Page 1

USER

MANUAL

MODEL 1045RC

Powered High Speed

Short Range Modem:

Rack Mount Card

CERTIFIED

An ISO-9001

Certified Company

Part # 07M1045RC-B

Doc# 054051UB

Revised 3/14/97

SALES OFFICE

(301) 975-1000

TECHNICAL SUPPORT

(301) 975-1007

http://www.patton.com

Page 2

1.0 WARRANTY INFORMATION

Patton Electronics warrants all Model 1045RC components to be

free from defects, and will—at our option—repair or replace the product

should it fail within one year from the first date of shipment.

This warranty is limited to defects in workmanship or materials, and

does not cover customer damage, abuse or unauthorized modification.

If this product fails or does not perform as warranted, your sole

recourse shall be repair or replacement as described above. Under no

condition shall Patton Electronics be liable for any damages incurred

by the use of this product. These damages include, but are not limited

to, the following: lost profits, lost savings and incidental or

consequential damages arising from the use of or inability to use this

product. Patton Electronics specifically disclaims all other warranties,

expressed or implied, and the installation or use of this product shall be

deemed an acceptance of these terms by the user.

1.1 RADIO AND TV INTERFERENCE

The Model 1045RC generates and uses radio frequency energy,

and if not installed and used properly—that is, in strict accordance with

the manufacturer’s instructions—may cause interference to radio and

television reception. The Model 1045RC has been tested and found to

comply with the limits for a Class A computing device in accordance

with the specifications in Subpart J of Part 15 of FCC rules, which are

designed to provide reasonable protection from such interference in a

commercial installation. However, there is no guarantee that

interference will not occur in a particular installation. If the Model

1045RC does cause interference to radio or television reception, which

can be determined by turning the power off or removing the card, the

user is encouraged to try to correct the interference by one or more of

the following measures: moving the computing equipment away from

the receiver, re-orienting the receiving antenna and/or plugging the

receiving equipment into a different AC outlet (such that the computing

equipment and receiver are on different branches). In the event the user

detects intermittent or continuous product malfunction due to nearby

high power transmitting radio frequency equipment, the user is strongly

advised to take the following steps: use only data cables with an

external outer shield bonded to a metal or metalized connector; and,

configure the rear card as shown in section 3.2.1 of this manual.

1.3 SERVICE

All warranty and non-warranty repairs must be returned freight

prepaid and insured to Patton Electronics. All returns must have a

Return Materials Authorization number on the outside of the shipping

container.This number may be obtained from Patton Electronics

Technical Support at: (301) 975-1007; http://www.patton.com; or,

support@patton.com.

Packages received without an RMA number

will not be accepted.

Patton Electronics' technical staff is also available to answer any

questions that might arise concerning the installation or use of your

Model 1045RC. Technical Service hours: 8AM to 5PM EST, Monday

through Friday.

1.2 CE NOTICE

The CE symbol on your Patton Electronics equipment indicates

that it is in compliance with the Electromagnetic Compatibility (EMC)

directive and the Low Voltage Directive (LVD) of the Union European

(EU). A Certificate of Compliance is available by contacting Technical

Support.

1

2

Page 3

2.0 GENERAL INFORMATION

3.0 CONFIGURATION

Thank you for your purchase of this Patton Electronics product.

This product has been thoroughly inspected by Patton’s qualified

technicians. If any questions or problems arise during installation or

use of this product, please do not hesitate to contact Patton Electronics

Technical Support at (301) 975-1007.

2.1 FEATURES

• Switch-selectable carrier control

• Field-selectable electrical interfaces, RS-232 and

V.35

• Synchronous or asynchronous operation

• Data rates of 32, 56 and 64 Kbps

• Distances to 6 miles

• Point-to-point or multipoint

• 2-wire or 4-wire operation

• V.54 loopback tests and V.52 compliant BER tests

• Seven easy-to-read LED indicators

• Transformer isolation

• Silicon Avalanche Diode surge protection

• Switchable 120V or 240V power supply

• Mounts in Patton’s 16-card rack chassis

• Made in the U.S.A.

2.2 DESCRIPTION

The Model 1045RC high speed SRM supports sync. and async.

data rates of 32, 56 and 64 Kbps, and distances to 6 miles. Sync.

transmit clock options are internal, external and receive loopback clock.

The Model 1045RC incorporates two V.54 test modes: local analog

loop and remote digital loop. These can be activated from the front

panel, or via the RS-232 or V.35 interface. Additionally, a built-in V.52

BER test generator can output 511 and 511E bit patterns. Seven easyto-read LED indicators monitor power, transmit data, receive data, RTS,

carrier detect, test mode and test pattern. For protection against

ground loops and transient surges, the Model 1045 incorporates both

isolation transformers and Silicon Avalanche Diode surge suppressors.

The Model 1045RC is designed to mount in Patton’s 2U high 19”

rack chassis. This 16-card chassis has a switchable 120/240 VAC

power supply (optional 48 VDC) and mounts cards in a mid-plane

architecture: The front card can be plugged into different rear cards.

This means that the Model 1045RC card can have several interface

options and can be switched with other Patton short haul cards.

This section describes the location and orientation of the Model

1045RC’s configuration switches and jumpers, and provides detailed

instructions for all possible settings.

The Model 1045RC uses a combination of DIP switches and

jumpers that allow configuration to an extremely wide range of

applications. Designed around a mid-plane architecture, the Model

1045RC incorporates both front and rear cards. Configuration of both

may be necessary. The switches/jumpers are accessible when the

cards are slid out of the rack chassis. Once configured, the Model

1045RC is designed to operate transparently, without need for frequent

re-configuration: just set it and forget it!

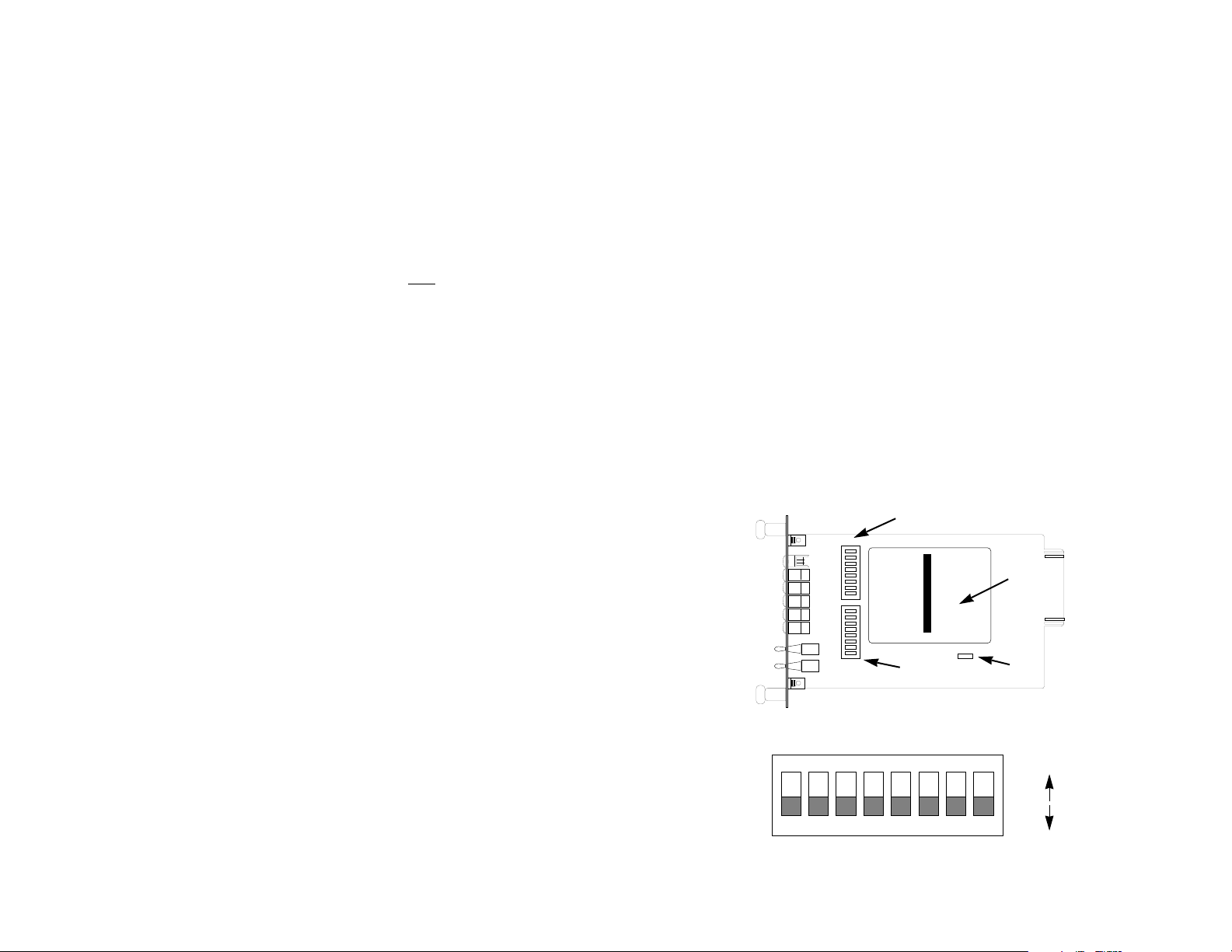

3.1 FRONT CARD CONFIGURATION

The Model 1045RC front card has two sets of eight switches (S1 &

S2), one jumper (JP3), and a reversible daughter board, which are all

mounted on the PC board (Figure 1, below). These configuration

devices allow you to select data rates, clocking methods, V.52 & V.54

tests, word lengths, extended signaling rates, async. or sync. mode,

2- or 4-wire operation, and RS-232 or V.35 terminal interface. The

ON/OFF orientation of the DIP switches is shown in figure 2 (above).

S1

daughter

board

S2

Figure 1. Model 1045RC board, showing location of switches/jumper

ON

JP3

ON

12345678

OFF

Figure 2. Close-up of DIP switches showing “ON” and “OFF” positions

3

4

Page 4

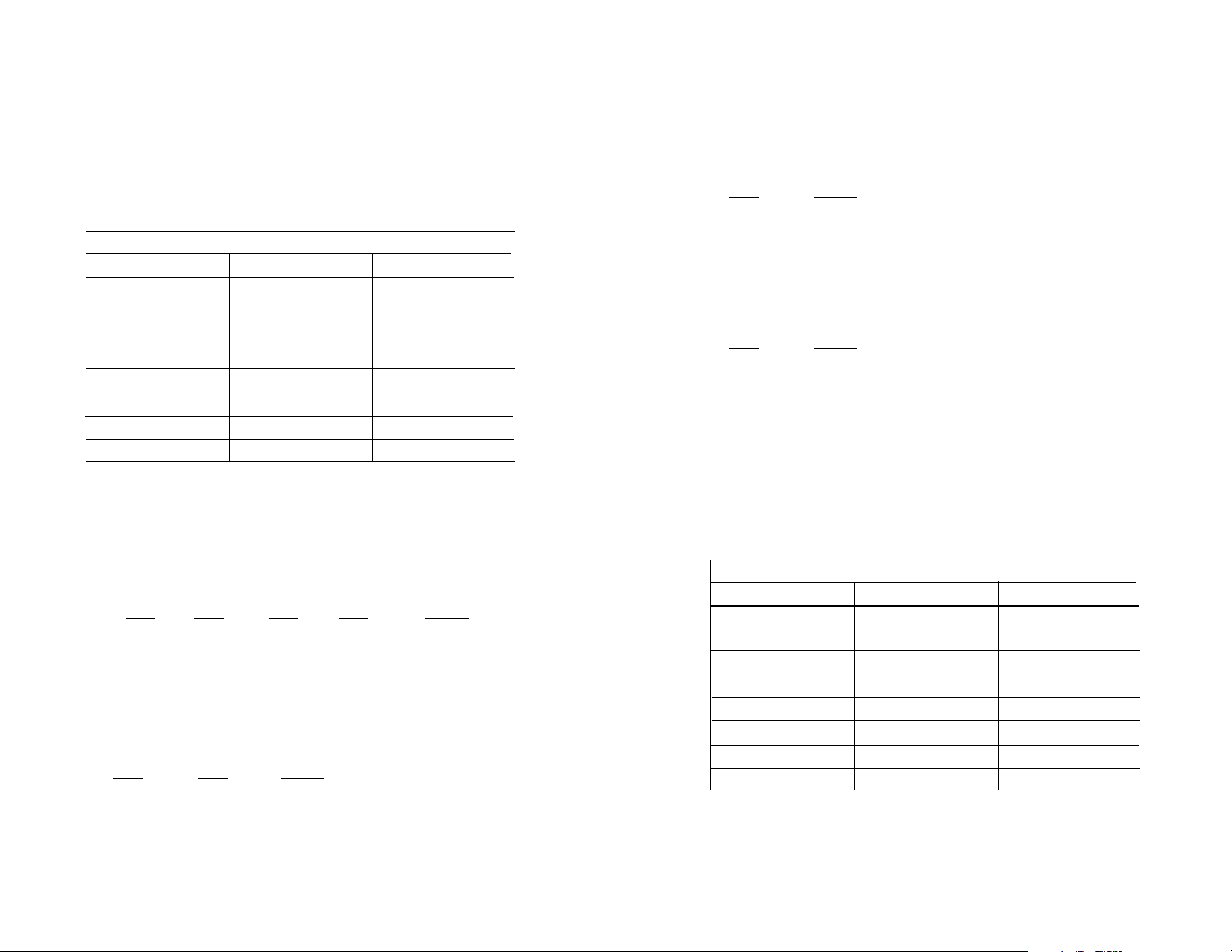

3.1.1 CONFIGURATION SWITCH SET “S1”

The eight DIP switches on pack S1 set data rate, clock source,

async/sync mode and carrier control method. Factory default settings

are summarized in Figure in the table below. Descriptions of all

possible S1 switch settings, including the Patton factory default

settings, are found on on pages 4 and 5.

S1 SUMMARY TABLE

Position Function Factory Default

S1-1 Data Rate Off

S1-2 Data Rate On

S1-3 Data Rate Off

S1-4 Data Rate Off

S1-5 Clock Source On

S1-6 Clock Source On

S1-7 Carrier Control Off Constantly On

S1-8 V.52/V.54 Tests Off Enable

S1-1 through S1-4: Data Rate Setting

Switches S1-1 through S1-4 are set in combination to determine

the asynchronous and synchronous data rate for the Model 1045RC.

Model 1045RC:

S1-1

Off Off On Off 32.0 kbps

Off On Off Off 56.0 kbps

On Off Off Off 64.0 kbps

S1-5 and S1-6: Clock Source

Switches S1-5 and S1-6 are set in combination to determine the

transmit clock source for the Model 1045RC.

S1-5

On On Internal transmit clock

Off On Receive recover clock

On Off External transmit clock

S1-2 S1-3 S1-4 Setting

S1-6 Setting

}

}

56 Kbps

Internal

The setting for switch S1-7 determines whether the carrier is

“constantly on” or “controlled by RTS”. This setting allows for operation

in switched carrier, multipoint and/or hardware handshaking

applications.

S1-7

Off Constantly on

On Controlled by RTS

S1-8: V.52 and V.54 Diagnostic Test

To reset the V.54 circuit, set switch S1-8 to the “ON” position, then

back to the “OFF” position.

S1-8 Setting

Off Enable (Normal Operation)

On Test Disabled

3.1.2 CONFIGURATION SWITCH SET “S2”

The eight DIP switches on pack S2 set RTS/CTS delay, word

length, extended signaling rate, async/sync mode and remote test

initiation. Factory default settings are summarized in the table below.

Descriptions of all possible S1 switch settings, including the Patton

factory default settings, are found on on pages 6 and 7.

Position Function Factory Default

Setting

S2 SUMMARY TABLE

S2-1 RTS/CTS Delay On

S2-2 RTS/CTS Delay On

S2-3 Word Length Off

S2-4 Word Length Off

S2-5 Extended Signaling Off -2.5% to +1%

S2-6 Async/Sync Off Sync

S2-7 DTE Control of LAL On Enable

S2-8 DTE Control of RDL On Enable

}

}

7 ms

10 bits

S1-7: Carrier Control Method

5

6

Page 5

S2-1 and S2-2: RTS/CTS Delay

S2-7: RS-232/V.35 Initiation of Local Analog Loopback Test

The combined settings for switches S2-1 and S2-2 determine the

amount of delay between the time the Model 1045RC “sees” RTS and

when it sends CTS. Options are no delay, 7 ms and 53 ms.

S2-1 S2-2 Setting

On On 7 ms

On Off 53 ms

Off On No delay

Off Off No delay

S2-3 and S2-4: Word Length

Switches S2-3 and S2-4 are set in combination to determine the

word length for asynchronous data.

S2-3

Off On 8 bits

On On 9 bits

Off Off 10 bits

On Off 11 bits

S2-5: Extended Signaling Rate

The setting for switch S2-5 determines the range of variability the

Model 1045RC “looks for” in asynchronous data rates (i.e., the actual

variance from a given frequency level the Model 1045RC will tolerate).

S2-5

Off -2.5% to +1% (normal)

On -2.5% to +2.3% (extended)

S2-4 Setting

Setting

The setting for switch S2-7 determines whether or not the Model

1045RC’s local analog loopback test can be initiated by raising pin 18

on the RS-232 interface (pin N on the V.35 interface).

S2-7

On RS-232/V.35 initiation enabled

Off RS-232/V.35 initiation disabled

S2-8: RS-232/V.35 Initiation of Remote Digital Loopback Test

The setting for switch S2-8 determines whether or not the Model

1045RC’s remote digital loopback test can be initiated by raising pin 21

on the RS-232 interface (pin L on the V.35 interface).

S2-8 Setting

On RS-232/V.35 initiation enabled

Off RS-232/V.35 initiation disabled

3.1.3 CONFIGURATION JUMPER “JP3”

Jumper JP3 is used to set 2-wire or 4-wire operation. Figure 3

(below) shows the possible positions of the strap on its pegs. Please

note the orientation of the jumper on the PC board.

Setting

Front of PC Board Rear of PC Board

S2-6: Asynchronous/Synchronous Mode

The setting for switch S2-6 determines whether the Model 1045RC

is in asynchronous or synchronous operating mode.

S2-6 Setting

On Asynchronous*

Off Synchronous

*Note: in asynchronous mode, the Clock Source must be set to

“Internal” (S1-5 = On, S1-6 = On)

7

123 123 123

Figure 5 Orientation of jumper JP3

(continued)

8

Page 6

JP3: 2-Wire/4-Wire Mode Selection

3.2 REAR CARD CONFIGURATION

The setting for jumper JP3 determines whether the Model 1045RC

is operating in 2-wire or 4-wire mode. Be careful not to lose the jumper!

JP3

Setting

Jumper on pins 1 & 2 2-wire (half duplex only)*

Jumper on pins 2 & 3 4-wire (full or half duplex)

Jumper removed Not a valid setting

*Note: in 2-wire mode, the Carrier Control Method switch must be set to

“RTS Control” (S1-7 = On)

3.1.4 REVERSIBLE “DAUGHTER BOARD”

The Model 1045RC supports both RS-232 and V.35 electrical

interfaces for the terminal connection port. Which electrical interface is

active is determined by the orientation of the small reversible daughter

board on the front card (see Figure 4, below). The daughter board is

clearly marked “This side up for RS-232” and “This side up for

V.35”. Note: When plugging the daughter board into the socket, the

arrow should always point toward the front of the PC board.

The Model 1045RC has four rear interface card options: DB-25 &

RJ-11, DB-25 & RJ-45, M/34 & RJ-11 and M/34 & RJ-45 (see Figure 5,

below). Each of these options supports one terminal connection and

one line connection.

RJ-11 (6-wire)

DB-25 F

Figure 5. Model 1045RC interface card options

RJ-45 (8-wire)

DB-25 F

RJ-11 (6-wire)

M/34 F

RJ-45 (8-wire)

M/34 F

Each of the four rear card options for the Model 1045RC has a

distinct model number. The four options and their model numbers are

shown below:

Interface Combination

Model Number

FRONT THIS SIDE UP FOR RS-232

Figure 4. Terminal interface selection “daughter board”

9

DB-25 & RJ-11 1000RCM12511

DB-25 & RJ-45 1000RCM12545

M/34 & RJ-11 1000RCM13411

M/34 & RJ-45 1000RCM13445

Prior to installation, you will need to examine the rear card you

have selected and make sure it is properly configured for your

application. Each rear card is configured by setting straps located on

the PC board. Section 3.5.1 describes the strap locations and possible

settings for each rear card.

10

Page 7

3.2.1 REAR CARD JUMPER SETTINGS

Line Shield & FRGND (JB2)

Figure 6 (below) shows jumper locations for the four rear card

options. These jumpers determine various grounding characteristics for

the RS-232/V.35 and twisted pair lines.

JB2

(peg 1 on left)

JB3

(peg 1 on top)

JB4

(peg 1 on left)

Figure 6. Rear card jumper locations

Figure 7 (below) shows the orientation of the rear interface card

jumpers. The jumper can either be on pegs 1 & 2, or on pegs 2 & 3.

This jumper affects the line interface. In the connected (closed)

position, it links RJ-11 pins 1 & 6, or RJ-45 pins 2 & 7 to frame ground.

These pins can be used as connections for the twisted pair cable

shield. In the open (disconnected) position, pins 1 & 6 (or 2 & 7)

remain connected to each other, but are “lifted” from the frame ground.

JB2

Position 1&2 = Line Shield and FRGND Connected

Position 2&3 = Line Shield and FRGND Not Connected

DTE Shield & Frame Ground (JB3)

In the connected position, this jumper links DB-25 pin 1 (M/34 pin

A) & frame ground. In the open position, pin 1(pin A) is “lifted” from

frame ground.

JB3

Position 1&2 = DTE Shield (DB-25 Pin 1 or M/34 Pin A)

and FRGND Connected

Position 2&3 = DTE Shield (DB-25 Pin 1 or M/34 Pin A)

and FRGND Not Connected

Signal Ground & Frame Ground (JB4)

123 123 123

Figure 7. Orientation of interface card straps

The table below provides an overview of interface jumper functions

for the rear interface cards. Following this overview is a detailed

description of each jumper’s function.

REAR CARD STRAP SUMMARY

Strap Function Position 1&2 Position 2&3

JB2 Line Shield & FRGND Connected Open*

JB3 DTE Shield (Pin1) & FRGND Connected Open*

JB4 FRGND & SGND Connected Open*

11

In the connected position, this jumper links DB-25 pin 7 or M/34 pin

B (Signal Ground) and frame ground. In the open position, pin 1 (or pin

B) is “lifted” from frame ground.

JB4

Position 1&2 = SGND (DB-25 pin 7 or M/34 pin B)

and FRGND Connected

Position 2&3 = SGND (DB-25 pin 7 or M/34 pin B)

and FRGND Not Connected

12

Page 8

4.0 INSTALLATION

This section describes the functions of the Model 1000R16 rack

chassis, tells how to install front and rear Model 1045RC cards into the

chassis, and provides diagrams for wiring the interface connections

correctly.

4.1 THE MODEL 1000R16 RACK CHASSIS

Switching the Power Supply On and Off

The power supply on/off switch is located on the front panel. When

plugged in and switched on, a red front panel LED will glow. Since the

Model 1000R16 is a “hot swappable” rack,

cards to be installed before switching on the power supply

supply may be switched off at any time without harming the installed

cards.

it is not necessary for any

. The power

The Model 1000R16 Rack Chassis (Figure 8) has sixteen short

range modem card slots, plus its own power supply. Measuring only

3.5” high, the Model 1000R16 is designed to occupy only 2U in a 19”

rack. Sturdy front handles allow the Model 1000R16 to be extracted

and transported conveniently.

Figure 8. Model 1000R16 Rack Chassis with power supply

4.1.1 THE RACK POWER SUPPLY

The power supply included in the Model 1000R16 rack uses the

same mid-plane architecture as the modem cards. The front card of

the power supply slides in from the front, and the rear card slides in

from the rear. They plug into one another in the middle of the rack.

The front card is then secured by thumb screws and the rear card by

conventional metal screws.

WARNING! There are no user-serviceable parts in the power

supply section of the Model 1000RC. Voltage setting changes

and fuse replacement should only be performed by qualified

service personnel. Contact Patton Electronics Technical support

at (301)975-1007 for more information.

4.2 INSTALLING THE MODEL 1045RC INTO THE CHASSIS

The Model 1045RC is comprised of a front card and a rear card.

The two cards meet inside the rack chassis and plug into each other by

way of mating 50 pin card edge connectors. Use the following steps as

a guideline for installing each Model 1045RC into the rack chassis:

1. Slide the rear card into the back of the chassis along the metal

rails provided.

2. Secure the rear card using the metal screws provided.

3. Slide the card into the front of the chassis. It should meet the

rear card when it’s almost all the way into the chassis.

4. Push the front card

rear card. It should “click” into place.

5. Secure the front card using the thumb screws.

NOTE: Since the Model 1000R16 chassis allows “hot swapping”

of cards, it is

install or remove a Model 1045RC.

4.3 WIRING THE MODEL 1045RC

Each of the rear interface cards compatible with the Model 1045RC

has one terminal interface port (DB-25 or M/34) and one 4-wire, twisted

pair port (RJ-11 or RJ-45). This section describes connection

procedures for the terminal cable and twisted pair cable.

not necessary to power down

gently

into the card-edge receptacle of the

the rack when you

1413

Page 9

4.3.1 TERMINAL INTERFACE CONNECTION

RJ-11/4-Wire

The Model 1045RC is wired as a DCE, and allows for three possible

terminal interface connections:

• RS-232C/V.24 (electrical) + DB-25 female (physical)

• V.35/RS-530 (electrical) + DB-25 female (physical)

• V.35 (electrical) + M/34 female (physical)

To select the appropriate

electrical

interface, please refer to

Section 3.1.4 of this manual. To select or construct a cable with the

appropriate

physical

interface pin-outs, please refer to the diagrams in

Appendix D and Appendix E of this manual.

Notice! Any terminal cable connected to the Patton Model

1045RC must be shielded cable, and the outer shield must be

360 degree bonded–at both ends–to a metal or metalized

backshell.

4.3.2 TWISTED PAIR CONNECTION

The Model 1045RC supports communications between RS-232 or

V.35 devices at distances to 6 miles and data rates up to 64 Kbps. The

Model 1045RC is designed to operate in a closed data circuit with other

1045RCs or 1045 plug-in units.

To function properly, the Model 1045RC needs two twisted pairs of

unconditioned, dry metallic wire between 19 and 26 AWG (higher

number gauges may limit distance somewhat). Both shielded and

unshielded wire yield favorable results. Flat modular telephone type

cable, dial-up analog circuits or leased lines that run through

signal/equalization equipment are NOT acceptable. For further

information about acceptable wire grades, please refer to the diagram

in appendix B.

SIGNAL PIN# PIN# SIGNAL

†

GND

RCV-

1 6.......................GND

◊

2 4.......................XMT-

XMT+ 3 5.......................RCV+

XMT- 4 2.......................RCV-

RCV+ 5 3.......................XMT+

GND 6 1.......................GND

RJ-45/4-W

ire

SIGNAL PIN# COLOR COLOR PIN# SIGNAL

†

GND

RCV-

2 7.......................GND

◊

3 5.......................XMT-

XMT+ 4 6.......................RCV+ XMT- 5 3

RCV-

RCV+ 6 4.......................XMT+

GND 7 2.......................GND

†

Connection to ground is optional

‡

Standard color codes—yours may be different

◊

The Model 1045RC is not sensitive to polarity

1 - Blue

2 - Yellow

3 - Green

4 - Red

5 - Black

6 - White

AT&T standard modular color codes

1 - Blue

2 - Orange

3 - Black

4 - Red

5 - Green

6 - Yellow

7 - Brown

8 - Slate

Point-to-Point Twisted Pair Connection

The 6-position RJ-11 and 8-position RJ-45 jack options for the

Model 1045RC are prewired for a standard TELCO wiring environment.

Connection of a 2-wire or 4-wire twisted pair circuit between two or

more Model 1045RCs requires a

crossover cable

as shown in the

following diagrams.

15

Notice! Any modular twisted pair cable connected to the

Model 1045RC must be shielded cable, and the outer shield

must be properly terminated to a shielded modular plug on both

ends of the cable.

16

Page 10

5.0 OPERATION

Once you have configured each Model 1045RC and connected the

cables, you are ready to operate the units. Section 5.0 describes the

power-up procedure and the built-in V.54 and V.52 test modes.

5.1 POWER-UP

There is no power switch on the Model 1045RC: Power is

automatically applied to the Model 1045RC when its card-edge

connector makes contact with the chassis’ mid-plane socket, or when

the chassis’ power supply is turned on.

Note: The Model 1045RC is a

“hot swappable” card—it will not be damaged by plugging it in or

removing it while the rack is powered up.

4. If the BER test indicates

toggle switch to the left, thus activating the “511/E” test with

periodic errors. If the test is working properly, the red “Error”

LED will glow. A successful “511/E” test will confirm that the

loop is in place, and that the Model 1045RC’s built-in “511”

generator and detector are working properly.

5. If the BER test indicates that errors

that the RS-232 cable connecting the DTE to the Model

1045RC is wired straight through, and is plugged in properly.

Also, ensure that the Model 1045RC is configured properly.

Then re-check your DTE equipment. If you still have errors,

call Patton Technical Support at (301) 975-1007.

no errors

are present, move the V.52

are

present, check to see

5.2 TEST MODES

The Model 1045RC offers two V.54 test modes and two V.52 test

modes to evaluate the condition of the modems and the communication

link. Both sets of tests can be activated physically from the front panel.

The V.54 test can also be activated from the RS-232 interface.

5.2.1 LOCAL ANALOG LOOPBACK (LAL)

The Local Analog Loopback (LAL) test checks the operation of the

local Model 1045RC, and is

data sent to the local Model 1045RC in this test mode will be echoed

(returned) back to the user device. For example, characters typed on

the keyboard of a terminal will appear on the terminal screen. To

perform a LAL test, follow these steps:

1. Activate LAL. This may be done in one of two ways: First, by

moving the upper front panel toggle switch RIGHT to “Analog”.

Second, by raising pin 18 on the RS-232 interface (note: be

sure DIP switch SW1-8 is enabled). Once LAL is activated,

the Model 1045RC transmit output is connected to its own

receiver. The “Test” LED should be lit.

2. Verify that the data terminal equipment is operating properly

and can be used for a test.

3. Locate the lower of the two toggle switches on the front panel

of the Model 1045RC and move it to the right. This will

activate the V.52 BER test mode and inject a “511” test pattern

into the local loop. If any errors are present in the loop, the

red “Error” LED will blink sporadically.

performed separately on each unit.

17

Any

5.2.2 REMOTE DIGITAL LOOPBACK (RDL)

The Remote Digital Loopback (RDL) test checks the performance of

both the local and remote Model 1045RCs,

between them. Any characters sent to the remote 1045RC in this test

mode will be returned back to the originating device. For example,

characters typed on the keyboard of the local terminal will appear on

the local terminal screen

1045RC and looped back. To perform an RDL test, follow these steps:

1. Activate RDL. This may be done in two ways: First, by

moving the upper front panel toggle switch LEFT to “Remote”.

Second, by raising pin 21 on the RS-232 interface.

2. Verify that the DTE equipment on the local end is operating

properly and can be used for a test.

3. Locate the lower of the two toggle switches on the front panel

of the 1045RC and move it to the right. This will activate the

V.52 BER test mode and inject a “511” test pattern into the

remote loop. If any errors are present in the loop, the red

“Error” LED will blink sporadically.

4. If the BER test indicates

toggle switch to the left, thus activating the “511/E” test with

periodic errors. If the test is working properly, the red “Error”

LED will glow. A successful “511/E” test will confirm that the

loop is in place, and that the Model 1045RC’s built-in “511”

generator and detector are working properly.

after

having been passed to the remote Model

no errors

18

and

the communication link

are present, move the V.52

Page 11

5. If the remote BER test indicates that errors

the local analog loopback/BER tests showed that both Model

1045RCs were functioning properly, this suggests a problem

with the twisted pair communication line connecting the two

modems. A common problem is improper crossing of the

pairs. Also, verify that the modular connections are pinned

properly, and the twisted pair line has continuity. If you still

have errors, call Technical Support at (301) 975-1007.

5.2.3 USING THE V.52 BER TEST INDEPENDENTLY

The Model 1045RC's V.52 BER test can be used independent of the

V.54 loopback tests. This requires two operators: one to initiate and

monitor the test at both the local and the remote Model 1045RC. To

use the V.52 BER test by itself, both operators should simultaneously

follow these steps:

1. Locate the lower of the two toggle switches on the front panel

of the Model 1045RC and move it to the right. This will

activate the V.52 BER test mode and transmit a “511” test

pattern to the other unit. If any errors are present, the

receiving modem’s red “Error” LED will blink sporadically.

Note: For this independent test to function, the “511” switch on

both

Model 1045RCs must be turned on.

2. If the test indicates no errors are present, move the V.52

toggle switch to the left, thus activating the “511/E” test with

errors present. If the test is working properly, the receiving

modem’s red “Error” LED will glow. A successful “511/E” test

will confirm that the link is in place, and that the Model

1045RC’s built-in “511” generator and detector are working

properly.

are

present, and

APPENDIX A

1045RC SPECIFICATIONS

Transmission Format: Synchronous or asynchronous,

2-wire or 4-wire

Internal Interface: Connection to Model 1000R16 rack

chassis via 50 pin male card edge

External Interface: DB-25 female (RS-232), M/34 female (V.35)

RJ-11 or RJ-45 (line)

Transmission Line: 2-wire or 4-wire unshielded twisted pair

(UTP), 19-24 AWG

Data Rates: 32, 56, 64 Kbps

Clocking: Internal, external or receive recover

RTS/CTS Delay: No delay, 7mS, 53mS

Controls: Carrier constantly “ON” or “controlled by

RTS”

Indicators: Bi-color LED indicators for TD, RD, RTS &

DCD; single LED indicators for Power, Test

and Error

Diagnostics: V.52 compliant bit error rate pattern; V.54

compliant— Local Analog Loopback and

Remote Digital Loopback, activated by front

panel switch or via terminal interface

Transformer Isolation: 1500 V RMS

Surge Protection: Silicon Avalanche Diodes

Temperature: 0-50°C / 32-122°F

Humidity: 4-95%, noncondensing

Dimensions: 0.95”w x 3.1”h x 5.4”l

19

20

Page 12

APPENDIX B

APPENDIX C

MODEL 1045RC CABLE RECOMMENDATIONS

The Patton Model 1045RC operates at frequencies of 64KHz or less

and has been performance tested by Patton technicians using twistedpair cable with the following characteristics:

Wire Gauge Capacitance Resistance

19 AWG 83nf/mi or 15.72 pf/ft. .0163 Ohms/ft.

22 AWG 83nf/mi or 15.72 pf/ft. .0326 Ohms/ft.

24 AWG 83nf/mi or 15.72 pf/ft. .05165 Ohms/ft.

To gain optimum performance from the Model 1045RC, please keep

the following guidelines in mind:

•

Always

• Use twisted pair wire with a capacitance of 20pf/ft or less.

• Avoid twisted pair wire thinner than 26 AWG (i.e. avoid higher

AWG numbers than 26)

• Use of twisted pair with a resistance greater than the above

specifications may cause a reduction in maximum distance

obtainable. Functionality should not be affected.

• Environmental factors too numerous to mention can affect the

maximum distances obtainable at a particular site. Use the above

data rate/distance table as a

use twisted pair wire—this is not an option.

general guideline only.

MODEL 1045RC FACTORY REPLACEMENT PARTS

The Patton Model 1045RC rack system features interchangeable

rear cards, power cords/fuses for international various operating

environments and other user-replaceable parts. Model numbers,

descriptions and prices for these parts are listed below:

Patton Model # Description

1000RPEM..........................120/240V Rear Power Entry Module

1000RPSM-2.......................120/240V Front Power Supply Module

1000RPEM-DC ...................DC Rear Power Entry Module

1000RPSM-48A..................48V Front Power Supply Module

1000RPEM-V......................120/240V CE Compliant Rear Power

Entry Module

1000RPSM-V......................120/240V CE Compliant Front Power

Supply Module

0805US...............................American Power Cord

0805EUR.............................European Power Cord CEE 7

0805UK...............................United Kingdom Power Cord

0805AUS.............................Australia/New Zealand Power Cord

0805DEN.............................Denmark Power Cord

0805FR ...............................France/Belgium Power Cord

0805IN.................................India Power Cord

0805IS.................................Israel Power Cord

0805JAP..............................Japan Power Cord

0805SW ..............................Switzerland Power Cord

0516FPB1...........................Single Width Blank Front Panel

0516FPB4...........................4-Wide Blank Front Panel

0516RPB1...........................Single Width Blank Rear Panel

0516RPB4...........................4-Wide Blank Rear Panel

21

056S1..................................Set of 16 #4 pan head screws/washers

22

Page 13

APPENDIX D

APPENDIX E

V.35 INTERFACE STANDARDS (DCE)

DIRECTION CCITT V.35/EIA-530 INTERFACE (DB-25) DIRECTION

To 1045RC Transmit Data B - 14

From 1045RC Transmit Clock A - 15

From 1045 Receive Data B - 16

From 1045RC Receive Clock A - 17

To 1045RC Local Analog Loop (LAL) - 18

To 1045RC Data Term. Ready (DTR) - 20

To 1045RC

To 1045RC External Clock A - 24

Remote Digital Loop

(RDL) - 21

CCITT V.35 Interface (M/34 Female)

1 - (FG) Frame Ground Common

2 - Transmit Data A To 1045RC

3 - Receive Data A From 1045RC

4 - (RTS) Request to Send To 1045RC

5 - (CTS) Clear to Send From 1045RC

6 - (DSR) Data Set Ready From 1045RC

7 - (SG) Signal Ground Common

8 - (CD) Carrier Detect From 1045RC

9 - Receive Clock B From 1045RC

11 - External Clock B To 1045RC

12 - Transmit Clock B From 1045RC

RS-232 INTERFACE STANDARDS (DCE)

DIRECTION RS-232C/V.24 INTERFACE (DB-25) DIRECTION

1- (FG) Frame Ground

From 1045RC Transmit Clock - 15

From 1045RC Receive Clock - 17

To 1045RC Analog Loop - 18

To 1045RC Data Term. Ready (DTR) - 20

To 1045RC Digital Loop - 21

To 1045RC External Clock - 24

2- (TD) Transmit Data To 1045RC

3- (RD) Receive Data From 1045RC

4- (RTS) Request to Send To 1045RC

5- (CTS) Clear to Send From 1045RC

6- (DSR) Data Set Ready From 1045RC

7- (SG) Signal Ground

8- (DCD) Data Carrier Detect From 1045RC

Frame Ground -A

Request to Send -C

Data Set Ready -E

Data Terminal Ready -H

(Not Used) -K

(Not Used) -M

Transmitted Data (A) -P

Transmitted Data (B) -S

External Clock (A) -U

External Clock (B) -W

Transmit Clock (A) -Y

Transmit Clock (B) -AA

A

H

M

S

W

BB

FF

KK

A

E

K

P

U

Y

DD

HH

MM

23

D

J

N

T

X

AA

EE

LL

B

B- Signal Ground

D- Clear To Send

F

F- Data Carrier Detect

L- Remote Digital Loop

L

N- Local Analog Loop

R

R- Receive Data (A)

T- Receive Data (B)

V- Receive Clock (A)

V

X- Receive Clock (B)

Z

CC

JJ

NN

Copyright ©

Patton Electronics Company

All Rights Reserved

24

Loading...

Loading...