Page 1

Monarch 415

Rewind

Operator’s Handbook

TM

TC0415OH Rev. D 5/96 ©1990-96 Monarch Marking Systems, Inc. All rights reserved.

Page 2

Each product and program carries a respective written

warranty, the only warranty on which the customer can rely.

Monarch reserves the right to make changes in the product

and the programs and their availability at any time and without

notice. Although Monarch has made every effort to provide

complete and accurate information in this manual, Monarch

shall not be liable for any omissions or inaccuracies. Any

update will be incorporated in a later edition of this manual.

Trademarks

MONARCH is a registered trademark of Monarch Marking Systems, Inc.

415 is a trademark of Monarch Marking Systems, Inc.

Paxar is a trademark of Paxar Corporation.

Monarch Marking Systems

P.O. Box 608

Dayton, Ohio 45401

Page 3

Table of Contents

1. Setting Up

2. Connecting Supplies

Rewinding on the Hub.................................................. 3

Rewinding on a Paper Core ......................................... 5

3. Operating the Rewind

Starting......................................................................... 7

Stopping ....................................................................... 8

4. Changing Hubs

5. Burster Option Setup and Operation

Supply Removal ......................................................... 19

.......................................................................... 1

........................................................ 3

....................................................... 7

................................................................. 9

............................ 11

6. Specifications and Supplies

7. Troubleshooting

Appendix A: Rewind Alignment

............................................................... 22

.......................................... 21

......................................... 23

i

Page 4

Monarch 415 Rewind Operator’s Handbook

ii

Page 5

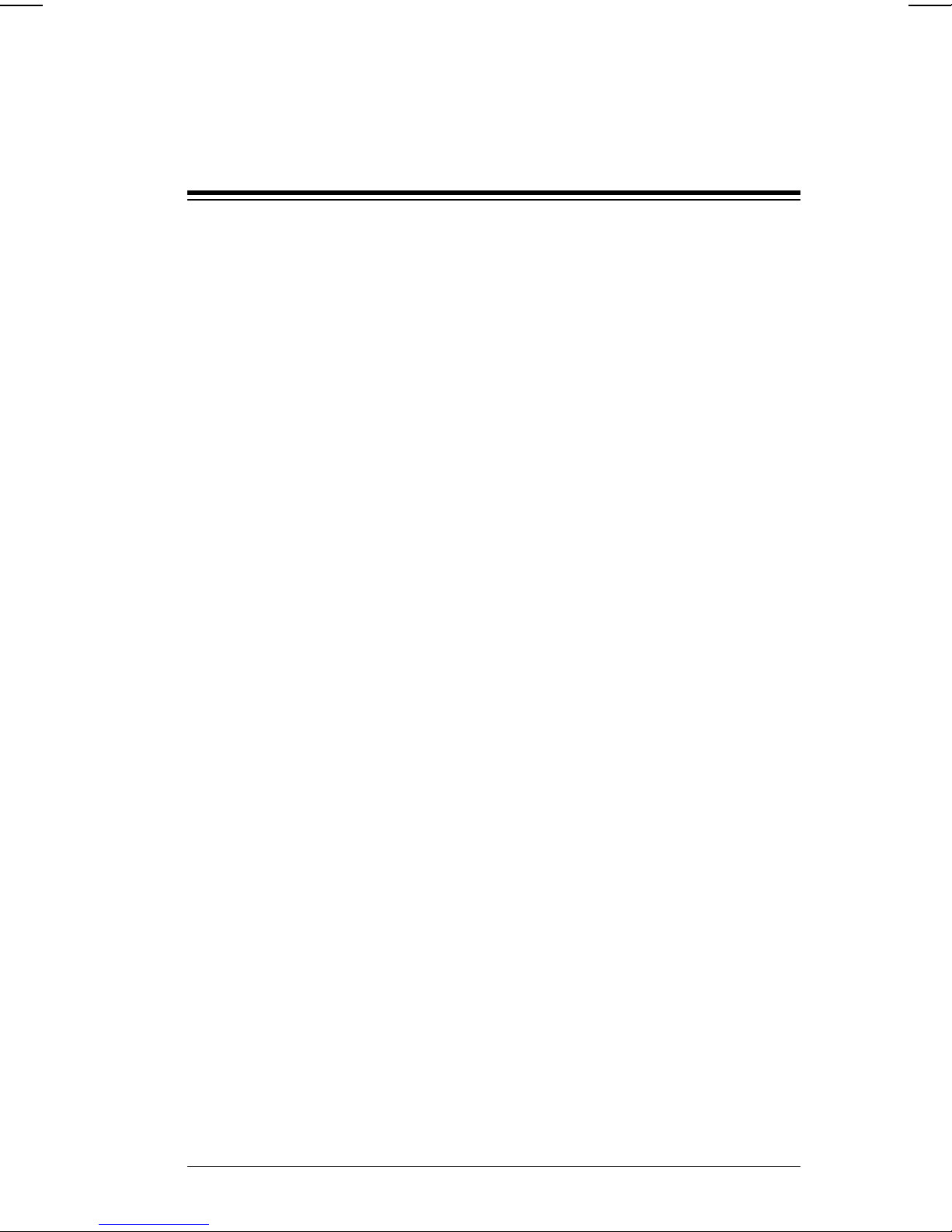

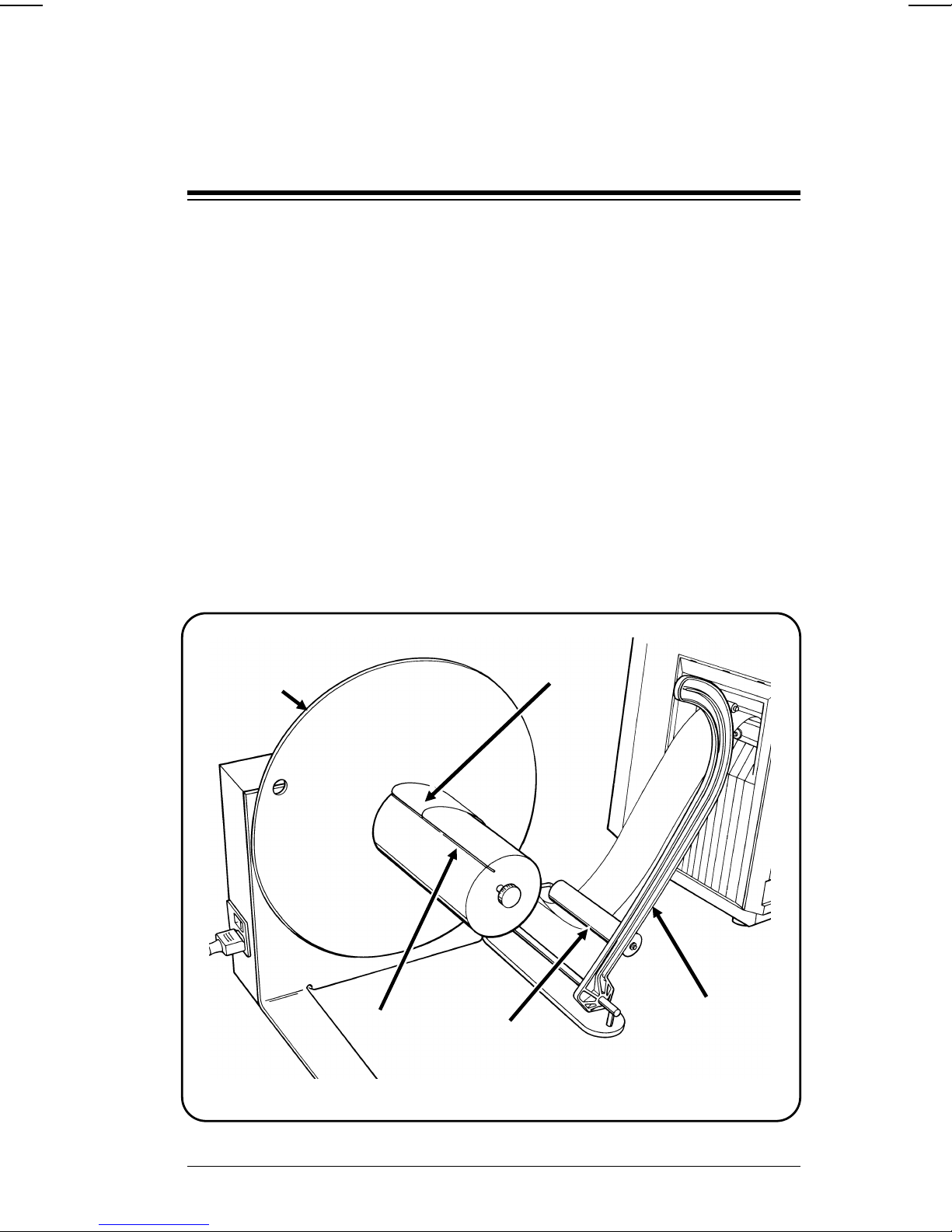

1. Setting Up

Push the 415 Rewind power switch

1.

Place the rewind on a level surface. Be sure it is at least

2.

OFF

.

ten inches away from the supply exit of the printer

(Figure 1).

Squarely align the rewind’s hub flange with the edge of the

3.

supply. See Appendix A, "Rewind Alignment."

Hub

Flange

Power

Switch

Hub

Printer

Supply

Exit

Figure 1

1

Page 6

Monarch 415 Rewind Operator’s Handbook

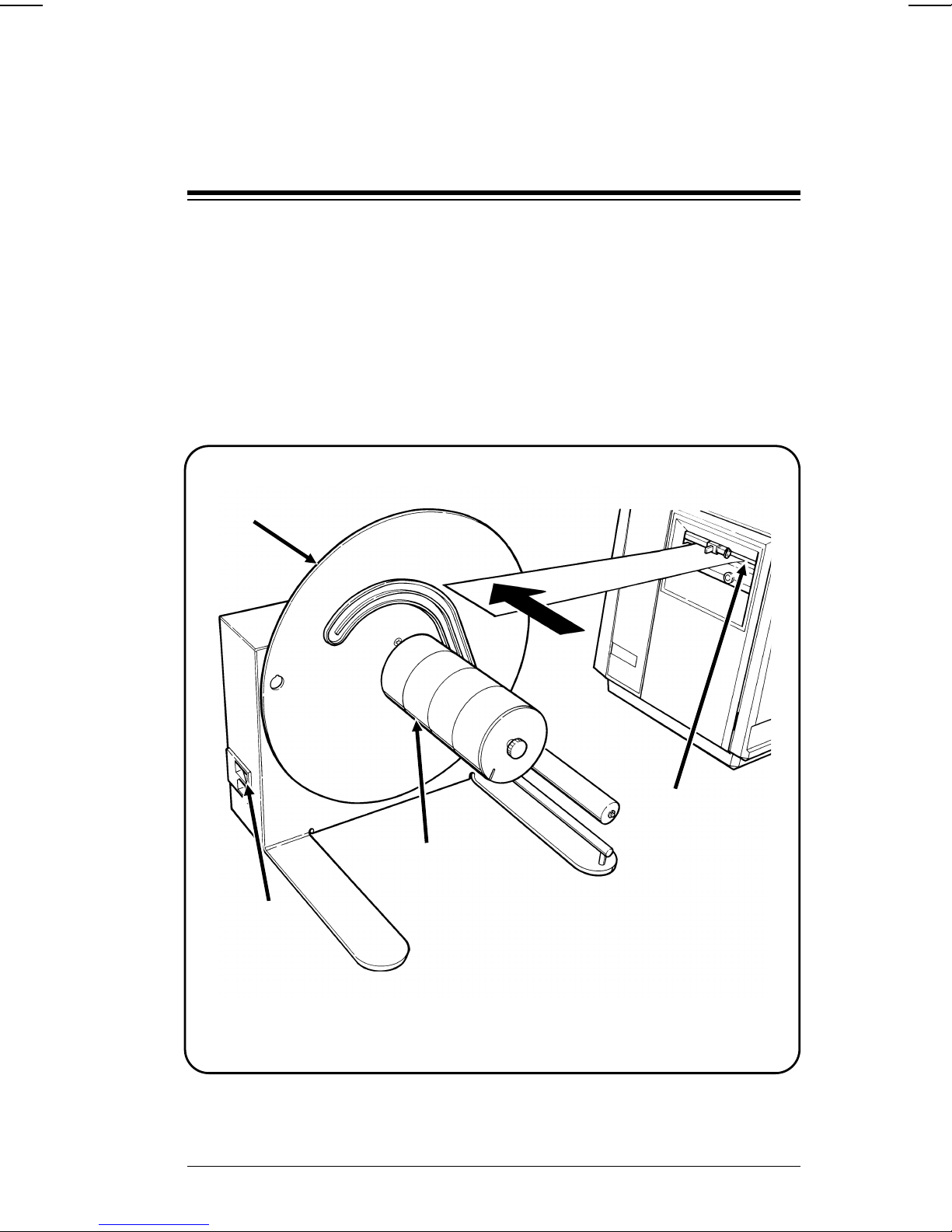

Plug the power cord into the rewind (Figure 2). Then, plug

4.

the power cord into a grounded electrical outlet.

Fuse Holder

Power

Cord

Power

Switch

Figure 2

2

Page 7

2. Connecting Supplies

Rewinding on the Hub

Slide the supply guide away from the hub flange and pull it

1.

away from the hub.

Print or feed enough supplies from the printer to wrap

2.

around the hub one and one half times.

Hold the hub flange and twist the hub

3.

clockwise

until it

stops.

Thread the supply strip under the dancer roller.

4.

Fold and insert the end of the supply strip into the slot

5.

(Figure 3). Be sure the supply is against the hub flange.

Supply

Hub

Flange

Strip

Slot

Dancer

Roller

Figure 3

Supply

Guide

3

Page 8

Monarch 415 Rewind Operator’s Handbook

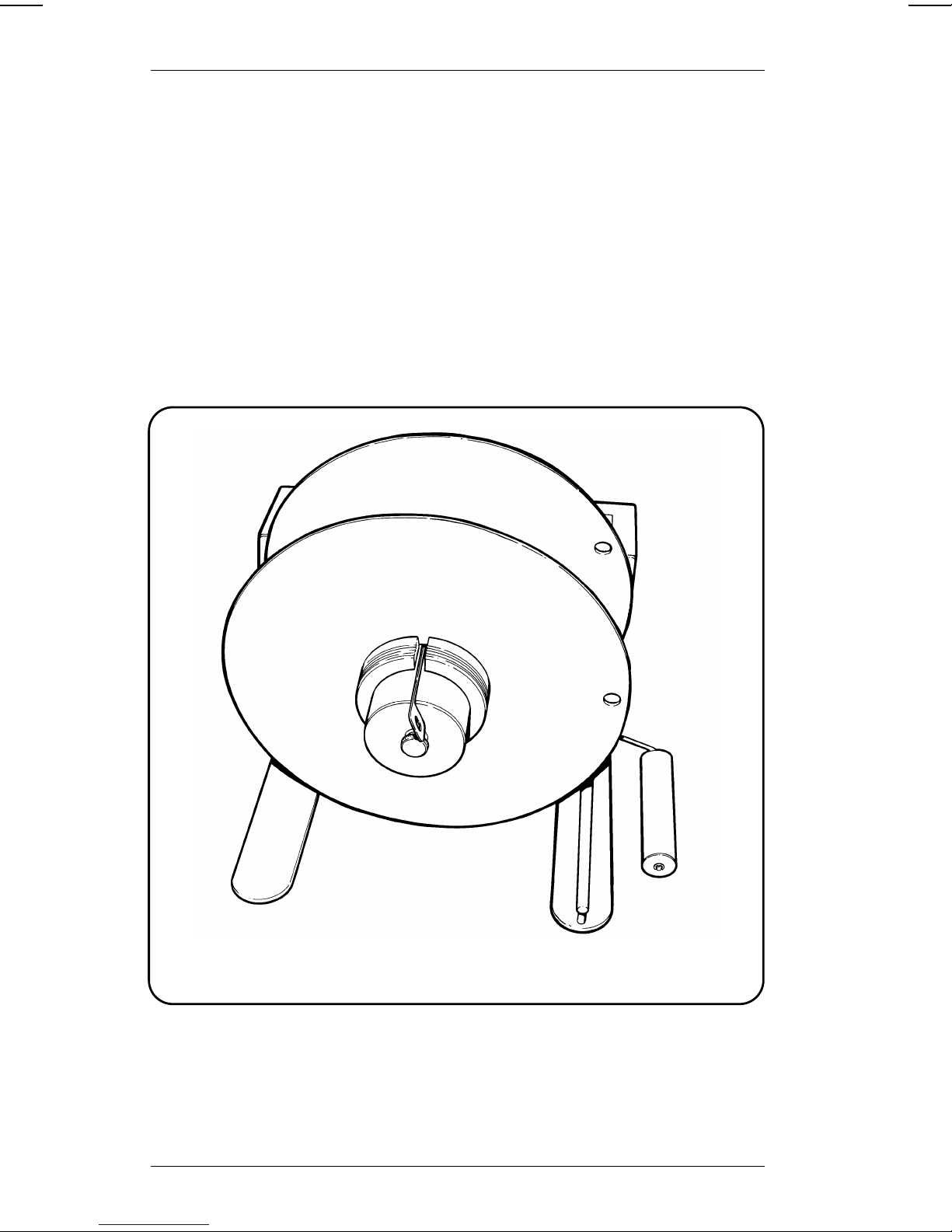

Turn the hub and hub flange at least one full turn

6.

counterclockwise

Push the supply guide against the hub then slide it against

7.

to tighten the supply strip.

the supply.

NOTE:

Units with 3" hubs have a flanged disk instead of

a supply guide.

Slide this disk over the hub and against the

stock/core (Figure 4).

4

Figure 4

Page 9

2. Connecting Supplies

Rewinding on a Paper Core

Slide the supply guide away from the hub flange and pull it

1.

away from the hub.

Push the paper core on the hub until it is against the hub

2.

flange.

Hold the hub flange and twist the hub

3.

clockwise

until the

paper core is tight.

Tape the supply strip to the paper core (Figure 5). Be sure

4.

the supply is against the hub flange.

Hub

Flange

Supply

Tape

Strip

Paper

Core

Hub

Figure 5

5

Page 10

Monarch 415 Rewind Operator’s Handbook

Turn the hub and hub flange at least one full turn

5.

counterclockwise

Push the supply guide against the hub then slide it against

6.

to tighten the supply strip.

the supply.

6

Page 11

3. Operating the Rewind

Starting

Turn the speed control knob (Figure 6) to

1.

Push the rewind power switch (Figure 7)

2.

NOTE:

The rewind will start to turn. When the dancer

SLOW

ON

roller is almost horizontal, the rewind will stop.

Start the printer.

3.

Adjust the rewind speed to the speed of the printer.

4.

NOTE:

If you stop the printer, the rewind will stop. If the

printer runs out of supplies, the rewind will keep

running until you turn it off.

Speed Control

Knob

.

.

Figure 6

Power

Switch

Figure 7

7

Page 12

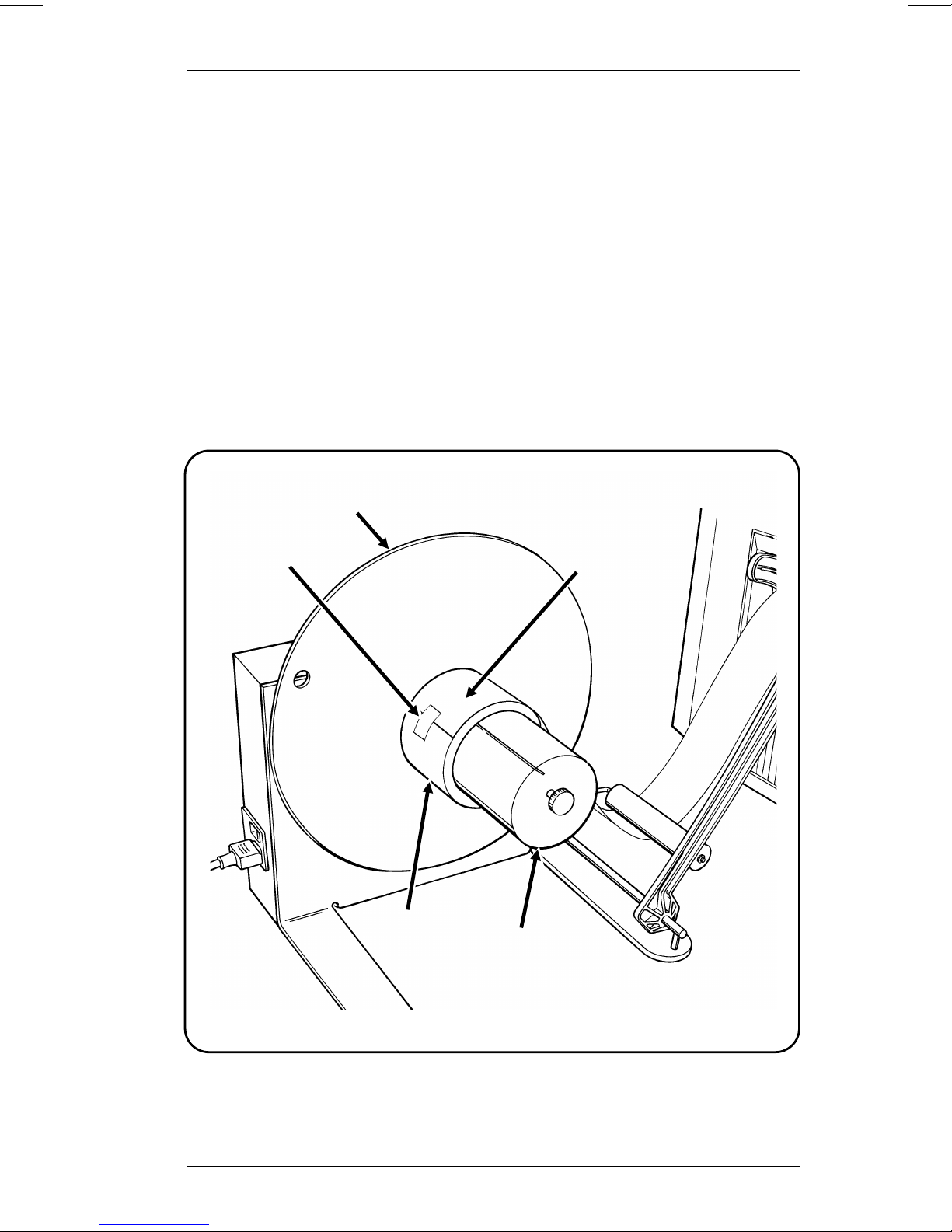

Monarch 415 Rewind Operator’s Handbook

Stopping

Stop the printer.

1.

Push the rewind power switch

2.

Pull the supply guide away from the hub.

3.

Cut the supply at the supply exit of the printer (Figure 8).

4.

Tape the end of the supply to the roll on the rewind.

5.

Pull the supply guide away from hub.

6.

Hold the hub flange and turn the hub

7.

OFF

.

counterclockwise

until the roll is loose.

Slide the roll off the hub.

8.

Supply

Strip

Figure 8

8

Page 13

4. Changing Hubs

If you change to a different supply, you may need to use a

different hub. One, three, and four inch diameter hubs (short

and long) are available from Monarch.

To change hubs

Pull the supply guide away from the hub (Figure 9).

1.

Supply

Guide

Figure 9

Unscrew the hub knob (Figure 10).

2.

NOTE:

The hub diameter must be the same as the inside

diameter of the supplies.

Hub

Sections

Figure 10

Hub

Knob

9

Page 14

Monarch 415 Rewind Operator’s Handbook

Remove the hub sections and replace them with the new

3.

ones (Figure 11).

Slide the new hub spindle on the shaft. Be sure the

a.

notch fits over the raised portion of the hub flange.

Slide the hub sections on to the shaft with the open

b.

ends facing out. The hub section that fits against the

hub spindle has two curved grooves instead of peg

holes. Be sure the slot in this section is aligned with

the smaller side of the hub spindle. Also be sure the

slots in the rest of the hub sections are aligned with

this section.

Slide the hub end on.

c.

NOTE:

For a four or six inch long hub, screw on the

extension shaft before you install the hub

sections.

Screw the hub knob on.

d.

Hub

Hub

End

Hub

Spindles

Extension

Shaft

Hub

Knob

10

Figure 11

Page 15

5. Burster Option Setup and

Operation

Proper positioning of the printer, burster, and supplies is

critical.

Place the Rewind/Burster assembly in the proper position

1.

in front of the printer. A drawing showing the correct

position for all supported printers and optional location

guides for alignment is inside the back cover.

Print or feed approximately 36 inches of labels from the

2.

printer.

Bend and separate the supply along the perforations into

3.

individual strips for about 18 inches (Figure 12).

Figure 12

11

Page 16

Monarch 415 Rewind Operator’s Handbook

Figure 13 shows the burster with the supplies installed.

4.

Place the separator bars in their approximate working

positions (i.e. in line with the perforations). When only one

bar is needed (for two part supply), slide unused bar to the

outboard side.

Separator

Bars

Figure 13

Thread the inner strip of supplies under the dancer arm

5.

roller, behind the two lower burster shafts, and in front of

the top shaft.

Thread the middle strip under the dancer arm roller,

6.

behind the lower burster shaft, and in front of the two top

shafts.

Thread the outer strip under the dancer arm roller, behind

7.

the two lower burster shafts, and in front of the top shaft.

12

Page 17

5. Burster Option Setup and Operation

Slide the first core onto the 415 hub until it is against the

8.

hub flange.

Hold the hub flange and twist the hub clockwise until the

9.

paper core is tight.

Position the slot in the hub to the top.

10.

Align the leading edge of the first label on the inside strip

11.

with the slot in the hub and tape the supply to the core

(Figure 14).

Label Edge

Slot

Figure 14

13

Page 18

Monarch 415 Rewind Operator’s Handbook

Slide the separator disk and the next core onto the hub

12.

(Figure 15).

Hold the core against the separator disk, insert the core

13.

lock (metal strip) into the slot, and slide it into the core.

Align the leading edge of the first label on the middle strip

14.

with the slot in the hub and tape the supply to the core.

First Separator

Label

Edge

Disk

Slot

Core

Lock

Figure 15

14

Page 19

5. Burster Option Setup and Operation

Hold the second separator disk with the inside notch up

15.

(in line with the core lock) and slide it onto the hub (Figure

16).

Place the third core over the core lock and slide it onto the

16.

hub.

Second Separator

Disk

Notch in

Disk

Core Lock

Figure 16

Third

Core

15

Page 20

Monarch 415 Rewind Operator’s Handbook

Slide the third core against the second separator disk

17.

(Figure 17).

Align the leading edge of the first label on the outside strip

18.

with the slot in the hub and tape the supply to the core.

Second

Label Edge

Separator Disk

Figure 17

Slot

16

Page 21

5. Burster Option Setup and Operation

Hold the flanged collar assembly with the opening in the

19.

collar up. Then install it on the hub as shown in Figure 18.

Opening in

Collar

Figure 18

17

Page 22

Monarch 415 Rewind Operator’s Handbook

Recheck the printer to rewind alignment and fine adjust as

20.

necessary.

Verify that the separator bars are located between the

21.

strip as shown in Figure 19.

Verify that the labels on all three strips are aligned.

22.

NOTE:

All labels must be aligned as though the supply

was never separated to prevent torn strips or

labels coming off.

Label

Edges

Turn the flange counterclockwise to take up any slack in

23.

the strips.

Set the speed control knob to SLOW.

24.

Turn on the rewind, operate the printer, and increase the

25.

speed if necessary.

18

Separator

Bars

Figure 19

Page 23

5. Burster Option Setup and Operation

Supply Removal

Remove the core lock (metal strip).

1.

Remove the flanged collar assembly.

2.

Remove the outside core and roll of labels.

3.

Remove the second separator disk.

4.

Remove the middle core and roll of labels.

5.

Remove the inside separator disk.

6.

Unlock the inside core.

7.

Remove the inside core and roll of labels

8.

19

Page 24

Monarch 415 Rewind Operator’s Handbook

20

Page 25

6. Specifications and Supplies

Specifications

Height:

Width:

Depth:

Weight:

Shipping Weight:

Power:

Fuse:

Temperature:

Relative Humidity:

Hub Diameter:

(Options)

13.75 inches (349.25 mm)

12.50 inches (317.5 mm)

11.5 inches (292.10 mm)

18 lbs. (8.14 kg)

20 lbs. (9.05 kg)

115 VAC 60 HZ 30 Watts .3 Amps

220/240 50/60 HZ 30 Watts .15 Amps

3/8 Amp

Operating: 50° to 95° F (10° to 35° C)

Storage: 15° to 120° F (-9° to 49° C)

Operating: 10 to 80%

Storage: 5 to 90%

1 inch (25 mm)

3 inch (76 mm)

4 inch (102 mm)

Hub Lengths: 3.62 inch (91.9 mm)

6.75 inch (171.5 mm)

Supplies

Supply Thickness

Tags or Labels:

Supply Width:

3.62 inch shaft

(91.9 mm)

6.75 inch shaft

(171.5 mm)

Minimum: .007 inches (.17 mm)

Maximum: .015 inches ( .4 mm)

Minimum: .75 inches (19.05 mm)

Maximum: 3.37 inches (85.6 mm)

Minimum: .75 inches (19.05 mm)

Maximum: 6.5 inches (165 mm)

21

Page 26

7. Troubleshooting

Problem Corrective Action

Power switch light does

not light.

Dancer arm does not

activate the rewind.

Connect the power cord.

Call Monarch Service.

Make sure the rewind is on a level

surface.

22

Page 27

Appendix A:

Rewind Alignment

Location Guide 113580

Location Guide 113576

Location Guide not availabl e

Location Guide 113576

Location Guide 113576

Location Guide 113576

Location Guide 114664

23

Page 28

For supplies, service, or assistance call:

TOLL FREE:

1-800-543-6650 (In the U.S.A.)

1-800-263-4650 (In Canada)

www.paxar.com

Loading...

Loading...