Page 1

Quick

Quick

Reference

Reference

Monarch

9855 RFID

®

Printer

®

TC9855RFIDQR Rev. AN 4/08 ©2007 Paxar Americas, Inc. a subsidiary of Avery Dennison Corp. All rights reserved.

Page 2

Each product and program carries a respective written warranty, the only warranty on

which the customer can rel y. Paxar reserves the right to make changes in the product, the

programs, and their availability at any time and without notice. Although Paxar has made

every effort to provide complete and accurate information in this manual, Paxar shall not be

liable for any omissions or inaccuracies. Any update will be incorporated in a later edition

of this manual.

© 2007 Paxar Americas, Inc. a subsidiary of Avery Dennison Corp. All rights reserved. No

part of this publicatio n may be reproduced, transmitte d, stored in a retrieval system, or

translated into any language in any form by any means, without the prior written permission

of Paxar Americas, Inc.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instr uction manual, may cause harm ful interference to radio communic ations.

Operation of this equipment in a residential area is likely to cause harmful interfe rence in which case

the user will be required to correct the interference at his own expense.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Réglement s ur le brouillage

radioélectrique édicte par le minist ère des Communications du Canada.

Radio Frequency Interference Requirements

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interferenc e, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

WARNING

CANADIAN D.O.C. WARNING

Trademarks

Monarch® and 9855 are trademarks of Paxar Americas, Inc.

Avery Dennison® is a trademark of Avery Dennison Corp.

EPCglobal, Inc.™ and Electronic Product Code™ (EPC) are trademarks of Uniform Code

Council, Inc. Uniform Code Council, Inc.® is a trademark of Uniform Code Council, Inc.

Avery Dennison Printer Systems Division

170 Monarch Lane

Miamisburg, OH 45342

Visit www.monarch.com for sales, service, supplies, information, and telephone numbers

for our International locations.

TOLL FREE:

1-800-543-6650 (U.S.A.)

1-800-363-7525 (Canada)

Page 3

Introduction

This Quick Reference contains supply loading and genera l maintenance

procedures. Additional RFID documents are available on the enclosed CD-ROM

and on our Web site (www .monarch.com).

Note: Information in this document supercedes information in previous versions.

Check our Web site for the latest documentation and release information.

RFID Overview

Your printer has been engineered to program (encode) an RFID (Radio Frequency

Identification) label (commonly called “RFID tags”) before the label’s format is

printed. RFID tags contain an embedded RFID inlay (chip and antenna).

RFID is only available on the Monarch® 9855™ printer using die cut or black mark

supplies. Linerless supplies are not currently suppor ted. The RFID printer is also

capable of printing standard (non-RFID) supplies. For more information about

supplies, see “RFID Supply Specifications.”

The UHF printer supports multi-protocol encoding, inc luding Class 1 Generation 1

(C1Gen1), Class 1 Generation 2 (C1Gen2), and EM4122 supplies.

The HF printer supports multi-protocol encoding, including ISO15693 and I•CODE®

UID protocols.

About Professional Services

Our Professional Services group can develop cus tom RFID scripts (applications) or

other types of data manipulation scrip ts. Our experts can ensure your RF ID

requirements are met. Custom programming can be fac tory-loaded at the time of

shipment. Call Customer Service for more information.

1

Page 4

Web Sites with RFID Information

AIM Gl obal

The association for Automatic Identification and Mobility.

EPCglobal, Inc.™

A joint venture between EAN International and the Uniform

Code Council, Inc., creating RFID standards for the

Electronic Product Code™ (EPC).

RFID Journal

An independent media company specializing in RFID.

Uniform Code Council, Inc.®

A global standards organization in supply chain management.

Avicon

Provides software to translate legacy codes to electronic

product codes (EPC) for Class 1 96-bit (and more)

representations.

www.aimglobal.org

www.epcglobalinc.org

www.rfidjournal.com

www.uc-council.org

www.epctranslato r.com

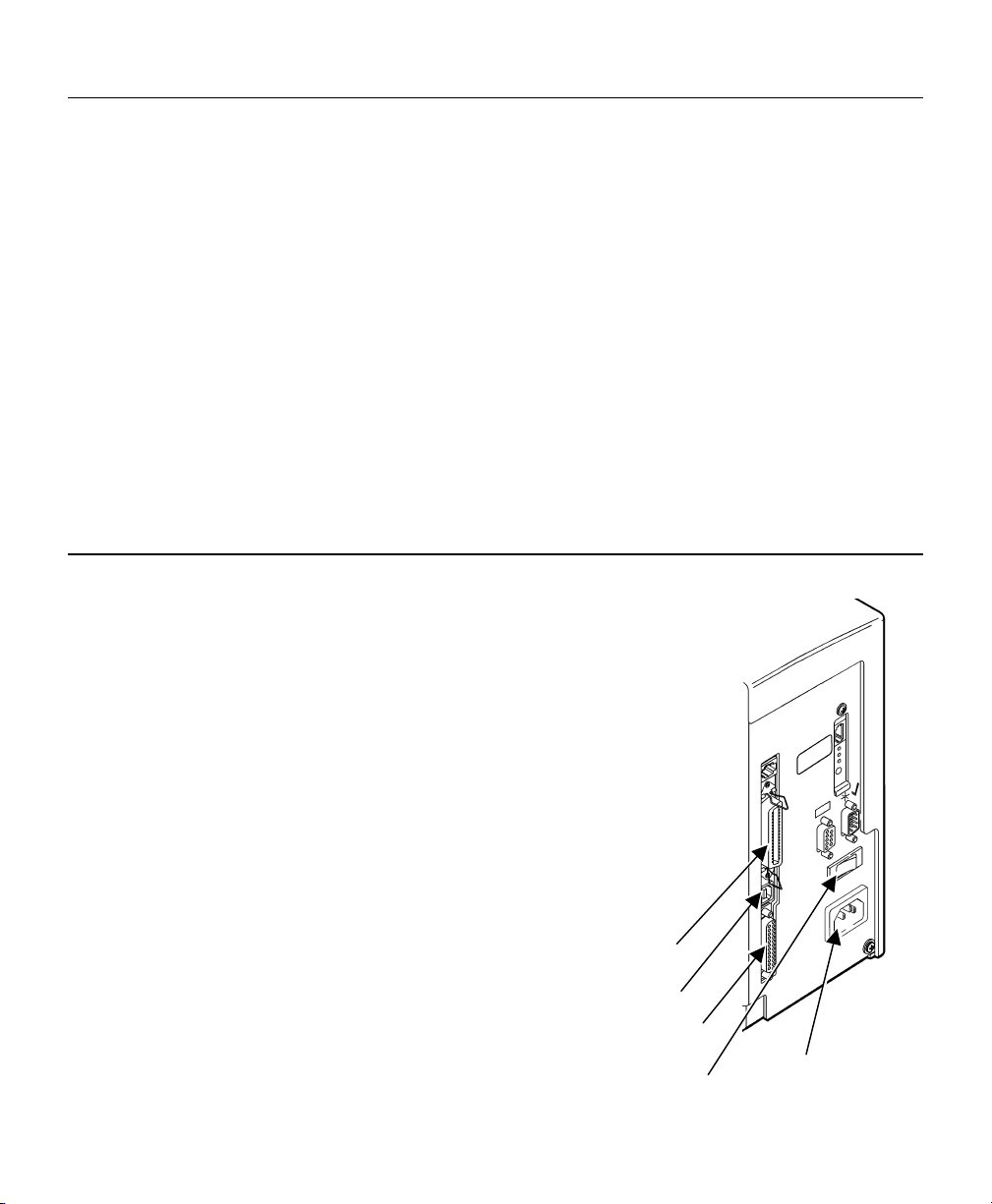

Connecting the Cables

The power supply automatically switches between 115V or 23 0V. There are no

operator settings required.

1. Plug the power cable into the socket. Plug the other end of

the cable into a grounded electrical outlet.

2. Connect the communication cable into the appropr iate port.

Secure the cable with the connecting screws (ser ial) or

spring clips (parallel).

If you are communicating with the host through the serial

port, make sure the printer's communication va lues match

those at the host. The factory default values are 9600 Baud,

8 bit data frame, 1 stop bit, no parity, and DTR flow control

(9600, N, 8, 1, DTR). Set the commun ication values on the

printer to match those at the host.

The printer also has a USB (Universal Serial Bus) version

2.0 communications port, which is compatible with

version 1.1.

Drivers are available on our Web site

for a variety of operating systems.

3. Turn on the printer. Press ( I ) to turn on

and ( O ) to turn off the printer.

Parallel Port

USB Port

Serial Port

Power Switch

Power Cable

Goes Here

2

Page 5

Using the Control Panel

The control panel has a two-line LCD disp lay, two

status lights, and five buttons. The control panel

displays error codes/messages, and allows you to

setup/configure the printer.

Power: The printer shows a steady green

light when it is on.

Fault: The printer shows a steady amber

light when it is out of labels or

ribbon, or when you have a supply

jam.

Feed/Cut: Prints a label in the on-demand

mode, feeds a blank label if there is

no print job, and prints a label w ith

error information that is useful to

your System Administrator if an error is displayed. When the

printer is offline, changes the displayed value by one or ten.

Enter/Pause: Pauses the current print job or resumes a paused print job.

Selects the displayed menu item.

Escape/Clear: When an error is present, clears the err or. When a job (batch) is

printing, cancels the pri nt job (batch). Enters the offline menu

mode or returns the display to th e next higher menu.

Å Displays the previous menu item.

Æ Displays the next menu item.

Å and Æ Prints a test label when you press the buttons at the same time.

Hold for one second and release.

3

Page 6

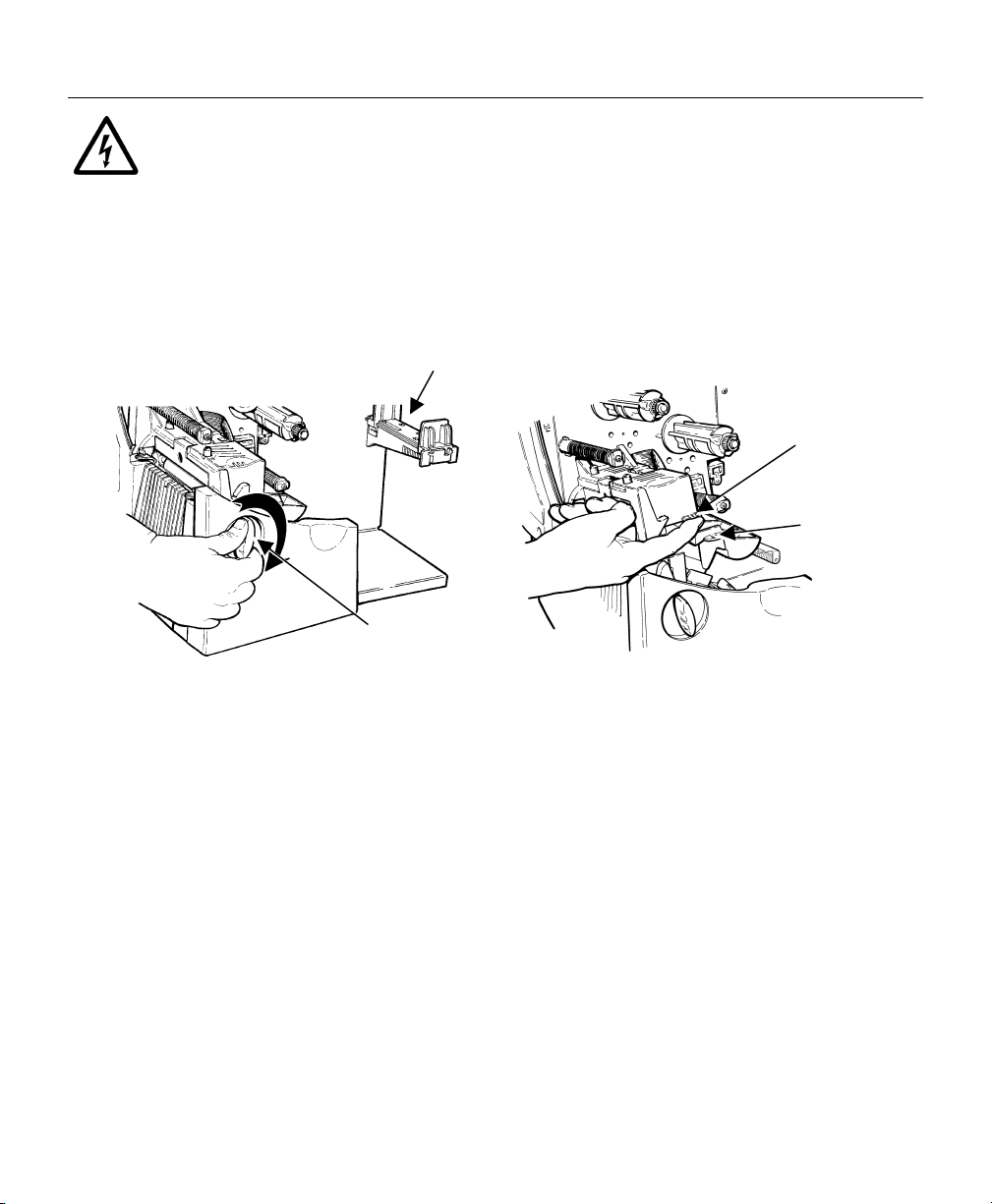

Loading RFID Labels

The RFID supplies are sensitive to static electricity and can be damaged

by static electricity. Ground yourself by touching some metal, such as the

printer’s metal base, before handling the supplies.

Refer to the 9855 Operator's Handbook for additional supply loading instructions if

using non-RFID supplies in your RFID printer .

1. Open the cover.

2. Unlock the printhead by turning the retaining la tch.

3. Lift the printhead assembly using the printhead tab until the assembly locks

into place.

Retaining Latch

Supply Holder

Printhead

Tab

Deflector

Tab

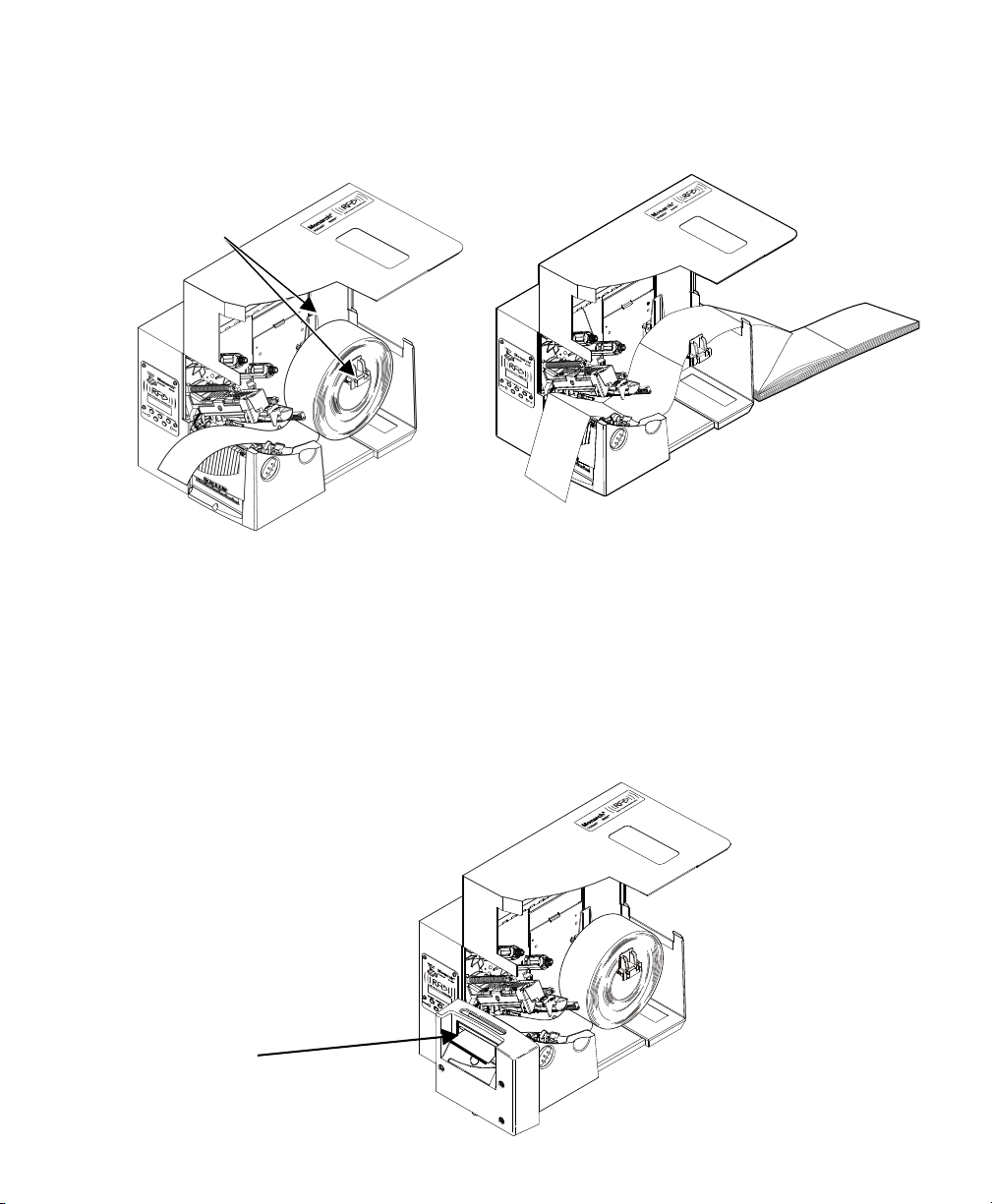

4. Place the roll of supply on the supply holder . For labels, the supply unrolls

from the top or the bottom. Do not pick up the printer by the supply holder.

4

Page 7

5. Adjust the supply holder guides so the sides barely touch the roll. Make sure

the supply roll turns freel y.

If you are using fan-fold supplies, place the supply stack behind the printer,

label side facing up.

Supply Holder Guides

6. Push down on the supply lever to unlock th e supply guides.

7. Lay the label strip across the supply guide so that a few inches extend past the

front of the printer. Tuck the supply under the nibs and in between the die cut

sensor. Do not feed supply between the sup ply roller and deflector.

For fan-fold supplies, lay the label strip over the supply holder and across the

supply guide so that a few inches extend past the front of the printer. Tuck the

supply under the nibs and in betwee n the die cut sensor.

8. For tag supplies using the optional knife, feed the supply through the knife.

Make sure at least 0.5 inches of supply is past the kn ife.

Tag

5

Page 8

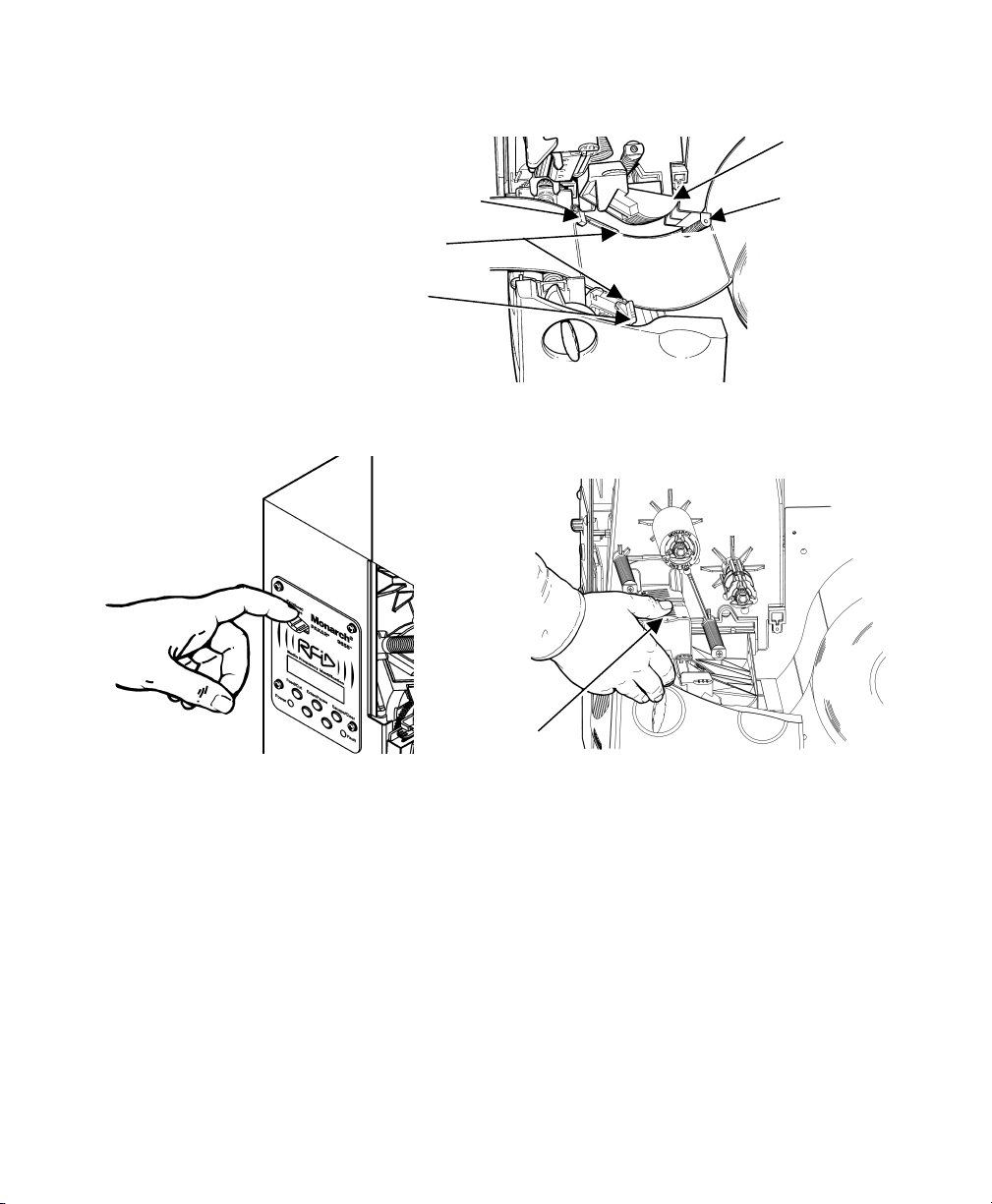

9. Adjust the supply guides so they touch the supply. Push up on the supply lever

to lock the supply guides into place.

Deflector

Die Cut Sensor

Supply

Lever

Supply Roller

10. Hold the printhead assembly by the printhead tab while pressing down on the

printhead release.

Thumb Well

11. Close the printhead by pressing down on the thumb well until you hear it click

into place.

12. Press Feed/Cut several times to feed at least three labels/tags to properly

position the supply and the ribbon.

6

Page 9

Loading Labels for the Optional Peel Mode

Peel mode (on-demand) must be purchased separately. In peel mode, the printer

separates the backing paper from the labe l. The next label is not printed until the

completed one is removed from the printer. Make sure the printer is configured for

on-demand mode and the correct supply type is installed. The minimum feed

length is 1.5 inches for peel mode. Hold the leading edge of peeled labels when

printing labels longer than si x inches. You must use non-perforated supplies for

peel mode. Follow the steps for load ing supplies from the previous section. Then,

follow these steps after you close the printhead.

1. Remove the labels from the first 10 inches of the backing paper.

2. Press down on the exit cover tabs to open the exit cover on the front of the

printer.

Exit Cover Tabs

3. Feed the backing paper over the peel bar.

7

Page 10

4. Feed the backing paper through the lower opening of the exit cover. Close the

exit cover. Pull down on the backing paper to remove any slack.

Peel

Bar

Lower

Opening

Tear

Edge

Backing

Paper

When removing the backing paper, pull up across the saw-toothed tear

edge. Make sure the backing paper tears at the edge.

5. Close the printer's cover.

6. Press Feed/Cut several times to feed at least three labels/tags to properly

position the supply and the ribbon.

Adjusting the Wide/Narrow Knobs

You may need to adjust the two wide /narrow knobs according to the width of your

supply. For supply that is more than two inches, adjust the knobs to the wide

setting. For supply that is two inches or less, adjust the knobs to the narrow

setting.

You must adjust both of the knobs to the same position.

If you experience ribbon smudging in cold, dr y

environments, adjust the wide/narrow knobs to the

wide setting.

For wide supplies, push down and turn the

wide/narrow knobs clockwise with a screwdriver.

For narrow supplies, turn the wide/narrow knobs

counter-clockwise with a screwdriver until it pops

back up.

The adjustment is shown in the wide p osition.

Wide/Narrow Knobs

8

Page 11

Loading Ribbon

1. Open the cover.

2. Unlock the printhead by turning the

retaining latch.

3. Lift printhead assembly using the

printhead tab until the assembly locks

into place.

4. Push the deflector tab down.

5. Slide the extra ribbon core on the

take-up reel as far as it w ill go with the

"This End Out" writing facing out. Use

your empty ribbon core as the take-up

core. The take-up core only fits on the

take-up reel one way.

6. Remove the new ribbon from the

package. Do not wrinkle or crush the new ribbon.

7. Slide the ribbon onto the back reel as far as it will go. The ribbon ro ll only fits

on the reel one way. Carefully unwind a few inches of ribbon from the bottom

of the roll.

Note: Make sure the “Monarch This End

Out” writing is facing out. The

ribbon roll only fits on the reel

one way.

8. Carefully feed the ribbon under bo th

ribbon rollers and printhead.

9. Align the ribbon and make sure it is

straight and centered throughout the

path.

10. Tape the ribbon to the take-up core. Do

not tape the ribbon to the take-up reel.

11. Rotate the take-up core until the leader

is past the printhead.

12. Remove any slack in the ribbon by turning the take-up reel clockwise.

13. Hold the printhead assembly by the prin thead tab while pressing down on the

printhead release.

13. Close the printhead by pressing down on the thumb well until you hear it click

into place. Close the cover. Press Feed/Cut several times to feed at least

three labels/tags to properly position the supply and the ribbon.

Printhead

Tab

Deflector

Tab

Take-up Core

Take-up Reel

Ribbon

Rollers

9

Page 12

Adjusting the Print Contrast

The print contrast controls the darkness of the printing on your supply.

1. From the Main Menu, select Setup, then Contrast.

You see the current setting, for example:

Enter contrast

[-699/699]: +0

2. Press Å or Æ to change the contrast. Pressing Æ darkens the print; Å lightens

the print. Feed/Cut acts as a toggle switch to change the value by 10 or 1.

For example, to make the contrast 50 (from the default 0), press Feed/Cut,

then press Æ five times (50). Press Enter/Pause to select the displayed value .

Test Label?

No Æ

3. Press Å or Æ to select either “Yes” or “No” to print a tes t label and check the

print contrast. Press Enter/Pause.

4. Press Escape/Clear until you see the Main Menu.

Printing

Before you print, make s ure the printer is connec ted and ready to receive data .

When you turn on the RFID printer, “Monarc h Initializing” flashes briefly and then

you see “Print Mode Ready.” If an error occurs while the printer is initializing, the

error message flashes briefly on the d isplay and then you see “Print Mode Ready.”

The printer displays “Not available” when you try to select the RF ID menus if the

module is inoperative.

The printer accepts RFID and non-RFID ba tches once you see “Print Mode Ready.”

1. Download a format and a batch. Refer to the optional Packet Reference

Manual for information on download ing print jobs.

2. The printer prints a strip of la bels or labels in on-demand mode. If printing

RFID supplies, you see

RFID Printing…

1 of 10

If the RFID tag is not programmable for any reason, the label may print

with an overstrike pattern, indicating that it should not be used. Your

System Administrator should se t the desired Error Action accord ingly.

10

Page 13

When printing on non-RFID supplies, you may also see a label with an

overstrike pattern. Do not use that label. When using “overstrike” as the

Error Action, the data prints on the non-RFID label, but there is no da ta

printed on the RFID labe l.

RFID Overstrike

Non- RFID Overstrike

Note: The RFID printer pauses while programming the RFID tag.

3. Remove the printed labels. If the pr inter will be unused for extended per iods of

time, we recommend leaving the printhead unlatched.

Menu Changes

Some changes were made to the menu str ucture for RFID. These menus should

only be accessed by your System Administrator . Refer to the RFIDMP (Mul ti-

Protocol) Application Notes or the HF (High Frequency) Application Notes available

on our Web site for more in formation.

11

Page 14

Clearing Jams

When you are printing and a jam occurs, the Fault light on the printer's front panel

blinks.

1. Turn off the printer and open the cover and printhead assembly.

2. If necessary, remove the label roll and ribbon.

3. Remove the jammed labels and reload the label roll.

4. Close the printhead assembly and turn on the printer.

5. Press Feed/Cut several times to feed at least three labels/tags to properly

position the supply and the ribbon.

Cleaning

CAUTION: Do not use sharp objects to clean the printhead or touch the printhead .

This may damage the printhead and require a service charge.

Note: You must clean the printhead as described below to maintain printhead

life.

The rate and frequency at which you print determines how often you mus t clean the

printer. You may need to clean the printhead, sensor, and platen roller :

♦ if there is any adhesive build-up in the supply path.

♦ after printing approximately three rolls of thermal

transfer/thermal direct supplies or after each ribbon.

♦ da ily if your printer is in an excessivel y dirty, hot, or humid

environment.

♦ if you frequently receive supply error codes or when you see

voids or streaking in the print as shown .

1. Turn off the printer and open the cover and printhead assembly.

2. Remove the label roll and ribbon (when clean ing the printhead).

3. Press down on the exit cover tabs to open the exit cover on the front of the

printer.

Voids

Streaks

12

Page 15

4. Clean the platen roller when you see signi ficant adhesive build-up or a label is

wrapped around the platen roller. Use

a dry, soft-bristle brush, such as a

toothbrush, to clean the platen roller.

If the brush does not remove

all the adhesive, use isopropyl alcohol

Platen

Roller

on the platen roller. Moisten a cotton

swab with isopropyl alcohol and run the

cotton swab across the platen roller.

Turn the platen roller with your finger

to make sure the platen roller is c lean

all the way around. After cleaning,

feed several inches of supply through

without printing to remove any remaining isopropyl alcohol.

5. Rub the cotton swab moistened with iso propyl alcohol across the peel bar and

remove any build-up.

6. Moisten another cotton swab with isopropyl alc ohol. Rub the cotton swab

across the printhead and remove any bu ild-up. You may need to use a

printhead CLEAN-STRIP if the printhead is e xtremely dirty or you see streaks

on the supply.

Printhead

Supply

Sensor

7. Rub the cotton swab across the supply sensor an d die cut sensor and remove

any build-up.

8. Clean the build-up in the supply path.

9. Let the printer dry before you reload supplies.

13

Page 16

10. Push on the exit cover f irmly to close it. Bo th latches will click into place.

11. Close the cover and printhead assembly.

12. Turn on the printer and press Feed/Cut several times to fee d at least three

labels/tags to properly position the supp ly and the ribbon. Resend your format,

batch, and check digit packets.

Troubleshooting

This section provides solutions to minor printing problems.

Problem Action

Error message appears

during startup

Does not print.

Does not feed. Set wide/narrow knobs correctly.

Partially printed data.

Printing shadows or

smears.

Light Printing.

Heavy Printing.

Voids in printing.

Serial bar codes do not

scan.

Backing paper is wrapped

around platen or peel

roller.

Turn OFF the printer, wait fifteen seconds and

then turn ON the printer. Cal l Service if the error

message reappears.

Check supply.

Check ribbon.

Send a corrected format and batch packet.

Clean the printhead.

Send a corrected format packet.

Clean the printhead.

Change supply.

Check ribbon.

Change supply.

Adjust the print contrast.

Check wide/narrow knobs.

Check ribbon.

Clean the printhead.

Change supply. Adjust the print contrast.

Check wide/narrow knobs.

Check ribbon.

Clean the printhead.

Change supply type.

Check ribbon.

Leave printhead unlatched when not in use.

Use a print speed of 2.5 IPS.

Adjust the print contrast.

Carefully remove the backing paper. Make sure

the backing paper tears at the saw-toothed tear

edge when using backfeed and peel mode .

14

Page 17

Problem Action

Blank labels print or 750

series errors.

Printer does not read or

program the RFID tag.

Clean supply sensors.

See your System Administrator. Make sure the

following are set correctly for your inlay (RFID tag)

type: Protocol (C1Gen1, EM4122), Read Power,

and Write Power. Refer to your RFID Setup Guide

& Supply Chart or HF Setup Guide & Supply Chart

for more information.

Common Errors

If the action does not resolve the problem, call Ser vice at the number listed on the

inside front cover of this manual.

Error Description/Action

002

005

018

025

052

053

101

226

228

229

230

400

403

409

410

411

Name must be 1 to 8 characters inside quo tes.

Supply width is invalid.

Code page selection defined in the field is invalid.

Data length is too long.

Data type in the RFID Da ta Field must be 0, 1, 2 , or 3. See your Syst em

Administrator for more informat ion.

The starting block in the RFID Data Field is invalid.

Format referenced by batch not in memory.

Rule Record Line xx. Upload device must be H (Host) for Option 6.

Memory class identifier is invalid. The identifier must be A (AFI),

D (DSFID), or E (EAS) f or Option 64. For more in formation, refer to the

HF Application Notes.

Byte code is invalid. Byte code must be an 8-b it (1 byte) character for

Option 64. For more inform ation, refer to the HF Application Notes.

Lock code is invalid. Lock code mus t be 0 (Unlock) or 1 (Lock) for Option

64. For more information , refer to the HF Application Notes.

Invalid character following {.

Field separator was not found.

Printer memory is full. Delete unnecessary formats or graphics from

memory.

Parity mismatch.

Framing error (baud rate mismatch).

15

Page 18

412

413

611

612

613

614

703

704

715

740

741

742

743

744

Flow control mismatch.

Online receive buffer is full. Check for a flow control problem.

Font, bar code, or density in the batch does not fit the format.

The data in this line of the batch is either missing or does not match the

format.

Reference point off supply.

Portion of field off supply or there may b e an invalid character in the

packet.

The printer sensed a calibration of differen t-sized black marks. Make

sure the correct supply type is loade d.

Printer has not sensed a supply mark when expected or is out of

supplies. Press Escape/Clear and try to continue printing. Change

supply.

Invalid data length/data mismatch. The data in the RFID Data Field has

an incorrect data length or there is a data type mismatch between

selected data type and actual data entered. For more information abou t

the data length and data type, refer to the RFIDM P Application Notes or

the HF Application Notes. This error also occurs when there is an error

in the Expanded C1Gen2 fields. Check with your System Administrator

about your format.

Command, hardware, inventory, or memory allocation error. There may

be an RFID hardware or memory allocation error.

RFID tag missing. Tag not found in RF Field. The RFID tag was not

found in the RF Field (area inside the printer where RFID tag is

programmed.) Check supply loading. If you made supply or print

position settings, make sure the RFID tag was not moved out of the

programmable range.

Tag erase failed. The RFID tag was found in the RF Field, but could not

be erased. Increase the number of re tries. For more information, refer

to the RFIDMP Application Notes or the HF Application Notes.

Program tag failed. The RFID tag was found in the RF Field, bu t could

not be programmed. Increase the number of retries. For more

information, refer to the RFIDMP Applica tion Notes or the HF Application

Notes.

Tag locked fail. The RFID tag is unable to be programmed because it is

already locked. This is considered a bad R FID tag. For more

information, refer to the RFIDMP Applica tion Notes or the HF Application

Notes.

16

Page 19

746

747

748

749

751

752

753

754

755

756

757

758

763

765

768

Lock tag fail. The RFID tag has not been locked to prevent

reprogramming. This is considered a bad RF ID tag. For more

information, refer to the RFIDMP Application Notes or the HF Application

Notes.

Time out failure. An RFID command (read, program, etc.) has failed to

complete in the maximum amount of allowed time.

Invalid data length/data mismatch from RFID in terrogator module. The

RFID interrogator module found a pro blem with the data received from

the printer. For more in formation, refer to the RFIDMP Application Notes

or the HF Application Notes.

RFID Verify Fail. The RF ID verification process failed after writing

(programming) tag. This is considered a bad RFID tag. For more

information, refer to the RFIDMP Application Notes or the HF Application

Notes.

Printer did not sense a black mark when expected. Press Escape/Clear

and try to continue printing. Change supply.

Printer sensed a mark in the wrong place.

Printer sensed a mark that is too long.

Check for a ribbon jam or remove any slack in the ribbon by turning the

take-up reel clockwise. Load a new ribbon.

Printhead is open. Close the printhea d.

Load supplies.

Load supplies (supply length mismatch). Press Feed/Cut.

Either the supply is not seen, the on- demand sensor is broken, or a label

was removed too quickly. Check for a label jam or reload supplies.

Waiting to dispense label. Press Feed/Cu t.

The printhead has less than 8 bad dots and can shift bar code fields to

avoid bad dots. Press Es cape/Clear to continue printing.

Printhead has more than 8 bad dots within the format area or is n ot

connected. Replace or connect printhead as necessar y.

The printer does not recalibrate (feed a blank label) a fter any RFID error. Refer to

the RFIDMP Application Notes or the HF Application Notes (on our Web site) for

more information.

17

Page 20

RFID Printer Specifications

Height:

Width:

Depth:

Weight:

Shipping Weight:

Power Source:

13 inches (330 mm)

12.5 inches (318 mm)

17.3 inches (439 mm)

29 lb. (13.2 kg)

34 lb. (15.5 kg)

90-132V

180-264V

Printhead:

Thermal at 4 inches (1012 mm) wide

203 dpi (8.0 dots per mm)

Optional 300 dpi (11.8 dots per mm)

Speed:

2.5, 4.0, 6.0, 8.0, and 10 .0 ips (inches per second). 12.0

ips (305 mm) printing is an op tion that must be purchased

separately. 2.5 is the default for serial bar codes.

Note: The RFID printer pauses while programming the

RFID tag.

Operating Temperatures

Direct:

Transfer:

Storage:

40°F to 104°F (4° C to 40°C)

40°F to 95°F (4° C to 35°C)

15°F to 120°F (-9° C to 49°C)

with autoselect 50/60Hz

AC

with autoselect 50/60Hz

AC

Humidity:

18

5% to 90% non-condensing

Page 21

RFID Supply Specifications

RFID supplies are available in a variety of sizes. Printing over the RFID inlay

causes printing irregularity. Refer to the RFID Setup Guide & Supply Chart or the

HF Setup Guide & Supply Chart for illustra tions to determine which type o f RFID

supplies you are using and basic prin ter configuration information.

Supply Types:

Supply Widths:

Supply Lengths:

Roll Inside

Diameter:

Roll Outside

Diameter:

Ribbon Width:

Ribbon Length:

Additional RFID supplies may be available by request. Contact your RFID

Representative for more information.

Thermal Transfer or Thermal Direct

Die Cut or Black Mark

0.75 inch (19 mm) minimum

4.0 inches (102 mm) maximum

1.0 inch (25.4 mm) minimum

13.0 inches (330 mm) maximum

Note: The supply length depends on the inlay selec ted.

4.0 inches (102 mm)

8.0 inches (203 mm) maximum

4.3 inches (110 mm) for 4.0 inch (102 mm) supply

23,600 inches (600 meters)

Tag Cut Dimensions

Use these specifications for the 926™ Knif e with the RFMP printer. Use only

Monarch®/Paxar® approved RFID tag supplies.

Widths: 1.5 inches to 4.0 inches (38 mm to 102 mm)

Lengths: 1.5 inches to 16.0 inches (38 mm to 406 mm)

Thickness: 7 mils to 14 mils

Batch Separator: 3.66 inches (93 mm)

Note: The limited warranty on knives used in or with RFID printers is one (1)

year from the date of shipment, or 500,000 cuts, wh ichever occurs first.

19

Page 22

RF Specifications

The UHF radio operates in the 902 – 928 MHz frequency range in accordance with

FCC Rules and Regulations.

The HF radio operates at 13.56 MHz in accordance with FCC Rules and

Regulations.

Additional frequencies may be available for internationa l locations by request.

Contact your RFID Representative for more information.

20

Page 23

Page 24

Loading...

Loading...