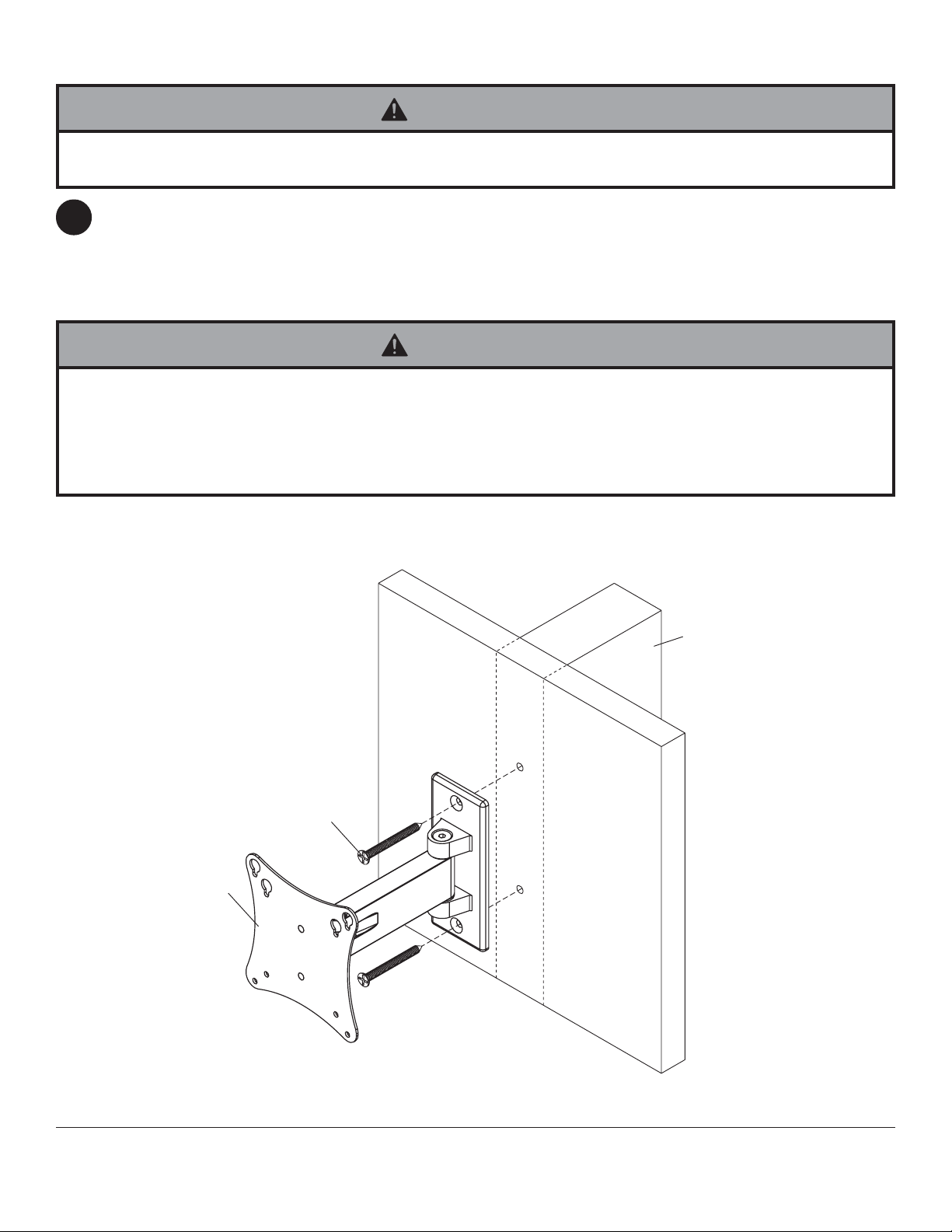

WARNING

• Do not begin to install your Peerless product until you have read and understood the instructions and warnings

contained in this Installation Sheet. If you have any questions regarding any of the instructions or warnings, call

Peerless customer service at 1-800-729-0307.

• This product should only be installed by someone of good mechanical aptitude, has experience with basic building

construction, and fully understands these instructions.

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

• Never mount this product to a metal stud wall construction unless the stud can be verified to be constructed of 25

gauge steel minimum, the drywall is 1/2" thick minimum and you obtain and use the Peerless accessory kit for metal

studs.

• Never exceed the Maximum UL Load Capacity .

• If mounting to wood wall stud wall construction, make sure that mounting screws are anchored into the center of the

studs. Use of an "edge to edge" stud finder is highly recommended.

• Always use an assistant or mechanical lifting equipment to safely lift and position equipment.

• Tighten screws firmly, but do not overtighten. Overtightening can damage the items, greatly reducing their holding

power. See suggested torque values where applicable within these instructions.

Tools Needed for Assembly

• stud finder ("edge to edge" stud finder is recommended)

• phillips screwdriver

• drill with 1/4" and 5/32" drill bits

Accessories

• Metal S tud Accessory Kit (ACC 908) (Not evaluated by UL)

Table of Contents

Parts List.............................................................................................................................................................................. 3

Installation to Wood Stud Wall ............................................................................................................................................. 4

Installation to Solid Concrete and Cinder Block ....................................................................................................................5

For customer care call (800) 729-0307 or (708) 865-8870.

2 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 3

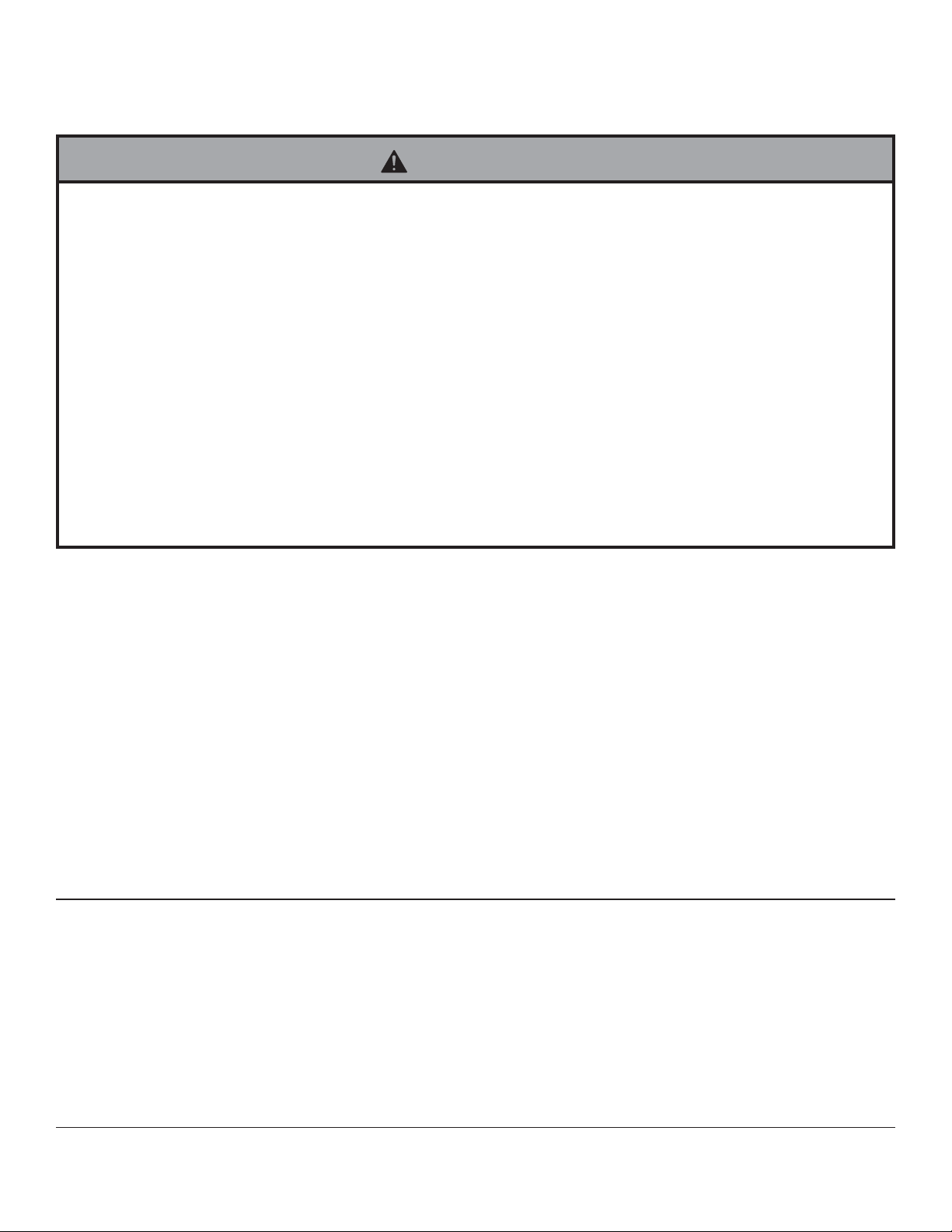

RTLPL-100S

Parts Li st

De scrip tion Qty. Par t # Par t #

wall arm 1 095-0383-B 095-0383-S

A

cord m anagem ent cli p 2 590-1264 590-2164

B

3/16" all en wrenc h 1 560-0071 560-0071

C

#14 x 2-1/ 2" fla t head wood s crew 2 520-1202 520-2165

D

All i gat or® anc hor 2 590-0097 590-0097

E

M4 x . 7 x 12 mm phi l l i ps s crew 4 504-9013 504-2013

F

M4 x . 7 x 20 mm phi l l i ps s crew 4 504-9020 504-2014

G

retaini ng spac er 4 590-5005 590-5003

H

5 mm al l en wrenc h 1 560-9640 560-9640

I

SP730P SP730P-S

D-LPL-100

A

F

G

H

B

B

I

C

D

E

3 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 4

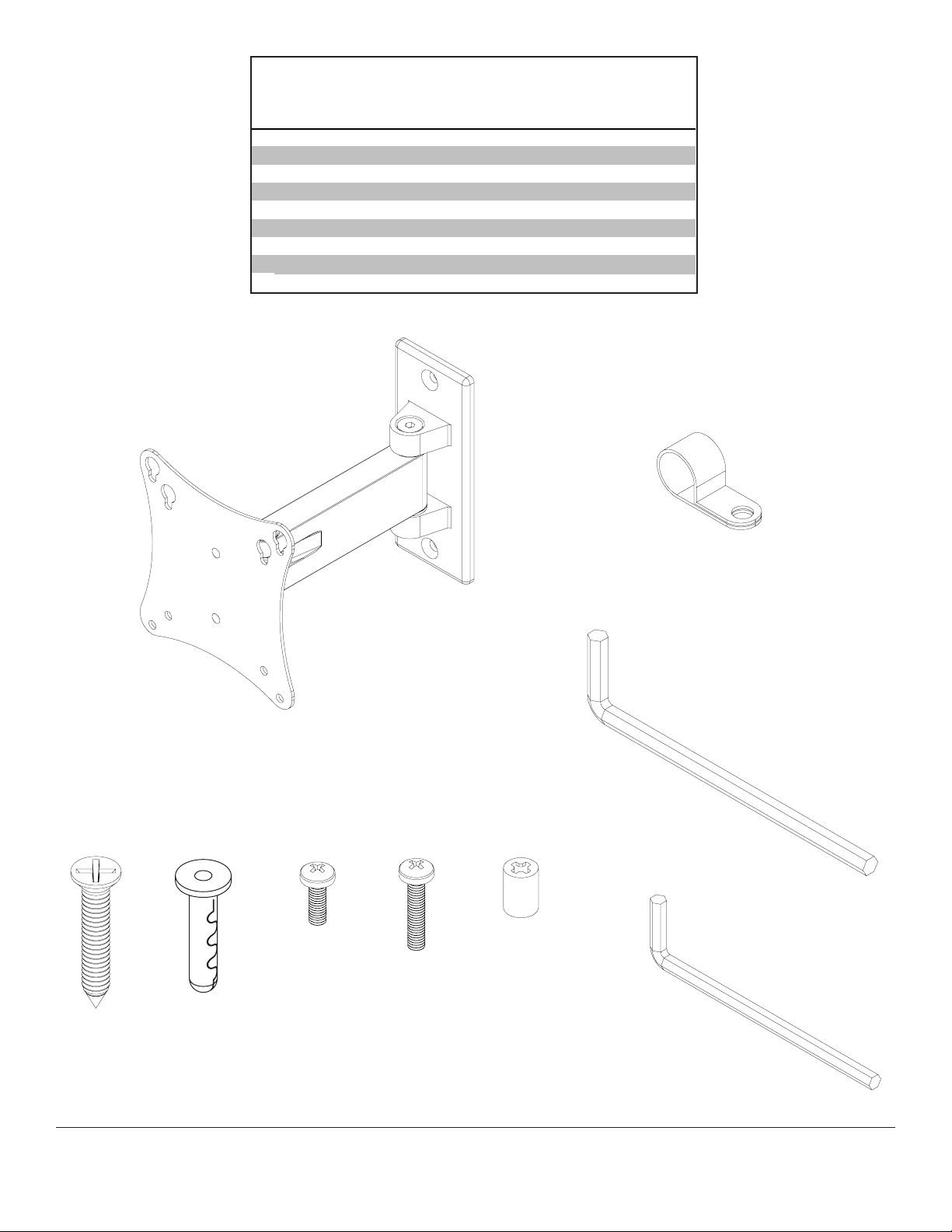

Installation to Wood Stud Wall

WARNING

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

Using a stud finder, locate and mark the edges of the wood stud used in mounting this product. Use of an edge to

1

edge stud finder is highly recommended. Use a level to draw a vertical line down the center of the stud. Use wall

plate as template to mark center of holes along the vertical line. Drill two 5/32" (4 mm) dia. holes 2.5" (65 mm)

deep. Att ach wall arm assembly (A) to wall using two #14 x 2.5" flat head wood screws (D) as shown.

Skip to step 2 on page 6.

WARNING

• Tighten screws so that wall plate is firmly attached, but do not overtighten. Overtightening can damage the screws,

greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

• Make sure that mounting screws are anchored into the center of the studs. The use of an "edge to edge" stud finder is

highly recommended.

A

WOOD

STUD

WALL

D

4 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 5

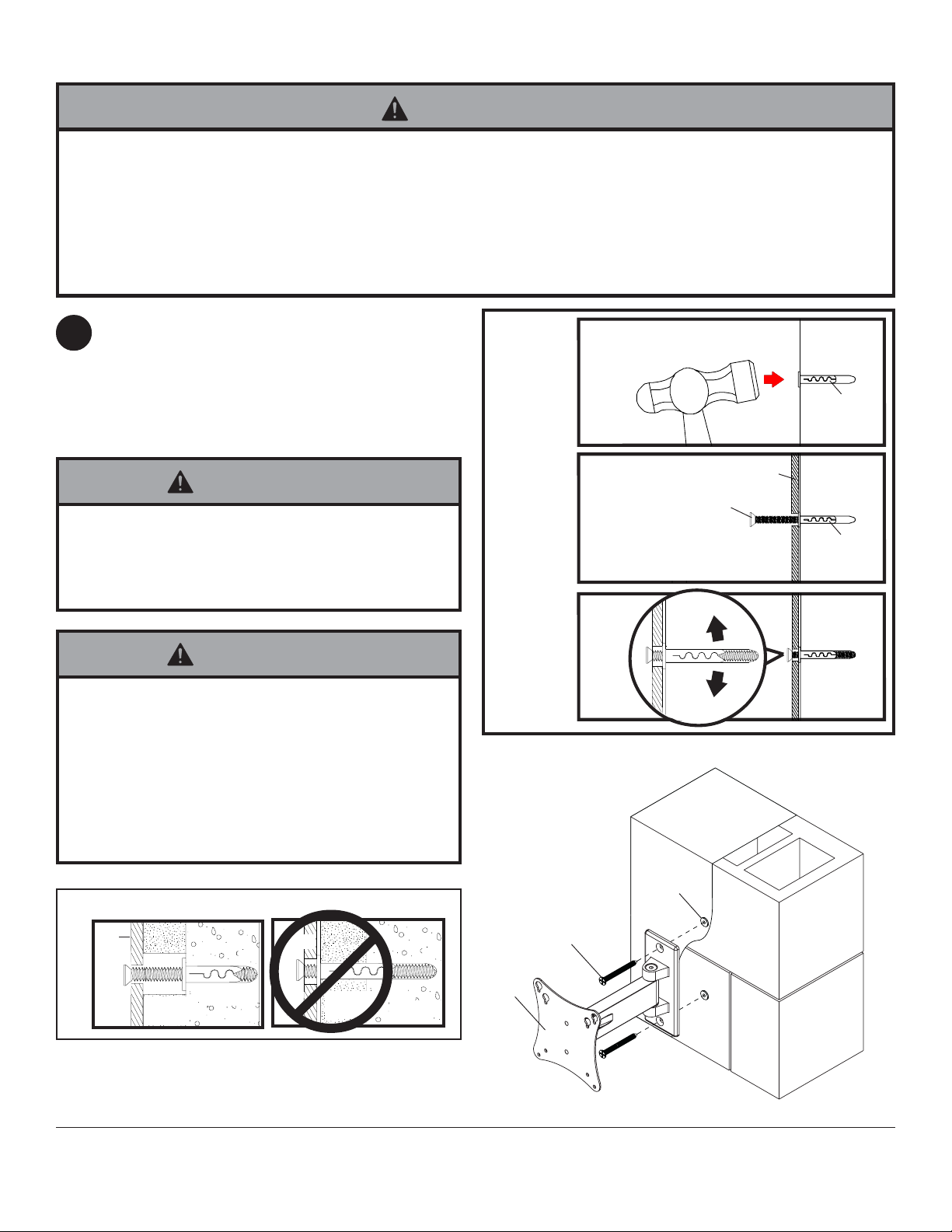

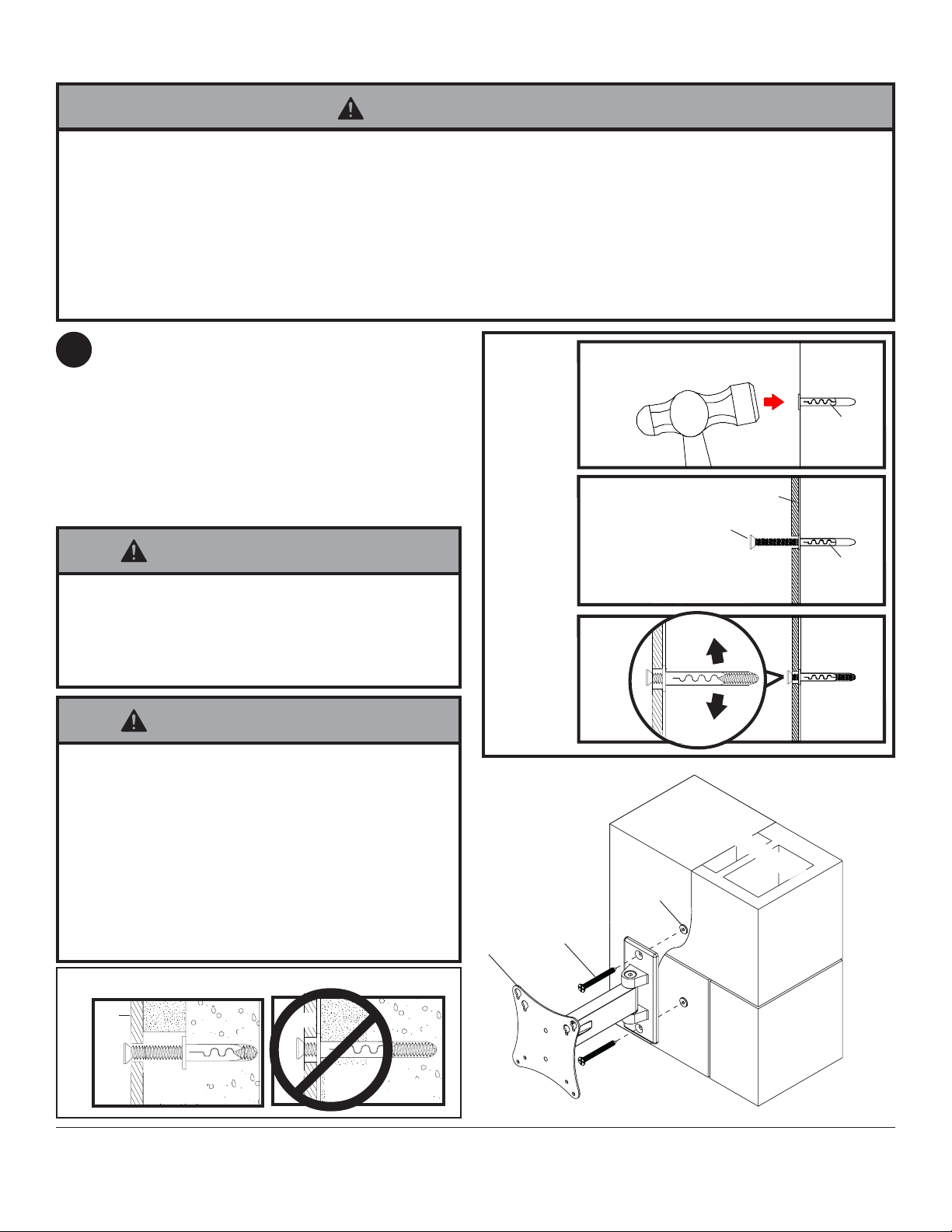

Installation to Solid Concrete and Cinder Block

WARNING

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" of actual concrete

thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount in a solid

part of the block, generally 1" minimum from the side of the block. Cinder block must meet ASTM C-90 specifications.

It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a hammer drill to avoid

breaking out the back of the hole when entering a void or cavity .

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor .

• Make sure that the supporting surface will safely support the combined load of the equipment and all attached

hardware and components.

Level and use wall plate as template to mark center

1

of holes. Drill two 1/4" (6 mm) dia. holes to a

minimum depth of 2" (51 mm). Insert anchors (E) in

holes flush with wall as shown in fig 1.3. Place wall

arm (A) over anchor and secure with wood screw (D)

as shown in figures 1.4 and 1.6. Make sure wall arm

is level, and tighten all fasteners. See figure 1.5.

WARNING

• Tighten screws so that wall plate is firmly attached,

but do not overtighten. Overtightening can damage the

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

WARNING

• Concrete anchors are not intended for attachment to

concrete wall covered with a layer of plaster, drywall,

or other finishing material as shown below. If mounting

to concrete wall covered with plaster/drywall is

unavoidable, plaster/drywall (up to 5/8" thick) must be

counterbored as shown below. Be sure concrete

anchors do not pull away from concrete when tightening screws. If plaster/drywall is thicker than

5/8", custom fasteners must be supplied by installer.

Drill holes

and insert

anchors.

Place wall

plate over

anchor and

secure with

screw.

Tighten all

fasteners.

fig 1.3

fig 1.4

fig 1.5

concrete

wall

E

WALL PLATE

D

E

CUT AW A Y VIEW

A

CORRECT

plaster/

dry wall

concrete

INCORRECT

A

plaster/

dry wall

concrete

5 of 24

E

D

A

fig 1.6

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 6

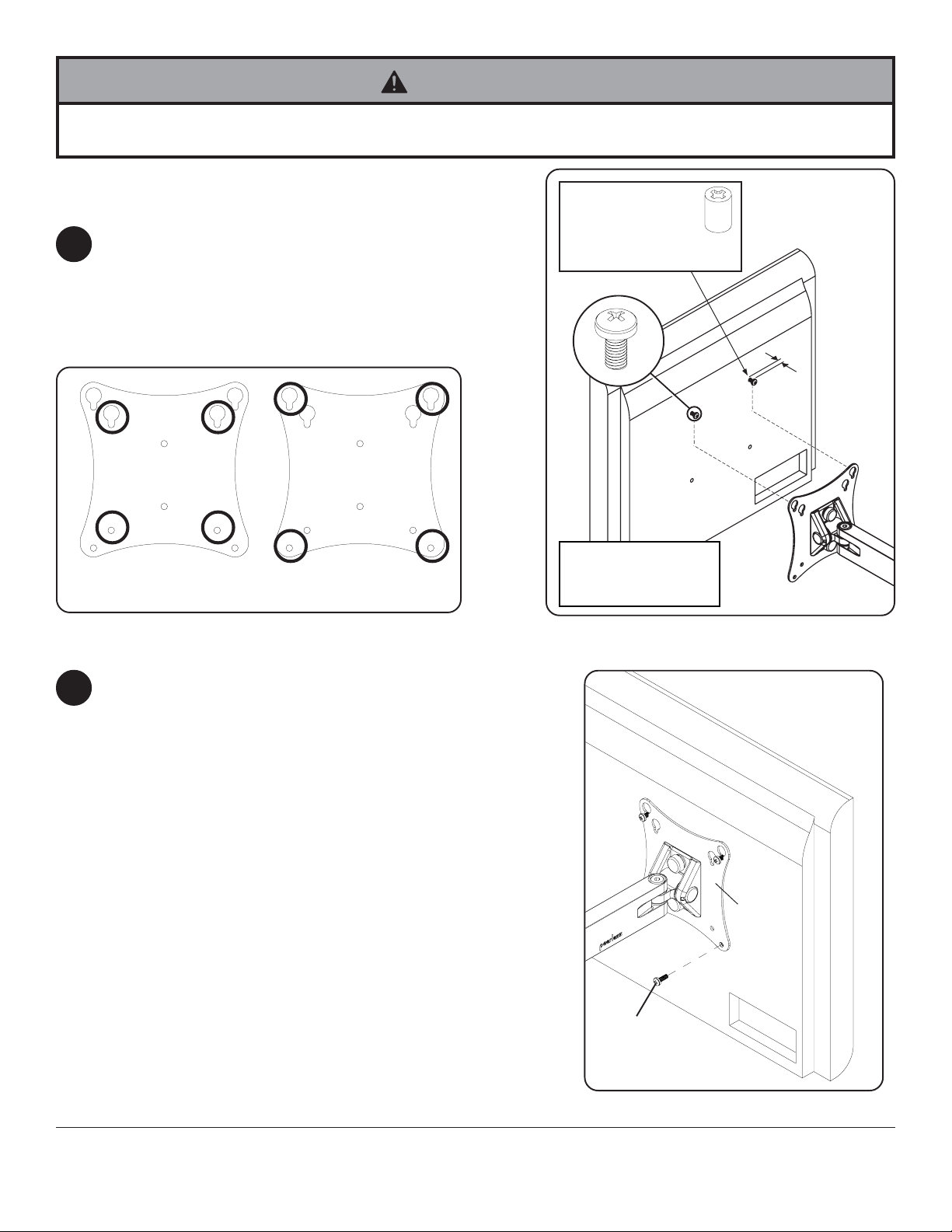

WARNING

• If screws don't get three complete turns in the screen inserts or if screws bottom out and bracket is still not tightly

secured, damage may occur to screen or product may fail.

Note: T o add security , order ACC 918 for security

screws. Refer to ACC 918 instruction sheet for

installing security screws.

Insert two M4 x 12 mm screws (F) into top two holes

2

of screen, leaving approximately 1/4" of exposed

thread. Hook screws onto keyslots of adapter plate

as indicated in figures 2.1 and 2.2.

*Note: If hole pattern is in a pocket, insert two M4 x

20 mm screws (G) with two retaining spacers (H)

into top two holes of screen as indicated right.

FOR VESA® 75

MOUNTING P A TTERN:

FOR VESA 100

MOUNTING P ATTERN:

*For screens with a

hole pattern in a

pocket, spacers (H)

go between adapter

plate and screen.

F

Screen may appear

slightly different than

illustrated

H

1/4"

fig. 2.1

Insert one M4 screw (F or G) through bottom hole of

3

adapter plate as shown in figure 3.1.

fig. 2.2

ADAPTER

PLATE

F or G

6 of 24

fig. 3.1

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 7

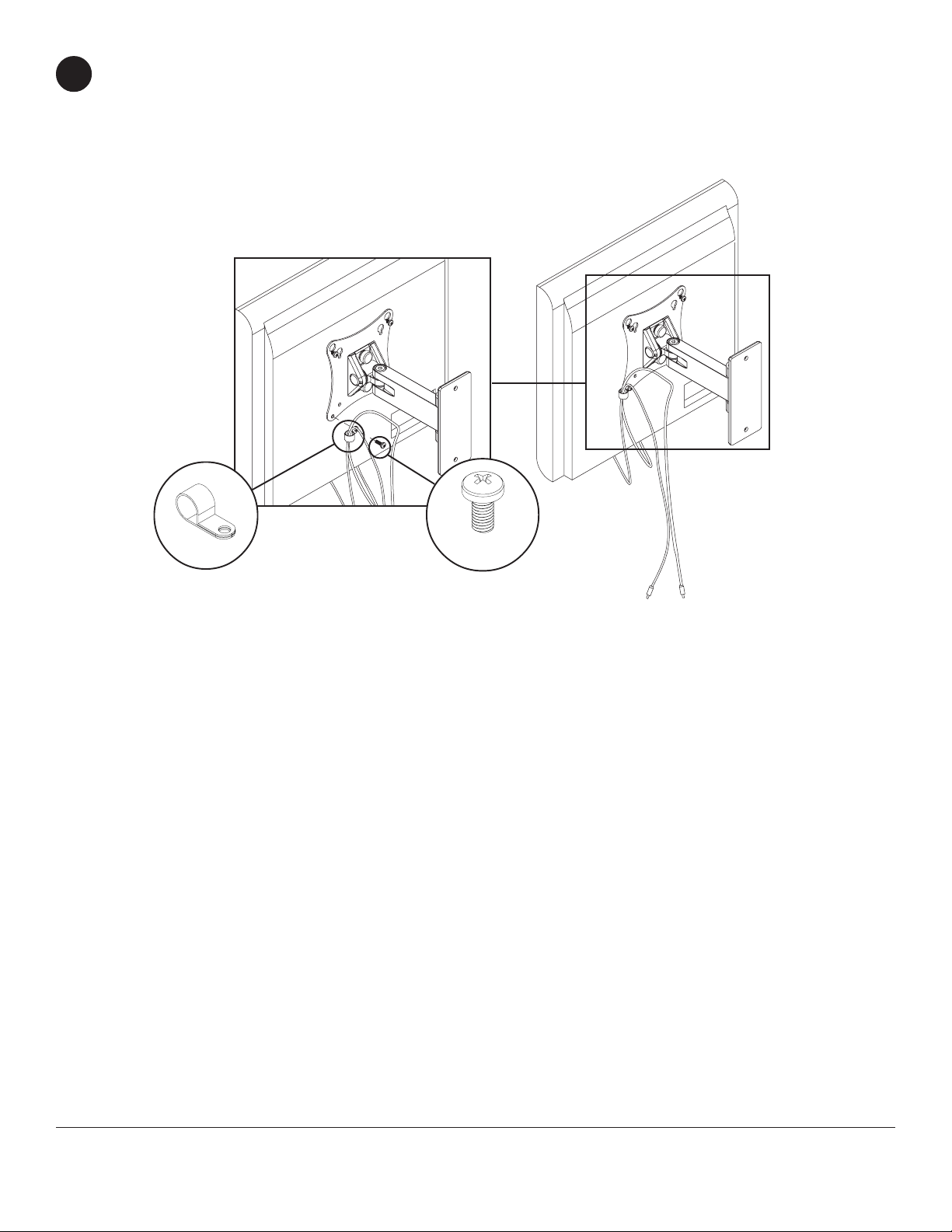

Route cords through center of cord management clip (B). Next, attach cord management clip (B) to adapter plate

4

using M4 screw (F or G) as shown in detail 1. Tighten all four screws (F or G).

Note: An additional cord management clip (B) was added for additional cords. If you want to use this additional clip,

remove the opposite bottom screw and repeat this step on opposite side of adapter plate.

B

detail 1

F or G

7 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 8

OPTIONAL

NOTE: Adjustment point s (socket screws) are factory torqued for optimal performance. This factory torque setting is

recommended to prevent the screen from slipping over time. If more or less tension is desired follow this optional

step. Y ou may not achieve optimal torque value if factory torque settings are adjusted.

If more or less tension is desired in tilt mechanism, remove snap caps as shown in detail 2. Insert a flat head screw

driver into slot and pry cap away from tilt mechanism. To adjust tilt, simply tighten or loosen socket screw no more

than half a turn using 5 mm allen wrench (I). To adjust roll, simply tighten or loosen 10-32 nylock nut.

WARNING

• Do not remove screw or loosen screw until it is no longer engaged with the mount. Doing so may cause the screen to fall.

10-32 NYLOCK NUT

SNAP CAP

SOCKET

SCREW

SLOT

If more or less tension is desired in the arm pivot points, do the following:

• To increase tension, turn socket screw clockwise with 3/16" allen wrench (C).

• To reduce tension, turn socket screw counter-clockwise with allen wrench (C). Do not turn more than half a turn.

SOCKET SCREW

detail 2

8 of 24

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

© 2006 Peerless Industries, Inc. All rights reserved.

Peerless is a registered trademark of Peerless Industries, Inc.

Page 9

Installation et assemblage :

Monture réglable pour fixation d’écran à cristaux

liquides sur un mur/une armoir e

Modèles : SP730P, SP730P-S, D-LPL-100, RTLPL-100S

Caractéristiques :

• Convient aux écrans à cristaux liquides de 25 à 55 cm (10 à 22 po)

• Le bras d’étend à une distance maximale de 15 cm (6 po) du mur et

se replie à plat pour économiser de la place

• Convient aux écrans dotés de trous de montage VESA® 75 ou 100

• L’écran comporte un joint à rotule qui accroît le pivotement latéral et

l’inclinaison vers le haut et vers le bas.

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 729-0307 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

Capacité de charge maximale :

1 1,3 kg (25 lb)

ISSUED: 06-10-05 SHEET #: 095-9225-7 08-28-06

R

Page 10

Remarques :

• Lisez entièrement la fiche d’instructions avant de commencer l’installation et l’assemblage.

• L'écran doit être fixé au bâti pour permettre l'inclinaison.

AVERTISSEMENT !

• Ne commencez pas à installer votre produit Peerless avant d’avoir lu et assimilé les instructions et les mises en

garde contenues dans cette fiche d’instructions. Pour toute question concernant les instructions ou les mises en

garde, appelez le service à la clientèle de Peerless au 01 1+1+(708) 865-8870.

• Ce produit ne doit être installé que par une personne ayant de bonnes aptitudes en mécanique, expérimentée en

travaux de construction de base, et démontrant une parfaite compréhension de ces instructions.

• Assurez-vous que la surface de support pourra soutenir sans difficulté la charge combinée de l’équipement, de toute

sa visserie et de tous ses composants.

• Ne montez jamais ce produit sur un mur à montants métalliques sans vous assurer que le montant est en acier de

calibre 25 au minimum, que la cloison sèche a au moins 12,5 mm (1/2 po) d’épaisseur et sans utiliser le kit

d’accessoires Peerless pour montants métalliques.

• Ne dépassez jamais la capacité de charge maximum.

• Si vous effectuez le montage sur un mur à montants en bois, assurez-vous que les vis de montage sont ancrées au

centre des montants.

• Pour lever et positionner l’équipement en toute sécurité, faites-vous toujours aider par une autre personne ou utilisez

un matériel de levage mécanique.

L ’usage d’un localisateur « bord à bord » est fortement conseillé.

• Serrez fermement les vis, mais sans excès. Un serrage excessif peut endommager les éléments et en réduire

considérablement le pouvoir de maintien. Référez-vous aux couples de serrage suggérés dans ces instructions, dans

les cas applicables.

Outils nécessaires pour l’assemblage

• localisateur de montants (le localisateur de montants « bord à bord » est recommandé)

• tournevis cruciforme

• perceuse à mèches de 6,35 mm (1/4 po) et 3,96 mm (5/32 po)

Accessoires

• Kit d’accessoires pour montants métalliques (ACC 908)

Table des matières

Liste des pièces ..................................................................................................................................................................11

Installation sur un mur à montants en bois ......................................................................................................................... 12

Installation sur du béton plein ou un bloc de béton de mâchefer ......................................................................................... 13

Pour le service à la clientèle, appelez le 01 1+1+(708) 865-8870.

10 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 11

RTLPL-100S

D-LPL-100

Liste des pi èces

Description QTÉ. Nº de P I ÈCE Nº de PI ÈCE

bras m ura l 1 095-0383-B 095-0383-S

A

clip à cordon 2 590-1264 590-2164

B

clé hexago nal e 3/16 po 1 560-0071 560-0071

C

vis à bois à t êt e plate nº14 x 2 1/ 2 po 2 520-1202 520-2165

D

anc rage A l l i ga tor® 2 590-0097 590-0097

E

vis cruc iforme M4 x 0,7 x 12 mm 4 504-9013 504-2013

F

vis cruc iforme M4 x 0,7 x 20 mm 4 504-9020 504-2014

G

entretoi se de retenue 4 590-5005 590-5003

H

clé hexago nal e 5 mm 1 560-9640 560-9640

I

SP730P SP730P-S

A

F

G

H

B

B

I

C

D

E

11 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 12

Installation sur un mur à montants en bois

AVERTISSEMENT !

• Assurez-vous que le mur pourra soutenir sans difficulté la charge combinée de l’équipement, de toute sa visserie et de

tous ses composants.

À l’aide d’un localisateur de montants, repérez et marquez les bords des montants en bois utilisés pour monter ce

1

produit. L’usage d’un localisateur bord à bord est fortement conseillé. Utilisez un niveau pour tracer une ligne

verticale le long du centre du montant. Utilisez la plaque murale comme gabarit pour marquer le centre des trous

situés le long de la ligne verticale. Percez deux trous de 4 mm (5/32 po) de diamètre et de 65 mm (2,5 po) de

profondeur. Fixez le bras mural (A) sur le mur à l’aide de deux vis à bois à tête plate nº14 x 2,5 po (D), comme

illustré.

Passez à l’étape 2, page 14.

AVERTISSEMENT !

• Serrez les vis de manière que la plaque murale soit fermement fixée, mais sans excès. Un serrage excessif peut

endommager les vis et en réduire considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

• Assurez-vous que les vis de montage sont ancrées au centre des montants. L ’usage d’un localisateur « bord à bord »

est fortement conseillé.

A

D

12 of 24

MUR À

MONTANTS

EN BOIS

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 13

Installation sur du béton plein ou un bloc de béton de mâchefer

AVERTISSEMENT !

• Si vous installez des montures murales Peerless sur un bloc de béton de mâchefer, vérifiez que vous disposez d’une

épaisseur de béton d’au moins 1 3/8 po dans le trou destiné aux ancrages de béton. Ne percez pas dans les joints

de mortier ! Veillez à ef fectuer le montage dans une partie pleine du bloc, généralement à au moins 1 po du côté du

bloc. Le bloc de béton de mâchefer doit être conforme aux spécifications de l’ASTM C-90. Pour percer le trou, il est

conseillé d’utiliser une perceuse électrique standard sur un réglage bas au lieu d’un marteau perforateur, afin d’éviter

de briser la partie arrière du trou lorsque vous pénétrez dans un vide ou une cavité.

• Le béton doit avoir une densité minimum de 2 000 psi.Un béton de densité moindre risquerait de ne pas retenir un

ancrage de béton.

• Assurez-vous que le mur pourra soutenir sans difficulté la charge combinée de l’équipement, de toute sa visserie et de

tous ses composants.

Mettez de niveau et utilisez la plaque murale comme

1

gabarit pour marquer le centre des trous. Percez

deux trous de 6 mm (1/4 po) de diamètre à une

profondeur minimum de 51 mm (2 po). Insérez les

ancrages (E) dans les trous au ras du mur, comme

illustré à la figure 1.3. Placez le bras mural (A) sur

l’ancrage et fixez avec une vis à bois (D), comme

illustré aux figures 1.4 et 1.6. Assurez-vous que le

bras est de niveau et serrez toutes les fixations.

Reportez-vous à la figure 1.5.

AVERTISSEMENT !

• Serrez les vis de manière que la plaque murale soit

fermement fixée, mais sans excès. Un serrage

excessif peut endommager les vis et en réduire

considérablement le pouvoir de maintien.

• Ne serrez jamais à plus de 9 Nm (80 po-lb).

AVERTISSEMENT !

• Les ancrages de béton ne sont pas prévus pour être

fixés sur un mur en béton recouvert d’une couche de

plâtre, une cloison sèche, ou autre matériau de

finition, comme illustré à droite. S’il est inévitable

d’effectuer le montage sur un mur en béton recouvert

de plâtre / cloison sèche, ces matériaux (jusqu’à 5/8

po d’épaisseur) doivent être chambrés, comme

illustré à droite. Assurez-vous que les ancrages de

béton ne se séparent pas du béton lorsque vous

serrez les vis. Si l’épaisseur du plâtre / de la cloison

sèche dépasse 5/8 po, des fixations adaptées

devront être fournies par l’installateur.

Percez des

trous et

insérez les

ancrages.

Placez la

plaque

murale sur

l’ancrage et

fixez avec

une vis.

Serrez

toutes les

fixations.

fig 1.3

fig 1.4

fig 1.5

D

E

PLAQUE MURALE

D

E

MUR EN BÉTON

E

CORRECT

A

plâtre /

VUE EN COUPE

cloison sèche

béton

INCORRECT

A

plâtre /

cloison sèche

béton

13 of 24

A

fig 1.6

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 14

AVERTISSEMENT !

• Si les vis ne sont pas enfoncées de trois tours complets dans les inserts ou si elles sont serrées au maximum sans

parvenir à fixer solidement le support, l’écran peut être abîmé ou le produit détérioré.

Remarque : Pour plus de sécurité, commandez les

vis de sécurité modèle ACC 918. V euillez consulter

le mode d’emploi des vis de sécurité ACC 918 avant

d’installer celles-ci.

Insérez deux vis M4 x 12 mm (F) dans les trous

2

supérieurs du moniteur, en laissant environ 0,64 cm

(1/4 po) de filetage exposé. Accrochez les vis aux

boutonnières de la plaque d’adaptation tel qu’indiqué

sur les figures 2.1 et 2.2.

*Remarque : Si les trous sont percés très près les

uns des autres, insérez deux vis M4 x 20 mm (G) et

deux entretoises de retenue (H) dans les deux trous

supérieurs du moniteur, tel qu’indiqué ci-contre.

* Dans le cas d’un

moniteur dont les trous

sont percés très près les

uns des autres, mettez des

entretoises (H) entre la plaque

d’adaptation et le moniteur.

F

H

1/4"

POUR UNE

DISPOSITION DE

MONT AGE VESAMD 75 :

POUR UNE

DISPOSITION DE

MONT AGE VESAMD 100 :

fig. 2.1

Insérez une vis M4 (F ou G) dans les trous inférieurs

3

de la plaque d’adaptation, tel qu’illustré à la figure 3.1.

Certains écrans

peuvent être

légèrement différents

de celui illustré ici.

fig. 2.2

PLAQUE

D’ADAPT ATION

PLAQUE

D’ADAPT ATION

14 of 24

F ou G

fig. 3.1

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 15

Mettez les cordons au centre de la bride de cordons (B). Ensuite, fixez la bride de cordons (B) à la plaque

4

d’adaptation à l’aide de vis M4 (F ou G) tel qu’illustré au détail 1. Serrez les quatre vis.

Remarque : L’emballage comprend une bride de cordons additionnelle (B) pour y placer des cordons

supplémentaires. Si vous désirez utiliser cette bride supplémentaire, retirez la vis inférieure opposée et refaites cette

étape du côté opposé du plateau d’adaptation.

B

détail 1

F ou G

15 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

© 2006 Peerless Industries, Inc. All rights reserved.

Page 16

OPTIONNEL

REMARQUE : Les points de réglage (vis à tête creuse) sont serrés à l’usine afin d’assurer une performance

optimale. Ce couple de serrage d’usine est celui que nous recommandons pour empêcher l’écran de glisser au fil du

temps. Si vous souhaitez augmenter ou diminuer la tension, suivez cette étape optionnelle. V ous risquez de ne pas

obtenir un serrage optimal si les réglages d’usine sont modifiés.

Si vous souhaitez augmenter ou diminuer la tension du mécanisme d’inclinaison, enlevez les capuchons

encliquetables comme illustré sur le détail 2. Insérez un tournevis à tête plate dans la fente et sortez le capuchon du

mécanisme d’inclinaison. Pour régler l’inclinaison, il suffit de serrer ou de desserrer la vis à tête creuse d’un

maximum d’un demi-tour à l’aide d’une clé hexagonale de 5 mm (I) Pour régler le roulis, il suffit de serrer ou de

desserrer l’écrou Nylock 10-32.

Procédez comme suit pour augmenter ou diminuer la tension des points de pivotement du bras :

A VERTISSEMENT

• N’enlevez pas la vis et ne la desserrez pas au point ou elle ne serait plus en contact avec la monture. Cela risquerait

de faire tomber l’écran.

ÉCROU NYLOCK

10-32

CAPUCHON

ENCLIQUETABLE

VIS À TÊTE

CREUSE

FENTE

• Pour augmenter la tension, tournez la vis à tête creuse dans le sens horaire avec la clé hexagonale de 5 mm (C).

• Pour diminuer la tension, tournez la vis à tête creuse dans le sens antihoraire avec la clé hexagonale (C). Ne tournez

pas de plus d’un demi-tour.

VIS À TÊTE CREUSE

détail 2

16 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 17

Instalación y montaje:

Soporte ajustable de pared o armario para pantalla LCD

Modelos: SP730P, SP730P-S, D-LPL-100, RTLPL-100S

Características:

• Apto para pantallas LCD de 10" a 22"

• El brazo se extiende hasta 6" de la pared o se pliega plano para

ahorrar espacio

• Soporta pantallas VESA® 75 ó 100 con agujeros de montaje

• Está provista de rótula en la pantalla para tener giro adicional de

lado a lado e inclinación hacia arriba y hacia abajo.

3215 W. North Ave. • Melrose Park, IL 60160 • (800) 729-0307 or (708) 865-8870 • Fax: (708) 865-2941 • www.peerlessmounts.com

Capacidad máxima de soportar carga:

25 lbs (1 1,3 kg)

ISSUED: 06-10-05 SHEET #: 095-9225-7 08-28-06

R

Page 18

Notas:

• Lea toda la hoja de instrucciones antes de iniciar la instalación y el montaje.

• La pantalla se debe unir al montaje para permitir la inclinación.

¡ADVERTENCIA!

• No comience la instalación de su producto Peerless sin antes haber leído y comprendido las instrucciones y los

avisos de precaución contenidos en esta hoja de instalación. Ante cualquier duda respecto a las instrucciones o

avisos de precaución, llame al departamento de servicio al cliente de Peerless al 00+1+(708) 865-8870.

• Este producto debe instalarlo una persona con buenas aptitudes mecánicas, experiencia en la construcción básica

de edificios y una comprensión total de estas instrucciones.

• Asegúrese de que la superficie de apoyo es capaz de soportar con toda seguridad la carga combinada del equipo y

todos los herrajes y componentes.

• Nunca monte este producto en una construcción de paredes con montantes (pies derechos) de metal a menos que

se pueda verificar que éstos están hechos de acero calibre 25 como mínimo, los tabiques de yeso-cartón tienen un

espesor mínimo de 1/2" y usted obtiene y utiliza el juego de accesorios Peerless para montantes de metal.

• Nunca sobrepase la capacidad máxima de carga.

• Si el montaje va ser en una construcción de paredes con montantes de madera, asegúrese de que los tornillos de

montaje estén anclados en el centro de los montantes. Se recomienda usar un localizador de montantes de “borde a

borde”.

• Siempre solicite la ayuda de un asistente o use un equipo de izar mecánico para levantar y colocar el equipo con

toda seguridad.

• Apriete los tornillos firmemente, pero no en exceso. El apriete excesivo puede dañar los artículos, reduciendo

enormemente su fuerza de fijación. Vea los valores de par de apriete sugeridos donde corresponda dentro de est as

instrucciones.

Herramientas necesarias para el montaje

• localizador de montantes (se recomienda usar el de “borde a borde”)

• destornillador phillips

• taladro con brocas de 1/4" y 5/32"

Accesorios

• Juego de accesorios para montantes de metal (ACC 908)

Contenido

Lista de piezas ................................................................................................................................................................... 19

Instalación en una pared con montantes de madera ........................................................................................................... 20

Instalación en una pared de concreto macizo y bloques de hormigón de escorias ............................................................. 21

Para atención al cliente, llame al 00+1+ (708) 865-8870.

18 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 19

RTLPL-100S

Lista de p iez as

Descripción Cant. N° de piez a N° de piez a

brazo de pared 1 095-0383-B 095-0383-S

A

cl ip para fijar el c ordón 2 590-1264 590-2164

B

llave allen de 3/16" 1 560-0071 560-0071

C

tornill o de c abez a pl ana para madera, #14 x 2-1/2" 2 520-1202 520-2165

D

Anclaje Alligator® 2 590-0097 590-0097

E

tornillo phillips M4 x 0,7 x 12 mm 4 504-9013 504-2013

F

tornillo phillips M4 x 0,7 x 20 mm 4 504-9020 504-2014

G

espac i ador de retenc ión 4 590-5005 590-5003

H

llave allen de 5 mm 1 560-9640 560-9640

I

SP730P SP730P-S

D-LPL-100

B

B

D

A

E

F

G

H

I

C

19 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 20

Instalación en una pared con montantes de madera

¡ADVERTENCIA!

• Asegúrese de que la pared es capaz de soportar con toda seguridad la carga combinada del equipo y todos los

herrajes y componentes.

Con la ayuda de un localizador de montantes, ubique y marque los bordes del montante de madera utilizado para

1

el montaje de este producto. Se recomienda usar un localizador de montantes de “borde a borde”. Use un nivel

para trazar una línea vertical por el centro del montante. Use la placa de pared como plantilla para marcar el

centro de los agujeros a lo largo de la línea vertical. Taladre dos agujeros de 5/32" (4 mm) de diámetro y 2.5" (65

mm) de profundidad. Fije el conjunto de brazo de pared (A) a la pared con los dos tornillos de cabeza plana #14 x

2.5" (D), como se muestra.

Proceda al paso 2 en la página 22.

¡ADVERTENCIA!

• Apriete los tornillos de tal modo que la placa de apoyo quede firmemente sujeta, pero no apriete en exceso. El

apriete excesivo puede dañar los tornillos, reduciendo enormemente su fuerza de fijación.

• Nunca apriete más de 80 pulg-lb (9 N•m).

• Asegúrese de que los tornillos de montaje queden fijados en el centro de los montantes. Se recomienda usar un

localizador de montantes de “borde a borde”.

A

D

20 of 24

PARED CON

MONTANTES DE

MADERA

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 21

Instalación en una pared de concreto macizo y bloques de hormigón de escorias

¡ADVERTENCIA!

• Cuando instale montajes de pared Peerless en bloques de hormigón de escorias, verifique que tiene un mínimo de

1-3/8" de superficie efectiva de concreto en el agujero que va a utilizar para los anclajes de concreto. ¡No perfore en

las juntas de mortero! Asegúrese de instalarlo en una parte sólida del bloque, generalmente a un mínimo de 1" del

costado del bloque. El bloque de hormigón de escorias debe ser de conformidad con las especificaciones C-90 de

ASTM. Se sugiere taladrar el agujero con un taladro eléctrico normal en velocidad lenta en vez de un taladro percutor

para evitar romper la parte trasera del agujero al entrar en un espacio o cavidad.

• El concreto debe tener una densidad mínima de 2000 psi. Un concreto menos denso podría no sujetar el anclaje para

concreto.

• Asegúrese de que la pared es capaz de soportar con toda seguridad la carga combinada del equipo y todos los

herrajes y componentes.

Nivele y utilice la placa de apoyo como plantilla

1

para marcar el centro de los agujeros. Taladre dos

agujeros de 1/4" (6 mm) de diámetro hasta una

profundidad mínima de 2" (51 mm). Inserte los

anclajes (E) en los agujeros a ras con la pared,

como se muestra en la figura 1.3. Coloque el brazo

de pared (A) sobre el anclaje y sujételo con el

tornillo para madera (D), como se muestra en las

figuras 1.4 y 1.6. Asegúrese de que el brazo de

pared esté nivelado y después apriete todas las

fijaciones. Vea la figura 1.5.

¡ADVERTENCIA!

• Apriete los tornillos de tal modo que la placa de

apoyo quede firmemente sujeta, pero no apriete en

exceso. El apriete excesivo puede dañar los tornillos,

reduciendo enormemente su fuerza de fijación.

• Nunca apriete más de 80 pulg-lb (9 N•m).

¡ADVERTENCIA!

• Los anclajes de concreto no están diseñados para

fijación a paredes de concreto recubiertas con una

capa de yeso, tabique de yeso-cartón, u otros

materiales de acabado, como se muestra a la

derecha. Si no se puede evitar el montaje a una

pared de concreto recubierta con yeso/tabique de

yeso-cartón, (hasta 5/8" de grosor), será necesario

escariar el acabado. Asegúrese de que los anclajes

de concreto no se alejan del concreto al apretar los

tornillos. Si la pared de yeso/tabique de yeso-cartón

es más gruesa que 5/8", el instalador deberá

suministrar fijaciones especiales.

Perfore los

agujeros y

después

inserte los

anclajes.

Coloque la

placa de

apoyo sobre

el anclaje y

sujétela con

el tornillo.

Apriete

todas las

fijaciones.

A

D

fig 1.3

fig 1.4

fig 1.5

PARED DE

CONCRETO

E

PLACA DE

APOYO

D

E

PARED DE CONCRET O

E

A

VISTA EN CORTE

CORRECTO

pared de

yeso/tabique

yeso-cartón

concreto

INCORRECTO

A

pared de

yeso/tabique

yeso-cartón

concreto

21 of 24

fig 1.6

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 22

¡ADVERTENCIA!

• Si los tornillos no pueden atornillarse tres vueltas completas en los insertos de la pantalla, o si los tornillos topan

fondo y la escuadra todavía no está firmemente sujeta, se podría dañar la pantalla o causar la falla del producto.

Nota: Para mayor seguridad, ordene ACC 918 para

tornillos de seguridad. Refiérase a la hoja de

instrucciones de ACC 918 p ara instalar los tornillos

de seguridad.

Coloque dos tornillos M4 x 2 mm (F) en los dos

2

agujeros superiores de la pantalla; deje

aproximadamente 1/4" de la rosca expuesta.

Enganche los tornillos en las ranuras de la placa

adaptadora como se indica en las figuras 2.1 y 2.2.

*Nota: Si la configuración de agujeros está en una

cavidad, coloque dos tornillos M4 x 20 mm (G) con

dos espaciadores de retención (H) en los dos

agujeros superiores como se indica “correcto”.

*En el caso de las pantallas que tienen la

configuración de agujeros en una

cavidad, los espaciadores (H) van entre

la placa adaptadora y la pantalla.

F

1/4"

H

EN EL CASO DE LA

CONFIGURACIÓN DE

MONT AJE DE VESA® 75:

EN EL CASO DE LA

CONFIGURACIÓN DE

MONT AJE DE VESA® 100:

fig. 2.1

Coloque un tornillo M4 (F o G) a través del agujero

3

inferior de la placa adaptadora como se muestra en

la figura 3.1.

La pantalla puede verse

un poco diferente a la

ilustración.

fig. 2.2

PLACA

ADAPTADORA

PLACA

ADAPTADORA

22 of 24

F o G

fig. 3.1

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 23

Pase los cables por el centro del clip de fijación de cables (B). Después fije el clip de fijación de cables (B) a la

4

placa adaptadora usando un tornillo M4 (F o G) como se muestra en el detalle 1. Apriete los cuatro tornillos (F o G).

Nota: Se agregó un clip de fijación de cables (B) para los cables adicionales. Si quiere usar el clip adicional (B),

quite el tornillo inferior del lado opuesto y repita este paso en el otro lado de la placa adaptadora.

B

detalle 1

F o G

23 of 24

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

Page 24

OPTATIVO

NOTA: Los puntos de ajuste (tornillos de cabeza hueca) son apretados en fábrica para tener un rendimiento óptimo.

Esta torsión de fábrica se recomienda para prevenir que se deslice la pantalla con el tiempo. Si se desea mayor o

menor tensión siga este paso opcional. Es posible que no reciba el valor óptimo de torsión si se ajusta la torsión de

fábrica.

Si se desea mayor o menor tensión en el mecanismo de inclinación, quite las tapas de presión como se muestra en

el detalle 2. Inserte un desarmador de punta plana en la ranura y levante y retire la tapa del mecanismo de

inclinación. Para ajustar la inclinación, simplemente apriete o afloje los tornillos de cabeza hueca no más de media

vuelta usando una llave allen 5mm (I). Para ajustar el giro, simplemente apriete o afloje la tuerca Nylock del número

Si se desea mayor tensión en los puntos de pivote del brazo, haga lo siguiente:

10-32.

¡ADVERTENCIA!

• No quite ni afloje el tornillo hasta que ya no esté enganchado al soporte. Hacerlo podría causar que se caiga la

pantalla.

TUERCA NYLOCK

DEL NÚMERO 10-32

TAP A DE PRESIÓN

TORNILLO DE

CABEZA HUECA

RANURA

• Para aumentar la tensión, gire el tornillo de cabeza hueca hacia la derecha con una llave allen de 3/16" (C).

• Para reducir la tensión, gire el tornillo de cabeza hueca hacia la izquierda con la llave allen T(C). No gire más de la

mitad de una vuelta.

TORNILLO DE CABEZA HUECA

detalle 2

24 of 24

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 06-10-05 SHEET #: 095-9225-8 09-25-06

© 2006 Peerless Industries, Inc. All rights reserved.

Peerless is a registered trademark of Peerless Industries, Inc.

Loading...

Loading...