Page 1

M

Equipment Manual

TC9445EM Rev. D 7/95

©1988 Monarch Marking Systems, Inc. All rights reserved.

Page 2

Each product and program carries a respective written

warranty, the only warranty on which the customer can rely.

Monarch reserves the right to make changes in the product

and the programs and their availability at any time and without

notice. Although Monarch has made every effort to provide

complete and accurate information in this manual, Monarch

shall not be liable for any omissi ons or inaccur ac ies. Any

update will be incorporated in a later edition of this manual.

WARNING

This equipment can interfere with radio communication if

not installed and used in accordance with the instruction

manual. It has been tested and found to comply with the

limits for a Class A computing device pursuant to FCC

Rules, Subpart B, Part 15, which provide reasonable

protection against such interference when operated in a

commercial environment. Operation in a residential area is

likely to cause interference which the user must correct at

their own expense.

CANADIAN D.O.C. WARNING

This digital apparatus does not exceed the Class A limits

for radio noise emissions from digital apparatus set out in

the Radio Interference Regulations of the Canadian

Department of Communications.

Le présent appareil numérique n’émet pas de bruits

radioélectriques dépassant les limites applicables aux

appareils numériques de la classe A prescrites dans le

Réglement sur le brouillage radioélectrique édicte par le

ministère des Communications du Canada.

Page 3

Preface

This manual contains information about the general setup and

maintenance of the 9445 printer. Some of the features in this

manual may not be available on your printer.

Other 9445 manuals include:

Preface

Operator’s

Handbook

User’s Manual

Programmer’s

Manual

Messages Manual

Explains how to enter data and print

labels.

Explains how to create and enter

formats. This manual also explains

special setup functions for the printer.

Explains communications and message

structures for sending formats and batch

data online.

Lists error messages and operator

responses.

i

Page 4

9445 Equipment Manual

ii

Page 5

Table of Contents

1. Installing the Printer

2. Loading Supply

Non-Peel Mode............ .......................... .............. .....2-1

Peel Mode.................................................................2-8

Loading Fan-Fold Supply .................... ....................2-16

Adjusting the Supply Sensor...................................2-18

Adjusting the On Demand Sensor.............. ............. 2-20

3. Loading a Ribbon

Loading a Ribbon Roll............... .. .. .... .. .. .. .... .. .. .. .... .. .. 3-2

Loading a Ribbon Cassette............. .. .... .. .. .... .. .. .. .... .. 3-6

4. Adjusting the Display

5. Cleaning the Printhead and Platen Roller

Appendix A. Converting the Keyboard for

T able Top Use

......................................................................A-1

.......................................................1-1

...............................................................2-1

............................................................ 3-1

....................................................4-1

Table of Contents

....................5-1

Appendix B. Troubleshooting

"Head Test Failure" Message....................................B-1

Start -Up and Pr inting................................................B-2

Start-Up and Printing (continued) .............................B-3

Cutting.......................................................................B-4

............................................B-1

iii

Page 6

9445 Equipment Manual

Appendix C. Specifications

Printer.......................................................................C-1

Supplies....................................................................C-2

...............................................C-1

iv

Page 7

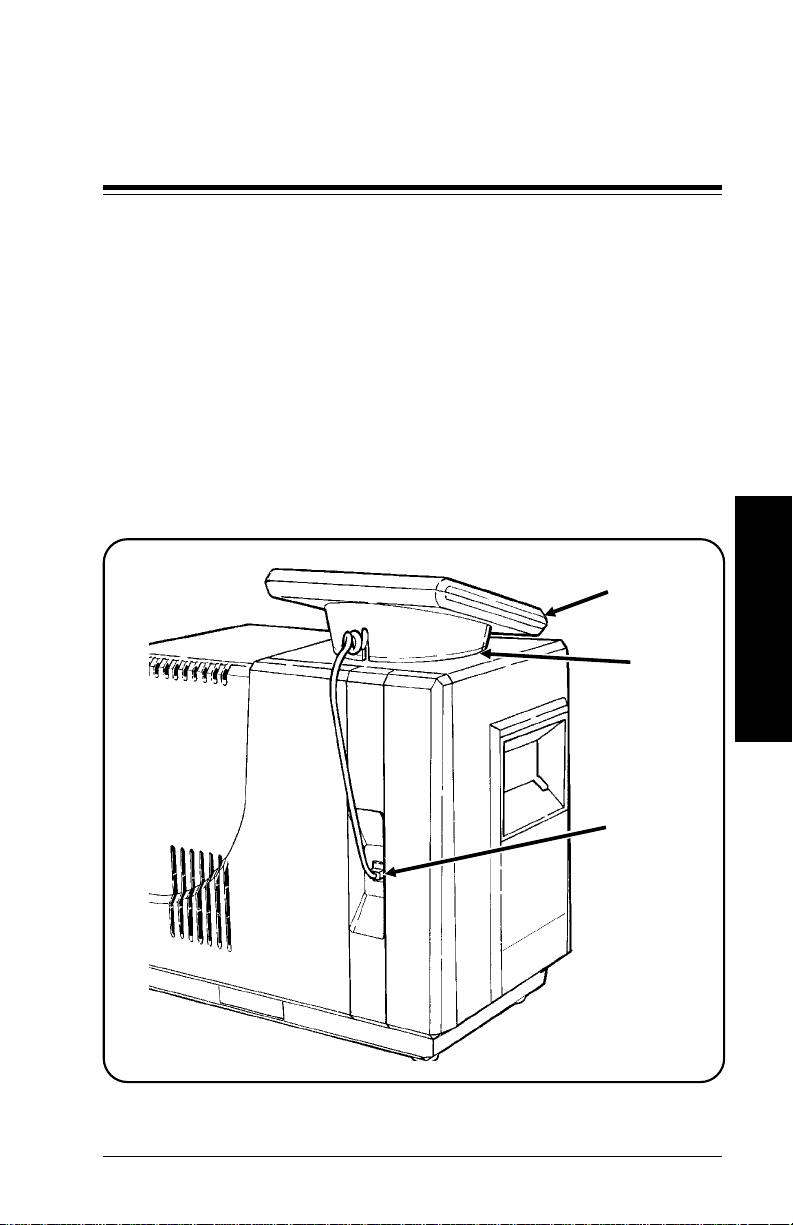

1. Installing the Printer

1.

Place the printer on a level surface.

2.

To install the keyboard on top of the printer:

a.

Remove the cord from the base of the keyboard.

b.

Plug the cord from the keyboard into the socket.

c.

Insert all of the cord ex ce pt a few co i l s back into the

base. Secure the cord by sliding a coil into the slot in

the base.

d.

Place the keyboard in the recess on top of the printer

as shown.

Installing the Printer

Keyboard

Recess

Socket

1-1

Page 8

9445 Equipment Manual

CAUTION

If your 9445 printer has been in storage below room

temperature, allow 10-12 hours for the printer to adjust to

room temperature

before

turning the power on. Failure to

do this may damage the printer.

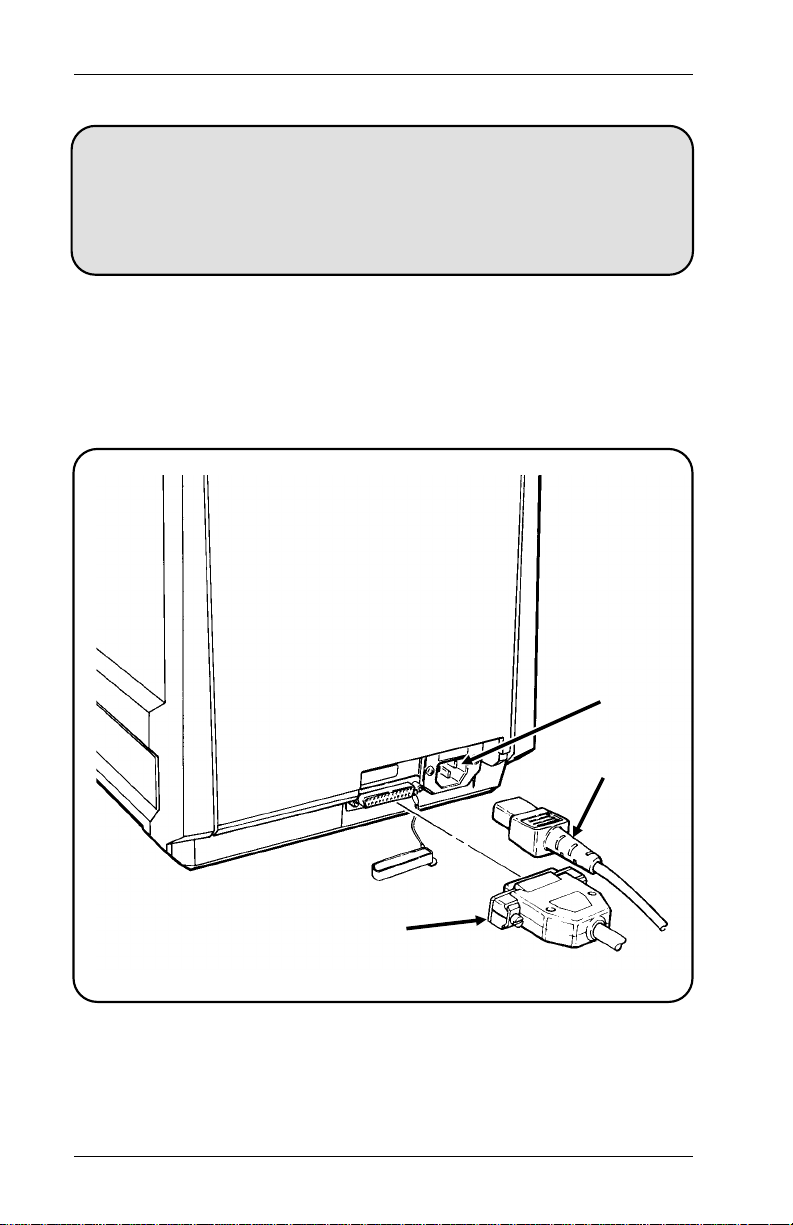

3.

Turn the power switch off and insert the power cord into

the socket. Plug the other end of the cord into a

grounded

115 VAC electrical outlet.

NOTE:

If you are going to use the printer online, also

connect the RS-232 cable.

Socket

Power Cord

RS-232 Cable

4.

On the initial startup, leave the printer on for 24 hours to

charge the new backup batteries.

1-2

Page 9

2. Loading Supply

The printer prints both tags and labels. The supply may be

wound with the printable side on either the inside or the

outside.

This chapter explains how to load supply for

•

Non-Peel Mode Printing (labels are printed in one strip.

This can be used with Continuous Printing.)

•

Peel Mode Printing (one label at a time while the

backing paper rewinds inside the printer. This must be

used with On Demand Printing.)

•

Fan-Fold Mode Printing (fan-fold supply is printed in

one strip). Call Service if you would like to use fan-fold

supply.

NOTE:

If your printer has a knife, follow the instructions under

"Non-Peel Mode ." You c annot use On Demand

printing with a knife. Also, if your printer has a knife, it

does not have the take-up spool shown in the

instructions for loading supply.

If you are going to use thermal direct supply (no

ribbon) and your printer is equipped with a ribbon roll

adapter, turn the thermal supply indicator to the right.

(See "Loading a Ribbon Roll" in Chapter 3.)

Non-Peel Mode

This mode is for both tags and labels. The printer dispenses

the desired amount of supply without separating the backing

paper from the label. This mode is us ually us ed with

continuous printing.

1.

Open the front panel.

Loading Supplies

2-1

Page 10

9445 Equipment Manual

Printhead

Lever

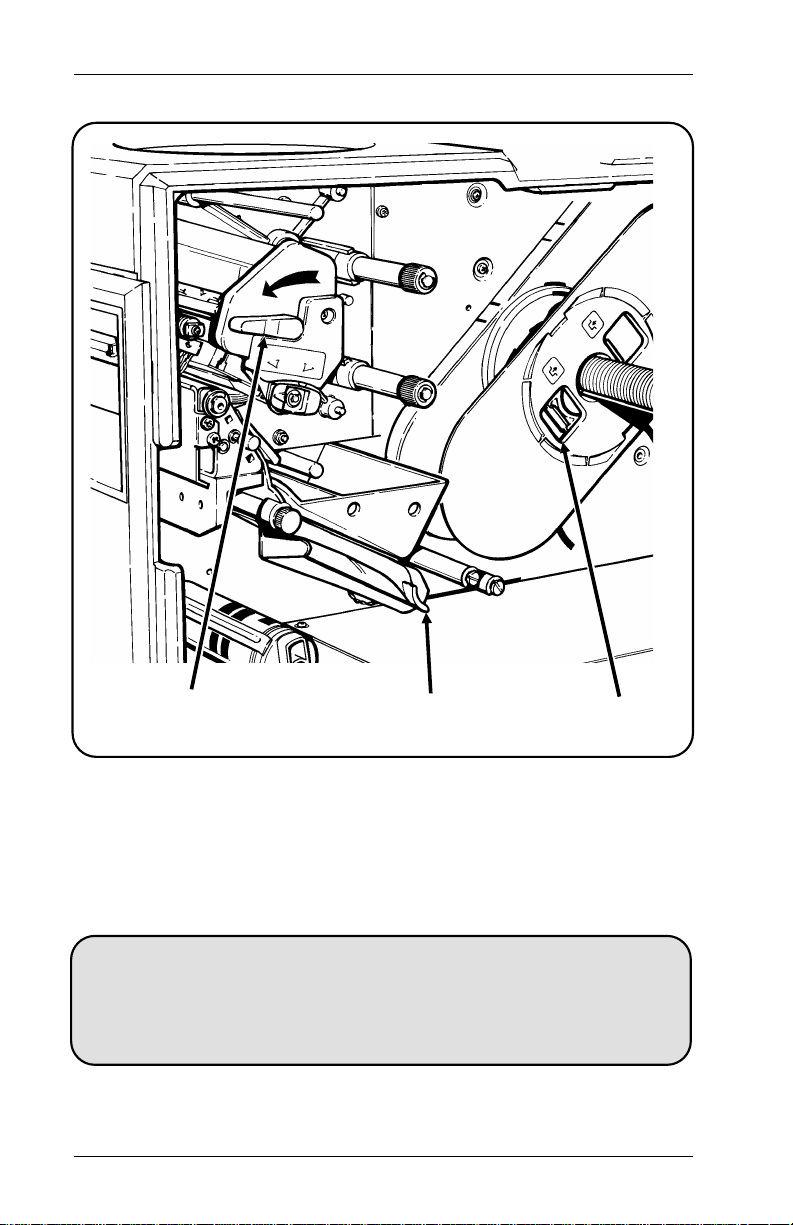

2.

Turn the printhead lev er to the left to release the printhead.

3.

Hold down the lower supply guide and rewind the old

Lower Supply

Guide

supply roll, if there is one.

4.

Release the lower supply guide.

CAUTION

If you run out of supply while printing, pull the supply strip

back through the printer.

DO NOT

pull it forward through

the printhead. Pulling it forward may cause jamming.

2-2

Lock

Page 11

2. Loading Suppl y

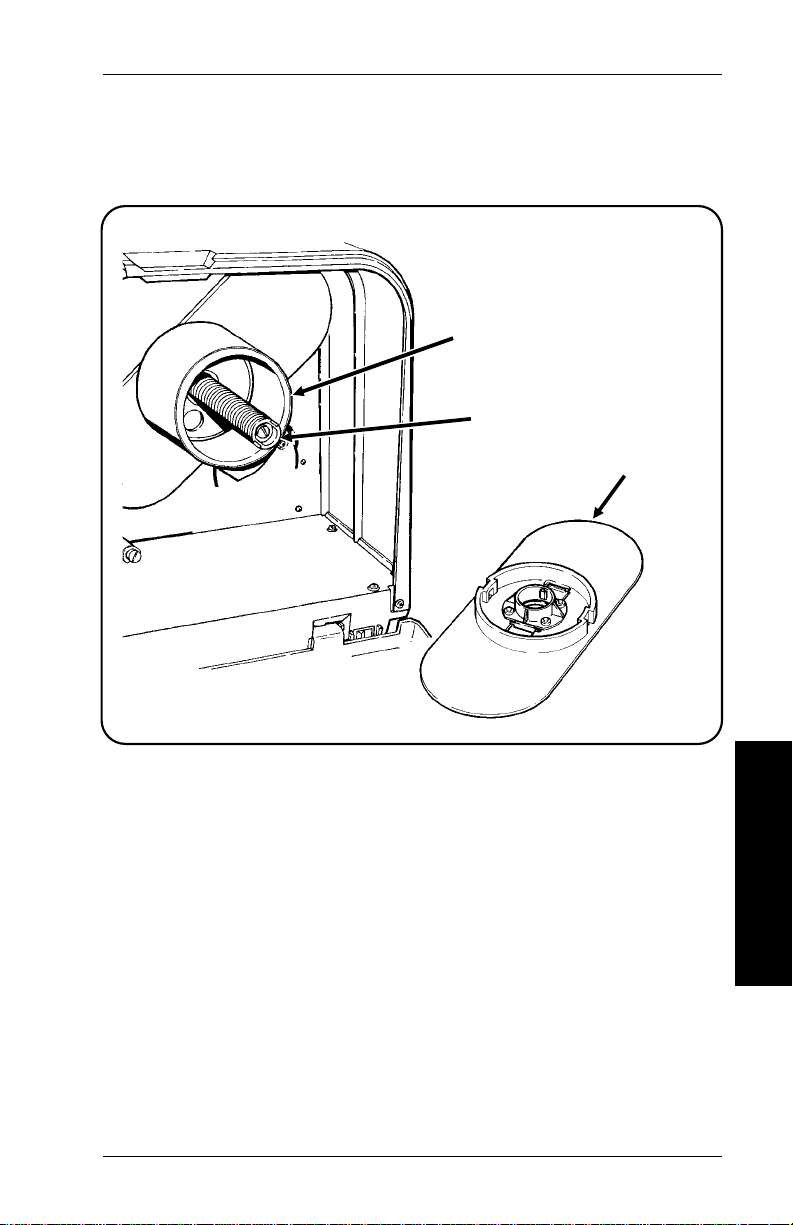

5.

Push the lock to the right to unlock the outer supply holder

and remove the outer supply holder from the supply shaft.

Remove the old supply core, if there is one.

Supply

Core

Supply

Shaft

Outer Supply

Holder

2-3

Loading Supplies

Page 12

9445 Equipment Manual

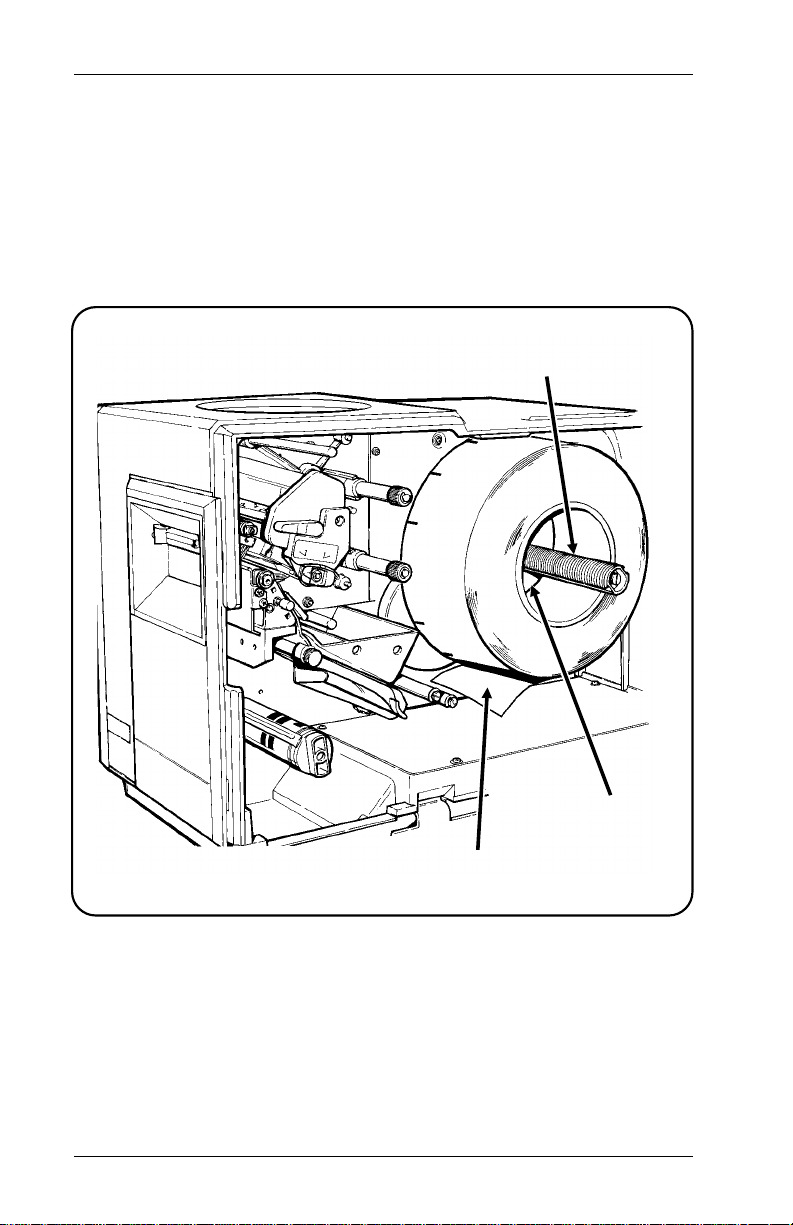

6.

Place the new supply roll on the supply shaft as shown.

NOTE:

a.

b.

If your supply has a 3-inch (76.2 mm) core:

Remove the hub from the inner supply holder .

Reverse the outer supply holder (so the smooth side

faces the supply).

Supply

Shaft

Printable

Side Inside

7.

Fit the supply core onto the inner supply holder and hold it

in place.

2-4

Inner

Supply

Holder

Page 13

2. Loading Suppl y

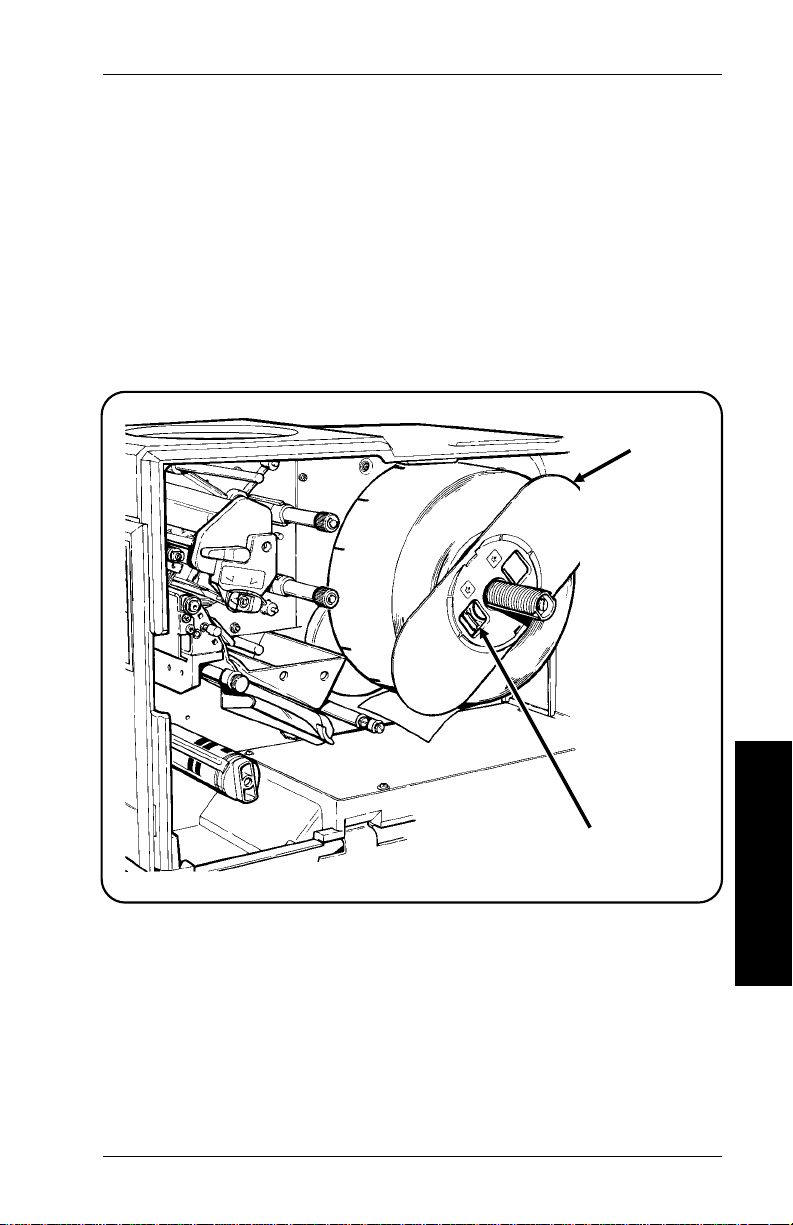

8.

Turn the outer supply holder so the lock faces out. Align

the supply holder tabs with the tracks on the shaft.

9.

Push the supply holder onto the supply shaft, against the

supply.

10.

Push the lock to the left to secure the outer supply holder.

Make sure the supply is free to unwind.

NOTE:

When the outer supply holder is reversed (for

3-inch core supply), push the lock to the right to

secure the outer supply holder.

Supply

Holder

Loading Supplies

Lock

2-5

Page 14

9445 Equipment Manual

11.

Pull enough supply from the roll to reach the printhead.

12.

Hold down the lower supply guide.

13.

Feed the supply past the out-of-stock switch, between the

upper and lower supply guides, and up past the printhead.

Upper Supply

Printhead

Lower Supply

Guide

14.

Align the supply with the top edge of the upper guide and

Guide

Out-of-Stock

Switch

Outer Supply

Holder

Supply

slide it against the back wall (away from you). Continue

threading the supply up to the printhead as shown.

sure the ribbon does not snag or wrinkle

.

Make

2-6

Page 15

2. Loading Suppl y

15.

To adjust for wide or narrow supply, turn the supply width

adjustment knob to:

NARROW

•

WIDE

•

NOTE:

Printhead

Lever

Supply Width

Adjustment

Knob

for supply

for supply

two inches in width or smaller

greater than two inches in width.

Be sure the adjustment knob snaps back into

place after you turn it.

.

Loading Supplies

16.

Turn the printhead lev er to the right to lock the printhead.

2-7

Page 16

9445 Equipment Manual

17.

Turn the printer on. If you are:

•

replacing the supply with a new roll of the same size,

press f to align the printer.

•

changing supply size, adjust the supply sensor. See

"Adjusting the Supply Sensor" later in this chapter.

NOTE:

Before you print, be sure the menu supply type

setting matches your supply type (e.g. Black

Mark/Die Cu t). See your Operator’s Handbook to

set supply options.

Peel Mode

This mode is only used with labels. The printer separates the

label from the backing paper . This mode must be used with On

Demand printing.

1.

Open the front panel.

2.

Turn the printhead lev er to the left to release the printhead.

Printhead

Lever

2-8

Page 17

3.

If you are reloading supply:

a.

Cut the backing paper in front of the paper take-up

spool, and then manually rewind the supply roll.

b.

While holding the backing paper with one hand, turn

the take-up spool knob counterclockwise about 1/4 turn

with the other hand.

c.

Slide the backing paper off the take-up spool.

2. Loading Suppl y

Paper Take-up

Spool

4.

Push the lock to the right to unlock the outer supply holder

Backing

Paper

Lock

Outer Supply

Holder

and remove the outer supply holder from the supply shaft.

Remove the old supply core, if there is one.

5.

Remove labels from the first 16 inches of backing paper

(on the new supply roll).

Loading Supplies

2-9

Page 18

9445 Equipment Manual

6.

Place the new supply roll on the supply shaft as shown.

Supply

Shaft

Printable

Side Inside

NOTE:

a.

b.

For 3-inch (76.2 mm) cores:

Remove the hub from the inner supply holder .

Reverse the outer supply holder (so the smooth side

faces the supply).

7.

Fit the supply core on the inner supply holder and hold it in

place.

2-10

Inner

Supply

Holder

Page 19

2. Loading Suppl y

8.

Turn the outer supply holder so the lock faces out. Align

the supply holder tabs with the tracks on the supply shaft.

9.

Push the supply holder onto the supply shaft, against the

supply.

10.

Push the lock to the left to secure the outer supply holder.

Make sure the supply is free to unwind.

NOTE:

When the outer supply holder is reversed (for

3-inch core supply), push the lock to the right to

secure the outer supply holder.

Supply

Holder

Loading Supplies

Lock

2-11

Page 20

9445 Equipment Manual

11.

With one hand, hold down the lower supply guide. With

the other hand, feed the backing paper between the lower

and upper supply guides, past the printhead and down to

the paper take-up spool. Then release the lower supply

guide.

12.

While holding the paper take-up spool with one hand, turn

the knob

counterclockwise

(1/4 turn) with the other hand.

This opens the clamp on the paper take-up spool.

Printhead

Upper

Supply

Guide

Knob

Paper

Take-up

Spool

13.

Insert the backing paper under the clamp .

Clamp

2-12

Lower

Supply Guide

Page 21

2. Loading Suppl y

14.

Turn the supply roll

countercloc kwise

to remove any

slack in the bac king paper. Your supply and backing paper

should be fed as shown.

Labels

Backing Paper

2-13

Loading Supplies

Page 22

9445 Equipment Manual

15.

To adjust for wide or narrow supply, turn the supply width

Adjustment Knob to:

NARROW

•

WIDE

•

NOTE:

Printhead

Lever

Supply Width

Adjustment

Knob

for supply

for supply

two inches in width or smaller

greater than two inches in width.

Be sure the adjustment knob snaps back into

place after you turn it.

16.

Turn the printhead lever to the right to lock the printhead.

2-14

Page 23

17.

Turn the printer on. If you are:

•

replacing the supply with a new roll of the same size,

press f to align the printer.

•

changing supply size, adjust the supply sensor. See

"Adjusting the Supply Sensor" later in this section.

2. Loading Suppl y

NOTE:

Before you print, be sure the menu supply type

setting matches your supply type (e.g. Black

Mark/Die C u t). See your Operator’s Handbook to

set supply options.

CAUTION

Turning the printer on and off rapidly can cause it to

malfunction. If you have turned the printer on (or off), wait

ten seconds before turning it back off (or on).

Loading Supplies

2-15

Page 24

9445 Equipment Manual

Loading Fan-Fold Supply

The 9445 has the ability to print fan-fold supply with the

optional fan-fold printer cover. If your printer does not have a

fan-fold slot, contact Monarch Service to order a fan-fold

printer cover.

To load fan-fold supply:

1.

Open the front panel.

2.

Open the printhead by turning the printhead lever to the

left.

3.

Fan all four sides of the supply stack and straighten any

curved or bent corners. This will prevent supply from

sticking together and causing feed jams.

4.

Place the supply approximately one fan-fold length behind

the printer, label side up.

Printhead

Exit

Chute

5.

Feed the supply through the slot in the back of the printer

Printhead

Lever

Lower

Supply

Guide

Upper Supply

Guide

length from printer

Out-of-Stock

Switch

Space supply at

least one fan-fold

Slot

and past the out-of-stock switch.

2-16

Page 25

2. Loading Suppl y

6.

With one hand, hold down the lower supply guide. With

the other hand, feed the backing paper between the upper

and lower guides, past the printhead, and then out through

the exit chute.

Space supply at

least one fan-fold

length from printer

Box for

fan-fold

labels

7.

Close the printhead by turning the printhead lever to the

right.

8.

Place an empty box below the printer’s exit chute to catch

the labels as they are printed.

NOTE:

Check the stack of printed labels a few times during

the print job to make sure the labels fold at the same

points at which they were folded before printing. If

you remov e som e or all of the printed labels, check

that the order of the folds is correct before you

resume printing.

Box of new

labels

Loading Supplies

2-17

Page 26

9445 Equipment Manual

Adjusting the Supply Sensor

The supply sensor controls how much supply feeds between

tags or labels. The sensor reads blac k m arks or feed apertures.

To read black marks or apertures, the sensor must be aligned

with the black mark or aperture on the tag. Otherwise, you’ll

see an error message when you try to print a batch.

When moving the sensor, tur n the sensor adjustment knob:

CLOCKWISE

•

edge of the supply.

COUNTERCLOCKWISE

•

the inside edge of the supply.

to move the sensor away from the inside

to move the sensor toward

2-18

Sensor

Adjustment

Knob

Page 27

2. Loading Suppl y

Die cut supply requires no sensor adjustment.

1.

Do one of the following:

For black mark supply, turn the sensor adjustment knob

counterclockwise

until it stops. Do not force the knob.

For feed apertures, turn the sensor adjustment knob

counterclockwise

clockwise

•

Measure from the edge of the supply to the center of

as determined below.

until it stops. Then turn the knob

the aperture.

•

Subtract 1/8 inch (3.1 mm) from the measurement.

•

Multiply the result by 36 (if you are measuring in millimeters, multiply by 1.41).

For example, if the measurement to the aperture center

is 3/8 inch (9.5 mm), turn the knob 9 turns to center the

sensor.

Sensor

Adjustment

Knob

2.

Close the front panel.

Loading Supplies

2-19

Page 28

9445 Equipment Manual

Adjusting the On Demand Sensor

The On Demand sensor stops the printer between tags or

labels when you print in the On Demand mode. The sensor

detects the presence of supply in the exit chute of the printer.

When you remov e the tag or label, another tag or label prints.

On Demand

Sensor

NOTE:

The On Demand sensor must be positioned over a

white or light area on the supply. If it is positioned

over a dark area, the entire batch may pr int before the

printer stops.

You can adjust the On Demand sensor either right or left by

pushing it with your finger.

2-20

Page 29

3. Loading a Ribbon

There are two types of supplies:

Thermal Direct

Thermal T ransfer

NOTE: DO NOT

supplies.

When installing a ribbon, remember

•

Ribbons may catch on supplies left in place.

•

Supplies can misalign the ribbon as you move the

supply up to the feed mark.

•

The width of your ribbon must closely match the width

of your supply.

To install a ribbon roll, refer to "Loading a Ribbon Roll," later in

this chapter. To install a ribbon cassette, refer to "Loading a

Ribbon Cassette," later in this chapter.

specially treated thermal supplies that

don’t use a ribbon for printing.

standard supplies that require a ribbon

for printing.

load a ribbon when printing on thermal direct

3-1

Loading a Ribbon

Roll

Page 30

9445 Equipment Manual

Loading a Ribbon Roll

To load a ribbon roll:

1.

Open the front panel.

2.

Turn the printhead lever to the left to release the printhead.

(Also see the supply loading figure inside the front panel.)

NOTE:

Printhead

Lever

Tab

Upper

Guide

If the printer has supplies loaded for continuous

printing, pull the leading edge back to the upper

supply guide before loading the ribbon.

3.

Grasp the tab on the ribbon roll adapter and pull it out until

the adapter locks into the extended position.

3-2

Page 31

3. Loading a Ribbo n

4.

Pull the ribbon spool holders off. Remove the old ribbon (if

there is one).

5.

Be sure the thermal supply indicator is pointing upward.

NOTE:

Thermal

Supply

Indicator

Turn the thermal supply indicator to the right only

if you are going to use thermal direct supplies (no

ribbon).

Spool

Holders

6.

Load a new ribbon onto the lower spool shaft so the ribbon

unwinds

clockwise

.

Loading a Ribbon

Roll

3-3

Page 32

9445 Equipment Manual

7.

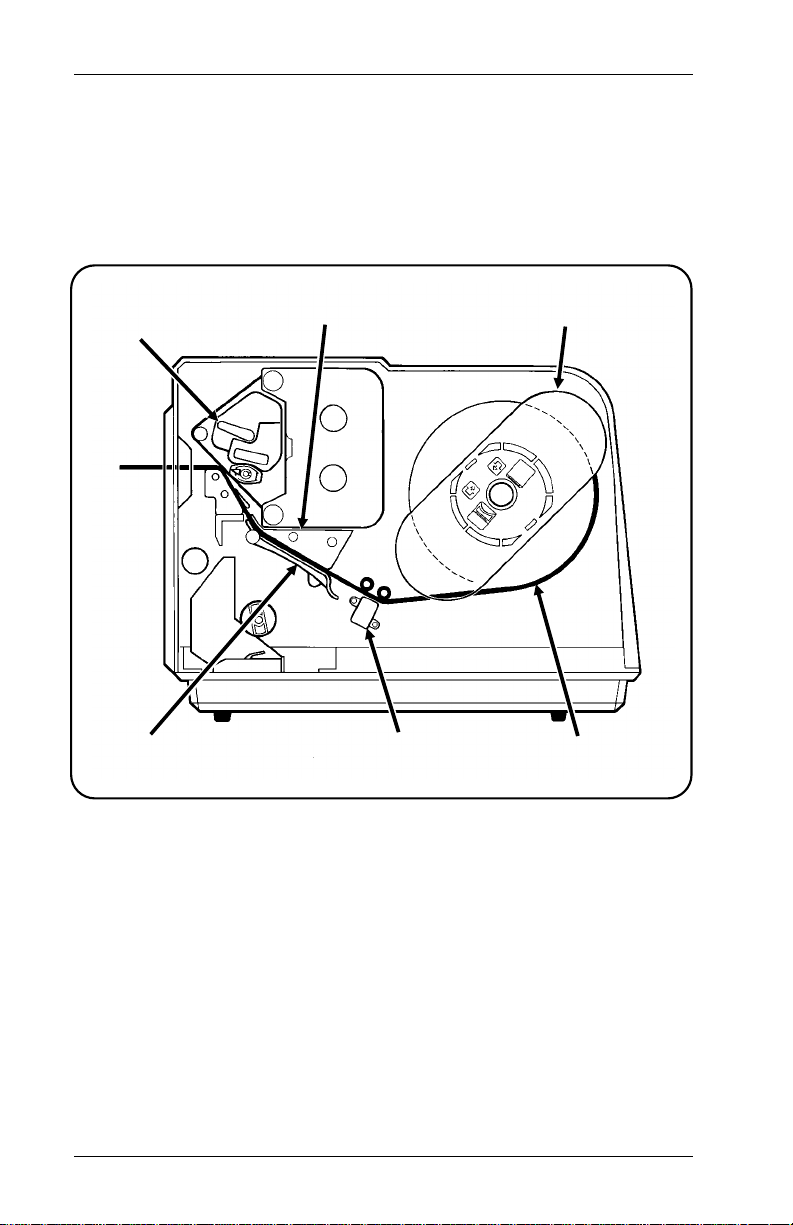

Guide the new ribbon around the rollers on the ribbon roll

adapter. Slide the upper spool onto the upper spool shaft.

Ribbon

Leader

Feed Mark

8.

Slide the ribbon spool holders against the spools.

9.

Turn the upper ribbon spool

tension to the ribbon.

Rollers

clockwise

Make sure the ribbon is tight but

Ribbon Roll

to add slight

not wrinkled or bunched.

10.

Slide the ribbon roll adapter in against the back wall of the

printer

NOTE:

To help slide the ribbon roll adapter in or out, it

may be necessary to increase or relax tension on

the ribbon by turning the spools.

3-4

Page 33

3. Loading a Ribbo n

11.

Turn the upper ribbon spool

clockwise

until the black part

of the ribbon is past the feed mark.

12.

If the printer has supplies loaded for continuous printing,

slide the supply up to the feed mark.

ribbon is correctly positioned

13.

Turn the printhead lev er to the right to move the printhead

Make sure the

.

against the ribbon and the supply.

14.

Close the front panel.

3-5

Loading a Ribbon

Roll

Page 34

9445 Equipment Manual

Loading a Ribbon Cassette

To load a ribbon cassette:

1.

Open the front panel.

2.

Turn the printhead lever to the left to open the printhead.

(Also see the supply loading figure inside the front panel.)

NOTE:

If the printer has supplies loaded for continuous

printing, pull the leading edge back to the upper

guide before loading the ribbon cassette.

3.

Remove the old ribbon cassette if necessary.

Printhead

Lever

3-6

Page 35

3. Loading a Ribbo n

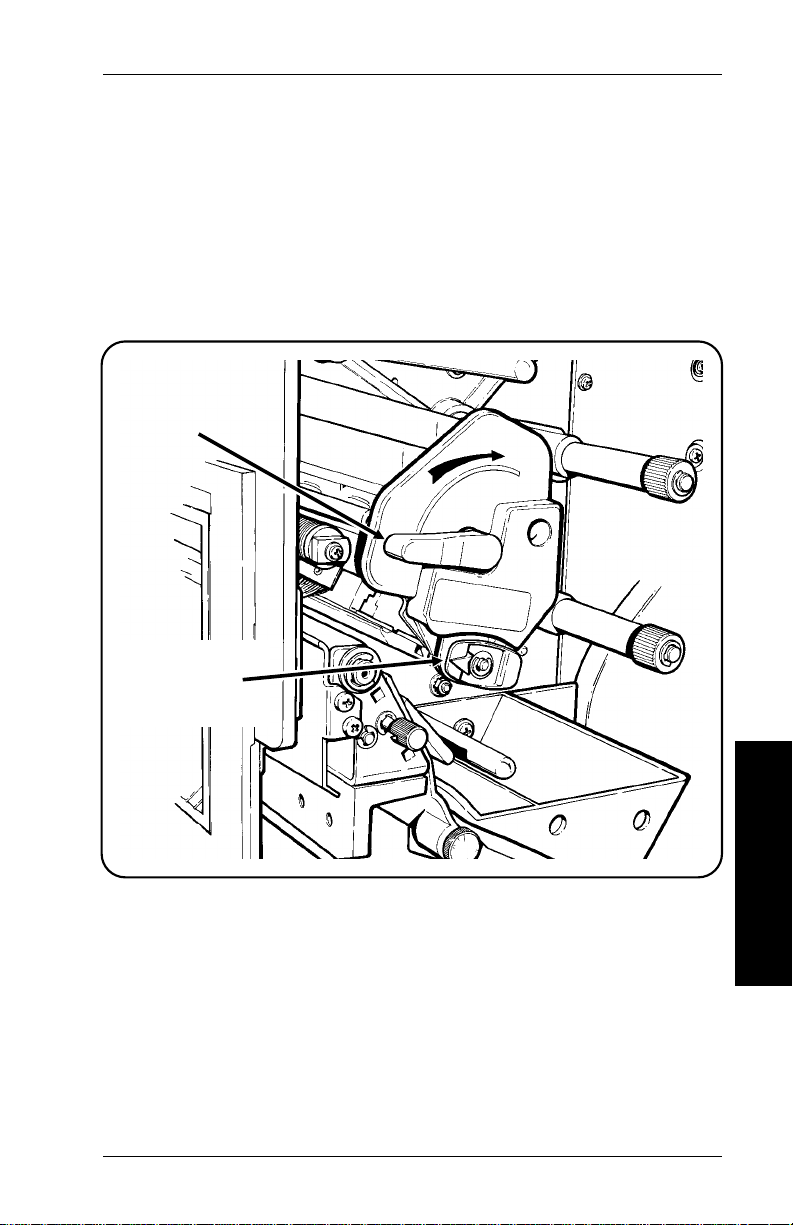

4.

Remove the ne w ribbon cassette from the pac k age . Then

loosen ribbon from cassette as shown below.

3-7

Loading a Ribbon

Roll

Page 36

9445 Equipment Manual

5.

Guide the edge of the ribbon around the ribbon guide post.

6.

Place the cassette on the ribbon spools and push it

against the back wall. The spool lock will drop out.

Upper

Ribbon

Spool

Ribbon

Guide

Post

Printhead

Lever

7.

Turn the upper ribbon spool

Make sure the ribbon is not wrinkled or bunched

tight.

8.

Slide the supply up to the feed mark.

ribbon is correctly positioned

9.

While holding the cassette in place, turn the printhead

clockwise

.

until the ribbon is

Make sure the

lev er to the right to lock the printhead in place. Do not

force the lever.

10.

Close the front panel.

3-8

.

Page 37

4. Adjusting the Display

The intensity adjustment wheel is on the right side of the

keyboard. Rotate the wheel to lighten or darken the display.

Loading the Ribbon

Cassette

NOTE:

See you Operator’s Handbook for a description of the

keyboard k eys.

Intensity Adjustment Wheel

4-1

Page 38

9445 Equipment Manual

4-2

Page 39

5. Cleaning the Printhead and

Platen Roller

WARNING

Turn the power off and unplug the power cord before

cleaning.

1.

Open the front panel.

2.

Turn the printhead lev er to the left to open the printhead.

3.

Wind the supplies back onto the supply roll.

4.

Remove the ribbon cassette if one is loaded.

CAUTION

Cleaning the Printhead

and Platen Roller

DO NOT

printhead. This can damage the printhead and void your

warranty.

use sharp or abrasive materials to clean the

5-1

Page 40

9445 Equipment Manual

5.

Lightly moisten a cotton swab with alcohol and rub it back

and forth across the printhead. Clean the platen roller the

same way.

Printhead

Platen

Roller

6.

Reload the supply and ribbon cassette, if necessary, and

close the printhead.

7.

Turn the power on.

8.

Press f twice to realign the supply.

9.

If printing is not improved, call Monarch Service.

5-2

Page 41

Appendix A. Converting the

Keyboard for Table To p Use

1.

Lift the keyboard from the printer and place it on the table.

Converting the Keyboard

for Table Top Use

2.

Turn the keyboard over and remove the length of cord you

need.

3.

Slide a coil of the cord into the slot to hold it in place.

A-1

Page 42

9445 Equipment Manual

A-2

Page 43

Appendix B. Troubleshooting

If you cannot fix a problem, call Monarch service.

"Head Test Failure" Message

The 9445 performs a printhead test when you turn on the

printer. If the printhead test fails for any reason (bad

connection, bad dot), the printer displays "Head test failure."

If you receive this error:

1.

Press

2.

Print a test label (or one of the actual labels you plan to

print).

3.

Check for any visible print problems and do one of the

following:

•

•

•

•

e

to clear the message.

If there are no visible print problems, continue printing.

If there is a visible print problem in a bar code, call

Monarch Service. You can check the quality of your

bar code if you have a bar code verifier.

If there is a visible print problem that is not in a bar

coed, but is acceptable to you, continue printing.

If there is a visible print problem that is not in a bar

code and is not acceptable to you, call Monarch

Service.

Troubleshooting

B-1

Page 44

9445 Equipment Manual

Start-Up and Printing

Problem Action

Error message appears

during start-up.

"Check ribbon" message

appears.

Heavy printing. Adjust print contrast.

Light printing. Adjust print contrast.

No print. Change supply.

Turn power off, then on and try again.

If an error message appears again,

call Monarch Service.

Load a new ribbon roll or cassette.

Reload ribbon cassette.

Clean the printhead.

Change supply.

Reload ribbon cassette.

Change supply.

Reload ribbon cassette.

Correct the format in Format Entry

mode, or send a corrected format

online.

Change ribbon cassette.

Partially printed data. Change ribbon cassette.

Correct the format in Format Entry

mode or send a corrected format

online.

B-2

Page 45

Appendix B. Troubleshooting

Start-Up and Printing (continued)

Problem Action

Printed data becomes

misaligned.

Printed data wraps

around.

Printing shadows or

smears.

Voids in printing. Clean the printhead.

Recalibrate the printer. Select Printer

Options from the main menu, then

select Define Supply Type. Select

A)lign to recalibrate the printer.

Change supply.

Correct the format in Format Entry

mode or send a corrected format

online.

Clean the printhead.

Change supply.

Reload ribbon cassette.

Change supply.

Reload ribbon cassette.

B-3

Troubleshooting

Page 46

9445 Equipment Manual

Cutting

Problem Explanation

Cut length is more than

0.03 inches from tag

length.

"Knife jam" message

appears.

No cut action (or sound)

when c key is pressed.

No cut action when

key is pressed, but there

is a slight hum.

c

Call Monarch Service.

Paper is jammed in knife. Clear paper

and clean away any gum residue.

Knife out of position. Press S, then

press c twice to adjust the knife.

Then press

message.

Blades are worn. Call Monarch

Service.

Knife is out of position. Press S,

then press c twice to adjust the

knife. Then press

the message.

Knife is locked. Unlock knife.

Your printer is not equipped with a

knife.

Call Monarch Service.

e

twice to clear the

e

twice to clear

B-4

Page 47

Appendix C. Specifications

Printer

Height:

Weight:

Power:

Fuse:

Operating and

Storage limits:

Relative Humidity:

Display:

Printhead:

Printing Method:

14.5 inches (368.30 mm) without

keyboard; 17.7 inches (449.58 mm) with

keyboard.

35 lbs. (15.88 kg) packaged.

115 volts, 60 Hz. (standard) 220 volts,

50-60 Hz. (optional).

3 amps.

40°F to 104°F (4°C to 40°C).

5% to 90% (no condensation).

Liquid crystal display with 2 lines 32

characters per line (alphanumeric).

Thermal at 4.15 inches (105.41 mm)

wide 192 dots per inch (7.6 dots per

mm) 0.06 inch (1.5 mm) reserve

non-print area.

Thermal transfer (ribbon) or thermal

direct.

Appendix C

Ribbon T ype:

Ribbon Storage:

One-time carbon; black.

41°F to 95°F (5°C to 35°C).

leave ribbons in direct sunlight, high

temperatures, or high humidity.

DO NOT

C-1

Page 48

9445 Equipment Manual

Print Speed

With ribbon:

Print Speed

Without ribbon:

Supplies

•

Bar code toward top/bottom of tag

3.6 IPS

•

Bar code toward left/right side of tag

2.5 IPS

•

Bar code toward top/bottom of tag

3.6 IPS

•

Bar code toward left/right side of tag

2.5 IPS

*IPS = Inches per second

Supply T ypes:

Width

(without knife)

Width

(with knife)

Length

Supply Thickness:

Roll Diameter:

Thermal transfer stock or thermal direct

stock.

Minimum: 1.0 inch (25.4 mm)

Maximum: 4.5 inches (114.3 mm).

Minimum: 1.0 inch (25.4 mm)

Maximum: 4.0 inches (101.6 mm).

Minimum: 0.75 inch (19.05 mm)

Maximum: 8.0 inches (203.2 mm).

Tags or Labels: 0.006 to 0.010 inch

(0.152 to 0.355 mm).

Maximum 9.0 inches (228.6 mm)

C-2

Page 49

Page 50

For supplies, service, or assistance call:

TOLL FREE:

1-800-543-6650 (In U.S.A.)

1-800-263-4650 (In Canada)

Printed in U.S.A.

Loading...

Loading...