Page 1

Operator's

Operator's

Handbook

Handbook

Monarch

Printers

9844™

9854™

®

TC9854OH Rev. AB 4/08 ©2007 by Avery Dennison Corp. All rights reserved.

Page 2

Copyright

© 1997-2008 by Avery Dennison. All rights reserved.

Monarch®, 9844, and 9854 are trademarks of Paxar Americas, Inc.

Avery Dennison® is a trademark of Avery Dennison Corp.

Reprinting and reproduction of these documents, including extracts, is only allowed

with the express permission of the manufacturer. More detailed information is

available from your supplier.

Copyright

Copy

Protected rights

Alterations

Guarantee

The documentation is subject to copyright. The copyright claims include all forms

and types of material and information which may be protected by current copyright

laws. No part of the documentation may be copied, reproduced in any other

manner, processed or translated into another language, irrespective of the manner

and fashion or with which means this takes place.

Electronically stored device information (CD-ROM, Internet) supplied by the

manufacturer may be printed out by the user, provided that the print medium serves

the use or servicing of the described product.

Names are generally given without any mention of existing patents, registered

designs or trademarks. The absence of a corresponding remark does not give any

implication that the name can be used at will. All trademarks are recognised.

No liability is assumed for the accuracy of the contents of this documentation. The

manufacturer reserves the right to alter technical or other specifications with no prior

notice. Deviations in the documentation from prevailing conditions do not represent

an obligation to redeliver.

The manufacturer does not guarantee the existence or non-existence of properties

with the description of subject contents. Nor does the manufacturer give any

express or tacit guarantee declarations whatsoever.

Page 3

05/08 Rev. AB OPERATOR’S HANDBOOK Safety

Safety Information

General notes on safety are found in this section.

Special safety notes and warnings about possibly dangerous operations are

listed at the top in the user manual.

¯ Warning notes and warning symbols are also attached directly to the

printer and components. Pay attention to these safety notes as well.

Warnings in the text

Important information that must be followed is marked as follows:

WARNING!

Indicates risks that could result in death or serious personal injury!

« Follow these safety instructions.

CAUTION!

Indicates risks that could lead to material damage or bodily injury (minor

injuries).

« The instructions must be followed to prevent damage or injury.

Page 4

05/08 Rev. AB OPERATOR’S HANDBOOK Safety

General safety notes

CAUTION! - The printer operates safely when you observe all necessary

information.

« Proper operation of the product requires the user to read and follow these

operating instructions. The warranty does not cover service required as a

result of operator error and/or failure to read and follow the documentation.

WARNING! - Any changes or modifications not expressly approved by us

could void the user's authority to operate the equipment.

« Only operate the printer using the system voltage indicated on the

nameplate!

« Only connect the printer to a grounded power outlet.

« Only use the printer within specified environmental conditions!

« Only operate the printer when the cover is closed!

« Only trained and authorized personnel should operate the printer!

« During operation, the printhead can become hot! Be careful when touching

the printhead!

« Do not make any modifications to the printer!

« Do not spill any liquids into the printer!

« Repairs to the device must be performed by authorized specialists!

« Before cleaning the printer, turn off the printer and disconnect the power

supply!

« Only use original accessories!

« Connect the printer only to other devices that fulfil SELV (safety extra-low

voltage) circuit requirements to EN 60950!

Keep long hair, loose jewelry, long sleeves, etc. away from the printer

during operation.

« Wear sufficient personal protection gear.

The printer can only be disconnected completely by removing the power

supply cable. For this reason:

« Make sure that the printer’s power supply socket is readily accessible!

« In case of emergency, turn off the printer and disconnect the power supply

cable!

« Keep these operating instructions in a safe place and make sure they are

read.

« The printer must be operated, adjusted and serviced by instructed and

authorized personnel.

« Carefully follow all procedures listed in this manual.

Service Special servicing, error searching and error correction are to be performed by

authorized personnel.

Page 5

05/08 Rev. AB OPERATOR’S HANDBOOK Safety

Equipment safety

Thermotransfer label printers are designed for printing label material, using

the thermal direct or thermal transfer printing process. It is possible to use a

wide range of label materials and thermal transfer ribbons. See

“Specifications” for more information.

Avery Dennison assumes no liability for damage due to improper use of the

printer and/or material.

Protect against injuries that can result from electrical

current

WARNING!

The printer is connected to a power supply! Contact with live electrical

components can result in life-threatening currents through the body and

burns.

« Only use the printer with the cover closed.

« Do not remove the cover.

« If liquids penetrate the printer, immediately turn off the printer and

disconnect the power supply.

Protect against injuries that can result from mechanical

actions

WARNING!

Risk of injury during operation due to moving or rapidly rotating parts! Keep

long hair, loose jewelry, long sleeves, etc. away from the printer during

operation.

« Wear sufficient personal protection gear.

« Turn off the printer before making any mechanical adjustments.

Page 6

05/08 Rev. AB OPERATOR’S HANDBOOK Safety

Disposal Procedures

Waste Electrical and Electronic Equipment (WEEE) for

European Union (EU) customers

Avery Dennison is fully committed to achieving the EU mandated WEEE

WEEE Symbol

directives.

This product, its components, and accessories must be sent to a designated

collection facility for proper disassembly and disposal in accordance with the

WEEE directives. Any product or accessory marked with the WEEE symbol

must be returned to a designated collection facility.

For proper disposal of the printer outside the U.S., send the printer and its

accessories to:

Paxar EMEA, 4 Awberry Court

Croxley Business Park, Hatters Lane

Watford WD18 8PD

U.S. Battery Disposal Information

Do not throw in trash. Dispose to your local regulations.

Batteries can also be returned postage-paid to:

ERC

200 Monarch Lane

Door #39

Miamisburg, OH 45342

Page 7

05/08 Rev. AB OPERATOR’S HANDBOOK Safety

FCC Regulations - Class B

WARNING

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to local radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his own expense.

CANADIAN D.O.C. WARNING

This digital apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Le présent appareil numérique n'émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de la classe B

prescrites dans le Réglement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

Page 8

05/08 Rev. AB OPERATOR’S HANDBOOK Table of Contents

Table of Contents

GETTING STARTED ......................................................................................................1-1

Installing the Printer............................................................................................................1-2

Unpacking the printer .........................................................................................................1-2

Carrying the Printer.............................................................................................................1-2

Printer Contents ..................................................................................................................1-3

Removing the Transportation Lock ....................................................................................1-3

Terms to Know ...................................................................................................................1-4

About the Printer.................................................................................................................1-5

About the 9854 Dispenser (Peel) and Internal Liner Takeup .............................................1-7

Identifying Printer Connections..........................................................................................1-8

Safety Information ..............................................................................................................1-9

Using the Control Panel (Display)....................................................................................1-10

Operating Modes...............................................................................................................1-11

Using the Printer ...............................................................................................................1-13

Connecting the Printer ......................................................................................................1-13

Setting the Interface ..........................................................................................................1-14

Using the 9854 Printer with Internal Liner Takeup ..........................................................1-14

Using the 9854 Printer with Dispenser .............................................................................1-15

Offline Operation ..............................................................................................................1-16

Online Operation...............................................................................................................1-17

Creating a Print job ...........................................................................................................1-18

Sending a Print Job ...........................................................................................................1-18

Using Compact Flash Cards..............................................................................................1-19

Setting the Realtime Clock (9854 only)............................................................................1-20

SETUP................................................................................................................................2-1

Loading Diagrams...............................................................................................................2-2

Selecting Ribbon/Material ..................................................................................................2-5

Loading Material.................................................................................................................2-6

Loading a Ribbon..............................................................................................................2-11

Material/Ribbon End.........................................................................................................2-13

Setting Printhead Support .................................................................................................2-14

Setting the Material Parameters ........................................................................................2-15

CARE & MAINTENANCE .............................................................................................3-1

Safety ..................................................................................................................................3-2

Troubleshooting ..................................................................................................................3-2

Note on Cleaning ................................................................................................................3-2

Cleaning the Printhead........................................................................................................3-3

Replacing the Printhead ......................................................................................................3-4

Cleaning the Print Roller ....................................................................................................3-5

Cleaning the Punch (Die Cut) Sensor .................................................................................3-6

SPECIFICATIONS..........................................................................................................A-1

Printers ...............................................................................................................................A-2

Supplies (Material).............................................................................................................A-3

Ribbon (Foil)......................................................................................................................A-3

Page 9

05/08 Rev. AB OPERATOR’S HANDBOOK

9844/9854

Getting Started

Installing the Printer

About the Printer

Using the Printer

1-1

Page 10

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Installing the Printer

Information in this document supercedes information in previous versions.

Check our Web site (www.monarch.com) for the latest documentation and

release information.

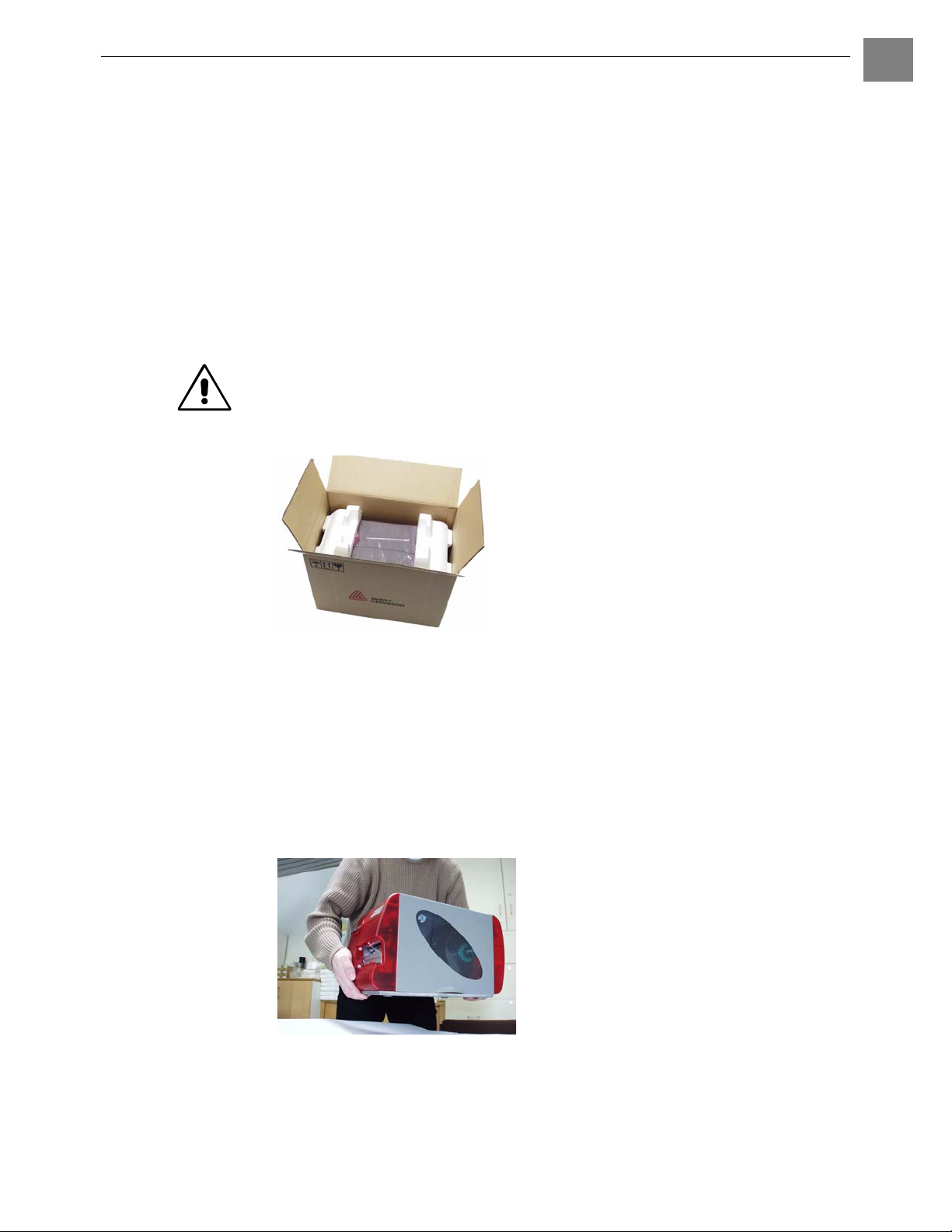

Unpacking the printer

Keep the box and packaging materials in case the printer ever needs repair.

1. Remove all loose objects from the packaging.

2. Carefully lift the printer and packaging out of the box.

¯ CAUTION! - Do not lift the printer by holding the plastic parts on the front

and back! This could damage the printer.

¯ CAUTION! - Do not grip the front cover to carry the printer! This could

damage the printer.

1-2

Fig. 1: 9854 in the original packaging.

3. Remove the packaging and plastic wrap from the printer.

4. Place the printer on an even surface.

Carrying the Printer

The printer weighs 31 lbs (14 kg).

« To carry the printer, grip the baseplate from the front and back (see Fig. 2).

Fig. 2: When lifting the printer, grip under the baseplate!

Packaging ¯ Always use the original packaging to move the printer.

Page 11

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Printer Contents

After you unpack your printer, make sure you have all the necessary

components and that the printer was not damaged during shipping.

• Printer

• Power supply cable

The plug for the power supply is different depending on the country of

delivery.

• Data cable

Centronics IEEE 1284 CA Cable 2 m.

• Core adapters

There are two core adapters each for the material rolls with a internal core

diameter of 3 inches (76mm) and 4 inches (101 mm). The core adapters are

placed on the printer material dispenser.

• Empty foil core

For rewinding the ribbon (foil). The backing paper is placed on foil rewind

reel.

1-3

9854 with

Internal Liner

Takeup Reel

• Operator’s Handbook

• Size 10 Torx screwdriver

Used to replace the print roller and add a dispensing (peel) edge.

• 9854 printer with installed deflector

• Housing front part, bottom side with screw (Fig. 3 right side)

¯ Use the housing parts if the printer does not have the internal liner takeup

reel (rewinder).

Fig. 3: These housing parts are shipped loose with the printer with internal liner takeup.

Removing the Transportation Lock

1. Open the cover.

9854 with

Dispenser

2. Remove the two foam pads holding the printhead in place.

« Remove the connector from its transport position at the printer bottom and

connect it to the front of the printer.

Page 12

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Terms to K now

Review these terms before you continue.

Dispenser Peel mode. The printer separates the

backing paper from the label as it prints.

The printer stops after each label to allow

you to remove it.

Material Supply (labels, tags, etc.)

Self-adhesive material Labels

Light barrier Material (supply) sensor

Transmission sensor Die cut sensor

Reflex sensor Black mark/aperture sensor

Punched material Die cut supply.

Reflex mark material Black mark or aperture supply.

Rewinder Internal liner takeup reel. Winds the

backing paper up as it is separated from

the labels in dispense (peel) mode.

1-4

External rewinder Optional device that rewinds printed

labels or backing paper after they exit the

printer.

Endless print quantity Continuous mode. The printer prints

labels without stopping.

Foil Ribbon

Page 13

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

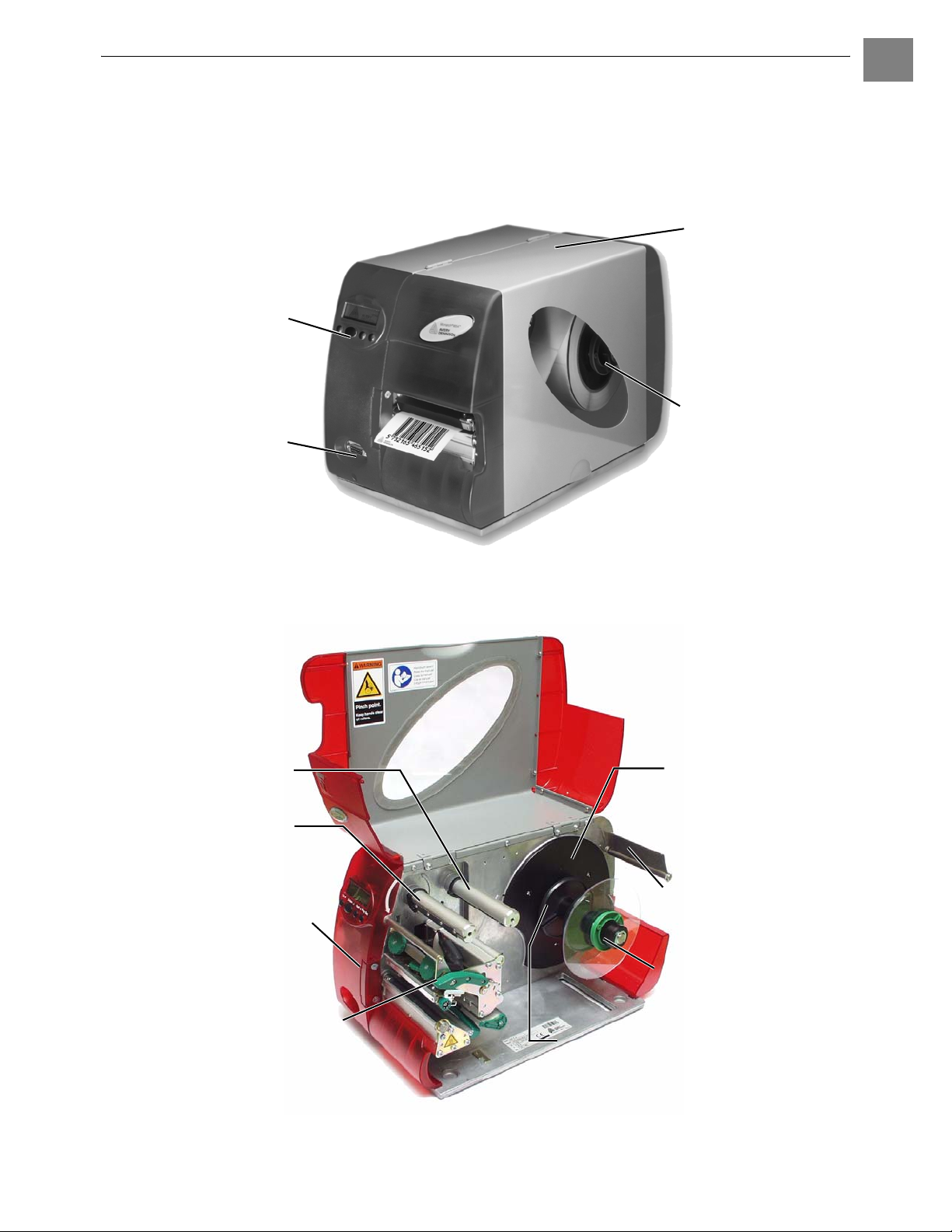

About the Printer

Cover

Open to insert material

and foil (ribbon).

1-5

LCD graphics display, 4 buttons;

Control panel

displays printer operating status,

enables parameter menu

settings.

Connection for additional

devices

Connection for

optional cutter.

Window

Allows material/foil check

without opening the

cover.

Fig. 4: Exterior view of the printer.

Foil unwinding reel

Holds the new foil roll.

Foil takeup roll reel

Holds the used foil.

Flange mount for additional

devices

Optional cutter may be

connected here.

Pressure lever

Opening the pressure lever raises the

printhead. Open when loading the

material or foil or to clean the printhead

or printing roller.

Fig. 5: Operating parts.

Material rewinder

Labelling material roller inserted

here.

Material tension roller

Ensures even feed of the

labelling material.

Guide plate

Prevents the material roll from

slipping sideways.

Adapter rings

To set the core to the material

roll’s diameter.

Page 14

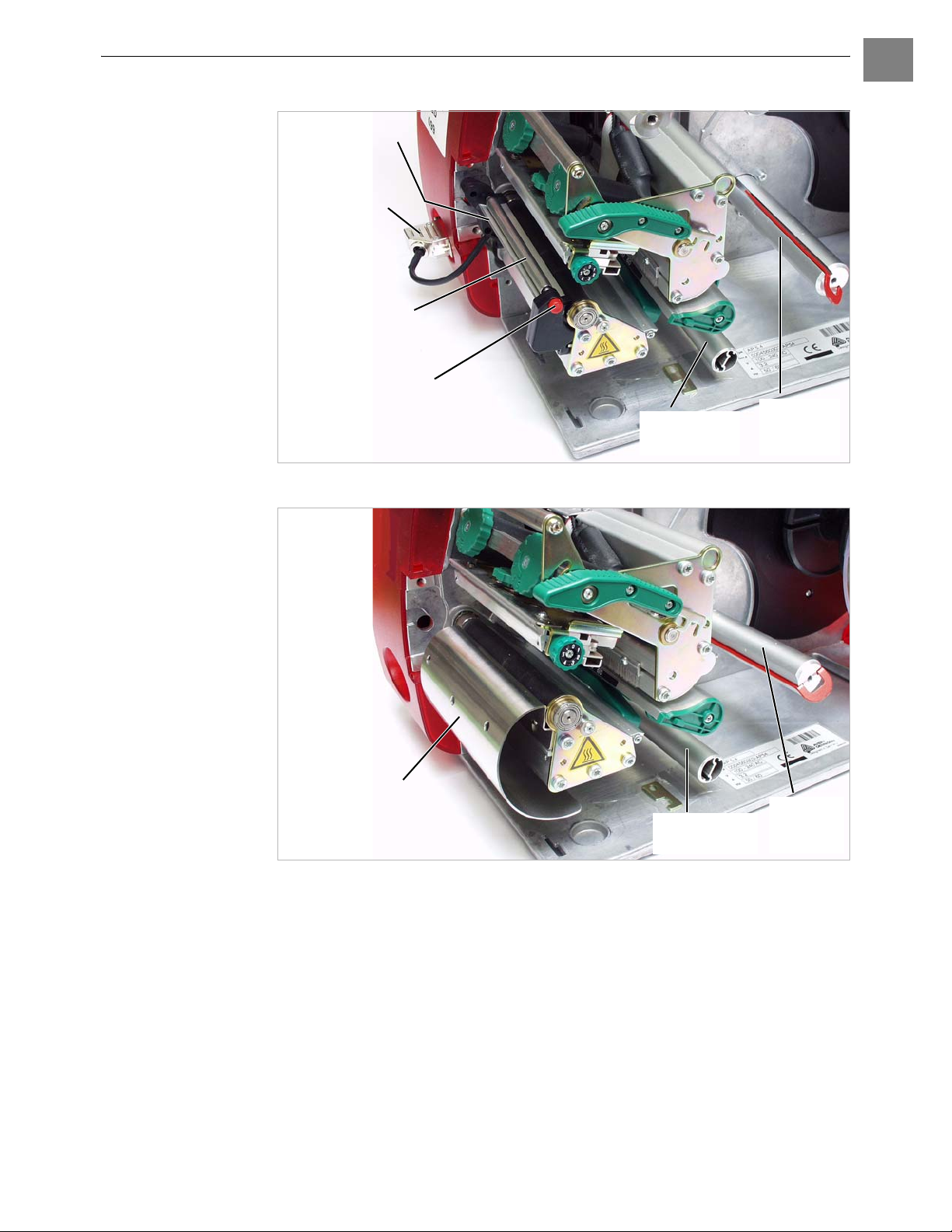

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

1-6

9854 with

Dispenser

(Peel) and Liner

Takeup

Dispensing edge

Removes the labels

from the backing

Connection of the

dispensing edge

Dispensing roller

Holds the material

Dispensing roller release button

paper.

Connector

sensor.

tight over the

dispensing edge.

Press the button to release the

dispensing roller.

Deflector

Deflects the

backing paper.

Fig. 6: Additional operating parts of the printer with dispenser.

Takeup Reel

Wraps up the

backing paper.

Deflects the printed label

without dispensing any

Deflector

labels.

Deflector

Deflects the labels.

Fig. 7: Additional operating parts of the printer with internal liner takeup.

Takeup Reel

Wraps up the

labels.

Page 15

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

About the 9854 Dispenser (Peel) and Internal Liner

Takeup

The 9854 printer has an internal liner takeup reel, which allows labels to be

dispensed (using the dispensing edge) or rewound inside the printer (using

the deflector) after printing.

After the printer is turned on, the takeup reel is initialized and the label

material is stretched.

If an error occurs, the takeup reel turns off automatically.

When the maximum diameter of the takeup roll is reached, a message

appears and the takeup reel turns off automatically.

The following modes of operation are available with the dispenser:

• Dispenser Mode with Dispensing Edge Sensor:

The printed label sticks to the dispensing edge (set dispensing position).

Once the label is removed, the next label prints.

• Dispenser Mode with Foot Switch:

Pressing the foot switch triggers the printing and dispensing of one label.

The next unprinted label is immediately positioned under the printhead.

1-7

P See “Using the Dispenser” for more information.

Page 16

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Identifying Printer Connections

¯ CAUTION! - Only use approved add-on devices or damage to the printer

may occur.

« Only connect devices that fulfill SELV (Safety Extra-Low Voltage) circuit

requirements to EN 60950.

« Connect only original accessories.

P Refer to the “Advanced Applications” section on your CD-ROM for more

information about the 9854 network connection.

1-8

Start/stop signal input

Connection for a foot switch

(signal starts the printer) or a

stacker (signal stops the

printer).

Serial Interface

RS232 or RS422/485, on the

optional I/O board.

Signal interface

4 inputs / 3 outputs, belongs to

the optional I/O board.

Keyboard connection

In offline mode, the keyboard

can be used for data input and

print job selection.

Centronics connection

For parallel data transfer.

USB connection

For USB data transfer.

Card insert (9854 only)

For Compact Flash cards,

which can be used to save

fonts, logos or graphics.

RS232 interface

For serial data transfer.

Status LED/Ethernet

(9854 only)

Network connection

(9854 only)

Connection for an Ethernet 10/

100 BaseT network.

Power switch

Turns printer on/off.

Fig. 8: Back view of the 9854 printer.

Power supply

Connection to the power supply

using the supply cable provided.

Page 17

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

6

9844/9854

Safety Information

!

WARNING

Keep hands clear

of rollers.

A534

1-9

Fig. 9: Warning signs of the printer.

The warning sign shown in Fig. 9 explains the risk of getting hands, fingers,

loose clothing, jewelry, etc. caught between rotating parts of the printer.

The warning sign shown in Fig. 9 warns of the risk of getting hands or fingers

burned at hot surfaces close to the printhead.

Plug the power supply into a grounded electrical outlet.

Page 18

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Using the Control Panel (Display)

Display

Cut button Online button Feed button Prog button

1-10

Fig. 10: Control panel

Display With 32 digits and two lines, the display shows the operating conditions

(modes) for parameters, values, status and errors. You can select the display

language. Backlighting ensures good legibility.

Button

Functions

Online Button

The buttons offer a multitude of operating functions. A logical menu structure

is used for operation. The meaning of each button varies according to the

operating mode and the menu item. Additionally, special functions have been

programmed for certain button combinations.

• Switches between online and offline mode.

• Confirms entries, menu items, and messages.

• Selects print jobs and enters values in standalone mode.

Cut Button

• Triggers a cut. Requirements:

– Cutter installed and enabled

– Printer offline

• Scrolls down through the menu and selects menu items

• Decreases values

Feed Button

• Feeds material when the printer is offline

• Starts the printing process once feed has been stopped (in online mode)

• Scrolls up through the menu and selects menu items

• Increases values

Prog Button

• Accesses the parameters menu when offline

• Returns to the previous menu item and/or exits the menu.

P For more detailed descriptions of the button functions, see

– “Offline Mode” and “Online Mode” in this manual

– or refer to the “Info-Printouts and Parameters” section on your CD-ROM.

Page 19

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Operating Modes

Offline Mode

Display Meaning

OFFLINE 0 JOBS No jobs are waiting to be processed.

Tab. 1:Display in offline mode.

Settings can be made when the printer is offline. The offline mode is normally

active when the printer is turned on. Print jobs are received with the selected

interface, but not processed.

¯ To configure the printer so it goes online when turned on, set the following

parameter to Online:

SYSTEM PARAMETER > Turn-on mode

Online Mode In online mode, print jobs are received and processed immediately.

Display Meaning

ONLINE 0 JOBS No jobs are waiting to be processed.

1-11

ONLINE 0. JOBS Current data transfer to the printer is shown on

the display by the dot on the bottom right, next to

the number of loaded jobs.

ONLINE 13 JOBS

Restcount: 25

During printing, the display also shows the

number of print jobs read (13) and the remaining

number of labels (25) to be printed in the current

job.

ONLINE 13 JOBS

Restcount: endless

If a print job recognizes an endless (continuous)

number of labels to be printed, then the remaining

number for this job is also shown as endless.

Tab. 2: Possible messages in online mode.

¯ To stop printing, press Online.

Message Mode The printer uses the message mode to signal an error or a particular

operating status. Message mode indicates that the printer is waiting to quit or

for a fault to be corrected. When exiting, the printer switches from message

mode to offline mode (depending on the error and the progress of the

previous process).

Display Meaning

Status 5001

No punch detected

Messages are made up of the status number and

a brief descriptive text.

Tab. 3: Example of a message.

The messages shown in Table 3 occur when the printer is set for using

labelling material with perforation, but continuous form material without

perforation is loaded. The printer continues to feed the material for a few

seconds before it generates an error message.

P Refer to the “Error Messages” section on your CD-ROM for more information

on message reports and a detailed list of all messages.

Page 20

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

1-12

Standalone

Mode

(9854 only)

In standalone mode, the print jobs are not transferred with a data cable, but

are stored on a Compact Flash card. They are selected from the printer’s

display or a keyboard connected to the printer.

P Refer to the “Advanced Applications” section on your CD-ROM for more

information on using standalone mode for the 9854 printer.

Page 21

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Using the Printer

Connecting the Printer

WARNING!

Touching live electrical parts causes exposure to hazardous electrical

currents that may lead to burns!

« Make sure the printer is turned off before connecting the power cable.

« Only connect the printer to an electrical outlet that provides the correct volt-

age, which can be found on the rating plate.

« Only connect the printer to a grounded electrical outlet fitted to authorized

standards.

« Connect the power cable so that:

– no one trips or steps on it.

– it can be easily unplugged from the power outlet.

1-13

1. Turn off the printer. On the back of the printer press (O) to turn off the printer.

2. Connect the printer to the power supply using the cable provided.

3. Using the data cable supplied, connect the Centronics interface on the

printer to the host computer.

4. Turn on the printer. On the back of the printer, press (I) to turn on the printer.

Display Description

System start... The boot loader has started.

System start...

Start user prog

Avery AP 5.4

V 1.02

Memory: 8MB

Flashcard: 32MB

OFFLINE 0 JOBS Offline mode

Tab. 4: Messages on the display when the printer is turned on.

5. Press Online to switch to the online mode:

Valid firmware recognized, program starts.

Printer type (for example: AP 5.4/9854)

Version number of the printer firmware.

Internal RAM (for example: 8 MB)

Optional RAM on the Compact Flash card (for

example: 32 MB) – only displayed when a

Compact Flash card is in use.

ONLINE 0 JOBS

¯ When the parameter SYSTEM PARAMETER > Turn-on mode is set to Online,

the printer switches to online mode when turned on.

Page 22

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Setting the Interface

By factory default, the printer is set for data transfer using the Centronics

interface. Print data can be transferred using the RS232, USB or Ethernet

interface (9854 only).

« Select the interface with the following parameter:

Set INTERF. PARAM. > EASYPLUGINTERPR to Interface

P Refer to the “Info-Printouts and Parameters” section on your CD-ROM for

more information about setting parameters.

P Refer to the “Advanced Applications” section of your CD-ROM for more

information about using 9854 Ethernet.

Using the 9854 Printer with Internal Liner Takeup

Disable « Set SYSTEM PARAMETER > Periph. Device to None

¯ If you do not insert printing material before enabling the liner takeup, an

error message appears.

1-14

P For more information on loading material, see “Loading Material.”

Enable 1. Set SYSTEM PARAMETER > Periph. Device to Intern Rewinder

When enabled, the rotational direction of the takeup is set.

Rewinder direct.

Facing outside

2. Press Cut/Feed to change the rotation direction.

3. Press Enter to confirm your setting.

The printer restarts. The main menu now contains the additional menu

REWINDER PARA, which holds the parameter Rewind direction. This can be used

to change the rotational direction.

During initialization, the printer attempts to stretch the label material.

Possible Errors Shortly after enabling the internal liner takeup, you may see

Status 5004

Rewinder mat. tear

Facing outside is the default setting.

Page 23

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Possible causes:

– Material is not loaded, or the material’s end was not fixed to the takeup

reel. Attach the end to the takeup reel and press Online.

– The material is not stretched tightly. Press Online.

The printer is now ready for the next print job. You may need to adjust the

basic initialization settings because of:

• Very small labels

• Very rough backing paper

• Backing paper much heavier than label

• Labels stuck to backing paper

• Backing paper perforated along label contour

Using the 9854 Printer with Dispenser

Disable « Set SYSTEM PARAMETER > Periph. Device to None

Enable « Set SYSTEM PARAMETER > Periph. Device to Dispenser

The printer restarts. The main menu now contains the additional menu

DISPENSER PARA , which holds the parameters required for dispenser

mode:

1-15

Parameter Possible Settings

Dispenser Mode Real 1:1 mode (default), batch mode, Normal 1:1 mode

Dispensing

Position

Display Mode Job rest quant. (default), Dispense counter

Dispense counter Preset Amount (default: 0)

Application Mode Safe mode (default), Immediate mode

Start Mode Edge (default), Level low active

Start Source Foot switch (default), Light barrier

Tab. 5: Parameters in the menu DISPENSER PARA.

P Refer to the “Info-Printouts and Parameters” section of your CD-ROM for

more information on the listed parameters.

Set in millimeters (default: 0.0 mm)

Page 24

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

1-16

Configuring the

Dispenser

Position

Label length

< 40 mm

• Application A:

The label is dispensed (peeled) so that a small portion still sticks to the

backing paper above the dispensing edge. After the dispensed label is

removed, the next label is immediately printed and dispensed.

« Set DISPENSER PARA > Dispenseposition to –6.0 mm (set to –8.0 mm if the

material is very adhesive).

« Set DISPENSER PARA > Start Source to Light barrier.

• Application B:

The printing and dispensing of the label is controlled by the optional foot

switch.

« Set SYSTEM PARAMETER > External Signal to Stacker full.

« Set DISPENSER PARA > Dispenseposition to –6.0 mm (set to –8.0 mm if the

material is very adhesive).

« Set DISPENSER PARA > Start Source to Foot switch.

¯ If using very short labels (< 40 mm) set PRINT PARAMETERS > Material length

< 40 mm (1.6 inches). The printer automatically initializes the material, which

improves the impression accuracy of the printout.

P Refer to the “Info-Printouts and Parameters” section on your CD-ROM for

more information on parameter DISPENSER PARA > Calibration mode.

Offline Operation

Press the buttons indicated in black to perform the listed functions.

• Switching from offline mode to online mode:

OFFLINE x JOBS ONLINE x JOBS

Online

• Switch to online mode when the print job is stopped:

OFFLINE x JOBS

Stopped xx

Online

ONLINE x JOBS

Stopped xx

• Slow material and ribbon feed:

OFFLINE x JOBS OFFLINE x JOBS

Online

Feed

feeding…

• Material travels backwards under the printhead:

OFFLINE x JOBS OFFLINE x JOBS

Cut Online

feeding…

• Reset:

OFFLINE x JOBS OFFLINE x JOBS

Cut Online

Feed

Page 25

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

•

Access the parameter menu:

1-17

OFFLINE x JOBS PRINT INFO

Prog

• Feed material until the next punch (die cut) is reached or when the button is

held down:

OFFLINE x JOBS OFFLINE x JOBS

Feed

feeding…

• Setting the label length automatically:

OFFLINE x JOBS OFFLINE x JOBS

After pressing the two buttons, the printer feeds the label material, until two

punches have passed the label sensor. The measured label length is

displayed and saved into parameter PRINT PARAMETERS > Material length. Next,

the parameter PRINT PARAMETERS > Material type is set to “punched.”

OFFLINE x JOBS

Displays the measured label length.

198.5 mm

Feed

Prog

Manual Calibrate

¯ The label length measured by this function is from label end to label end.

If material with very large punches is used, this measurement does not work

properly. In this case, measure and set the label length manually (label length

+ punch length).

Online Operation

Press the buttons indicated in black to perform the listed functions.

• Switching to offline mode:

ONLINE x JOBS OFFLINE x JOBS

Online

• Setting the print contrast: Press Feed to increase and Cut to decrease the

print contrast.

ONLINE x JOBS Print contrast

Prog

xxx%

• Interrupting the print job: The printer finishes printing the current label.

ONLINE X JOBS

Prog

Restcount XXX

a) The message “Stopped xxx” alternates with “Press Feed.”

ONLINE X JOBS

Stopped XXX

a

• Switching to offline mode while the print job is stopped:

ONLINE X JOBS

Stopped XXX

Online

OFFLINE x JOBS

Page 26

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

•

Continuing the print job:

ONLINE X JOBS

Stopped XXX

Feed

ONLINE X JOBS

Restcount XXX

• Standalone operation (9854 only): Selecting a print job stored on a Compact

Flash card (for example, Testdat.FOR):

1-18

Windows

Printer Driver

File with Print

Commands

ONLINE x JOBS Choose a file

ProgOnline

Testdat.FOR

Creating a Print job

There are two ways to create a print job: Use the Microsoft® Windows printer

driver, or create a text file using print commands.

• Printer drivers are available for different versions of Windows. You can print

from nearly every Windows application using the printer drivers. However,

functionality is strongly dependent on the choice of software. We recommend

label layout programs.

« Printer drivers for different versions of Windows are available on our Web site

(http://www.machines.averydennison.com/printersystems_gb.nsf/

wview/L4L3?OpenDocument). Select the drivers for models AP4.4 (9844)

and AP5.4 (9854).

P See the printer driver’s help function for more information. Refer to your

Windows operating system help to install a driver.

• You can write a sequence of commands in a text file and send it to the printer.

To do this, you can use any text editor and the MS-DOS copy command.

Easy Plug provides a special command language to program print jobs.

However, writing a print job in text file format requires some programming

knowledge. You cannot preview the resulting printout on the screen. Print a

test print to see a copy of the finished result.

P Refer to the Easy Plug manual for examples of print jobs.

Sending a Print Job

The printer processes print jobs once the jobs are sent to the printer’s RAM

either by direct transfer from your computer with a data cable, or by saving to

a Compact Flash (CF) card for the 9854 printer.

Data Cable The print job can be sent using parallel or serial communication. Connect the

computer and the printer with the serial or parallel cable. Send the print job

file – from the DOS window – to the interface (for example, “copy testjob.txt

lpt1” to send the print job to the parallel interface).

To send the print job from a text program, make sure the printer driver is

installed.

Page 27

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

1-19

Compact Flash

Card

You need the following to load a print job from a Compact Flash card:

• a 9854 printer

• a Compact Flash card (copy the print job to the \FORMATS directory)

• a computer with a PCMCIA drive and

• an adapter for the Compact Flash card.

Rename the print job file on the Compact Flash card to autostrt.for so the

printer recognizes it. Once this is finished, the printer completes the print job

as soon as it is set to online mode.

Using Compact Flash Cards

¯ CAUTION! - Only use approved Compact Flash cards (order number

160002).

¯ CAUTION! - Wait five seconds after turning off the printer before

removing or inserting the Compact Flash card!

¯ The printer firmware cannot use more than 128 MB of card storage

capacity.

Wide guide notchSlim guide notch

Inserting a

CF card

Fig. 11: Example of a 32 MB Compact Flash card.

1. Turn off the printer. Wait five seconds.

2. Insert the Compact Flash card completely into the card slot. The wide guide

notch should face upwards (see Fig. 12).

¯ Push the Compact Flash card into the slot until the release button (1)

comes out. The card sits flush with the back wall.

Fig. 12: Inserting a Compact Flash card into a 9854 printer. If the Compact Flash card is

inserted correctly, it sits flush with the printer’s back wall (right).

Page 28

05/08 Rev. AB OPERATOR’S HANDBOOK Getting Started

9844/9854

Setting the Realtime Clock (9854 only)

The 9854 printer’s realtime clock can be used to calculate and print the

expiration date of perishable goods.

To set the realtime clock:

1. Navigate to the parameter SYSTEM PARAMETERS > Realtime clock

1-20

Realtime clock

dd.mm.yyyy hh:mm

2. To enter the date and time, press Cut to shift the cursor, Feed to change the

setting, and Online to save it.

P Refer to the “Info Printouts and Parameters” section on your CD-ROM for

more information on setting parameters.

dd=day, mm=month, yyyy=year, hh=hour,

mm=minute

Outputting the realtime clock value using Easy Plug

Use the following Easy Plug commands to output the current realtime clock

value:

• #YC realtime as text

• #YS realtime as bar code

• #VDD defining date and time variables

P Refer to the Easy Plug manual for more information.

Page 29

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Setup

Loading Diagrams

Printer with Dispenser (Peel)

Selecting Ribbon/Material

Loading Material

Loading a Ribbon

Material/Ribbon End

Setting Printhead Support

2-1

Page 30

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Loading Diagrams

The loading diagrams show the material and ribbon path through the printer.

• Material is wound with the labels facing outwards

• Ribbon is wound with the colored side facing inwards.

12

3

11

2-2

10

9

0

6

1

5

2

3

4

8

7

6

Fig. 1: Material and ribbon path in printer.

No. Description

1 Ribbon rewinding reel

2 Ribbon unwinding reel

3 Material tension roller

4 Guide disk

5 Material roll

6 Material guide

7 Light barrier fitting

8 Print roller

4

5

Bild_3/Z0194.cdr

9 Adjusting wheel for printhead support

10 Pressure lever

11 Ribbon deflection roller

Tab. 1:Operating parts of the printer.

Page 31

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

9854 Printer with Internal Liner Takeup Reel (Rewinder)

12

3

15

2-3

14

13

0

6

1

5

2

3

12

4

7

8

91011

6

Fig. 2: Material and ribbon path through printer with internal liner takeup.

No. Description

1 Ribbon rewinding reel

2 Ribbon unwinding reel

3 Material tension roller

4 Guide disk

5 Material roll

6 Clip

4

5

Bild_3/Z0194.cdr

7 Internal liner takeup reel

8 Deflection roller

9 Material guide

10 Light barrier fitting

11 Deflection plate

12 Print roller

13 Adjusting wheel for printhead support

14 Pressure lever

15 Ribbon deflection roller

Tab. 2: Operating parts of the printer with internal liner takeup.

Page 32

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

9854 Printer with Dispenser (Peel)

12

3

15

2-4

14

13

0

6

1

5

2

3

4

12

11

8

910

6

7

Fig. 3: Material and ribbon path through printer with dispenser (peel).

No. Description

1 Ribbon rewinding reel

2 Ribbon unwinding reel

3 Material tension roller

4 Guide disk

5 Material roll

6 Clip

4

5

Bild_3/Z0194.cdr

7 Internal liner takeup reel

8 Deflection roller

9 Material guide

10 Light barrier fitting

11 Deflection plate

12 Dispensing edge (peel)

13 Adjusting wheel for printhead support

14 Pressure lever

15 Ribbon deflection roller

Tab. 3: Operating parts of the printer with dispenser (peel).

Page 33

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Selecting Ribbon/Material

About Material

Use Monarch-approved material. See “Specifications” for more information.

About Ribbons

Use Monarch-approved ribbon. See “Specifications” for more information.

2-5

Page 34

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Loading Material

WARNING!

Rotating axles! – Keep long hair,

loose clothing, jewelry, etc. away

from the printer!

« Do not operate the printer with the

cover open!

« Be careful when touching the

printhead. It may be hot.

The printer can use both roll and fan-fold

material. Follow these steps to load

material.

P See “Specifications” for more information

about the media.

2-6

1. Open the cover.

2. Release the printhead pressure lever (1).

3. Remove the external guide plate (2) from

the material roller.

4. Push the material roll onto the correctly

sized adapter disc (3) on the unwinder.

Push the guide plate back on.

¯ The material roll turns counter-

clockwise when unwinding!

¯

¯

5. Insert the material as shown (Fig. 2).

¯ Be sure to thread the material around

the material tension roller (4) as well!

1

2

Page 35

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

2-7

6. Push the material guide (5) up to the edge

of the material, without pinching the

material (Fig. 3).

7. Slide the light barrier fitting using the grip

(6) until the pointer (7) is located above the

material perforations (Fig. 4).

¯ The optional reflex sensor is located

5mm to the right of the pointer below the

material!

8. Thermodirect printing: Close the pressure

lever. Thermotransfer printing: See

“Loading Ribbon” to continue.

3

4

Page 36

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Loading Fan-fold Material

Follow these steps to load fan-fold

material:

1. Open the cover.

2. Release the printhead pressure lever (1).

2-8

3. Position the fan-folded material behind the

printer (Fig. 1).

4. Guide the material over the material

unwinder. Push the material guide up to

the edge of the material without pinching

the material.

5. Slide the light barrier fitting using the grip

(6) until the pointer (7) is located above the

material perforations (Fig. 2).

¯ The optional reflex sensor is located

5mm to the right of the pointer below the

material!

1

2

6. Thermodirect printing: Close the pressure

lever. Thermotransfer printing: See

“Loading Ribbon” to continue.

Page 37

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Loading the 9854 with the

Internal Liner Takeup Reel

1. Follow the steps for loading material from

the previous section. Then, follow these

steps.

2-9

2. Thread the end of the material to the

internal liner takeup reel (1) as shown and

secure it with the clip (2) (Fig. 1).

3. Choose the rotation direction of the takeup

reel (face inside or outside): Select

parameter REWINDER PARA > Rewind

direction.

After turning on the printer, the takeup reel

rotates slowly until the material is pulled

tight.

You may see

Status 5004

Rewinder mat. tear

before the material is pulled tight.

« If this happens, press Online to clear the

message. You may have to press it several

times.

1

Page 38

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Dispensing (Peel) 9854 only

2-10

1. Follow the steps for loading material from

the previous section. Then, follow these

steps.

2. Remove the labels from the first 10 inches

(25 mm) of backing paper (Fig. 1).

3. Press the red button (1) at the dispensing

edge to release the peel roller (Fig. 1).

4. Remove the peel roller, feed the label web

through as illustrated (Fig. 1) and press

the roller back between its bearings.

5. Thread the backing paper backwards to

the takeup reel (2) as shown (fig. 2).

6. Wrap the end of the backing paper

clockwise around the takeup reel (2) and

secure it with the clip (3).

7. Turn the takeup reel counter-clockwise

until the backing paper is pulled tight.

1

2

After turning on the printer, the reel rotates

slowly until the material web is pulled tight

(Fig. 3).

You may see

Status 5004

Rewinder mat. tear

before the material is pulled tight.

« If this happens, press Online to clear the

message. You may need to press it several

times.

3

Page 39

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Loading a Ribbon

WARNING!

Rotating axles! – Keep long hair,

loose clothing, jewelry, etc. away

from the printer!

« Do not operate the printer with the

cover open!

« Be careful when touching the

printhead. It may be hot.

¯ Ribbon is only needed for the

thermotransfer printing.

1. Open the cover.

2. Release the printhead pressure lever (1).

2-11

3. Push the ribbon roll onto the ribbon unwind

reel (2) as far as it will go. Push an empty

ribbon sleeve onto the rewind reel (3).

¯ The ribbon turns counter-clockwise

when unwinding.

4. Load the ribbon as shown into the printer

(Figs. 1 and 2). Secure the ribbon end to

the empty ribbon sleeve.

5. Turn the rewind reel counter-clockwise a

few times until the ribbon is crease-free.

Replacing a used ribbon

1. Open the printhead pressure lever.

2. Remove the used ribbon roll from the

rewind reel.

3. Remove the empty ribbon core from the

unwind reel and place it on the rewind reel.

4. Load a new ribbon roll following the steps

above.

1

2

Page 40

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Quick ribbon exchange

2-12

1. Open the pressure lever (Fig. 1).

2. Remove both ribbon rolls from the ribbon

reels. Remove the ribbon from underneath

the printhead (Fig. 2).

1

2

Load the new ribbon as follows:

1. Push the ribbon, which is between the

rolls, under the printhead (Fig. 2).

2. Push both ribbon rolls onto the ribbon

reels as shown (Fig. 1).

3

Page 41

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Material/Ribbon End

Material Stock End

If the material end has passed the material sensor, you see

Status 5002

Material end

« Release the pressure lever and pull the end of the remaining material from the

front side of the printer.

Ribbon End

If the ribbon roll is emptied (the ribbon unwind reel is not turning), you see

Status 5008

Ribbon end

« See “Loading a Ribbon” to continue.

¯ Ribbon end detection can be turned off for theromodirect printing.

2-13

« To do so, set the parameter SYSTEM PARAMETERS > Ribbon autoecon. to

Thermal printing.

P Refer to the “Info-Printouts and Parameters” section on your CD-ROM for

more information.

Page 42

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Setting Printhead Support

When printing narrow labels, the printhead may come into contact with the

print roller where there is no material. This can lead to premature wear of the

printhead and to different print intensity between the two edges of the label.

¯ When using narrow labels, enable the printhead support. Small = material

width < printhead width.

Change the printhead support by using the adjusting wheel (1). Position 0 is

recommended for wide labels.

2-14

Fig. 1: The adjusting wheel for the printhead support.

1. For narrow labels, turn the adjusting wheel clockwise until the pointer

indicates 1 on the dial. This causes the printhead to be raised at the outside.

2. Print a test print and check for even print quality. If the print quality is still

uneven, turn the adjusting wheel a little further.

3. Repeat steps 1 to 3 until the print quality is the same across the entire width

of the label.

Page 43

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

Setting the Material Parameters

Use the following three parameters to set the material properties:

Parameter Function

PRINT PARAMETERS/

Material type

PRINT PARAMETERS/

Material length

PRINT PARAMETERS/

Material width

SYSTEM PARAMETERS/

Light sens

. type

Tab. 1:Important parameters for setting the material properties.

P Refer to the “Info-Printouts and Parameters” section on your CD-ROM for

more information on setting parameters.

Sets the material type (perforated or

endless)

Sets the material length

Sets the material width

Sets the sensor type (reflex or transmission)

based on the material (marks or

perforations)

2-15

Page 44

05/08 Rev. AB OPERATOR’S HANDBOOK Setup

9844/9854

2-16

Page 45

05/08 Rev. AB OPERATOR’S HANDBOOK

9844/9854

Care & Maintenance

Cleaning the Printhead

Cleaning the Print Roller

Cleaning the Punch (Die Cut) Sensor

3-1

Page 46

05/08 Rev. AB OPERATOR’S HANDBOOK Care & Maintenance

9844/9854

Care & Maintenance

Regular maintenance is required to make sure the printer is always operating

safely.

Safety

WARNING!

Maintenance and cleaning may result in hazardous situations. Accidents can

occur if safety instructions are not followed!

« Turn off the printer and disconnect the power supply before any cleaning or

maintenance work!

« Do not spill liquid into the printer!

« Do not spray any cleaner directly on the printer! Moisten a cloth with the

recommended cleaning agent to clean the printer!

3-2

Troubleshooting

Error Messages When an error occurs, read the messages first and refer to the

documentation for more information.

Calling

Technical

Support

If you need to call Service, have your printer’s model number and serial

number ready.

Call Service to order spare parts.

Note on Cleaning

Frequency of

Care

Frequent maintenance and cleaning is required to make sure the printer is

operating properly. The rate and frequency at which you print determine how

often you must clean the printer.

¯ Frequently check the printhead and feed rollers for paper or adhesive

buildup.

¯ WARNING! - Do not use any cleaning agent that could damage or destroy

the resin surface, labelling, display, nameplates, electrical components, etc.

¯ WARNING! - Do not use any cleaning agents that are abrasive or

damaging to plastics. Avoid acid or alkaline solutions.

Page 47

05/08 Rev. AB OPERATOR’S HANDBOOK Care & Maintenance

9844/9854

Cleaning the Printhead

CAUTION! - The printhead is

sensitive to static electricity, which

can damage the printhead or

reduce its life. Ground yourself by

touching a metal surface, such as

the printer’s metal base, before

cleaning the printhead.

« Do not use sharp objects to clean

the printhead!

You may need to clean the printhead when

you see voids or streaks in the printing or

notice uneven printing.

1. Turn off the printer.

3-3

2. Open the printhead pressure lever. The

printhead lifts upwards.

3. Remove the material and ribbon.

Cleaning with the cleaning pen (order

part number 114226):

4. Applying light pressure, go over the

printhead (1) a few times with the cleaning

pen (Fig. 1).

Cleaning with isopropyl alcohol:

¯ Use isopropyl alcohol if you do not have

a cleaning pen.

« Moisten a cotton swab with isopropyl

alcohol and wipe the printhead clean.

1

Page 48

05/08 Rev. AB OPERATOR’S HANDBOOK Care & Maintenance

9844/9854

3-4

Replacing the Printhead

Fig. 1: Printhead (1) with bracket (2).

CAUTION! - Printhead (1) and

bracket (2) were adjusted exactly

using special tools.

« Do not loosen the screws (3)

attaching the printhead to the

bracket.

Removing the printhead:

1. Turn off the printer and disconnect the

power supply.

1

2

2. Remove the material and ribbon.

3. Close the pressure lever (1).

4. Remove the two thumb screws (Fig. 1).

5. Open the pressure lever.

The printhead is released from the fastener

and remains on the print roller (Fig. 2).

6. Remove both printhead cables from the

printhead (Fig. 3).

Connecting the printhead:

Note the resistance of the new printhead

listed on the printhead’s label.

1. Connect the printhead cable.

2. Press the printhead against the fastener

from below and tighten the thumb screws.

3. Navigate to the parameter SYSTEM

PARAMETERS > Head resistance and

enter the printhead resistance from the

printhead’s label.

3

4

Page 49

05/08 Rev. AB OPERATOR’S HANDBOOK Care & Maintenance

9844/9854

3-5

Cleaning the Print Roller

Clean the print roller when you see

adhesive buildup or dirt on the roller.

1. Turn off the printer and disconnect the

power supply.

2. Remove the material and ribbon.

¯ You can easily access the print roller if

you remove the tear-off edge (1) first.

3. Remove the tear-off edge and unfasten

the screw (2) in the middle of the tear-off

edge with a size 10 Torx screwdriver

(Fig. 2).

4. Moisten a lint-free cloth with isopropyl

alcohol and wipe the print roller (Fig. 3)

clean. Turn the roller with your finger to

clean all the way around.

5. Replace the tear-off edge.

1

2

3

Page 50

05/08 Rev. AB OPERATOR’S HANDBOOK Care & Maintenance

9844/9854

3-6

Cleaning the Punch

(Die Cut) Sensor

During printing, the punch sensor can

become contaminated with lint and unable

to sense material.

1. Remove the cover (1) gently and swivel

downwards (Fig. 1).

2. Remove the sensor arm (2) (Fig. 2).

3. Clean the opening (3) with compressed

air.

¯ The transmission sensor is located in

the upper and the lower part of the sensor

arm on a level with the indicator (4). You

can find the reflex sensor about 5 mm

further below.

CAUTION! - The sensor surface is

very sensitive to scratches!

« Do not use sharp objects or

solvents when cleaning the

sensors.

1

2

Page 51

05/08 Rev. AB OPERATOR’S HANDBOOK

9844/9854

Specifications

Printers

Supplies (Material)

Ribbon (Foil)

A-1

Page 52

05/08 Rev. AB OPERATOR’S HANDBOOK Specifications

9844/9854

Specifications

Printers

Height: 10.7 inches (272 mm)

Width: 10.3 inches (260 mm)

Depth: 18.2 inches (462 mm)

Weight: 31 lb. (14 kg)

35 lb. (16 kg) with dispenser (peel)

Operating Limits: 40° to 100°F (4° to 38°C)

Storage: 24° to 140°F (-4° to 60°C)

Humidity: 30% to 85% non-condensing

Printhead: 203 dpi (8 dots per mm) or

300 dpi (12 dots per mm)

A-2

Printing Method: Thermotransfer (ribbon) or Thermodirect

Print Width: 4.2 inches (105 mm) maximum

Print Speed: 2 to 8 ips (50 to 200 mms)

2 to 6 ips (50 to 150 mms) with 300 dpi

Page 53

05/08 Rev. AB OPERATOR’S HANDBOOK Specifications

9844/9854

Supplies (Material)

Width: 0.6 to 4.8 inches (15 to 120 mm)

1.2 to 4.3 inches (30 to 110 mm) - 9854 with

dispenser

Min. Length: 0.2 inches (5 mm)

1.2 inches (30 mm) - 9854 with dispenser

Roll Diameter: 8.35 inches (210 mm) maximum outer diameter

4.9 inches (125 mm) - 9854 with liner takeup

When selecting a material, note the following items:

– The abrasiveness of the printing surface.

– The chemical reaction when the ink is transferred.

– The temperature required to transfer the ink.

A-3

Abrasive

Material

Printhead

temperature

If the material is very abrasive, the printhead wears more quickly than normal.

This is important in thermodirect printing. It is not so critical for thermotransfer

printing, because the ribbon can be wider than the material, ensuring that the

printhead is protected across the entire width of the material.

The same applies if the temperature of the printhead is too high. The material

and ribbon take longer to cool down, the print quality is more critical and the

printhead wears out more quickly.

For paper thicker than 240g, adjust the contact pressure and the position of

the printhead.

Ribbon (Foil)

Width: 9844: 1.0 to 4.4 inches (25 to 110 mm)

9854: 1.0 to 4.5 inches (25 to 114 mm)

Length: 500 m (maximum)

The ribbon width must be greater than the material width. Since some

material is more abrasive to printheads than others, using a ribbon wider than

your material helps protect the printhead. Replacement printheads are

expensive.

Page 54

05/08 Rev. AB OPERATOR’S HANDBOOK Specifications

9844/9854

A-4

Page 55

Page 56

Visit for sales, service,

www.monarch.com

supplies, information, and telephone numbers

for our locations throughout the world.

TOLL FREE:

1-800-543-6650 (In the U.S.A.)

1-800-363-7525 (In Canada)

Loading...

Loading...